Upscaling of a Mechanochemical Devulcanization Process for EPDM Rubber Waste from a Batch to a Continuous System

Abstract

1. Introduction

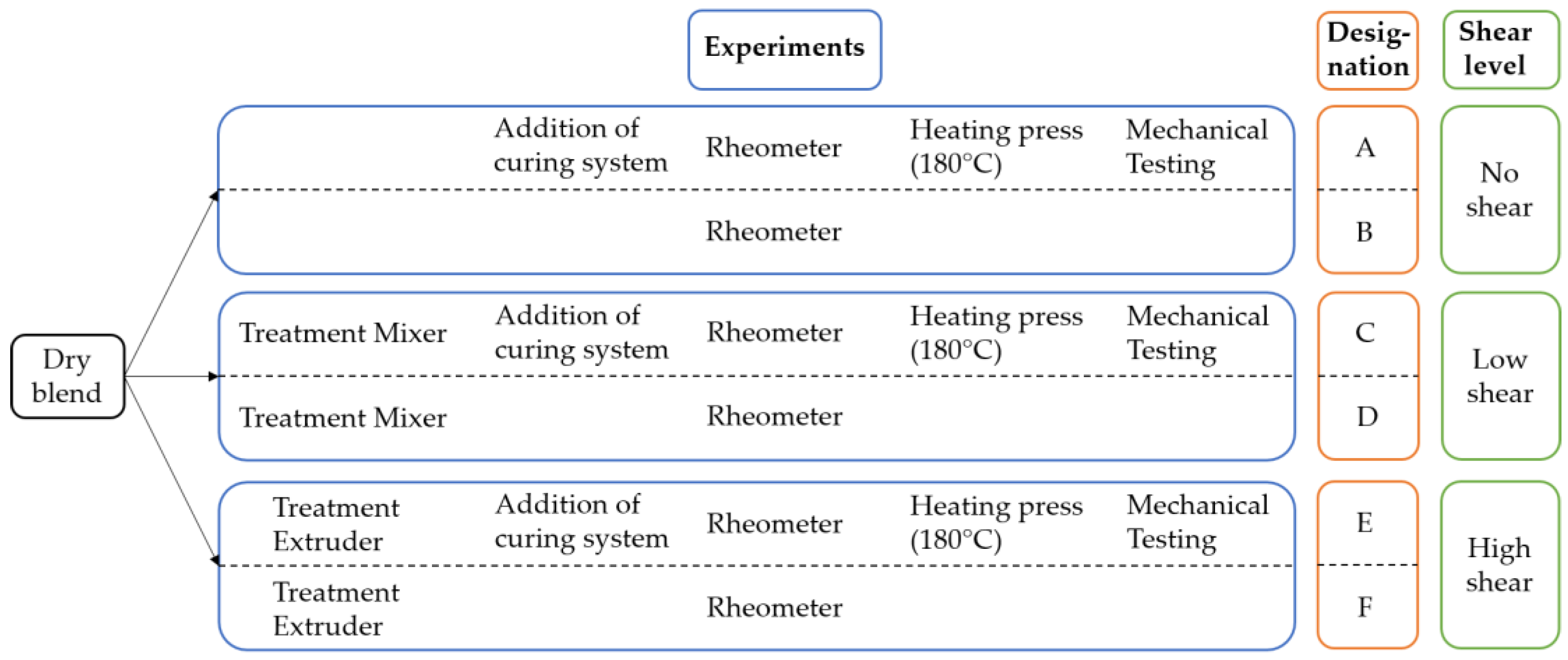

2. Results and Discussion

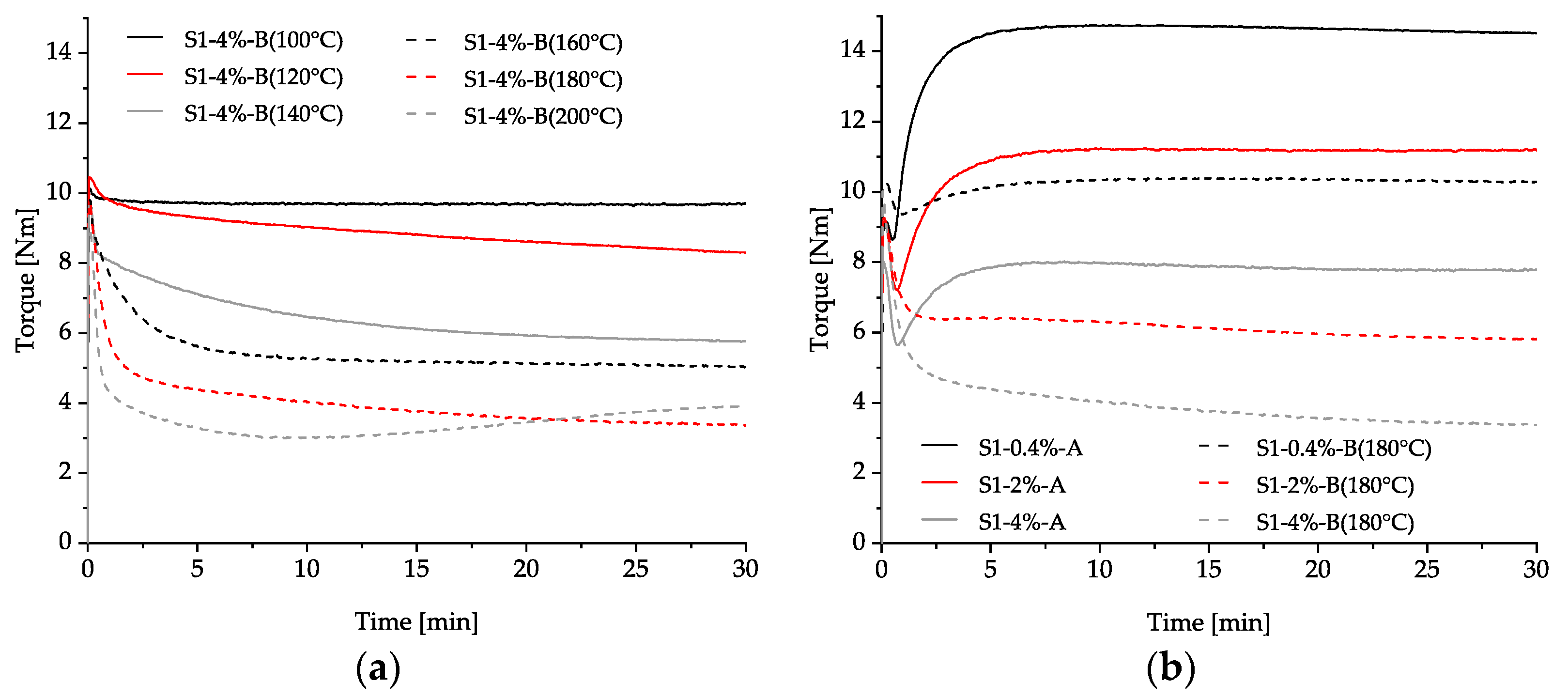

2.1. Devulcanization with No Shear

2.2. Devulcanization with Low Shear

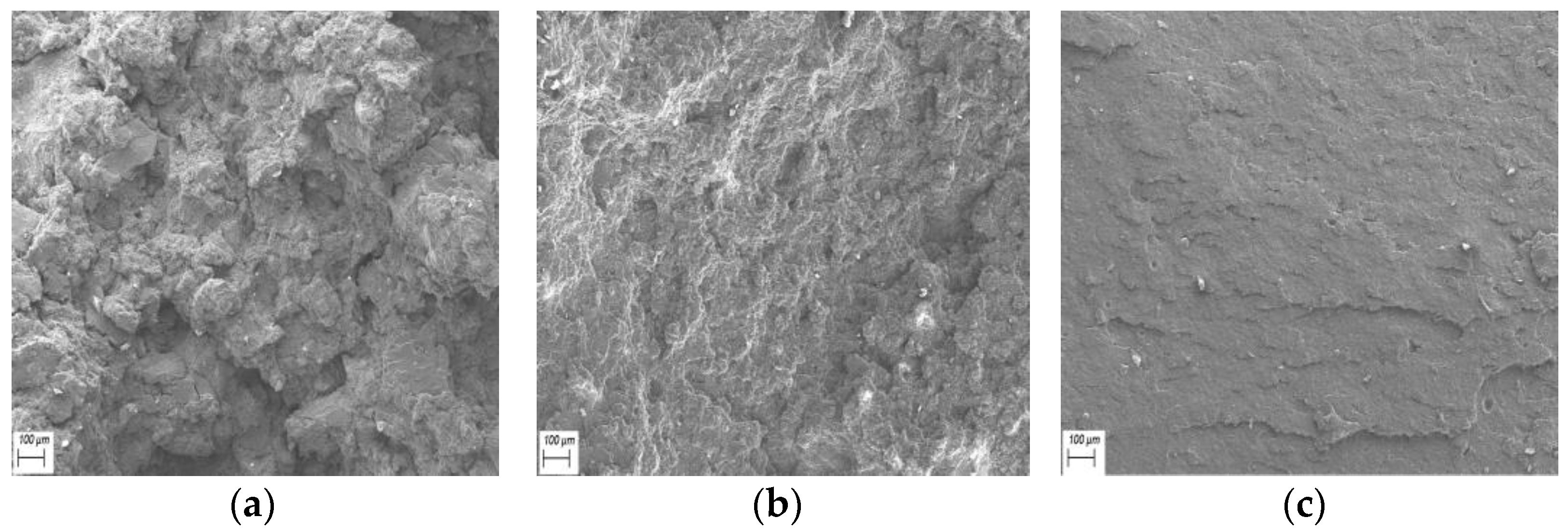

2.3. Devulcanization with High Shear

2.4. Comparison between Batch and Continuous Systems

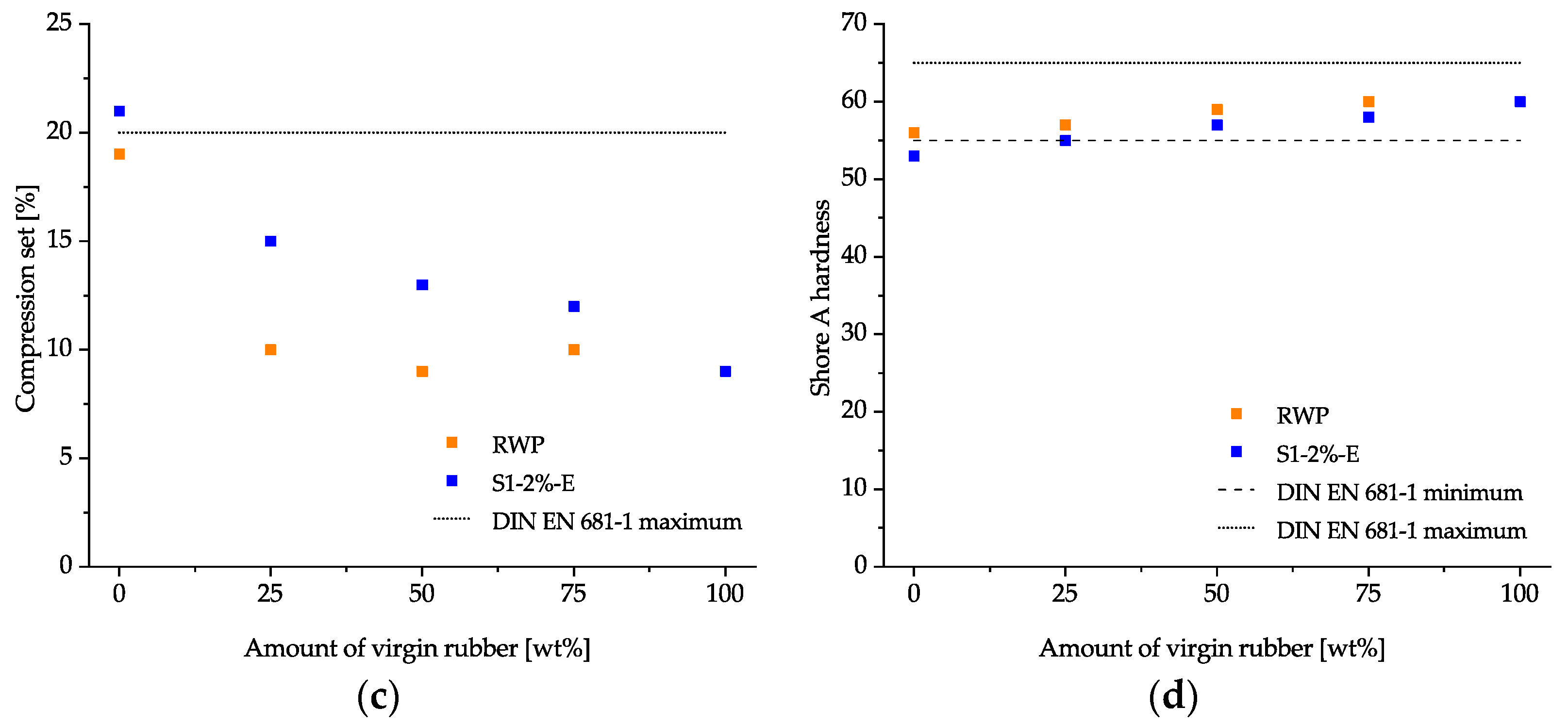

2.5. Preparation of Virgin Rubber Blends

3. Materials and Methods

3.1. Materials

3.2. Preparation of Samples and Blends

3.3. Characterization of Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- Myhre, M.; Saiwari, S.; Dierkes, W.; Noordermeer, J. Rubber Recycling: Chemistry, processing, and applications. Rubber Chem. Technol. 2012, 85, 408–449. [Google Scholar] [CrossRef]

- Joseph, A.; George, B.; Madhusoodanan, K.; Alex, R. Current status of sulphur vulcanization and devulcanization chemistry: Devulcanization. Rubber Sci. 2016, 29, 62–100. [Google Scholar]

- Zedler, Ł.; Kosmela, P.; Olszewski, A.; Burger, P.; Formela, K.; Hejna, A. Recycling of Waste Rubber by Thermo-Mechanical Treatment in a Twin-Screw Extruder. Proceedings 2021, 69, 10. [Google Scholar]

- Colom, X.; Canavate, J.; Formela, K.; Shadman, A.; Saeb, M.R. Assessment of the devulcanization process of EPDM waste from roofing systems by combined thermomechanical/microwave procedures. Polym. Degrad. Stab. 2021, 183, 109450. [Google Scholar] [CrossRef]

- Ostad Movahed, S.; Ansarifar, A.; Zohuri, G.; Ghaneie, N.; Kermany, Y. Devulcanization of ethylene-propylene-diene waste rubber by microwaves and chemical agents. J. Elastomers Plast. 2016, 48, 122–144. [Google Scholar] [CrossRef]

- Nabil, H.; Ismail, H.; Azura, A.R. Compounding, mechanical and morphological properties of carbon-black-filled natural rubber/recycled ethylene-propylene-diene-monomer (NR/R-EPDM) blends. Polym. Test. 2013, 32, 385–393. [Google Scholar] [CrossRef]

- Vahdatbin, M.; Jamshidi, M. Using chemical agent in microwave assisted devulcanization of NR/SBR blends: An effective recycling method. Resour. Conserv. Recycl. 2022, 179, 106045. [Google Scholar] [CrossRef]

- Xiankui, Z.; Huihui, S.; Chuansheng, W. Experimental Research on Seal Ring in the Pipeline Mixed with r-EPDM. Adv. Mater. Res. 2011, 221, 490–494. [Google Scholar]

- Ghorai, S.; Mondal, D.; Hait, S.; Ghosh, A.K.; Wiessner, S.; Das, A.; De, D. Devulcanization of Waste Rubber and Generation of Active Sites for Silica Reinforcement. ACS Omega 2019, 4, 17623–17633. [Google Scholar] [CrossRef]

- Ghosh, J.; Hait, S.; Ghorai, S.; Mondal, D.; Wießner, S.; Das, A.; De, D. Cradle-to-cradle approach to waste tyres and development of silica based green tyre composites. Resour. Conserv. Recycl. 2020, 154, 104629. [Google Scholar] [CrossRef]

- Saiwari, S.; Waesateh, K.; Lopattananon, N.; Thititammawong, A.; Kaesaman, A. Study on reuse of diphenyl disulfide-devulcanized natural rubber from truck tires. Macromol. Symp. 2015, 354, 155–162. [Google Scholar] [CrossRef]

- Pirityi, D.Z.; Pölöskei, K. Thermomechanical Devulcanisation of Ethylene Propylene Diene Monomer (EPDM) Rubber and Its Subsequent Reintegration into Virgin Rubber. Polymers 2021, 13, 1116. [Google Scholar] [CrossRef] [PubMed]

- Dierkes, W.K.; Dijkhuis, K.; Hoek, H.V.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Saiwari, S.; Blume, A. Designing of cradle-to-cradle loops for elastomer products. Plast. Rubber Compos. 2019, 48, 3–13. [Google Scholar] [CrossRef]

- Dijkhuis, K.A.J. Recycling of Vulcanized EPDM-Rubber—Mechanistic Studies into the Development of a Continuous Process Using Amines as Devulcanization Aids. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 17 April 2008. [Google Scholar]

- Davis, A.R. Plasticizing GR-S and natural rubber. Ind. Eng. Chem. 1947, 39, 94–100. [Google Scholar] [CrossRef]

- Rajan, V.V.; Dierkes, W.K.; Joseph, R.; Noordermeer, J.W.M. Effect of Diphenyldisulfides with Different Substituents on the Reclamation of NR Based Latex Products. J. Appl. Polym. Sci. 2007, 104, 3562–3580. [Google Scholar] [CrossRef]

- van Hoek, J.W.; Heideman, G.; Noordermeer, J.W.M.; Dierkes, W.K.; Blume, A. Implications of the use of silica as active filler in passenger car tire compounds on their recycling options. Materials 2019, 12, 725. [Google Scholar] [CrossRef] [PubMed]

- Rajan, V.V.; Dierkes, W.K.; Joseph, R.; Noordermeer, J.W.M. Recycling of NR based cured latex material reclaimed with 2,2′-dibenzamidodiphenyldisulphide in a truck tire tread compound. J. Appl. Polym. Sci. 2006, 102, 4194–4206. [Google Scholar] [CrossRef]

- van Hoek, H.; Noordermeer, J.; Heideman, G.; Blume, A.; Dierkes, W. Best Practice for De-Vulcanization of Waste Passenger Car Tire Rubber Granulate Using 2-2-dibenzamidodiphenyldisulfide as De-Vulcanization Agent in a Twin-Screw Extruder. Polymers 2021, 13, 1139. [Google Scholar] [CrossRef]

- Ostad Movahed, S.; Ansarifar, A.; Karbalaee, S.; Athary Far, S. Devulcanization and recycling of waste automotive EPDM rubber powder by using shearing action and chemical additive. Prog. Rubber Plast. Recycl. Technol. 2015, 31, 87–116. [Google Scholar] [CrossRef]

- Jalilvand, A.R.; Ghasemi, I.; Karrabi, M.; Azizi, H. A study of EPDM devulcanization in a co-rotating twin-screw extruder. Iran. Polym. J. 2007, 16, 327–335. [Google Scholar]

- Salimi, A.; Abbassi-Sourki, F.; Karrabi, M.; Reza Ghoreishy, M.H. Investigation on viscoelastic behavior of virgin EPDM/ reclaimed rubber blends using Generalized Maxwell Model (GMM). Polym. Test. 2021, 93, 106989. [Google Scholar] [CrossRef]

- Sabzekar, M.; Zohuri, G.; Chenar, M.P.; Mortazavi, S.M.; Kariminejad, M.; Asadi, S. A new approach for reclaiming of waste automotive EPDM rubber using waste oil. Polym. Degrad. Stab. 2016, 129, 56–62. [Google Scholar] [CrossRef]

- Saiwari, S. Post-Consumer Tires Back into New Tires. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 23 May 2013. [Google Scholar]

- Guo, L.; Lv, D.; Ren, D.; Qu, L.; Wang, W.; Hao, K.; Guo, X.; Chen, T.; Sun, J.; Wang, C.; et al. Effectiveness of original additives in waste rubbers for revulcanization after reclamation with a low-temperature mechanochemical devulcanization method. J. Clean. Prod. 2021, 297, 126620. [Google Scholar] [CrossRef]

- Li, W.; Wang, Q.; Jin, J.; Li, S. A life cycle assessment case study of ground rubber production from scrap tires. Int. J. Life Cycle Assess. 2014, 19, 1833–1842. [Google Scholar] [CrossRef]

- Costamagna, M.; Brunella, V.; Luda, M.P.; Romagnolli, U.; Muscato, B.; Girotto, M.; Baricco, M.; Rizzi, P. Environmental assessment of rubber recycling through an innovative thermo-mechanical devulcnaization process using a co-rotating twin-screw exrtruder. J. Clean. Prod. 2022, 348, 131352. [Google Scholar] [CrossRef]

- Hunt, L.K.; Kovalak, R.R. Devulcanization Of Cured Rubbe. US005891926A, 6 April 1999. [Google Scholar]

- Gschwind, L.; Jordan, C.S.; Vennemann, N. Devulcanization of EPDM rubber waste. Effect of diphenyl disulfide derivate as devulcanizing agent on vulcanization, and devulcanization process. J. Appl. Polym. Sci. 2022, 139, 52141. [Google Scholar] [CrossRef]

- Joseph, A.M.; George, B.; Madhusoodanan, K.N.; Alex, R. Cure characteristics of devulcanized rubber: The issue of low scorch. Rubber Chem. Technol. 2017, 90, 536–549. [Google Scholar] [CrossRef]

- Joseph, A.; George, B.; Madhusoodanan, K.; Alex, R. Current status of sulphur vulcanization and devulcanization chemistry: Process of vulcanization. Rubber Sci. 2015, 28, 82–121. [Google Scholar]

- de Sousa, F.D.B.; Zanchet, A.; Marczynski, E.S.; Pistor, V.; Fiorio, R.; Crespo, J.S. Devulcanized EPDM without paraffinic oil in the production of blends as a potential application of the residues from automobile industry. J. Mater. Cycles Waste Manag. 2020, 22, 273–284. [Google Scholar] [CrossRef]

- Tao, G.; He, Q.; Xia, Y.; Jia, G.; Yang, H.; Ma, W. The effect of devulcanization level on mechanical properties of reclaimed rubber by thermal-mechanical shearing devulcanization. J. Appl. Polym. Sci. 2013, 129, 2598–2605. [Google Scholar] [CrossRef]

- De, D.; Maiti, S.; Adhikari, B. Reclaiming of rubber by a renewable resource material (RRM). III. Evaluation of properties of NR reclaim. J. Appl. Polym. Sci. 2000, 75, 1493–1502. [Google Scholar] [CrossRef]

- Saiwari, S.; van Hoek, J.W.; Dierkes, W.K.; Reuvekamp, L.E.A.M.; Heideman, G.; Blume, A.; Noordermeer, J.W.M. Upscaling of a batch de-vulcanization process for ground car tire rubber to a continuous process in a twin screw extruder. Materials 2016, 9, 724. [Google Scholar] [CrossRef] [PubMed]

- Sutanto, P.; Picchioni, F.; Janssen, L.P.B.M. Modelling a continuous devulcanization in an extruder. Chem. Eng. Sci. 2006, 61, 7077–7086. [Google Scholar] [CrossRef]

- Yun, J.; Yashin, V.V.; Isayev, A.I. Ultrasonic devulcanization of carbon black-filled ethylene propylene diene monomer rubber. J. Appl. Polym. Sci. 2004, 91, 1646–1656. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Z.; Peng, Z.; Formela, K.; Wang, S. Dynamic mechanical properties and flexing fatigue resistance of tire sidewall rubber as function of waste tire rubber reclaiming degree. J. Appl. Polym. Sci. 2021, 138, e51290. [Google Scholar] [CrossRef]

- Lv, X.L.; Huang, H.X.; Lv, B.Y. Balancing mechanical properties and processability for devulcanized ground tire rubber using industrially sized single-screw extruder. J. Appl. Polym. Sci. 2016, 133, 43761. [Google Scholar] [CrossRef]

- Seghar, S.; Asaro, L.; Rolland-Monnet, M.; Aït Hocine, N. Thermo-mechanical devulcanization and recycling of rubber industry waste. Resour. Conserv. Recycl. 2019, 144, 180–186. [Google Scholar] [CrossRef]

- Simon, D.Á.; Bárány, T. Effective thermomechanical devulcanization of ground tire rubber with a co-rotating twin-screw extruder. Polym. Degrad. Stab. 2021, 190, 109626. [Google Scholar] [CrossRef]

- Bilgili, E.; Arastoopour, H.; Bernstein, B. Pulverization of rubber granulates using the solid state shear extrusion process: Part II. Powder characterization. Powder Technol. 2001, 115, 277–289. [Google Scholar] [CrossRef]

- Bilgili, E.; Arastoopour, H.; Bernstein, B. Pulverization of rubber granulates using the solid-state shear extrusion (SSSE) process: Part I. Process concepts and characteristics. Powder Technol. 2001, 115, 265–276. [Google Scholar] [CrossRef]

- Tozzi, K.A.; Canto, L.B.; Scuracchio, C.H. Reclaiming of Vulcanized Rubber Foam Waste from the Shoe Industry Through Solid-state Shear Extrusion and Compounding with SBR. Macromol. Symp. 2020, 394, 2000094. [Google Scholar] [CrossRef]

- Mouri, M.; Sato, N.; Okamoto, H.; Matsushlta, M.; Honda, H.; Nakashima, K.; Takeushi, K.; Suzuki, Y.; Owaki, M. Continuous devulcanisation by shear flow stage reaction control technology for rubber recycling. Part 4. Devulcanisation mechanism for EPDM. Int. Polym. Sci. Technol. 2000, 27, T17–T22. [Google Scholar]

- Grundler, M. Optimierung der Thermischen Leitfähigkeit Hochgefüllter Graphit-Polymer-Compounds zur Wärmeableitung. Ph.D. Thesis, Universität Duisburg-Essen, Duisburg, Germany, 15 July 2021. [Google Scholar]

- Irfan, M.S.; Umer, R.; Rao, S. Optimization of Compounding Parameters for Extrusion to Enhance Mechanical Performance of Kenaf-Polypropylene Composites. Fibers Polym. 2021, 22, 1378–1387. [Google Scholar] [CrossRef]

- Kohlgrüber, K. Der Gleichläufige Doppelschneckenextruder—Grundlagen, Technologie, Anwendungen, 2nd ed.; Carl Hanser Verlag: München, Germany, 2016; pp. 290+470. [Google Scholar]

- Macsiniuc, A.; Rochette, A.; Rodrigue, D. Understanding the regeneration of EPDM rubber crumbs from used tyres. Prog. Rubber Plast. Recycl. Technol. 2010, 26, 51–81. [Google Scholar] [CrossRef]

- Tripathy, A.R.; Morin, J.E.; Williams, D.E.; Eyles, S.J.; Farris, R.J. A novel approach to improving the mechanical properties in recycled vulcanized natural rubber and its mechanism. Macromolecules 2002, 35, 4616–4627. [Google Scholar] [CrossRef]

- Mohaved, S.O.; Ansarifar, A.; Nezhad, S.K.; Atharyfar, S. A novel industrial technique for recycling ethylene-propylene-diene waste rubber. Polym. Degrad. Stab. 2015, 111, 114–123. [Google Scholar] [CrossRef]

- Dobrota, D.; Dobrota, G. Reducing of Energy Consumption by Improving the Reclaiming Technology in Autoclave of a Rubber Wastes. Energies 2019, 12, 1460. [Google Scholar] [CrossRef]

- Mandal, S.K.; Alam, N.; Debnath, S.C. Reclaiming of ground rubber tire by safe multifunctional rubber additives: I. Tetra benzylthiuram disulfide. Rubber Chem. Technol. 2012, 85, 629–644. [Google Scholar] [CrossRef]

- Ghosh, J.; Ghorai, S.; Bhunia, S.; Roy, M.; De, D. The role of devulcanizing agent for mechanochemical devulcanization of styrene butadiene rubber vulcanizate. Polym. Eng. Sci. 2018, 58, 74–85. [Google Scholar] [CrossRef]

- Lepadatu, A.M.; Asaftei, S.; Vennemann, N. Investigation of new composite materials based on activated EPDM rubber waste particles by liquid polymers. J. Appl. Polym. Sci. 2015, 132, 42097. [Google Scholar] [CrossRef]

- Lepadatu, A.M. Recycling of EPDM Rubber Waste Particles by Chemical Activation with Liquid Polymers. Ph.D. Thesis, University of Osnabrück, Osnabrück, Germany, 2015. [Google Scholar]

- Barbosa, R.; Ambrosio, J.D. Devulcanization of natural rubber compounds by extrusion using thermoplastics and characterization of revulcanized compounds. J. Polym. Res. 2019, 26, 160. [Google Scholar] [CrossRef]

- Herrmann, V.; Hanning, S.; Kreyenschmidt, M. Untersuchung zur Diffusion des Schwefels in Rezyklat-Kautschukmischungen Teil 1: Bestimmung des Diffusionskoeffizienten. GAK Gummi Fasern Kunstst. 2018, 71, 232–241. [Google Scholar]

- Herrmann, V.; Hanning, S.; Kreyenschmidt, M.; Wolff, A. Untersuchungen zur Diffusion des Schwefels in Rezyklat-Kautschukmischungen Teil 2: Schwefeldiffusion in Mischungen mit Gummimehl. GAK Gummi Fasern Kunstst. 2018, 71, 232–241. [Google Scholar]

- Pistor, V.; Scuracchio, C.H.; Oliveira, P.J.; Fiorio, R.; Zattera, A.J. Devulcanization of ethylene-propylene-diene polymer residues by microwave—Influence of the presence of paraffinic oil. Polym. Eng. Sci. 2011, 51, 697–703. [Google Scholar] [CrossRef]

| t90 [min] | tS2 [min] | ML [Nm] | MH [Nm] | ∆M [Nm] | |

|---|---|---|---|---|---|

| S1-0.4%-C (160 °C) | 3.4 | 0.9 | 7.6 | 14.3 | 6.7 |

| S1-2%-C (160 °C) | 4.0 | 1.3 | 5.8 | 10.6 | 4.9 |

| S1-4%-C (160 °C) | 4.1 | 1.6 | 4.1 | 8.1 | 3.9 |

| X HZ 1 [°C] | Torque Minimum [Nm] | Tensile Strength [MPa] | Nominal Strain at Break [%] |

|---|---|---|---|

| 120 | 4.1 | 8.3 ± 0.8 | 243 ± 20 |

| 140 | 4.4 | 8.5 ± 0.8 | 235 ± 16 |

| 160 | 4.5 | 8.6 ± 0.3 | 257 ± 3 |

| Rotational Speed [1/min] | Shear Rate [1/s] | Mass Temperature [°C] | ||

|---|---|---|---|---|

| S1-2%-D(120 °C) | 150 | 183 | 125 | |

| S1-2%-F(4.5 gpm) | 50 | 263 | 89 | |

| 125 | 656 | 99 | (HZ 5–7) | |

| 200 | 1050 | 114 | ||

| Sample Name | S1-0.4% | S1-2% | S1-4% | S2-5% |

|---|---|---|---|---|

| RWP | 100 wt% | 100 wt% | 100 wt% | 100 wt% |

| DBD | 0.4 wt% | 2 wt% | 4 wt% | |

| A89 | 5 wt% |

| Ingredients | Amount [phr] |

|---|---|

| Polymer | 100 |

| Zinc oxide | 4 |

| Stearic acid | 2 |

| CBS | 2.5 |

| ZBEC | 0.7 |

| Sulfur | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gschwind, L.; Jordan, C.-S. Upscaling of a Mechanochemical Devulcanization Process for EPDM Rubber Waste from a Batch to a Continuous System. Recycling 2023, 8, 8. https://doi.org/10.3390/recycling8010008

Gschwind L, Jordan C-S. Upscaling of a Mechanochemical Devulcanization Process for EPDM Rubber Waste from a Batch to a Continuous System. Recycling. 2023; 8(1):8. https://doi.org/10.3390/recycling8010008

Chicago/Turabian StyleGschwind, Larissa, and Carmen-Simona Jordan. 2023. "Upscaling of a Mechanochemical Devulcanization Process for EPDM Rubber Waste from a Batch to a Continuous System" Recycling 8, no. 1: 8. https://doi.org/10.3390/recycling8010008

APA StyleGschwind, L., & Jordan, C.-S. (2023). Upscaling of a Mechanochemical Devulcanization Process for EPDM Rubber Waste from a Batch to a Continuous System. Recycling, 8(1), 8. https://doi.org/10.3390/recycling8010008