Abstract

The production and consumption of plastics, which is indispensable in our modern life, has caused severe environmental impacts. Hence, academics and policymakers have been advocating the circularity of plastics. The role of businesses—particularly manufacturing companies—is pivotal to ensuring the circularity of plastics. This study, therefore, attempted to investigate whether chief executives of manufacturing companies based in the EU are keen on the uptake of recycled plastic and, furthermore, whether the uptake of recycled plastic is a worthwhile business strategy. This study found that the attitude, subjective norms and perceived behavioral control of chief executives positively shape their behavioral intention toward the circularity of plastics. Furthermore, the behavioral intentions of chief executives positively influence the uptake of recycled plastic in manufacturing companies, which could consequently improve business performance. This study suggests measures to increase the uptake of recycled plastic among businesses.

1. Introduction

The invention of plastics is undoubtedly one of the key advances that has significantly improved our modern life. Plastic, due to its inherent properties, is considered the most suitable material for various goods and is, thus, indispensable in our modern life. However, the production and consumption of plastics, which have been ever-increasing since the invention of the first synthetic plastic, have been causing severe environmental impacts [1]. Notwithstanding the debate on these environmental impacts, the production and consumption of plastics are expected to increase further in the upcoming decades [2,3].

An underlying issue worthy of attention is that the total plastics produced each year, which typically consume around 8% of the global crude oil extracted [4], turn into a huge quantity of plastic waste and, thereby, entail a huge loss of resources. To avoid this loss of resources and mitigate the environmental impacts of plastics, academics and policymakers have been urging for recycling plastic waste and, more preferably, improving the circularity of plastics [5,6].

The circularity of plastics implies sustaining the economy by utilizing the maximum value of plastics without cascading negative burdens on the environment [7]. Although a majority of plastics may be reutilized or upcycled [8], more than 90% of the total plastic waste produced globally is not yet recycled [2]. The EU is currently losing around 95% of the value of materials in the case of single-use plastics [9]. There is no other way to meet the future demand for plastics except by utilizing plastics in a resourceful manner [10]. Policymakers and businesses have started to realize that waste materials can be reutilized or upcycled, indicating a shift in mindset towards a circular economy [11].

The role of businesses, particularly manufacturing companies, is crucial in this regard, and therefore governments of several countries in the world, including the EU, have been introducing various initiatives to support them in the transition towards a circular economy [12]. The European Commission, knowing the potential to reutilize plastic waste, announced a specific strategy for the circularity of plastics and set ambitious targets for recycling plastic waste [9].

The European Commission aims to increase recycling rates. For that, the European Commission is not only improving the separate collection of plastic waste but also supporting innovations to make plastic products more easily recyclable [9]. The European Commission also aims to increase the uptake of recycled plastic. For that, the European Commission is creating viable markets for trading recycled and renewable plastics [9].

The uptake of recycled plastic would lead to a reduction in global crude oil extraction and consequently curb carbon emissions. While many chief executives or entrepreneurs perceive the prevention of plastic waste as a business opportunity, the current statistics suggest that there is only a 6% demand for recycled plastic in the EU [9]. It is, therefore, imperative to understand what factors hinder the uptake of recycled plastic and how the uptake of recycled plastic could be increased [11].

Several academics have been proposing technical solutions to tackle plastic waste [8,13]. However, tackling the huge amount of plastic waste being generated each year is not a simple problem, nor could technical solutions alone resolve this problem since the viability of such solutions is often undermined by human behavioral traits [14]. The circularity of plastics can only be achieved by conflating both technical solutions and behavioral interventions. The theory of planned behavior (TPB) has been widely employed by academics for explaining human behavior and devising behavioral interventions [15].

Many studies have employed TPB to assess waste recycling behavior at an individual level [16,17,18,19,20]. However, only a few studies have assessed such behavior at an organizational level [6]. There is increasing research on the technical aspects of the circularity of plastics; however, managerial or organizational aspects of this topic have been scarcely investigated [6,21,22]. More specifically, there is a paucity of research on the perceptions of chief executives regarding the uptake of recycled plastic.

This study aims to explore whether chief executives of manufacturing companies are keen to uptake recycled plastic, and if they do so, whether it is worthwhile as a business strategy. In other words, this study assesses the determinants of the behavioral intention of chief executives toward the circularity of plastics. Furthermore, whether their behavioral intention leads to the uptake of recycled plastic, and if they uptake recycled plastic in their companies, whether it consequently improves the business performance.

This study assumes that the personal values or moral attitudes of chief executives can often directly influence the strategic decisions of their companies. Although circular economy decisions are considered inherently complex but personal values or moral attitudes of chief executives could encourage them to proactively take such complex decisions despite the risks involved [23]. Hence, understanding the perceptions of chief executives is pivotal to increasing the circularity of plastics.

2. Theoretical Framework

Waste recycling behavior could be assessed through various theoretical frameworks but the ones that have been widely employed are norm activation, reasoned action and TPB [24]. Notably, TPB, being the most effective framework, is employed in various disciplines for explicating factors shaping human behavior and designing respective behavioral interventions [25]. TPB states that actual behavior is subject to behavioral intention, which is indeed shaped by its antecedents—namely, attitude, subjective norms and perceived behavioral control [26].

Attitude, the first antecedent of behavioral intention, is defined as “the degree to which a person has a favorable or unfavorable evaluation or appraisal of the behavior in question” [26]. Briefly, if a person maintains a positive attitude toward certain behavior, then it would not simply strengthen the intention of that person but may glide that person to conduct that behavior. In contrast, a negative attitude would weaken the intention of that person, which may hold that person back from conducting that behavior.

Several studies on waste recycling behavior have reported a positive correlation between behavioral intention and its antecedent attitude [6,17,18,24]. A case study on circular economy in manufacturing companies highlighted that environmentally conscious chief executives are usually not afraid of the risks involved but rather naturally inclined to introduce sustainability-oriented initiatives [23]. This study, therefore, formulates a hypothesis that chief executives who maintain a positive attitude toward a circular economy would be more interested in the uptake of recycled plastic in their manufacturing companies.

Subjective norms, the second antecedent of behavioral intention, are defined as “the perceived social pressure to perform or not to perform the behavior” [26]. Briefly, expectations of society (or group) to which a person belongs usually influence the intention of that person, which may eventually transform the actual behavior of that person. Several studies on waste recycling behavior have reported a positive correlation between behavioral intention and its antecedent subjective norms [17,19,27,28].

A recent study highlighted that the intention of a chief executive is usually affected in two ways: first, whether companies neighboring his/her company are taking steps toward a circular economy and second, whether other individuals in his/her company are prepared to follow similar steps [6]. This study, therefore, formulates a hypothesis that chief executives who are sensing societal pressure for the circularity of plastics would be more interested in the uptake of recycled plastic in their manufacturing companies.

Perceived behavioral control, the third antecedent of behavioral intention, is defined as “the perceived ease or difficulty of performing the behavior” [26]. Briefly, the capacity of a person to conduct a certain behavior influences the intention of that person, which may eventually transform the actual behavior of that person. This capacity can be interpreted as knowledge of that certain matter and power to take decisions [6,29]. Several studies on waste recycling behavior have reported a positive correlation between behavioral intention and its antecedent perceived behavioral intention [6,16,18].

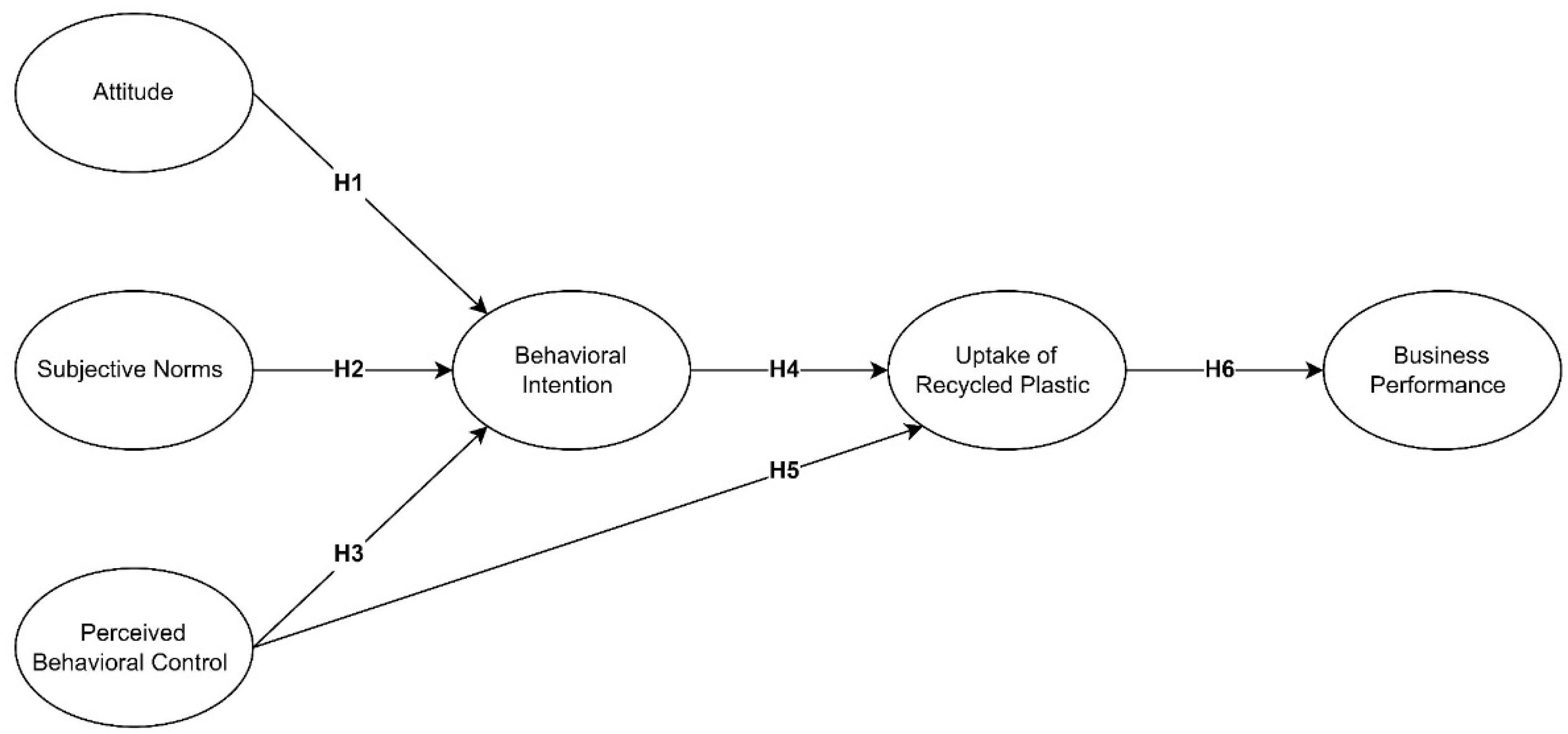

This study, therefore, formulates a hypothesis that chief executives who maintain stronger perceived behavioral control would be more interested in the uptake of recycled plastic in their manufacturing companies. Theoretically speaking, perceived behavioral control could influence actual behavior in both ways—that is, directly and indirectly in the form of mediation via behavioral intention [30]. However, many studies on waste recycling behavior did not consider the direct relationship between perceived behavioral control and actual behavior [16,18]. This study nonetheless considers both relationships. Summing up the above discussion, the first, second, third and fourth hypotheses of this study are presented below (see Figure 1).

Figure 1.

Research model (hypotheses).

H1.

Attitude of chief executives has a positive relationship with their intention toward the circularity of plastics.

H2.

Subjective norms sensed by chief executives have a positive relationship with their intention toward the circularity of plastics.

H3.

Perceived behavioral control of chief executives has a positive relationship with their intention toward the circularity of plastics.

H4.

Perceived behavioral control of chief executives has a positive relationship with the uptake of recycled plastic in their companies.

This study considers behavioral intention as a perceived likelihood or subjective probability of chief executives that they would uptake recycled plastic in their manufacturing companies. Studies have reported a positive correlation between behavioral intention and waste separation behavior [24]. The research on this topic is still in its infancy.

There is limited evidence of whether behavioral intention positively influences plastic recycling [17]. A recent study nonetheless suggested that positive behavioral intention leads to the circularity of plastics [6]. Hence, it could be assumed that chief executives that maintain a positive intention would be more interested in the uptake of recycled plastic in their manufacturing companies. Manufacturing companies led by such chief executives would indeed contribute to the circularity of plastics.

Many academics generally believe that the circular economy is beneficial for the whole society; however, currently, there is limited empirical evidence on whether it improves the overall business performance [12,31]. Plastic recycling is undoubtedly an ongoing need [2]. It is worth mentioning here that there may be no prior research or no empirical evidence available regarding the benefits achieved by companies through plastic recycling.

This is an open question of whether chief executives of companies across sectors are willing to uptake recycled plastic; however, the point to be noted here is that their willingness depends on whether companies doing so are attaining any sort of benefits [11]. This study, therefore, formulates a respective hypothesis and assesses whether manufacturing companies that uptake recycled plastic attain improved business performance. Summing up the above discussion, the fifth and sixth hypotheses of this study are presented below (see Figure 1).

H5.

Behavioral intention of chief executives has a positive relationship with the uptake of recycled plastic in their companies.

H6.

The uptake of recycled plastic in companies has a positive relationship with their business performance.

3. Methodology

3.1. Context and Instrument

Manufacturing companies have been shaping and continuously improving our modern life. However, most of these companies follow unsustainable production and consumption pattern [32]. The manufacturing industry is certainly a significant contributor to the GDP of many countries in the world; however, particularly in the EU, this industry is the backbone of the economy.

For instance, this industry in the EU accounts for 83% of exports and provides around 30 million jobs [33]. The EU has been framing various policies for sustainable development and emphasizing eco-efficiency and competitiveness in the manufacturing industry realizing growing competition from Asia and America [33]. More recently, a new action plan for a circular economy and a specific strategy for plastics are presented [9]. Hence, the EU countries seem suitable to test the proposed hypotheses. This study specifically focused on manufacturing companies located in France, Germany, Italy and Spain since these EU countries are among the top industrialized countries in the world [34].

This study followed a rigorous methodology in the sense that first, the extant literature was reviewed, and then a survey questionnaire was developed, which was later further adapted considering the feedback of practitioners. This survey questionnaire was designed with statements adapted from previous studies to measure the constructs involved in the proposed research model [6,12,29]. These constructs are Attitude (ATT), Subjective Norms (SN), Perceived Behavioral Control (PBC), Behavioral Intention (BI), Uptake of Recycled Plastic (URP) and Business Performance (BP) and were operationalized as the reflective measurement model.

For ATT, SN, PBC and BI, the respondents were requested to rate on a five-point Likert scale (from 1 to 5) whether they disagreed or agreed with the presented statements. For URP, respondents were requested to rate on a five-point Likert scale (from 1 to 5) whether they were not considering or had already implemented the presented strategies. For BP, respondents were requested to rate on a five-point Likert scale (from 1 to 5) the improvement level of the presented aspects.

3.2. Data Collection

The data needed for this study was collected through an online survey that remained active for one month period. This was a sequential process wherein, first, as per the NACE classification, a list of manufacturing companies based in the above-mentioned EU countries was acquired through the Orbis database. Companies that manufacture products, such as beverages, chemicals, food products, pharmaceuticals, plastic products, textiles and apparel, were only considered in that list since these manufacturing companies compared to other manufacturing companies either use more plastics or generate more plastic waste. This study did not consider those manufacturing companies that either use a small amount of plastics or do not use plastics at all.

In the next step, around 1000 manufacturing companies out of that list were randomly selected. Finally, through email invitations, they were requested to participate in the online survey. Consequently, 291 responses were received. However, this study did not compromise in ensuring data quality but rather strictly followed recommended guidelines [35]. First, the social desirability bias was limited by ensuring the confidentiality of respondents [36].

Second, a specific question was included to check whether the respondents were attentive while completing the online survey. Accordingly, inattentive responses were excluded. Thirdly, responses having missing values of more than 15% were deleted [37]. Lastly, straight-lining responses were also excluded. In short, only 228 responses were retained for the analysis. The sample analyzed in this study was diverse; however, most respondents were SMEs (see Table 1).

Table 1.

Sample description.

3.3. Data Analysis

The collected data in this study were analyzed using SmartPLS 4 software through the PLS-SEM technique [38,39]. This study conceptualized and analyzed a mixed-determinants model that contained both individual and organizational-level constructs [40]. A two-level analysis is considered an effective approach and has been used by various studies [6,29]. A sample size could roughly be estimated through a generic rule of thumb, which entails multiplying the maximum number of arrowheads pointing toward a construct in the model by ten.

However, this rule of thumb is no longer advised, and instead Cohen’s statistical formula is considered more reliable [37]. Nonetheless, the sample size in this study is sufficient to assess the proposed hypotheses. PLS-SEM is usually examined and interpreted in two steps, first, the measurement model and then the structural model are assessed [41]. This study followed the same sequence. In short, all rules and guidelines were respected while conducting PLS-SEM in SmartPLS 4 and reporting the analysis [41,42].

4. Results

4.1. Measurement Model

The measurement model was assessed in terms of the reliability, consistency and convergent and discriminant validity of items following the established guidelines [42]. According to these established guidelines, the loadings of items should be above 0.708 in an ideal scenario. However, if the AVE of a construct is above 0.500, then there is no problem in retaining items that have loadings ranging from 0.400 and 0.708 [43]. The loading values of all items ranged from 0.548 to 0.906 while the AVE values of all constructs ranged from 0.548 to 0.800 (see Table 2). Again, according to the established guidelines, CR and Cronbach’s α values of constructs should be above 0.700 in an ideal scenario. The CR values ranged from 0.784 to 0.923, while Cronbach’s α values ranged from 0.629 to 0.875 (see Table 2). Hence, the reliability, consistency and convergent validity of items were comfortably established in this study [42].

Table 2.

Measurement model reliability and validity.

Although the discriminant validity of items could be assessed through cross-loadings, Fornell–Larcker criterion and HTMT criterion, the HTMT criterion is considered the most reliable, and thus it is preferred [44]. This criterion posits that HTMT values must be below 0.850 in an ideal scenario [42]. The HTMT values of all constructs ranged from 0.09 to 0.707 (see Table 3). Hence, the discriminant validity of items was comfortably established in this study [42].

Table 3.

HTMT criterion.

4.2. Structural Model

The structural model was assessed in terms of multicollinearity, predictive power and relevancy and model fitness. The VIF values of constructs were under the threshold limits, which implies that there was no issue of multicollinearity in this study [42]. The R2 values for BI, BP and URP were, respectively, 0.377, 0.036 and 0.146, which implies that the predictive power of the model is satisfactory knowing the fact that the topic of this study is emerging or under-represented [42]. The Q2 values of BI, BP and URP were, respectively, 0.341, 0.013 and 0.118, which implies that the predictive relevance of the model ranges from small to medium and is certainly acceptable [42]. The SRMR value was 0.078, which is below the threshold limit of 0.08 [37].

The proposed hypotheses were assessed through a bootstrapping function. The analysis indicated that ATT, SN and PBC, respectively, influenced BI by correlation values of 0.289 (p < 0.001), 0.202 (p < 0.01) and 0.257 (p < 0.001). Therefore, H1, H2 and H3 are accepted (see Table 4). The analysis further indicated that BI and PBC, respectively, influenced the URP by correlation values of 0.184 (p < 0.05) and 0.256 (p < 0.01) while URP influenced the BP by a correlation value of 0.190 (p < 0.01). Therefore, H4, H5 and H6 are accepted (see Table 4).

Table 4.

Hypotheses testing.

5. Discussion

The findings of this study validate that attitude, subjective norms and perceived behavioral control of chief executives are significant antecedents that shape their behavioral intentions. Furthermore, the behavioral intentions of chief executives influence the uptake of recycled plastic in manufacturing companies, which could consequently improve business performance.

This study suggests that attitude is the foremost significant antecedent of behavioral intention, which is in line with published studies on waste-recycling behavior [18,24]. Furthermore, this specific finding is also in line with published studies focused on the circular economy [6,45]. In this study, 81% of respondents expressed a positive aggregative attitude toward the circularity of plastics. Plastic recycling is certainly beneficial for the entire society as agreed by 98% of respondents. However, the perceptions of chief executives seem to be divided when it comes to taking responsibility for accelerating the circularity of plastics.

This is a somewhat concerning situation as only 60% of respondents agreed that their company should take responsibility for contributing to the circularity of plastics. Nonetheless, the bright side is that chief executives are becoming increasingly inclined toward the use of recycled materials compared to the situation in past decades [46]. An important point is that 78% of respondents agreed that the uptake of recycled plastic is financially rewarding, and 88% of respondents agreed that doing so would give them moral satisfaction. In short, policies regarding the circular economy should be devised keeping these aspects in mind.

Published studies on waste recycling behavior and circular economy reported that perceived behavioral control is an insignificant antecedent of behavioral intention [17,27,45]. In contrast with those studies, this study generally indicates that perceived behavioral control is a significant antecedent of behavioral intention, which is interestingly in line with recently published studies focused on similar topics [6,20].

In this study, 73% of respondents expressed that they held a positive aggregative perceived behavioral control. While 12% of respondents explicitly expressed that they had no idea how they could uptake recycled plastic in their companies. This implies that chief executives need to be informed about the potential applications of recycled plastic in their companies and more importantly how they can manage the required resources to implement a circular economy.

Published studies highlighted an insignificant relationship between subjective norms and the behavioral intention of respondents toward recycling [18,20]. This study, in contrast to those referred studies but consistent with many published studies [6,17,19,27,45], suggests that subjective norms, though not so strong, are yet a significant antecedent of behavioral intention. Indeed, subjective norms are recognized to yield the least correlation values with behavioral intention compared to the other two antecedents—namely, attitude and perceived behavioral control [29].

It is unsurprising that only 62% of respondents agreed that aggregative societal pressure or norms are not yet so stringent for the circularity of plastics. More specifically, only 54% of respondents perceived that their neighboring companies are aligning their business strategies in line with circular economy objectives. Published studies argued that there is a lack of supply and demand for recycled plastic since the plastic industry as a whole is still underdeveloped in connection to a circular economy [10,47,48]. It is nonetheless interesting that 64% of respondents agreed that most people inside their companies are favoring a shift toward a circular economy, which implies that, sooner or later, the demand for recycled plastic will evolve.

As proposed by academics perceived behavioral control and behavioral intention are significant antecedents of actual behavior [15], and this study affirms the same. Although 84% of respondents expressed positive aggregative intention toward the circularity of plastics, most manufacturing companies seem to be involved mainly in using recycled plastic in product packaging.

Most manufacturing companies have not yet commenced using recycled plastic as a raw material nor they have established a take-back system for their own product plastic packaging. Indeed, only 31% and 21% of respondents reported that their companies are using recycled plastic as a raw material and have established a take-back system for their own product plastic packaging. Most manufacturing companies are not yet contributing to the circularity of plastics.

Academics are optimistic that the circularity of plastics is not an impossible task but rather feasible in several ways, for instance, plastic waste from one company or sector can become input for another and plastic waste, which cannot be used for any reason, can still be used in other technologies [11,49]. However, to do so, strong collaboration between different actors is necessary [10,48,50]. Businesses would probably be keen to know whether the circularity of plastics is worthwhile for them. Manufacturing companies before establishing such collaborations would like to assess whether the uptake of recycled plastic is worthwhile as a business strategy.

In this regard, this study affirms a positive correlation between the uptake of recycled plastic and business performance, which is in line with published studies on similar topics [6,12]. In short, 73% of respondents agreed that the operational costs of their companies were decreased. 57% and 55% of respondents, respectively, agreed that the reputation of their companies was improved while the annual turnover was increased. Lastly, 37% and 34% of respondents, respectively, agreed that the brand value was improved while the profit growth of their companies was increased.

6. Conclusions

The core objective of this study was to understand the perceptions of chief executives toward the circularity of plastics. This study assessed the antecedents of the behavioral intention of chief executives concerning the uptake of recycled plastic and tested whether that strategic move unfolds any tangible benefits to their companies. This study concludes that chief executives possess positive intentions toward the circularity of plastics, yet most manufacturing companies are not using recycled plastic. This intention–behavior gap occurs due to various factors, and, for that, appropriate policies are needed [11]. Nonetheless, this study cautiously concludes that manufacturing companies that have been enacting the circularity of plastics enjoy improved business performance.

This study suggests certain measures to increase the uptake of recycled plastic. Governments or regulatory bodies may offer incentives or subsidies to manufacturing companies that are enacting the uptake of recycled plastic. They may support businesses in conducting life-cycle analysis. There is a need to create a push or momentum toward the circularity of plastics. Governments or regulatory bodies may nurture norms for the circularity of plastics by mandating that a certain percentage of recycled materials must be used either in product or manufacturing operations. Chief executives or top management with a clear and sustainability-oriented vision can stimulate product and process innovation that can increase the uptake of recycled materials.

Therefore, governments should motivate and train chief executives by engaging them in various campaigns. Trade associations should introduce initiatives focused on promoting networking and knowledge exchange. They should consider establishing a platform where businesses and recyclers could contact each other and thereby know potential uses and trade recycled materials. Chief executives should emphasize knowledge management for circular economy objectives, nurture the culture of sustainability, revamp their governing style and attempt to obtain environmental certifications since this would not only reduce operational costs but also improve brand value and attract more customers.

This study, despite its merits, suffers certain limitations. This study considered antecedents of the behavioral intention of chief executives but did not consider other factors, such as regulatory pressure, market pressure and technical standards for the product in question, although these factors are perceived as more important when it comes to the shifting from primary to secondary material. Although this study strived to avoid social desirability bias, which is an inherent feature of online surveys, such biases could not be completely ruled out.

Hence, the perceptions of certain respondents may not be in line with the rational reality. This study includes another limitation in the sense that the uptake of recycled plastic and related business performance was measured through self-reported data. It was not feasible to measure them objectively due to various constraints. This study is limited to a sample size of 228 manufacturing companies taken from four EU countries; thus, its findings should be generalized to other countries with caution. Nevertheless, it is expected that this study would open future research possibilities.

A similar study, for instance, could be replicated in various parts of the world to obtain more valuable insights. It would be interesting to empirically assess the barriers that cause the intention—behavior gap in implementing the circularity of plastics. Lastly, a qualitative study could be conducted to better understand the perceptions of managers across different departments in companies to showcase how successful companies have implemented a circular economy for plastics.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The author declares no conflict of interest.

References

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-Use Plastics: Production, Usage, Disposal, and Adverse Impacts. Sci. Total Environ. 2021, 752, 141772. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; OECD Publishing: Paris, France, 2022; ISBN 9789264654945. [Google Scholar]

- Huysman, S.; De Schaepmeester, J.; Ragaert, K.; Dewulf, J.; De Meester, S. Performance Indicators for a Circular Economy: A Case Study on Post-Industrial Plastic Waste. Resour. Conserv. Recycl. 2017, 120, 46–54. [Google Scholar] [CrossRef]

- Milios, L.; Davani, A.E.; Yu, Y. Sustainability Impact Assessment of Increased Plastic Recycling and Future Pathways of Plastic Waste Management in Sweden. Recycling 2018, 3, 33. [Google Scholar] [CrossRef]

- Khan, O.; Daddi, T.; Slabbinck, H.; Kleinhans, K.; Vazquez-Brust, D.; De Meester, S. Assessing the Determinants of Intentions and Behaviors of Organizations towards a Circular Economy for Plastics. Resour. Conserv. Recycl. 2020, 163, 105069. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics & Catalysing Action; Ellen Macarthur Foundation: Cowes, UK, 2017. [Google Scholar]

- Ragaert, K.; Huysveld, S.; Vyncke, G.; Hubo, S.; Veelaert, L.; Dewulf, J.; Du Bois, E. Design from Recycling: A Complex Mixed Plastic Waste Case Study. Resour. Conserv. Recycl. 2020, 155, 104646. [Google Scholar] [CrossRef]

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Milios, L.; Holm Christensen, L.; McKinnon, D.; Christensen, C.; Rasch, M.K.; Hallstrøm Eriksen, M. Plastic Recycling in the Nordics: A Value Chain Market Analysis. Waste Manag. 2018, 76, 180–189. [Google Scholar] [CrossRef]

- Van der Vegt, M.; Velzing, E.-J.; Rietbergen, M.; Hunt, R. Understanding Business Requirements for Increasing the Uptake of Recycled Plastic: A Value Chain Perspective. Recycling 2022, 7, 42. [Google Scholar] [CrossRef]

- Khan, O.; Daddi, T.; Iraldo, F. The Role of Dynamic Capabilities in Circular Economy Implementation and Performance of Companies. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 3018–3033. [Google Scholar] [CrossRef]

- Sandhiya, R.; Ramakrishna, S. Correction to: Investigating the Applicability of Blockchain Technology and Ontology in Plastics Recycling by the Adoption of ZERO Plastic Model. Mater. Circ. Econ. 2021, 3, 8. [Google Scholar] [CrossRef]

- Heidbreder, L.M.; Bablok, I.; Drews, S.; Menzel, C. Tackling the Plastic Problem: A Review on Perceptions, Behaviors, and Interventions. Sci. Total Environ. 2019, 668, 1077–1093. [Google Scholar] [CrossRef]

- Ajzen, I. From Intentions to Actions: A Theory of Planned Behavior. In Action Control; Springer: Berlin/Heidelberg, Germany, 1985; pp. 11–39. [Google Scholar]

- Taylor, S.; Todd, P. An Integrated Model of Waste Management Behavior: A Test of Household Recycling and Composting Intentions. Environ. Behav. 1995, 27, 603–630. [Google Scholar] [CrossRef]

- Khan, F.; Ahmed, W.; Najmi, A. Understanding Consumers’ Behavior Intentions towards Dealing with the Plastic Waste: Perspective of a Developing Country. Resour. Conserv. Recycl. 2019, 142, 49–58. [Google Scholar] [CrossRef]

- Tonglet, M.; Phillips, P.S.; Read, A.D. Using the Theory of Planned Behaviour to Investigate the Determinants of Recycling Behaviour: A Case Study from Brixworth, UK. Resour. Conserv. Recycl. 2004, 41, 191–214. [Google Scholar] [CrossRef]

- Huang, M.; Law, K.M.Y.; Geng, S.; Niu, B.; Kettunen, P. Predictors of Waste Sorting and Recycling Behavioural Intention among Youths: Evidence from Shenzhen, China and Turku, Finland. Waste Manag. Res. 2022, 40, 721–735. [Google Scholar] [CrossRef]

- Botetzagias, I.; Dima, A.F.; Malesios, C. Extending the Theory of Planned Behavior in the Context of Recycling: The Role of Moral Norms and of Demographic Predictors. Resour. Conserv. Recycl. 2015, 95, 58–67. [Google Scholar] [CrossRef]

- Li, H.; Aguirre-Villegas, H.A.; Allen, R.D.; Bai, X.; Benson, C.H.; Beckham, G.T.; Bradshaw, S.L.; Brown, J.L.; Brown, R.C.; Cecon, V.S.; et al. Expanding Plastics Recycling Technologies: Chemical Aspects, Technology Status and Challenges. Green Chem. 2022, 24, 8899–9002. [Google Scholar] [CrossRef]

- N, S. Plastic Waste Management: A Road Map to Achieve Circular Economy and Recent Innovations in Pyrolysis. Sci. Total Environ. 2022, 809, 151160. [Google Scholar] [CrossRef]

- Khan, O.; Daddi, T.; Iraldo, F. Microfoundations of Dynamic Capabilities: Insights from Circular Economy Business Cases. Bus. Strategy Environ. 2020, 29, 1479–1493. [Google Scholar] [CrossRef]

- Zaikova, A.; Deviatkin, I.; Havukainen, J.; Horttanainen, M.; Astrup, T.F.; Saunila, M.; Happonen, A. Factors Influencing Household Waste Separation Behavior: Cases of Russia and Finland. Recycling 2022, 7, 52. [Google Scholar] [CrossRef]

- Yuriev, A.; Dahmen, M.; Paillé, P.; Boiral, O.; Guillaumie, L. Pro-Environmental Behaviors through the Lens of the Theory of Planned Behavior: A Scoping Review. Resour. Conserv. Recycl. 2020, 155, 104660. [Google Scholar] [CrossRef]

- Ajzen, I. The Theory of Planned Behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar] [CrossRef]

- Chen, M.-F.; Tung, P.-J. The Moderating Effect of Perceived Lack of Facilities on Consumers’ Recycling Intentions. Environ. Behav. 2010, 42, 824–844. [Google Scholar] [CrossRef]

- Sidique, S.F.; Lupi, F.; Joshi, S.V. The Effects of Behavior and Attitudes on Drop-off Recycling Activities. Resour. Conserv. Recycl. 2010, 54, 163–170. [Google Scholar] [CrossRef]

- Khan, O.; Bellini, N.; Daddi, T.; Iraldo, F. Effects of Behavioral Intention and Dynamic Capabilities on Circular Economy Adoption and Performance of Tourism SMEs. J. Sustain. Tour. 2022, 1–20. [Google Scholar] [CrossRef]

- Fishbein, M.; Ajzen, I. Predicting and Changing Behavior: The Reasoned Action Approach; Psychology Press: New York, NY, USA, 2011; ISBN 9781136874734. [Google Scholar]

- Zhu, Q.; Geng, Y.; Lai, K. Circular Economy Practices among Chinese Manufacturers Varying in Environmental-Oriented Supply Chain Cooperation and the Performance Implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Bjørnbet, M.M.; Skaar, C.; Fet, A.M.; Schulte, K.Ø. Circular Economy in Manufacturing Companies: A Review of Case Study Literature. J. Clean. Prod. 2021, 294, 126268. [Google Scholar] [CrossRef]

- Federal Ministry for Economic Affairs and Climate Action European Industrial Policy. Available online: https://www.bmwk.de/Redaktion/EN/Artikel/Industry/european-industrial-policy.html (accessed on 10 October 2022).

- Eurostat Industrial Production Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Industrial_production_statistics (accessed on 10 October 2022).

- Kostyk, A.; Zhou, W.; Hyman, M.R.; Paas, L. Securing Higher-Quality Data from Self-Administered Questionnaires. Int. J. Mark. Res. 2021, 63, 685–692. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Hair, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM), 2nd ed.; Sage: Thousand Oaks, CA, USA, 2017; ISBN 9781483377445. [Google Scholar]

- Ringle, C.M.; Wende, S.; Becker, J.-M. SmartPLS 4; SmartPLS GmbH: Oststeinbek, Germany, 2022. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a Silver Bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Klein, K.J.; Dansereau, F.; Hall, R.J. Levels Issues in Theory Development, Data Collection, and Analysis. Acad. Manag. Rev. 1994, 19, 195–229. [Google Scholar] [CrossRef]

- Chin, W.W. How to Write Up and Report PLS Analyses. In Handbook of Partial Least Squares; Springer: Berlin/Heidelberg, Germany, 2010; pp. 655–690. ISBN 978-3-540-32825-4. [Google Scholar]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to Use and How to Report the Results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Hair, J.F.; Sarstedt, M.; Ringle, C.M.; Mena, J.A. An Assessment of the Use of Partial Least Squares Structural Equation Modeling in Marketing Research. J. Acad. Mark. Sci. 2012, 40, 414–433. [Google Scholar] [CrossRef]

- Ali, F.; Rasoolimanesh, S.M.; Sarstedt, M.; Ringle, C.M.; Ryu, K. An Assessment of the Use of Partial Least Squares Structural Equation Modeling (PLS-SEM) in Hospitality Research. Int. J. Contemp. Hosp. Manag. 2018, 30, 514–538. [Google Scholar] [CrossRef]

- Singh, M.P.; Chakraborty, A.; Roy, M. Developing an Extended Theory of Planned Behavior Model to Explore Circular Economy Readiness in Manufacturing MSMEs, India. Resour. Conserv. Recycl. 2018, 135, 313–322. [Google Scholar] [CrossRef]

- Lanhrehr, V.B.; Langrehr, F.W.; Tatreau, J. Business Users’ Attitudes toward Recycled Materials. Ind. Mark. Manag. 1992, 21, 361–367. [Google Scholar] [CrossRef]

- Ritzén, S.; Sandström, G.Ö. Barriers to the Circular Economy—Integration of Perspectives and Domains. Procedia CIRP 2017, 64, 7–12. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring Institutional Drivers and Barriers of the Circular Economy: A Cross-Regional Comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and Drivers in a Circular Economy: The Case of the Built Environment. In Proceedings of the 26th CIRP Conference on Life Cycle Engineering (LCE) Purdue University, West Lafayette, IN, USA, 7–9 May 2019. [Google Scholar]

- Paletta, A.; Leal Filho, W.; Balogun, A.L.; Foschi, E.; Bonoli, A. Barriers and Challenges to Plastics Valorisation in the Context of a Circular Economy: Case Studies from Italy. J. Clean. Prod. 2019, 241, 118149. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).