Abstract

The mechanical properties of virgin/recycled high-density polyethylene (HDPE) blends over the complete concentration range was thoroughly investigated in this work. In particular, a focus was made on the long-term properties via mechanical fatigue. Two different mixing methods, namely powder mixing (dry blending) and extrusion mixing (melt blending), were used to determine the effect of processing conditions on the tensile and fatigue behavior of the blends after compression molding. It was found that both tensile (modulus, ultimate strength) and fatigue performances were improved with increasing vHDPE content. Based on the obtained data, a correlation between the blends composition and mechanical properties is reported. Moreover, it was observed that increasing the vHDPE content led to slower crack propagation rate, probably due to less defects (contamination) in the blends. Finally, a negligible difference in mechanical properties (fatigue resistance) between both mixing approaches was observed, but samples produced via powder mixing showed less viscous dissipation (heat generation) as the vHDPE content increased, leading to lower surface temperature rise which can be an advantage for specific applications.

1. Introduction

Petroleum-based polymers can leave noticeable environmental footprint after their service life. Still today, most of the synthetic polymers end up in landfills and oceans, while only a small percentage is recycled. For example, only 9% [1] and 5% [2] of waste plastics were recycled in Canada and USA, respectively, despite years of effort. Recent studies reported that plastics will contribute to 15% of the global carbon budget with respect to greenhouse gas emissions (GHG) by 2050 under the current production rate [3]. However, a stringent cap for carbon emission has been set globally as 45% reduction in CO2 emissions compared to 2010, which must be achieved by 2030 [4]. This situation conflicts between increasing demands for plastics and more concern for environmental protection, which must be balanced. Therefore, the producers, policy makers and researchers are now under pressure to take responsibility and find solutions for this challenge. This is why several investigations focused on recycling polymers (plastics) to convert the conventional linear economy of the plastics industry into a circular one [5,6,7,8,9].

Mechanical recycling is one of the most effective and commonly used approaches to tackle the plastics residues problem. From an engineering point of view, the challenges of the polymer recycling industry are related to difficulty to predict and obtain consistent/uniform/stable mechanical properties depending on the source/origin of the material and the recycling process used [10]. The source/origin can affect the molecular weight distribution because the recovered plastics can be a mixture of resins with different molecular properties. For example, neat-recycled HDPE could contain HDPE with different molecular weights. In another case, the recycled HDPE could be contaminated by other polymers with different resins such as polystyrene (PS), polyethylene terephthalate (PET), etc. in open-loop recycling. Additionally, the presence of low molecular weight impurities, such as solvent residues (esters and alcohols), additives and other degradation products, can influence the molecular weight [11,12,13]. In addition, the recycling conditions, such as temperature, pressure and speed, can modify the molecular weight distribution resulting in significant mechanical and rheological changes. This is because, on the one hand, mechanical degradation of the polymer occurs due to high shear and elongational rates preferentially breaking the polymer chains near their midpoint [14,15,16]. It was found that the molecular weight (MW) at the peak of the molecular weight distribution (MWD) of degraded polyacrylamide was shifted to the left (lower values) by about 50% of the highest MW compared to a virgin polymer sample. On the other hand, polymer backbones (long chains) start to break (scission) at high temperature and these macroradicals then attach to unsaturated ends of other chains producing chain branching during thermal degradation [17].

For example, high-density polyethylene (HDPE) shows different behaviors during extrusion. At higher temperatures, the longer chains having higher entanglements probability are subjected to pulling/elongational stresses [17,18]. Furthermore, the dissolved oxygen (high oxygen content) leads to thermo-oxidative chain scission of the polymer backbones. In contrast, shear-induced chain scission dominates over chain branching at low oxygen content [18,19]. On the other hand, shorter chains are less sensitive to mechanical stresses, but more incline towards chain branching [19,20,21]. Another observation was that chain branching is the dominant phenomenon up to about 30 extrusion cycles [5,20,21], while chain scission dominates between 30 and 60 extrusion cycles [5,22]. Finally, crosslinking shows the highest probability for higher number of recycling cycles [5,23,24]. Therefore, these parameters will control the variation of mechanical properties, such as modulus, toughness, ultimate strength, deformation at break, fatigue resistance and so forth.

A wide range of studies havereported on the changes in mechanical properties after polymer recycling, but different resins behave differently. For example, the mechanical performance of reprocessed polyethylene terephthalate (rPET) was reported to be about 56–70% less for tensile strength compared to a virgin one. Moreover, the impact strength of rPET was reduced by 93–98% [25]. Therefore, significant loss of mechanical properties for rPET is not desirable to return the polymer for new applications. The elongation at break of recycled polypropylene (rPP) was reported to decrease by 30% compared to virgin PP after nine recycling cycles [9,26]. High-density polyethylene (HDPE) was reported to lose hardness and modulus only after ten cycles [23], while the modulus (E) of recycled polystyrene (rPS) can drop by 30% combined with limited reduction in hardness (3%) after eight reprocessing cycles [27].

However, several studies were performed to improve the specific mechanical properties after recycling. For example, the tensile strength of recycled high impact polystyrene (rHIPS) was slightly increased after four cycles, while the tensile strength was improved by 125% after 4 cycles for a HIPS nanocomposite (HIPS + 5 wt.% clay) [28]. Recycled polyvinylchloride (rPVC) did not show significant reduction in its modulus and tensile strength, but improved impact strength was reported [29]. The elastic modulus of rPP can be increased by around 18% after nine recycling cycles [9]. Recent studies also reported that the tensile strength of rHDPE specimens manufactured via 3D printing increased by 23% after 5 recycling cycles. The flexural and impact strengths were also found to increase by 19% and 53% after three and two, respectively [6].

Hence, to control the performance of regenerated/recycled materials from waste plastics, different strategies, such as re-stabilization, rebuilding, compatibilization and addition of additives/fillers, are usually applied [30]. However, blending recycled resins with virgin ones is a simple and easy method to mitigate the overall properties of recycled polymers. For example, blending virgin/recycled HDPE up to 70% of recycled contents can provide similar mechanical and rheological properties as the virgin HDPE when compatibilizing agents, such as linear low-density polyethylene (LLDPE), was added [31]. Mixing medium density polyethylene (MDPE) with rHDPE at 50/50 was reported to give the best impact resistance. It was also found that specimens prepared by compression molding can achieve better impact resistance than rotational molding due to better compaction [32]. Another experimental study reported that increasing the rHDPE weight content can significantly decrease the flexural and tensile strength of v/rHDPE blends [33].

The current literature has identified the uncertainty about the mechanical properties of recycled polymers and methods have been developed to resolve this challenge. However, most of the work focused on improving the tensile, impact and flexural properties of recycled polymers. Unfortunately, very limited information is available on how these modifications affect the long-term properties, such as the fatigue behavior of recycled polymers. Furthermore, the mechanical characterizations are mainly performed under quasi-static conditions (uniaxial tensile) and cannot provide fatigue information under dynamic loadings [10]. This information must now be determined to better understand the relationships between recycling (processes and conditions) on the fatigue performance of recycled polymers to reuse them properly. Additionally, recycled polymers are often contaminated (impurities). Therefore, it is necessary to investigate the differences between recycled and virgin resins from both a chemical and mechanical perspective.

The aim of this study is to determine the effect of blending virgin polymers with recycled ones on both the tensile (short term) and fatigue (long term) properties. In addition, the effect of different mixing approaches, such as powder mixing (solid/dry mixing) and extrusion (melt mixing), are compared. The long-term mechanical properties of these materials are significant for structural, safety and design purposes. However, these dynamic properties under cyclic loadings are not well understood and studied. Therefore, this investigation is based on the commodity polymer HDPE, which was selected as a proof of concept to address these concerns.

2. Results and Discussion

2.1. Morphology Analysis of v/rHDPE Blends

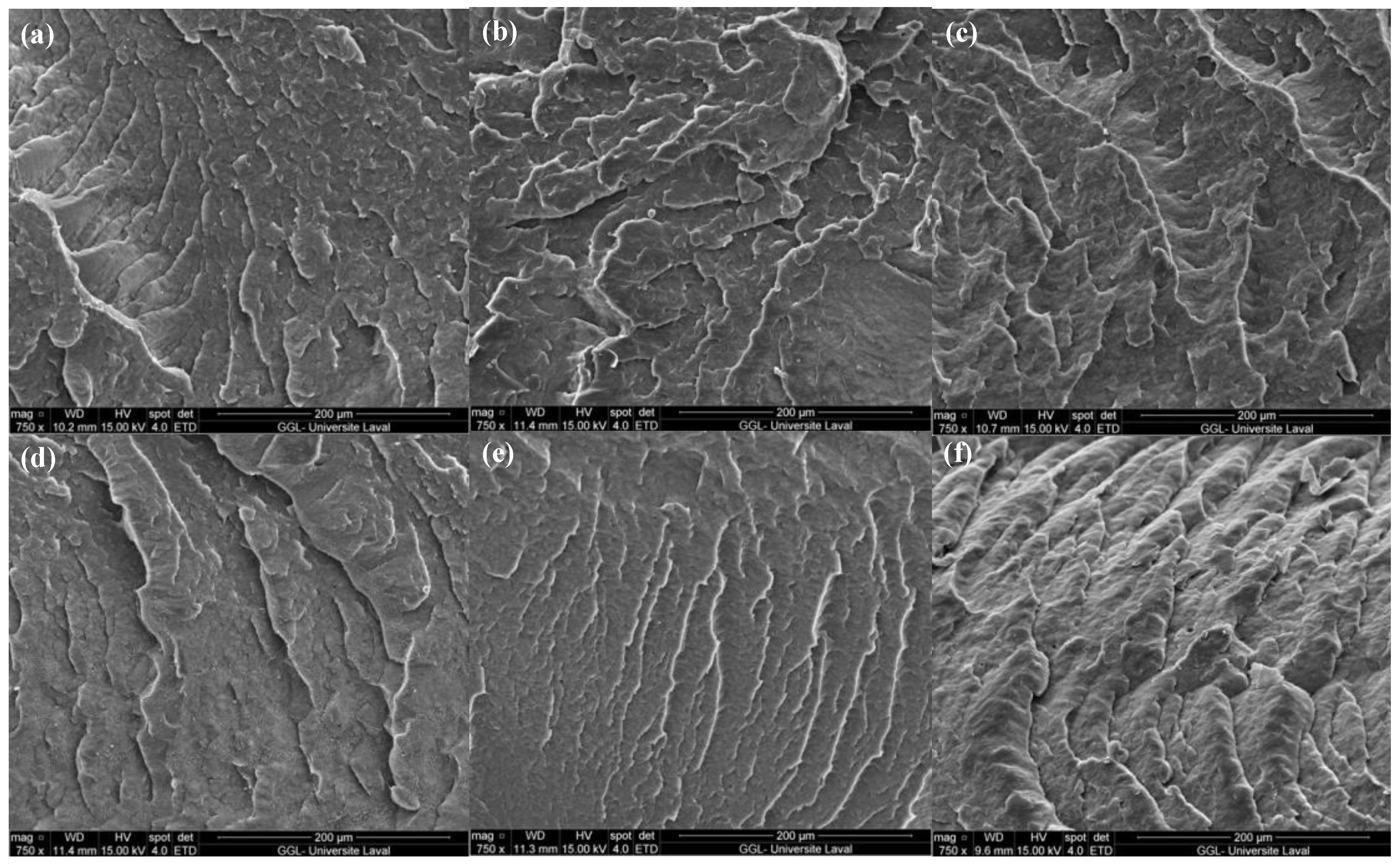

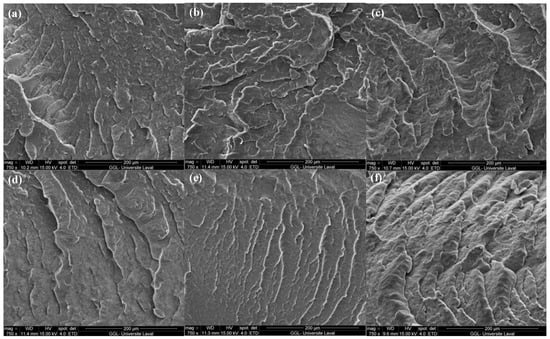

Morphological characterization by scanning electron microscopy (SEM) allows to investigate the structural organization and composition. The surface structure of the blends prepared by powder mixing for a vHDPE concentration of 0 wt.%, 60 wt.% and 100 wt.% can be observed in Figure 1a–c, respectively. Then, the surface morphology of specimens from extrusion mixing at the same vHDPE concentration can be found in Figure 1d–f. A layered structure can be observed in all tested materials. Although all these blends were prepared by different methods (PM vs. EM) at different vHDPE weight concentration, there is no significant difference of their general morphologies. This indicates that both preparation methods cannot be used to differentiate the performances as described later.

Figure 1.

SEM micrographs of the morphology (×750) of: (a,d) vHDPE, (b,e) 60 wt.% vHDPE + 40 wt.% rHDPE and (c,f) rHDPE. The top row (a–c) is powder mixing (PM), and the bottom row (d–f) is extrusion mixing (EM).

2.2. Thermal Properties

2.2.1. Differential Scanning Calorimetry (DSC) Analysis and Melting Flow Index (MFI)

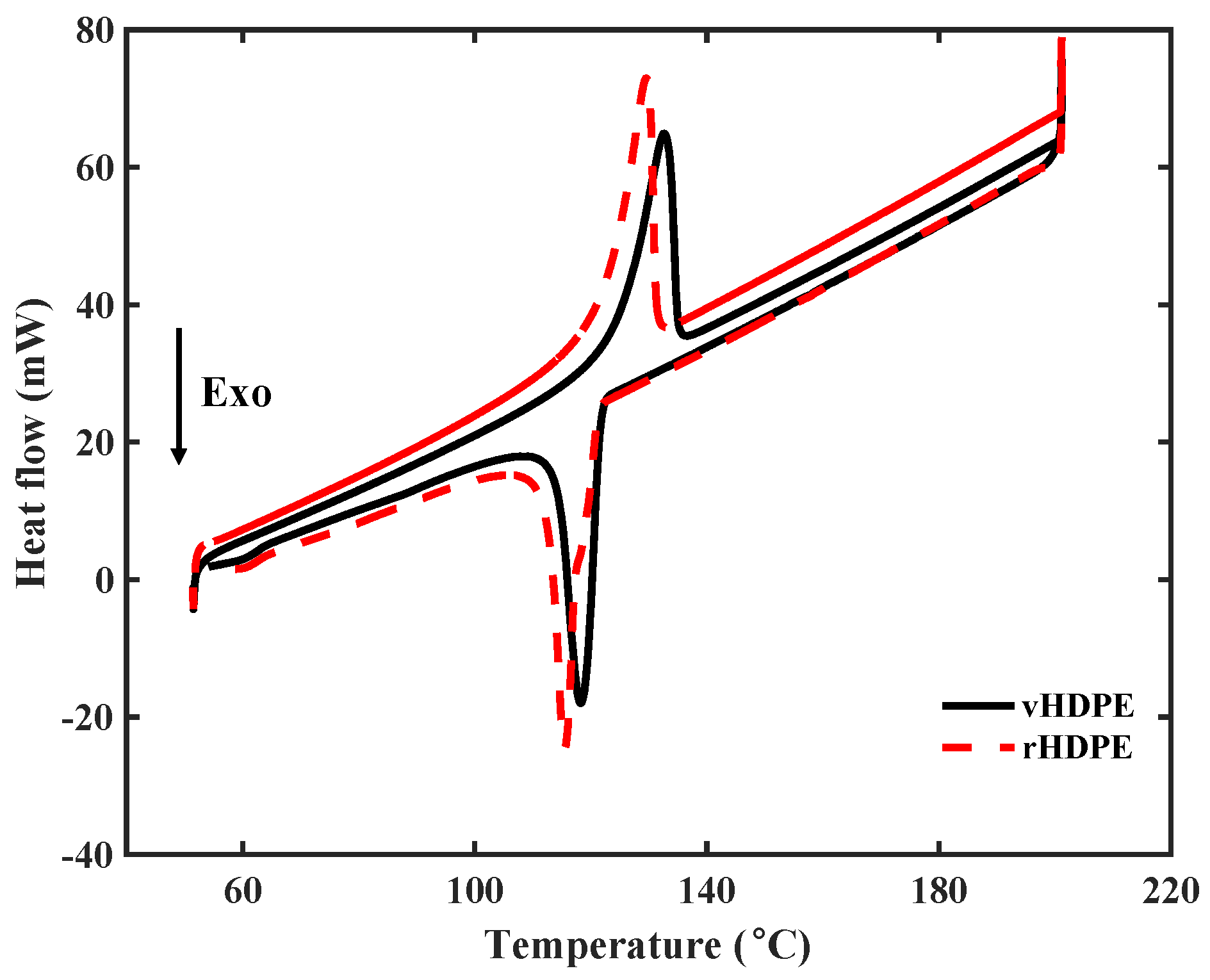

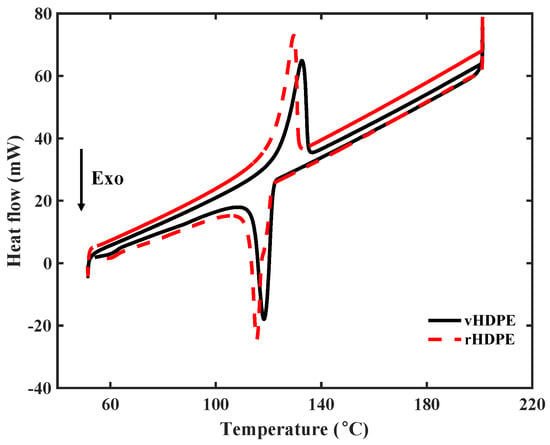

Figure 2 compares the DSC thermograms of virgin and recycled HDPE showing similar thermal behaviors. As reported in Table 1, the melting/crystallization temperature are very similar, but the crystallinity level of rHDPE (55.7%) is much lower than vHDPE (72.8%). This indicates that, there are more regularly aligned polymer chains in vHDPE compared to rHDPE. The intermolecular bounding is more significant in vHDPE resulting in higher strength leading to oriented chains when subjected to deformation. Table 1 reports MFI of r/vHDPE and it is observed that, the MFI value of vHDPE (0.67 g/10 min) is one order of magnitude lower than that of rHDPE (6.7 g/10 min). This indicates higher viscosity of vHDPE compared to rHDPE.

Figure 2.

DSC thermograms of vHDPE and rHDPE.

Table 1.

Melting and crystallization temperatures with their corresponding crystallinity degree and MFI of virgin and recycled HDPE.

2.2.2. Thermogravimetric Analysis (TGA)

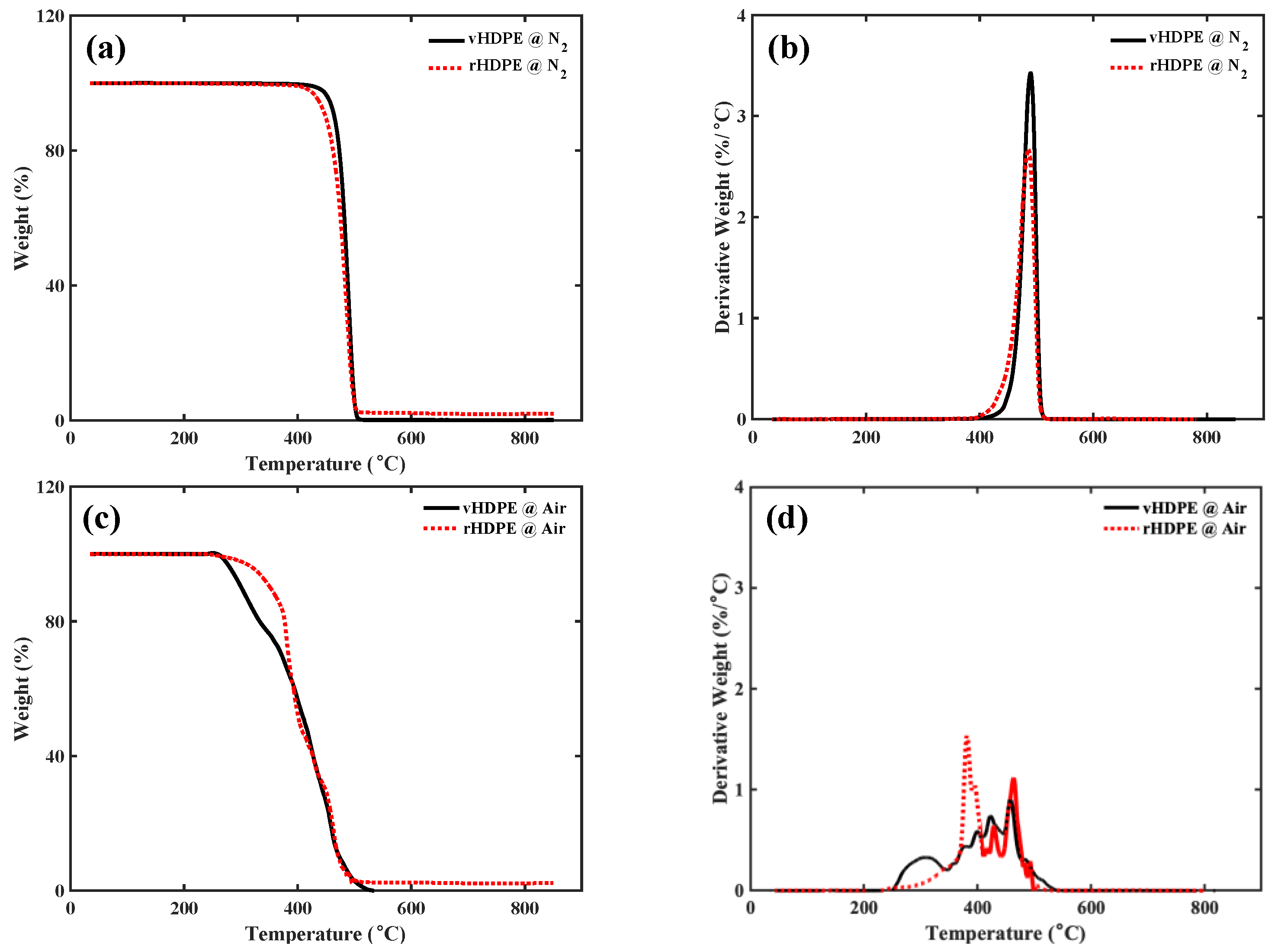

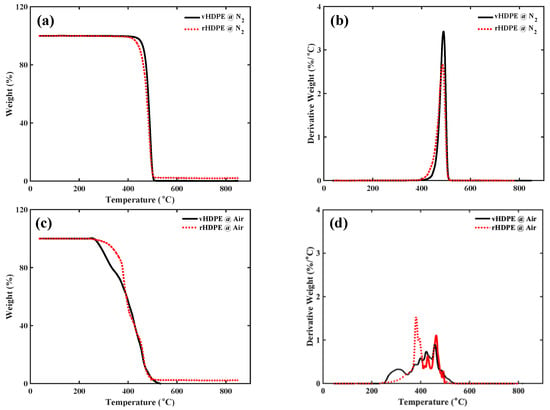

TGA is an important characterization to determine the thermal stability of HDPE since the recycling and regeneration processes can cause degradation and further affect their long-term properties [34]. Figure 3 presents the weight curves as temperature increases with their corresponding derivative (DTG) in both air and nitrogen atmosphere. Figure 3a shows that the degradation onset is around 400 °C for rHDPE in nitrogen, while the value for vHDPE is about 20 °C higher (420 °C). This indicates a reduced thermal stability of the recycled material under nitrogen. However, Figure 3b shows that the maximum degradation temperature occurs around 500 °C in nitrogen regardless of the polymer (virgin or recycled). In addition, rHDPE has more residues (at 850 °C) compared to vHDPE indicating possible impurities (ashes/inorganics) from its use/recycling.

Figure 3.

Weight curves and their derivative as a function of temperature for v/rHDPE in: (a,b) nitrogen and (c,d) air.

TGA in an oxidative environment is much more informative as shown in Figure 3c,d. To begin, the onset degradation temperature is shifted to lower temperatures around 290 °C compared to nitrogen (400–420 °C). The presence of oxygen leads to oxidation and thermal degradation which is easier to initiate (lower temperature). The TGA curves are also different from the smooth ones obtained in nitrogen as the degradation in air is more complicated. This is why more information can be obtained via DTG (Figure 3d) where multiple peaks can be seen. However, rHDPE has generally stronger peaks than vHDPE under an oxidative atmosphere. This can be attributed to the presence of more impurities/additives associated with the recycled origin of these materials resulting in less thermal stability in oxidative environment as well.

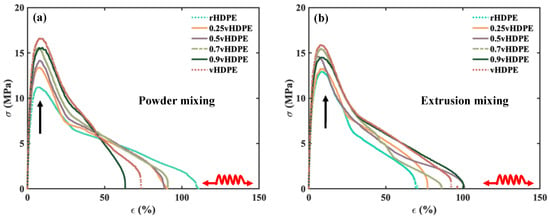

2.3. Tensile Test

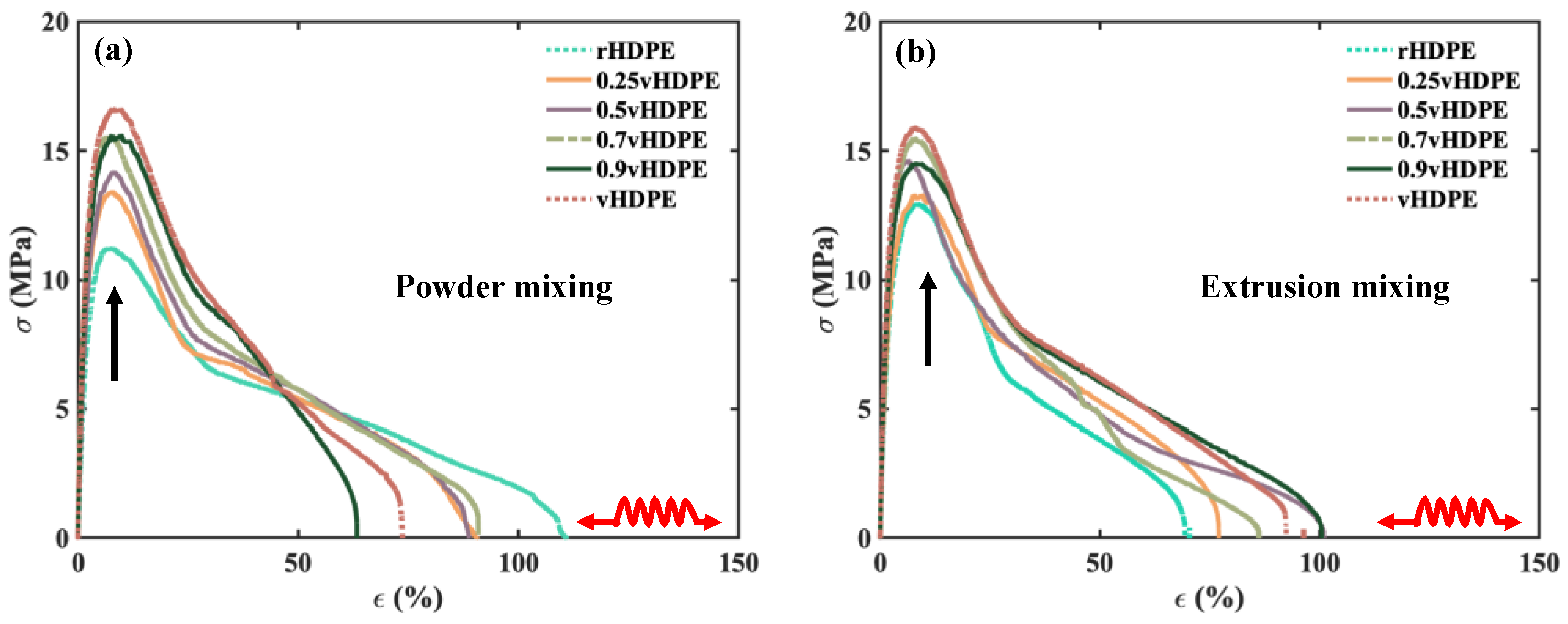

Quasi-static tensile tests can provide important information on the mechanical properties of a material and Figure 4 presents the stress–strain curves of typical samples. It can be seen that rHDPE has a lower modulus (E) and ultimate strength (σU) than vHDPE regardless of the mixing methods. For both treatments, increasing the vHDPE content in the blend can improve the modulus (E) and ultimate strength (σU) as shown in Figure 4a,b. However, the elongation at break does not give a general trend with respect to the vHDPE content.

Figure 4.

Effect of vHDPE content on the tensile stress–strain curves of the blends for both processing methods: (a) powder mixing and (b) extrusion mixing. Tensile tests are performed at a strain rate of 5 mm/min. The red springs indicate the oscillation of elongation at break.

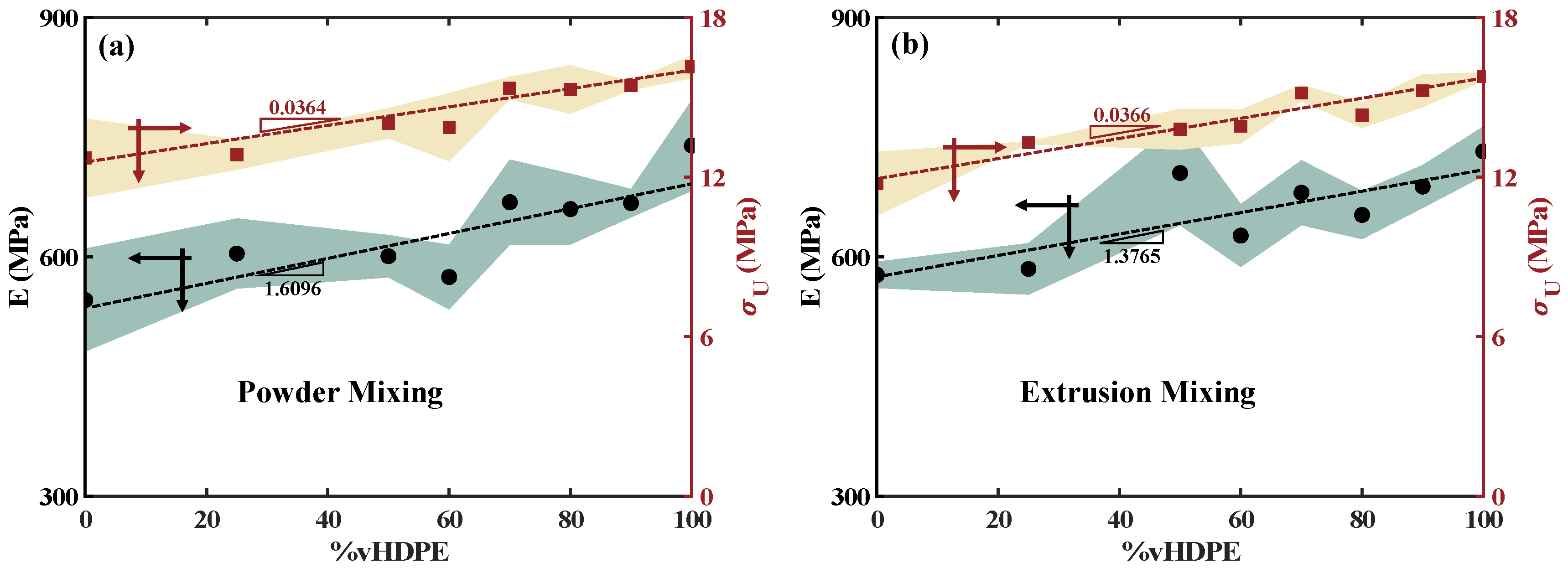

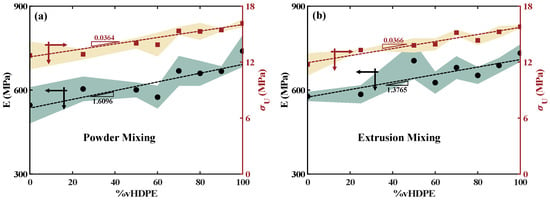

To quantify these improvements, Figure 5 plots how the modulus (E) and ultimate strength (σU) change with vHDPE content for both mixing methods. Compared to rHDPE, E and σU are both increased by about 10% when 50 wt.% of vHDPE is blended via powder mixing. On the other hand, including 50 wt.% of rHDPE in the blend would not significantly reduce the mechanical properties of vHDPE as only 18% and 13% decreases are observed for E and σU, respectively. Similar trends are observed for extrusion mixing indicating again that the processing method is not the main factor here.

Figure 5.

Effect of vHDPE content on the tensile modulus (E) and ultimate strength (σU) of the blend for both processing methods: (a) powder mixing and (b) extrusion mixing. Standard deviations are shown as shaded areas.

To extract the relationship between the vHDPE content and modulus (E)/ultimate strength (σU), linear regressions were performed for both blending methods (powder mixing and extrusion mixing). It is interesting to note that both methods give similar results. Figure 5 shows that the slope for the modulus fit (dE/d(%vHDPE)) gives 1.61 for powder mixing, while a value of 1.38 is obtained for extrusion mixing. The difference is even less for tensile strength (dσU/d(%vHDPE)): 0.0364 (PM) vs. 0.0366 (EM). These results indicates that the blending method has a negligible effect on both parameters.

2.4. Dynamic Fatigue Characterization

2.4.1. Strain–Life Curve

The fatigue lifetime (Nf) is correlated to the applied strain amplitude (ε0) for vHDPE, rHDPE and their blends prepared under different conditions. Figure 6 presents the strain–life curves, which generally follow a power-law correlation as [35]:

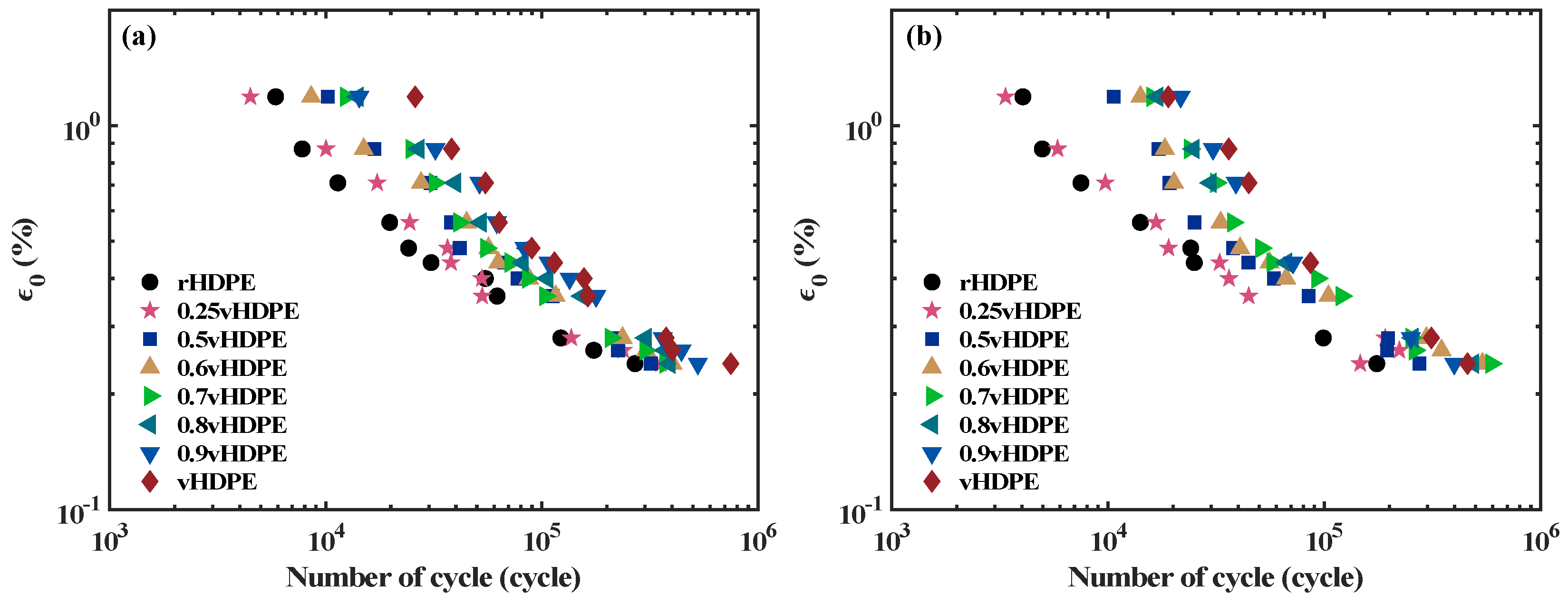

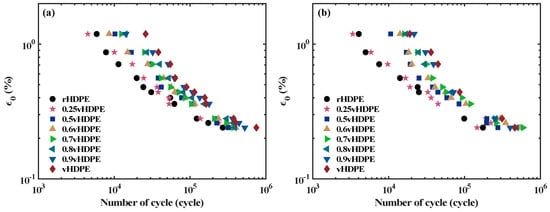

Figure 6.

Strain–life curves of the rHDPE/vHDPE blends for both processing methods: (a) powder mixing and (b) extrusion mixing.

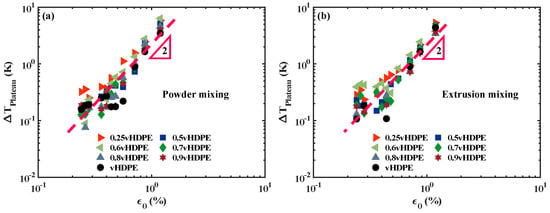

The prefactor A and power-law index m are listed in Table 2. The m values are close to each other and independent of the vHDPE content (0–100%) or the mixing method (PM vs. EM). This is expected since they have similar molecular structures/properties which are controlling the mechanical properties of polymers, such as fatigue [36]. For this reason, the power-law index m was averaged for each method: m1 = −0.439 (PM) and m2 = −0.442 (EM). Since both values are very close, m’ was set as −0.44 for easier comparison between the different blends (composition effect). A similar exponent m’ allows to compare the prefactor A to quantify the fatigue difference between them [10,36]. Table 2 shows that the prefactor A is generally increasing with the vHDPE content indicating the improvement of fatigue lifetime for both mixing methods. It is interesting to note that specimens prepared by powder mixing (PM) shows better fatigue performance than extrusion mixing (EM) since PM has higher A than EM for a similar m’. This is understandable as the materials go through more thermal and mechanical degradation during the extrusion process causing a possible reduction in their mechanical properties. Although, with increasing vHDPE content the fatigue lifetime shows positive correlation, it is noticeable that a small amount of vHDPE (e.g., 25 wt.% vHDPE) does not significantly improve the fatigue resistance of the blends, especially under large strain amplitudes.

Table 2.

Fitting parameters (m, m’ and A) of the Wöhler curves for powder mixing (PM) and extrusion mixing (EM).

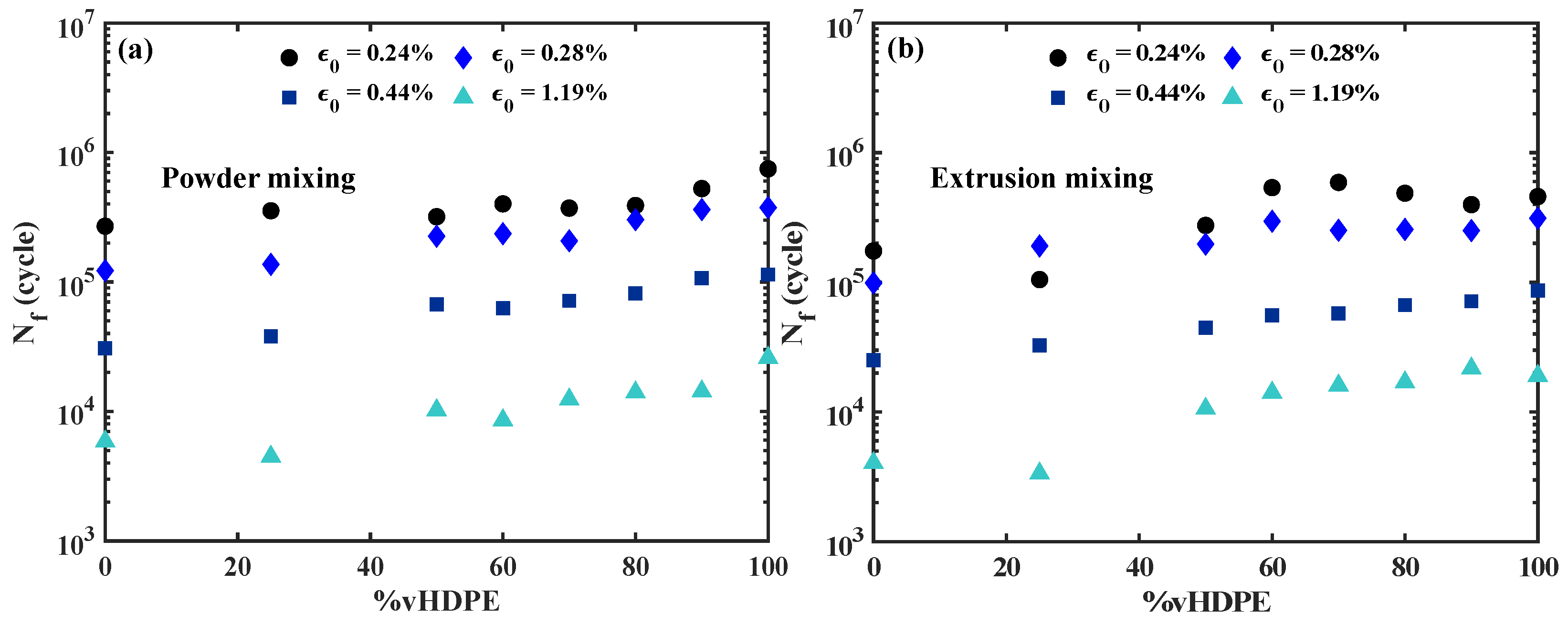

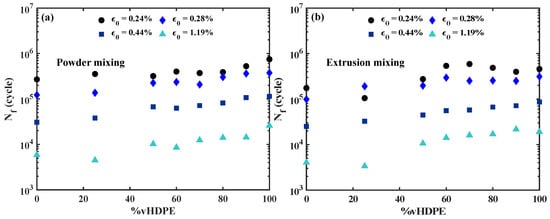

To more clearly show the trend between the vHDPE content and the fatigue lifetime for both mixing methods, Figure 7 plots the fatigue lifetime for different strain amplitudes. It can be seen that adding more vHDPE into the blends improves the fatigue resistance for all the conditions investigated. For example, increasing the vHDPE content from 25% to 90% for specimens prepared by powder mixing (extrusion mixing) can increase the fatigue time by a factor of 0.48 (1.28) to 2.19 (5.45) when the strain amplitude was changed from 0.24% to 1.19%. Considering the experimental uncertainties, it can be concluded that adding more vHDPE with better mechanical properties than recycled one can improve the fatigue resistance of the blends, especially as the strain amplitude increases.

Figure 7.

Correlation between the vHDPE content and the fatigue lifetime (Nf) under different strain amplitudes for both processing methods: (a) powder mixing and (b) extrusion mixing.

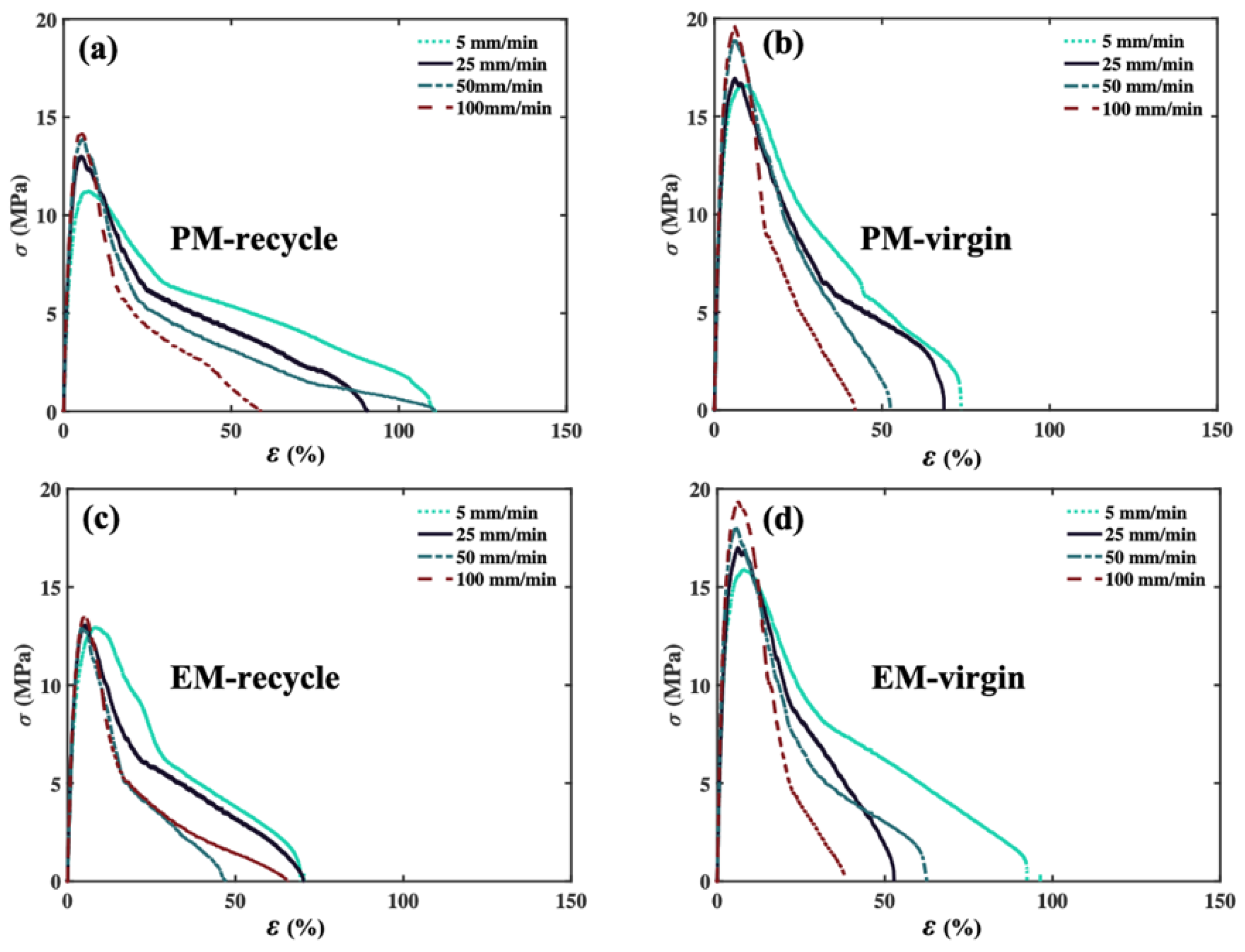

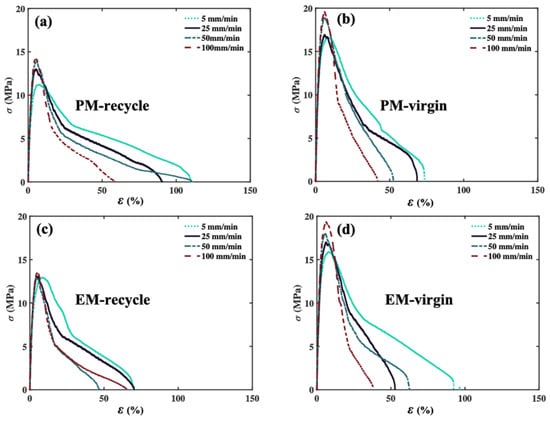

To further investigate the mechanical properties of the samples, different strain rates ( = 5 mm/min to 100 mm/min) under tensile testing were applied on both virgin and recycled HDPE; i.e., to determine their strain rate hardening behavior. Figure 8 shows that both virgin HDPE (PM and EM) can reach higher Young’s modulus (E) and ultimate strength (σU) than recycled ones at similar strain rate, but E and σU are increasing with increasing strain rate. The value for σU can reach almost 20 MPa at ε = 6.03% at a strain rate of 100 mm/min for PM virgin case (Figure 8b), which is more than 33% higher than PM recycled case (~15 MPa at ε = 5.38%) in Figure 8a under the same condition. Similar trends can be confirmed for the extrusion mixing method (Figure 8c,d) except that the corresponding values (E, σU) are lower than for powder mixing. Therefore, virgin polymers with better mechanical properties than recycled polymers can be highly helpful to improve the fatigue resistance of recycled polymers under large amplitude loading conditions because such virgin material can sustain higher stress at larger strain.

Figure 8.

Stress–strain curves at different strain rates for the virgin and recycled HDPE prepared by: (a,b) powder mixing (PM) and (c,d) extrusion mixing (EM).

2.4.2. Crack Propagation

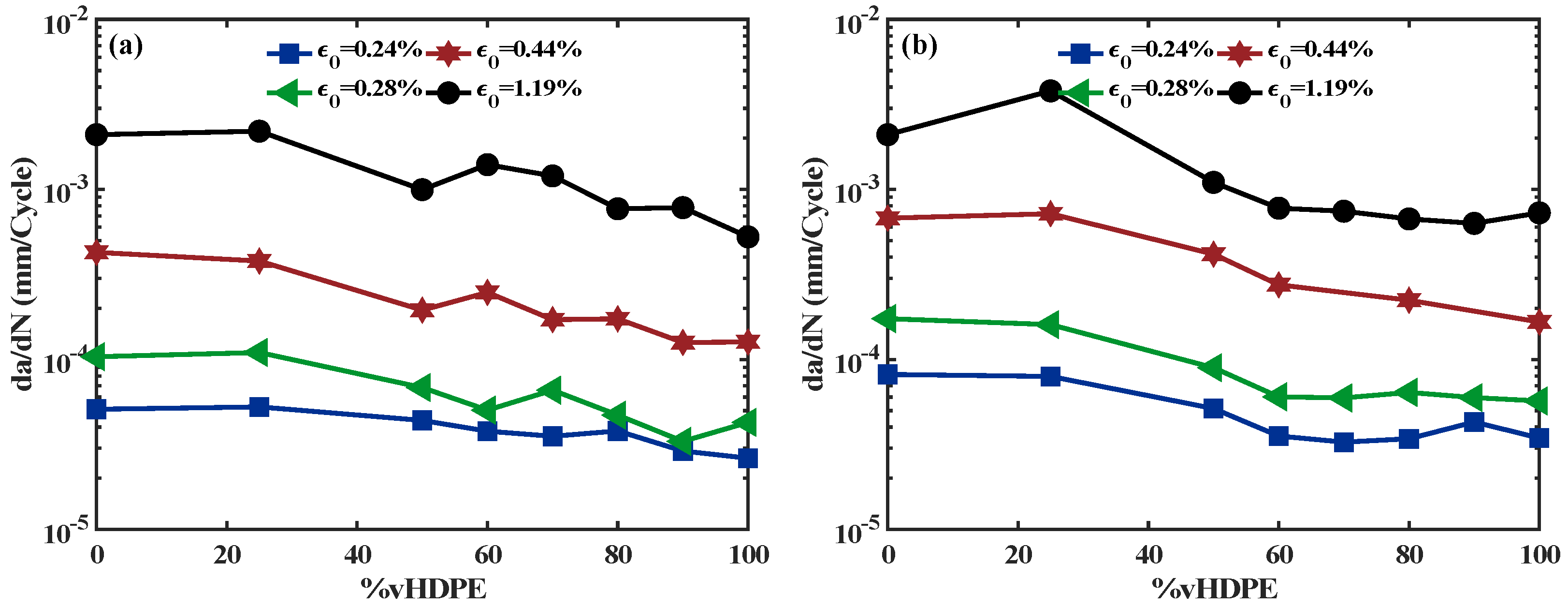

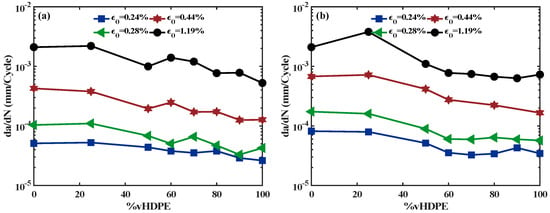

The crack propagation results are shown in Figure 9 for blends with different vHDPE content under various strain amplitudes. Increasing the strain amplitude from 0.24% to 1.19% implies faster crack growth regardless of the vHDPE content and mixing method (PM or EM). However, the crack propagation can be slowed down by introducing more vHDPE, with better mechanical properties compared to the recycled one, into the blends for a given strain amplitude and this effect is even more apparent at larger strain amplitude. For example, the crack propagation rate for blends produced via powder mixing (extrusion mixing) with 25 wt.% vHDPE at ε0 = 0.24% is around 5 × 10−5 (8 × 10−5) mm/cycle. The value is reduced to 3 × 10−5 (4 × 10−5) mm/cycle when the vHDPE content is increased to 90 wt.%. This represents a crack growth rate reduction of 40% and 50% for powder mixing and extrusion mixing, respectively. On the other hand, the crack propagation rate for blends prepared via powder mixing (extrusion mixing) with 25 wt.% vHDPE content at ε0 = 1.19% is around 2 × 10−3 (4 × 10−3) mm/cycle. For the 90 wt.% vHDPE blends, da/dn decreases to 8 × 10−4 (6 × 10−4) mm/cycle which represents a 60% and 85% reduction for powder mixing and extrusion mixing, respectively.

Figure 9.

Crack propagation rate at different strain amplitudes as a function of the vHDPE content for both processing methods: (a) powder mixing and (b) extrusion mixing.

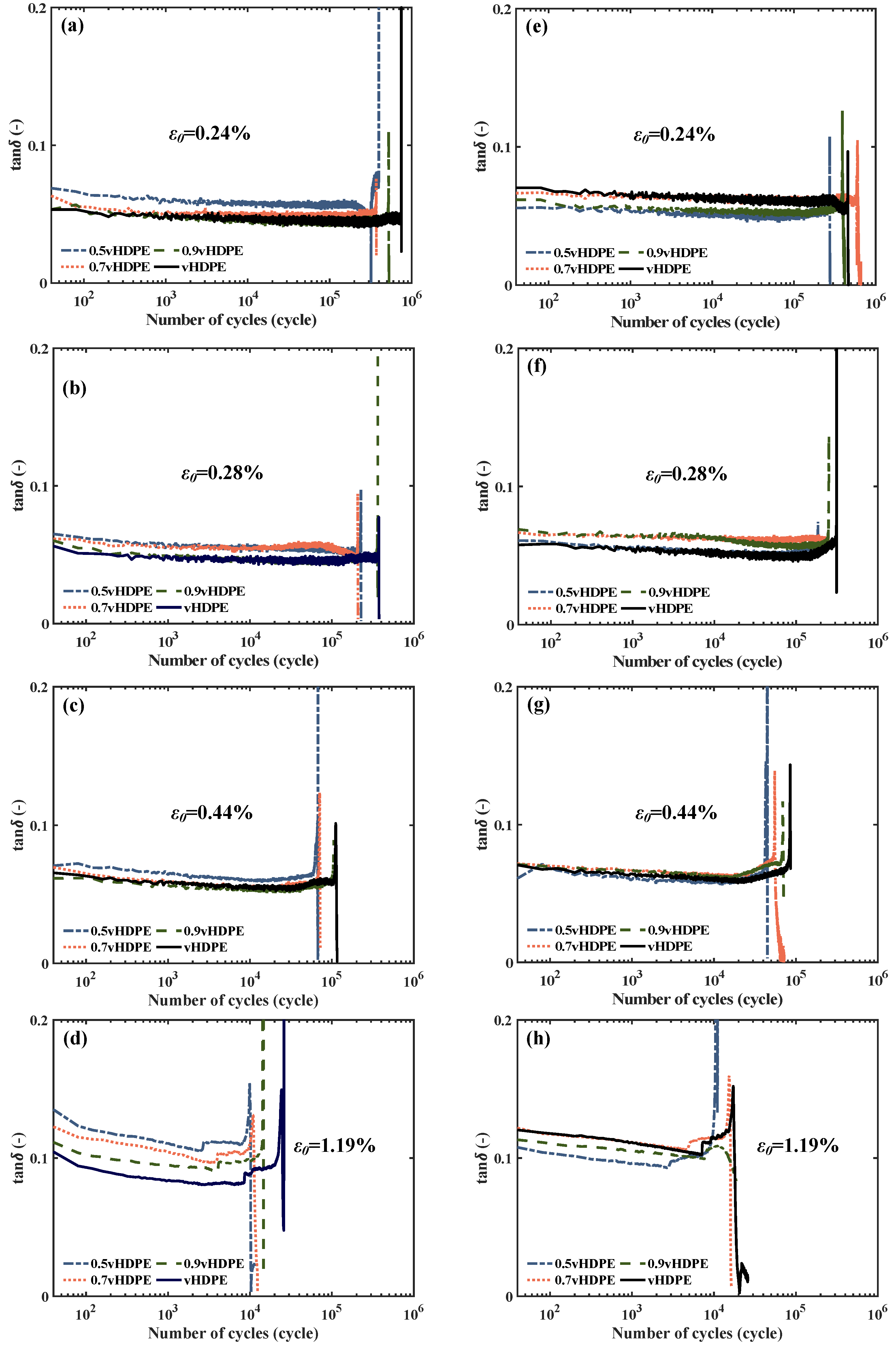

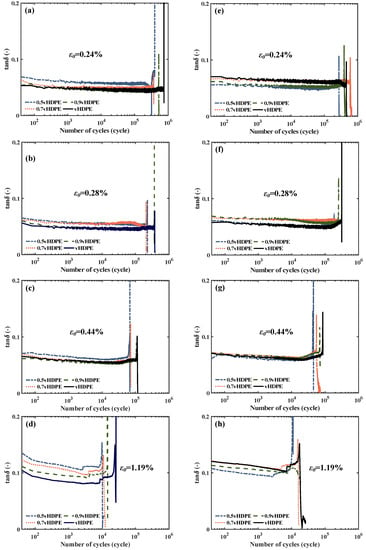

2.4.3. Loss Factor (tanδ)

The dimensionless loss factor (tanδ = E″/E’) represents the ratio between the loss modulus and storage modulus. To compare the effect of the vHDPE content on the fatigue behavior of the blends under small (0.24%) and large (1.19%) strain amplitude, the values are reported in Figure 10. The loss factor decreases with the number of cycles for all these investigated cases indicating that viscous effects are comparably decreasing during the cyclic loadings. In addition, the loss factor is found to be strongly dependent on the test load level with the highest loss factor at the highest strain amplitude (1.19%). This is expected as the level of irreversible deformation increases with higher loading level. At a strain amplitude of 1.19%, crack initiation is easier compared to lower strain amplitudes and these cracks can significantly decrease the storage modulus (E’) resulting in significant changes in the loss factor (tanδ). Furthermore, the loss factor decreases with increasing vHDPE content for the powder mixing approach, which is not clearly observed for extrusion mixing. The recycled polymer has a stronger viscous behavior than the virgin one and introducing more virgin polymer decreases the viscous contributions in the blends. This is probably the reason why this effect is not well identified for extrusion mixing since the virgin material was extruded once similar to the recycled materials.

Figure 10.

Effect of the vHDPE content on the fatigue behavior under different strain amplitudes for the blends processed by both mixing methods: (a–d) PM and (e–h) EM.

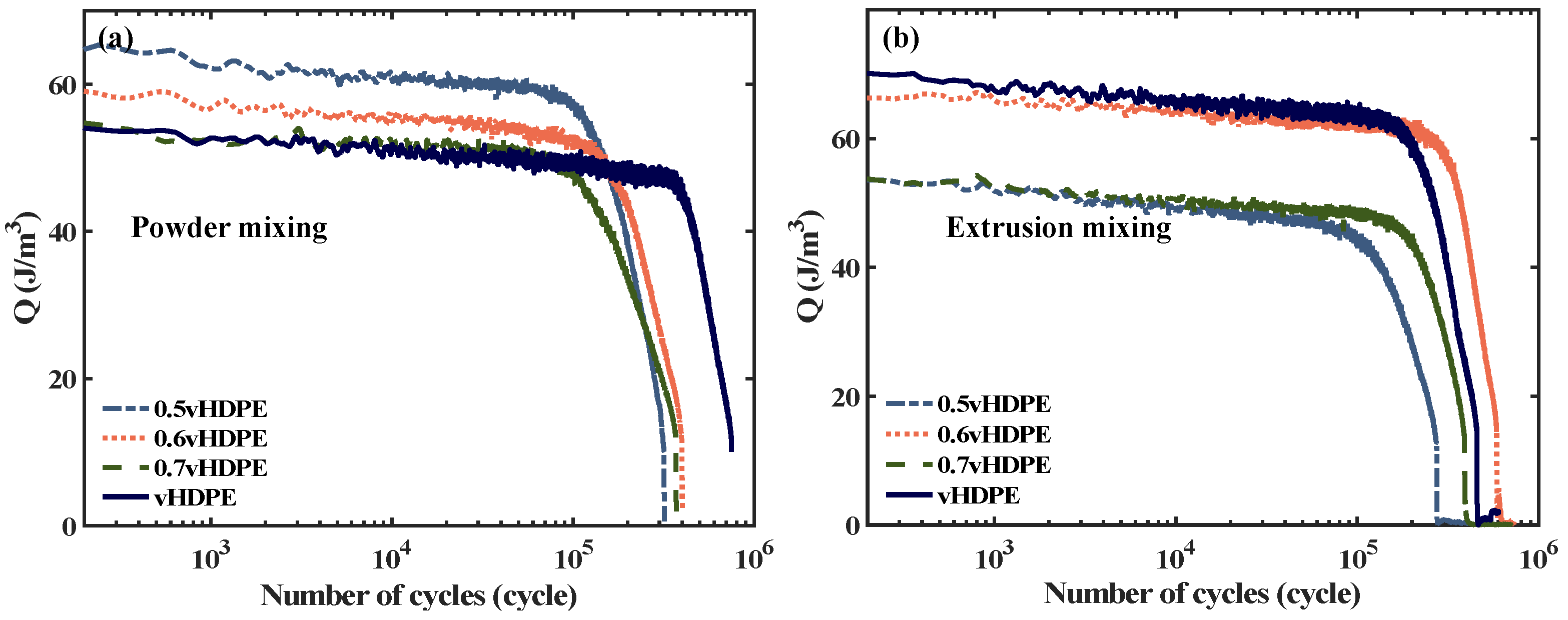

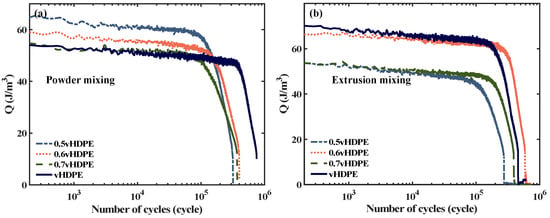

2.5. Energy Generation and Surface Temperature

Section 2.4.3 reported a decrease in the viscous effect of the blends (tanδ) during fatigue tests, which will have a direct effect on the heat generation. Investigation on the heat generation, calculated via Equation (2), as a function of the number of cycles is displayed in Figure 11. The heat generation decreases with the number of cycles until the ultimate destruction of the specimen. Notably, increasing the vHDPE content can reduce the heat generation for powder mixing as shown in Figure 11a. The average energy generation rate is about 60 J/m3 before crack onset for 50 wt.% vHDPE blends, which is 19.5% higher than for the virgin HDPE generating around 51 J/m3 under the same testing conditions. This information suggests that introducing vHDPE into the blends produced by powder mixing can improve the fatigue resistance, but also better controls the heat generation under cyclic loadings compared to use extrusion mixing. However, this trend is not well observed in extrusion mixing (Figure 11b). Such difference is associated with the fact that the extrusion of virgin material can modify its viscoelastic behavior making it a less well-suited mixing method in this case in terms of heat generation under fatigue. Even a single extrusion step of the vHDPE can apparently change its behavior as compared in Figure 11a,b.

Figure 11.

Heat generation as a function of the number of cycles for different vHDPE content during fatigue testing at ε0 = 0.24%, R = 0.3 and f = 5 Hz for the blends produced via: (a) powder mixing and (b) extrusion mixing.

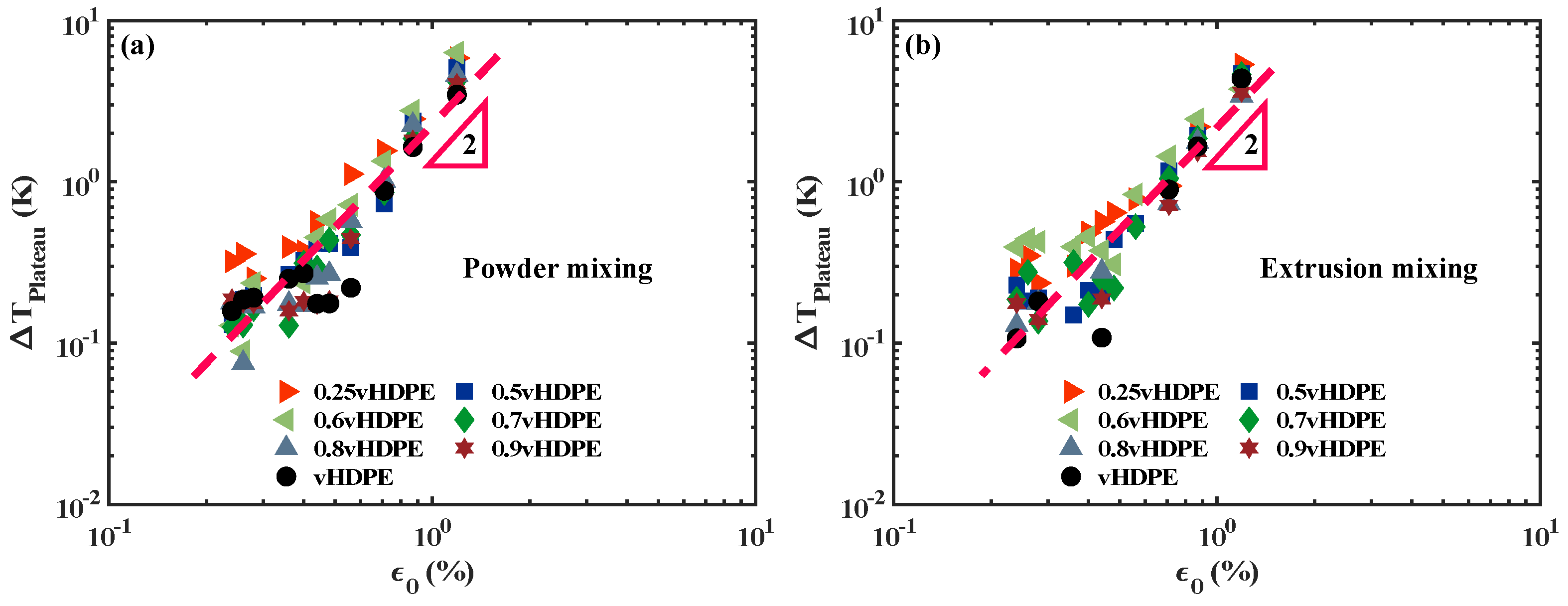

The energy generation of specimen during fatigue test can be more intuitively observed by its surface temperature during fatigue tests. The surface temperature of specimen firstly increases and ultimately reach a plateau value during fatigue tests until a final drop due to crack initiation. The difference between the initial temperature and final plateau value is defined as ΔTPlateau and plotted in Figure 12. Larger strain amplitude produces higher energy generation for both powder and extrusion mixing. Noticeable temperature (>1 K) can be identified at a strain amplitude above 0.7% for both powder and extrusion mixing. A quadratic relation (Equations (2) and (3)) between ΔTPlateau and ε0 can be observed regardless of the processing method. It is interesting to determine the difference between the temperature rise of vHDPE before and after extrusion. The plateau temperature of vHDPE from powder mixing is in the lower end of investigated cases (Figure 12a). However, an extrusion step imposes some changes on the material. This also corresponds to the heating generation behavior in Figure 11. These differences can be attributed to the mixing method which influence the viscous effect as discussed above.

Figure 12.

Surface temperature rise of the blends with different vHDPE content during fatigue tests at ε0 = 0.24–1.19%, R = 0.3 and f = 5 Hz for samples produced via: (a) powder mixing and (b) extrusion mixing.

3. Materials and Methods

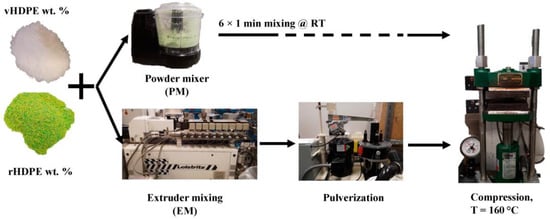

The recycled high-density polyethylene (rHDPE) was sourced from rigid HDPE bottles and provided by Service Conseil Sinclair (Canada). In fairness, the mechanical properties of recycled polymers could be worse [23,25,26,27] or better [6,28,29]. This dilemma for rHDPE constrains its large-scale application in practice due to this uncertainty [10]. Therefore, including virgin HDPE A60-7019 (Solvay, Alpharetta, GA, USA) was investigated as a possible approach to regain stable mechanical properties for rHDPE. The rHDPE was mixed with vHDPE at six different mass concentrations (25% to 90% vHDPE), which can be referred to Table 3. The pure rHDPE and vHDPE were also included as experimental benchmarks.

Table 3.

Manufacturing (Mfr.) information and proportion of virgin/recycled HDPE during mixing.

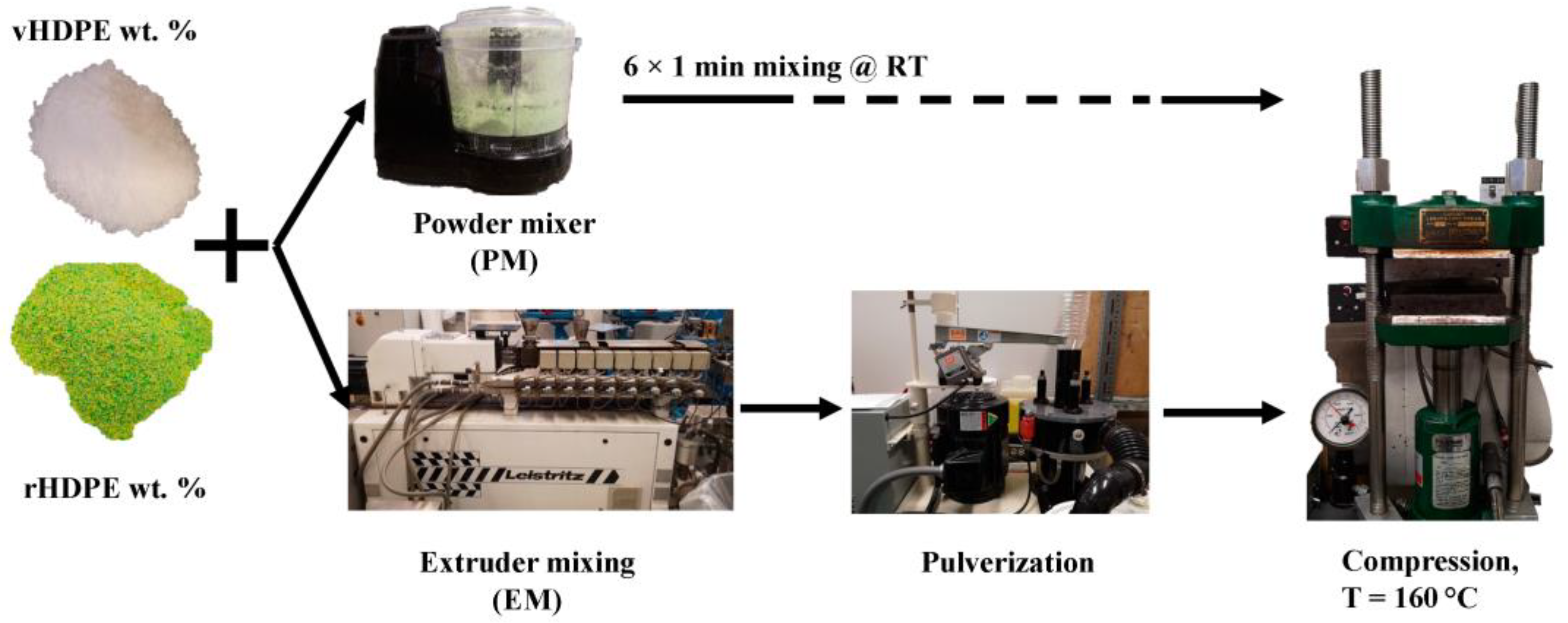

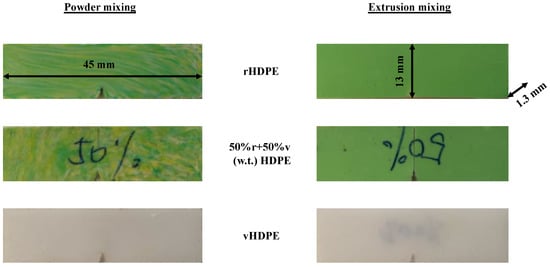

To obtain homogeneous mixture, the r/vHDPE were blended either by a powder mixer (Toastmaster Mini, Boonville, MO, USA) for 6 min at room temperature or were extruded at 170 °C in a Leistritz ZSE-27 (40 L/D) to produced pellets. Then, the pellets were pulverized (Powder King, Phoenix, AZ, USA) to produce a 500 μm powder (Figure 13). The prepared blends were hot pressed at a temperature of 160 °C into notched specimen with dimensions of length l = 13 mm, width w = 45 mm and thickness h = 1.3 mm as shown in Figure 14. The V-notch was in the middle of one long side with an angle of 45°.

Figure 13.

Schematic workflow of the specimen preparation by powder mixing (PM) and extrusion mixing (EM).

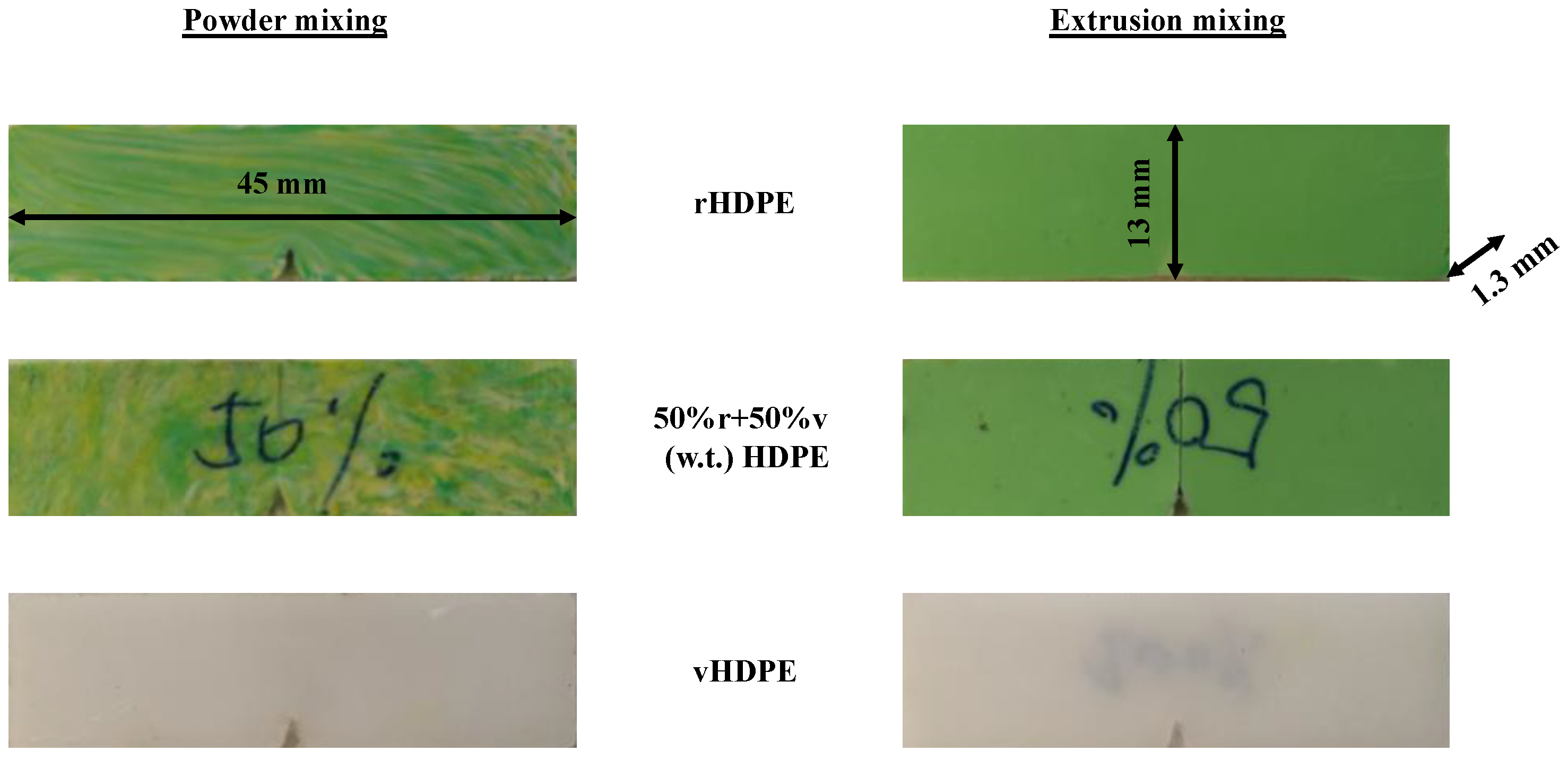

Figure 14.

Appearance comparison (surface image) of typical specimens prepared by powder mixing (left) and extrusion mixing (right).

Figure 14 shows that both blending methods (powder and extrusion mixing) delivers completely different appearance of the specimen. The specimen belonging to extrusion mixing has a more homogeneous surface (color/texture) than the one produced by powder mixing. Streaks due to various pigments from rHDPE can be easily observed from the surface of powder mixing specimen. This could be unattractive for applications requiring uniform appearance (aesthetics) but might be a cost reduction process when possible (hidden parts, internal layers, etc.).

The morphology of the specimens was examined via scanning electron microscopy (SEM, FEI Inspect F50, Hillsboro, OR, USA) to investigate the internal structure after different blending processes. The SEM was operated at an accelerating voltage of 15 kV providing magnifications of ×175 and ×750. The samples were first broken in liquid nitrogen and the exposed surface was covered by a Au/Pd conductive layer.

Thermal properties, such as melting and crystallization, were evaluated by differential scanning calorimetry (DSC). A DSC 7 (Mettler, Columbus, OH, USA) was used to report the heat flow as a function of time/temperature to characterize the phase transitions. The crystallinity (χ) was calculated according to DSC as:

where ΔHm is the enthalpy of fusion of the specimen and ΔHm0 is the melting enthalpy of 100% crystalline HDPE (285.8 J/g) [37]. The tests were performed at a heating and cooling rate of 10 °C/min between 50 °C and 200 °C in a nitrogen atmosphere.

Thermogravimetric analysis (TGA) was conducted on a Q5000IR (TA Instruments, New Castle, DE, USA) to determine the thermal stability of the blends. A constant heating rate of 10 °C/min was applied to over a temperature range of 35 °C to 850 °C in both air and nitrogen.

The melt flow index (MFI) was determined following ASTM D1238 at a temperature of 190 °C and a weight of 2.16 kg. Each test was repeated for 3 times.

To begin with quasi-static tensile tests, the specimens were uniaxially stretched at a strain rate of 5 mm/min to compare the tensile properties. These measurements were conducted for three replicates on an Acumen 3 (MTS, Eden Prairie, MN, USA) with a 3 kN load cell. Moreover, fatigue characterization was performed on the same setup under strain-controlled sinusoidal loading with amplitudes (ε0) from 0.24% to 1.19%, which is within the linear stress–strain response of the materials obtained from their stress–strain (σ-ε) curves. The testing frequency was set to f = 5 Hz and the strain ratio was fixed as R = εmin/εmax = 0.3. The time series of force and displacement were recorded by a data acquisition device at a sampling rate of 200 points per cycle [38,39,40]. All these experiments were conducted at room temperature (~23 °C) and the surface temperature of the specimens was followed by a thermal camera (FLIR ThermoVision A320, Wilsonville, OR, USA) at a sampling rate of 35 Hz. The obtained data were analyzed by an in-house MATLAB code based on short-time Fourier transform (STFT). This technique can convert the stress signal from the time (t) domain into the frequency (ω) domain to reconstruct the change of linear and nonlinear mechanical fatigue parameters, such as modulus (E’, E″) and higher harmonics (I2/1, I3/1,…) in time, respectively. More details on the theory can be found in the literature [38,40,41,42].

Under cyclic loadings, the work imposed to the specimen is partly dissipated (Wdiss) as heat due to viscous and plastic effects inside polymers. The dissipated energy (Q), associated with the viscous effect, depends on loss modulus (E″) and strain amplitude (ε0) as:

E″ is independent of the strain amplitude (ε0) in the linear regime but depends on ε0 in the nonlinear regime (large strain amplitude) [43]. The dissipated energy can increase the surface temperature of the specimen which is governed by Fourier law as:

where k is the thermal conductivity and ∇T is the temperature gradient generated.

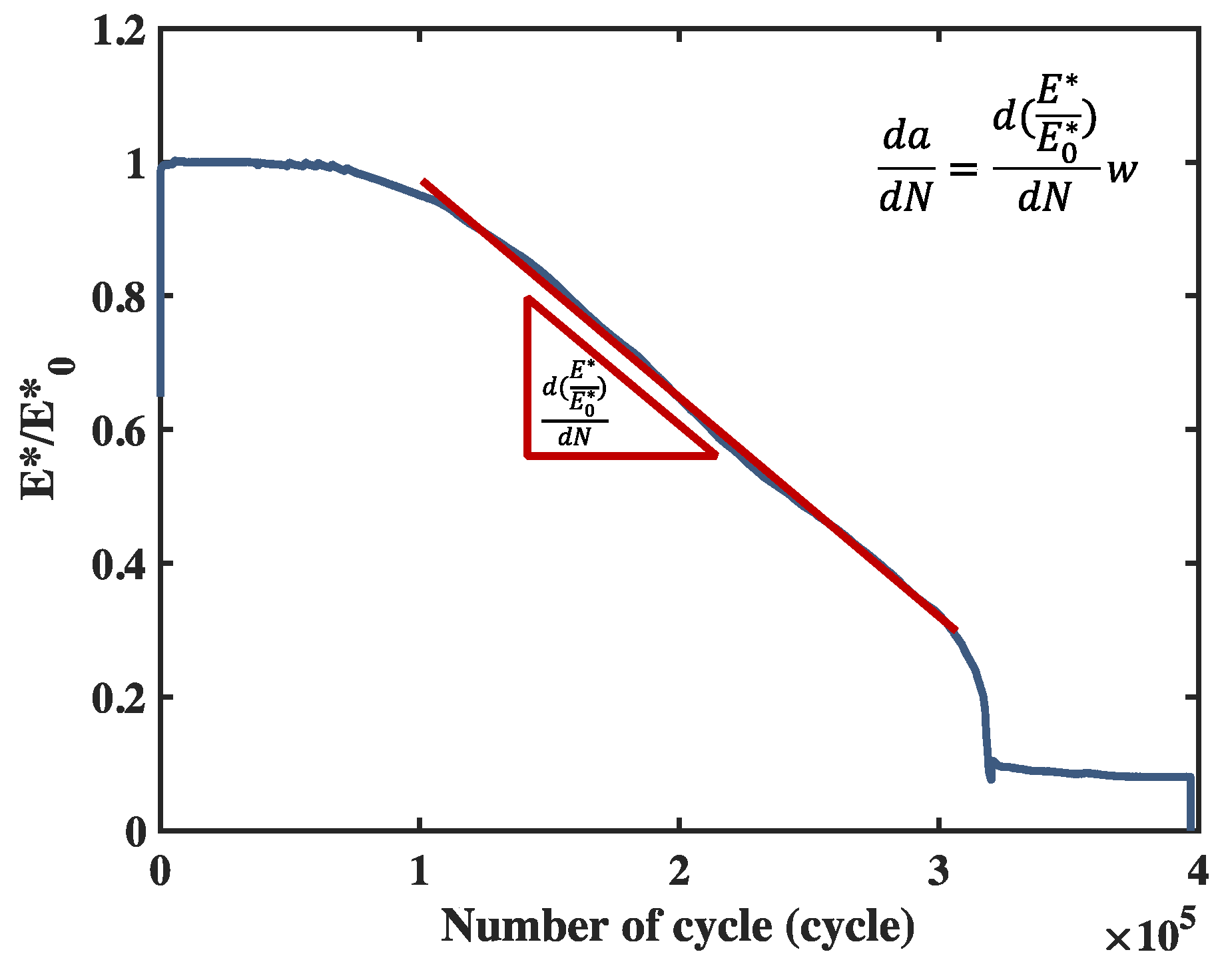

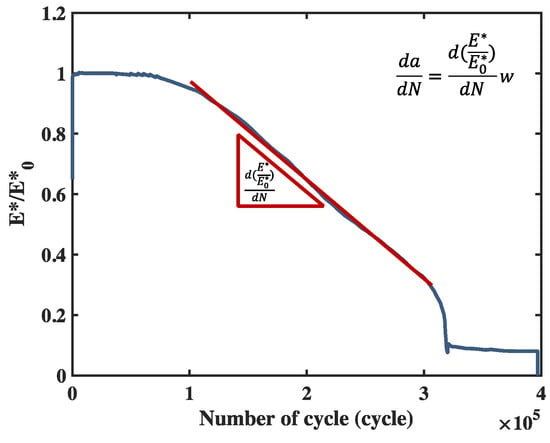

To obtain the crack propagation rate (da/dN) as a function of the number of cycles (N), a method of correlating the crack propagation rate with the change of complex modulus (E*) for notched specimens in tension–tension derived from massive experimental investigations is applied [44]:

In Figure 15, the complex modulus E* is normalized to its initial value () and the slope of the is proportional to the crack propagation rate by a factor related to the specimen width (w).

Figure 15.

Typical time evolution of the normalized complex modulus () as a function of the number of cycles during a fatigue test of vHDPE in tension–tension at ε0 = 0.24%, f = 5 Hz and R = 0.3. Red line indicates the slop.

4. Conclusions

Redirecting recycled polymers into production streams is a technical challenge due to their unpredictable mechanical properties depending on their source/origin and recycling process. To find potential approaches to stabilize the mechanical properties of recycled polymers, especially long-term fatigue performance, which should be cost-effective and easy, blending virgin polymers with recycled ones under different processing approaches, namely powder mixing and extrusion mixing, was thoroughly investigated. This was carried out via different characterization methods: morphology, thermal stability and mechanical properties. A total of six concentrations of virgin/recycled polymer blends ranging from 25% to 90% of vHDPE were prepared and firstly characterized by SEM, DSC, TGA and MFI before being tested under cyclic loadings (ε0 = 0.24–1.19%, R = 0.3 and f = 5 Hz) to understand their mechanical fatigue behavior. The results were compared with both the virgin and recycled HDPE.

The experimental results indicate that introducing virgin HDPE with better mechanical properties than recycled one into blends improve the Young’s modulus, ultimate strength and fatigue lifetime regardless of being prepared by powder mixing and extrusion mixing, but the trends were not clear for the elongation at break. Increasing the vHDPE content led to higher Young’s modulus, ultimate strength and fatigue resistance. This improvement was more apparent at higher strain amplitudes (ε0 = 1.19% vs. 0.24%). This trend was also confirmed for the effect of vHDPE content on the crack propagation rate: more vHDPE seemed to slow down the crack propagation, especially at higher loading conditions. This gives a clear and important message that only small amounts of virgin material is required to obtain similar fatigue performance to virgin resins under small strain amplitudes. It also represents a cost-effective approach to reuse a high amount of recycled materials in blends for the conditions investigted. It was also found that introducing higher vHDPE content into the blends was able to reduce the viscous behavior and further decreased the heat generation and surface temperature rise when the specimens were prepared via powder mixing, while this pattern was not clear for the blends prepared by extrusion. A critical strain amplitude (ε0 ≈ 0.8%) seemed to necessary to produce a 1 K surface temperature rise for powder mixing, which is 12.5% higher compared to ε0 ≈ 0.7% for extrusion mixing. This difference between powder mixing and extrusion mixing suggests that, although both methods can provide similar mechanical properties improvement (especially for fatigue resistance), extrusion mixing led to more homogeneous samples (more uniform appearance). Nevertheless, the relationships between heat generation and vHDPE content is more difficult to predict, especially for extrusion mixing. This is why more work is needed to complete the analysis via different mechanical characterization (flexion, impact, etc.).

Author Contributions

J.Z.: Formal analysis (lead); investigation (lead); methodology (lead); software (equal); validation (lead); visualization (lead); writing—original draft (lead). V.H.: Formal analysis (supporting); investigation (supporting); methodology (supporting); software (lead); supervision (supporting); validation (supporting); writing—original draft (supporting). D.R.: Conceptualization (supporting); funding acquisition (lead); project administration (lead); resources (lead); supervision (lead); writing—review and editing (lead). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science and Engineering Research Council of Canada (NSERC, RGPIN-2016-05958).

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the financial support of the natural Science and Engineering Research Council of Canada (NSERC).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Environment and Climate Change Canada. Economic Study of the Canadian Plastic Industry, Markets and Waste: Summary Report to Environment and Climate Change Canada; Environment and Climate Change Canada: Montréal, QC, Canada, 2019; ISBN 9780660304472.

- Milbrandt, A.; Coney, K.; Badgett, A.; Beckham, G.T. Quantification and Evaluation of Plastic Waste in the United States. Resour. Conserv. Recycl. 2022, 183, 106363. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to Reduce the Global Carbon Footprint of Plastics. Nat. Clim. Chang. 2019, 9, 374–378. [Google Scholar] [CrossRef]

- SDG—SDG Indicators. Available online: https://unstats.un.org/sdgs/report/2021/goal-13/ (accessed on 29 July 2022).

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Maniadi, A. Sustainable Additive Manufacturing: Mechanical Response of High-Density Polyethylene over Multiple Recycling Processes. Recycling 2021, 6, 4. [Google Scholar] [CrossRef]

- Jin, H.; Gonzalez-Gutierrez, J.; Oblak, P.; Zupančič, B.; Emri, I. The Effect of Extensive Mechanical Recycling on the Properties of Low Density Polyethylene. Polym. Degrad. Stab. 2012, 97, 2262–2272. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Lorenzo, V.; Acosta, J.; de la Orden, M.U.; Martínez Urreaga, J. Effect of Simulated Mechanical Recycling Processes on the Structure and Properties of Poly(Lactic Acid). J. Environ. Manag. 2018, 216, 25–31. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of Recycling on the Microstructure and the Mechanical Properties of Isotactic Polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Zhang, J.; Hirschberg, V.; Rodrigue, D. Mechanical Fatigue of Recycled and Virgin High-/Low-density Polyethylene. J. Appl. Polym. Sci. 2022, 140, e53312. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Lv, X.D.; Ni, H.G. Solvent-Based Separation and Recycling of Waste Plastics: A Review. Chemosphere 2018, 209, 707–720. [Google Scholar] [CrossRef]

- Karlsson, S. Recycled Polyolefins. Material Properties and Means for Quality Determination. In Long Term Properties of Polyolefins. Advances in Polymer Science; Albertsson, A.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2004; Volume 169, pp. 201–230. [Google Scholar] [CrossRef]

- Stangenberg, F.; Gren, S.A.; Karlsson, S. Quality Assessments of Recycled Plastics by Spectroscopy and Chromatography. Chromatographia 2004, 59, 101–106. [Google Scholar] [CrossRef]

- Basedow, A.M.; Ebert, K.H.; Hunger, H. Effects of Mechanical Stress on the Reactivity of Polymers: Shear Degradation of Polyacrylamide and Dextran. Macromol. Chem. Phys. 1979, 180, 411–427. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Díaz, F.A.; Torné, J.P.; Prada, A.; Perez, G. Shear Degradation Model of HPAM Solutions for the Design of Regulator Valves in Polymer Flooding EOR. J. Pet. Explor. Prod. Technol. 2020, 10, 2587–2599. [Google Scholar] [CrossRef]

- Pinheiro, L.A.; Chinelatto, M.A.; Canevarolo, S.V. The Role of Chain Scission and Chain Branching in High Density Polyethylene during Thermo-Mechanical Degradation. Polym. Degrad. Stab. 2004, 86, 445–453. [Google Scholar] [CrossRef]

- Goecke, A. Rheological Investigation of Mechanically Recycled PE and Investigation of PE Pyrolysis Condensates with a 1 H-NMR Spectrometer. Master Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2022. [Google Scholar]

- Cuadri, A.A.; Martín-Alfonso, J.E. The Effect of Thermal and Thermo-Oxidative Degradation Conditions on Rheological, Chemical and Thermal Properties of HDPE. Polym. Degrad. Stab. 2017, 141, 11–18. [Google Scholar] [CrossRef]

- Loultcheva, M.K.; Proietto, M.; Jilovb, N.; La Mantis, F.P. Recycling of High Density Polyethylene Containers. Polym. Degrad. Stab. 1997, 57, 77–81. [Google Scholar] [CrossRef]

- Abedini, H.; Yousefi, S.; Khonakdar, H.A. A Simplified Moment Model for Prediction of Long-Chain Branching during Peroxide Modification of HDPE. Mater. Des. 2017, 130, 16–25. [Google Scholar] [CrossRef]

- Andersson, T.; Stålbom, B.; Wesslén, B. Degradation of Polyethylene during Extrusion. II. Degradation of Low-Density Polyethylene, Linear Low-Density Polyethylene, and High-Density Polyethylene in Film Extrusion. J. Appl. Polym. Sci. 2004, 91, 1525–1537. [Google Scholar] [CrossRef]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and Mechanical Properties of Extensively Recycled High Density Polyethylene. Polym. Degrad. Stab. 2015, 114, 133–145. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, B.K. Crosslinking of HDPE during Reactive Extrusion: Rheology, Thermal, and Mechanical Properties. J. Appl. Polym. Sci. 1993, 48, 981–986. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the Loop for PET, PE and PP Waste from Households: Influence of Material Properties and Product Design for Plastic Recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Brachet, P.; Høydal, L.T.; Hinrichsen, E.L.; Melum, F. Modification of Mechanical Properties of Recycled Polypropylene from Post-Consumer Containers. Waste Manag. 2008, 28, 2456–2464. [Google Scholar] [CrossRef] [PubMed]

- Remili, C.; Kaci, M.; Benhamida, A.; Bruzaud, S.; Grohens, Y. The Effects of Reprocessing Cycles on the Structure and Properties of Polystyrene/Cloisite15A Nanocomposites. Polym. Degrad. Stab. 2011, 96, 1489–1496. [Google Scholar] [CrossRef]

- Nunes, M.A.B.S.; Galvão, L.S.; Ferreira, T.P.M.; Luiz, E.J.F.T.; Bastos, Y.L.M.; Santos, A.S.F. Reprocessability of High Impact Polystyrene/Clay Nanocomposites in Extrusion. Polym. Degrad. Stab. 2016, 125, 87–96. [Google Scholar] [CrossRef]

- Wencuanc’, M.A.; La Mantiazt, F.P. Processing and Mechanical Properties of Recycled PVC and of Homopolymer Blends with Virgin PVC. J. App. Polym. Sci. 1996, 59, 759–767. [Google Scholar] [CrossRef]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Ramírez-Vargas, E.; Sandoval-Arellano, Z.; Hernández-Valdez, J.S.; Martínez-Colunga, J.G.; Sánchez-Valdés, S. Compatibility of HDPE/Postconsumer HDPE Blends Using Compatibilizing Agents. J. Appl. Polym. Sci. 2006, 100, 3696–3706. [Google Scholar] [CrossRef]

- Cestari, S.P.; Martin, P.J.; Hanna, P.R.; P. Kearns, M.; Mendes, L.C.; Millar, B. Use of Virgin/Recycled Polyethylene Blends in Rotational Moulding. J. Polym. Eng. 2021, 41, 509–516. [Google Scholar] [CrossRef]

- Tesfaw, S.; Fatoba, O.; Mulatie, T. Evaluation of Tensile and Flexural Strength Properties of Virgin and Recycled High-Density Polyethylene (HDPE) for Pipe Fitting Application. Mater. Today. Proc. 2022, 62, 3103–3113. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Rodrigue, D. Highly Filled Thermoplastic Elastomers from Ground Tire Rubber, Maleated Polyethylene and High Density Polyethylene. Plast. Rubber Compos. 2013, 42, 115–122. [Google Scholar] [CrossRef]

- Hamdi, A.; Fathallah, R.; Belkhiria, S.; Fathallah, R. Strain-Based Criterion for Uniaxial Fatigue Life Prediction for an SBR Rubber: Comparative Study and Development. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. 2020, 234, 897–909. [Google Scholar] [CrossRef]

- Hirschberg, V.; Schwab, L.; Cziep, M.; Wilhelm, M.; Rodrigue, D. Influence of Molecular Properties on the Mechanical Fatigue of Polystyrene (PS) Analyzed via Wöhler Curves and Fourier Transform Rheology. Polymer 2018, 138, 1–7. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Phase Morphology, Mechanical, and Thermal Properties of Fiber-Reinforced Thermoplastic Elastomer: Effects of Blend Composition and Compatibilization. J. Reinf. Plast. Compos. 2019, 2022, 7–8. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Hirschberg, V.; Rodrigue, D. Mechanical Fatigue of Biodegradable Polymers: A Study on Polylactic Acid (PLA), Polybutylene Succinate (PBS) and Polybutylene Adipate Terephthalate (PBAT). Int. J. Fatigue 2022, 159, 106798. [Google Scholar] [CrossRef]

- Hirschberg, V.; Wilhelm, M.; Rodrigue, D. Fatigue Behavior of Polystyrene (PS) Analyzed from the Fourier Transform (FT) of Stress Response: First Evidence of I2/1(N) and I3/1(N) as New Fingerprints. Polym. Test 2017, 60, 343–350. [Google Scholar] [CrossRef]

- Hirschberg, V.; Wilhelm, M.; Rodrigue, D. Fatigue Life Prediction via the Time-Dependent Evolution of Linear and Nonlinear Mechanical Parameters Determined via Fourier Transform of the Stress. J. Appl. Polym. Sci. 2018, 135, 46634. [Google Scholar] [CrossRef]

- Hirschberg, V.; Faust, L.; Rodrigue, D.; Wilhelm, M. Effect of Topology and Molecular Properties on the Rheology and Fatigue Behavior of Solid Polystyrene/Polyisoprene Di- and Triblock Copolymers. Macromolecules 2020, 53, 5572–5587. [Google Scholar] [CrossRef]

- Hirschberg, V.; Lacroix, F.; Wilhelm, M.; Rodrigue, D. Fatigue Analysis of Brittle Polymers via Fourier Transform of the Stress. Mech. Mater. 2019, 137, 103100. [Google Scholar] [CrossRef]

- Hirschberg, V.; Wilhelm, M.; Rodrigue, D. Combining Mechanical and Thermal Surface Fourier Transform Analysis to Follow the Dynamic Fatigue Behavior of Polymers. Polym. Test 2021, 96, 107070. [Google Scholar] [CrossRef]

- Hirschberg, V.; Faust, L.; Wilhelm, M.; Rodrigue, D. Universal Strain-Life Curve Exponents for Thermoplastics and Elastomers under Tension-Tension and Torsion. Macromol. Mater. Eng. 2021, 306, 2100165. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).