Washing Post-Consumer Flexible Polyethylene Packaging Waste

Abstract

1. Introduction

2. Materials and Methods

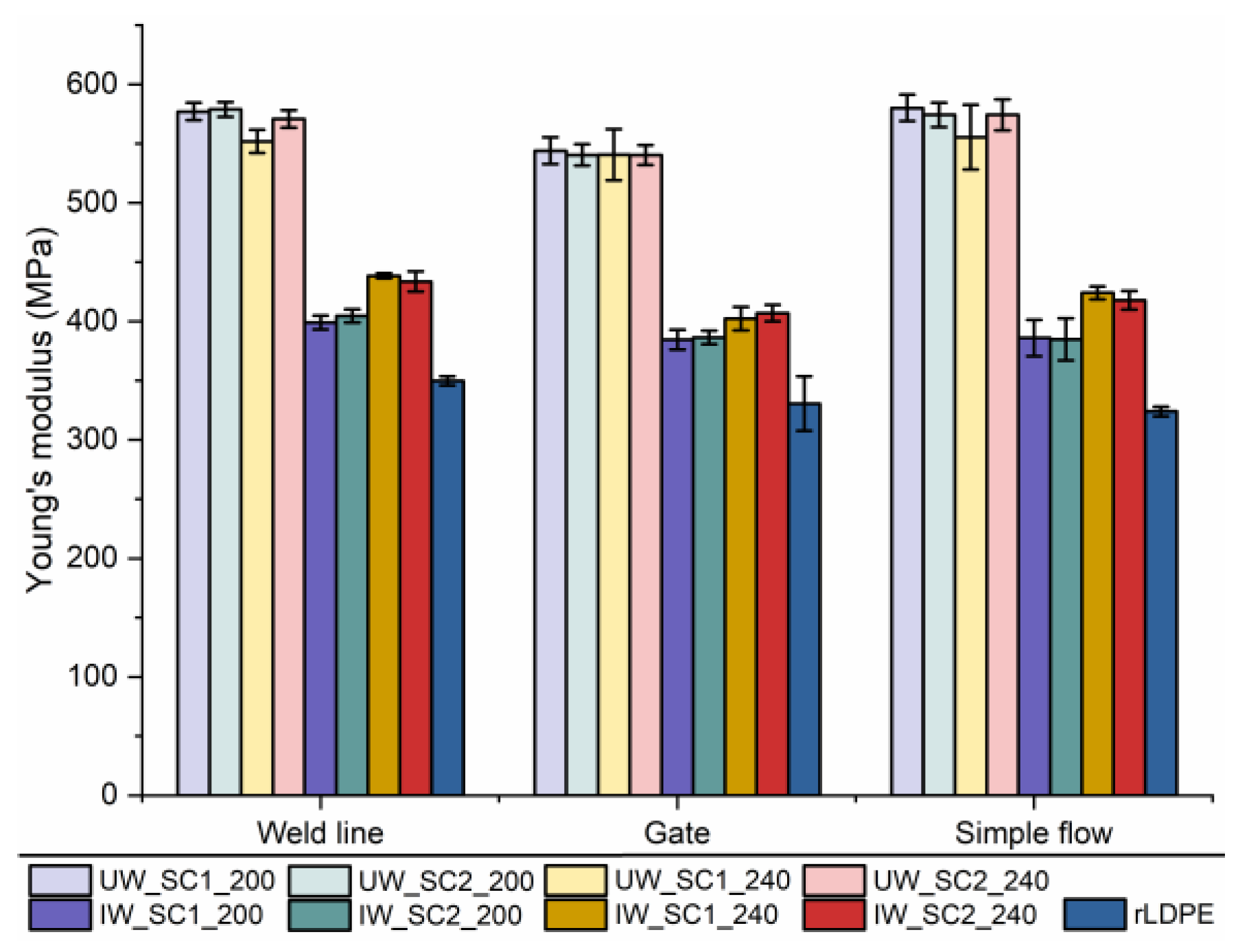

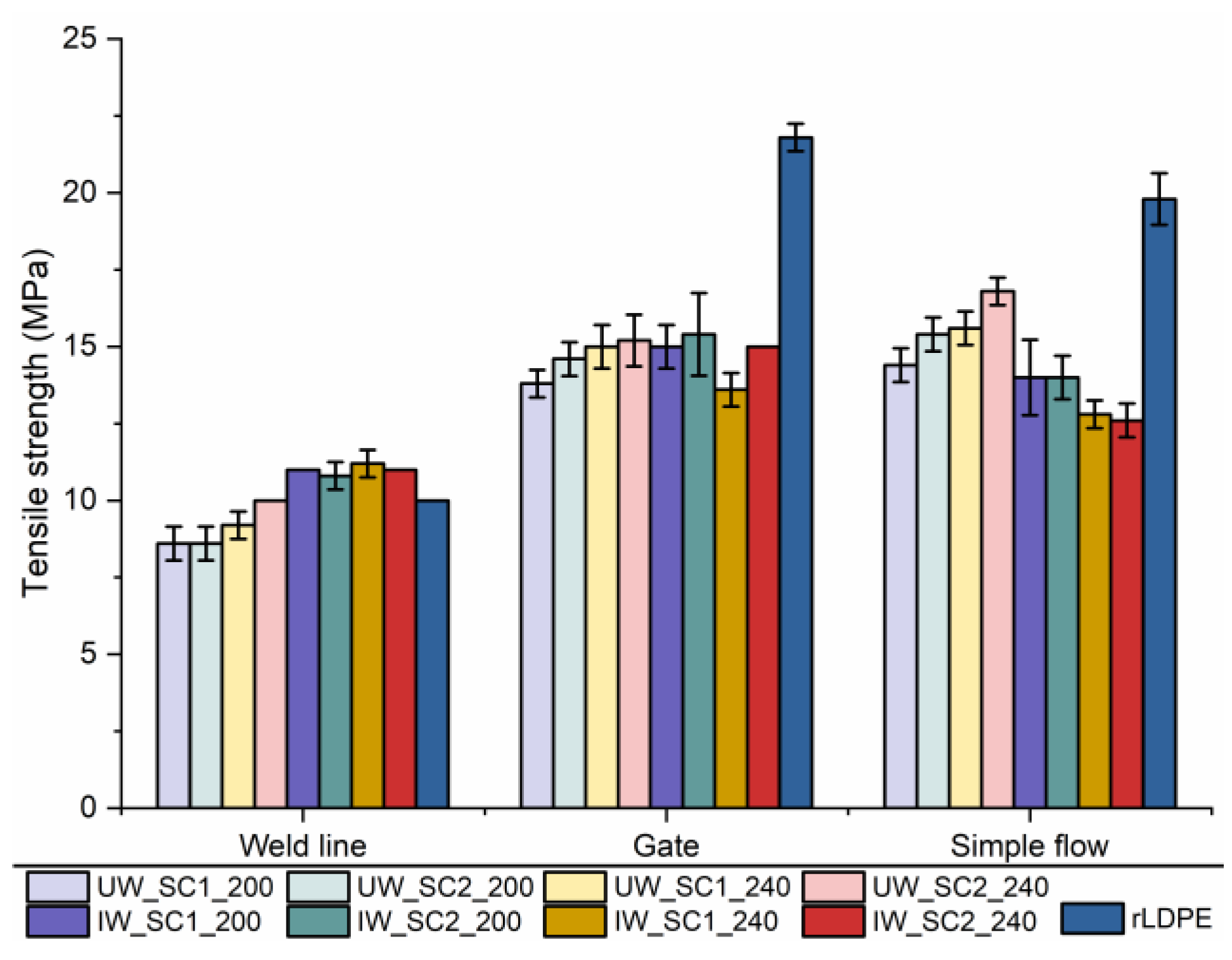

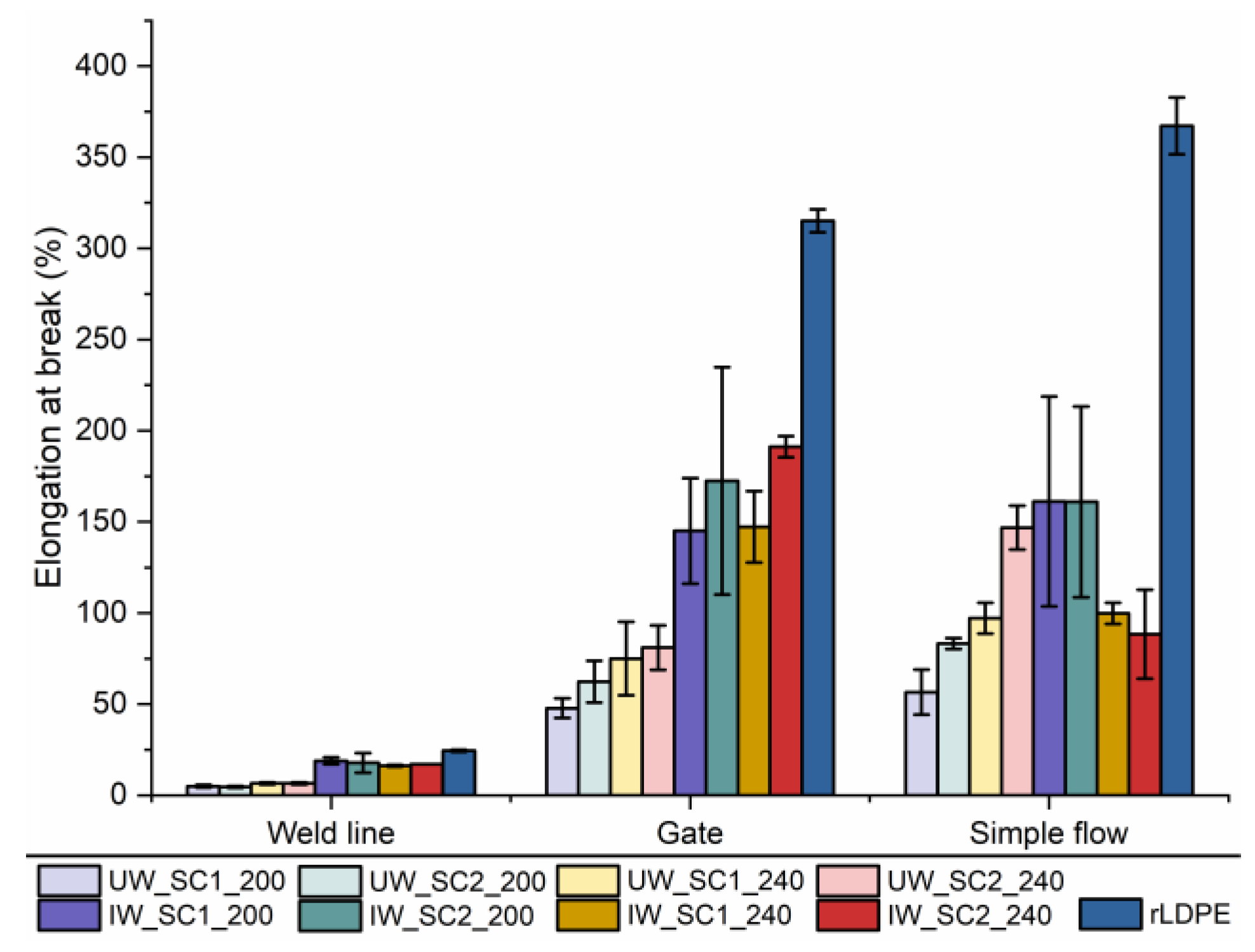

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ellen MacArthur Foundation The New Plastics Economy: Rethinking the Future of Plastics & Catalysing Action. Available online: https://ellenmacarthurfoundation.org/the-new-plastics-economy-rethinking-the-future-of-plastics-and-catalysing (accessed on 9 October 2022).

- European Parliament and the Council Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018L0852 (accessed on 24 February 2022).

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of Post-Consumer Plastic Packaging Waste in EU: Process Efficiencies, Material Flows, and Barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef] [PubMed]

- Ellen MacArthur Foundation Flexible Packaging: The Urgent Actions Needed to Deliver Circular Economy Solutions. Available online: https://ellenmacarthurfoundation.org/flexible-packaging-the-urgent-actions-needed-to-deliver-circular-economy (accessed on 9 October 2022).

- Jönkkäri, I.; Poliakova, V.; Mylläri, V.; Anderson, R.; Andersson, M.; Vuorinen, J. Compounding and Characterization of Recycled Multilayer Plastic Films. J. Appl. Polym. Sci. 2020, 137, 49101. [Google Scholar] [CrossRef]

- Schmidt, J.; Grau, L.; Auer, M.; Maletz, R.; Woidasky, J. Multilayer Packaging in a Circular Economy. Polymers 2022, 14, 1825. [Google Scholar] [CrossRef] [PubMed]

- Gala, A.; Guerrero, M.; Serra, J.M. Characterization of Post-Consumer Plastic Film Waste from Mixed MSW in Spain: A Key Point for the Successful Implementation of Sustainable Plastic Waste Management Strategies. Waste Manag. 2020, 111, 22–33. [Google Scholar] [CrossRef]

- Ronca, S. Polyethylene. In Brydson’s Plastics Materials, 8th ed.; Gilbert, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 247–278. [Google Scholar]

- PlascticsEurope; EPRO Plastics—The Facts. 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 28 January 2022).

- Hahladakis, J.N.; Iacovidou, E. Closing the Loop on Plastic Packaging Materials: What Is Quality and How Does It Affect Their Circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef] [PubMed]

- Van Belle, A.V.; Demets, R.; Mys, N.; Van Kets, K.V.; Dewulf, J.; Van Geem, K.V.; De Meester, S.D.; Ragaert, K. Microstructural Contributions of Different Polyolefins to the Deformation Mechanisms of Their Binary Blends. Polymers 2020, 12, 1171. [Google Scholar] [CrossRef]

- Bashirgonbadi, A.; Saputra Lase, I.; Delva, L.; Van Geem, K.M.; De Meester, S.; Ragaert, K. Quality Evaluation and Economic Assessment of an Improved Mechanical Recycling Process for Post-Consumer Flexible Plastics. Waste Manag. 2022, 153, 41–51. [Google Scholar] [CrossRef]

- Pospíšil, J.; Horák, Z.; Kruliš, Z.; Nešpůrek, S. The Origin and Role of Structural Inhomogeneities and Impurities in Material Recycling of Plastics. Macromol. Symp. 1998, 135, 247–263. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Devlieghere, F.; De Meulenaer, B.; Sekitoleko, P.; Garcia, A.A.E.; Huyghebaert, A. Evaluation, Modelling and Optimization of the Cleaning Process of Contaminated Plastic Food Refillables. Food Addit. Contam. 1997, 14, 671–683. [Google Scholar] [CrossRef] [PubMed]

- Möllnitz, S.; Feuchter, M.; Duretek, I.; Schmidt, G.; Pomberger, R.; Sarc, R. Processability of Different Polymer Fractions Recovered from Mixed Wastes and Determination of Material Properties for Recycling. Polymers 2021, 13, 457. [Google Scholar] [CrossRef]

- Santana, R.M.C.; Gondim, G. Influence of Cleaning Conditions on the Degradation of Recycled HDPE. J. Appl. Polym. Sci. 2009, 112, 1454–1460. [Google Scholar] [CrossRef]

- Soto, J.M.; Martín-Lara, M.A.; Blázquez, G.; Godoy, V.; Quesada, L.; Calero, M. Novel Pre-Treatment of Dirty Post-Consumer Polyethylene Film for Its Mechanical Recycling. Process Saf. Environ. Prot. 2020, 139, 315–324. [Google Scholar] [CrossRef]

- Streit, A.F.M.; de Santana, M.P.; de Oliveira Júnior, D.L.; Bassaco, M.M.; Tanabe, E.H.; Guilherme, D.L.; Bertuol, D.A. Development of a Pre-Treatment Process of Polymeric Wastes (HDPE, LDPE/LLDPE, PP) for Application in the Qualification of Selectors of Recyclable Materials. Environ. Dev. Sustain. 2022, 24, 6349–6371. [Google Scholar] [CrossRef]

- Welle, F. Investigation into Cross-Contamination during Cleaning Efficiency Testing in PET Recycling. Resour. Conserv. Recycl. 2016, 112, 65–72. [Google Scholar] [CrossRef]

- Thoden van Velzen, E.U.; Chu, S.; Alvarado Chacon, F.; Brouwer, M.T.; Molenveld, K. The Impact of Impurities on the Mechanical Properties of Recycled Polyethylene. Packag. Technol. Sci. 2020, 34, 219–228. [Google Scholar] [CrossRef]

- Cecon, V.S.; Da Silva, P.F.; Vorst, K.L.; Curtzwiler, G.W. The Effect of Post-Consumer Recycled Polyethylene (PCRPE) on the Properties of Polyethylene Blends of Different Densities. Polym. Degrad. Stab. 2021, 190, 109627. [Google Scholar] [CrossRef]

- Sánchez-Soto, M.; Rossa, A.; Sánchez, A.J.; Gámez-Pérez, J. Blends of HDPE Wastes: Study of the Properties. Waste Manag. 2008, 28, 2565–2573. [Google Scholar] [CrossRef]

- Gall, M.; Wiener, M.; Chagas de Oliveira, C.; Lang, R.W.; Hansen, E.G. Building a Circular Plastics Economy with Informal Waste Pickers: Recyclate Quality, Business Model, and Societal Impacts. Resour. Conserv. Recycl. 2020, 156, 104685. [Google Scholar] [CrossRef]

- Soto, J.M.; Blázquez, G.; Calero, M.; Quesada, L.; Godoy, V.; Martín-Lara, M.Á. A Real Case Study of Mechanical Recycling as an Alternative for Managing of Polyethylene Plastic Film Presented in Mixed Municipal Solid Waste. J. Clean. Prod. 2018, 203, 777–787. [Google Scholar] [CrossRef]

- Lechner, M.D. Polymers. In Springer Handbook of Materials Data. Springer Handbooks; Warlimont, H., Martienssen, W., Eds.; Springer: Cham, Switzerland, 2018; pp. 489–540. [Google Scholar]

- Jiang, Z.; Guo, Z.; Zhang, Z.; Qi, Y.; Pu, C.; Wang, Q.; Jia, Z.; Xiao, C. Preparation and Properties of Bottle-Recycled Polyethylene Terephthalate (PET) Filaments. Text. Res. J. 2019, 89, 1207–1214. [Google Scholar] [CrossRef]

- Karlsson, K.; Assargren, C.; Gedde, U.W. Thermal Analysis for the Assessment of Antioxidant Content in Polyethylene. Polym. Test. 1990, 9, 421–431. [Google Scholar] [CrossRef]

- Dordinejad, A.K.; Sharif, F.; Ebrahimi, M.; Rashedi, R. Rheological and Thermorheological Assessment of Polyethylene in Multiple Extrusion Process. Thermochim. Acta 2018, 668, 19–27. [Google Scholar] [CrossRef]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Andersson, T.; Stålbom, B.; Wesslén, B. Degradation of Polyethylene during Extrusion. II. Degradation of Low-Density Polyethylene, Linear Low-Density Polyethylene, and High-Density Polyethylene in Film Extrusion. J. Appl. Polym. Sci. 2004, 91, 1525–1537. [Google Scholar] [CrossRef]

- Azmi, A.; Sata, S.A.; Rohman, F.S.; Aziz, N. Melt Flow Index of Low-Density Polyethylene Determination Based on Molecular Weight and Branching Properties. J. Phys. Conf. Ser. 2019, 1349, 012094. [Google Scholar] [CrossRef]

- Bremner, T.; Rudin, A.; Cook, D.G. Melt Flow Index Values and Molecular Weight Distributions of Commercial Thermoplastics. J. Appl. Polym. Sci. 1990, 41, 1617–1627. [Google Scholar] [CrossRef]

- Ram, A.; Narkis, M. Melt Viscosity of Polyethylene: Shear Dependence. J. Appl. Polym. Sci. 1966, 10, 481–489. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the Loop for PET, PE and PP Waste from Households: Influence of Material Properties and Product Design for Plastic Recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Demets, R.; Van Kets, K.; Huysveld, S.; Dewulf, J.; De Meester, S.; Ragaert, K. Addressing the Complex Challenge of Understanding and Quantifying Substitutability for Recycled Plastics. Resour. Conserv. Recycl. 2021, 174, 105826. [Google Scholar] [CrossRef]

- Tjäder, T.; Seppälä, J.; Jääskeläinen, P. Effect of Material Characteristics of Polyolefins on Weld Line Morphology and Its Correlation to Mechanical Properties. J. Mater. Sci. 1998, 33, 923–931. [Google Scholar] [CrossRef]

- Ram, A.; Miltz, J. Materials Structure-Property Relationships in Low-Density Polyethylene. Int. J. Polym. Mater. 1972, 2, 39–47. [Google Scholar] [CrossRef]

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Al-Dousari, N.M.; Joseph Abraham, G.; D’souza, M.A.; Al-Qabandi, O.A.; Al-Zakri, W. Effect of Die Head Temperature at Compounding Stage on the Degradation of Linear Low Density Polyethylene/Plastic Film Waste Blends after Accelerated Weathering. Int. J. Polym. Sci. 2016, 2016, 5147209. [Google Scholar] [CrossRef]

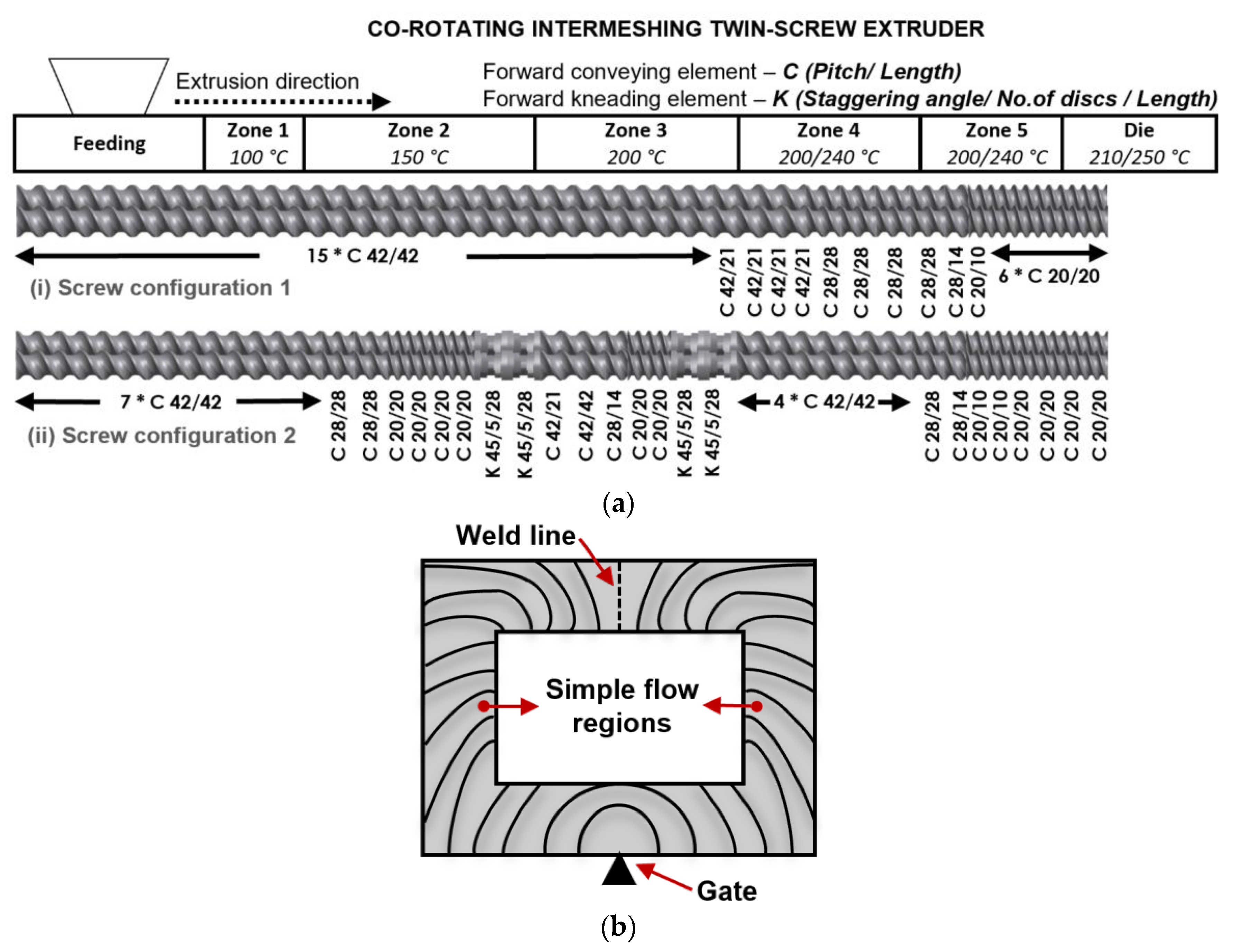

| Treatment | Compounding Parameters | Sample Code | |

|---|---|---|---|

| Screw Design | Temperature Profile (°C) | ||

| Unwashed | SC1 | 100-150-200-200-200-210 | UW_SC1_200 |

| Unwashed | SC1 | 100-150-200-240-240-250 | UW_SC1_240 |

| Unwashed | SC2 | 100-150-200-200-200-210 | UW_SC2_200 |

| Unwashed | SC2 | 100-150-200-240-240-250 | UW_SC2_240 |

| Industrially washed | SC1 | 100-150-200-200-200-210 | IW_SC1_200 |

| Industrially washed | SC1 | 100-150-200-240-240-250 | IW_SC1_240 |

| Industrially washed | SC2 | 100-150-200-200-200-210 | IW_SC2_200 |

| Industrially washed | SC2 | 100-150-200-240-240-250 | IW_SC2_240 |

| Industrially recycled (washed and melt-filtered) | N/A | N/A | rLDPE |

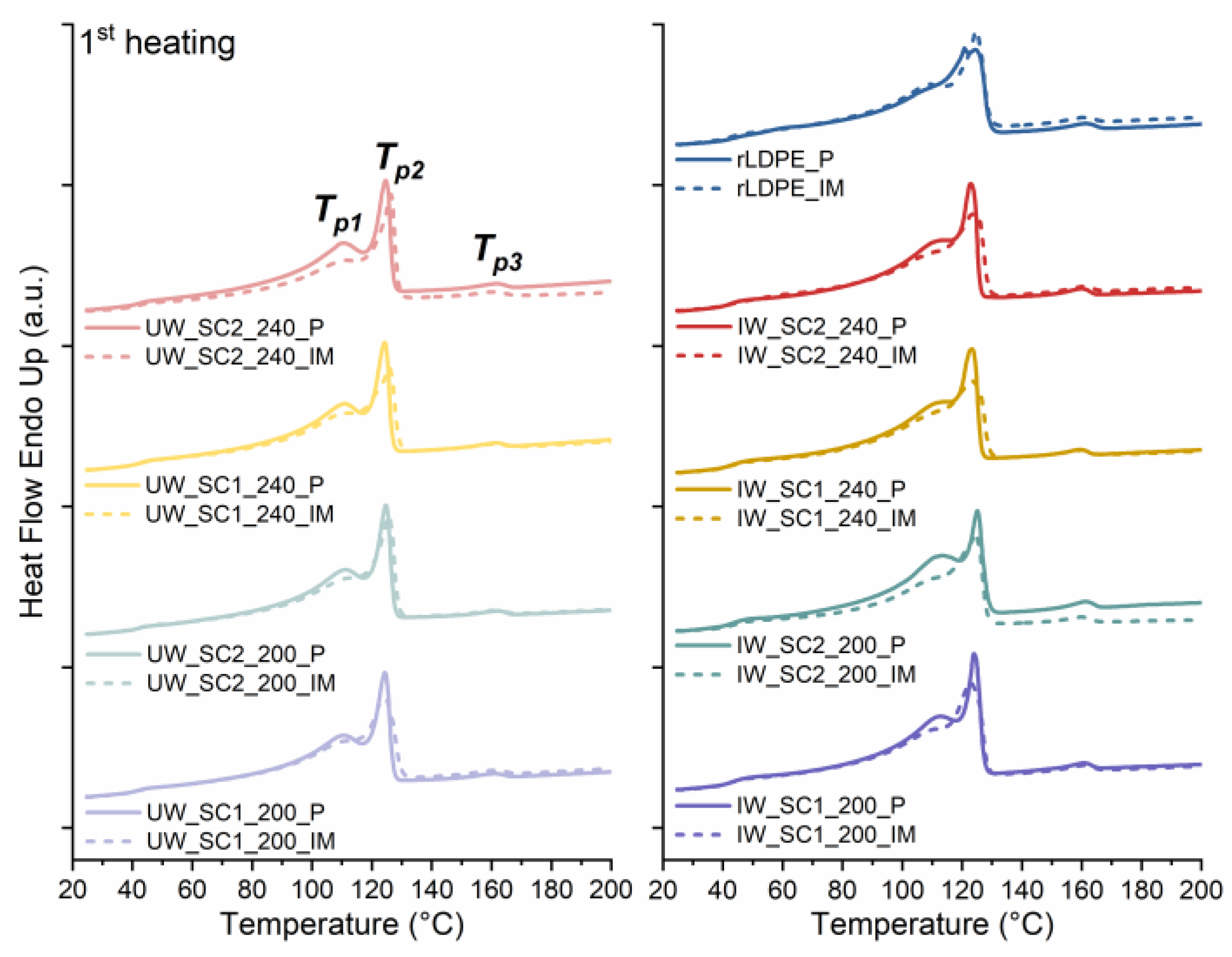

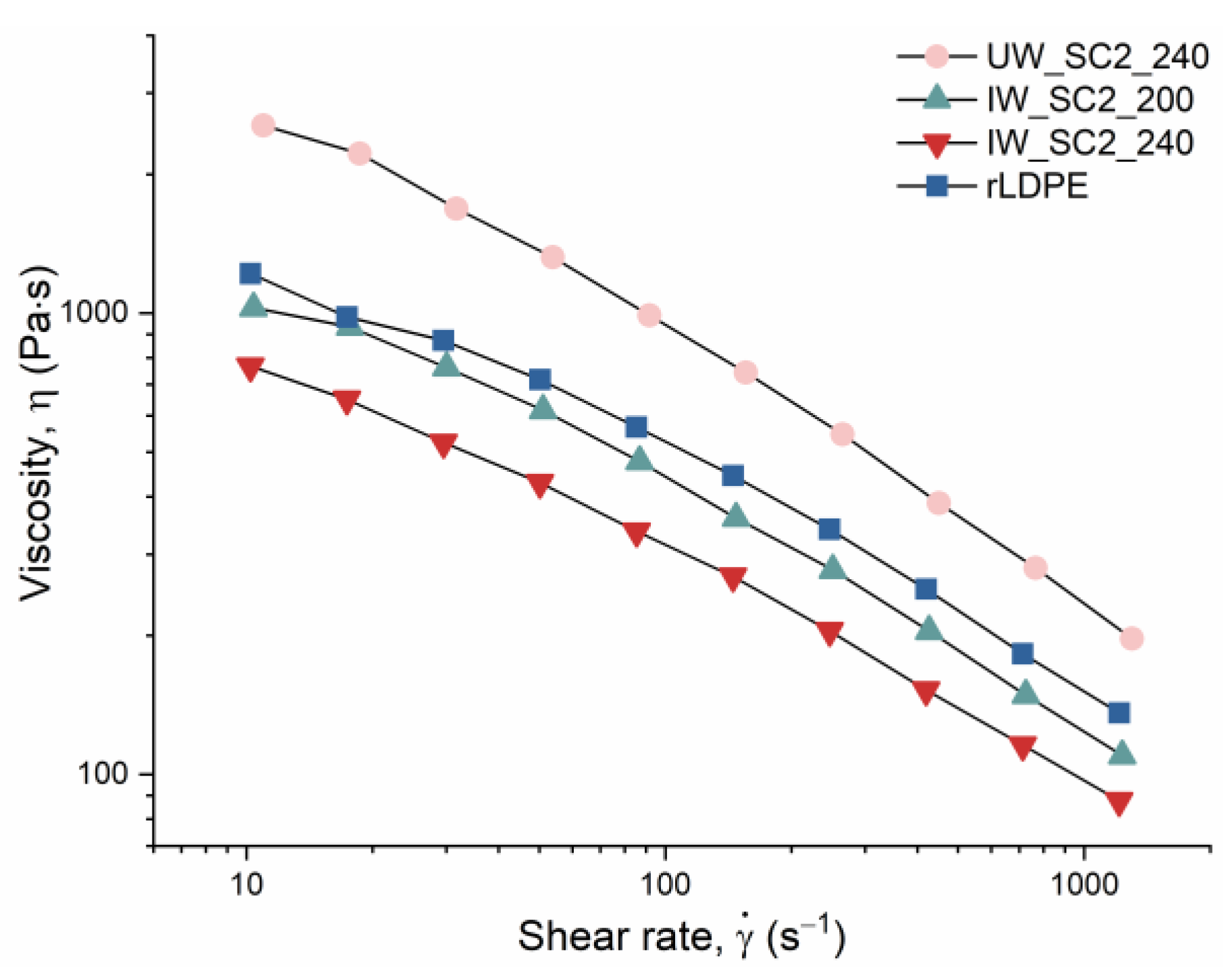

| Sample | Tp1 (°C) | Tp2 (°C) | Tp3 (°C) | ΔH (J/g) | Tox (°C) | Ash Content at 550 °C (%) | Mw (g/mol) | PDI | MFR (g/10 min) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | IM | P | IM | P | IM | P | IM | P | IM | |||||

| UW_SC1_200 | 111 | 111 | 125 | 125 | 161 | 161 | 66 | 63 | 224 | 223 | 11.5 | 123,000 | 4.8 | 0.5 |

| UW_SC2_200 | 111 | 112 | 125 | 126 | 162 | 161 | 68 | 66 | 232 | 231 | 11.3 | 124,500 | 5.2 | 0.5 |

| UW_SC1_240 | 111 | 112 | 124 | 126 | 161 | 161 | 67 | 63 | 226 | 226 | 10.5 | N/A | N/A | 0.6 |

| UW_SC2_240 | 111 | 112 | 125 | 127 | 161 | 160 | 69 | 64 | 231 | 232 | 11.2 | 122,000 | 5.0 | 0.6 |

| IW_SC1_200 | 113 | 111 | 125 | 122 | 161 | 161 | 76 | 71 | 192 | 195 | 5.2 | N/A | N/A | 1.9 |

| IW_SC2_200 | 113 | 111 | 126 | 123 | 161 | 161 | 76 | 71 | 195 | 194 | 5.3 | 87,000 | 4.1 | 2.4 |

| IW_SC1_240 | 113 | 111 | 123 | 124 | 159 | 160 | 76 | 70 | 180 | 182 | 5.1 | N/A | N/A | 4.8 |

| IW_SC2_240 | 113 | 110 | 123 | 123 | 160 | 160 | 76 | 71 | 184 | 184 | 5.3 | 71,500 | 4.4 | 3.9 |

| rLDPE | 118 | 109 | 125 | 125 | 161 | 161 | 74 | 69 | 188 | 193 | 5.1 | 103,500 | 4.0 | 14.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boz Noyan, E.C.; Venkatesh, A.; Boldizar, A. Washing Post-Consumer Flexible Polyethylene Packaging Waste. Recycling 2022, 7, 90. https://doi.org/10.3390/recycling7060090

Boz Noyan EC, Venkatesh A, Boldizar A. Washing Post-Consumer Flexible Polyethylene Packaging Waste. Recycling. 2022; 7(6):90. https://doi.org/10.3390/recycling7060090

Chicago/Turabian StyleBoz Noyan, Ezgi Ceren, Abhijit Venkatesh, and Antal Boldizar. 2022. "Washing Post-Consumer Flexible Polyethylene Packaging Waste" Recycling 7, no. 6: 90. https://doi.org/10.3390/recycling7060090

APA StyleBoz Noyan, E. C., Venkatesh, A., & Boldizar, A. (2022). Washing Post-Consumer Flexible Polyethylene Packaging Waste. Recycling, 7(6), 90. https://doi.org/10.3390/recycling7060090