Abstract

This study aims to investigate the effect and the possibility of using waste plastic as a sustainable cost-effective polymer to modify bitumen binders. Different types of waste plastic have been used in this modification, including polyethylene terephthalate (PET), high-density polyethylene (HDPE), and low-density polyethylene (LDPE). The modification targets the physical characteristics, rheological properties, and binders’ resistance to ageing. Both long- and short-term ageing are investigated to determine the durability and ageing resistance of the modified binder using rolling thin film oven tests (RTFOT) and pressure ageing vessels (PAVs). Penetration tests and dynamic shear rheometer (DSR) tests were conducted to investigate and evaluate the complex shear modulus, stiffness, elasticity, and viscous properties. The results show that 2% and 4% of HDPE and LDPE are recommended as ideal contents for good performance, as reflected by the penetration tests before and after ageing. However, higher contents, such as 6% and 8% HDPE and LDPE, are not significant in improving the stiffness, elasticity, and ageing resistance. Therefore, samples of 6–8% HDPE and LDPE are more vulnerable to permanent deformation. Furthermore, using waste PET exhibits obvious improvements in terms of the physical characteristics, rheological properties, stiffness, elasticity, and ageing resistance with up to 8% PET-modified bitumen. Based on the results, the ideal type and content is 6–8% PET waste plastic.

1. Introduction

With the growing importance of geotechnical and pavement issues, research in these areas took the momentum to solve recycle materials inclusion in civil engineering projects. The application of numerical tools [1] and laboratory testing [2,3,4,5,6,7,8] on the aggregate issues are well-documented. On the other hand, waste creation is increasing day by day. This has led to a considerable rise in the cost of waste dumping, blocking future sites for landfills. The application of waste materials as an alternative to new materials in the road-construction industry has several advantages. One is the substantial savings in terms of reduced costs, and the second is the cutting down of waste deposited in landfills. Thus, utilising waste plastic in asphalt modification must focus on enhancing the properties of pavement construction [9,10,11,12,13,14,15].

Joint research by Awwad and Shbeeb [16] investigated the results of the use of polyethylene polymers to improve the engineering properties of asphalt mixtures. Their study was conducted to determine the most optimum type of polyethylene and its proportion in an asphalt mixture to obtain the best properties. Hence, they applied two types of polyethylenes to the aggregate coating: low-density polyethylene (LDPE) and high-density polyethylene (HDPE). The addition of the polymers to the mixture was carried out in two forms: ground and unground. The produced mixture samples showed that the ground HDPE imparted better engineering properties to the resulting mixture. The most appropriate percentage of the modifier to be added to the mixture was found to be 12% by bitumen weight. The results of this experiment further confirm that the introduced HDPE can improve the mixture stability, slightly increase the air voids (VIM) and voids of the mineral aggregate (VMA) in it, and reduce the asphalt mixture density [16]. Another study that focused on the potential of LDPE was jointly conducted by Al-Hadidy and Tan Yi-qiu [17] to study the engineering properties of this polymer as a modifier that could be applied to asphalt-mix modification and improvement. The results confirmed that the softening point of the binders modified by LDPE is comparatively higher while its ductility values were fixed at the minimum specification range (100+ cm), which, in turn, resulted in a decrease in the weight loss percentage due to heat and air. This indicates a significant improvement in the overall durability of the original SMA. Furthermore, the results revealed that the LDPE-modified SMA mixture could be the optimal mixture for pavement construction and coating in regions with extreme temperature fluctuations and excessive moisture [17].

Hinishoglu and Agar [18] used other kinds of waste plastic materials with HDPE to modify binders at various blending temperatures, times lengths, and HDPE percentages. For this experiment, they used the Marshall stability, Marshall quotient, and Marshall flow. It was concluded that 4% of HDPE at 165 °C blended continuously for 30 min provided the best Marshall stability, Marshall flow, and Marshall quotient (MQ). As a result, as a new condition applied to this experiment, the percentage of the Marshall quotient was raised by 50% in comparison to that of the control mixture. Furthermore, researchers noted that the resistance of the HDPE-modified bituminous mix against severe deterioration and deformation was significantly increased (Hinishoglu and Agar 2004).

A study by Zoorob and Suparma [19] revealed that using LDPE waste plastic in bituminous mixtures could result in a significant enhancement of their stability of approximately 2.5 times greater than the stability of the control mixtures and durability while decreasing its density. In addition, the outcomes of the study showed that the plastiphalt fatigue life of the modified mixtures was longer than that of the control ones [19]. Based on the results of these experiments, adding the polymer significantly increased the rutting resistance of the asphalt-modified mixture. Moreover, using polyethylene as a polymer for asphalt mixtures results in improvements to the fatigue resistance, workability, and efficiency of the modified mixture [20,21].

According to previous reports [22,23,24,25], using waste plastic for asphalt modification could help reduce environmental contamination and reduce additional costs. Further, introducing waste plastic into asphalt will also improve the temperature susceptibility and stiffness. Thus, waste plastic-modified bitumen results in an enhancement in the rutting and fatigue resistance [26,27,28]. Modifying and improving the properties of the bitumen and asphalt mix by using certain additives, such as plastic polymers, is one way of increasing the service life of road surfaces.

In 2018, the plastic ban by China, Malaysia, and India put significant pressure on the Australian recycling industry, and researchers have worked to find an effective solution to manage this issue [29]. One significant proposal involved using Australian waste plastic in asphalt and pavement engineering. In 2019, there were some trial sections in Sydney that incorporated waste glass, crumb rubber, and waste plastic bags in asphalt mixtures using the dry mix method; however, these trials did not investigate the mechanical characteristics, rheological properties, durability, and engineering prospects of bitumen plastic modifiers using wet mix methods [30].

Currently, at Curtin University, Perth, scientific research on using waste/by-product in geotechnical and pavement projects is being conducted [31]. The plastic inclusion as a bitumen modifier is being conducted to improve the benefits of using waste plastic to produce asphalt mixtures modified with cost-effective waste polymers, which also have a high resistance to permanent deformation. At Curtin University’s laboratory, Mashaan et al. [30,32] investigated the possibility of using waste PET to improve the engineering properties of the C320 bitumen binder, finding promising results. However, more investigation is required to examine the impact of other types of waste plastic on the engineering properties of modified binders in Australia. The aforementioned literature indicates that there is a lack of research on the impact of waste HDPE and LDPE on C320 bitumen binders, which are most commonly used for road design in Australia. Therefore, it is imperative to conduct more research into this.

2. Materials and Methodology

2.1. Materials

SEM is a useful tool to compare the surfaces [8]. In this study, C320 bitumen was used, provided by SAMI Bitumen Technologies, Perth, Western Australia. Table 1 shows the properties of the bitumen.

Table 1.

Bitumen properties.

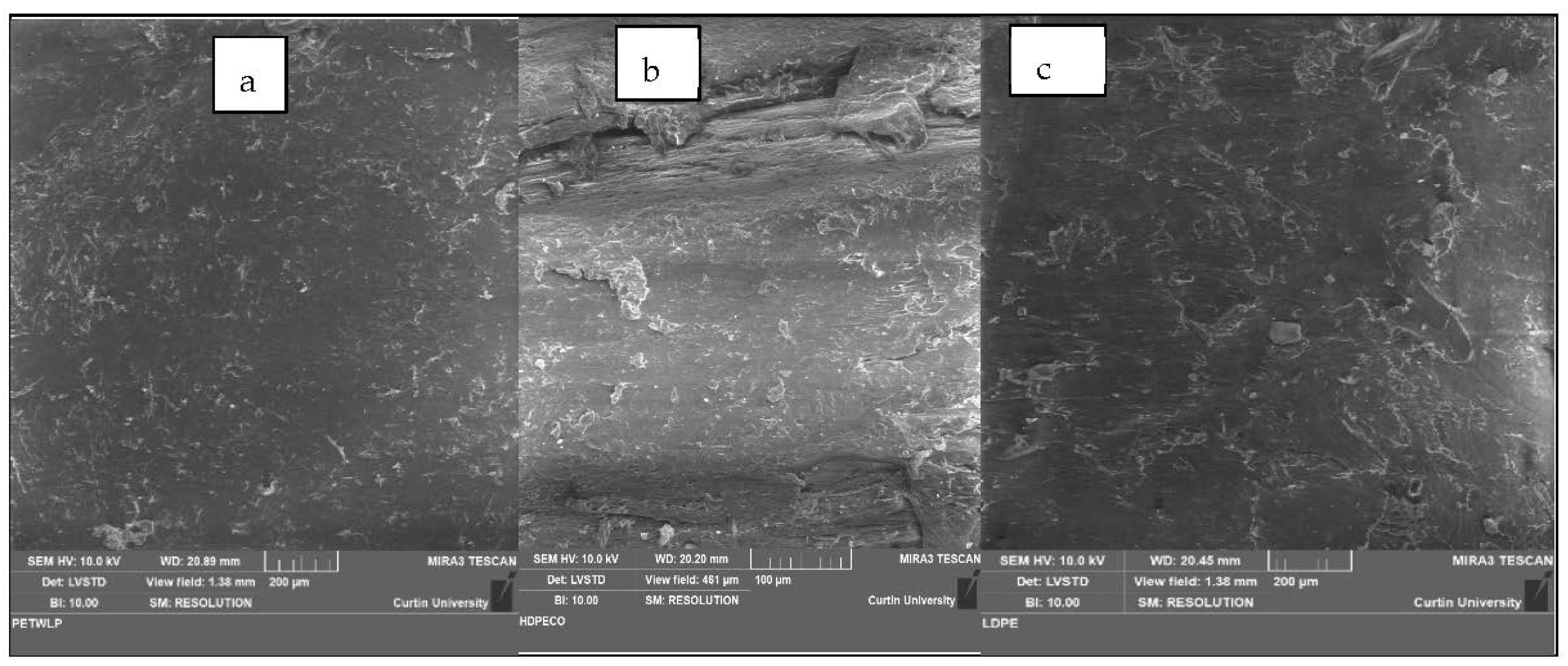

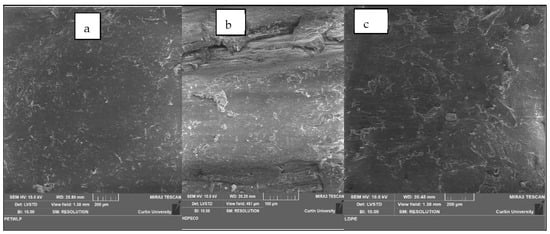

Different contents of different plastic types were used in this study, mainly comprising PET, HDPE, and LDPE, as shown in Figure 1. These plastics were collected from local communities in Perth, washed, and ground to a size of about 0.245 mm.

Figure 1.

SEM of waste plastic: (a) PET, (b) HDPE, and (c) LDPE.

2.2. Sample Production

Three different types of waste plastic—PET, HDPE, and LDPE—were used to prepare the modified binder using the wet-mixing method in different percentages: 0%, 2%, 4%, 6%, and 8%. The blending parameters were 45 min of blending time, a temperature of 180 °C, and a 2000 rpm shear velocity; this selection was based on numerous trial blends. The mixing commenced at a low shear rate of 700–800 rpm for the first 15 min to ensure fewer air voids; subsequently, the speed was increased to 2000 rpm for 30 min. DSR tests were conducted to assess and verify the viscoelastic performance and examine the rutting and fatigue resistance of the modified bitumen binders.

2.3. Methodology and Testing

2.3.1. Penetration Test

The penetration test was conducted following the specifications laid out in AS 2341.12. The penetration test measures the distance, in millimetres, of a standard needle that is perpendicularly diffused in the bitumen sample under specific conditions: 5 s of time, 25 °C temperature, and 100 g for loading. The main purpose of this test is to establish the stability of the bitumen and, thus, the ability to resist rutting failure and cracking deformation.

2.3.2. Dynamic Shear Rheometer (DSR) Test

To examine the viscoelastic behaviour at high temperatures and the bitumen’s resistance to rutting and fatigue, both treated and nontreated binder samples were subjected to the dynamic shear rheometer (DSR) test following the AASHTO 315 standard. This test focuses on determining the shear stress and linear viscoelastic properties of bitumen tested in oscillatory shear using parallel plates. The main aim of the test is to measure the complex shear modulus, which is known as the stiffness indicator G*, and measure the phase angle, which is known as the elasticity indicator.

2.3.3. Rolling Thin Film Oven Test (RTFOT)

To simulate the ageing conditions during pavement construction and under traffic loads, the rolling thin film oven test (RTFOT) is conducted. Figure 2 shows the apparatus at Curtin University. This test was carried out in the Curtin laboratory following the procedure and specification standards as AS/NZS 2341.10:2015 (Standards Australia 2015).

Figure 2.

Apparatus of the RTFOT test at Curtin University.

2.3.4. Pressure Ageing Vessel (PAV) Test

To simulate the long-term and in-service ageing of the bitumen binder after five to ten years of traffic service, the pressure ageing vessel (PAV) test is conducted, where the bitumen binders are subjected to a high pressure of 2.1 MPa for a period of 20 h under a high temperature of 110 °C.

3. Results and Discussion

3.1. Physical Properties of Waste Plastic-Modified Bitumen

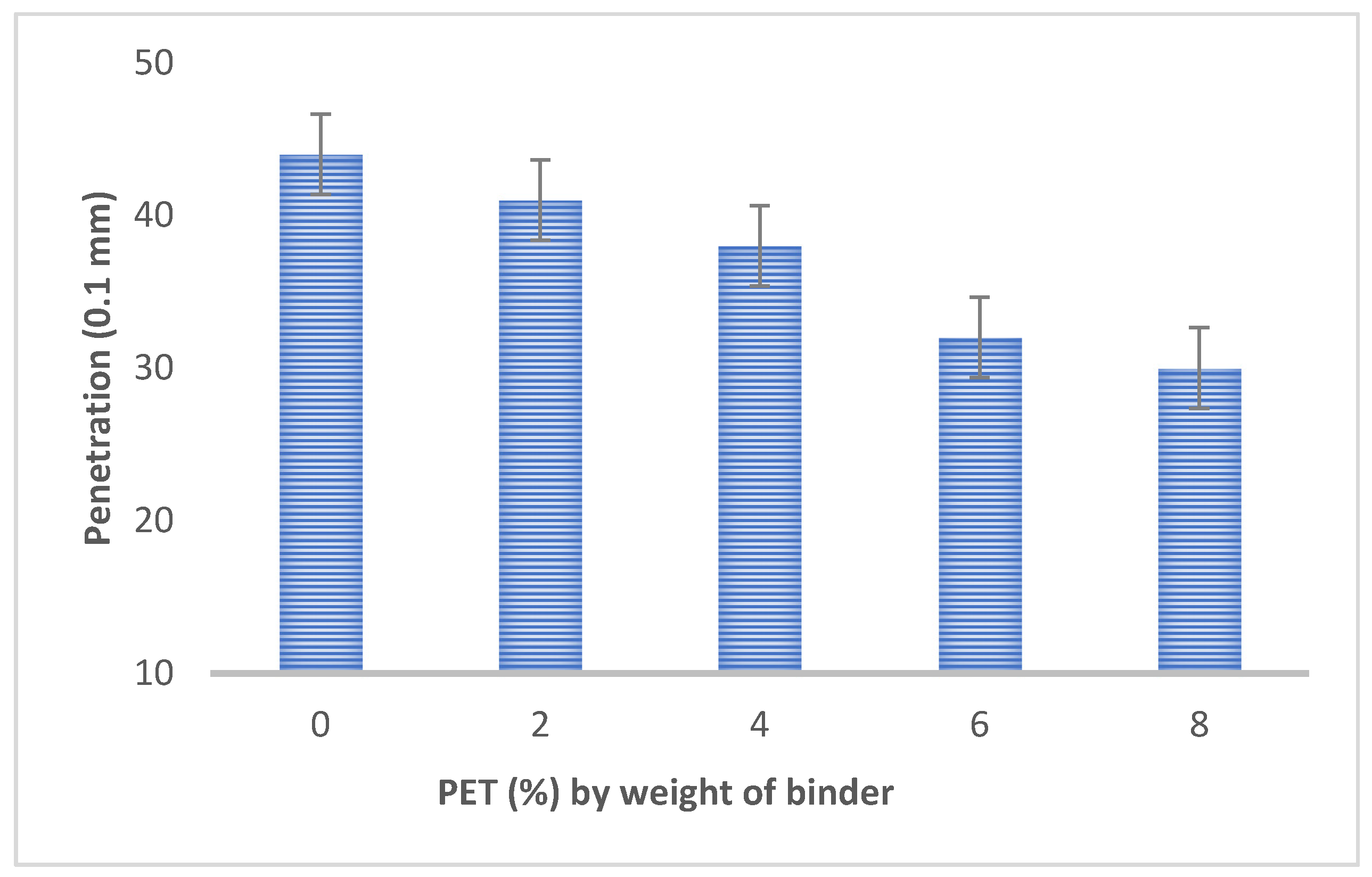

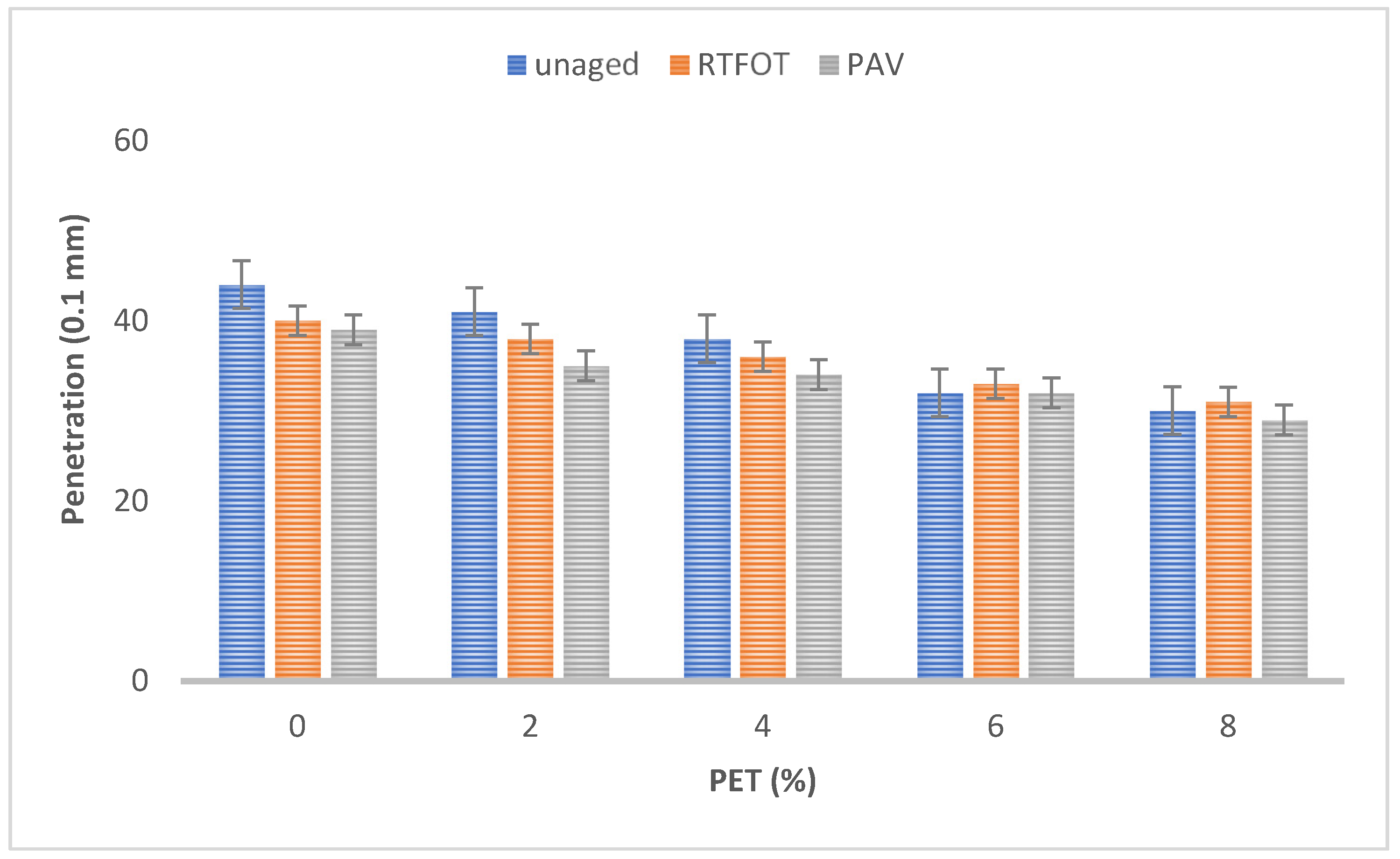

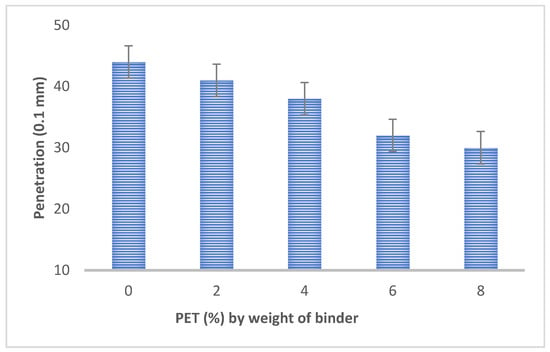

To investigate the physical properties of the modified bitumen, a penetration test was conducted first. The penetration test is a simple, reliable, and rapid test to establish the stiffness behaviour of the binder, indicating the capability of the bitumen to withstand permanent deformation. The penetration of different contents of PET, HDPE, and LDPE plastic waste for unaged specimens was found, as shown in Figure 3, Figure 4 and Figure 5, respectively. Figure 3 shows the impact of different contents of PET on the penetration. As can be seen, the higher the PET content, the lower the penetration values. The penetration of C320 (0% plastic) was 44 mm, which reduced to 30 mm when using 8% PET. This, in turn, implies that the modified binder becomes stiffer. At 6% and 8%, the behaviour of the modified bitumen is at the same level of resistance as permanent deformation. However, all PET-modified C320 samples exhibited a substantial effect on the penetration results in comparison to unmodified bitumen C320.

Figure 3.

Results for the penetration of unaged PET-modified bitumen.

Figure 4.

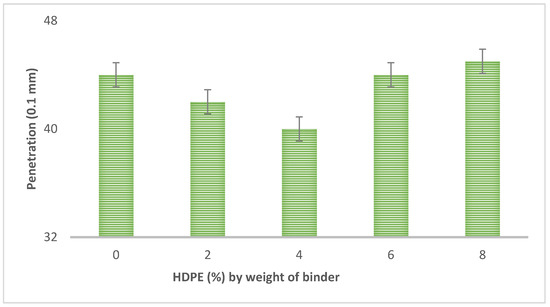

Results for the penetration of unaged HDPE-modified bitumen.

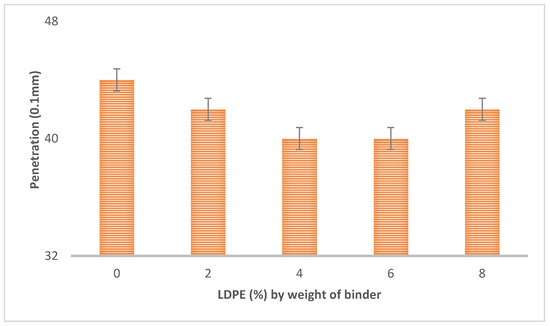

Figure 5.

Results for the penetration of unaged LDPE-modified bitumen.

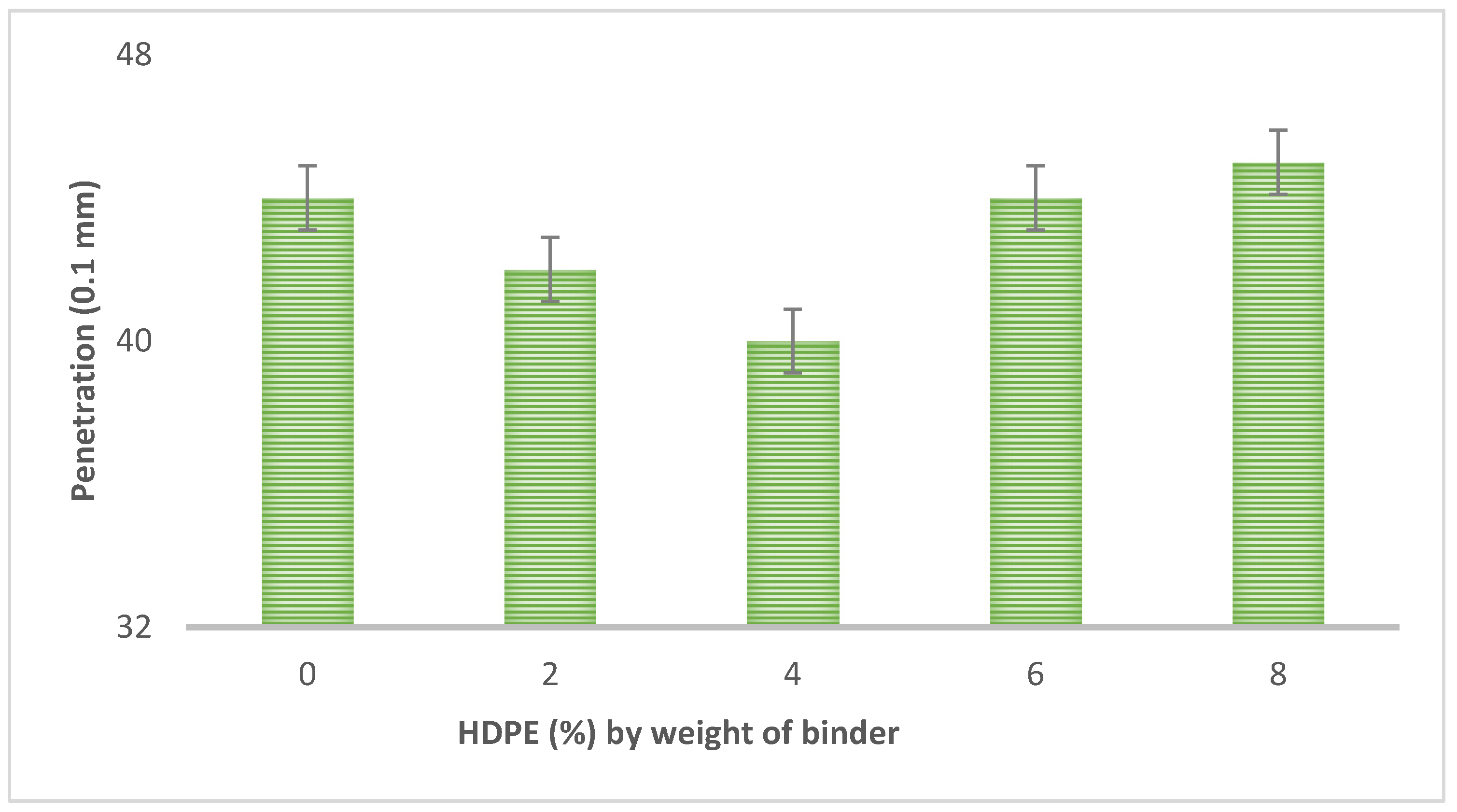

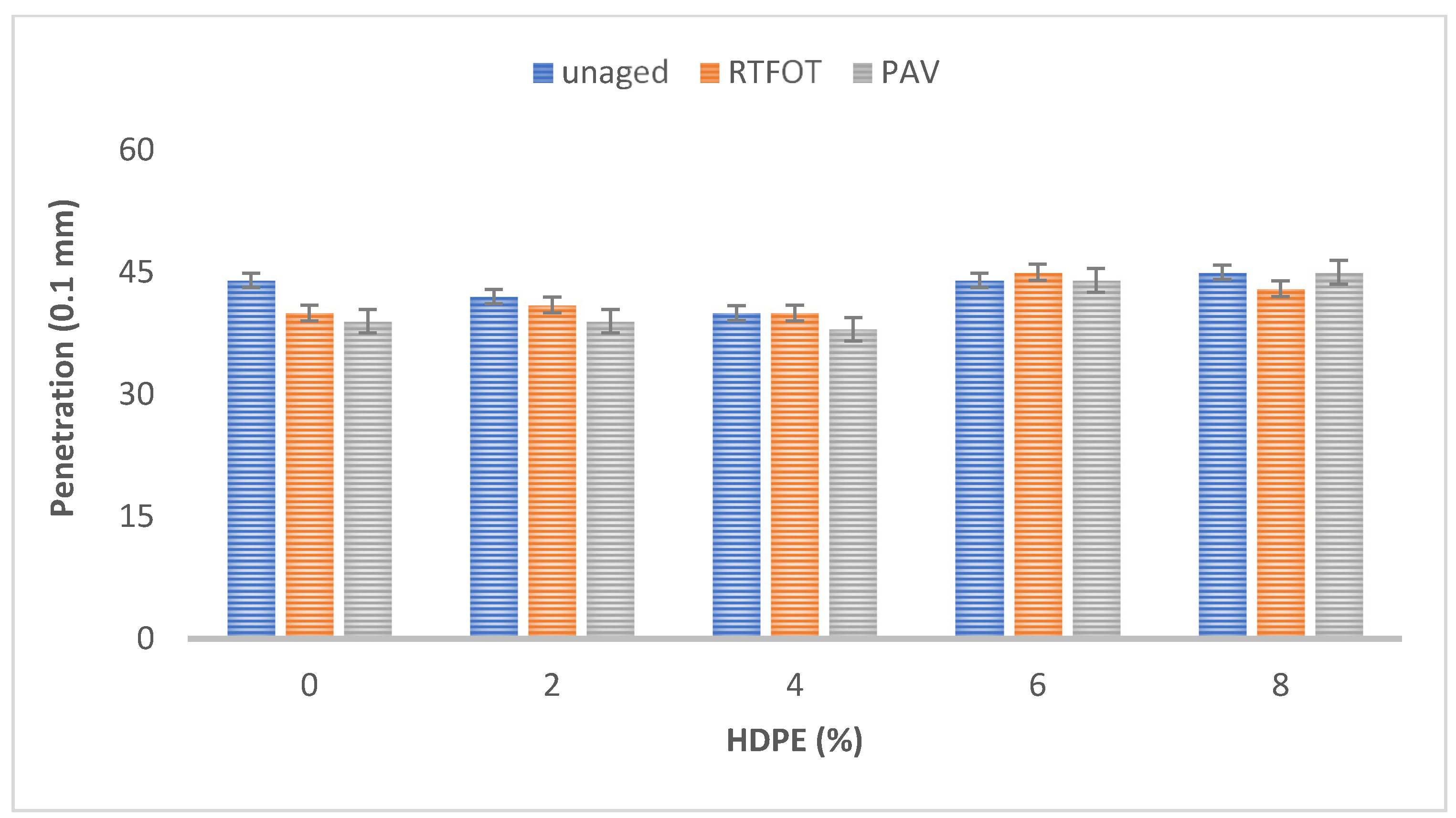

Figure 4 shows the penetration results for various contents of waste HDPE (0%, 2%, 4%, 6%, and 8%). The depth of penetration began to decrease at 2% and 4% to about 42 mm and 40 mm, respectively, which increased to 44 mm and 45 mm for samples of 6% and 8%, respectively. It can be seen that higher percentages of HDPE had a negative impact on the penetration. The considerable influence of HDPE on penetration was only reconsidered at 2% and 4%; however, the decrease was close to that of the unmodified C320 bitumen.

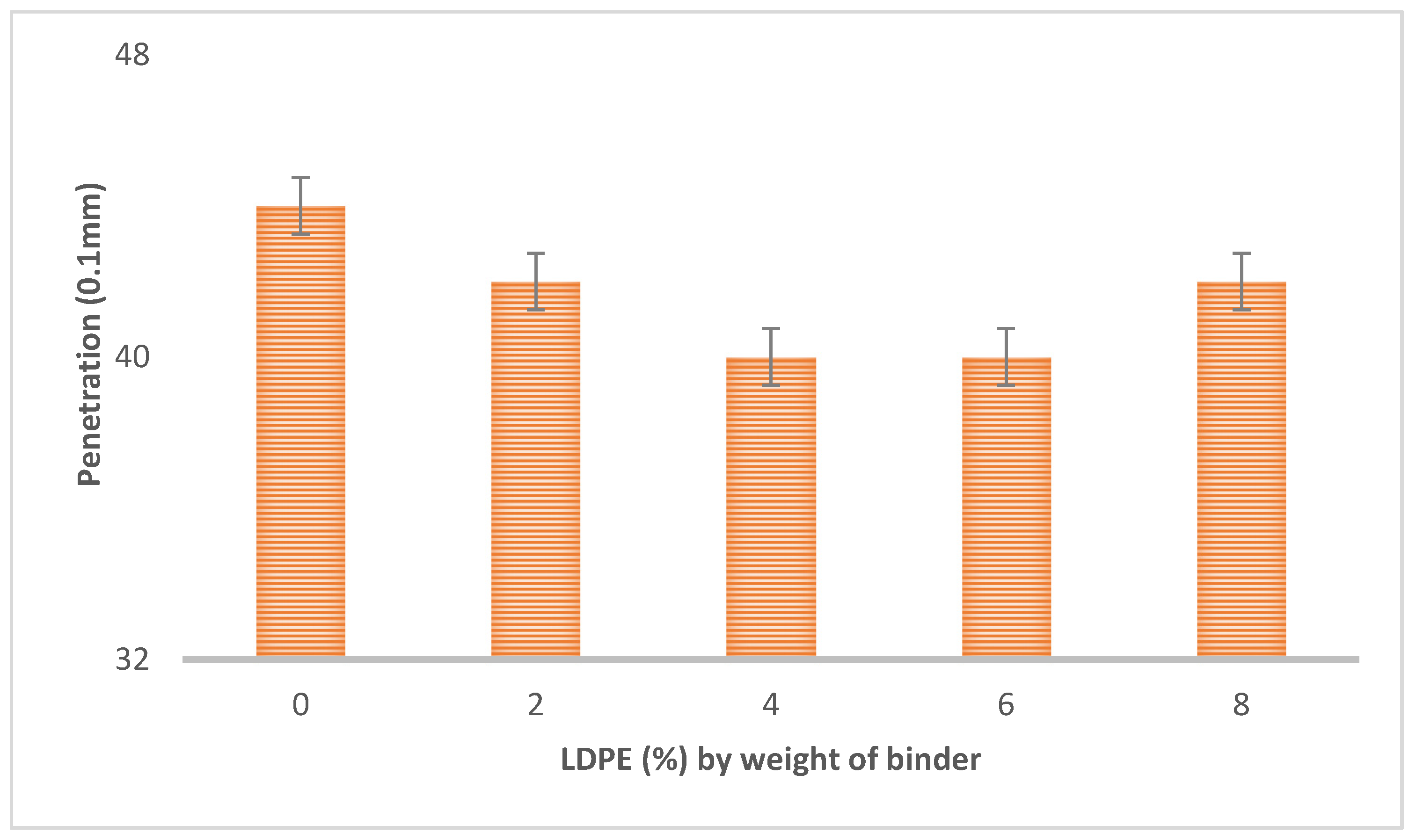

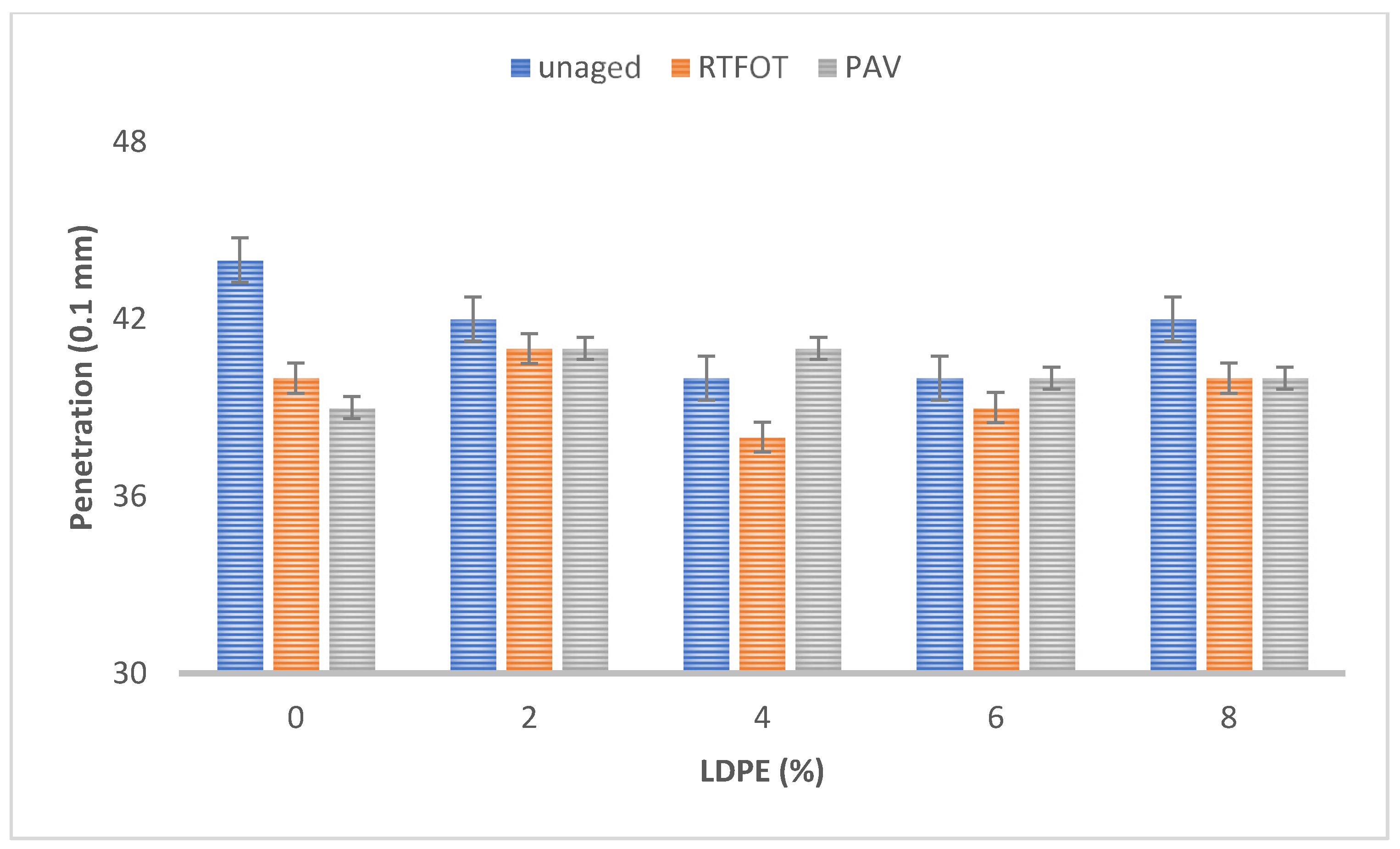

Figure 5 shows the results for penetration when using different contents of LDPE. The results for penetration were 44 mm, 42 mm, 40 mm, 40 mm, and 42 mm for the LDPE contents of 0%, 2%, 4%, 6%, and 8%, respectively. The results exhibit a decrease in penetration as the amount of LPDE increases up to 4%, which remains steady at 6% at about 40 mm. However, when increasing the LDPE to 8%, the penetration increased to about 42 mm. These results show that a high percentage of LDPE in the bitumen binder does not significantly affect the penetration characteristics.

Figure 3, Figure 4 and Figure 5 show the impact of different types of waste plastic on the penetration results. The penetration decreases significantly with the addition of PET content up to 8%. However, the HDPE- and LDPE-modified bitumen exhibited an insignificant decrease in penetration through the addition of high percentages of these waste materials. It can be argued that the PET-modified bitumen has the optimum ability to increase the stiffness modulus and, as such, indicates an increase in viscosity. The significant reduction in penetration values because of the addition of waste PET emphasizes the physical–chemical reaction of the modified bitumen. As such, the PET-modified bitumen results highlighted the changes in the properties of the C320 bitumen, and these changes can be mainly attributed to increases in the asphaltene content and decreases in the resin content with increasing PET during the blending process. The amalgamation between PET particles and bitumen particles results in the swelling of the bitumen particles and, as such, increases the dispersion of the polymer phase in the bitumen, enhancing the elasticity [24,28,30,33]. On the other hand, the penetration results when using waste HDPE and LDPE exhibit a nonlinear decrease in penetration. Higher contents of waste HDPE and LDPE increased the penetration and lowered the binder resistance to permanent deformation, making it highly susceptible to hardening and rutting failure.

3.2. Penetration Properties after RFTOT and PAV Tests

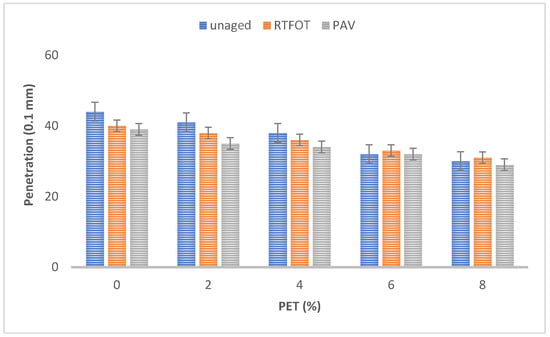

To examine the durability and ageing resistance of the binders, ageing RFOT and PAV tests were conducted. Figure 6, Figure 7 and Figure 8 show the penetration results after RTFOT tests and PAV tests on different contents of PET, HDPE, and LDPE samples. Figure 6 shows the significant role of PET in improving the ageing resistance during construction and after long-term service, as indicated by the decrease in penetration from 40 mm—at 0% PET—to 31 mm (after RTFOT) and 29 mm (after PAV) using 8% PET.

Figure 6.

Penetration results for PET-modified bitumen after the RTFOT and PAV tests.

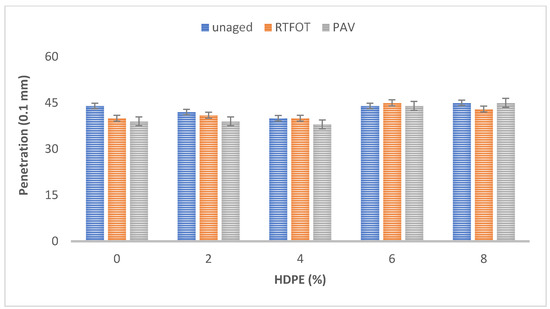

Figure 7.

Penetration results for HDPE-modified bitumen after the RTFOT and PAV tests.

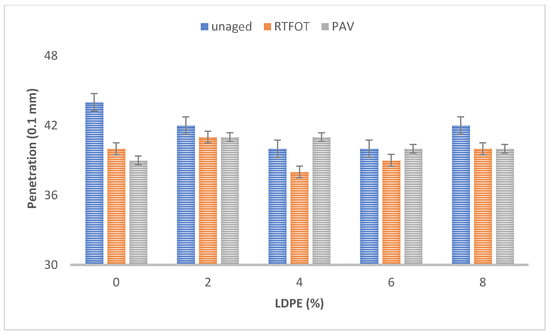

Figure 8.

Penetration results for LDPE-modified bitumen after the RTFOT and PAV tests.

Figure 7 shows the insignificant impact of using a high content of HDPE plastic, as this results in a lower ageing resistance. By adding 8% of HDPE, the penetration increases to 43 mm after RTFOT and 45 mm after PAV ageing. As such, the binder is more sensitive to shear stress and is subjected to rutting and fatigue deformation. A similar trend was found in using high contents of LDPE, as shown in Figure 8. As can be seen from the results, the penetration results show no significant difference when using more LDPE, which could be related to the incomplete reaction of the polymer–bitumen phase under bleeding conditions. Despite there being some improvement in the penetration results when using 2–4% LDPE after the RTFOT tests, the results after PAV ageing exhibited some insignificant differences and showed no improvement.

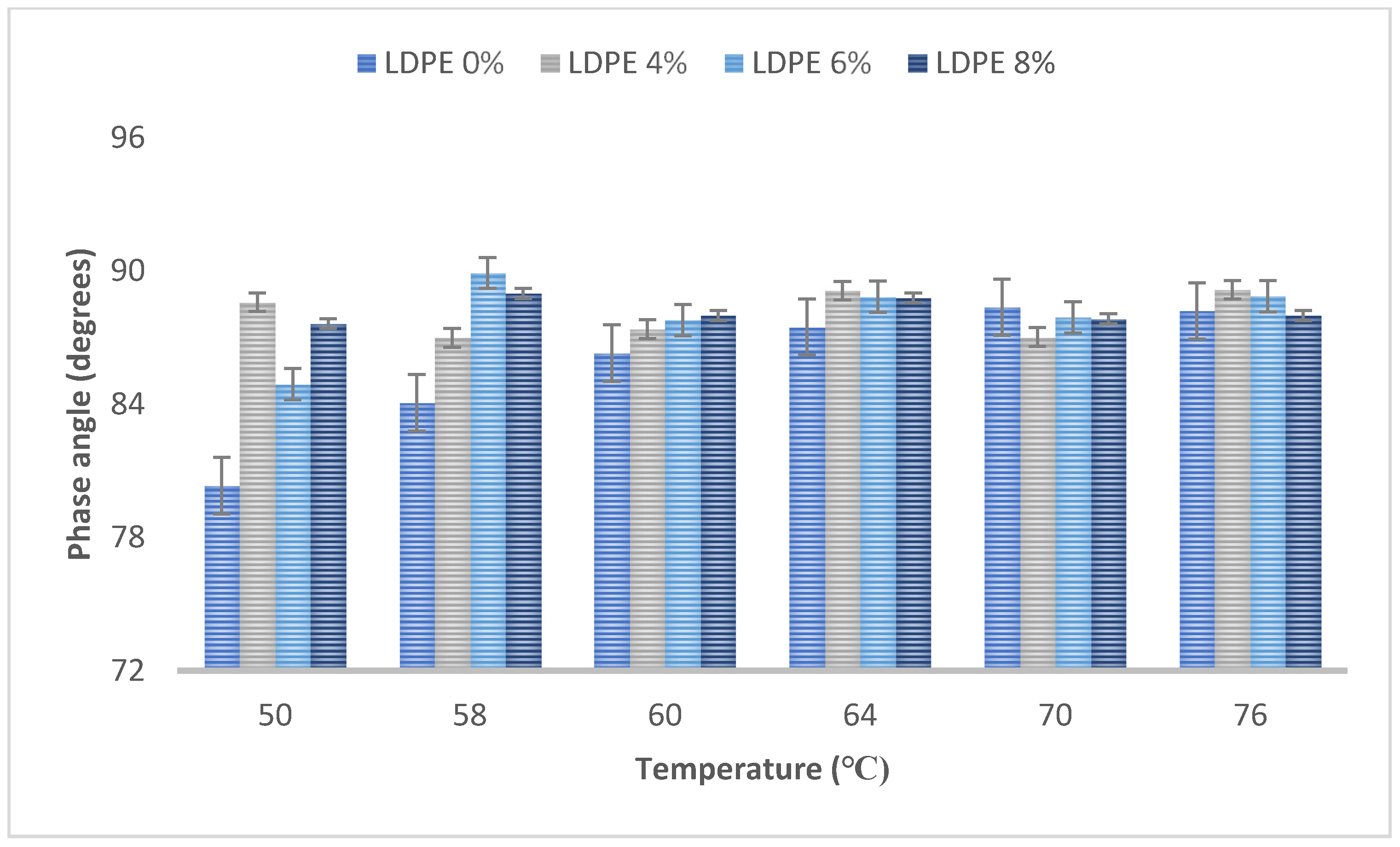

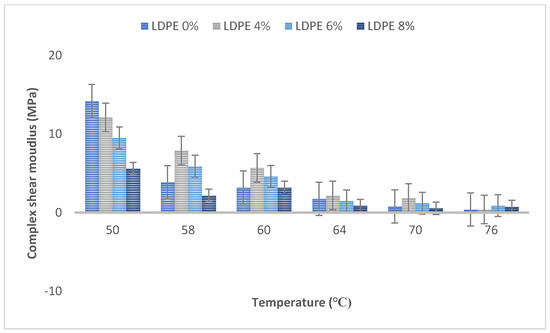

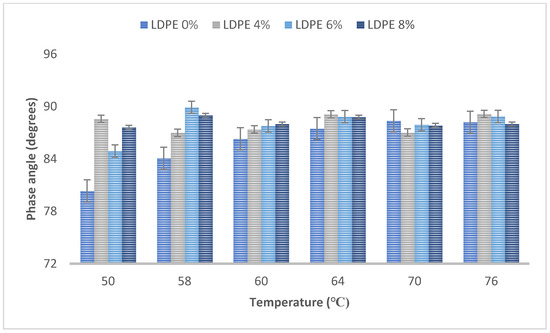

3.3. Rheological Properties

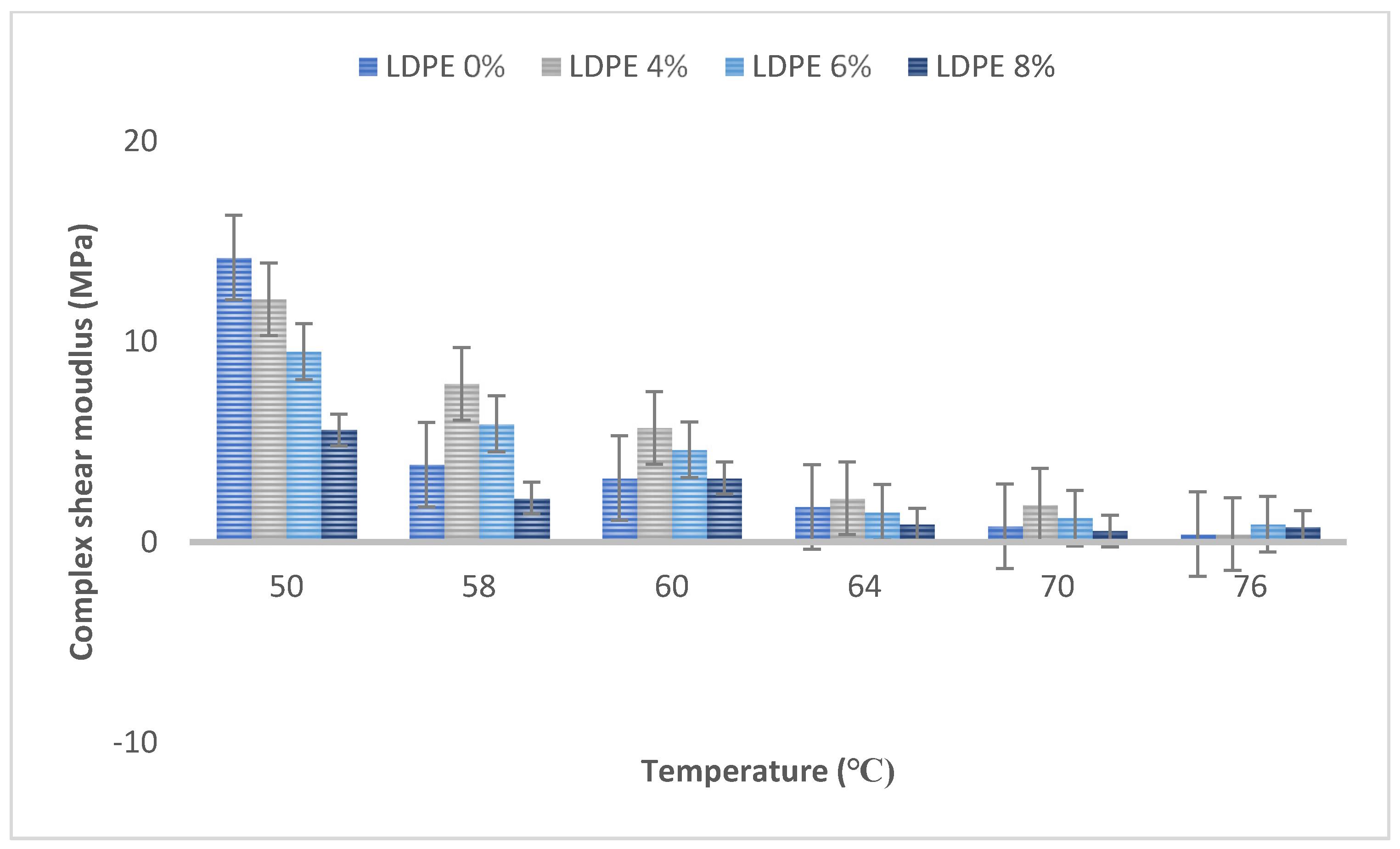

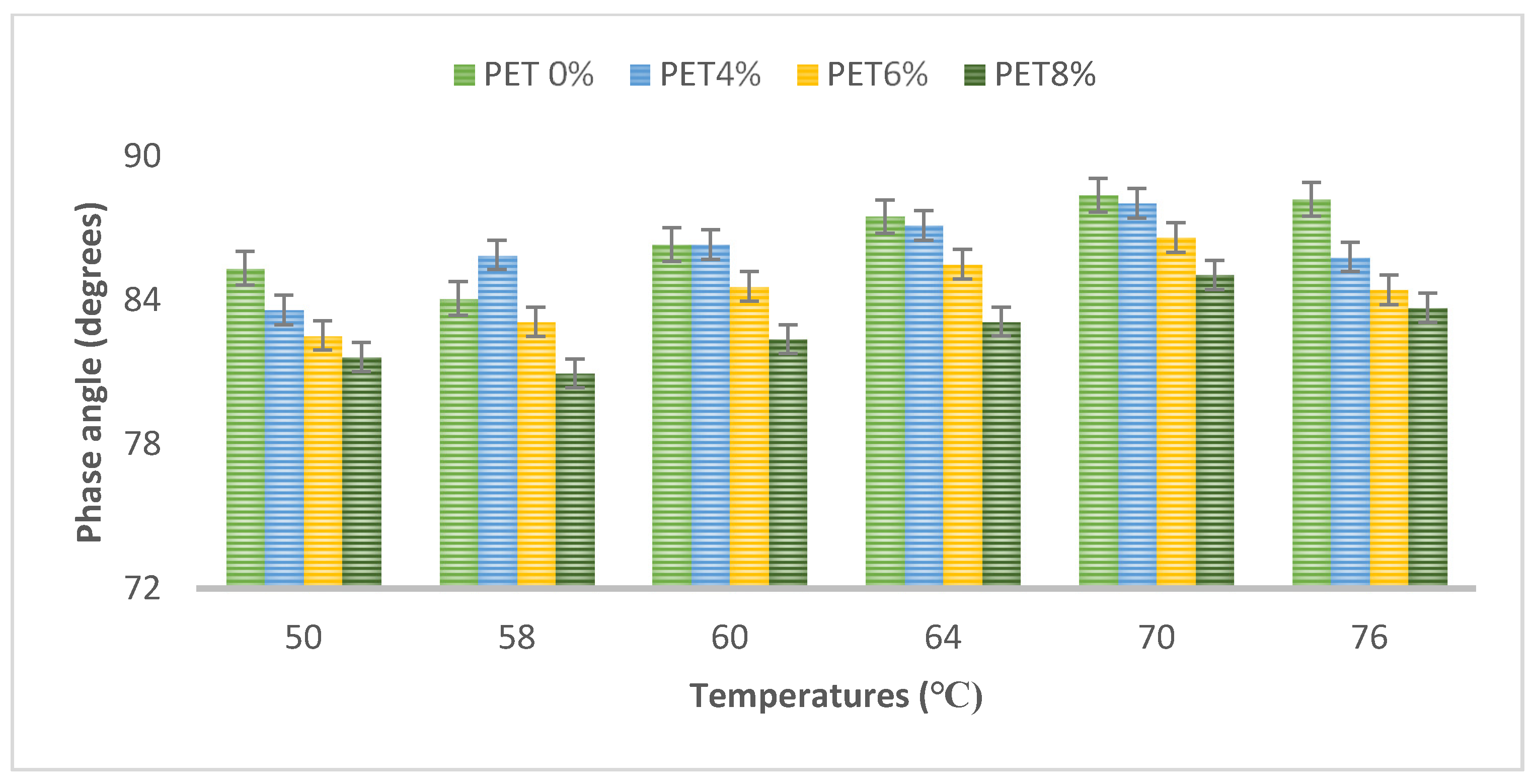

Dynamic shear rheometer tests can help obtain the data regarding the complex shear modulus and phase angle, which can be used as indicators of the stiffness, elasticity, viscosity, and resistance to the deformation of the bitumen binders, respectively. At different temperatures of 50 °C, 58 °C, 60 °C, 64 °C, 70 °C, and 76 °C, Figure 9 and Figure 10 show the effect of LDPE content on the complex shear modulus and phase angle of modified bitumen. As can be seen from Figure 9, increasing the temperature of the testing from 50 to 76 °C decreases the complex shear modulus. At 64 °C, the 8% LDPE sample had a lower shear modulus than the unmodified bitumen. As a result, a high content of LDPE increases the binder’s susceptibility to permanent deformation. On the other hand, elasticity and elastic behaviours could be achieved at 4% LDPE; however, the elasticity—as indicated by the phase angle—was low and did not exhibit significant differences at 6% and 8%. In general, adding a polymer to the bitumen should improve the phase angle by reducing its values; however, Figure 10 shows increases in the phase angle, which suggests that LDPE-modified bitumen samples with high contents of 6 and 8% are more rigid and not able to return to their shapes after deformation. Hence, the resistance to permanent deformation will not be obtained, and high temperatures will lead to mixture failure and deformation [34,35,36].

Figure 9.

LDPE waste plastic effects on the complex shear modulus.

Figure 10.

Phase angle results of LDPE-modified bitumen.

As can be seen from Figure 9 and Figure 10, 2% and 4% of LDPE are the optimum for improving the complex shear modulus, phase angle, and resistance performance; however, the higher content of LDPE results in less impact on the rheological parameters. In the current study, we targeted a high content of plastic of 6% and higher, such that more waste plastic could be used to produce a cheaper polymer with a higher performance in terms of pavement design and environment friendliness. The results indicate that the reaction between the bitumen and waste plastic LDPE is more physical, as no chemical change could occur in the aromatic phase of the modified bitumen [37].

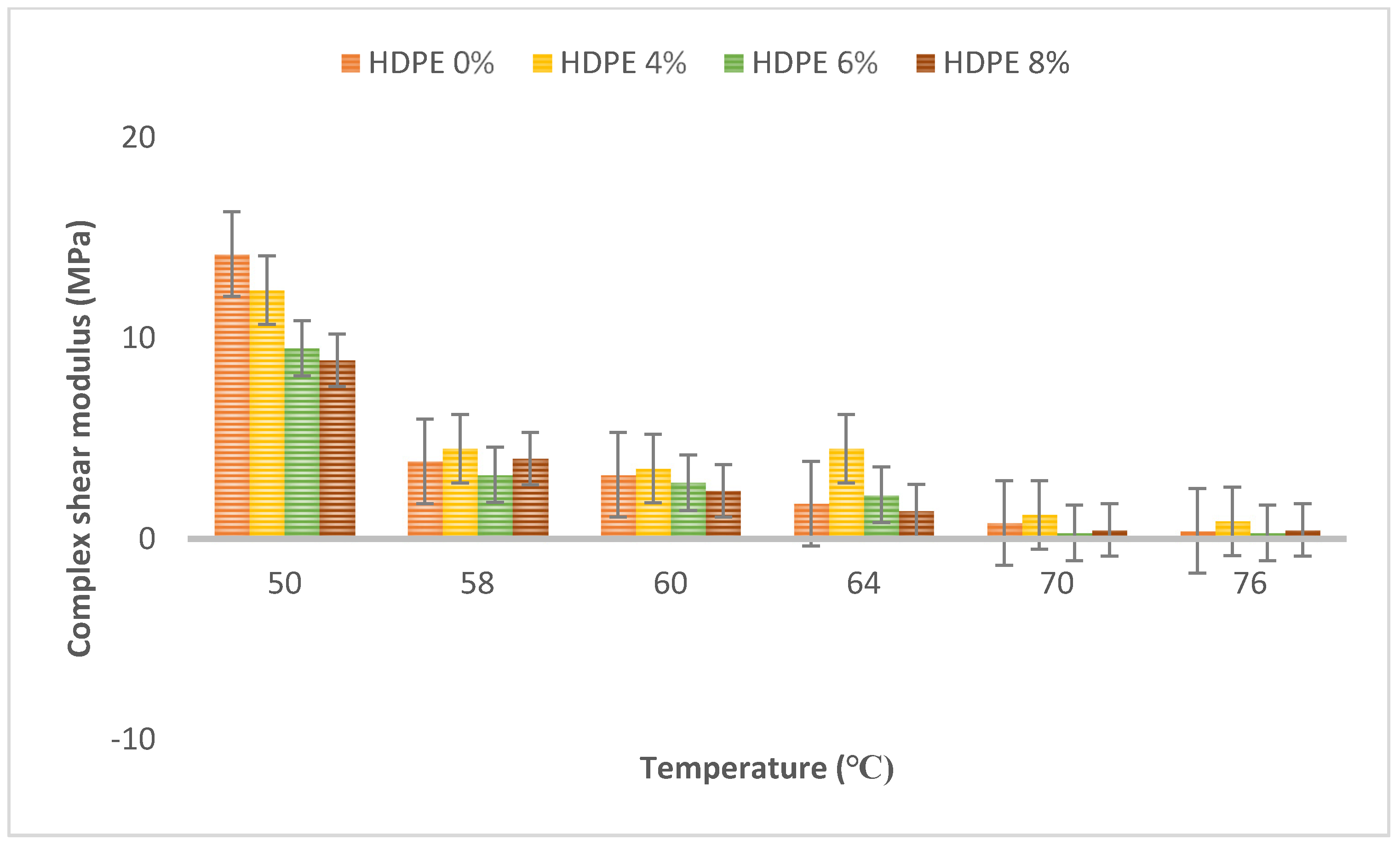

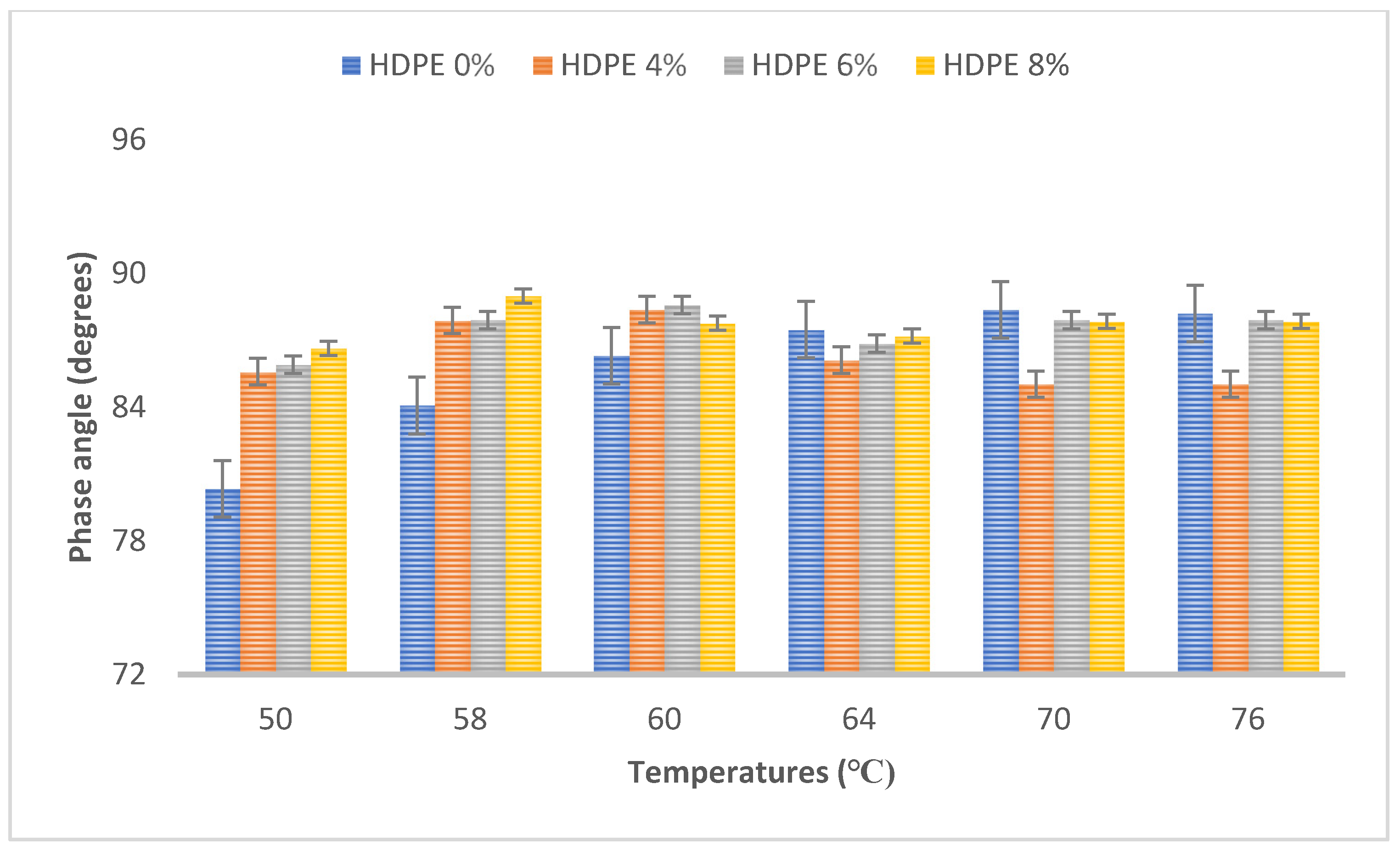

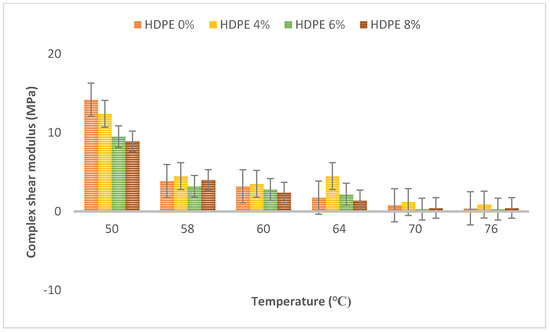

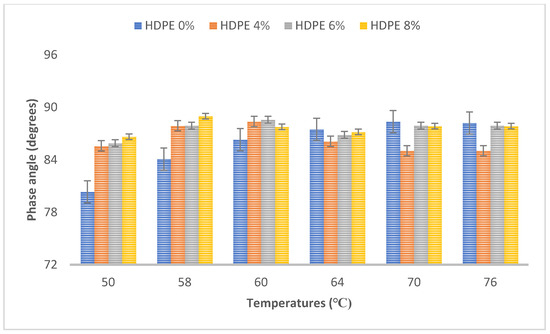

As shown in Figure 11, there is an obvious reduction in the complex shear modulus when the temperature increases from 50 to 76 °C; however, 4% of HDPE shows an increase in the complex shear modulus at all high temperatures. The phase angle results are presented in Figure 12 and exhibit nonlinear behaviour at different temperatures. In general, the HDPE-modified bitumen samples have better performance than the unmodified bitumen samples. At temperatures of 50–76 °C, the 4% HDPE-modified bitumen shows better performance, as the phase angles improved slightly in comparison to the unmodified C320 bitumen. From previous studies, it is suggested to use low contents of HDPE, as high contents could result in less compatibility of the blended mixtures. In addition, the high content of 4% is not able to significantly improve the bonding and cohesion of the bitumen–aggregate structure [23,32,38].

Figure 11.

HDPE waste plastic effect on the complex shear modulus.

Figure 12.

Phase angle results of the HDPE-modified bitumen.

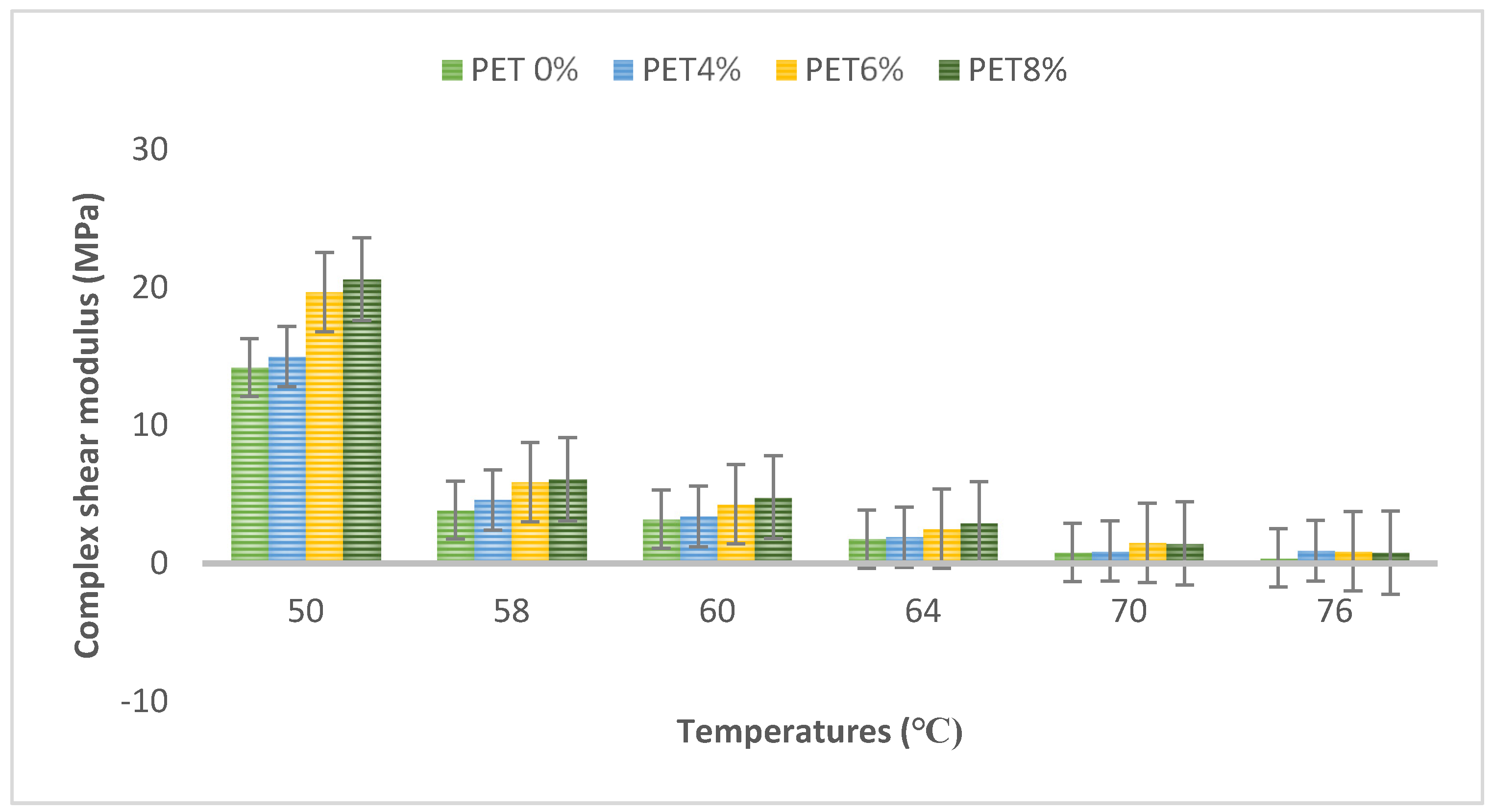

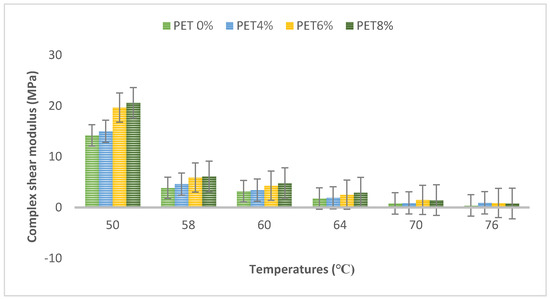

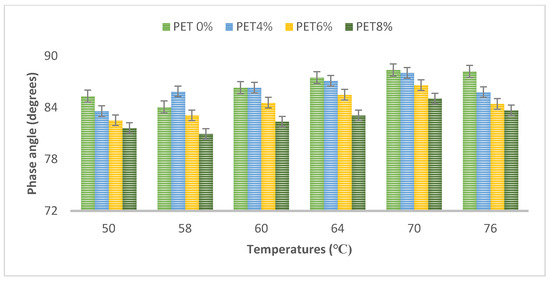

The use of waste PET in C320 bitumen modification significantly improves its stiffness and elasticity properties because of the increase in the complex shear modulus and phase angle at different temperatures, as shown in Figure 13 and Figure 14.

Figure 13.

PET waste plastic effect on the complex shear modulus.

Figure 14.

Phase angle results of the PET-modified bitumen.

Figure 13 and Figure 14 show the influence of various contents of waste PET on the rheological characteristics of modified bitumen. Different testing temperatures, ranging from 50 °C to 70 °C, were used to ascertain the complex shear modulus (G*) and phase angle (δ). As demonstrated from the results in Figure 13, adding waste PET led to an increase in the complex shear modulus and a decrease in the phase angle. On the one hand, the waste PET-modified bitumen samples have the tendency to work as elastic materials, which, in turn, reflect the ability of the PET-modified bitumen to absorb high loads and resist permanent deformation, such as rutting [23,30]. On the other hand, this ability to resist permanent deformation has been confirmed by increases in the phase angle, as shown in Figure 14. The phase angle emphasises the bitumen’s transformation from viscous to elastic behaviour. Thus, a high phase angle indicates that the bitumen exhibits viscous behaviour; in contrast, a lower phase angle indicates high elasticity.

The improved phase angle increases the elasticity performance; therefore, the PET-modified bitumen samples had better compatibility and exhibited good swelling of the plastic–bitumen interaction phase. From an engineering point of view, the better swelling and diffusion when blending the bitumen would enhance the bitumen–polymer interaction and improve the physical and mechanical properties of the resulting modified bitumen binders [12].

Moreover, the results for the complex shear modulus and phase angle could be attributed to the fact that both C320 bitumen and PET plastic have dissimilar chemical and physical properties; thus, they have different polar and molecular structures. Furthermore, these properties would be impacted during high shear blending and long-term mixing, changing the dimensions of the plastic–bitumen particles. This change could improve the engineering properties and increase the elasticity. Moreover, increasing the elasticity is a fundamental property that would result in better bonding between the molecules and increase the cohesion in the modified binder’s structure [23,39,40].

From the above results and analysis, it is clear that the waste PET-modified bitumen samples have the potential to significantly enhance the rheological properties, increase the complex shear modulus, increase the elasticity, improve the stiffness, and enhance the mechanical properties. Consequently, PET increases the binders’ rutting resistance and improves the viscosity, exhibiting a better arrangement of the plastic–bitumen particles.

4. Conclusions

The main objective of this paper was to determine the ideal type and content of waste plastic that could be used to modify C320 bitumen, helping it resist permanent deformation. The conclusions can be summarized as follows:

- The utilization of waste plastic as an environmentally friendly modifier in Australian bitumen was examined. The results show the possibility of using waste plastic in modifying C320 bitumen.

- Two and four percent of HDPE and LDPE are recommended contents that exhibit good performance, as displayed by the penetration tests before and after ageing. As for the DSR tests, a similar trend found that higher contents of 6–8% do not significantly improve the stiffness or elasticity. As for the ageing properties, the modified binder is more susceptible to ageing, and as such, the samples are more vulnerable to permanent deformation.

- The results of long-term ageing show that nearly all waste PET samples had a longer fatigue life, lower ageing, and a higher resistance to fatigue and cracking in comparison to C320 bitumen. Using more waste PET plastic, up to 8%, shows significant improvement in terms of a better resistance to permanent deformation.

- Based on the results, the ideal type and content is 6% and 8% PET waste plastic that show better resistance to permanent deformation.

- Research on using different sizes of waste plastic; different shapes of waste plastic; different bitumen types; and different blending conditions (in terms of time, temperature, and shear velocity) are recommended for future research. In addition, using advanced technology to examine the chemical development and changes in the plastic–bitumen interaction phase are required for a better understanding of the engineering properties.

Author Contributions

Conceptualization, N.M. and A.C.; methodology, N.M. and A.C.; validation, N.M., A.C. and H.N.; formal analysis, N.M.; investigation, N.M.; resources, N.M. and A.C.; data curation, N.M.; writing—original draft preparation, N.M.; writing—review and editing, N.M.; visualization, N.M.; project leader, A.C.; project administration, N.M., A.C. and H.N. All authors have read and agreed to the published version of the manuscript.

Funding

Research Training Program fund, RTP.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge the contribution of the Australian Government Research Training Program (RTP 2018) in supporting this research project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chegenizadeh, A.; Ghadimi, B.; Nikraz, H.; Şimşek, M. A novel two-dimensional approach to modelling functionally graded beams resting on a soil medium. Struct. Eng. Mech. 2014, 51, 727–741. [Google Scholar] [CrossRef]

- Al-Rkaby, A.H.; Chegenizadeh, A.; Nikraz, H. Cyclic behavior of reinforced sand under principal stress rotation. J. Rock Mech. Geotech. Eng. 2017, 9, 585–598. [Google Scholar] [CrossRef]

- Al-rkaby, A.H.J.; Chegenizadeh, A.; Nikraz, H.R. Directional-dependence in the mechanical characteristics of sand: A review. Int. J. Geotech. Eng. 2016, 10, 499–509. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Composite Soil: Fiber Inclusion and Strength. Adv. Mater. Res. 2011, 308–310, 1646–1650. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Investigation on Strength of Fiber Reinforced Clay. Adv. Mater. Res. 2011, 261–263, 957–963. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Nikraz, H. Liquefaction resistance of fibre reinforced low-plasticity silt. Soil Dyn. Earthq. Eng. 2018, 104, 372–377. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A. Effect of Particle Shape on Monotonic Liquefaction: Natural and Crushed Sand. Exp. Mech. 2017, 57, 1341–1348. [Google Scholar] [CrossRef]

- Keramatikerman, M.; Chegenizadeh, A.; Nikraz, H. An investigation into effect of sawdust treatment on permeability and compressibility of soil-bentonite slurry cut-off wall. J. Clean. Prod. 2017, 162, 1–6. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Abdul Wahhab, H.I. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Rezagholilou, A.; Nikraz, H. Waste Polymer as Additive in Asphalt pavement reinforcement: A review. In Proceedings of the 18th AAPA International Flexible Pavements Conference 2019, Sydney, NSW, Australia, 18–21 August 2019. [Google Scholar]

- Piromanski, B.; Chegenizadeh, A.; Mashaan, N.; Nikraz, H. Study on HDPE Effect on Rutting Resistance of Binder. Build. 2020, 10, 156. [Google Scholar] [CrossRef]

- Zakaria, N.M. Characterisation of Bitumen and Asphalt Mixture with Recycled Waste Plastic (RWP) Modified Binder. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2020. [Google Scholar]

- Ali, A.H.; Mashaan, N.S.; Karim, M.R. Investigations of Physical and Rheological Properties of Aged Rubberised Bitumen. Adv. Mater. Sci. Eng. 2013, 2013, 239036. [Google Scholar] [CrossRef] [Green Version]

- White, G. A Synthesis on the Effects of Two Commercial Recycled Plastics on the Properties of Bitumen and Asphalt. Sustainability 2020, 12, 8594. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Hadizadeh Pirbasti, M.; Ranjbar Pirbasti, Z. Investigating the Effect of Using Waste Ul-tra-high-molecular-weight Polyethylene on the Fatigue Life of Asphalt Mixture. Period. Polytech. Civ. Eng. 2020, 64, 1170–1180. [Google Scholar]

- Awwad, M.; Shbeeb, L. The Use of Polyethylene in Hot Asphalt Mixtures. Am. J. Appl. Sci. 2007, 4, 390–396. [Google Scholar] [CrossRef]

- Al-Hadidy, A.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Hinishoglu, S.; Ağar, E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater. Lett. 2004, 58, 267–271. [Google Scholar] [CrossRef]

- Zoorob, S.; Suparma, L. Laboratory design and investigation of the properties of continuously graded Asphaltic concrete containing recycled plastics aggregate replacement (Plastiphalt). Cem. Concr. Compos. 2000, 22, 233–242. [Google Scholar] [CrossRef]

- Ahmed, L.A. Improvement of marshall properties of the asphalt concrete mixture using the polyethylene as additive. Eng. Tecnol. 2007, 25, 383–394. [Google Scholar]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Asare, P.N.A.; Kuranchie, F.A.; Ofosu, E.A. Evaluation of incorporating plastic wastes into asphalt materials for road construction in Ghana. Cogent Environ. Sci. 2019, 5, 1576373. [Google Scholar] [CrossRef]

- Santos, J.; Pham, A.; Stasinopoulos, P.; Giustozzi, F. Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci. Total Environ. 2021, 751, 141842. [Google Scholar] [CrossRef] [PubMed]

- Jamshidi, A.; White, G. Evaluation of Performance and Challenges of Use of Waste Materials in Pavement Construction: A Critical Review. Appl. Sci. 2020, 10, 226. [Google Scholar] [CrossRef] [Green Version]

- Hake, S.L.; Damgir, R.M.; Awsarmal, P.R. Utilization of Plastic waste in Bitumen Mixes for Flexible Pavement. Trans-Portation Res. Procedia 2020, 48, 3779–3785. [Google Scholar] [CrossRef]

- Haider, S.; Hafeez, I.; Jamal, M.; Ullah, R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr. Build. Mater. 2020, 235, 117496. [Google Scholar] [CrossRef]

- Al-Haydari, I.S.; Al-Haidari, H.S. Mechanical Properties of Polyethylene Terephthalate-Modified Pavement Mixture. IOP Conf. Ser. Mater. Sci. Eng. 2020, 870, 012073. [Google Scholar] [CrossRef]

- Kumar, R.; Khan, M.A. Use of plastic waste along with bitumen in construction of flexible pavement. Int. J. Eng. Res. Technol. 2020, 9, 153–158. [Google Scholar]

- O’Farrell, K. 2016–17 Australian Plastics Recycling Survey—National Report; Project Reference: A21502; Australian Government, Department of Environment and Energy: Sydney, Australia, 2018.

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Keramatikerman, M.; Panizza, S.; Nikraz, H. Effect of Powdered Recycled Tire on Sulfate Resistance of Cemented Clay. J. Mater. Civ. Eng. 2017, 29, 04017160. [Google Scholar] [CrossRef]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Laboratory Properties of Waste PET Plastic-Modified Asphalt Mixes. Recycling 2021, 6, 49. [Google Scholar] [CrossRef]

- Ma, Y.; Zhou, H.; Jiang, X.; Polaczyk, P.; Xiao, R.; Zhang, M.; Huang, B. The utilization of waste plastics in asphalt pavements: A review. Clean. Mater. 2021, 2, 100031. [Google Scholar] [CrossRef]

- Fernandes, S.; Silva, H.M.R.D.; Oliveira, J.R.M. Mechanical, surface and environmental evaluation of stone mastic asphalt mixtures with advanced asphalt binders using waste materials. Road Mater. Pavement Des. 2017, 20, 316–333. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffens and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Xu, F.; Zhao, Y.; Li, K. Using Waste Plastics as Asphalt Modifier: A Review. Materials 2022, 15, 110. [Google Scholar] [CrossRef] [PubMed]

- Costa, L.M.; Silva, H.M.; Peralta, J.; Oliveira, J.R. Using waste polymers as a reliable alternative for asphalt binder modification —Performance and morphological assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Ameri, M.; Nasr, D. Performance properties of devulcanized waste PET modified asphalt mixtures. Pet. Sci. Technol. 2017, 35, 99–104. [Google Scholar] [CrossRef]

- Airey, G.D.; Singleton, T.M.; Collop, A.C. Properties of Polymer Modified Bitumen after Rubber-Bitumen Interaction. J. Mater. Civ. Eng. 2002, 14, 344–354. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).