1. Introduction

Glass fiber is widely used in various modern industrial applications. Its application advantages include the following: corrosion resistance, high temperature resistance, low moisture absorption, good electrical insulation, non-perishable, and high chemical stability, as well as it can be used in various processing procedures [

1]. However, because glass fiber is brittle, easy to break, and not wear resistant, there are still certain limitations in its application. In addition, static electricity is easily generated after friction, which limits industrial applications. In order to meet industry standards, silane coupling agents (i.e., surface sizing agents) are widely used to increase the strength of the substrate and fiber interface, that is, the strength of the glass fiber is enhanced by forming a polymer composite material on the glass fiber [

2]. In the process of manufacturing glass fiber, a specific procedure is designed to coat the surface of the glass fiber with a surface sizing agent [

3]. The ductility facilitates processing, such as fiber weaving. [

4]. Inevitably, used glass fibers will eventually become waste during the product life cycle. Therefore, for decades, the treatment or recycling of glass fiber waste has been an important issue in environmental engineering [

5].

During the manufacturing process, 10~15% of the total amount of glass fiber becomes waste materials. The shape of glass fiber waste is a disorderly and filamentous and its surface layer contains surface sizing agents such as epoxy resin, polyvinyl alcohol, starch, wax and silane. The complex characteristics of glass fiber such as high flexibility, disordered shapes, and complicated chemical coatings always make it difficult to recycle. For instance, glass raw materials should be melted for drawing processes to fabricate the very small diameter (from 0.05 to 0.2 times of hair) of a single glass fiber; however, glass fibers covered with sizing agent cannot be completely melted, which results in the failure of glass fiber recycling. In addition, concrete with mixing glass fiber waste leads to very low compressive strength due to the chemical coating with low attachment ability [

4]. As a result, glass fiber waste is currently treated by solidification, stabilization, or heat treatment techniques. In practice, glass fiber waste is usually treated by mixing it with soil for landfills [

6]. Such treatment needs abundant land resources for burying glass fiber waste. Since land is a very critical and rare resource not only to the ecosystem but also economics in Taiwan, the deep burial method is no longer feasible.

One successful case about recycling pure glass fiber waste without sizing agent has been reported [

7,

8]. This recycling process could generate value-added materials by mixing with cements. This technology has already converted 250,000 ton/year of discarded glass fiber waste into beneficial use applications in the concrete construction industry. In this process, glass fiber waste is ground to a fine powder that effectively functions as a reactive pozzolanic admixture for use in Portland cement-based building materials and products. Such reactive pozzolanic admixture is especially suited for white concrete applications. According to the above illustration, glass fiber waste possesses a high potential for recycling if the sizing agent on the surface can be removed. Hence, there is a need for a removal technique with market value for the recycled glass fiber waste.

In order to effectively recycle glass fiber waste, an innovative technique to remove the surface sizing agent is the key recycling procedure. In this study, the removal techniques that were evaluated included: (1) removal of sizing agent by organic solvents and (2) removal of sizing agent by heating process. Afterwards, the treated glass fiber waste was used to replace sand to build CLSM (controlled low-strength material, CLSM) concrete. A controlled low-strength material (CLSM) concrete is usually constructed using cement, sand, recycled waste, and water. The properties of CLSM concrete include compressive strength, subsidence, permeability, and re-excavation. Among them, the most important property is the compressive strength for practical applications. According to the industry specification standard of CLSM concrete in Taiwan, its compressive strength should reach 84 kgf/cm2. The focus of this study is to create a feasible technology for removing the sizing agent from the outer layer of glass fiber waste and to recycle the glass fiber waste into CLSM concrete.

2. Materials and Methods

The experimental samples of glass fiber waste were collected from a certain waste site located in the central region of Taiwan. The surface of the glass fiber waste was covered with some kinds of sizing agent. Three experimental processes were conducted including: 1. removal of sizing agent by organic solvents, 2. removal of sizing agent by heating process, and 3. CLSM concrete constructed with treated glass fiber waste. The reasons why we chose glass fiber waste to replace sand in the CLSM concrete include: 1. the main chemical component is silica dioxide, which is the same as that in sand, 2. the glass fiber waste can play the gradation role during the solidification function with cements.

2.1. Removal of Sizing Agent by Organic Solvents

Ethyl acetate and toluene were used to remove the surface sizing agent. First, 45 g of the sample were soaked in 500 mL of organic solvent at room temperature for 30 min. Then, the sample was processed by ultrasonic vibration for 5 h. During the ultrasonic vibration, the surface structure of the sample was observed with a 400× optical microscope every hour, and an X-ray diffractometer (Rigaku, MiniFlex, Tokyo, Japan) was used to analyze the sample to evaluate the removal of the surface sizing agent.

2.2. Removal of Sizing Agent by Heating Process

In order to remove the surface treatment agent, a heat treatment method can also be used, in which the glass fiber waste is cured in hot air (from 450 °C to 550 °C) or heated in an oxygen-free environment (i.e., pyrolysis) [

9,

10]. The filaments of glass fiber waste were crushed into fine powders by a hammer-crushing device, then, the samples were heated in the furnace at 500, 600, 700, or 800 °C for 2 h. Afterwards, each sample, under different temperatures, formed a block. This block was crushed to powder and observed by the same optical microscope to clarify the removal of surface sizing agent. In addition, an X-ray diffraction instrument (Rigaku, MiniFlex, Tokyo, Japan) was applied to analyze the samples and gain insights into the lattice of the treated glass fiber waste.

2.3. CLSM Concrete Constructed with Treated Glass Fiber Waste

According to the ASTM C109 method, the mixing ratio of cement to sand is 1:2.75. In this study, the sand in the concrete were completely replaced by the treated sample. In the beginning of constructing the concrete, the inner layer of the mold was coated with lubricant. Then, the mixed slurry (treated glass fiber waste, cement, and water) was poured into the mold two times (each layer was about 2.5 cm). Then, the slurry was guided 32 times with a rod and finally scraped off the excess slurry outside the mold. The mold was placed in a constant temperature and humidity box. After 24 h, the concrete sample was removed from the mold and cured for 7 days. At last, the compressive strength of the sample (kgf/cm2) was determined.

3. Results

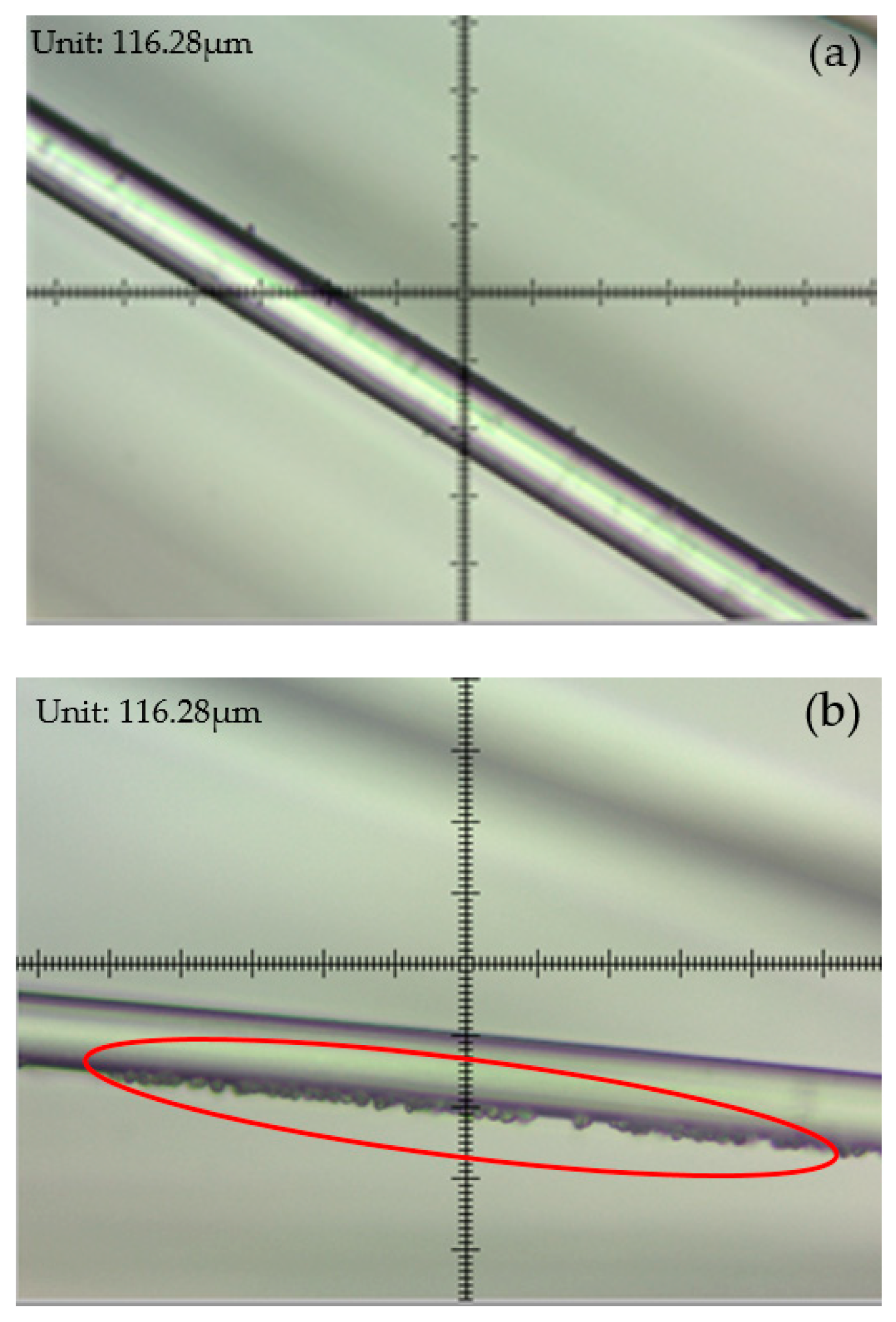

Figure 1 shows the microscopic images of glass fiber waste under different solvent treatments. By comparing

Figure 1a,b, it can be seen that there is a distinct layer coated on the glass fiber and this coated layer possesses minor damage by ethyl acetate under ultrasonic for 5 h. The ethyl acetate tests (data not shown here) of various treated hours present similar phenomena to

Figure 1b. In addition to the incomplete removal of surface sizing agent from the glass fiber waste, the procedures with organic solvents consume a relatively long time. Moreover, such a technique yields another liquid waste (i.e., used organic solvents) that also need to be effectively treated. Taking the above into consideration, the removal efficiency of solvent technique is not effective. Likewise, the same conclusion pertaining to toluene solvent can be drawn by comparing

Figure 1a,c. In

Figure 1c, some irregular obstructive can be observed.

Figure 1d shows the XRD spectrum of using organic solvents to remove sizing agent and

Figure 1e shows the original waste glass fiber XRD spectrum. By comparing the two, the effect is not obvious.

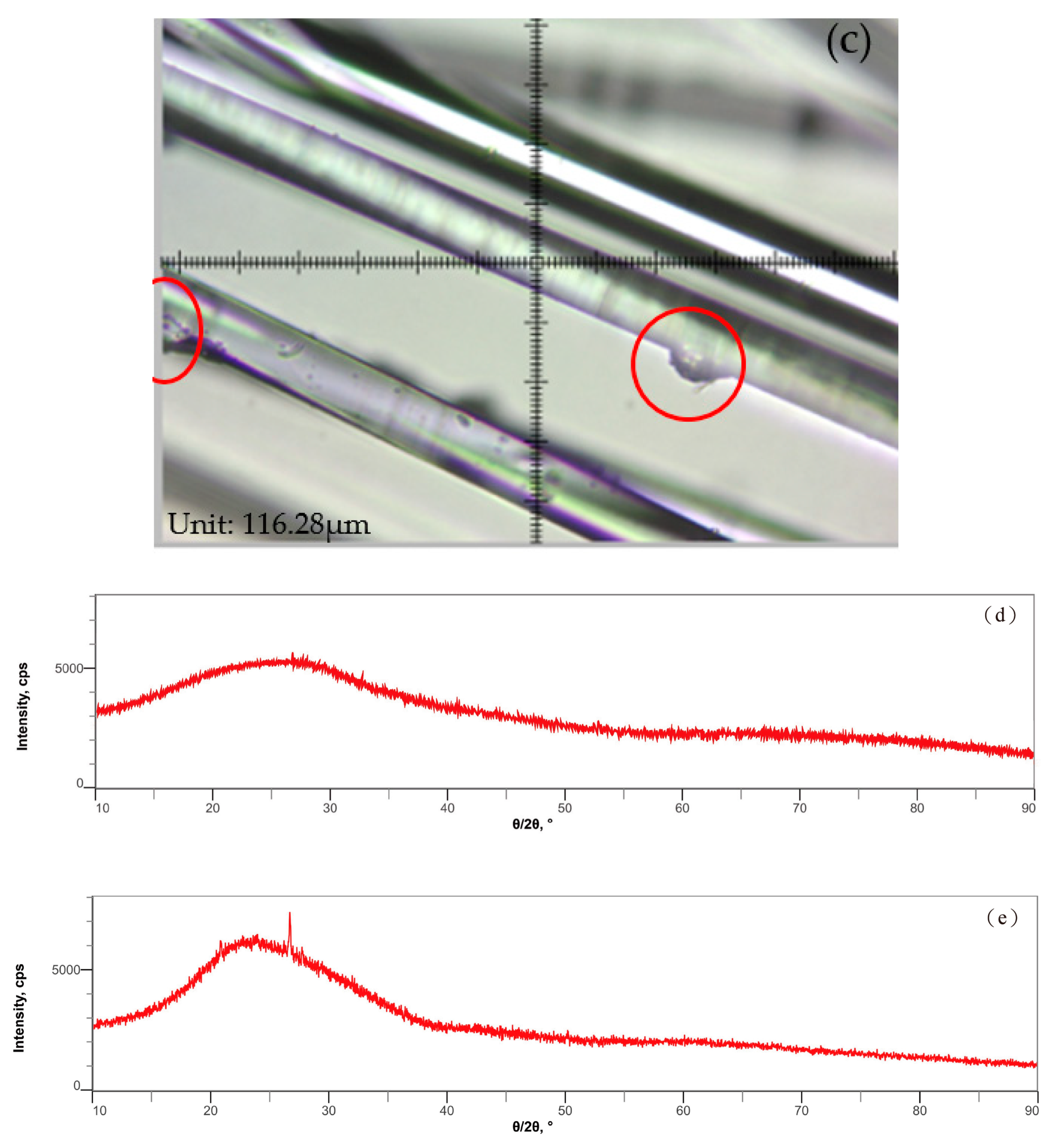

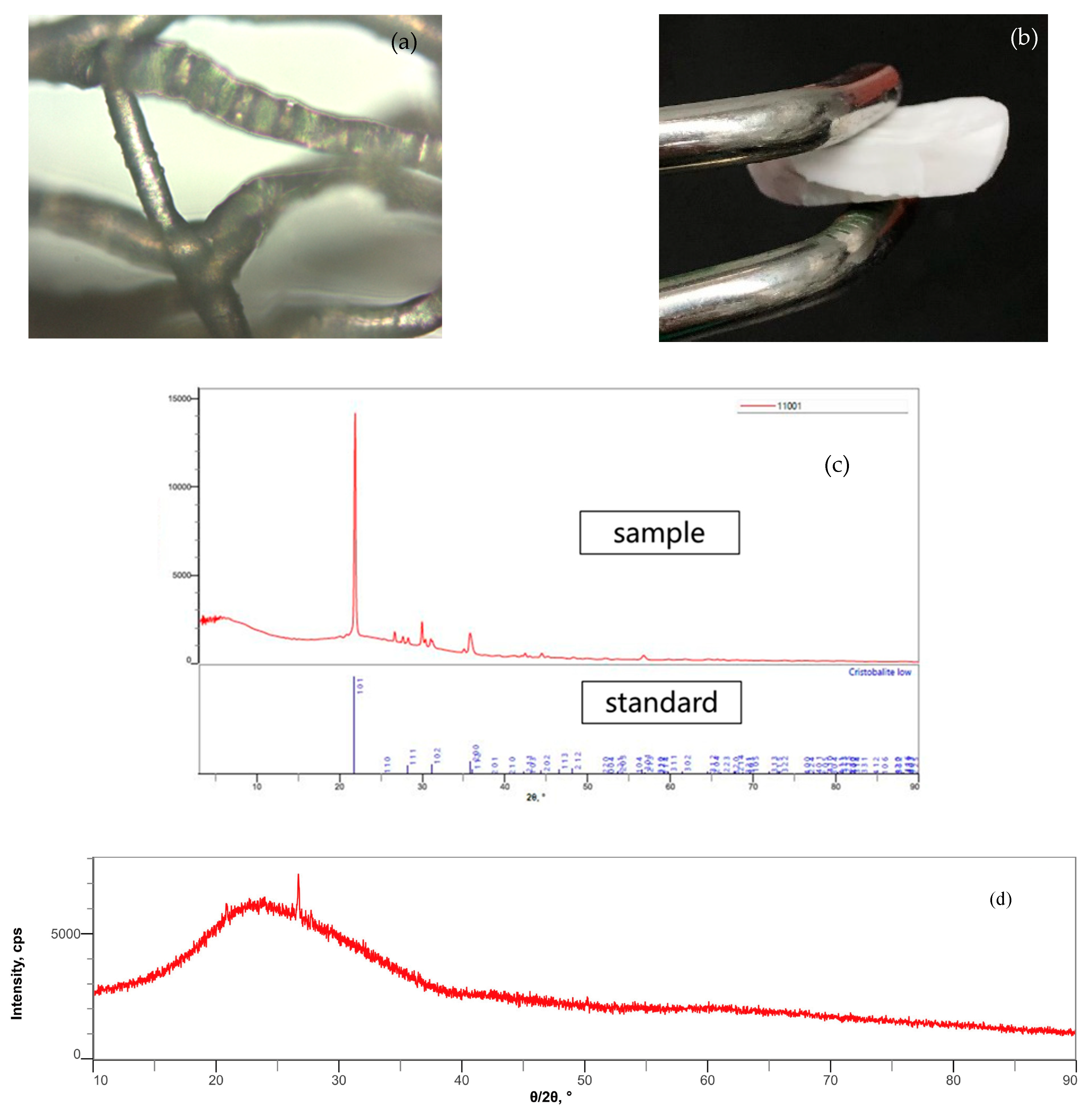

As the glass fiber waste (without grinding) is heated at 800 °C for 2 h, the surface sizing agent is carbonized (shown in

Figure 2a). In contrast, a lump occur (as shown in

Figure 2b) as the glass fiber waste (with grinding) is heated at 800 °C for 2 h. The lump also appears even when the sample is heated at 500, 600, and 700 °C (data not shown here). This implies that the grinding procedure is beneficial to the removal of surface sizing agent and the lattice transformation of the silicate.

Figure 2c,d shows the XRD spectrum of glass fiber waste with and without heating treatment, respectively. By comparing

Figure 2c,d, it can be observed that a large amount of high-purity cristobalite was produced after the heating process. This cristobalite material may possess high potential as a recycling material to replace sand for CLSM concrete.

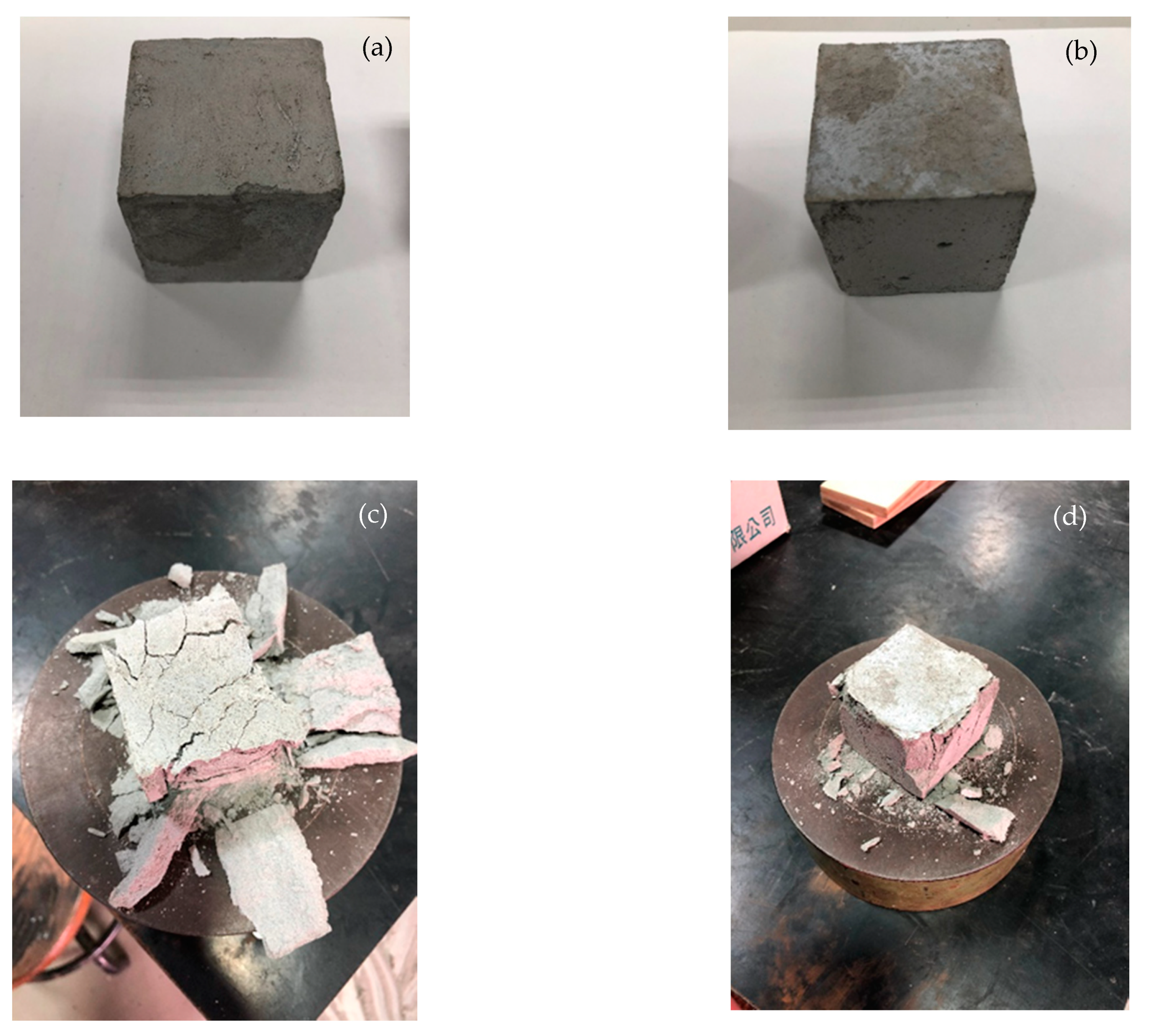

Figure 3 shows the images of concrete samples under different situations. Concretes No. 1 and No. 2 are made of the cement mixed with sand and heated glass fiber, respectively. The organic solvent method cannot remove the surface sizing agent on the outer layer of the waste glass fiber. The removal efficiency of surface sizing agent using organic solvent method is not good and the time for processing is too long. In addition to judging by microscope, it is also judged by XRD spectrum. If it is made into cement, it will crack and not agglomerate.

Figure 3a,b shows that concrete No. 2 has a white color, which may be due to the cristobalite. It can be observed that the surface of concrete No. 2 looks smoother than concrete No. 1, which can be attributed to the fine particle size of the cristobalite. By comparing

Figure 3c,d, concrete No. 2 seems to remain intact, and fails the compressive test at a lower load as compared with concrete No. 1. In addition,

Table 1 lists the compressed strength of different concrete samples. From

Table 1, the compressive strength values of concretes No. 1 and No. 2 are 269.44 and 226.28 kgf/cm

2, respectively. The compressive strength of concrete No. 2 is only 16% lower than that of concrete No. 1. Such compressive strength of concrete No. 2 still reaches the regular structure criteria. Apparently, its compressive strength is much higher than the CLSM industry specification of 84 kgf/cm

2 for drainage roads, irrigation ditches, or for unreinforced concrete structures. Because the cost of sand, treatment income of glass fiber waste, transport fee, and thermal operation cost is around 15, 100, 50, and 30 USD per ton, respectively, the recycling profit is around 35 USD per ton (i.e., 15 + 100 − 5 − 30 = 35).