Recycling of Rubber Wastes as Fuel and Its Additives

Abstract

1. Introduction

1.1. Ecosystem Limitation

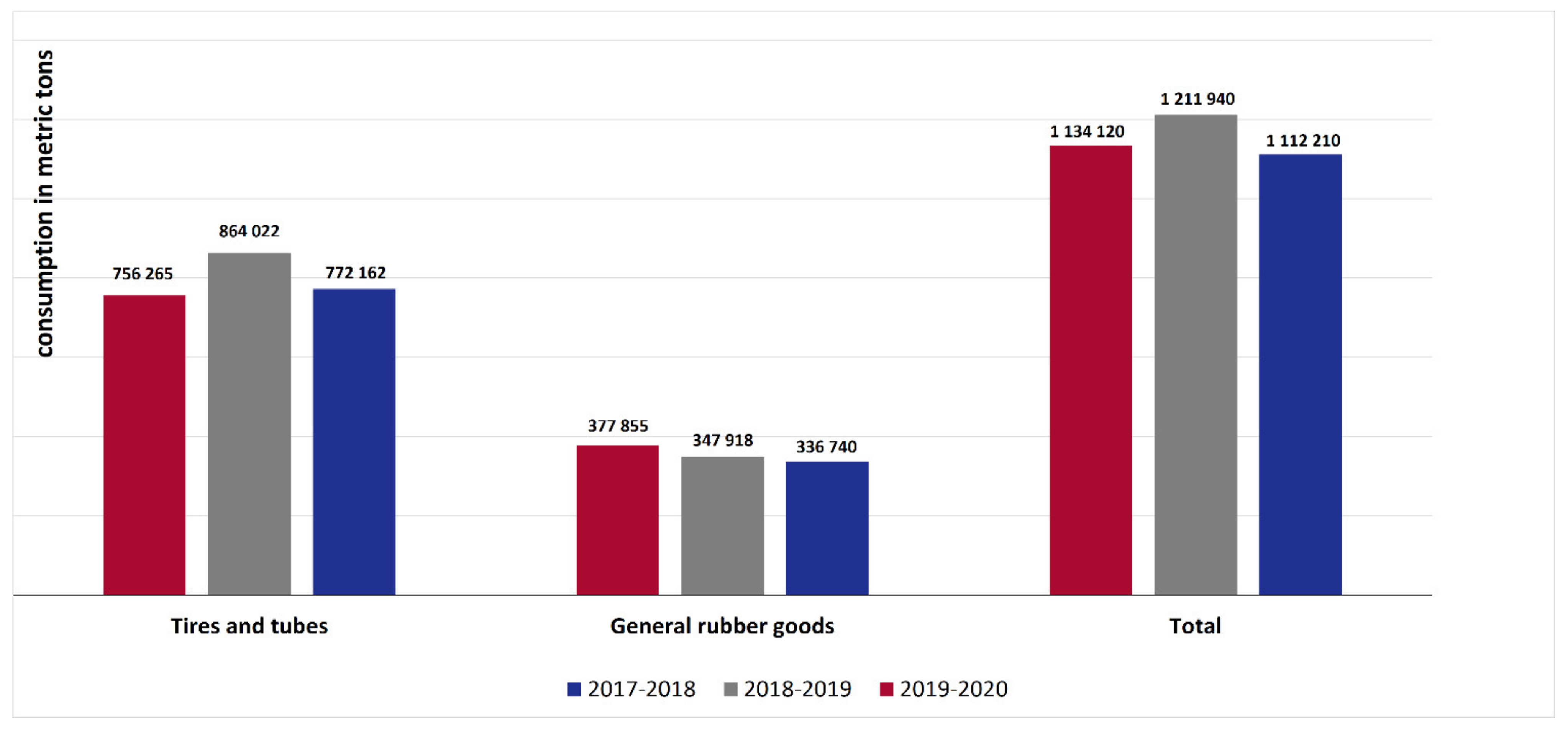

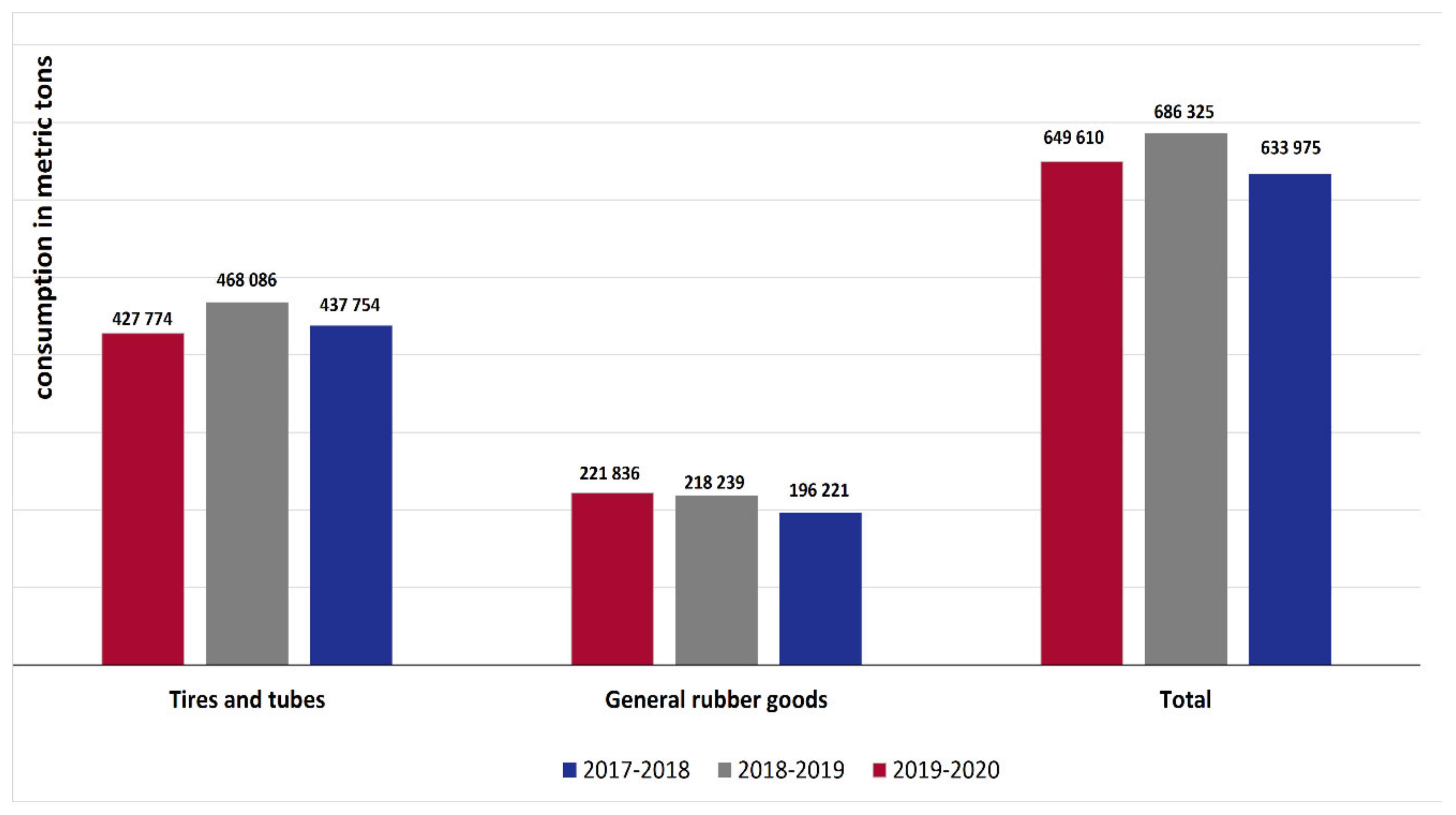

1.2. Rubber-Application Growth

2. Current Usage of Waste Rubber

2.1. Waste-Tire Recycling Industry

- Total amount of rubber recycled at its end-of-life: typically, 3–15%;

- Total of waste rubber re-used in some way (e.g., retreading, new products, etc.): 5–23%;

- Total of waste rubber used for energy recovery: 25–60%;

- Total of waste rubber send out to landfill or stored: 20–30%.

2.2. Recycling Advantage

2.3. Construction Field

2.4. Sustainable Treatment

3. Various Techniques for Using Waste Rubber as Fuel and Its Additive

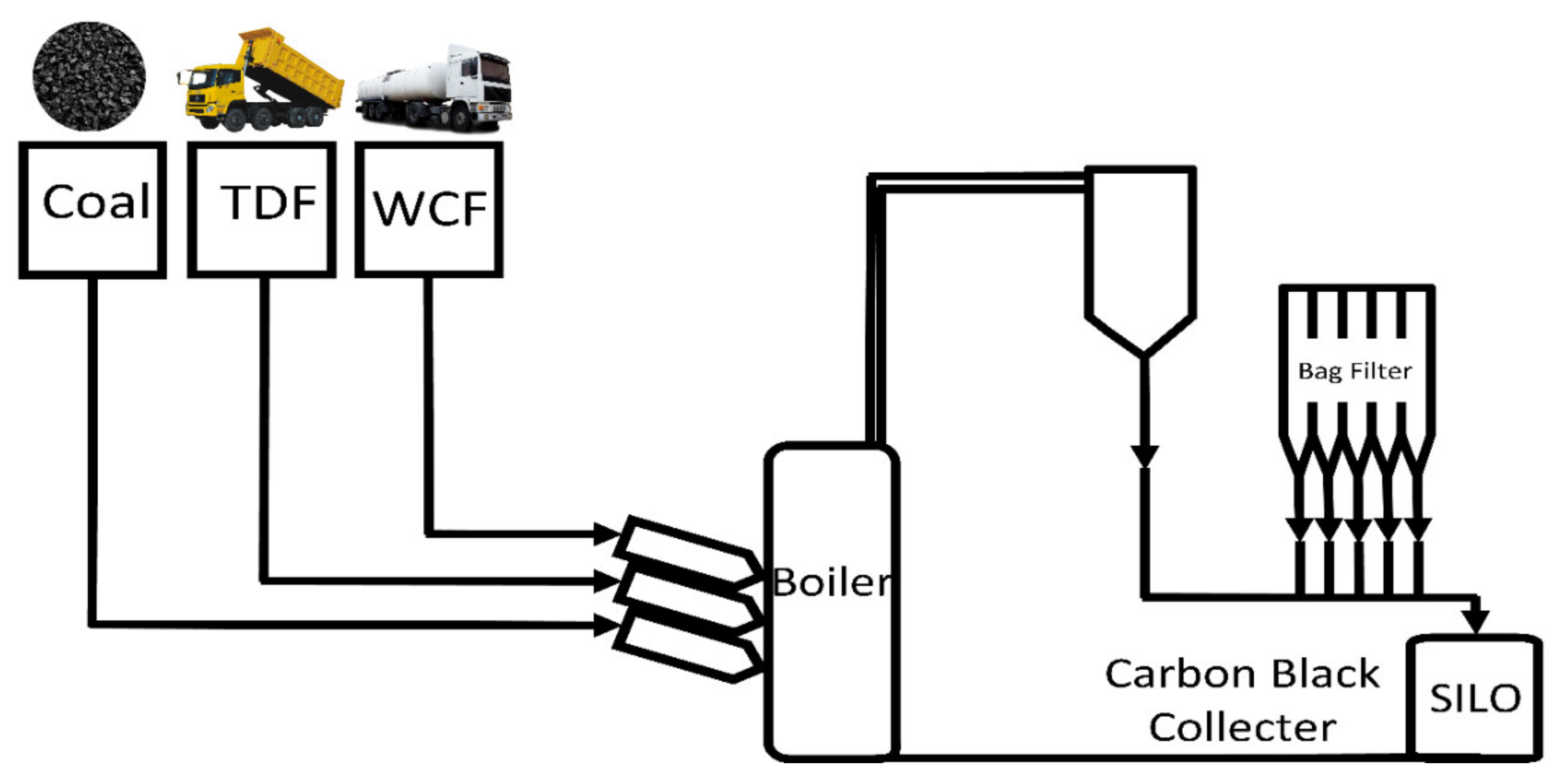

3.1. Tire-Derived Fuel (TDF)

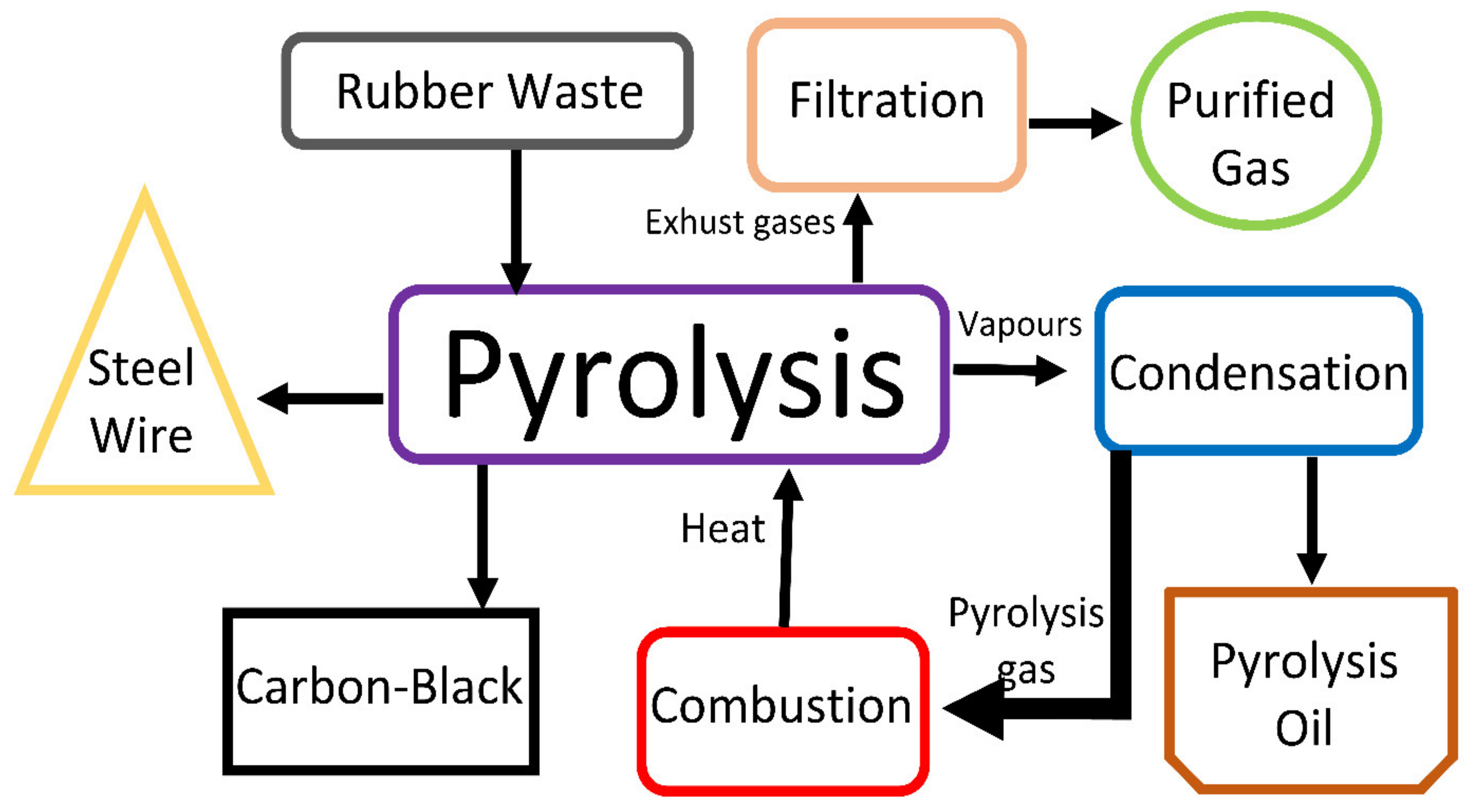

3.2. Pyrolysis

3.2.1. Definition

3.2.2. Pyrolysis Reactors

3.2.3. Types of Pyrolysis

Slow Pyrolysis

Fast Pyrolysis

4. Pyrolysis Parameters

4.1. Effect of Reactor Temperature and Pressure

4.2. Effect of Reactor Pressure

4.3. Rubber-Waste Particle Size

4.4. Feedstock Composition

4.5. Pyrolysis Time

4.6. Catalyst Role

5. Process Improvements for Pyrolysis to Be More Environmentally Acceptable

6. Environmental Assessment Outcomes

7. Conclusions and Future Aspects of Rubber Waste as a Fuel Additive

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liquete, C.; Piroddi, C.; Drakou, E.; Gurney, L.; Katsanevakis, S.; Charef, A.; Egoh, B. Current Status and Future Prospects for the Assessment of Marine and Coastal Ecosystem Services: A Systematic Review. PLoS ONE 2013, 8, e67737. [Google Scholar] [CrossRef]

- Costanza, R.; D’Arge, R.; De Groot, R.; Farber, S.; Grasso, M.; Hannon, B.; Limburg, K.; Naeem, S.; O’Neill, R.V.; Paruelo, J.; et al. The value of the world’s ecosystem services and natural capital. Nature 1997, 387, 253–260. [Google Scholar] [CrossRef]

- Capolupo, M.; Sørensen, L.; Jayasena, K.D.R.; Booth, A.M.; Fabbri, E. Chemical composition and ecotoxicity of plastic and car tire rubber leachates to aquatic organisms. Water Res. 2020, 169, 115270. [Google Scholar] [CrossRef] [PubMed]

- Beaumont, N.J.; Aanesen, M.; Austen, M.C.; Börger, T.; Clark, J.R.; Cole, M.; Hooper, T.; Lindeque, P.K.; Pascoe, C.; Wyles, K.J. Global ecological, social and economic impacts of marine plastic. Mar. Pollut. Bull. 2019, 142, 189–195. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, M.; Gutow, L.; Klages, M. Marine Anthropogenic Litter; Springer: Gothenburg, Sweden, 2015; pp. 1–447. [Google Scholar]

- Barboza, L.G.; Cózar, A.; Gimenez, B.C.; Barros, T.L.; Kershaw, P.J.; Guilhermino, L. Microplastics Pollution in the Marine Environment, World Seas: An Environmental Evaluation Volume III: Ecological Issues and Environmental Impacts; Elsevier: London, UK, 2018; pp. 329–351. [Google Scholar]

- GESAMP. Joint Group of Experts on the Scientific Aspects of Marine Environmental Protection. Sources, fate and effects of microplastics in the marine environment: A global assessment. Rep. Stud. GESAMP 2015, 90, 96. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Andrady, A.L. Persistence of Plastic Litter in the Oceans. In Marine Anthropogenic Litter; Springer: Singapore, 2015; pp. 57–72. [Google Scholar]

- Ophardt, C.E. Virtual Chembook, Boiling Points of Hydrocarbons. Available online: http://chemistry.elmhurst.edu/vchembook/403rubber.html (accessed on 27 May 2021).

- Greve, H.-H.; Threadingham, D.R. Survey, Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Global Tires. The Freedonia Group. Available online: https://www.freedoniagroup.com/industry-study/global-tires-3687.htm (accessed on 27 May 2021).

- Statista U.S. Original Equipment Passenger Tire Shipments 2017–2019. 2020. Available online: https://www.statista.com/statistics/276159/passenger-tire-shipments-in-the-united-states/ (accessed on 27 May 2021).

- Basic Information Scrap Tires US EPA. Available online: https://archive.epa.gov/epawaste/conserve/materials/tires/web/html/basic.html (accessed on 27 May 2021).

- Redling PBA. Scrap Tire Recycling Markets Not Keeping Pace with Generation, Report Shows. Recycling Today. Available online: https://www.recyclingtoday.com/article/united-states-scrap-tire-recycling-markets-2019/ (accessed on 27 May 2021).

- Sebola, M.; Mativenga, P.; Pretorius, J. A Benchmark Study of Waste Tyre Recycling in South Africa to European Union Practice. Proc. CIRP 2018, 69, 950–955. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Brown, D. Proceedings of the Recycling of Rubber Meeting; Institute of Materials: London, UK, 2008. [Google Scholar]

- Forrest, M.J. Recycling and Re-Use of Waste Rubber; De Gruyter: Boston, MA, USA; Berlin, Germany, 2019. [Google Scholar]

- REDISA (Recycling and Economic Development Initiative of South Africa). Annual Report. 2015. Available online: http://www.redisa.org.za/Satellite/000161%20-%20REDISA%20Annual%20Report%20v5.pdf (accessed on 27 May 2021).

- Fang, Y.; Zhan, M.; Wang, Y. The status of recycling of waste rubber. Mater. Des. 2000, 22, 123–127. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable Practice in Pavement Engineering through Value-Added Collective Recycling of Waste Plastic and Waste Tyre Rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Kumar Mishra, R.; Mohanty, K. Co-pyrolysis of waste biomass and waste plastics (polystyrene and waste nitrile gloves) into renewable fuel and value-added chemicals. Carbon Resour. Convers. 2020, 3, 145–155. [Google Scholar] [CrossRef]

- Hamdi, A.; Abdelaziz, G.; Farhan, K.Z. Scope of reusing waste shredded tires in concrete and cementitious composite materials: A review. J. Build. Eng. 2021, 35, 102014. [Google Scholar] [CrossRef]

- Verma, P.; Zare, A.; Jafari, M.; Bodisco, T.; Rainey, T.; Ristovski, Z.; Brown, R.J. Diesel engine performance and emissions with fuels derived from waste tyres. Sci. Rep. 2018, 8, 2457. [Google Scholar] [CrossRef]

- Karaagac, B.; Şen, M.; Deniz, V.; Güven, O. Recycling of gamma irradiated inner tubes in butyl based rubber compounds. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2007, 265, 290–293. [Google Scholar] [CrossRef]

- Recyclebank. Because You Asked: Are Bike Inner Tubes Recyclable? Available online: https://livegreen.recyclebank.com/column/because-you-asked/are-bike-inner-tubes-recyclable (accessed on 27 May 2021).

- Johnson, A. Keep Mattresses out of the Landfill—Green Business Bureau. Available online: https://greenbusinessbureau.com/blog/keep-mattresses-out-of-the-landfill (accessed on 27 May 2021).

- Adesina, A. Overview of the influence of waste materials on the thermal conductivity of cementitious composites. Clean. Eng. Technol. 2021, 2, 100046. [Google Scholar] [CrossRef]

- Taak, N.; Sharma, L.; Lallotra, B. Influence of Compression Casting Technique and Chipped Rubber Usage on the Strength Parameters of Concrete; Elsevier: Chandigarh, India, 2021; Volume 45, pp. 3462–3468. [Google Scholar]

- Hyeok-Jung, K.; Sang-Min, P.; Subbiah, K.; Seung-Jun, K. Durability performance evaluation of concrete containing TDFA (Tire Derived Fuel Ash). Constr. Build. Mater. 2017, 133, 376–386. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, J.; Cai, D.; Lou, L.; Xiao, F. A novel application of thermoplastic polyurethane/waste rubber powder blend for waterproof seal layer in high-speed railway. Transp. Geotech. 2021, 27, 100503. [Google Scholar] [CrossRef]

- Saputra, R.; Walvekar, R.; Khalid, M.; Mubarak, N.M.; Sillanpää, M. Current progress in waste tire rubber devulcanization. Chemosphere 2021, 265, 129033. [Google Scholar] [CrossRef]

- Song, P.; Wan, C.; Xie, Y.; Formela, K.; Wang, S. Vegetable derived-oil facilitating carbon black migration from waste tire rubbers and its reinforcement effect. Waste Manag. 2018, 78, 238–248. [Google Scholar] [CrossRef]

- Lopes, D.; Ferreira, M.J.; Russo, R.; Dias, J.M. Natural and synthetic rubber/waste—Ethylene-Vinyl Acetate composites for sustainable application in the footwear industry. J. Clean. Prod. 2015, 92, 230–236. [Google Scholar] [CrossRef]

- Corrosionpedia. Fuel Additives. Available online: https://www.corrosionpedia.com/definition/1625/fuel-additives-corrosion (accessed on 27 May 2021).

- Singh, S.; Nimmo, W.; Gibbs, B.; Williams, P. Waste tyre rubber as a secondary fuel for power plants. Fuel 2009, 88, 2473–2480. [Google Scholar] [CrossRef]

- Choi, M.J.; Kim, Y.J.; Kim, H.J.; Lee, J.J. Performance evaluation of the use of tire-derived fuel fly ash as mineral filler in hot mix asphalt concrete. J. Traffic Transp. Eng. 2020, 7, 249–258. [Google Scholar] [CrossRef]

- Pegg, M.J.; Amyotte, P.R.; Fels, M.; Cumming, C.R.; Poushay, J.C. An Assessment of the Use of Tires as an Alternative Fuel; Final Report; Minist Environ Labour Nov Scotia Environ Labour: Halifax, NS, Canada, 2007. [Google Scholar]

- Clark, C.; Meardon, K.; Russell, D. Burning Tires for Fuel and Tire Pyrolysis: Air Implications; Environmental Protection Agency (EPA): North Carolina, CA, USA, 1991.

- Ramirez-Canon, A.; Muñoz-Camelo, Y.F.; Singh, P. Decomposition of Used Tyre Rubber by Pyrolysis: Enhancement of the Physical Properties of the Liquid Fraction Using a Hydrogen Stream. Environment 2018, 5, 72. [Google Scholar] [CrossRef]

- Bennett, G. Scrap Tire Technology and Markets; Elsevier: Washington, DC, USA, 1993. [Google Scholar]

- Kan, T.; Strezov, V.; Evans, T. Fuel production from pyrolysis of natural and synthetic rubbers. Fuel 2017, 191, 403–410. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Ma, L.; Chang, J. Vacuum pyrolysis of waste tires with basic additives. Waste Manag. 2008, 28, 2301–2310. [Google Scholar] [CrossRef]

- Scheirs, J. Overview of Commercial Pyrolysis Processes for Waste Plastics. Feedstock Recycl. Pyrolysis Waste Plast. Convert. Waste Plast. Diesel Other Fuels 2006, 24, 381–433. [Google Scholar]

- Williams, P. Pyrolysis of waste tyres: A review. Waste Manag. 2013, 33, 1714–1728. [Google Scholar] [CrossRef]

- Mishra, R.K.; Iyer, J.S.; Mohanty, K. Conversion of waste biomass and waste nitrile gloves into renewable fuel. Waste Manag. 2019, 89, 397–407. [Google Scholar] [CrossRef]

- Okoro, E.E.; Sanni, S.; Emetere, M.; Orodu, D. Process Scheme for the Production of Liquid Fuel from used tires via Fast Pyrolysis. Proc. Manuf. 2019, 35, 847–853. [Google Scholar] [CrossRef]

- Mabood, F.; Jan, M.R.; Jabeen, F. Catalytic pyrolysis of waste inner rubber tube into fuel oil using alumina and calcium carbonate base catalysts. J. Chem. Soc. Pak. 2011, 33, 38–42. [Google Scholar]

- Veses, A.; Sanahuja-Parejo, O.; Martínez, I.; Callén, M.S.; López, J.M.; García, T.; Murillo, R. A pyrolysis process coupled to a catalytic cracking stage: A potential waste-to-energy solution for mattress foam waste. Waste Manag. 2021, 120, 415–423. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Buekens, A. Introduction to Feedstock Recycling of Plastics. In Feedstock Recycling and Pyrolysis of Waste Plastics: Converting Waste Plastics into Diesel and Other Fuels; Wiley: Brussels, Belgium, 2006; pp. 1–41. [Google Scholar]

- Venderbosch, R.; Prins, W. Fast pyrolysis technology development. Biofuels Bioprod. Biorefin. 2010, 4, 178–208. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Williams, P.T. Composition of oils derived from the batch pyrolysis of tyres. J. Anal. Appl. Pyrolysis 1998, 44, 131–152. [Google Scholar] [CrossRef]

- Murillo, R.; Aylón, E.; Navarro, M.V.; Callén, M.; Aranda, A.; Mastral, A. The application of thermal processes to valorise waste tyre. Fuel Process. Technol. 2006, 87, 143–147. [Google Scholar] [CrossRef]

- Aylón, E.; Fernández-Colino, A.; Murillo, R.; Navarro, M.V.; García, T.; Mastral, A.M. Valorisation of waste tyre by pyrolysis in a moving bed reactor. Waste Manag. 2010, 30, 1220–1224. [Google Scholar] [CrossRef]

- Mastral, A.M.; Murillo, R.; Callén, M.S.; García, T.; Snape, C. Influence of Process Variables on Oils from Tire Pyrolysis and Hydropyrolysis in a Swept Fixed Bed Reactor. Energy Fuels 2000, 14, 739–744. [Google Scholar] [CrossRef]

- De Marco Rodriguez, I.; Laresgoiti, M.F.; Cabrero, M.A.; Torres, A.; Chomon, M.J.; Caballero, B. Pyrolysis of scrap tyres. Fuel Process Technol. 2001, 72, 9–22. [Google Scholar] [CrossRef]

- Ucar, S.; Karagoz, S.; Ozkan, A.R.; Yanik, J. Evaluation of two different scrap tires as hydrocarbon source by pyrolysis. Fuel 2005, 84, 1884–1892. [Google Scholar] [CrossRef]

- Shah, J.; Jan, M.R.; Mabood, F. Catalytic conversion of waste tyres into valuable hydrocarbons. J. Polym. Environ. 2007, 15, 207–211. [Google Scholar] [CrossRef]

- Ilkılıç, C.; Aydın, H. Fuel production from waste vehicle tires by catalytic pyrolysis and its application in a diesel engine. Fuel Process. Technol. 2011, 92, 1129–1135. [Google Scholar] [CrossRef]

- Alvarez, J.; Lopez, G.; Amutio, M.; Mkhize, N.; Danon, B.; van der Gryp, P.; Gorgens, J.; Bilbao, J.; Olazar, M. Evaluation of the properties of tyre pyrolysis oils obtained in a conical spouted bed reactor. Energy 2017, 128, 463–474. [Google Scholar] [CrossRef]

- Aydın, H.; Ilkılıç, C. Optimization of fuel production from waste vehicle tires by pyrolysis and resembling to diesel fuel by various desulfurization methods. Fuel 2012, 102, 605–612. [Google Scholar] [CrossRef]

- Kaminsky, W.; Mennerich, C.; Zhang, Z. Feedstock recycling of synthetic and natural rubber by pyrolysis in a fluidized bed. J. Anal. Appl. Pyrolysis 2009, 85, 334–337. [Google Scholar] [CrossRef]

- Lopez, G.; Olazar, M.; Aguado, R.; Bilbao, J. Continuous pyrolysis of waste tyres in a conical spouted bed reactor. Fuel 2010, 89, 1946–1952. [Google Scholar] [CrossRef]

- Conesa, J.A.; Font, A.R.; Marcilla, A. Gas from the Pyrolysis of Scrap Tires in a Fluidized Bed Reactor. Energy Fuels 1996, 10, 134–140. [Google Scholar] [CrossRef]

- Conesa, J.A.; Martín-Gullón, I.; Font, R.; Jauhiainen, J. Complete Study of the Pyrolysis and Gasification of Scrap Tires in a Pilot Plant Reactor. Environ. Sci. Technol. 2004, 38, 3189–3194. [Google Scholar] [CrossRef]

- Ma, S.; Leong, H.; He, L.; Xiong, Z.; Han, H.; Jiang, L.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Effects of pressure and residence time on limonene production in waste tires pyrolysis process. J. Anal. Appl. Pyrolysis 2020, 151, 104899. [Google Scholar] [CrossRef]

- Li, S.-Q.; Yao, Q.; Chi, Y.; Yan, A.J.-H.; Cen, K.-F. Pilot-Scale Pyrolysis of Scrap Tires in a Continuous Rotary Kiln Reactor. Ind. Eng. Chem. Res. 2004, 43, 5133–5145. [Google Scholar] [CrossRef]

- Bikane, K.; Yu, J.; Long, X.; Paterson, N.; Millan, M. Linking char reactivity to structural and morphological evolution during high pressure pyrolysis of Morupule coal. Chem. Eng. Sci. X 2020, 8, 100072. [Google Scholar] [CrossRef]

- González, J.F.; Encinar, J.M.; Canito, J.L.; Rodríguez, J.J. Pyrolysis of automobile tyre waste. Influence of operating variables and kinetics study. J. Anal. Appl. Pyrolysis 2001, 58–59, 667–683. [Google Scholar] [CrossRef]

- Encinar, J.; González, J.F.G. Fixed-bed pyrolysis of Cynara cardunculus L. Product yields and compositions. Fuel Process. Technol. 2000, 68, 209–222. [Google Scholar] [CrossRef]

- Beaumont, O.; Schwob, Y. Influence of physical and chemical parameters on wood pyrolysis. Ind. Eng. Chem. Process. Des. Dev. 1984, 23, 637–641. [Google Scholar] [CrossRef]

- Bouvier, J.; Charbel, F.; Gelus, M. Gas-solid pyrolysis of tire wastes—Kinetics and material balances of batch pyrolysis of used tires. Resour. Conserv. 1987, 15, 205–214. [Google Scholar] [CrossRef]

- Dai, X.; Yin, X.; Wu, C.; Zhang, W.; Chen, Y. Pyrolysis of waste tires in a circulating fluidized-bed reactor. Energy 2001, 26, 385–399. [Google Scholar] [CrossRef]

- Barbooti, M.; Mohamed, T.J.; Hussain, A.A.; Abas, F.O. Optimization of pyrolysis conditions of scrap tires under inert gas atmosphere. J. Anal. Appl. Pyrolysis 2004, 72, 165–170. [Google Scholar] [CrossRef]

- Oyedun, A.O.; Lam, K.L.; Fittkau, M.; Hui, C.-W. Optimisation of particle size in waste tyre pyrolysis. Fuel 2012, 95, 417–424. [Google Scholar] [CrossRef]

- Rofiqul Islam, M.; Haniu, H.; Rafiqul Alam Beg, M. Liquid fuels and chemicals from pyrolysis of motorcycle tire waste: Product yields, compositions and related properties. Fuel 2008, 87, 3112–3122. [Google Scholar] [CrossRef]

- Larsen, M.B.; Schultz, L.; Glarborg, P.; Skaarup-Jensen, L.; Dam-Johansen, K.; Frandsen, F.; Henriksen, U.B. Devolatilization characteristics of large particles of tyre rubber under combustion conditions. Fuel 2006, 85, 1335–1345. [Google Scholar] [CrossRef]

- Williams, P.T.; Besler, S. Pyrolysis-thermogravimetric analysis of tyres and tyre components. Fuel 1995, 74, 1277–1283. [Google Scholar] [CrossRef]

- Kyari, M.; Cunliffe, A.; Williams, P.T. Characterization of Oils, Gases, and Char in Relation to the Pyrolysis of Different Brands of Scrap Automotive Tires. Energy Fuels 2005, 19, 1165–1173. [Google Scholar] [CrossRef]

- Root, T. Nationalgeographic, Tires: The Plastic Polluter You Never Thought about. Available online: https://www.nationalgeographic.com/environment/article/tires-unseen-plastic-polluter (accessed on 27 May 2021).

- Shulman, V.L. Tyre Recycling. In Waste; European Tyre Recycling Association (ETRA): Brussels, Belgium, 2011; pp. 297–320. [Google Scholar] [CrossRef]

- Seidelt, S.; Müller-Hagedorn, M.; Bockhorn, H. Description of tire pyrolysis by thermal degradation behaviour of main components. J. Anal. Appl. Pyrolysis 2006, 75, 11–18. [Google Scholar] [CrossRef]

- Alsaleh, A.; Sattler, M.L. Waste Tire Pyrolysis: Influential Parameters and Product Properties. Curr. Sustain. Energy Rep. 2014, 1, 129–135. [Google Scholar] [CrossRef]

- Olazar, M.; Lopez, G.; Arabiourrutia, M.; Elordi, G.; Aguado, R.; Bilbao, J. Kinetic modelling of tyre pyrolysis in a conical spouted bed reactor. J. Anal. Appl. Pyrolysis 2008, 81, 127–132. [Google Scholar] [CrossRef]

- Cheung, K.-Y.; Lee, K.-L.; Lam, K.-L.; Chan, T.-Y.; Lee, C.-W.; Hui, C.-W. Operation strategy for multi-stage pyrolysis. J. Anal. Appl. Pyrolysis 2011, 91, 165–182. [Google Scholar] [CrossRef]

- Soria-Verdugo, A.; Rubio-Rubio, M.; Goos, E.; Riedel, U. On the characteristic heating and pyrolysis time of thermally small biomass particles in a bubbling fluidized bed reactor. Renew. Energy 2020, 160, 312–322. [Google Scholar] [CrossRef]

- Dũng, N.; Mhodmonthin, A.; Wongkasemjit, S.; Jitkarnka, S. Effects of ITQ-21 and ITQ-24 as zeolite additives on the oil products obtained from the catalytic pyrolysis of waste tire. J. Anal. Appl. Pyrolysis 2009, 85, 338–344. [Google Scholar] [CrossRef]

- Kar, Y. Catalytic pyrolysis of car tire waste using expanded perlite. Waste Manag. 2011, 31, 1772–1782. [Google Scholar] [CrossRef] [PubMed]

- Nalluri, P.; Kumar, P.P.; Sastry, M.C. Experimental Study on Catalytic Pyrolysis of Plastic Waste Using Low Cost Catalyst; Elsevier BV: Gudlavalleru, India, 2021; Volume 45, pp. 7216–7221. [Google Scholar]

- Chen, Z.; Wang, D.; Yang, H.; Zhang, Y.; Li, Y.; Li, C.; Yu, J.; Gao, S. Novel application of red mud as disposal catalyst for pyrolysis and gasification of coal. Carbon Resour. Convers. 2021, 4, 10–18. [Google Scholar] [CrossRef]

- Pilusa, J.; Muzenda, E. Combustion Characteristics of Waste Tyre Pyrolysis Fuel as Industrial Burner Fuel. In Developments in Combustion Technology; Kyprianidis, K., Skvaril, J., Eds.; IntechOpen: Johannesburg, South Africa, 2016; Chapter 4. [Google Scholar]

- Senneca, O.; Salatino, P.; Chirone, R. A fast heating-rate thermogravimetric study of the pyrolysis of scrap tyres. Fuel 1999, 78, 1575–1581. [Google Scholar] [CrossRef]

- Rowhani, A.; Rainey, T.J. Scrap Tyre Management Pathways and Their Use as a Fuel—A Review. Energies 2016, 9, 888. [Google Scholar] [CrossRef]

- Putra, A.E.E.; Amaliyah, N.; Syam, M.; Rahim, I. Effect of Residence Time and Chemical Activation on Pyrolysis Product from Tires Waste. J. Jpn. Inst. Energy 2019, 98, 279–284. [Google Scholar] [CrossRef]

- Berrueco, C.; Esperanza, E.; Mastral, F.; Ceamanos, J.; García-Bacaicoa, P. Pyrolysis of waste tyres in an atmospheric static-bed batch reactor: Analysis of the gases obtained. J. Anal. Appl. Pyrolysis 2005, 74, 245–253. [Google Scholar] [CrossRef]

- Shah, J.; Rasul Jan, M.; Mabood, F. Catalytic pyrolysis of waste tyre rubber into hydrocarbons via base catalysts. Iran. J. Chem. Chem. Eng. 2008, 27, 103–109. [Google Scholar]

- Chwist, M.; Gruca, M.; Pyrc, M.; Szwaja, M. By-products from thermal processing of rubber waste as fuel for the internal combustion piston engine. Combust Engines 2020, 181, 11–18. [Google Scholar] [CrossRef]

- Quantis. Life Cycle Assessment of Plastic Energy Technology for the Chemical Recycling of Mixed Plastic Waste; Quantis: London, UK, 2020. [Google Scholar]

- Wu, Q.; Leng, S.; Zhang, Q.; Xiao, J. Resource and environmental assessment of pyrolysis-based high-value utilization of waste passenger tires. Waste Manag. 2021, 126, 201–208. [Google Scholar] [CrossRef]

- Appleton, T.; Colder, R.; Kingman, S.; Lowndes, I.; Read, A. Microwave technology for energy-efficient processing of waste. Appl. Energy 2005, 81, 85–113. [Google Scholar] [CrossRef]

- Lam, S.S.; Chase, H.A. A Review on Waste to Energy Processes Using Microwave Pyrolysis. Energies 2012, 5, 4209–4232. [Google Scholar] [CrossRef]

- Chia Yang, A.L.; Ani, F.N. Controlled microwave-induced pyrolysis of waste rubber tires. Int. J. Technol. 2016, 7, 314–322. [Google Scholar] [CrossRef][Green Version]

- Hu, J. Accelerate the Aging of Polymer as Energy-Saving Method Prior to the Pyrolysis Process; IntechOpen: Avenches, Switzerland, 2021. [Google Scholar]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Janik, H.; Borzędowska-Labuda, K.; Kucinska-Lipka, J. Environmentally friendly polymer-rubber composites obtained from waste tyres: A review. J. Clean. Prod. 2017, 147, 560–571. [Google Scholar] [CrossRef]

- Nkosi, N.; Muzenda, E.; Mamvura, T.A.; Belaid, M.; Patel, B. The Development of a Waste Tyre Pyrolysis Production Plant Business Model for the Gauteng Region, South Africa. Processes 2020, 8, 766. [Google Scholar] [CrossRef]

- Aylón, E.; Murillo, R.; Fernández-Colino, A.; Aranda, A.; García, T.; Callén, M.; Mastral, A. Emissions from the combustion of gas-phase products at tyre pyrolysis. J. Anal. Appl. Pyrolysis 2007, 79, 210–214. [Google Scholar] [CrossRef]

- Undri, A.; Rosi, L.; Frediani, M.; Frediani, P. Microwave pyrolysis of polymeric materials: Waste tires treatment and characterization of the value-added products. J. Anal. Appl. Pyrolysis 2011, 103, 149–158. [Google Scholar] [CrossRef]

- Diaz, R.; Colomines, G.; Peuvrel-Disdier, E.; Deterre, R. Thermo-mechanical recycling of rubber: Relationship between material properties and specific mechanical energy. J. Mater. Process. Technol. 2018, 252, 454–468. [Google Scholar] [CrossRef]

| Type of Product Waste | Type of Rubber (Natural/Synthetic) | Method of Reuse/Recycling | Reference |

|---|---|---|---|

| Glove (nitrile) | Synthetic | Recycling | [24] |

| Tire | Combination | Both | [25,26] |

| Tubes | Combination | Both | [27,28] |

| Mattresses | Natural | Recycling | [29] |

| Type of Product Waste | Method of Production of Fuel | Fuel/Fuel Additives Product | Reference |

|---|---|---|---|

| Glove (nitrile) | co-pyrolysis | Fuel Additives | [48] |

| Tire | pyrolysis | Fuel | [49] |

| Tubes | pyrolysis | Fuel | [50] |

| Mattresses | pyrolysis | Fuel | [51] |

| Processing Parameters Used | Made of (Natural/Synthetic Rubber Waste) | Reference |

|---|---|---|

| Temperature | Combination | [94] |

| Higher heating | [95] | |

| Particle Size | Synthetic | [96] |

| Feedstock Composition | Combination | [53] |

| Residence Time | Synthetic | [97] |

| Atmospheric Pressure | [98] | |

| Catalyst | [99] |

| Recycling Type | Power KW | CO2 Emission | Hazardous Gas Release (H2S, CO, etc.) | Reference |

|---|---|---|---|---|

| Pyrolysis | 15 | 2.9% | 3.5% | [109,110] |

| Microwave Pyrolysis | 3 (2.45 GHz) | <1% | <1% | [111] |

| Thermo-mechanical recycling (devulcanization) | 9 | - | - | [112] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akbas, A.; Yuhana, N.Y. Recycling of Rubber Wastes as Fuel and Its Additives. Recycling 2021, 6, 78. https://doi.org/10.3390/recycling6040078

Akbas A, Yuhana NY. Recycling of Rubber Wastes as Fuel and Its Additives. Recycling. 2021; 6(4):78. https://doi.org/10.3390/recycling6040078

Chicago/Turabian StyleAkbas, Ahmed, and Nor Yuliana Yuhana. 2021. "Recycling of Rubber Wastes as Fuel and Its Additives" Recycling 6, no. 4: 78. https://doi.org/10.3390/recycling6040078

APA StyleAkbas, A., & Yuhana, N. Y. (2021). Recycling of Rubber Wastes as Fuel and Its Additives. Recycling, 6(4), 78. https://doi.org/10.3390/recycling6040078