Enhancement of WEEE Management Practices in MTN Phone Village, Rumukurushi, Port Harcourt, Nigeria

Abstract

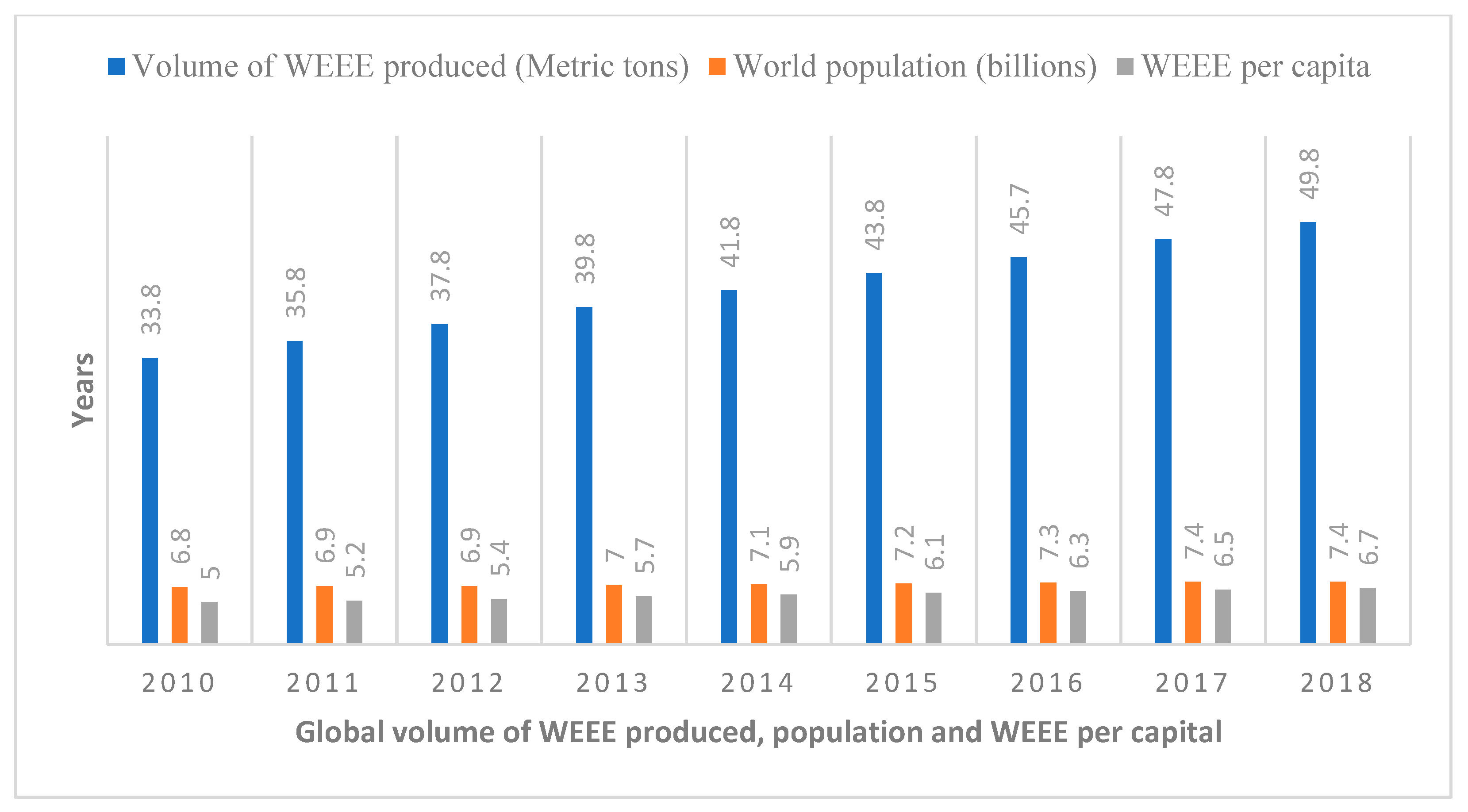

:1. Introduction

1.1. A Review of Past Research Efforts to Manage WEEE

Research Gap

1.2. The Need to Reduce the Activities of Informal Recyclers in WEEE Management in the Study Location

- They lack training, orientation, and formal education on the use of personal protective equipment, PPE, and first aid treatment application during an emergency;

- They lack the basic facilities required for effective WEEE management;

- The government does not offer them financial support and any form of recognition;

- Their WEEE management techniques expose them, individuals in the location, and the environment to risk;

- They usually do not adopt the use of safety gadgets to protect themselves from materials that are hazardous or expose them to health risk;

- There is no access to training opportunities on the types of materials and waste, technologies, finance, and conditions of the environment;

- There is no access to required health facilities;

- They lack the appropriate facility and knowledge to manage substances/elements that are harmful to life and the environment.

1.3. How to Reduce the Activities of Informal Recyclers in WEEE Management

- Avoid purchasing electrical or electronic devices that you do not need;

- Patronise the manufacturers of electronic or electrical devices that adopt the use of green technologies, as well as take-back systems;

- Encourage WEEE recyclers in your community. You can throw away your WEEE by visiting their location;

- Avoid discarding electrical or electronic devices, such as solar panels, light bulbs, batteries, and printed circuit boards, into regular refuse.

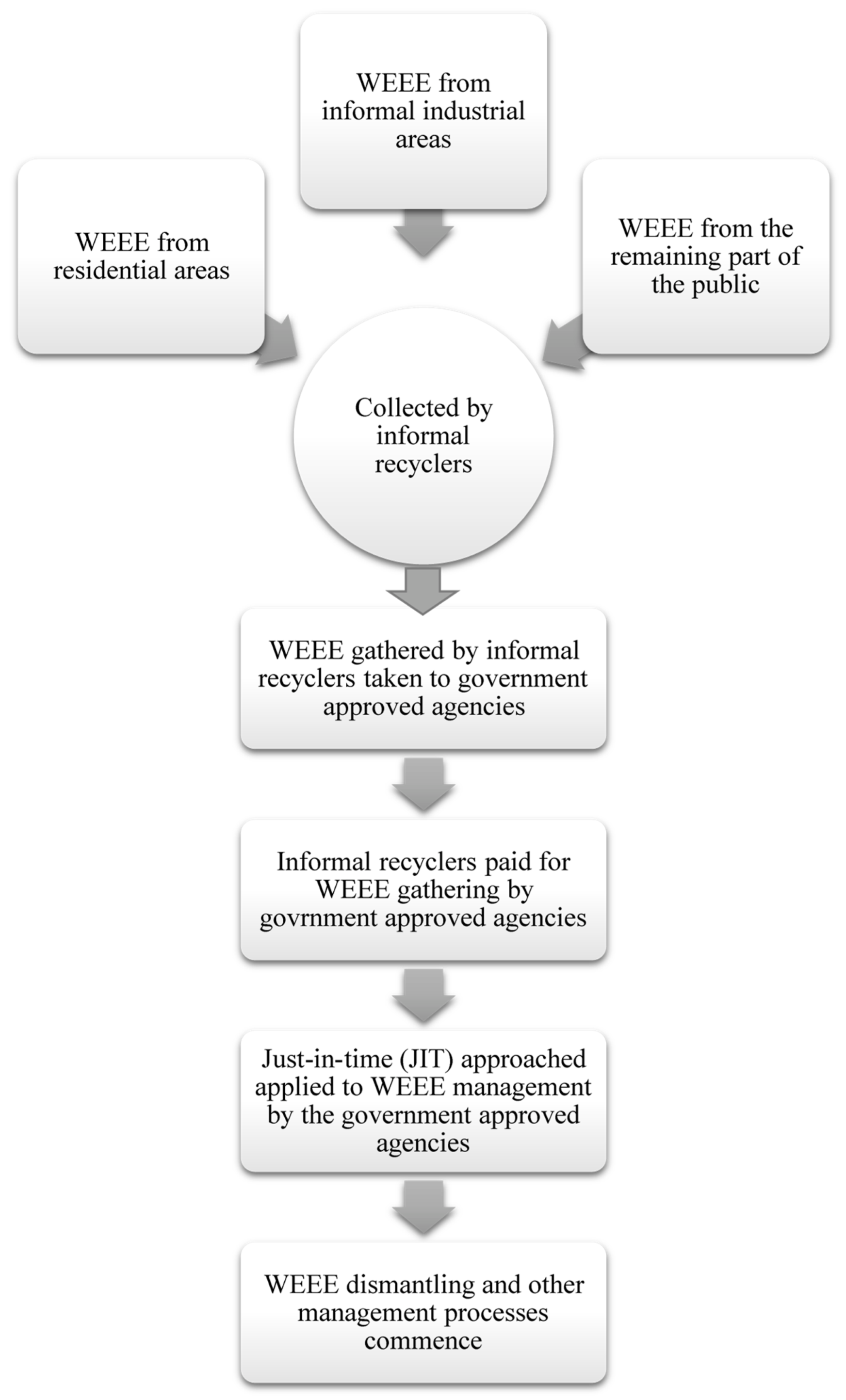

1.4. WEEE Management System

- Recovering WEEE from residents, informal recyclers, and the remaining part of the public for sorting, processing, treatment, and recycling by government-approved agencies;

- Applying the just-in-time (JIT) lean management principles to the current WEEE management system in the location.

1.4.1. Lean Concepts

1.4.2. Just-in-Time Concept

- WEEE collection and gathering at government-approved collection centres will be carried out on demand;

- WEEE gathered are processed, and the dumping ground at the government-approved collection centres are emptied for re-use;

- The health challenges associated with offensive odour from the decay of WEEE are eliminated, since the WEEE collected are processed almost immediately;

- It helps to reduce waste of land or storage space, unlike the existing WEEE management system, in which WEEE occupies a lot of space and produces an offensive odour that can cause health challenges;

- The collection and gathering of WEEE serves as a source of income to the informal recyclers and all those involved in WEEE collection.

1.4.3. Advantages of the WEEE Management System for Port Harcourt City, Nigeria

- It will enhance the safe and sustainable disposal of hazardous materials;

- Valuable materials or precious metals, such as gold, copper, etc., will be recovered for reuse and recycling;

- It will enhance the sorting of hazardous materials from non-hazardous materials after dismantling;

- It will help to check and reduce the activities of informal WEEE recyclers, since they lack the required skills and experience for proper WEEE treatment, processing, and disposal;

- With this system in place, the recovery, reduction, reuse, repurpose, and recycling of WEEE is possible;

- It will create job opportunities;

- It will help to make suggestions to policymakers on how to address the issues related to WEEE;

- It will help to reduce other risks associated with informal WEEE processing, treatment, and disposal in Nigeria.

2. Materials and Method

Data Collection Using Semi-Structured Phone Interviews

Empirical Findings

Data Analysis Method

- i.

- Becoming familiar with the available data;

- ii.

- Initial code generation;

- iii.

- Themes generation;

- iv.

- Reviewing of themes;

- v.

- Definition of themes, as well as naming;

- vi.

- Report writing up.

Ethical Issues

Interview Procedure

Coding and Theme Generation

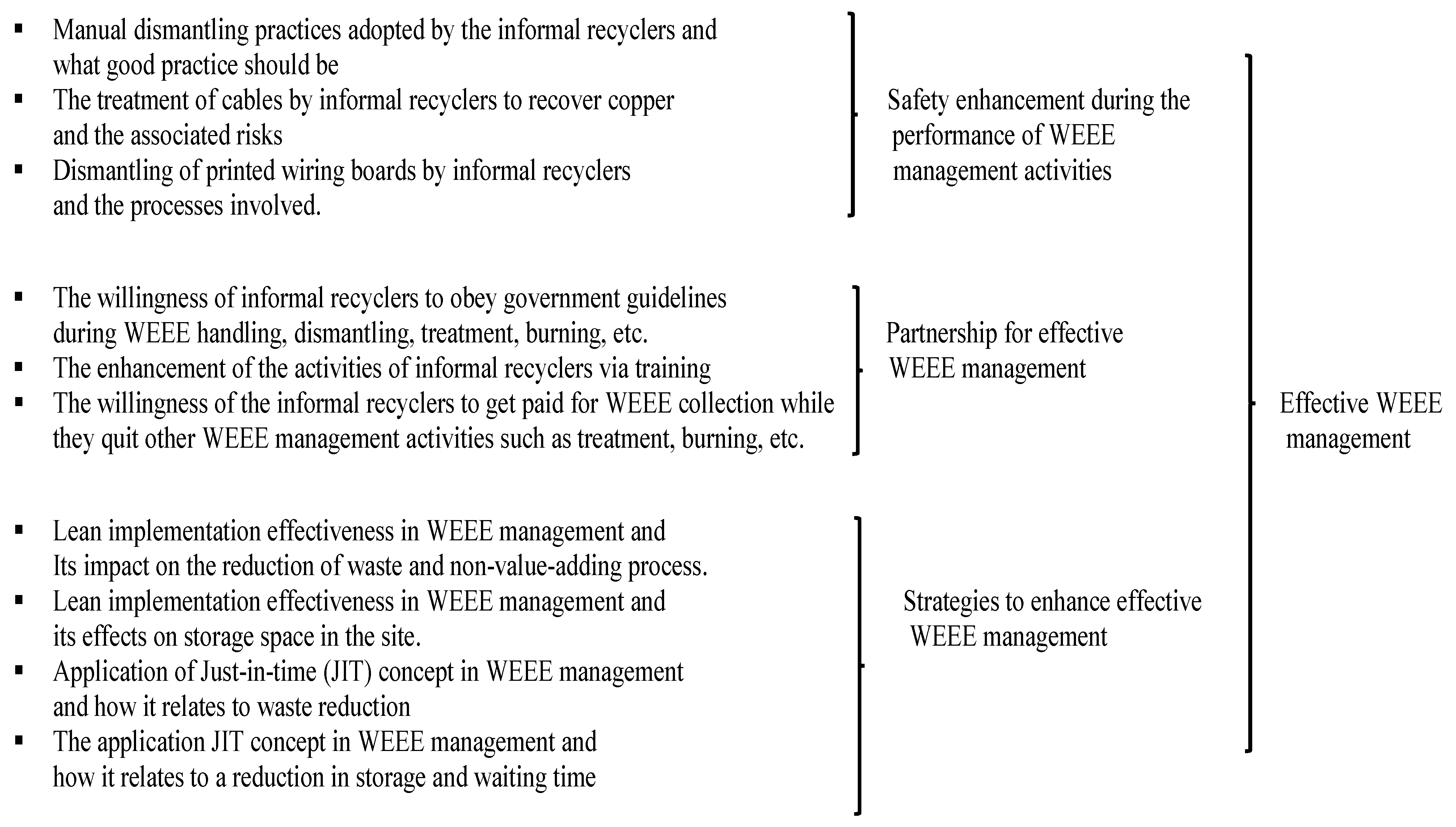

3. Results

- i.

- Manual dismantling practices adopted by the informal recyclers, and what good practice should be;

- ii.

- The treatment of cables by informal recyclers to recover copper and the associated risks;

- iii.

- The dismantling of printed wiring boards by informal recyclers and the processes involved;

- iv.

- The willingness of informal recyclers to obey government guidelines during WEEE handling, dismantling, treatment, burning, etc.;

- v.

- The enhancement of the activities of informal recyclers via training;

- vi.

- The willingness of informal recyclers to get paid for WEEE collection while they quit other WEEE management activities, such as treatment, burning, etc.;

- vii.

- Lean implementation effectiveness in WEEE management and its impact on the reduction in both waste and the non-value-adding process;

- viii.

- Lean implementation effectiveness in WEEE management and its effects on storage space in the site;

- ix.

- Application of the just-in-time (JIT) concept in WEEE management and how it relates to waste reduction;

- x.

- The application of the JIT concept in WEEE management and how it relates to the reduction in storage and waiting time.

- Manual dismantling practices adopted by the informal recyclers and what good practice should be.

“The last time I visited one of the recycling sites, the informal recyclers engage in forced opening of the refrigerators, they either smash and/or break the plastic or metal encasing structure, that practice is bad…”.B1, 22.07.2020

“I did not see them make use of safer devices like a screwdriver to help with controlled opening, they even crush the inside part without any form of personal protective equipment, PPE…”.A1, 20.07, 2020

“What I observed during one of my visits to one of the locations is that they don’t make use of PPE, instead to just smash and break the refrigerator, without the proper separation and containment of hazardous constituents being released and this practice is bad…”.C1, 23.07.2020

“As regards the dismantling of refrigerators, I think the informal recyclers need complete orientation and training on the dangers of their technique, as they are exposing themselves as well as the environment to health risk…”.B2, 22.07.2020

“The manual dismantling done by the informal recyclers is bad, a good practice begins with used refrigerator being returned by the public to authorised collection centres and facilities and none is existing, then they should be stored in a proper centre, before any treatment, fridges should be separated based on the type of refrigerants gases they contain…”.B3, 22.07.2020

“I think the informal recyclers should only be allowed to collect WEEE as their style of dismantling refrigerators is not safe, a good practice includes the use of tools fit-for-purpose, PPE, and training to increase their knowledge on WEEE management and the dangers associated with unsafe practice…”.B4, 22.07.2020

- b.

- The treatment of cables by informal recyclers to recover copper and the associated risk.

“On three different occasions, I observed the informal recycler burn off waste cables in open fires that incinerate the outer insulating plastic covering leaving copper as a residue, which is then collected without considering the associated health risk…”.A2, 20.07.2020

“The informal recycler is not concerned about any associated health risk, they just burn the waste cable to extract the copper…”.D1, 17.07.2020

“Burning of the insulation part of cables, dioxins and mercury, as well as harmful chlorine, compounds e.g., polychlorinated biphenyls are released, these make the practice bad…”.A3, 20.07.2020

“Stripping and mechanical granulation of cables is a good technique, it is simple, its cost is relatively low, and the insulation part of the cable can be recovered safely instead of burning…”.D2, 17.07.2020

“Instead of using the burning technique, I think the use of chemical treatment is good, besides, heat recovery is another option where the cables can be incinerated in high-temperature kilns with proper emission control, while the heat is captured for use…”.E1, 15.07.2020

- c.

- Dismantling of printed wiring boards by informal recyclers and the processes involved.

“During my last visit to one of the shops own by an informal recycler, I noticed they adopt the wet chemical leaching technique to extract metals such as gold or silver, the technique is hazardous and should be carried out only by experienced professionals in the laboratory…”.F1, 16.07.2020

“Some of the informal recyclers tend to apply heat to solder in order to de-solder certain components on PWB, they usually carry out this activity under uncontrolled conditions given room for the release of hazardous substances…”.F2, 16.07.2020

“I think the parts of the printed wiring boards should be removed by unscrewing and dislodging, goggles and gloves should be worn besides, it is better to store different fractions in their respective containers…”.E3, 15.07.2020

“It is advisable to work on one material at a time, e.g. first remove all aluminium parts and store them in the aluminium container, next, remove all the ferrous parts and store them in the relevant container and so on, this will help to avoid mixing up materials…”.G1, 14.07.2020

- d.

- The willingness of informal recyclers to obey government guidelines during WEEE handling, dismantling, treatment, burning, etc.

“Majority of the informal recyclers do not have basic education as they cannot read or write in English language, some have English speaking deficiency, this makes learning and development extremely difficult…”.C1, 23.07.2020

“The few among them who have good English speaking and listening skills are willing to obey government’s guidelines on WEEE management…”.A1, 20.07.2020

“Yes, obeying government’s guidelines on the discharge of their duties is good but this may be difficult to realise as they are mainly illiterates…, maybe informal recycling should be discouraged…”.G1, 14.07.2020

“There is a lot to be done to make the informal recyclers obey government guidelines due to their level of education, I feel that government should either put an end to the activities of informal recyclers or limit their services to WEEE collection only…”.A3, 20.07.2020

- e.

- The enhancement of the activities of informal recyclers via training

“Organising regular training workshops for the informal recyclers will enhance their skill acquisition but there is a high level of illiteracy among them…”.G3, 14.07.2020

“Illiteracy is the main challenge I observed with the informal recyclers the last time I visited their site to distribute fliers, some of them tend to hide for fear of being apprehended due to the illegal nature of their business”.F4, 16.07.2020

- f.

- The willingness of the informal recyclers to get paid for WEEE collection while they quit other WEEE management activities, such as treatment, burning, etc.

“We have had several conversations with the informal recyclers, they engage in the recycling business to enable them to earn a living and will be happy if they can get money from the government or the private individuals for WEEE collection…”.C1, 23.07.2020

“They actually find it easy to gather WEEE, as such if the government can prepare to pay them for WEEE collection and in the process stop them from other activities like dismantling, treatment, etc., it will be a step in the right direction…”.E4, 15.07.2020

“…money is the target in the business, the moment they start getting paid for WEEE collection, they will concentrate more on that aspect and gradually their concentration on the other WEEE management activities will depreciate…”.F4, 16.07.2020

- g.

- Lean implementation effectiveness in WEEE management and its impact on the reduction in both waste and the non-value-adding process.

“…Since, the concept has to do with the elimination of waste, that’s fine, I am sure, this will help to cut down the amount of WEEE in circulation…”.A4, 20.07.2020

“I read online about this concept recently but yet to understand its application but I think it is beginning to make sense to me now…”.D2, 17.07.2020

“One of the challenges we experience at WEEE dumpsites is that it occupies space that normally would have been put to good use…”.D3, 17.07.2020

- h.

- Lean implementation effectiveness in WEEE management and its effects on storage space in the site.

“…from all I have gathered from you, with this concept, WEEE collection can be carried out on demand, it therefore means, any available space for storage can be put to good use…”.D1, 17.07.2020

“If more WEEE can be collected when there is a need, it means more will be collected if the available ones are processed and there is space for new intakes, this will go a long way to reduce the amount of space used for storage…”.D2, 17.07.2020

- i.

- Application of the just-in-time (JIT) concept in WEEE management and how it relates to waste reduction

“WEEE collection, dismantling, etc. carried out in a timely manner, implies a timely waste reduction…”.B3, 22.07.2020

“If collected WEEE materials are processed in a timely manner, it will lead to waste reduction…”.F2, 16.07.2020

- j.

- The application of the JIT concept in WEEE management and how it relates to the reduction in storage and waiting time

“Since, this concept involves the on-time supply of WEEE for example, at the collection point when in demand, the waiting time of the workers as well as the duration at which they are kept or stored before demanded, also reduces…”.A1, 20.07.2020

“With timely response to WEEE management activities, idleness at the site is drastically reduced and consequently waiting time also reduces…”.B2, 22.07.2020

- i.

- Safety enhancement during the performance of WEEE management activities;

- ii.

- Partnership for effective WEEE management;

- iii.

- Strategies to enhance effective WEEE management.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Konya, R.S.; Babatunde, B.B.; Iniefe, D. Assessment of e-waste status in Port Harcourt city and its environs. Environ. Sci. 2015, 3, 45–66. [Google Scholar] [CrossRef]

- Amadi, A.I.; Chijioke, A.K. Economic and Environmental Sustainability of Informal Sector Recycling of Construction and Demolition Waste in Nigeria. AASCIT J. Environ. 2018, 3, 1–10. [Google Scholar]

- Ohajinwa, C.M.; van Bodegom, P.M.; Vijver, M.G.; Peijnenburg, W.J.G.M. Health risks awareness of electronic waste workers in the informal sector in Nigeria. Int. J. Environ. Res. Public Health 2017, 14, 911. [Google Scholar] [CrossRef]

- Omosimua, I.J.; Oluranti, O.I.; Obindah, G.; Busayo, A. Working Conditions and Career Aspirations of Waste Pickers in Lagos State. Recycling 2020, 6, 1. [Google Scholar] [CrossRef]

- Amechi, E.P.; Oni, B.A. Import of Electronic Waste into Nigeria: The Imperative of a Regulatory Policy Shift. Chin. J. Environ. Law 2019, 3, 141–166. [Google Scholar] [CrossRef] [Green Version]

- Wideman, B.N. Grappling with the African E-Waste Pandemic: Contributing Factors and Future Deterrence. Master’s Dissertation, Portland State University, Portland, OR, USA, 2019. [Google Scholar]

- Bilitewski, B.; Wagner, J.; Reichenbach, J. Best Practice Municipal Waste Management Information Pool on Approaches towards a Sustainable Design of Municipal Waste Management and Supporting Technologies and Equipment; Umweltbundesamt: Dessau-Roßlau, Germany, 2018. [Google Scholar]

- Erhardt, A.J.; Rezende, C.E.; Walker, B.G.; Franceschi, D.; Downie, D. Mercury concentrations and awareness in Campos dos Goytacazes, Brazil: Baseline measures for examining the efficacy of the Minamata Convention. J. Environ. Stud. Sci. 2015, 5, 517–525. [Google Scholar] [CrossRef]

- Aidonis, D.; Achillas, C.; Folinas, D.; Keramydas, C.; Tsolakis, N. Decision Support Model for Evaluating Alternative Waste Electrical and Electronic Equipment Management Schemes—A Case Study. Sustainability 2019, 11, 3364. [Google Scholar] [CrossRef] [Green Version]

- Rai, V.; Liu, D.; Xia, D.; Jayaraman, Y.; Gabriel, J.-C.P. Electrochemical Approaches for the Recovery of Metals from Electronic Waste: A Critical Review. Recycling 2021, 6, 53. [Google Scholar] [CrossRef]

- Grigorescu, R.M.; Grigore, M.E.; Iancu, L.; Ghioca, P.; Ion, R.-M. Waste Electrical and Electronic Equipment: A Review on the Identification Methods for Polymeric Materials. Recycling 2019, 4, 32. [Google Scholar] [CrossRef] [Green Version]

- Herat, S. 3R Technologies for WEEE. In Proceedings of the 8th Regional 3R Forum in Asia and the Pacific, Indore, Madhya Pradesh, India, 9–12 April 2018; pp. 1–47. [Google Scholar]

- Kumar, S.; Smith, S.R.; Fowler, G.; Velis, C.; Jyoti, K.S.; Arya, S.; Kumar, R. Challenges and opportunities associated with waste management in India. R. Soc. Open Sci. 2017, 4, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Akon-Yamga, G.; Daniels, C.U.; Quaye, W.; Ting, B.M.; Asante, A.A. Transformative innovation policy approach to e-waste management in Ghana: Perspectives of actors on transformative changes. Sci. Public Policy 2021, 48, 387–397. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, L. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef]

- Sethurajan, M.; Hullebusch, E.D.V.; Fontana, D.; Akcil, A.; Deveci, H.; Batinic, B.; Leal, J.P.; Gasche, T.A.; Kucuker, M.A.; Kuchta, K.; et al. Recent advances on hydrometallurgical recovery of critical and precious elements from end of life electronic wastes—A review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 212–275. [Google Scholar] [CrossRef] [Green Version]

- Hennebel, T.; Boon, N.; Maes, S.; Lenz, M. Biotechnologies for critical raw material recovery from primary and secondary sources: R&D priorities and future perspectives. New Biotechnol. 2015, 32, 121–127. [Google Scholar]

- Murakami, H.; Nishihama, S.; Yoshizuka, K. Separation and recovery of gold from waste LED using ion exchange method. Hydrometallurgy 2015, 157, 194–198. [Google Scholar] [CrossRef]

- Tan, Q.; Li, J.; Zeng, X. Rare Earth Elements Recovery from Waste Fluorescent Lamps: A Review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 749–776. [Google Scholar] [CrossRef]

- Gorewoda, T.; Eschen, M.; Charasinska, J.; Knapik, M.; Kozlowicz, S.; Anyszkiewicz, J.; Jadwinski, M.; Potempa, M.; Gawliczek, M.; Chmielarz, A.; et al. Determination of metals’ content in components mounted on printed circuit boards from end-of-life mobile phones. Recycling 2020, 5, 20. [Google Scholar] [CrossRef]

- Monneron-Enaud, B.; Wiche, O.; Schlömann, M. Biodismantling, a Novel Application of Bioleaching in Recycling of Electronic Wastes. Recycling 2020, 5, 22. [Google Scholar] [CrossRef]

- Ueberschaar, M.; Schlummer, M.; Jalalpoor, D.; Kaup, N.; Rotter, V.S. Potential and Recycling Strategies for LCD Panels from WEEE. Recycling 2017, 2, 7. [Google Scholar] [CrossRef] [Green Version]

- Abalansa, S.; el Mahrad, B.; Icely, J.; Newton, A. Electronic Waste, an Environmental Problem Exported to Developing Countries: The GOOD, the BAD and the UGLY. Sustainability 2021, 13, 5302. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Vaccari, M.; Jandric, A.; Chung, T.D.; Dias, M.I.; Hursthouse, A.; Salhofer, S. A device-specific prioritization strategy based on the potential for harm to human health in informal WEEE recycling. Environ. Sci. Pollut. Res. 2018, 25, 683–692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daum, K.; Stoler, J.; Grant, R.J. Toward a more sustainable trajectory for e-waste policy: A review of a decade of e-waste research in Accra, Ghana. Int. J. Environ. Res. Public Health 2017, 14, 135. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Islam, A.; Ahmed, T.; Awual, M.R.; Rahman, A.; Sultana, M.; Aziz, A.A.; Monir, M.U.; Teo, S.H.; Hasan, M. Advances in sustainable approaches to recover metals from e-waste—A review. J. Clean. Prod. 2020, 244, 118815. [Google Scholar] [CrossRef]

- Wang, K.; Qian, J.; Liu, L. Understanding environmental pollutions of informal e-waste clustering in global south via multi-scalar regulatory frameworks: A case study of Guiyu Town, China. Int. J. Environ. Res. Public Health 2020, 17, 2802. [Google Scholar] [CrossRef] [PubMed]

- Ceballos, D.; Dong, Z.; Frank, M. Formal E-Recycling: The Complexity of Solving the E-Waste Problem Worldwide. Hoffman Program on Chemicals and Health. 26 August 2016. Available online: https://sites.sph.harvard.edu/hoffman-program/2016/08/26/formal-e-recycling-the-complexity-of-solving-the-e-waste-problem-worldwide/ (accessed on 22 July 2021).

- Grant, K.; Goldizen, F.C.; Sly, P.D.; Brune, M.N.; Neira, M.; Van, D.B.M.; Norman, R.E. Health consequences of exposure to e-waste: A systematic review. Lancet Glob. Health 2013, 1, 350–361. [Google Scholar] [CrossRef] [Green Version]

- Julander, A.; Lundgren, L.; Skare, L.; Grander, M.; Palm, B.; Vahter, M.; Liden, C. Formal recycling of e-waste leads to increased exposure to toxic metals: AN occupational exposure study from Sweden. Environ. Int. 2014, 73, 243–251. [Google Scholar] [CrossRef] [Green Version]

- Xu, R.; Zheng, X.; Lin, Y.; Lin, C.; Guo, Y.; Huo, X. Assessment of dust trace elements in an e-waste recycling area and related children’s health risks. Sci. Total Environ. 2021, 791, 148154. [Google Scholar] [CrossRef]

- Rautela, R.; Arya, S.; Vishwakarma, S.; Lee, J.; Kim, K.H.; Kumar, S. E-waste management and its effects on the environment and human health. Sci. Total Environ. 2021, 773, 145623. [Google Scholar] [CrossRef]

- Shahady, T.; Boniface, H. Water quality management through community engagement in Costa Rica. J. Environ. Stud. Sci. 2018, 8, 488–502. [Google Scholar] [CrossRef] [Green Version]

- Charette, A.T.; Collins, M.B.; Mirowsky, J.E. Assessing residential socioeconomic factors associated with pollutant releases using EPA’s Toxic Release Inventory. J. Environ. Stud. Sci. 2021, 11, 247–257. [Google Scholar] [CrossRef]

- Adeola, F.O. WEEE generation and the consequences of its improper disposal. In Waste Electrical and Electronic Equipment Recycling; Woodhead Publishing: Cambrige, UK, 2018; pp. 13–31. [Google Scholar]

- Jaiswal, A.; Samuel, C.; Patel, B.S.; Kumar, M. Go Green with WEEE: Eco-friendly Approach for Handling E-waste. Procedia Comput. Sci. 2015, 46, 1317–1324. [Google Scholar] [CrossRef] [Green Version]

- Fang, C.C. The case for environmental advocacy. J. Environ. Stud. Sci. 2021, 11, 169–172. [Google Scholar] [CrossRef] [PubMed]

- Lawal, S. Nigeria Has Become an E-Waste Dumpsite for Europe, US and Asia. TRT World 2019. Available online: www.trtworld.com (accessed on 23 November 2021).

- Charles, R.G. Assessment and Exploitation of the Inherent Value of Waste Electrical and Electronic Equipment (WEEE) for Circular Economy. Ph.D. Thesis, Swansea University, Wales, UK, 2018. [Google Scholar]

- ILO. Tackling Informality in E-Waste Management: The Potential of Cooperative Enterprises; International Labour Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Işıldar, A.; Van, H.E.D.; Lenz, M.; Du, L.G.; Maria, A.; Cesaro, A.; Panda, S.; Akcil, A.; Kucuker, M.A.; Kuchta, K. Biotechnological strategies for the recovery of valuable and critical raw materials from waste electrical and electronic equipment (WEEE)—A review. J. Hazard. Mater. 2019, 362, 467–481. [Google Scholar] [CrossRef]

- Ndunda, H.K.; Ambole, L.A. IRS-2018-8 Product-Service Systems Design for E-Waste Management: A Case Study of Waste Electrical and Electronic Equipment Centre in Nairobi County. In Innovation Research Symposium; School of Arts and Design, University of Nairobi: Nairobi, Kenya, 2018; pp. 73–81. [Google Scholar]

- Gervich, C.D.; Briere, C.; Lopez, N.; Eudene, J.; Evans, C.; Fonzone, J.; Barbencena, R.O.; Witney, A.; Hastings, E.; Fernandez, A. Toxic Release! The role of educational games in teaching and learning about hazardous pollution. J. Environ. Stud. Sci. 2015, 6, 589–596. [Google Scholar] [CrossRef]

- Okorhi, J.O.; Amadi-Echendu, J.E.; Aderemi, H.O.; Uhunmwangho, R.; Agbatah, O.B. Solving the waste electrical and electronic equipment problem: Socio-economic assessment on sustainable e-waste management in South Eastern Nigeria. Int. J. Environ. Technol. Manag. 2017, 20, 300–320. [Google Scholar] [CrossRef]

- Richmond, M. Toxic chemicals: Environmental impact, regulation, controversy, and education: Editor’s introduction. J. Environ. Stud. Sci. 2016, 6, 541–542. [Google Scholar] [CrossRef] [Green Version]

- Bimir, M.N. Revisiting e-waste management practices in selected African countries. J. Air Waste Manag. Assoc. 2020, 70, 659–669. [Google Scholar] [CrossRef]

- Ilankoon, I.; Ghorbani, Y.; Chong, M.N.; Herath, G.; Moyo, T.; Petersen, J. E-waste in the international context—A review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery. J. Waste Manag. 2018, 82, 258–275. [Google Scholar] [CrossRef]

- Mihai, F.; Gnoni, M.-G.; Meidiana, C.; Ezeah, C.; Elia, V. Waste electrical and electronic equipment (WEEE): Flows, quantities and management, a global scenario. Electron. Waste Manag. Treat. Technol. 2019, 1–34. [Google Scholar] [CrossRef]

- Ogbuanya, T.C.; Afeez, Y.S. Advancing Electronic Waste Management Techniques among Electrical/Electronic Technicians’ Workshops for Sustainable Healthy Society. Insights Min. Sci. Technol. 2019, 1, 90–104. [Google Scholar]

- George, F.; Mapa, M.T.; Dinggai, S.A. IOP CoPreliminary Study on Waste Electrical and Electronic Equipment (WEEE) Management by Households in the Kota Kinabalu City. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Langkawi, Malaysia, 3–4 December 2019; pp. 1–10. [Google Scholar]

- Arya, S.; Gupta, A.; Bhardwaj, A. Electronic Waste Management Approaches—A Pilot Study in Northern Indian States. Int. J. Waste Resour. 2018, 8, 1–5. [Google Scholar] [CrossRef]

- Yang, H.; Ma, M.; Thompson, J.R.; Flower, R.J. Waste management, informal recycling, environmental pollution and public health. J. Epidemiol. Community Health 2018, 72, 237–243. [Google Scholar] [CrossRef]

- Alabi, R.A.; Wohlmuth, K. The Case of Sustainable Management of Waste in Germany (and Bremen) and Practical Lessons for Nigeria (and Lagos); University of Bremen: Bremen, Germany, 2019. [Google Scholar]

- Deranek, K.; Chopra, S.; Mosher, G.A. Lean Adoption in a Small and Medium Enterprise: Model Validation. Manag. Appl. Eng. J. Technol. 2017, 33, 1–13. [Google Scholar]

- Wee, H.M.; Wu, S. Lean supply chain and its effect on product cost and quality: A case study on Ford Motor Company. Supply Chain Manag. Int. J. 2009, 14, 335–341. [Google Scholar] [CrossRef]

- Rever. Lean Safety—Improve Workplace Safety with Lean Principles. Rever Team. 22 March 2020. Available online: https://reverscore.com/lean-safety/ (accessed on 28 May 2020).

- Hamja, A.; Hossain, A.; Maalouf, M.M.; Hasle, P. A review paper on Lean and Occupational Health and Safety (OHS) in RMG industry. In Proceedings of the International Conference on Mechanical Engineering and Renewable Energy, Chittagong, Bangladash, 18–20 December 2017; pp. 1–5. [Google Scholar]

- Alkhoraif, A.; Rashid, H.; McLaughlin, P. Lean implementation in small and medium enterprises: Literature review. Oper. Res. Perspect. 2019, 6, 1–19. [Google Scholar] [CrossRef]

- McKinney, P.; Scalia, S. Just in Time Inventory: Definition, Advantages & Examples. Study.com. 2019. Available online: https://study.com/academy/lesson/just-in-time-inventory-definition-advantages-examples.html (accessed on 22 August 2020).

- Chan, A. The Benefits of the Just-in-Time Approach. Unleashed. 2017. Available online: https://www.unleashedsoftware.com/blog/benefits-jit-system-approach (accessed on 22 August 2020).

- Wu, H.; Dong, X.; Wang, Q. New principle of busbar protection based on a fundamental frequency polarity comparison. PLoS ONE 2019, 14, e0213308. [Google Scholar] [CrossRef]

- Singh, G.; Ahuja, I.S. Just-in-time manufacturing: Literature review and directions. Int. J. Bus. Contin. Risk Manag. 2012, 3, 57. [Google Scholar] [CrossRef]

- Davies, J. How to Improve Productivity with Just-In-Time by Toyota. Winman. 22 August 2020. Available online: https://www.winman.com/blog/how-to-improve-productivity-with-just-in-time-by-toyota (accessed on 23 August 2020).

- Kivunja, C.; Kuyini, A.B. Understanding and Applying Research Paradigms in Educational Contexts. Int. J. High. Educ. 2017, 6, 26–41. [Google Scholar] [CrossRef] [Green Version]

- Ragab, M.A.; Arisha, A. Research Methodology in Business: A Starter’s Guide. Manag. Organ. Stud. 2017, 5, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Evans, C.; Lewis, J. Analysing Semi-Structured Interviews Using Thematic Analysis: Exploring Voluntary Civic Participation among Adults; SAGE Publications, Ltd.: Thousand Oaks, CA, USA, 2018; pp. 1–3. [Google Scholar]

- Caulfield, J. How to Do Thematic Analysis|A Step-by-Step Guide & Examples. Scribbr. 26 September 2019. Available online: https://www.scribbr.com/methodology/thematic-analysis/ (accessed on 22 May 2020).

- Nowell, L.S.; Norris, J.M.; White, D.E.; Moules, N.J. Thematic Analysis: Striving to Meet the Trustworthiness Criteria. Int. J. Qual. Methods 2017, 16, 1–13. [Google Scholar] [CrossRef]

- Elliott, V. Thinking about the Coding Process in Qualitative Data Analysis. Qual. Rep. 2018, 23, 2850–2861. [Google Scholar] [CrossRef]

- Poucher, Z.A.; Tamminen, K.A.; Caron, J.G.; Sweet, S.N. Thinking through and designing qualitative research studies: A focused mapping review of 30 years of qualitative research in sport psychology. Int. Rev. Sport Exerc. Psychol. 2020, 13, 163–186. [Google Scholar] [CrossRef] [Green Version]

- Vaismoradi, M.; Snelgrove, S. Theme in qualitative content analysis and thematic analysis. FQS Forum Qual. Soc. Res. 2019, 20, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Szedlak, C.; Smith, M.J.; Day, M.C.; Greenlees, I.A. Effective behaviours of strength and conditioning coaches as perceived by athletes. Int. J. Sports Sci. Coach. 2015, 10, 967–984. [Google Scholar] [CrossRef]

- Lydall, M.; Nyanjowa, W.; James, Y. Mapping South Africa’s Waste Electrical and Electronic Equipment (WEEE) Dismantling, Pre-Processing and Processing Technology Landscape; Mintek Private Bag X3015: Randburg, South Africa, 2017. [Google Scholar]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global E-Waste Monitor 2017: Quantities, Flows, and Resources; United Nations University (UNU): Bonn, Germany; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Vienna, Austria, 2017. [Google Scholar]

- Fischer, D.; Seidu, F.; Yang, J.; Felten, M.K.; Garus, C.; Kraus, T.; Fobil, J.N.; Kaifie, A. Health Consequences for E-Waste Workers and Bystanders—A Comparative Cross-Sectional Study. Int. J. Environ. Res. Public Health 2020, 17, 1534. [Google Scholar] [CrossRef] [Green Version]

- Lenz, K.; Afoblikame, R.; Kacher, Y.S.; Kotoe, L.; Schluep, M.; Smith, E.; Schroder, P.; Valdivia, S. E-Waste Training Manual; Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH: Bonn, Germany, 2019. [Google Scholar]

- Jain, A. Compendium of Technologies for the Recovery of Materials from WEEE E-Waste; United Nations Environment Programme, (UNEP): Nairobi, Kenya, 2017. [Google Scholar]

- Manzouri, M.; Ab-Rahman, M.N.; Zain, C.R.C.M.; Jamsari, E.A. Increasing production and eliminating waste through lean tools and techniques for Halal food companies. Sustainability 2014, 6, 9179–9204. [Google Scholar] [CrossRef] [Green Version]

- Cerra, J. Advantages and Disadvantages of Just-in-Time (JIT) Manufacturing. Planet Together. 23 May 2019. Available online: https://www.planettogether.com/blog/advantages-and-disadvantages-of-just-in-time-jit-manufacturing (accessed on 8 December 2020).

| Position of Participants | Number of Interviewees | Duration of the Interview (Minutes) |

|---|---|---|

| Senior Manager (SM), dismantling | 4 | 20 |

| Senior Manager (SM), treatment and packaging | 4 | 20 |

| Senior Manager (SM), human resources | 1 | 20 |

| Storage officer | 4 | 20 |

| Officer I | 4 | 20 |

| Officer II | 4 | 20 |

| WEEE collector | 4 | 20 |

| Position of Participants | Code |

|---|---|

| Senior Manager (SM), dismantling | A |

| Senior Manager (SM), treatment and packaging | B |

| Senior Manager (SM), human resources | C |

| Storage officer | D |

| Officer I | E |

| Officer II | F |

| WEEE collector | G |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okwu, O.; Hursthouse, A.; Viza, E.; Idoko, L. Enhancement of WEEE Management Practices in MTN Phone Village, Rumukurushi, Port Harcourt, Nigeria. Recycling 2021, 6, 77. https://doi.org/10.3390/recycling6040077

Okwu O, Hursthouse A, Viza E, Idoko L. Enhancement of WEEE Management Practices in MTN Phone Village, Rumukurushi, Port Harcourt, Nigeria. Recycling. 2021; 6(4):77. https://doi.org/10.3390/recycling6040077

Chicago/Turabian StyleOkwu, Ogechukwu, Andrew Hursthouse, Evi Viza, and Linus Idoko. 2021. "Enhancement of WEEE Management Practices in MTN Phone Village, Rumukurushi, Port Harcourt, Nigeria" Recycling 6, no. 4: 77. https://doi.org/10.3390/recycling6040077

APA StyleOkwu, O., Hursthouse, A., Viza, E., & Idoko, L. (2021). Enhancement of WEEE Management Practices in MTN Phone Village, Rumukurushi, Port Harcourt, Nigeria. Recycling, 6(4), 77. https://doi.org/10.3390/recycling6040077