Abstract

Bio-composites have been formulated by exploiting post-industrial PLA derived from thin film production and silver skin, a by-product of the coffee’s roasting process. The mix design for the compounds exploits the effects of regrading and toughening agents. The mechanical properties of the materials have been investigated as well as the thermal and physical ones. The recycled material mixed with the regrading additive shows good mechanical properties. The filler addition increases the elastic modulus of PLA up to a 20% but decreases the mechanical properties (about 20% on tensile strength), leading to a brittle behavior (minus 35% of impact strength). The use of a toughening agent restores the plastic deformation ability of the matrix.

1. Introduction

The future progressive withdrawal from oil exploitation drives the industry towards the use of polymers deriving from renewable sources. Polylactide (PLA) is presently the most commercialized one, all over the world [1]. According to the large volumes of PLA commodities produced, mainly for packaging [2,3], PLA waste recycling is becoming an important issue. Although tertiary recycling, either chemical [4] or enzymatic [5], can be a possible route [6], mechanical recycling offers many advantages [7]. One of these is the possibility to obtain composites though a single step extrusion process. In the new material, the recycled polymer acts as a matrix filled by a second phase. If this second phase is another waste, the overall price of the material is lowered and a further positive environmental benefit is obtained [8]. The decrease of the mechanical properties of the derived composites, caused both by the polymer degradation and the scanty filler-matrix interaction, can be a drawback for subsequent applications [9,10,11]. Since the decrease of the mechanical properties of the degraded matrix derives from the reduction in the value of the average molecular weight, during the extrusion process the addition of regrading molecules [12,13,14] can restore the value. Moreover, to increase the polymer filler interaction, the use of a compatibilizer, a modified polymer [15,16,17] having affinity with both phases, can instead improve the mechanical properties. When the extreme brittleness of the material becomes the limiting factor to the final application, the microstructural modification through the insertion of a toughening phase [18,19,20,21,22] can be performed. In the present research the production of composites based on post-industrial PLA and a filler deriving from the roasting process of coffee beans has been investigated. The amount of silver skin deriving from the roasting process is remarkable, since it is estimated that it makes up a 4% weight of the bean [23]. Coffee silver skin has consequently attracted a lot of interest in the production of bio-composites due to its widespread availability and to its composition that contains antioxidant and UV radiation absorbing molecules such as phenols and Maillard reaction products [24,25]. In order to overcame possible problems deriving from the reduced mechanical properties of the composites, a mix design of the investigated materials including also a regrading chain extender and a toughening phase is proposed. The effect on the mechanical properties of the different composition has been evaluated in view of a possible reuse in the formulation of packaging items.

2. Experimental

2.1. Materials

Post-industrial PLA, deriving from films production, kindly supplied by Taghleef (Como, Italy).

Coffee silver skins (hereafter defined as CSS) deriving from a mixture (80/20 wt%) of Arabica and Robusta variety have been ball milled to obtain powders with a dimension lower than 200 µm. In details, the filler had a D10 value of 7 µm, a D50 of 34 µm and a D90 value of 107 µm.

Chain extender: Chain extender (hereafter referred to as CE) is Jonkryl ADR 4368-C (BASF).

Toughening additive (hereafter referred to as T) is a thermoplastic polyurethane Elastollan N65A12P (BASF)

2.2. Compounding

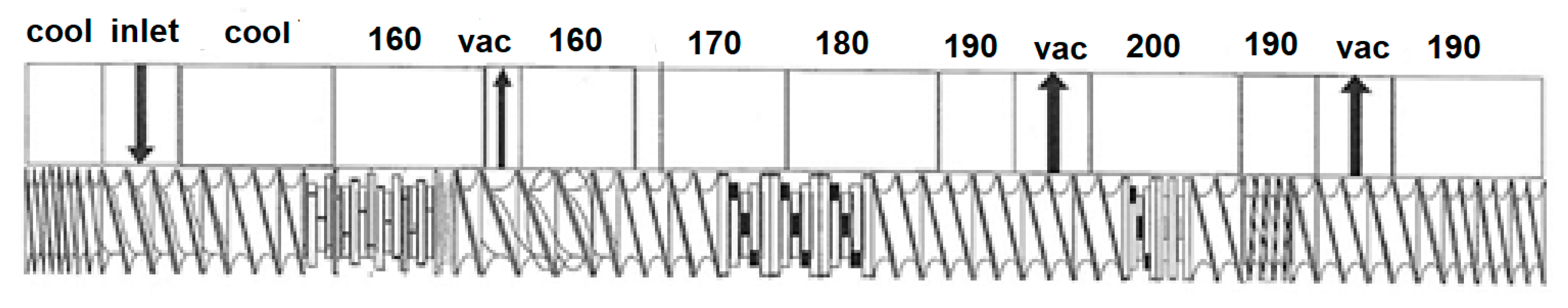

Before compounding, all components were kept in dynamic vacuum at 60 °C for 12 h to eliminate moisture. A twin screw extruder (Coperion ZSK-18) was used, having an output of 5 kg/h and a round die (4mm diameter). The complete screw profile is reported in Figure 1.

Figure 1.

Screw profile.

As to the extrusion parameters, a temperature profile of 160, 170, 180, 190, 200, 190 and 190 °C in the extruder was applied and the rotational speed of the screw was 250 rpm. The obtained pellets were dryed and afterwards used to prepare suitable samples for the subsequent characterizations by injection molding by means of a Negri Bossi, VE70 injection machine. The process conditions were the following: temperature 140–160–180–190 (last is nozzle temp), max injection pressure 800 bar. Holding pressure: 100 bar for 4 s, mold cooled at 25 °C, cycle time 50 s.

In Table 1 the composition (wt%) of the investigated materials is reported as well as the codes that will be used henceforth in the paper.

Table 1.

Compositions (wt%) and codes of the investigated compounds.

Figure 2 shows the specimens derived by injection molding to be submitted to the mechanical characterization.

Figure 2.

Specimens derived by injection molding (reported composition is of PLA_CSS).

2.3. Tests

Thermal analysis was performed by DSC (Q10, TA Instruments) from 0 to 170 °C in nitrogen flux (40 mL/min). Three scans were performed. The first one from 30 to 170, followed by an isothermal treatment at the highest temperature, erased the previous polymer history. Afterwards, a cooling scan to 0 °C at 15 °C/min was performed, followed by a third heating scan at 15 °C/min to 170 °C. The amount of crystalline phase was calculated accoding to the following expression:

where is the melting enthalpy of the fully crystallized material ΔHm is the calculated enthalpy of the investigated sample and fw is the PLA amount in the sample.

The thermal stability was studied by TGA (Perkin Elmer) from 40 to 700 °C in nitrogen flux (50 mL/min).

Tensile mechanical tests were performed by an INSTRON 5966 series instrument with a 10 kN load cell operating at test speed of 5 mm/min on the dog bone specimens reported in Figure 2. The laboratory temperature was 22 ± 1 °C and a 60 ± 10% relative humidity. The average of five different test for each material was obtained. Impact strength was determined in the Charpy configuration on unnotched samples in the previous laboratory conditions. Charpy tests were performed by using a Ceast Resil 5.5 Impact Strength Machine (CEAST S.p.a., Torino, Italy) according to ISO 179 on specimens of 4 × 10 × 80 mm derived from the injection moulded dog-bone ones (Figure 2).

The surfaces of the composite specimens fractured in the Charpy test, were observed by scanning electron microscopy (SEM, FEI XL20) after gold metallization (Quorum 150R ES).

3. Results

Table 2.

Thermal analysis results of the investigated materials 1.

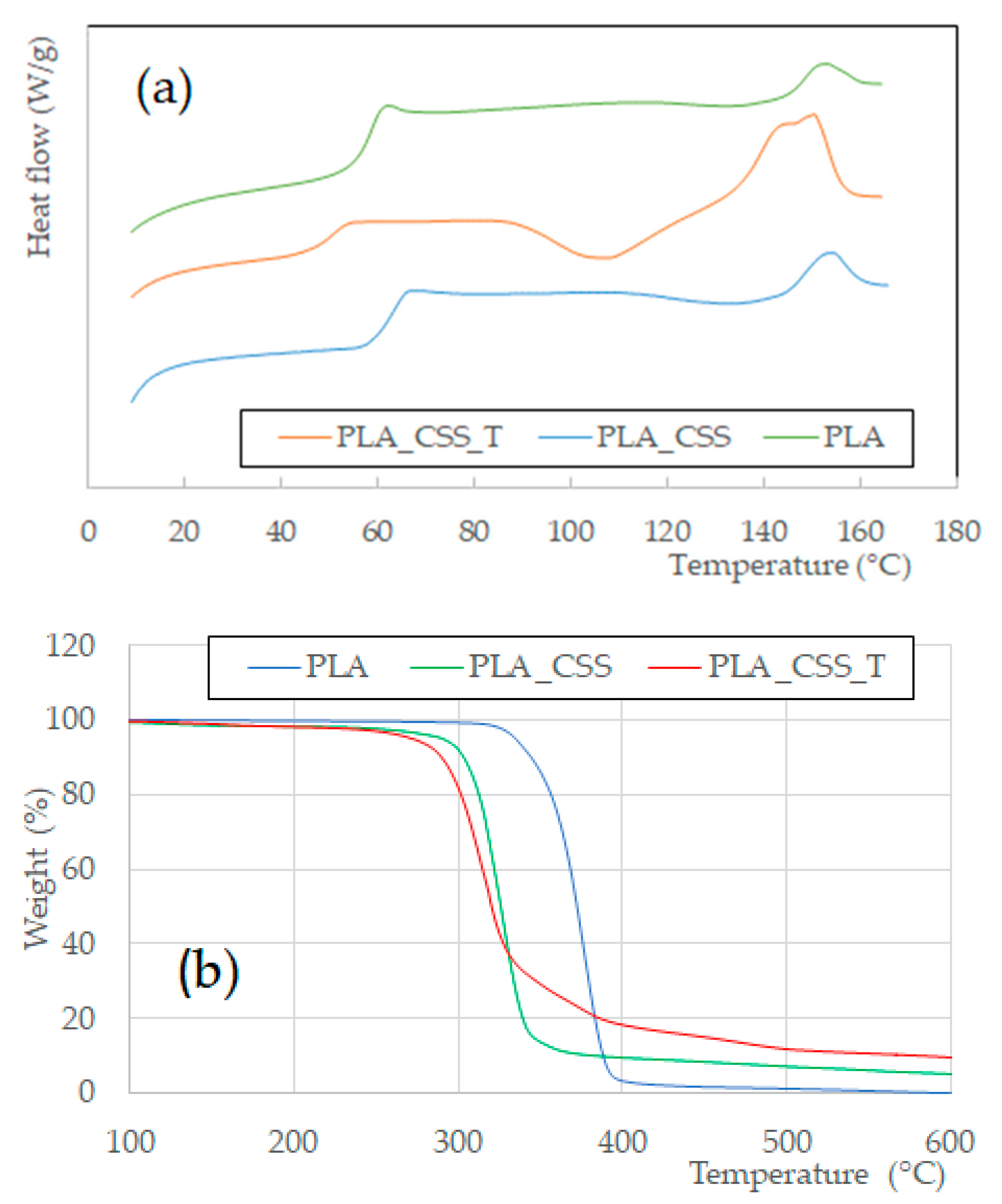

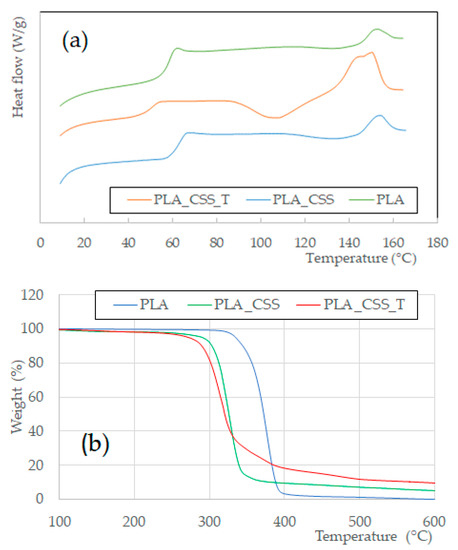

Figure 3.

(a) thermograms derived by DSC; (b) TGA analysis.

All the investigated materials have close values of glass transition and melting temperatures. Only a small fraction of the regraded PLA is crystallized. CSS addition seems to hinder the development of the ordered phase, while the presence of the polyurethane acts possibly as a nucleating agent, creating crystals of different sizes as evidenced by the melting peak broadening. This leads to a higher fraction of crystallinity, as can be seen from the normalized percentage value in Table 2. The selected melting enthalpy value for the fully crystalline PLA phase is of 93 J/g, as reported in [26].

In Table 3, the results of the TGA analysis derived from Figure 3b are summarized. The onset temperature of decomposition (Tonset) of the polymer is decreased by the presence of the filler as well as by the presence of the polyurethane. Nevertheless, in all cases the onset decomposition temperature is always above the highest compounding one (i.e., 200 °C) and consequently the possible degrading reactions taking place during compounding, should be comparable in all the samples. The same trend is recorded for the temperature of the maximum degradation rate.

Table 3.

Thermogravimetric analysis results of the investigated materials.

The average values, as well as the standard deviations, of the tensile properties and of the impact strength (IS) are summarized in Table 4.

Table 4.

Mechanical properties, from the tensile tests, of the investigated materials.

The filler strongly increases the value of the modulus (about 20%) but at the same time induces a more brittle behavior of the composite and negatively affects the values of the tensile strength. This feature is common to other types of organic fillers such as vine and grapes, potato pulp, wood flour, hemp hurd powder and alfalfa [11,27,28,29]. The effect derives from the weak adhesion between the filler and PLA, a feature that could be modified by adding a compatibilizer or by the surface modification of the filler [30]. These procedures would however would affect the cost of the process. Although being reduced by the CSS addition, the mechanical properties of the composites are however still eligible for many packaging applications.

The results of the impact strength tests are summarized in Table 4. The bare matrix still shows good mechanical properties, a feature that possibly underlines the positive effect of the chain extender during the processing step. As can be seen, the presence of the filler causes an embrittlement of the polymer, as a 50% decrease in the IS value takes place. The use of the toughening additive, however restores almost completely the matrix behavior.

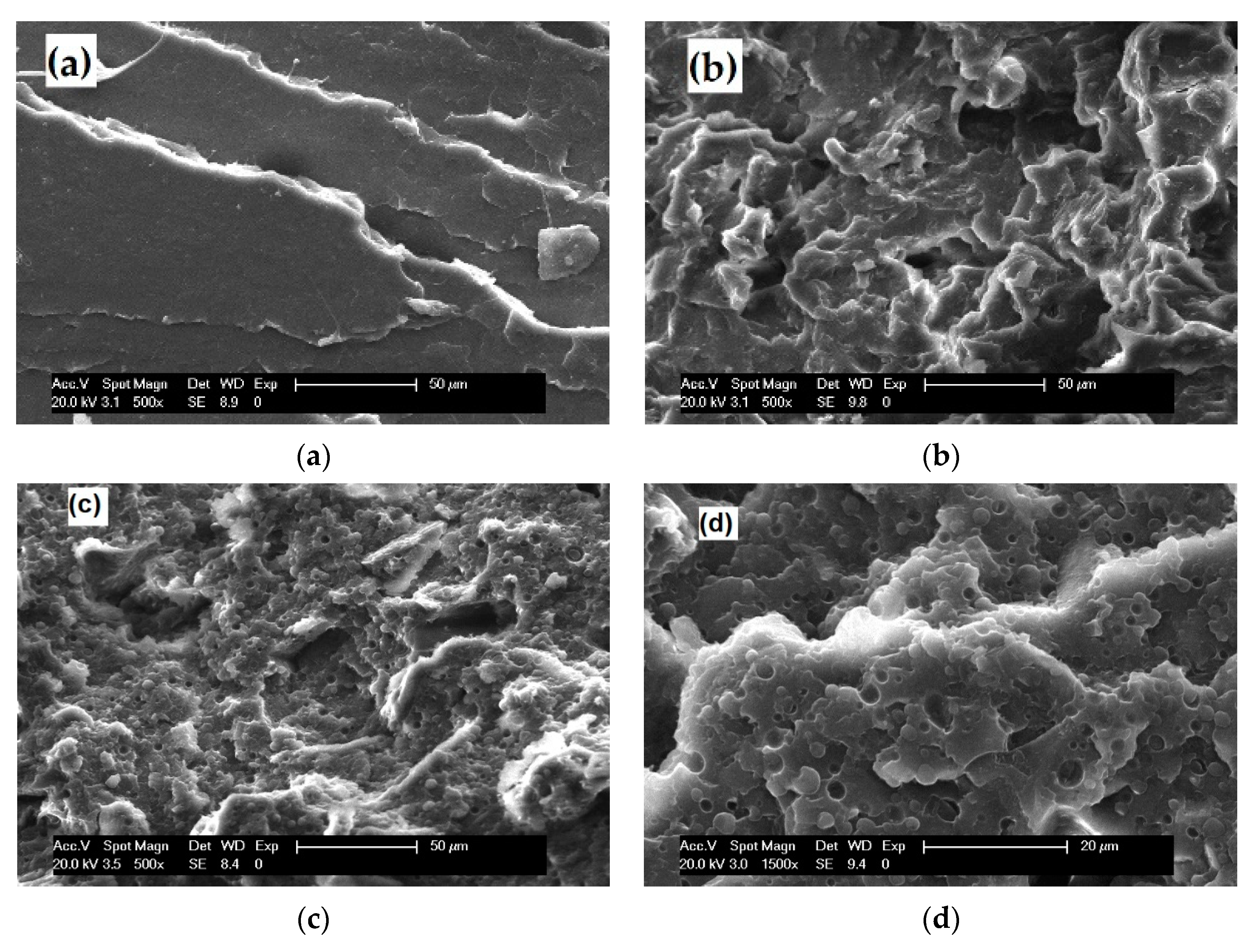

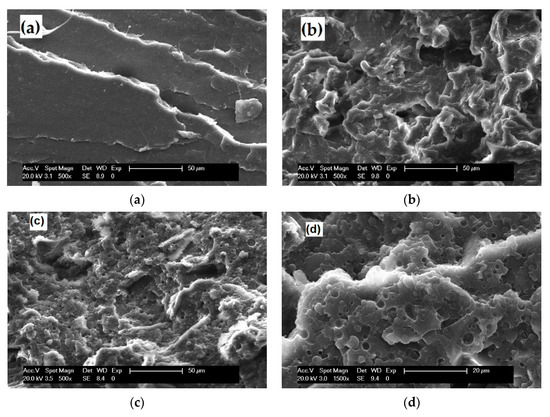

The microstructure of the composites, as well as the one of the plain matrix, is shown in Figure 4, where the fracture surfaces of the samples deriving from the Charpy test are reported. The filler presence leads to a rougher surface than the one of PLA (a). CSS modification creates a rougher fracture surface that the one of the bare matrix. The compounding process manages to evenly disperse the CSS particles inside the matrix leading to a homogeneous microstructure without the presence of CSS clusters or agglomeration. Both in micrograph (b) and (c) the silver skin particles are well enclosed inside the matrix without visible porosities at the interphase. The presence of the toughening phase leads to an even rougher surface, where this second phase appears as homogeneously dispersed in the PLA matrix, as highlighted in Figure 4d. The average dimension of this second phase is of about 3 µm.

Figure 4.

Fracture surface of PLA (a), PLA-CSS (b), PLA_CSS_T (c), and PLA_CSS_T (d) at higher magnification.

4. Conclusions

Although a deeper understanding of the effects of the compounding process on the PLA characteristics is required, the present experimental work forecasts the possibility to recycle post-industrial PLA for the production composite materials, where an agro-waste can be used as a filler. In the present research the filler has been used without any chemical treatments that could have improved its interaction with the biopolymer. However, these treatments necessarily imply an economical draw back affecting the whole process. This feature on one side promotes the concepts of circular economy, on the other side allows to reduce the overall amount of biopolymer used thus decreasing the final material cost. Moreover, it could allow the recovery of at least a fraction of the large volume of coffee silver skin produced all over the world. The filler decreases the impact and tensile strength of the composites but on the other side it increases the value of the elastic modulus. The behavior of the plain PLA can be restored by properly modifying the composite microstructure by adding on a single mixing step a further toughening phase in the formulation.

Author Contributions

Conceptualization, M.F. and A.S.; methodology, M.F.; validation A.S.; formal analysis G.B.; investigation, G.B. and M.F.; data curation, G.B.; writing—original draft preparation, G.B.; writing—review and editing, A.S. and M.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kosmalska, D.; Janczak, K.; Raszkowska-Kaczor, A.; Stasiek, A.; Ligor, T. Polylactide as a Substitute for Conventional Polymers Biopolymer Processing under Varying Extrusion Conditions. Environments 2022, 9, 57. [Google Scholar] [CrossRef]

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A review of the applications and biodegradation of polyhydroxyalkanoates and poly(Lactic acid) and its composites. Polymers 2021, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Payne, J.; Jones, M.D. The Chemical Recycling of Polyesters for a Circular Plastics Economy: Challenges and Emerging Opportunities. ChemSusChem 2021, 14, 4041–40705. [Google Scholar] [CrossRef]

- Tamoor, M.; Samak, N.A.; Jia, Y.; Mushtaq, M.U.; Sher, H.; Bibi, M.; Xing, J. Potential use of microbial enzymes for the conversion of plastic waste into value-added products: A viable solution. Front. Microbiol. 2021, 12, 777727. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, M.N.; Redhwi, H.H.; Al-Arfaj, A.A.; Achilias, D.S. Chemical recycling of PET in the presence of the bio-based polymers, PLA, PHB and PEF: A review. Sustainability 2021, 13, 10528. [Google Scholar] [CrossRef]

- Dedieu, I.; Peyron, S.; Gontard, N.; Aouf, C. The thermo-mechanical recyclability potential of biodegradable bio polyesters: Perspectives and limits for food packaging application. Polym. Test. 2022, 111, 107620. [Google Scholar] [CrossRef]

- Moustafa, H.; Youssef, A.M.; Darwish, N.A.; Abou-Kandil, A.I. Eco-friendly polymer composites for green packaging: Future vision and challenges. Comp. Part B Eng. 2019, 172, 16–25. [Google Scholar] [CrossRef]

- David, G.; Gontard, N.; Angellier-Coussy, H. Mitigating the impact of cellulose particles on the performance of biopolyester-based composites by gas-phase esterification. Polymers 2019, 11, 200. [Google Scholar] [CrossRef]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Massa, C.A.; Bronco, S.; Stäbler, A.; Lazzeri, A. Thermal, mechanical, and rheological properties of biocomposites made of poly(Lactic acid) and potato pulp powder. Int. J. Mol. Sci. 2019, 20, 675. [Google Scholar] [CrossRef]

- Saccani, A.; Sisti, L.; Manzi, S.; Fiorini, M. PLA composites formulated recycling residuals of the winery industry. Pol. Comp. 2019, 40, 1378–1383. [Google Scholar] [CrossRef]

- Nekhamanurak, B. Property improvement of processed PLA/PBAT using chain extenders. Mater. Res. Express 2022, 9, 064002. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Infante, C.; de la Orden, M.U.; Martínez Urreaga, J. Mechanical recycling of poly(lactic acid): Evaluation of a chain extender and a peroxide as additives for upgrading the recycled plastic. J. Clean. Prod. 2019, 219, 46–56. [Google Scholar] [CrossRef]

- Ghalia, M.A.; Dahman, Y. Investigating the effect of multi-functional chain extenders on PLA/PEG copolymer properties. Int. J. Biol. Macromol. 2017, 95, 494–504. [Google Scholar] [CrossRef] [PubMed]

- Hamdan, M.H.M.; Siregar, J.P.; Rejab, M.R.M.; Bachtiar, D.; Jamiluddin, J.; Tezara, C. Effect of Maleated Anhydride on Mechanical Properties of Rice Husk Filler Reinforced PLA Matrix Polymer Composite. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 113–124. [Google Scholar] [CrossRef]

- Rahem, Z.; Mayouf, I.; Guessoum, M.; Delaite, C.; Douibi, A.; Lallam, A. Compatibilization of biocomposites based on sponge-gourd natural fiber reinforced poly(lactic acid). Polym. Comp. 2019, 40, 4489–44991. [Google Scholar] [CrossRef]

- Robledo-Ortíz, J.R.; Martín Del Campo, A.S.; Blackaller, J.A.; González-López, M.E.; Pérez Fonseca, A.A. Valorization of sugarcane straw for the development of sustainable biopolymer-based composites. Polymers 2021, 13, 3335. [Google Scholar] [CrossRef]

- Dos Santos Filho, E.A.; Luna, C.B.B.; Siqueira, D.D.; Ferreira, E.D.S.B.; Araújo, E.M. Tailoring poly(Lactic acid) (PLA) properties: Effect of the impact modifiers EE-g-GMA and POE-g-GMA. Polymers 2022, 14, 136. [Google Scholar] [CrossRef]

- He, L.; Song, F.; Guo, Z.-W.; Yang, N.; Wang, X.-L.; Wang, Y.-Z. Toward strong and super-toughened PLA via incorporating a novel fully bio-based copolyester containing cyclic sugar. Comp. Part B Eng. 2021, 207, 108558. [Google Scholar] [CrossRef]

- Yildiz, S.; Karaaǧaç, B.; Ozkoc, G. Toughening of poly(lactic acid) with silicone rubber. Polym. Eng. Sci. 2014, 54, 2029–2036. [Google Scholar] [CrossRef]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber Toughening of Polylactic Acid (PLA) with Poly(butylene adipate-co-terephthalate) (PBAT): Mechanical Properties, Fracture Mechanics and Analysis of Ductile-to-Brittle Behavior while Varying Temperature and Test Speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Kfoury, G.; Raquez, J.-M.; Hassouna, F.; Leclere, P.; Toniazzo, V.; Ruch, D.; Dubois, P. Toughening of poly(lactide) using polyethylene glycol methyl ether acrylate: Reactive versus physical blending. Polym. Eng. Sci. 2015, 55, 1408–1419. [Google Scholar] [CrossRef]

- Garcia, C.; Kim, Y. Spent coffee grounds and coffee silver skin as potential materials for packaging. J. Polym. Environ. 2021, 29, 2372–2384. [Google Scholar] [CrossRef]

- Klingel, T.; Kremer, J.; Gottstein, V.; Rajcic de Rezende, T.; Schwarz, S.; Lachenmeier, D.W. A review of coffee by-products including leaf, flower, cherry, husk, silver skin, and spent grounds as novel foods within the European Union. Foods 2020, 9, 665. [Google Scholar] [CrossRef]

- Narita, Y.; Inouye, K. Review on the utilization and composition of coffee silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Rathi, S.; Kalish, J.P.; Coughlin, E.B.; Hsu, S.L. Utilization of oligo (lactic acid) for studies of chain conformation and chain packing in Poly(lactic acid). Macromolecules 2011, 44, 3410–3415. [Google Scholar] [CrossRef]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Stäbler, A.; Lazzeri, A. Thermal and mechanical properties of biocomposites made of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and potato pulp powder. Polymers 2019, 11, 308. [Google Scholar] [CrossRef]

- Morreale, M.; Liga, A.; Mistretta, M.C.; Ascione, L.; La Mantia, F.P. Mechanical, thermomechanical and reprocessing behavior of green composites from biodegradable polymer and wood flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef]

- Battegazzore, D.; Noori, A.; Frache, A. Natural wastes as particle filler for poly(lactic acid)-based composites. J. Compos. Mater. 2019, 53, 783–797. [Google Scholar] [CrossRef]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of different compatibilizers on sustainable composites based on a PHBV/PBAT matrix filled with coffee silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).