Encouraging Sustainable Use of RAP Materials for Pavement Construction in Oman: A Review

Abstract

:1. Introduction

- Gain utilization of recycled materials on highways in the most economical and practical range, likely with equal or improved public accomplishment.

- Encouragement of the purpose of RAP is intended to apply the considerable economic, environmental, and engineering influences to asphalt pavement recycling.

2. The Use of RAP in the Gulf Countries

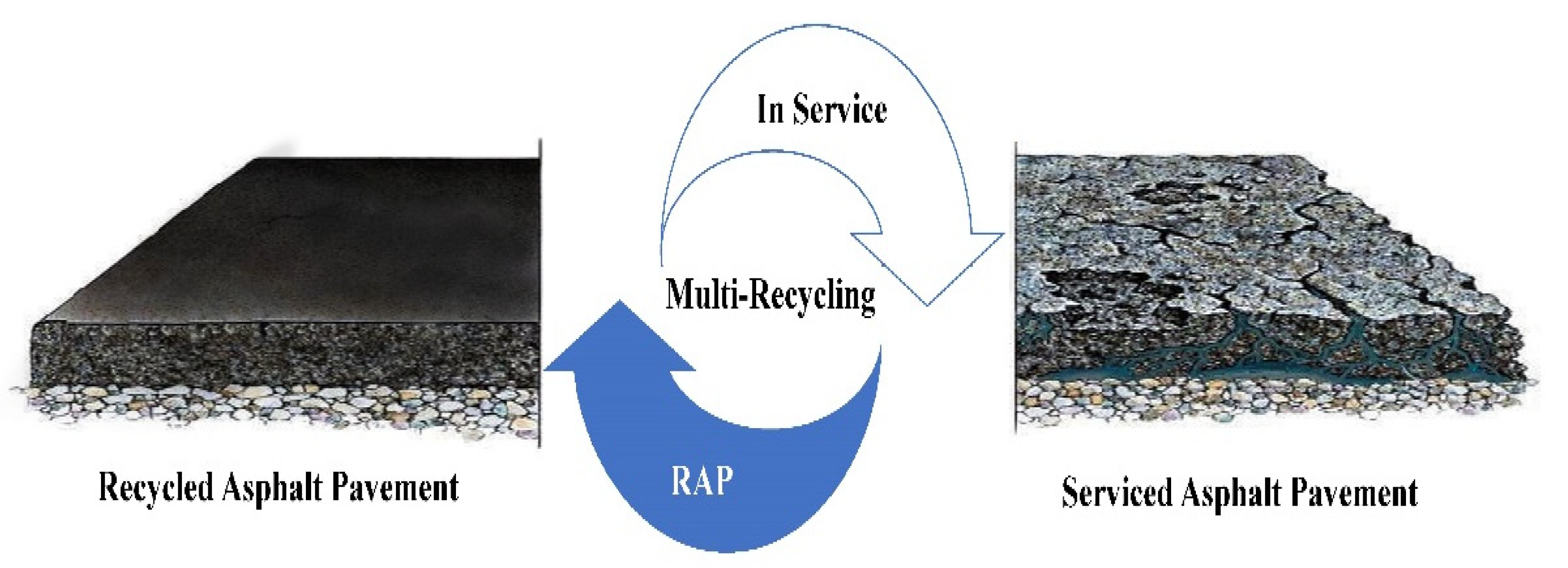

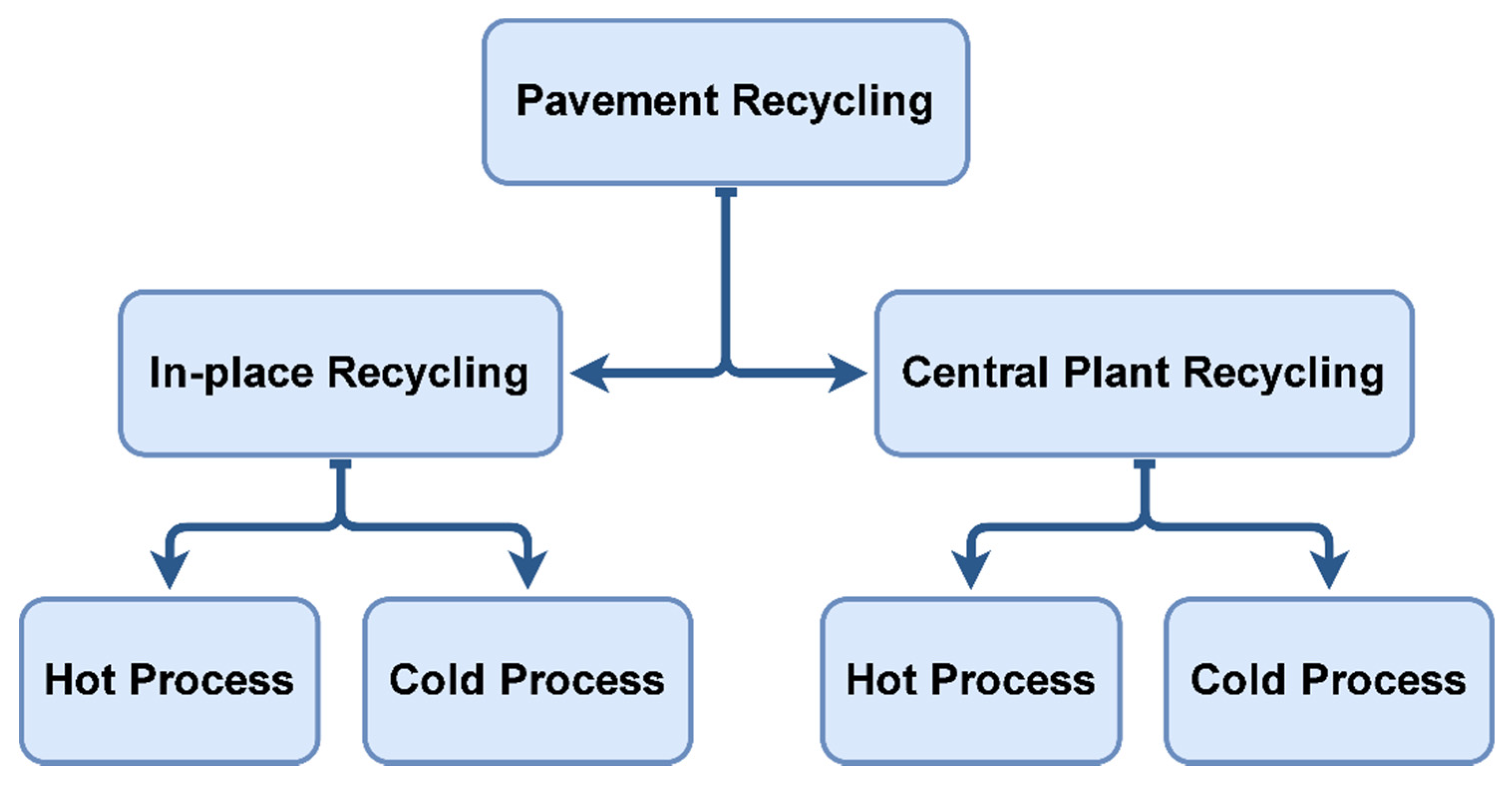

3. Classification of RAP Recycling Methods

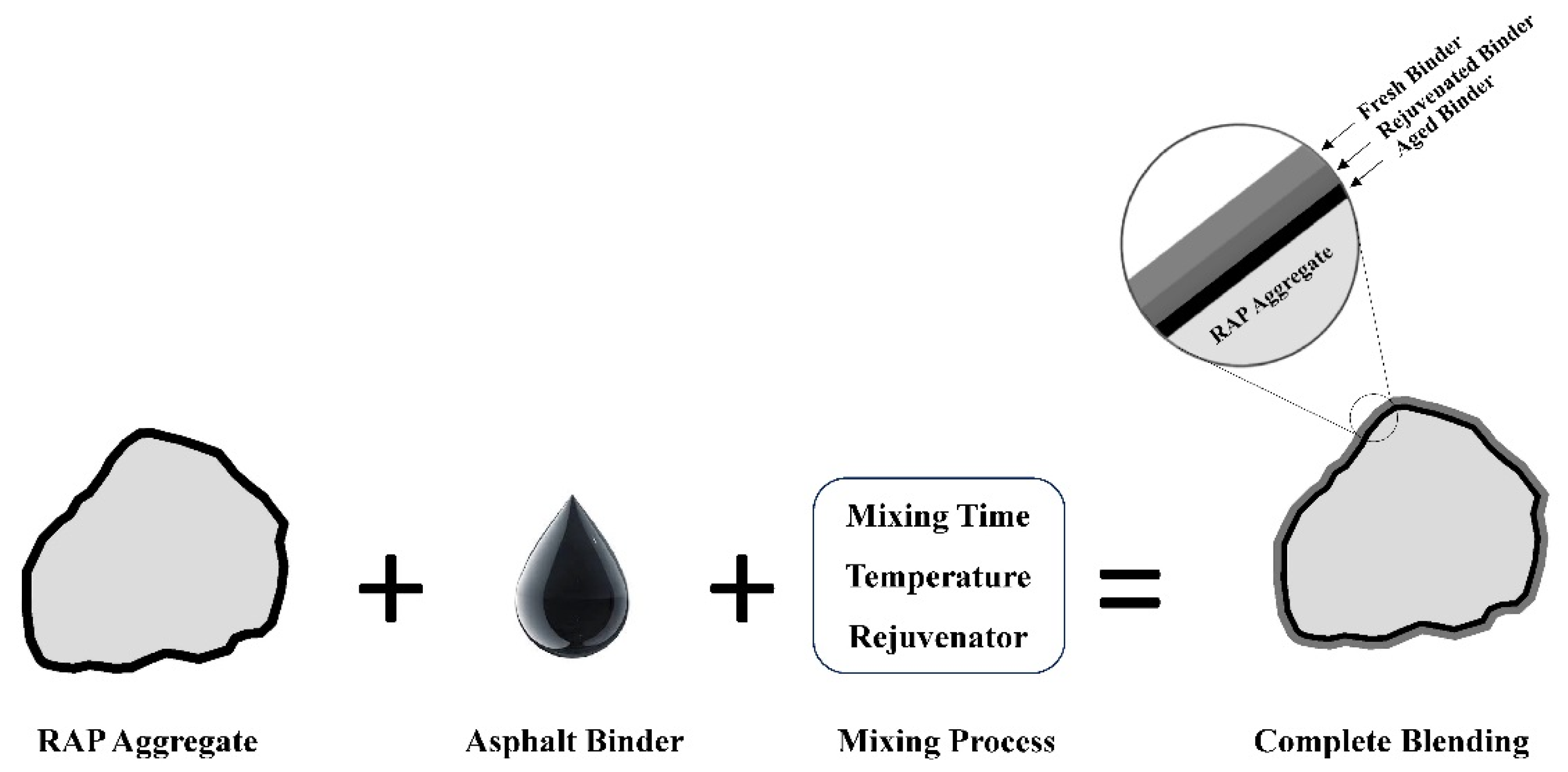

4. RAP Standards and Mixed Design

5. RAP Performance Analysis

6. Characteristics of Incorporating RAP

7. Case Studies for RAP Application

7.1. Case Studies in the United States of America

7.2. Case Studies in European Countries

7.3. Case Studies in Asian Countries

8. Conclusions

- The design and manufacture of a high-quality RAP mixture is more challenging than conventional asphalt and thus should be done by experienced pavement engineers.

- The RAP mixture design is dependent on the standards, scope of application and the impact of RAP technologies on the environment and economy.

- For the Oman scenario, this review guideline is for engorgement RAP applications for flexible pavement layers using WMA and HMA.

- Assembling homogeneousness in RAP material quality check is essential and should be carried out from the commencement phase of old pavement reclamation to its final paving.

- The maintenance and rehabilitation costs and the environmental influence, as RAP methods use recycled materials, finally reducing waste established along the previous research works stated.

- The CIR method is often used for rehabilitation and construction work because it consumes less energy, emits fewer greenhouse gases and is more cost-effective than other on-site pavement recycling methods.

- The RAP application encouragements as a value are used as a granular base material for roadway, airport runways, shoulders, engineered fill, and culvert backfill.

- This study suggests that using RAP can be used by adding a percentage less than 20% because it is less complex and does not need additions of asphalt binder. Thus, it will be an encouraging step toward improving environmental sustainability constructions in Oman.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kowalski, K.J.; Król, J.; Radziszewski, P.; Casado, R.; Blanco, V.; Pérez, D.; Viñas, V.M.; Brijsse, Y.; Frosch, M.; Le, D.M.; et al. Eco-friendly materials for a new concept of asphalt pavement. Transp. Res. Procedia 2016, 14, 3582–3591. [Google Scholar] [CrossRef] [Green Version]

- Zafar, S. Waste Management Outlook for the Middle East. In The Palgrave Handbook of Sustainability; Brinkmann, R., Garren, S., Eds.; Palgrave Macmillan: Cham, Switzerland, 2018; pp. 159–181. [Google Scholar]

- Okedu, K.E.; Barghash, H.F.; Al Nadabi, H.A. Sustainable Waste Management Strategies for Effective Energy Utilization in Oman: A Review. Front. Bioeng. Biotechnol. 2022, 10, 825728. [Google Scholar] [CrossRef] [PubMed]

- Aljuboury, D.A.; Palaniandy, P.; Maqbali, K.S.A.A. Evaluating of performance of landfills of waste in Al-Amerat and Barka, in Oman. Mater. Today Proc. 2019, 17, 1152–1160. [Google Scholar] [CrossRef]

- Milad, A.A.; Ali, A.S.B.; Yusoff, N.I.M. A review of the utilization of recycled waste material as an alternative modifier in asphalt mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Al-Saffar, Z.; Mashaan, N.S.; Memon, Z.A.; Milad, A.; Yusoff, N.I.M. Effects of Waste Frying Oil and Crumb Rubber on the Characteristics of a Reclaimed Asphalt Pavement Binder. Materials 2021, 14, 3482. [Google Scholar] [CrossRef]

- Wahhab, H.A.A.; Ali, M.F.; Asi, I.M.; AI-Dubabe, I.A. Adaptation of Shrp Performance Based Binder Specifications to the Gulf Countries; Final Report, KACST Project AR-14-60; King Abdulaziz City for Science and Technology: Riyadh, Saudi Arabia, 1995. [Google Scholar]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Memon, Z.A.; Omar, H.A.; Izzi, N.; Yusoff, M.; Milad, A. Mechanical Performance of Reclaimed Asphalt Pavement Modified with Waste Frying Oil and Crumb Rubber. Materials 2021, 14, 2781. [Google Scholar] [CrossRef]

- Taha, R.; Ali, G.; Basma, A.; Al-Turk, O. Evaluation of reclaimed asphalt pavement aggregate in road bases and subbases. Transp. Res. Rec. 1999, 1652, 264–269. [Google Scholar] [CrossRef]

- Taha, R.; Al-Rawas, A.; Al-Jabari, K.; Al-Harthy, A.; Hassan, H.; Al-Oraimi, S. An overview of waste materials recycling in the Sultante of Oman. Resour. Conserv. Recyc. 2004, 41, 293–306. [Google Scholar] [CrossRef]

- Milad, A.; Taib, A.M.; Ahmeda, A.G.F.; Solla, M.; Yusoff, N.I.M. A review of the use of reclaimed asphalt pavement for road paving applications. J. Teknol. 2020, 82, 3. [Google Scholar] [CrossRef] [Green Version]

- Arshad, A.; Karim, Z.A.; Shaffie, E.; Hashim, W.; Rahman, Z.A. Marshall properties and rutting resistance of hot mix asphalt with variable reclaimed asphalt pavement (RAP) content. In Materials Science and Engineering Conference Series; IOP Publishing: Bristol, UK, 2017; Volume 271, p. 012078. [Google Scholar]

- Guthrie, W.S.; Cooley, D.; Eggett, D.L. Effects of reclaimed asphalt pavement on mechanical properties of base materials. Transp. Res. Rec. 2007, 2005, 44–52. [Google Scholar] [CrossRef] [Green Version]

- Vandewalle, D.; Antunes, V.; Neves, J.; Freire, A.C. Assessment of Eco-Friendly Pavement Construction and Maintenance Using Multi-Recycled RAP Mixtures. Recycling 2020, 5, 17. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavement: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Tran, N.; Taylor, A.; Turner, P.; Holmes, C.; Porot, L. Effect of rejuvenator on performance characteristics of high RAP mixture. Road Mater. Pavement Des. 2016, 18, 183–208. [Google Scholar] [CrossRef]

- Cooper, S.J. Asphalt Pavement Recycling with reclaimed asphalt pavement (RA). In Proceedings of the NWPMA, 18th Annual Fall Pavement Conference, Portland, OR, USA, 20 October 2011. [Google Scholar]

- Alwetaishi, M.; Kamel, M.; Al-Bustami, N. Sustainable applications of asphalt mixes with reclaimed asphalt pavement (RAP) materials: Innovative and new building brick. Int. J. Low-Carbon Technol. 2019, 14, 364–374. [Google Scholar] [CrossRef] [Green Version]

- Sultan, S.A.; Abduljabar, M.B.; Abbas, M.H. Improvement of the mechanical characteristics of reclaimed asphalt pavement in Iraq. Int. J. Struct. Civil Eng. Res. 2013, 2, 22–29. [Google Scholar]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Life cycle assessment of roadworks in United Arab Emirates: Recycled construction waste, reclaimed asphalt pavement, warm-mix asphalt and blast furnace slag use against traditional approach. J. Clean. Prod. 2020, 257, 120531. [Google Scholar] [CrossRef]

- Farooq, M.A.; Mir, M.S. Use of reclaimed asphalt pavement (RAP) in warm mix asphalt (WMA) pavements: A review. Innov. Infrastruct. Solut. 2017, 2, 10. [Google Scholar] [CrossRef] [Green Version]

- Trsi, G.; Tataranni, P.; Sangiorgi, C. The Challenges of Using Reclaimed Asphalt Pavement for New Asphalt Mixtures: A Review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef]

- Mousa, E.; Azam, A.; El-Shabrawy, M.; El-Badawy, S. Laboratory characterization of reclaimed asphalt pavement for road construction in Egypt. Can. J. Civ. Eng. 2017, 44, 417–425. [Google Scholar] [CrossRef] [Green Version]

- Mousa, E.; El-Badawy, S.; Azam, A. Evaluation of reclaimed asphalt pavement as base/subbase material in Egypt. Transp. Geotech. 2021, 26, 100414. [Google Scholar] [CrossRef]

- El-Maaty, A.E.A.; Elmohr, A.I. Characterization of recycled asphalt pavement (RAP) for use in flexible pavement. Am. J. Eng. Appl. Sci. 2015, 8, 233–248. [Google Scholar] [CrossRef]

- Alam, T.B.; Abdelrahman, M.; Schram, S. Laboratory characterization of recycled asphalt pavement as a base layer. Int. J. Pavement Eng. 2010, 11, 123–131. [Google Scholar] [CrossRef]

- Hasan, A.; Hasan, U.; Whyte, A.; Al Jassmi, H. Lifecycle Analysis of Recycled Asphalt Pavements: Case Study Scenario Analyses of an Urban Highway Section. CivilEng 2022, 3, 242–262. [Google Scholar] [CrossRef]

- Srour, I.M.; Chehab, G.R.; Gharib, N. Recycling construction materials in a developing country: Four case studies. Int. J. Eng. Manag. Econ. 2012, 3, 135–151. [Google Scholar] [CrossRef]

- Hamdar, Y.S.; Bakchan, A.; Chehab, G.R.; Al-Qadi, I.; Little, D. Benchmarking pavement practices in data-scarce regions–case of Saudi Arabia. Int. J. Pavement Eng. 2021, 22, 294–306. [Google Scholar] [CrossRef]

- Jain, S.; Singh, B. Cold mix asphalt: An overview. J. Clean. Prod. 2021, 280, 124378. [Google Scholar] [CrossRef]

- Kandhal, P.; Mallick, R. Pavement Recycling Guidelines for State and Local Governments; Federal Highway Administration FHWA-SA-98-042; Federal Highway Administration: Washington, DC, USA, 1997. [Google Scholar]

- Epps, J.; Terrel, R.; Little, D.; Holmgreen, R. Guidelines for recycling asphalt pavements. J. Assoc. Asph. Paving Technol. 1980, 49, 144–176. [Google Scholar]

- Jones, G. Recycling of bituminous pavements on the road. Assoc. Asph. Paving Technol. Proc. 1979, 48, 240–251. [Google Scholar]

- Mosey, J.; Defoe, J. In-place recycling of asphalt pavements. Assoc. Asph. Paving Technol. Proc. 1979, 48, 261–272. [Google Scholar]

- Milad, A.; Ali, A.S.B.; Babalghaith, A.M.; Memon, Z.A.; Mashaan, N.S.; Arafa, S.; Yusoff, N.I. Utilisation of Waste-Based Geopolymer in Asphalt Pavement Modification and Construction—A Review. Sustainability 2021, 13, 3330. [Google Scholar] [CrossRef]

- Wolters, R. Bituminous hot mix recycling in Minnesota. Assoc. Asph. Paving Technol. Proc. 1979, 48, 295–327. [Google Scholar]

- Betenson, W. Recycled asphalt concrete in Utah. Assoc. Asph. Paving Technol. Proc. 1979, 48, 272–295. [Google Scholar]

- Cross, S.A.; Kearney, E.R.; Justus, H.G.; Chesner, W.H. Cold-in-Place Recycling in New York State; C-06-21; New York State Energy Research and Development Authority: Albany, NY, USA, 2010. [Google Scholar]

- Khan, K.M.; Kamal, M.A.; Ali, F.; Ahmed, S.; Sultan, T. Performance Comparison of Cold in Place Recycled and Conventional HMA Mixes. J. Mech. Civ. Eng. 2012, 4, 27–31. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Diefenderfer, B.K. Evaluation of Cold In-Place and Cold Central-Plant Recycling Methods Using Laboratory Testing of Field-Cored Specimens. J. Mater. Civ. Eng. 2013, 25, 1712–1720. [Google Scholar] [CrossRef]

- Stimilli, A.; Ferrotti, G.; Graziani, A.; Canestrari, F. Performance evaluation of a cold-recycled mixture containing high percentage of reclaimed asphalt. Road Mater. Pavement Des. 2013, 14, 149–161. [Google Scholar] [CrossRef]

- Feisthauer, B.; Lacroix, D.; Carter, A.; Perraton, D. Simulation and Influence of Early-life Traffic Curing for Cold In-place Recycling and Full-depth Reclamation Materials. Proc. Annu. Conf.-Can. Soc. Civ. Eng. 2013, 5, 4469–4478. [Google Scholar]

- Hafeez, I.; Ozer, H.; Al-Qadi, I.L. Performance characterization of hot in-place recycled asphalt mixtures. J. Transp. Eng. 2014, 140, 04014029. [Google Scholar] [CrossRef]

- Bhavsar, H.; Dubey, R.; Kelkar, V. Rehabilitation by in-situ cold recycling technique using reclaimed asphalt pavement material and foam bitumen at vadodara halol road project (SH87)—A case study. Transp. Res. Procedia 2016, 17, 359–368. [Google Scholar] [CrossRef]

- Turk, J.; Pranjić, A.M.; Mladenovič, A.; Cotič, Z.; Jurjavčič, P. Environmental comparison of two alternative road pavement rehabilitation techniques: Cold-in-place-recycling versus traditional re-construction. J. Clean. Prod. 2016, 121, 45–55. [Google Scholar] [CrossRef]

- Noferini, L.; Simone, A.; Sangiorgi, C.; Mazzotta, F. Investigation on performances of asphalt mixtures made with Reclaimed Asphalt Pavement: Effects of interaction between virgin and RAP bitumen. Int. J. Pavement Res. Technol. 2017, 10, 322–332. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, J. Using recycled asphalt pavement in construction of transportation infrastructure: Alaska experience. J. Clean. Prod. 2018, 177, 155–168. [Google Scholar] [CrossRef]

- Graziani, A.; Iafelice, C.; Raschia, S.; Perraton, D.; Carter, A. A procedure for characterizing the curing process of cold recycled bitumen emulsion mixtures. Constr. Build. Mater. 2018, 173, 754–762. [Google Scholar] [CrossRef]

- Vázquez, V.F.; Terán, F.; Huertas, P.; Paje, S.E. Field assessment of a Cold-In place-recycled pavement: Influence on rolling noise. J. Clean. Prod. 2018, 197, 154–162. [Google Scholar] [CrossRef]

- Bowers, B.F.; Diefenderfer, B.K.; Wollenhaupt, G.; Stanton, B.; Boz, I. Laboratory properties of a rejuvenated cold recycled mixture produced in a conventional asphalt plant. In Airfield and Highway Pavements 2019: Testing and Characterization of Pavement Materials; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 100–108. [Google Scholar]

- Gonzalo-Orden, H.; Linares-Unamunzaga, A.; Pérez-Acebo, H.; Díaz-Minguela, J. Advances in the Study of the Behavior of Full-Depth Reclamation (FDR) with Cement. Appl. Sci. 2019, 9, 3055. [Google Scholar] [CrossRef] [Green Version]

- Matić, B.; Jovanović, S.; Marinković, M.; Sremac, S.; Kumar Das, D.; Stević, Ž. A Novel Integrated Interval Rough MCDM Model for Ranking and Selection of Asphalt Production Plants. Mathematics 2021, 9, 269. [Google Scholar] [CrossRef]

- Iwański, M.; Mazurek, G.; Buczyński, P.; Iwański, M.M. Effects of hydraulic binder composition on the rheological characteristics of recycled mixtures with foamed bitumen for full depth reclamation. Constr. Build. Mater. 2022, 330, 127274. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, Y.B.; Hassan, N.A.; Al-Saffar, Z.; Ahmad, K.; Rogo, K. Performance of Aged Asphalt Binder Treated with Various Types of Rejuvenators. Civ. Eng. J. 2021, 7, 502–517. [Google Scholar] [CrossRef]

- Officials, Transportation. AASHTO Guide for Design of Pavement Structures; The American Association of State Highway and Transportation Officials: Washington, DC, USA, 1993. [Google Scholar]

- Bukowski, J.R. Guidelines for the Design of Superpave Mixtures Containing Reclaimed Asphalt Pavement (RAP). In Proceedings of the Memorandum, ETG Meeting, FHWA Superpave Mixtures Expert Task Group, San Antonio, TX, USA, 28 March 1997. [Google Scholar]

- Al-Qadi, I.L.; Carpenter, S.H.; Roberts, G.; Ozer, H.; Aurangzeb, Q.; Elseifi, M.; Trepanier, J. Determination of Usable Residual Asphalt Binder in RAP; Illinois Center for Transportation (ICT): Rantoul, IL, USA, 2009. [Google Scholar]

- Lee, K.W.; Soupharath, N.; Shukla, A.; Franco, C.A.; Manning, F.J. Rheological and mechanical properties of blended asphalts containing recycled asphalt pavement binders. J. Assoc. Asph. Paving Technol. 1999, 68, 89. [Google Scholar]

- National Cooperative Highway Research Program (NCHRP). Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method: Guidelines; Research Results Digest 253; National Academy Press: Washington, DC, USA, 2001. [Google Scholar]

- Olita, S.; Ciampa, D. SuPerPave® Mix Design Method of Recycled Asphalt Concrete Applied in the European Standards Context. Sustainability 2021, 13, 9079. [Google Scholar] [CrossRef]

- Terrel, R.; Joseph, P.; Fritchen, D. Five-year experience on low-temperature performance of recycled hot mix. Transp. Res. Rec. 1992, 2, 56–65. [Google Scholar]

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review. Illinois 2007. Available online: http://hdl.handle.net/2142/46007 (accessed on 27 March 2022).

- Huang, B.; Zhang, Z.; Kingery, W.; Zuo, G. Fatigue crack characteristics of HMA mixtures containing RAP. In Proceedings of the Fifth International RILEM Conference on Reflective Cracking in Pavements, Limoges, France, 5–7 May 2004; RILEM Publications SARL: Paris, France, 2004; pp. 631–638. [Google Scholar]

- Kandahl, P.S.; Rao, S.S.; Watson, D.E.; Young, B. Performance of Recycled Hot Mix Asphalt Mixtures, NCA Technology Report, 95-01; 1995. Available online: https://rosap.ntl.bts.gov/view/dot/13635 (accessed on 16 April 2022).

- West, R. Reclaimed Asphalt Pavement Management: Best Practices; NCAT Draft Report; National Center for Asphalt Technology: Auburn, AL, USA, 2010. [Google Scholar]

- Zhan, Y.; Wu, H.; Song, W.; Zhu, L. Molecular Dynamics Study of the Diffusion between Virgin and Aged Asphalt Binder. Coatings 2022, 12, 403. [Google Scholar] [CrossRef]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Boriack, P.; Katicha, S.W.; Flintsch, G.W. Laboratory Study on Effects of High Reclaimed Asphalt Pavement and Binder Content: Stiffness, Fatigue Resistance, and Rutting Resistance. Transp. Res. Rec. 2014, 2445, 64–74. [Google Scholar] [CrossRef]

- Enieb, M.; Al-Jumaili, M.A.H.; Al-Jameel, H.A.E.; Eltwati, A.S. Sustainability of using reclaimed asphalt pavement: Based-reviewed evidence. J. Phys. Conf. Ser. 2021, 1973, 012242. [Google Scholar] [CrossRef]

- Pradyumna, T.A.; Mittal, A.; Jain, P.K. Characterization of Reclaimed Asphalt Pavement (RAP) for Use in Bituminous Road Construction. Procedia Soc. Behav. Sci. 2013, 104, 1149–1157. [Google Scholar] [CrossRef] [Green Version]

- Abu El-Maaty, A.E.; El-Moher, A.E. Evaluation of hot asphalt mixtures containing reclaimed asphalt pavements. Int. J. Eng. Adv. Technol. 2015, 4, 197–206. [Google Scholar]

- Abo-Qudais, S.; Ibrahim, A.; Al-Ramahi, E. Utilizing Reclaimed Asphalt Pavement in Asphalt Mixtures: Laboratory Performance and Environmental and Cost Impacts. J. Geotech. Transp. Eng. 2016, 2, 26–32. [Google Scholar]

- Tabaković, A.; Gibney, A.; McNally, C.; Gilchrist, M.D. The influence of recycled asphalt pavement on the fatigue performance of asphalt concrete base courses. J. Mater. Civ. Eng. 2010, 22, 643. [Google Scholar] [CrossRef]

- Sunil, S.; Mallesh, K.M.; Chandrasekaraiah, T. Experimental investigations on the performance of bituminous mixes with reclaimed asphalt pavement (RAP) materials (case study Tumkur to Chitradurga-NH4). Int. J. Res. Eng. Technol. 2014, 3, 297–303. [Google Scholar]

- Chaitanyaa, G.; Srib, M.R.; Reddyc, K.S. Fatigue performance of bituminous mixes containing reclaimed asphalt pavement (RAP) material. In Proceedings of the 3rd Conference of Transportation Research Group of India, Kolkata, India, 17−20 December 2015. [Google Scholar]

- Mannan, U.A.; Islam, M.R.; Tarefder, R.A. Effects of recycled asphalt pavements on the fatigue life of asphalt under different strain levels and loading frequencies. Int. J. Fatigue 2015, 78, 72–80. [Google Scholar] [CrossRef]

- Johnson, E.; Watson, M.; Olson, R.; Moon, K.H.; Turos, M.; Marasteanu, M. Recycled Asphalt Pavement: Study of High-RAP Asphalt Mixtures on Minnesota County Roads; Report No. MN/RC 15; Minnesota Department of Transportation: St. Paul, MN, USA, 2013. [Google Scholar]

- Solanki, P.; Zaman, M.; Adje, D.; Hossain, Z. Effect of Recycled Asphalt Pavement on Thermal Cracking Resistance of Hot-Mix Asphalt. Int. J. Geomech. 2015, 15, A4014001. [Google Scholar] [CrossRef]

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; Rep. No. FHWA-HRT-11-021; Research, Development, and Technology Turner-Fairbank Highway Research Center: McLean, VA, USA, 2011; pp. 1–60. [Google Scholar]

- Saliani, S.S.; Carter, A.; Baaj, H.; Tavassoti, P. Characterization of Asphalt Mixtures Produced with Coarse and Fine Recycled Asphalt Particles. Infrastructures 2019, 4, 67. [Google Scholar] [CrossRef] [Green Version]

- Calabi-Floody, A.; Valdés-Vidal, G.A.; Sanchez-Alonso, E.; Mardones-Parra, L.A. Evaluation of Gas Emissions, Energy Consumption and Production Costs of Warm Mix Asphalt (WMA) Involving Natural Zeolite and Reclaimed Asphalt Pavement (RAP). Sustainability 2020, 12, 6410. [Google Scholar] [CrossRef]

- Gottumukkala, B.; Kusam, S.R.; Tandon, V.; Muppireddy, A.R.; Mullapudi, R.S. Restriction of RAP% in HMA Based on Aggregate Gradation and Binder Properties. CivilEng 2021, 2, 811–822. [Google Scholar] [CrossRef]

- Eltwati, A.S.; Enieb, M.; Al-Saffar, Z.H.; Mohamed, A. Effect of glass fibers and waste engine oil on the properties of RAP asphalt concretes. Int. J. Pavement Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Koting, S.; Katman, H.Y.B.; Ibrahim, M.R.; Babalghaith, A.M.; Asqool, O. Performance of High Content Reclaimed Asphalt Pavement (RAP) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Eltwati, A.S.; Enieb, M.; Al-Saffar, Z.H.; Mohamed, A. A laboratory study of the effect of fiberglass additive on the behavioural properties of RAP asphalt mixtures. J. Phys. Conf. Ser. 2021, 1973, 012241. [Google Scholar] [CrossRef]

- Kennedy, T.W.; Tam, W.O.; Solaimanian, M. Optimizing use of reclaimed asphalt pavement with the Superpave system. J. Assoc. Asph. Paving Technol. 1998, 67, 311–333. [Google Scholar]

- Romanoschi, S.A.; Hossain, M.; Gisi, A.; Heitzman, M. Accelerated pavement testing evaluation of the structural contribution of full-depth reclamation material stabilized with foamed asphalt. Transp. Res. Rec. 2004, 1896, 199–207. [Google Scholar] [CrossRef]

- Berthelot, C.; Gerbrandt, R. Cold In-Place Recycling and Full-Depth Strengthening of Clay-Till Subgrade Soils Results with Cementitious Waste Products in Northern Climates. Transp. Res. Record 2002, 1787, 3–12. [Google Scholar] [CrossRef]

- Mhlongo, S.; Abiola, O.S.; Ndambuki, J.M.; Kupolati, W.K. Use of Recycled Asphalt Materials for Sustainable Construction and Rehabilitation of Roads. In Proceedings of the International Conference on Biological, Civil and Environmental Engineering (BCEE-2014), Dubai, United Arab Emirates, 17–18 March 2014; pp. 91–94. [Google Scholar]

- Lin, T.; Ishikawa, T.; Luo, B. Applicability of Modified University of Illinois at Urbana–Champaign Model for Unbound Aggregate Material with Different Water Content. Transp. Res. Record 2019, 2673, 439–449. [Google Scholar] [CrossRef]

- Diefenderfer, B.K.; Bowers, B.F.; Schwartz, C.W.; Farzaneh, A.; Zhang, Z. Dynamic modulus of recycled pavement mixtures. Transp. Res. Rec. 2016, 2575, 19–26. [Google Scholar] [CrossRef]

- Alharbi, F.; Alshubrumi, F.; Almoshaogeh, M.; Haider, H.; Elragi, A.; Elkholy, S. Sustainability Evaluation of Cold In-Place Recycling and Hot Mix Asphalt Pavements: A Case of Qassim, Saudi Arabia. Coatings 2022, 12, 50. [Google Scholar] [CrossRef]

- Willis, X.P. Analysis of the Use of Reclaimed Asphalt Pavement (RAP) in Europe. 2016. Available online: file:///C:/Users/MDPI/Downloads/Tesi_XavierPlanasWillis.pdf (accessed on 16 April 2022).

- Vázquez, V.F.; García-Hoz, A.M.; Terán, F.; Gil-Abarca, A.; Paje, S.E. Functional characterization of a Cold-In Place-Recycled pavement at different stages of the curing process. Sci. Total Environ. 2021, 789, 148065. [Google Scholar] [CrossRef] [PubMed]

- Magar, S.; Xiao, F.; Singh, D.; Showkat, B. Applications of reclaimed asphalt pavement in India—A review. J. Clean. Prod. 2022, 335, 130221. [Google Scholar] [CrossRef]

- Islam, M.R.; Hossain, M.I.; Tasfiqur, M.R. Investigating the Prospect of Reclaimed Asphalt Pavement (RAP) as Stabilized Base in the Context of Bangladesh. In Proceedings of the International Conference on Transportation and Development 2018: Airfield and Highway Pavements, Pittsburgh, PL, USA, 15–18 July 2018; American Society of Civil Engineers: Reston, VA, USA, 2018. [Google Scholar]

- Gao, J.; Yang, J.; Yu, D.; Jiang, Y.; Ruan, K.; Tao, W.; Sun, C.; Luo, L. Reducing the variability of multi-source reclaimed asphalt pavement materials: A practice in China. Constr. Build. Mater. 2021, 278, 122389. [Google Scholar] [CrossRef]

| Researchers [Refs] | Country | Year | Method | ||||

|---|---|---|---|---|---|---|---|

| Cold Recycling | Hot Recycling | ||||||

| CIR | CCPR | FDR | HIR | HMAR | |||

| Cross et al. [38] | The U.S.A | 2010 | √ | ||||

| Kamran et al. [39] | Pakistan | 2012 | √ | ||||

| Apeagyei et al. [40] | The U.S.A. | 2013 | √ | ||||

| Stimilli et al. [41] | Italy | 2013 | √ | ||||

| Feisthauer et al. [42] | Canada | 2013 | √ | ||||

| Hafeez et al. [43] | The U.S.A. | 2014 | √ | ||||

| Bhavsar et al. [44] | India | 2016 | √ | ||||

| Turk et al. [45] | Slovenia | 2016 | √ | ||||

| Noferini et al. [46] | Australia | 2017 | √ | ||||

| Zhao & Liu [47] | The U.S.A. | 2018 | √ | ||||

| Graziani et al. [48] | Italy | 2018 | √ | ||||

| Vázquez et al. [49] | Spain | 2018 | √ | ||||

| Bowers et al. [50] | The U.S.A. | 2019 | √ | ||||

| Gonzalo et al. [51] | Spain | 2020 | √ | ||||

| Jovanović et al. [52] | Serbia | 2021 | √ | ||||

| Iwański et al. [53] | Poland | 2022 | √ | ||||

| Equation No. | Calculation Model | Purpose of Use |

|---|---|---|

| 1 | where: Mc = Moisture content expressed as a percentage = Weight of aggregate in stockpile condition = Weight of aggregate in SSD condition | Calculate the Moisture content of RAP |

| 2 | where: Gmm = Maximum specific gravity of the mixture Gb = Specific gravity of the asphalt cement Pb = Asphalt cement content as a percentage of the total mixture | Calculate the effective specific gravity of RAP |

| 3 | where: Gse = Effective specific aggregate gravity of aggregate Gsb = Bulk Specific Gravity of the aggregate Pba = Asphalt absorption of the aggregate Gb = Specific gravity of the asphalt cement | Calculate the bulk specific gravity of RAP |

| 4 | where: Tvirgin = Critical temperature of the virgin asphalt binder Tblend = Critical temperature of the blended asphalt binder %RAP = Percentage of RAP to be used; and TRAP = Critical temperature of the recovered RAP binder. | Calculate the percentage of RAP |

| 5 | where: MdryRAP = Mass of dry RAP MdryAgg = Mass of RAP aggregate and binder Pb = RAP binder content | Calculate the mass of dry RAP |

| 6 | where: Tc (high) = at which G*/sinδ is equal to 1.00 kPa G1 = G*/sinδ at temperature T1 T1 = Critical temperature a = slope of the stiffness-temperature curve | Determine the critical high temperature |

| 7 | where: Tc (high) = At which G*/sinδ is equal to 2.2 kPa G1 = G*/sinδ at temperature T1 T1 = Critical temperature a = Slope of the stiffness-temperature curve | Determine the critical high temperature based on RTFO |

| 8 | where: Tc (Int) = At which G*sinδ is equal to 5000 kPa G1 = G*/sinδ at temperature T1 T1 = Critical temperature a = Slope of the stiffness-temperature curve | Determine the critical intermediate temperature |

| 9 | where: Tc (S) = Critical low temperature S1 = S-value at temperature T1 T1 = Critical temperature | Determine the critical low temperature |

| 10 | where: Tc (m) = Critical low temperature m1 = m-value at temperature T1 T1 = Critical temperature a = Slope of the stiffness-temperature curve | Determine the critical low temperature |

| 11 | where: Tvirgin = Critical temperature of the virgin asphalt binder TRAP = Critical temperature of the blended asphalt binder %RAP = Percentage of RAP to be used TRAP = Critical temperature of the recovered RAP binder. | Determine the critical temperature of the blended asphalt binder |

| 12 | where: Tvirgin = critical temperature of the virgin asphalt binder Tblend = critical temperature of the blended asphalt binder %RAP = percentage of RAP to be used; and TRAP = critical temperature of the recovered RAP binder. | Determine the critical temperature of the virgin asphalt binder |

| 13 | where: XRAP binder(s) = RAP binder volume fraction Xrejuvenator = Rejuvenator oil volume fraction | Calculate the binder content for the asphalt mix |

| 14 | where: A = RAP percent binder content B = RAP percent in mixture D = Rejuvenator dosePEN = the penetration × 0.1 mm | Calculate the rejuvenator dosage |

| 15 | where: E = energy (lb.in/in) P = ultimate load at failure d = specimen vertical deformation at the ultimate load (in) t = specimen thickness (in) | Calculate the absorbed energy |

| 16 | where: PER = Percent of absorbed energy Econditioned = Average level of absorbed energy for conditioned specimens Ecotrol = Average level of absorbed energy for control specimens | Calculate the percentage of absorbed energy |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dughaishi, H.A.; Lawati, J.A.; Bilema, M.; Babalghaith, A.M.; Mashaan, N.S.; Yusoff, N.I.M.; Milad, A. Encouraging Sustainable Use of RAP Materials for Pavement Construction in Oman: A Review. Recycling 2022, 7, 35. https://doi.org/10.3390/recycling7030035

Dughaishi HA, Lawati JA, Bilema M, Babalghaith AM, Mashaan NS, Yusoff NIM, Milad A. Encouraging Sustainable Use of RAP Materials for Pavement Construction in Oman: A Review. Recycling. 2022; 7(3):35. https://doi.org/10.3390/recycling7030035

Chicago/Turabian StyleDughaishi, Husam Al, Jawad Al Lawati, Munder Bilema, Ali Mohammed Babalghaith, Nuha S. Mashaan, Nur Izzi Md. Yusoff, and Abdalrhman Milad. 2022. "Encouraging Sustainable Use of RAP Materials for Pavement Construction in Oman: A Review" Recycling 7, no. 3: 35. https://doi.org/10.3390/recycling7030035

APA StyleDughaishi, H. A., Lawati, J. A., Bilema, M., Babalghaith, A. M., Mashaan, N. S., Yusoff, N. I. M., & Milad, A. (2022). Encouraging Sustainable Use of RAP Materials for Pavement Construction in Oman: A Review. Recycling, 7(3), 35. https://doi.org/10.3390/recycling7030035