Development and Evaluation of Sustainable Bituminous Paver Blocks

Abstract

1. Introduction

2. Materials

2.1. Bitumen

2.2. Aggregate

2.3. Sustainable Materials

3. Methodology

3.1. Design of HMA

3.2. Specimen Preparation

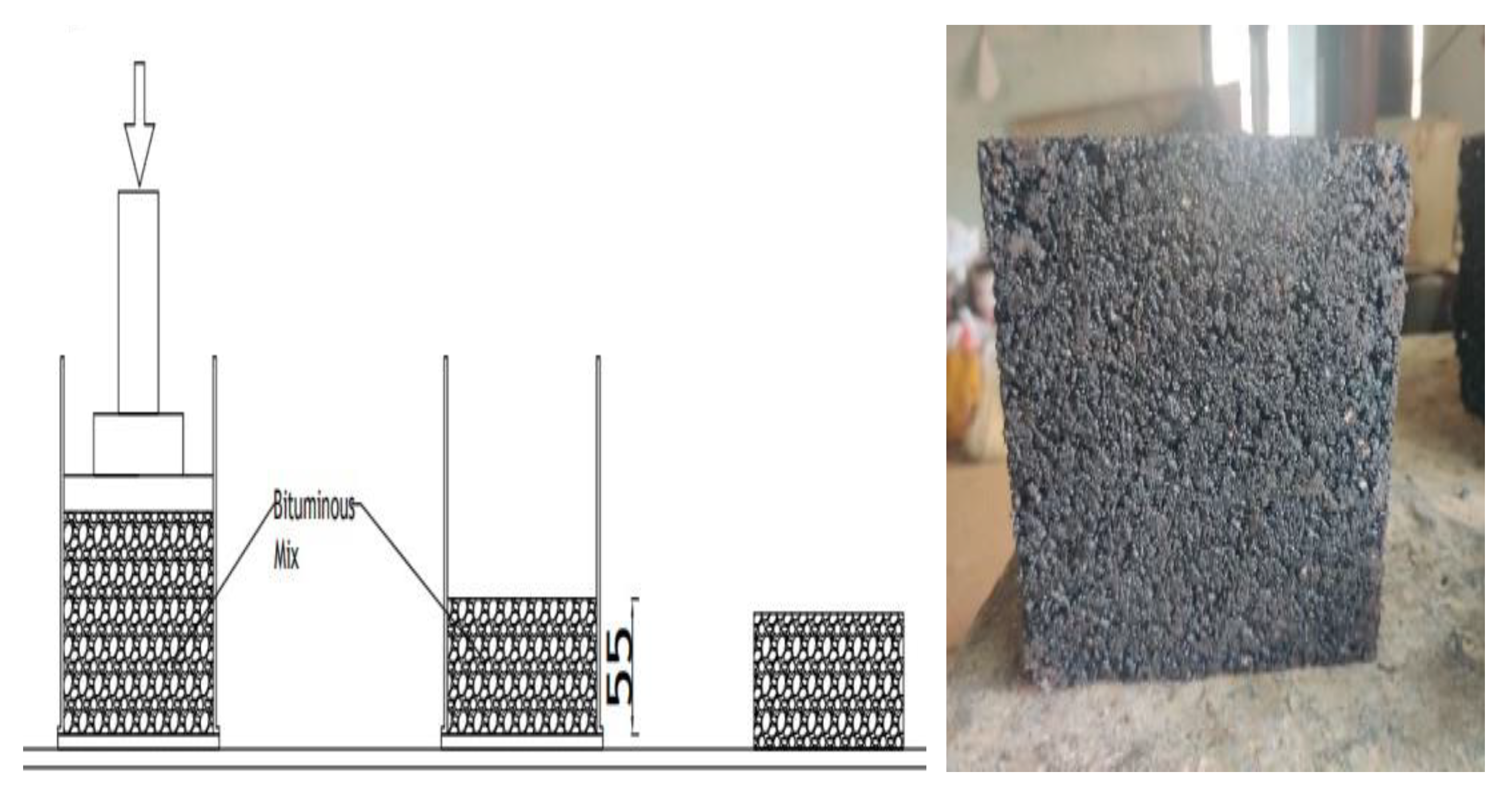

3.3. Preparation of Bituminous Blocks

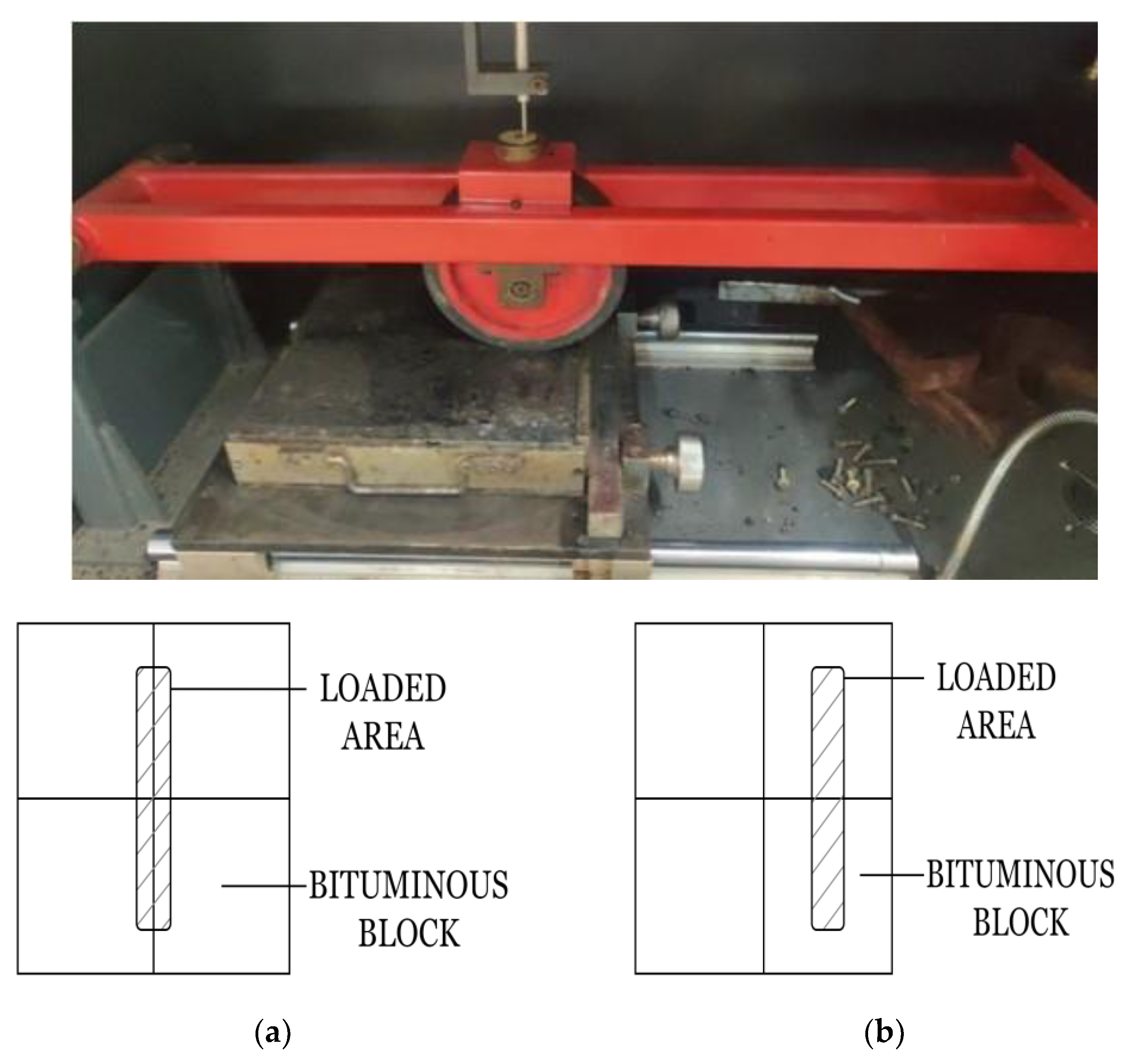

3.4. Test on Bituminous Blocks

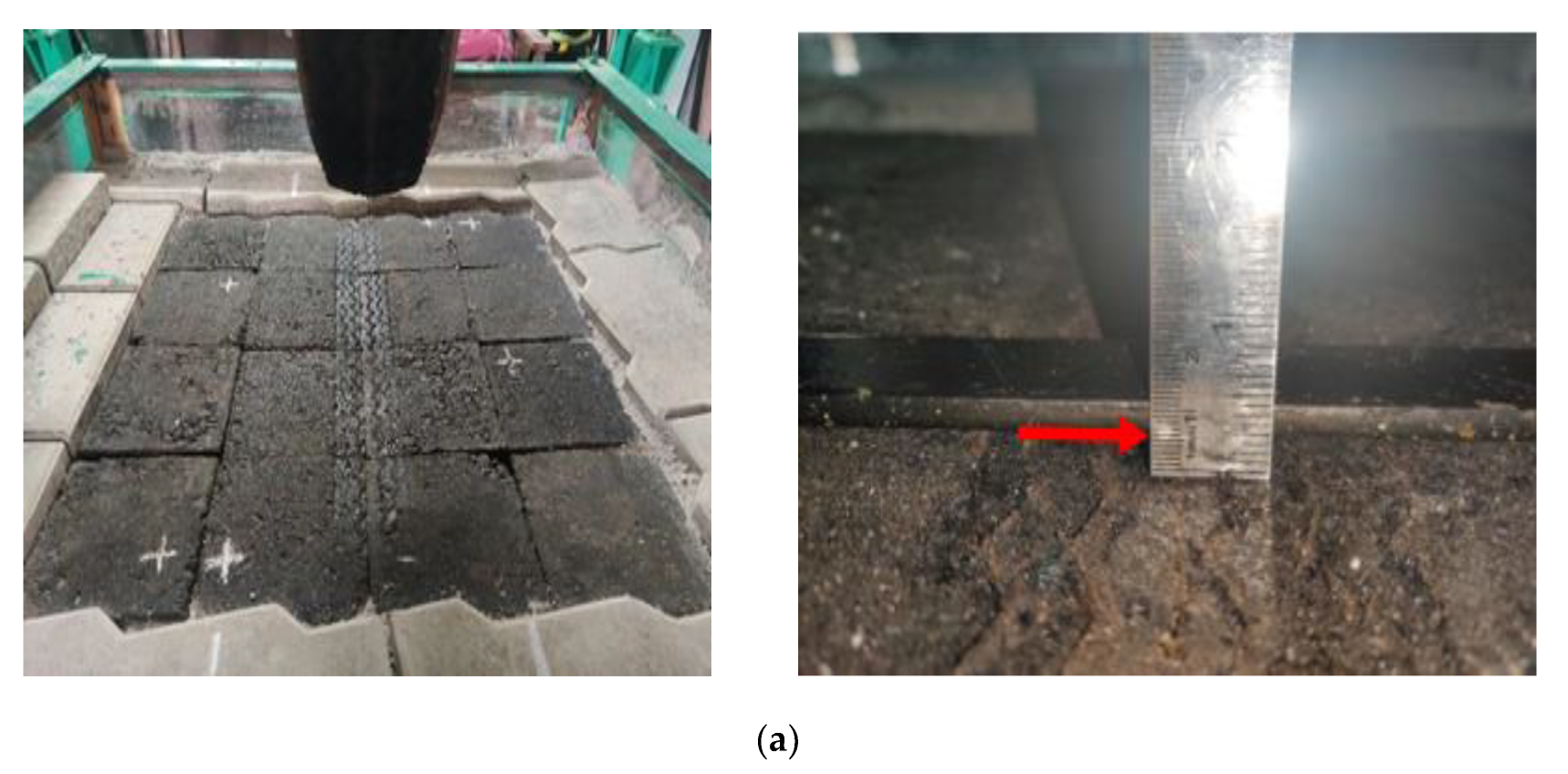

3.5. Field Simulation Test

4. Results and Discussion

4.1. Marshall Stability

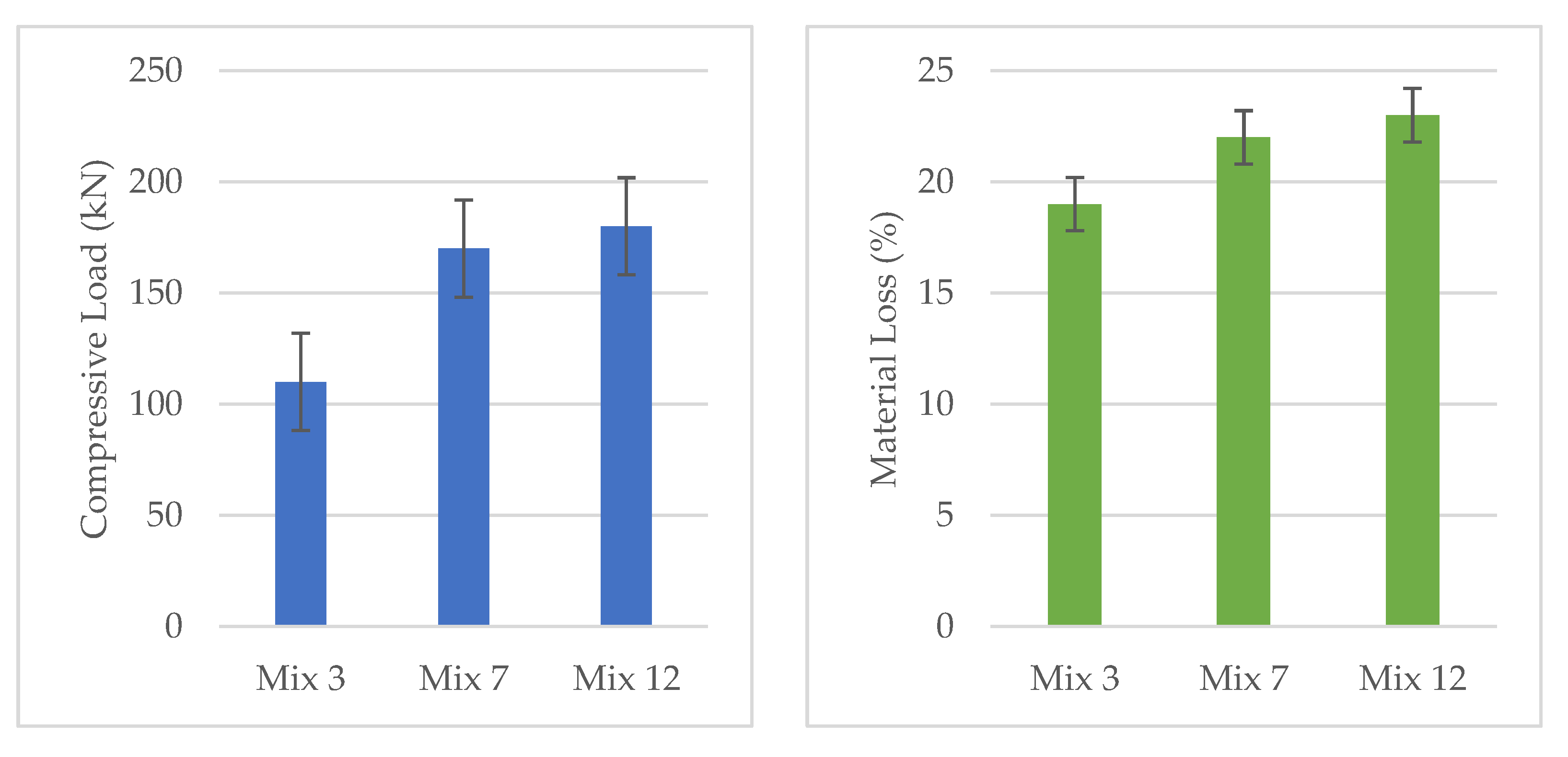

4.2. Evaluation of Bituminous Blocks

4.3. Field Simulation Test

4.4. Cost Comparison

4.5. Trial Implementation in a Parking Lot

4.6. Achievement of Sustainable Development Goals

5. Conclusions

- Optimum bituminous mixes are obtained based on the Marshall test, and the optimum binder content is about 5.5% for the control mix.

- Utilization of sustainable materials in the bituminous mixes could reduce the use of conventional materials by 65%.

- Rut resistance offered by the sustainable bituminous paver blocks using RAP and marble is about 55% and 73%, respectively.

- As per the cost comparison, bituminous pavement blocks cost about 56% less than conventional paver blocks.

- As per the field trial test conducted, the bituminous pavement was found to be in a good and stable condition even after a year, promising durability too.

- From the field simulation test, it can be concluded that the bituminous block does not require any jointing material due to the flexibility in nature of the bituminous mix.

- However, a jointing material could improve the performance of bituminous blocks and load transfer; this needs further study.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MORTH. Basic _Road_Statics_of_India.pdf. 2019. Available online: https://morth.nic.in/basic-road-statistics-india (accessed on 10 November 2020).

- Bressi, S.; Santos, J.; Orešković, M.; Losa, M. A comparative environmental impact analysis of asphalt mixtures containing crumb rubber and reclaimed asphalt pavement using life cycle assessment. Inter. J. Pavem. Eng. 2021, 22, 524–538. [Google Scholar] [CrossRef]

- Forestier, O.; Kim, R.E. Cherry-picking the Sustainable Development Goals: Goal prioritization by national governments and implications for global governance. Sustain. Dev. 2020, 28, 1269–1278. [Google Scholar] [CrossRef]

- United Nations General Assembly. Transforming our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/publications/transforming-our-world-2030-agenda-sustainable-development-17981 (accessed on 17 May 2022).

- Papagiannakis, A.T.; Masad, E.A. Pavement Rehabilitation. Pavement Des. Mater. 2012, in press. [CrossRef]

- Akatsu, K.; Kanou, Y.; Akiba, S. Technical Approaches to the Recycling of Reclaimed Asphalt Pavement into Aggregate and Binder. Constr. Mater. 2022, 2, 85–100. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The Challenges of Using Reclaimed Asphalt Pavement for New Asphalt Mixtures: A Review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef]

- Zhang, J.; Sesay, T.; You, Q.; Jing, H. Maximizing the Application of RAP in Asphalt Concrete Pavements and Its Long-Term Performance: A Review. Polymers 2022, 14, 4736. [Google Scholar] [CrossRef]

- Hand, A.J.T.; Ragavan, P.; Elias, N.G.; Hajj, E.Y.; Sebaaly, P.E. Evaluation of Low Volume Roads Surfaced with 100% RAP Millings. Materials 2022, 15, 7462. [Google Scholar] [CrossRef]

- Olita, S.; Ciampa, D. SuPerPave® Mix Design Method of Recycled Asphalt Concrete Applied in the European Standards Context. Sustainability 2021, 13, 9079. [Google Scholar] [CrossRef]

- Sang, L.; Idowu, T.; Okumu, V. Evaluation of the performance of waste marble dust as a mineral filler in hot-mix asphalt concrete. J. Civ. Eng. Sci. Technol. 2021, 12, 1–14. [Google Scholar] [CrossRef]

- Shekhawat, V.S.; Choudhary, P. Use of Marble Dust As Fillers in Asphalt Pavement. Int. J. Mod. Trends Eng. Res. 2017, 4, 196–204. [Google Scholar] [CrossRef]

- Sufian, M.; Ullah, S.; Ostrowski, K.; Ahmad, A.; Zia, A.; Śliwa-Wieczorek, K.; Siddiq, M.; Awan, A. An Experimental and Empirical Study on the Use of Waste Marble Powder in Construction Material. Materials 2021, 14, 3829. [Google Scholar] [CrossRef]

- Benjeddou, O.; Mashaan, N. Experimental Study of the Usability of Recycling Marble Waste as Aggregate for Road Construction. Sustainability 2022, 14, 3195. [Google Scholar] [CrossRef]

- Wang, T.; Yang, W.; Zhang, J. Experimental Studies on Mechanical Properties and Microscopic Mechanism of Marble Waste Powder Cement Cementitious Materials. Crystals 2022, 12, 868. [Google Scholar] [CrossRef]

- Gautam, P.K.; Kalla, P.; Nagar, R.; Agrawal, R.; Jethoo, A.S. Laboratory investigations on hot mix asphalt containing mining waste as aggregates. Constr. Build. Mater. 2018, 168, 143–152. [Google Scholar] [CrossRef]

- Mistry, R.; Karmakar, S.; Kumar Roy, T. Experimental evaluation of rice husk ash and fly ash as alternative fillers in hot-mix asphalt. Road Mater. Pavement Des. 2019, 20, 979–990. [Google Scholar] [CrossRef]

- Stępień, J.; Maciejewski, K. Using Reclaimed Cement Concrete in Pavement Base Mixes with Foamed Bitumen Produced in Cold Recycling Technology. Materials 2022, 15, 5175. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; Yang, C.; Xie, J.; Xiao, Y.; Zhao, Z.; Wang, F.; Zhang, L. Quantitative Assessment of Road Performance of Recycled Asphalt Mixtures Incorporated with Steel Slag. Materials 2022, 15, 5005. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.; Hassan, N.; Al-Saffar, Z.; Mashaan, N.; Memon, Z.; Milad, A.; Yusoff, N. Effects of Waste Frying Oil and Crumb Rubber on the Characteristics of a Reclaimed Asphalt Pavement Binder. Materials 2021, 14, 3482. [Google Scholar] [CrossRef]

- Khan, Z.H.; Koting, S.; Katman, H.; Ibrahim, M.; Babalghaith, A.; Asqool, O. Performance of High Content Reclaimed Asphalt Pavement (RAP) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Llopis-Castelló, D.; Alonso-Troyano, C.; Álvarez-Troncoso, P.; Marzá-Beltrán, A.; García, A. Design of Sustainable Asphalt Mixtures for Bike Lanes Using RAP and Ceramic Waste as Substitutes for Natural Aggregates. Sustainability 2022, 14, 15777. [Google Scholar] [CrossRef]

- Awed, A.M.; Tarbay, E.W.; El-Badawy, S.M.; Azam, A.M. Performance characteristics of asphalt mixtures with industrial waste/by-product materials as mineral fillers under static and cyclic loading. Road Mater. Pavement Des. 2020, 23, 335–357. [Google Scholar] [CrossRef]

- Edeh, J.E.; Ugama, T.; Okpe, S.A. The use of cement treated reclaimed asphalt pavement-quarry waste blends as highway material. Int. J. Pavement Eng. 2020, 21, 1191–1198. [Google Scholar] [CrossRef]

- Tran, N.; West, R.; Taylor, A.; Willis, R. Evaluation of moderate and high RAP mixtures at laboratory and pavement scales. Int. J. Pavement Eng. 2017, 18, 851–858. [Google Scholar] [CrossRef]

- Nandi, S.; Ransinchung, G.D.R.N. Laboratory investigation of Portland cement concrete paver blocks made with Reclaimed Asphalt Pavement aggregates. Road Mater. Pavement Des. 2022, 23, 546–564. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Zhang, S. A High Proportion Reuse of RAP in Plant-Mixed Cold Recycling Technology and Its Benefits Analysis. Coatings 2022, 12, 1283. [Google Scholar] [CrossRef]

- Saride, S.; Avirneni, D.; Javvadi, S.C.P. Utilization of Reclaimed Asphalt Pavements in Indian Low-Volume Roads. J. Mater. Civ. Eng. 2016, 28, 04015107. [Google Scholar] [CrossRef]

- El-Maaty AE, A.; Elmohr, A.I. Characterization of recycled asphalt pavement (RAP) for use in flexible pavement. Am. J. Eng. Appl. Sci. 2015, 8, 233–248. [Google Scholar] [CrossRef]

- Miró, R.; Valdés, G.; Martínez, A.; Segura, P.; Rodríguez, C. Evaluation of high modulus mixture behaviour with high reclaimed asphalt pavement (RAP) percentages for sustainable road construction. Constr. Build. Mater. 2011, 25, 3854–3862. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Sebaaly, P.E.; Shrestha, R. Laboratory evaluation of mixes containing recycled asphalt pavement (rap). Road Mater. Pavement Des. 2009, 10, 495–517. [Google Scholar] [CrossRef]

- Vega, A.D.L.; Santos, J.; Martinez-Arguelles, G. Life cycle assessment of hot mix asphalt with recycled concrete aggregates for road pavements construction. Int. J. Pavement Eng. 2022, 23, 923–936. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.; Poon, C.S. Promoting effective construction and demolition waste management towards sustainable development: A case study of Hong Kong. Sustain. Dev. 2020, 28, 1713–1724. [Google Scholar] [CrossRef]

- Pham, N.H.; Sauzéat, C.; Di Benedetto, H.; González-León, J.A.; Barreto, G.; Nicolaï, A. Fatigue and Thermal Cracking of Hot and Warm Bituminous Mixtures with Different RAP Contents. Sustainability 2020, 12, 9812. [Google Scholar] [CrossRef]

- Hidalgo, A.; Moreno-Navarro, F.; Tauste, R.; Rubio-Gámez, M. The Influence of Reclaimed Asphalt Pavement on the Mechanical Performance of Bituminous Mixtures. An Analysis at the Mortar Scale. Sustainability 2020, 12, 8343. [Google Scholar] [CrossRef]

- Antunes, V.; Neves, J.; Freire, A.C. Performance Assessment of Reclaimed Asphalt Pavement (RAP) in Road Surface Mixtures. Recycling 2021, 6, 32. [Google Scholar] [CrossRef]

- Barraj, F.; Khatib, J.; Castro, A.; Elkordi, A. Effect of Chemical Warm Mix Additive on the Properties and Mechanical Performance of Recycled Asphalt Mixtures. Buildings 2022, 12, 874. [Google Scholar] [CrossRef]

- Saboo, N.; Prasad, A.N.; Sukhija, M.; Chaudhary, M.; Chandrappa, A.K. Effect of the use of recycled asphalt pavement (RAP) aggregates on the performance of pervious paver blocks (PPB). Constr. Build. Mater. 2020, 262, 120581. [Google Scholar] [CrossRef]

- Vandewalle, D.; Antunes, V.; Neves, J.; Freire, A.C. Assessment of Eco-Friendly Pavement Construction and Maintenance Using Multi-Recycled RAP Mixtures. Recycling 2020, 5, 17. [Google Scholar] [CrossRef]

- Moon, K.H.; Falchetto, A.C. Double-Recycled Reclaimed Asphalt Pavement: A Laboratory Investigation at Low Temperatures Based on Different Mathematical Approaches. Materials 2020, 13, 3032. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Huang, J.; Yang, J.; Song, L.; Xu, J.; Lu, X. Effect of Hot Mixing Duration on Blending, Performance, and Environmental Impact of Central Plant Recycled Asphalt Mixture. Buildings 2022, 12, 1057. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C. Skid Resistance Performance of Asphalt Mixtures Containing Recycled Pavement Materials under Simulated Weather Conditions. Recycling 2022, 7, 47. [Google Scholar] [CrossRef]

- Kore, S.D.; Vyas, A.K. Impact of marble waste as coarse aggregate on properties of lean cement concrete. Case Stud. Constr. Mater. 2016, 4, 85–92. [Google Scholar] [CrossRef]

- Mohan, G.; Faizy, P.; Jacob, A.; Raju, G. Effect of Marble Waste and Coir Fibre Content on the Indirect Tensile Strength of Bituminous Concrete Mixtures. Int. J. Curr. Eng. Technol. 2016, 6, 1287–1294. [Google Scholar]

- Sinha, R.; Kumar, S.; Garg, S.; Prasad, N.M. Use of electronic waste plastic in asphalt mix with marble dust as filler. Indian J. Eng. Mater. Sci. 2021, 28, 36–45. [Google Scholar]

- Moghadas Nejad, F.; Azarhoosh, A.R.; Hamedi, G.H. Laboratory Evaluation of Using Recycled Marble Aggregates on the Mechanical Properties of Hot Mix Asphalt. J. Mater. Civ. Eng. 2013, 25, 741–746. [Google Scholar] [CrossRef]

- Ullah, S.; Alam, M.; Khan, R. Re-use of Marble Waste as Filler Substitute in Bituminous Roads. Int. J. Eng. Res. Appl. 2017, 7, 58–62. [Google Scholar] [CrossRef]

- Priya, P.; Archana, K.; Gohila, C.; Saraswathi, R. Utilization of Waste Plastic in Flexible Pavement with Marble Chips as Aggregate. Int. J. Latest Technol. Eng. 2017, 6, 159–162. [Google Scholar]

- Akbulut, H.; Gürer, C. Use of aggregates produced from marble quarry waste in asphalt pavements. Build. Environ. 2007, 42, 1921–1930. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Fu, X.; Sui, B.; Lv, L. Comparative study on mechanical characteristics of precast HMA block versus concrete block. Int. J. Pavement Eng. 2018, 21, 549–558. [Google Scholar] [CrossRef]

- Abdelgalil, A.; Nor, H. The influence of block thickness on the performance of asphalt paving blocks. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 2129–2134. [Google Scholar] [CrossRef]

- IS 1201; Methods for Testing Tar and Bituminous Materials: Determination of Specific Gravity. Bureau of Indian Standards: New Delhi, India, 1978; Volume 2.

- IS 1203; Methods for Testing tar and Bituminous Materials: Determination of Penetration. Bureau of Indian Standards: New Delhi, India, 1978; Volume 2.

- IS 1205; Methods for Testing Tar and Bituminous Materials: Determination of Softening Point. Bureau of Indian Standards: New Delhi, India, 1978.

- IS 1208; Methods of Testing tar and Bituminous Materials: Determination of Ductility. Bureau of Indian Standards: New Delhi, India, 1978; Volume 1.

- MoRTH. Specifications for Road and Bridge; Ministry of Road Transport and Highways: New Delhi, India, 2013; Third Revision. [Google Scholar]

- SevilKofteci; Niyaziugurkockal. Using Marble Wastes as Fine Aggregate in Hot Mix Asphalt Production. In Proceedings of the International Conference on Advances in Civil, Structural And Construction Engineering-CSCE, Rome, Italy, 7–8 June 2014; Volume 1, Issue 3. pp. 117–121. Available online: http://seekdl.org/nm.php?id=3648 (accessed on 9 June 2020).

- IRC 37; Guidelines for the Design of Flexible Pavements. (Issue Fourth Revision). Indian Road Congress: New Delhi, India, 2018.

- IS 516; Method of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 1959; pp. 1–30.

- Texas DoT, M. and T. D. Test Procedure for Cantabro loss. In TxDoT. Available online: https://ftp.dot.state.tx.us/pub/txdot-info/cst/TMS/200-F_series/pdfs/bit245.pdf (accessed on 1 August 2021).

- Rafiq, W.; Musarat, M.A.; Altaf, M.; Napiah, M.; Sutanto, M.H.; Alaloul, W.S.; Javed, M.F.; Mosavi, A. Life cycle cost analysis comparison of hot mix asphalt and reclaimed asphalt pavement: A case study. Sustainability 2021, 13, 4411. [Google Scholar] [CrossRef]

| RAP Studies | Ref. Literature |

|---|---|

| Mechanical behavior | [19,34,35,36,37] |

| Construction (recycling) | [38,39] |

| Structural performance | [19,20,25,40,41] |

| Serviceability conditions | [19,20,42] |

| Name of the Test | Obtained Result | Standards |

|---|---|---|

| Specific gravity test on bitumen (IS:1202) | 1 | 0.99 minimum |

| Penetration test on bitumen (IS:1203) | 67 | 50–70 |

| Softening point test on bitumen (IS:1205) | 52 °C | 40 –52 °C |

| Ductility test on bitumen (IS:1208) | 77 cm | 75cm minimum |

| Aggregate Nominal Size | Sieve Size (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| 12 mm | 100 | 51.33 | 2.67 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 6 mm | 100 | 100 | 92.58 | 14.04 | 0 | 0 | 0 | 0 | 0 | 0 |

| Filler | 100 | 100 | 100 | 100 | 88.30 | 68.1 | 55.82 | 37.62 | 24.63 | 9.03 |

| Marble | 100 | 100 | 100 | 93.75 | 81.25 | 65.63 | 48.44 | 25 | 15.63 | 6.25 |

| Material (Grams) | Mix 1 | Mix 2 | Mix 3 | Mix 4 |

|---|---|---|---|---|

| 12 mm aggregate | 240 | 240 | 240 | 240 |

| 6 mm aggregate | 360 | 360 | 360 | 360 |

| Filler | 600 | 600 | 600 | 600 |

| Binder Content | 54 | 60 | 66 | 72 |

| Binder % | 4.5 | 5 | 5.5 | 6 |

| Material (Grams) | RAP Mix | Marble Mix | ||||||

|---|---|---|---|---|---|---|---|---|

| Mix 5 | Mix 6 | Mix 7 | Mix 8 | Mix 9 | Mix 10 | Mix 11 | Mix 12 | |

| 12mm aggregate | 216 | 192 | 168 | 144 | 168 | 168 | 168 | 168 |

| 6mm aggregate | 324 | 288 | 252 | 216 | 252 | 252 | 252 | 252 |

| Filler | 540 | 480 | 420 | 360 | 315 | 210 | 105 | 0 |

| RAP | 120 | 240 | 360 | 480 | 360 | 360 | 360 | 360 |

| RAP % | 10 | 20 | 30 | 40 | 30 | 30 | 30 | 30 |

| Bitumen in RAP | 5 | 10 | 15 | 20 | 15 | 15 | 15 | 15 |

| Virgin bitumen | 61 | 56 | 51 | 46 | 51 | 51 | 51 | 51 |

| Marble | 0 | 0 | 0 | 0 | 105 | 210 | 315 | 420 |

| Marble % | 0 | 0 | 0 | 0 | 25 | 50 | 75 | 100 |

| Parameter | RAP Mix | Marble Mix | ||||||

|---|---|---|---|---|---|---|---|---|

| Mix 5 | Mix 6 | Mix 7 | Mix 8 | Mix 9 | Mix 10 | Mix 11 | Mix 12 | |

| Stability (kN) | 9.81 | 11.45 | 12.13 | 10.52 | 10.41 | 10.91 | 11.46 | 12.09 |

| Type | Position | Notation | Rut Depth | Standard Deviation |

|---|---|---|---|---|

| Control Mix | Joint | CMJ | 4.15 | 1.46 |

| Control Mix | Center | CMC | 3.82 | 0.94 |

| RAP Mix | Joint | RMJ | 1.86 | 0.43 |

| RAP Mix | Center | RMC | 1.58 | 0.47 |

| Marble Mix | Joint | MMJ | 1.08 | 0.32 |

| Marble Mix | Center | MMC | 0.77 | 0.18 |

| LVDT | Surface Deformation (mm) | |||||

|---|---|---|---|---|---|---|

| Position | Control Mix Joint | Control Mix Center | Marble Mix Joint | Marble Mix Center | RAP Mix Joint | RAP Mix Center |

| A | 3.6 | 4.6 | 1.85 | 3.4 | 2.21 | 3.36 |

| B | 2.1 | 1 | 1.09 | 1.82 | 0.7 | 0.93 |

| C | 2.9 | 3.1 | 1.12 | 2.89 | 3.9 | 4.3 |

| D | 1.34 | 0.77 | 1.55 | 3.02 | 3.2 | 4.8 |

| Materials | Quantity (kg) | Rate (₹/kg) | Cost (₹) |

|---|---|---|---|

| Bituminous Block | |||

| 12 mm | 2.16 | 0.5 | 1.08 |

| 6 mm | 3.24 | 0.5 | 1.62 |

| Dust | 5.4 | 0.4 | 2.16 |

| Bitumen | 0.594 | 34.6 | 20.55 |

| Total | ₹25.41 ($0.30) | ||

| Conventional Pavement Block | |||

| Coarse Aggregate | 6 | 0.5 | 3 |

| Fine Aggregate | 9 | 1 | 9 |

| Cement | 3 | 9 | 27 |

| Total | ₹39.00 ($0.47) | ||

| Sl. No. | SDG Achieved | Contribution from the Present Work |

|---|---|---|

| 1 | SDG 9: Industry, Innovation and Infrastructure Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation |

|

| 2 | SDG 12: Responsible Consumption and Production Ensure sustainable consumption and production patterns Target 12.5: Substantially reduce waste generation through prevention, reduction, recycling and reuse |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radhakrishnan, P.; Dhurai, V. Development and Evaluation of Sustainable Bituminous Paver Blocks. Recycling 2023, 8, 7. https://doi.org/10.3390/recycling8010007

Radhakrishnan P, Dhurai V. Development and Evaluation of Sustainable Bituminous Paver Blocks. Recycling. 2023; 8(1):7. https://doi.org/10.3390/recycling8010007

Chicago/Turabian StyleRadhakrishnan, Padmakumar, and Vignesh Dhurai. 2023. "Development and Evaluation of Sustainable Bituminous Paver Blocks" Recycling 8, no. 1: 7. https://doi.org/10.3390/recycling8010007

APA StyleRadhakrishnan, P., & Dhurai, V. (2023). Development and Evaluation of Sustainable Bituminous Paver Blocks. Recycling, 8(1), 7. https://doi.org/10.3390/recycling8010007