Recycling of Aseptic Beverage Cartons: A Review

Abstract

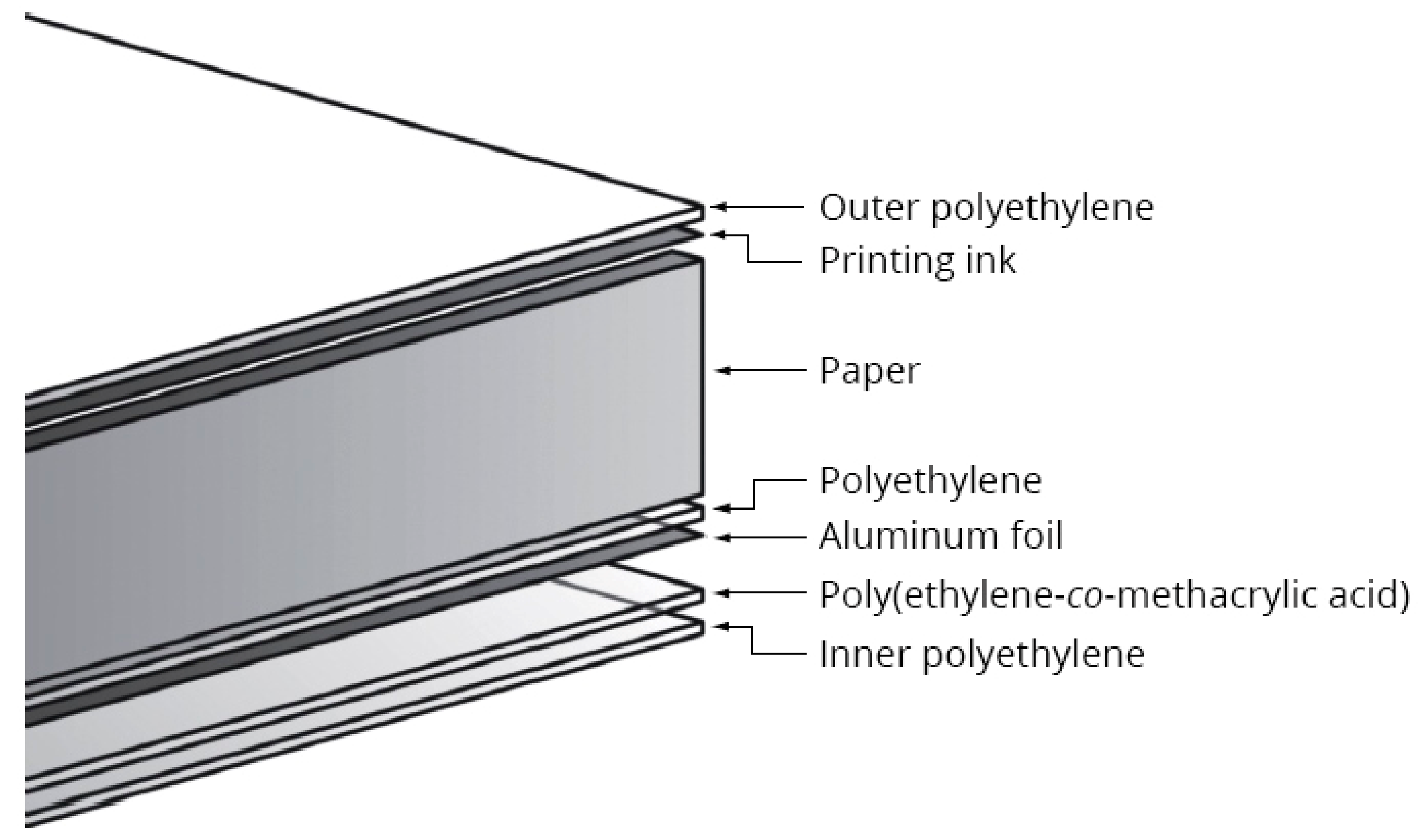

:1. Aseptic Carton Construction

2. Recycling Options

2.1. Recovery of the Paper Fibers

2.2. Construction Materials

2.2.1. Veneers

2.2.2. Addition of Plastics

2.2.3. Blends

2.2.4. Fire Performance

2.2.5. Roofing Tiles

2.2.6. Wall Cladding

2.2.7. Layering of Cartons

2.2.8. Irradiation

2.2.9. Novel Application

3. Pyrolysis

4. Recycling the Polyethylene and Aluminum (PolyAl) Residual

4.1. Mechanical

4.2. Chemical

4.3. Thermal

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robertson, G.L. The paper beverage carton: Past and future. Food Technol. 2002, 56, 46–51. [Google Scholar]

- Pieper, G.; Petersen, K. Free fatty acids from orange juice absorption into laminated cartons and their effects on adhesion. J. Food Sci. 1995, 60, 1088–1091. [Google Scholar] [CrossRef]

- Lopes, C.M.A.; Felisberti, M.I. Composite of low-density polyethylene and aluminum obtained from the recycling of postconsumer aseptic packaging. J. Appl. Polym. Sci. 2006, 101, 3183–3191. [Google Scholar] [CrossRef]

- Colvin, R. Tetra Pak Makes Materials Change for Liquids Packaging. Plastics Today 9th February 2006. Available online: www.plasticstoday.com/tetra-pak-makes-materials-change-liquids-packaging/ (accessed on 23 November 2020).

- Zawadiak, J.; Wojciechowski, S.; Piotrowski, T.; Krypa, A. Tetra Pak recycling—current trends and new developments. Am. J. Chem. Eng. 2017, 5, 37–42. [Google Scholar] [CrossRef] [Green Version]

- Henshaw, J.M.; Han, W. An overview of recycling issues for composite materials. J. Thermoplast. Compos. Mater. 1996, 9, 4–20. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Alliance for Beverage Cartons and the Environment. Available online: www.beveragecarton.eu/wp-content/uploads/2020/06/ACE_best_practices_BC_recycling_202006.pdf (accessed on 11 February 2021).

- Carton Council. Available online: www.recyclecartons.com/about/ (accessed on 11 February 2021).

- Bajpai, P. Stock preparation. In Biermann’s Handbook of Pulp and Paper: Paper and Board Making, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 2, pp. 65–76. [Google Scholar]

- Abreu, M. Recycling the Fibres on Tetra Pak Cartons; Tetra Pak Canada Inc.: Markham, ON, Canada, 2000; p. 44. [Google Scholar]

- Hyder, A.; Nyström, T. Method and Apparatus for Separating Paper Fiber and Plastics from Mixed Waste Materials and Products Obtained Thereby. U.S. Patent US5390860A, 14 April 1993. [Google Scholar]

- Platnieks, O.; Barkane, A.; Ijudina, N.; Gaidukova, G.; Thakur, V.K.; Gaidukovs, S. Sustainable tetra pak recycled cellulose/Poly(Butylene succinate) based woody-like composites for a circular economy. J. Clean. Prod. 2020, 270, 122321. [Google Scholar] [CrossRef]

- Downs, M.L.; Schmitt, M.G. Composite Board and Method of Manufacture. U.S. Patent 3718536, 22 April 1970. [Google Scholar]

- Nilsson, I. A Method for the Manufacture of Fibreboards. European Patent 0358119A1, 1 September 1989. [Google Scholar]

- Heuser, H.; Knorr, N. Process for the Production of a Composite Particle Object and Object so Obtained. European Patent 0588023A1, 22 July 1993. [Google Scholar]

- Günther, J.; Ridder, C. SONY: Addressing different stages of the product’s life cycle. UNEP Ind. Environ. 1997, 20, 28. [Google Scholar]

- Nyström, T. Production of Panel Board—A World Overview; Tetra Pak Carton Packaging Division: Lund, Sweden, 2000; p. 11. [Google Scholar]

- Peña, M.; Méndez, M.; Chacón, R. Multifactorial analysis for the characterization and prototyping of recyclable cardboard panels of short and long term. Artículo Investig. Rev. Cienc. Ing. 2016, 37, 177–186. [Google Scholar]

- Quintero, M.; Rodríguez, P.; Rubio, J.; Jaramillo, L.; Nuñez-Moreno, F. Bending and compression characterization of hollow structural elements made of recycled Tetra Pak®-Based Boards (RTPBB) and an approximated calculation of the carbon footprint involved in their production. Rev. Ing. Construcción 2018, 32, 131–148. [Google Scholar] [CrossRef] [Green Version]

- Ayrilmis, N.; Candan, Z.; Hiziroglu, S. Physical and mechanical properties of cardboard panels made from used beverage carton with veneer overlay. Mater. Des. 2008, 29, 1897–1903. [Google Scholar] [CrossRef]

- Sen, S.; Ayrilmis, N.; Candan, Z. Fungicide and insecticide properties of cardboard panels made from used beverage carton with veneer overlay. Afr. J. Agric. Res. 2010, 5, 159–165. [Google Scholar]

- Rhamin, H.; Madhoushi, M.; Ebrahimi, A.; Faraji, F. Effect of resin content, press time and overlaying on physical and mechanical properties of carton board made from recycled beverage carton and MUF resin. Life Sci. J. 2013, 10, 613–619. [Google Scholar]

- Murathan, A.; Murathan, A.S.; Gürü, M.; Balbas, M. Manufacturing low density boards from waste cardboards containing aluminium. Mater. Des. 2007, 28, 2215–2217. [Google Scholar] [CrossRef]

- Parada-Soria, A.; Yao, H.F.; Alvarado-Tenorio, B.; Sanchez-Cadena, L.; Romo-Uribe, A. Recycled HDPE-tetrapack composites. Isothermal crystallization light scattering and mechanical properties. MRS Online Proc. Library 2012, 1485, 77–82. [Google Scholar] [CrossRef]

- Carrillo, J.G.; Ventura, D.A.P.; Gamboa, R.A.; Cruz-Estrada, R.H. Improvement on mechanical properties of a particle board made of recycled material based on Tetra Brik®. Mater. Res. Soc. Symp. Proc. 2014, 1611, 13–18. [Google Scholar] [CrossRef]

- Chan-Koyoc, M.C.; Cruz-Estrada, R.H.; Cruz-Delgado, V.J.; Carrillo, J.G. Effect of natural and accelerated aging on the mechanical performance of a composite based on recycled multilayer carton. J. Polym. Environ. 2019, 27, 2509–2522. [Google Scholar] [CrossRef]

- Bekhta, P.; Lyutyy, P.; Hiziroglu, S.; Ortynska, G. Properties of composite panels made from Tetra Pak and polyethylene waste material. J. Polym. Environ. 2016, 24, 159–165. [Google Scholar] [CrossRef]

- Aranda-García, F.J.; González-Pérez, M.M.; Robledo-Ortíz, J.R.; Sedano-de la Rosa, C.; Espinoza, K.; Ramírez-Arreola, D.E. Influence of processing time on physical and mechanical properties of composite boards made of recycled multilayer containers and HDPE. J. Mater. Cycles Waste Manag. 2020, 22, 2020–2028. [Google Scholar] [CrossRef]

- Guillén-Mallette, J.; Carrillo-Baeza, J.; Aranda-Ayala, A.; Rivero- Ayala, M. Optimization of processability and physical and mechanical properties of extruded polyethylene—Tetra Pak cartons composites by experimental design. J. Thermoplast. Compos. Mater. 2019, 1–26. [Google Scholar] [CrossRef]

- Hwang, G.-S.; Wang, E.-C.; Su, Y.-C. Preparation of composite board using foil-laminated and plastic-laminated liquid packaging paperboard as raw materials. J. Wood Sci. 2006, 52, 230–235. [Google Scholar] [CrossRef]

- Moya, R.; Camacho, D.; Mata, J.; Fallas, R.S. Fungal decay, coating, burning properties and change of color of particleboards manufactured with woody biomass, agricultural wastes and Tetra Pak residues. J. Biomater. Nanobiotech. 2013, 4, 334–342. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Zhang, Q.-H. Study on the optimum hot-pressing process and surface decoration of waste Tetra Pak/sawdust composite board. Adv. Mater. Res. 2013, 710, 147–151. [Google Scholar] [CrossRef]

- Ebadi, M.; Farsi, M.; Narchin, P.; Madhoushi, M. The effect of beverage storage packets (Tetra Pak™) waste on mechanical properties of wood–plastic composites. J. Thermoplast. Compos. Mater. 2016, 29, 1601–1610. [Google Scholar] [CrossRef]

- Ebadi, M.; Farsi, M.; Narchin, P. Some of the physical and mechanical properties of composites made from Tetra Pak™/LDPE. J. Thermoplast. Compos. Mater. 2017, 31, 1054–1065. [Google Scholar] [CrossRef]

- Hassanin, A.H.; Candan, Z. Novel Bio-Based Composites Panels from Tetra Pak Waste. Key Eng. Mater. 2016, 689, 138–142. [Google Scholar] [CrossRef]

- Nassef, M.G.; El-Galy, I.; Hassanin, A. Mechanical and dynamic characterization of sustainable composites based on food packaging waste. MATEC Web Conf. 2018, 249, 01002. [Google Scholar] [CrossRef] [Green Version]

- Hassanin, A.H.; Candan, Z.; Demirkir, C.; Hamouda, T. Thermal insulation properties of hybrid textile reinforced biocomposites from food packaging waste. J. Ind. Text. 2018, 47, 1024–1037. [Google Scholar] [CrossRef]

- Mohareb, A.O.S.; Hassanin, A.H.; Candelier, K.; Thévenon, M.F.; Candan, Z. Developing biocomposites panels from food packaging and textiles wastes: Physical and biological performance. J. Polym. Environ. 2017, 25, 126–135. [Google Scholar] [CrossRef]

- Hamouda, T.; Hassanin, A.H.; Saba, N.; Demirelli, M.; Kilic, A.; Candan, Z.; Jawaid, M. Evaluation of mechanical and physical properties of hybrid composites from food packaging and textiles wastes. J. Polym. Environ. 2019, 27, 489–497. [Google Scholar] [CrossRef]

- Figen, A.K.; Terzi, E.; Yilgör, N.; Kartal, S.N.; Piskin, S. Thermal degradation characteristic of Tetra Pak panel boards under inert atmosphere. Korean J. Chem. Eng. 2013, 30, 878–890. [Google Scholar] [CrossRef]

- Yilgor, N.; Köse, C.; Terzi, E.; Figen, A.K.; Ibach, R.; Kartal, S.N.; Piskin, S. Degradation behavior and accelerated weathering of composite boards produced from waste Tetra Pak® packaging materials. BioResources 2014, 9, 4784–4807. [Google Scholar] [CrossRef]

- Xu, C.; Jian, W.; Xing, C.; Zhou, H.; Zhao, Y.; Pan, H.; Xiong, X. Flame retardancy and mechanical properties of thermal plastic composite panels made from Tetra Pak waste and high-density polyethylene. Polym. Compos. 2016, 37, 1797–1804. [Google Scholar] [CrossRef]

- Araújo, D.C.; Morais, C.R.S.; Altides, M.E.D. Avaliação mecânica e físico-química entre telhas convencionais e alternativas usadas em habitações populares. Mechanical and physical-chemical evaluation between conventional and alternative tiles used in popular housing. J. Mater. Process. 2008, 3, 50–56. [Google Scholar]

- Foti, D.; Adamopoulos, S.; Voulgaridis, E.; Passialis, C.; Amiandamhen, S.O.; Daniel, G. Microstructure and compressive strength of gypsum-bonded composites with papers, paperboards and Tetra Pak recycled materials. J. Wood Sci. 2019, 65, 42–50. [Google Scholar] [CrossRef]

- Gallego, S.M.; Aponte, A.G.; Sierra, R.B.; Marín, J.F. Evaluation of mechanical properties of composites manufactured from recycled Tetra Pak containers. Tecnura 2020, 24, 36–46. [Google Scholar] [CrossRef]

- Antón, N.; González-Fernández, Á.; Villarino, A. Reliability and mechanical properties of materials recycled from multilayer flexible packages. Materials 2020, 13, 3992. [Google Scholar] [CrossRef]

- Olfos, L.; Valdes, F.; Sarabia, G.; Barros, P. Thermal insulating panels based on recycled Tetra-Pak® packaging materials. IOP Conf. Ser. Earth and Environ. Sci. 2020, 503, 012076. [Google Scholar] [CrossRef]

- Pons, O.; Abt, T. Evaluation of household waste materials for façade components in primary educational workshops. Mechanical and fire properties. J. Build. Eng. 2020, 29, 101202. [Google Scholar] [CrossRef]

- Habibi, S.; Pons, O.; Abt, T. Evaluation of household waste materials for façade components in primary educational workshops. Degradation behavior and mechanical properties of aged samples. J. Build. Eng. 2021, 33, 101573. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Barrera-Díaz, C.E.; Cuevas-Yañez, E.; Varela-Guerrero, V.; Vigueras-Santiago, E.; Ávila-Córdoba, L.; Martínez-López, M. Waste cellulose from Tetra Pak packages as reinforcement of cement concrete. Adv. Mater. Sci. Eng. 2015, 682926. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Barrera, G.; del Coz-Diaz, J.J.; Alonso-Martínez, M.; Martínez-López, M. Lamellae of waste beverage packaging (Tetra Pak) and gamma radiation as tools for improvement of concrete. Case Stud. Constr. Mater. 2020, 12, e00315. [Google Scholar] [CrossRef]

- Martínez-López, M.; Martínez-Barrera, G.; Barrera-Díaz, C.; Ureña-Núñez, F.; Laredo dos Reis, J.M. Waste Tetra Pak particles from beverage containers as reinforcements in polymer mortar: Effect of gamma irradiation as an interfacial coupling factor. Constr. Build. Mater. 2016, 121, 1–8. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Martínez-López, M.; González-Rivas, N.; del Coz-Diaz, J.J.; Ávila-Córdoba, L.; Laredo dos Reis, J.M.; Gencel, O. Recycled cellulose from Tetra Pak packaging as reinforcement of polyester based composites. Constr. Build. Mater. 2017, 157, 1018–1023. [Google Scholar] [CrossRef]

- Xu, C.; Liu, J.; Zhu, X.; Zhu, Y.; Xiong, X.; Cheng, X. Electromagnetic interference shielding boards produced using Tetra Paks waste and iron fiber. J. Mater. Cycles Waste Manag. 2015, 17, 391–398. [Google Scholar] [CrossRef]

- Arshad, H.; Sulaiman, S.A.; Hussain, Z.; Naz, Y.; Basrawi, F. Microwave assisted pyrolysis of plastic waste for production of fuels: A review. MATEC Web Conf. 2017, 131, 02005. [Google Scholar] [CrossRef] [Green Version]

- Korkmaz, A.; Yanik, J.; Brebu, M.; Vasile, C. Pyrolysis of the tetra pak. Waste Manag. 2009, 29, 2836–2841. [Google Scholar] [CrossRef] [PubMed]

- Zúñiga-Muro, N.M.; Bonilla-Petriciolet, A.; Mendoza-Castillo, D.I.; Duran-Valle, C.J.; Silvestre-Albero, J.; Reynel-Ávila, H.E.; Tapia-Picazo, J.C. Recycling of Tetra pak wastes via pyrolysis: Characterization of solid products and application of the resulting char in the adsorption of mercury from water. J. Clean. Prod. 2021. [Google Scholar] [CrossRef]

- Haydary, J.; Dudáš, D.S.J. Pyrolysis of aseptic packages (tetrapak) in a laboratory screw type reactor and secondary thermal/catalytic tar decomposition. Waste Manag. 2013, 33, 1136–1141. [Google Scholar] [CrossRef]

- Tekin, K.; Ucar, S.; Karagöz, S. Influence of co-pyrolysis of waste Tetra Pak with waste motor oil on product distribution and properties for fuel application. Energy Fuels 2019, 33, 11101–11112. [Google Scholar] [CrossRef]

- Lokahita, B.; Aziz, M.; Yoshikawa, K.; Takahashi, F. Energy and resource recovery from Tetra Pak waste using hydrothermal treatment. Appl. Energy 2017, 207, 107–113. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhu, Y.; Liu, Z.; Su, J.; Fang, C.; Xu, D.; Song, W.; Wang, S. Influences of operating parameters on liquefaction performances of Tetra Pak in sub-/supercritical water. J. Environ. Manag. 2019, 237, 545–551. [Google Scholar] [CrossRef]

- Von Zuben, F.; Neves, F.L. Recycling of Aluminum and Polyethylene Present in Tetra Pak Carton Packaging; International Aluminum Recycling Seminar: São Paulo, Brazil, 1999; pp. 96–109. [Google Scholar]

- Von Zuben, F.; Neves, F.L. Recycling of aluminum and polyethylene from Tetra Pak carton packages as plastic composite. In Proceedings of the GPEC 2003—Global Plastics Environmental Council, Detroit, MI, USA, 26–27 February 2003. [Google Scholar]

- Von Zuben, F.; Orsato, R.J.; Van Wassenhove, L. Turning waste into wealth. Int. Commer. Rev. 2007, 7, 116–123. [Google Scholar] [CrossRef]

- Hidalgo, M. Manufacturing rigid board by packaging waste containing aluminum and polyethylene. J. Sci. Ind. Res. 2011, 70, 232–234. [Google Scholar]

- Hidalgo-Salazar, M.A.; Neves, F.L.; Baena, E. Possibilities of fabrication of aluminium polyethylene obtained from multilayer package recycling. Inf. Técnico 2013, 77, 100–109. [Google Scholar]

- Hidalgo-Salazar, M.A.; Mina, J.H.; Herrera-Franco, P.J. The effect of interfacial adhesion on the creep behaviour of LDPE–Al–Fique composite materials. Compos. Part B 2013, 55, 345–351. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Muñoz, M.F.; Mina, J.H. Influence of incorporation of natural fibers on the physical, mechanical, and thermal properties of composites LDPE-Al reinforced with fique fibers. Int. J. Polym. Sci. 2015, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-Vélez, M.F.; Hidalgo-Salazar, M.A.; Mina-Hernández, J.H. Effect of content and surface modification of fique fibers on the properties of a low-density polyethylene (LDPE)-Al/Fique composite. Polymers 2018, 10, 1050. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayrilmis, N.; Kaymakci, A.; Akbulut, T.; Elmas, G.M. Mechanical performance of composites based on wastes of polyethylene aluminum and lignocellulosics. Compos. Part B 2013, 47, 150–154. [Google Scholar] [CrossRef]

- Ovchinnikov, V.; Mastalygina, E.E.; Pantyukhov, P. Investigation of novel polymer composites based on recycled multilayer combined packaging materials. Solid State Phenom. 2020, 299, 94–99. [Google Scholar] [CrossRef]

- Valim, F.C.F.; Silveira, D.C.; Costa, M.L.; Pereira, M.S.; Botelho, E.C. Study of the morphological, thermal and mechanical properties of recycled aluminum and low density polyethylene particulate composite. Matéria 2015, 20, 852–865. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Alvareza, A.; De la Torre Ibarrab, M.H.; Santoyo, F.M. Thermal performance comparison of recycled and clay roof tiles due heat radiation by digital holographic interferometry. Rev. Mex. Física 2019, 65, 678–683. [Google Scholar] [CrossRef] [Green Version]

- Lecce, R.; Cerutti, S. Method for Recycling Composite Material. European Patent 2123418A1, 21 May 2008. [Google Scholar]

- Cravero, F.; Frache, A. Improving fire performances of PEAL: More second-life options for recycled Tetra Pak®. Polymers 2020, 12, 2357. [Google Scholar] [CrossRef]

- Johansson, H.; Ackermann, P.W. Method of Recovering Individual Component Parts from Packaging Material Waste. U.S. Patent 5421526, 27 May 1992. [Google Scholar]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of polymer-based multilayer packaging: A review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Prawisudha, P.; Mu’min, G.F.; Yoshikawa, K.; Pasek, A.D. Experimental study on separation of metal layer in aluminum-plastic packaging by employing hydrothermal process. In Proceedings of the Advancement in Technology and Management for Tomorrow; 2014. Available online: https://www.semanticscholar.org/paper/Experimental-Study-on-Separation-of-Metal-Layer-in-Prawisudha-Mu%E2%80%99min/73dce3b6c9c000728e6920f6437f42a067eabd39 (accessed on 24 January 2021).

- Mu’min, G.F.; Prawisudha, P.; Zaini, I.N.; Aziz, M.; Pasek, A.D. Municipal solid waste processing and separation employing wet torrefaction for alternative fuel production and aluminum reclamation. Waste Manag. 2017, 67, 106–120. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.F.; Yan, D.H.; Li, Z.H. The recycling of the Tetra-Pak packages: Research on the wet process separation conditions of aluminum and polythene in the Tetra-Pak packages. In Proceedings of the 2009 3rd International Conference on Bioinformatics and Biomedical Engineering, Beijing, China, 11–13 June 2009. [Google Scholar]

- Zhang, S.F.; Zhang, L.L.; Luo, K.; Sun, Z.X.; Mei, X.X. Separation properties of aluminium–plastic laminates in post-consumer Tetra Pak with mixed organic solvent. Waste Manag. Res. 2014, 32, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Luo, K.; Zhang, L.; Mei, X.; Cao, S.; Wang, B. Interfacial separation and characterization of Al–PE composites during delamination of post-consumer Tetra Pak materials. J. Chem. Technol. Biotechnol. 2015, 90, 1152–1159. [Google Scholar] [CrossRef]

- Yan, D.; Peng, Z.; Liu, Y.; Huang, Q.; Xie, M.; Wang, Q. Optimizing and developing a continuous separation system for the wet process separation of aluminum and polyethylene in aseptic composite packaging waste. Waste Manag. 2015, 35, 21–28. [Google Scholar] [CrossRef]

- Rodríguez-Gómez, J.E.; Silva-Reynoso, Y.Q.; Varela-Guerrero, V.; Núñez-Pineda, A.; Barrera-Díaz, C.E. Development of a process using waste vegetable oil for separation of aluminum and polyethylene from Tetra Pak. Fuel 2015, 149, 90–94. [Google Scholar] [CrossRef]

- Samorì, C.; Cespi, D.; Blair, P.; Galletti, P.; Malferrari, D.; Passarini, F.; Vassura, I.; Tagliavini, E. Application of switchable hydrophilicity solvents for recycling multilayer packaging materials. Green Chem. 2017, 19, 1714–1720. [Google Scholar] [CrossRef]

- Pappa, G.; Boukouvalas, C.; Giannaris, C.; Ntaras, N.; Zografos, V.; Magoulas, K.; Lygeros, A.; Tassios, D. The selective dissolution/precipitation technique for polymer recycling: A pilot unit application. Resour. Conserv. Recycl. 2001, 34, 33–44. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Lv, X.D.; Ni, H.G. Solvent-based separation and recycling of waste plastics: A review. Chemosphere 2018, 209, 707–720. [Google Scholar] [CrossRef]

- Georgiopoulou, I.; Pappa, G.D.; Vouyiouka, S.N.; Magoulas, K. Recycling of post-consumer multilayer Tetra Pak® packaging with the Selective Dissolution-Precipitation process. Resour. Conserv. Recycl. 2021, 165, 105268. [Google Scholar] [CrossRef]

- Tagliavini, E.; Galletti, P.; Samori, C.; Malferrari, D. Method for Separating and Recovering Polyethylene and Aluminum from a Polylaminate Material. World Patent WO 2018/087653 A2, 7 November 2017. [Google Scholar]

- Mumladze, T.; Yousef, S.; Tatariants, M.; Kriūkienė, R.; Makarevicius, V.; Lukošiūtė, S.-I.; Bendikieneb, R.; Denafasa, G. Sustainable approach to recycling of multilayer flexible packaging using switchable hydrophilicity solvents. Green Chem. 2018, 20, 3604–3618. [Google Scholar] [CrossRef]

- Nieminen, J.; Anugwoma, I.; Kallioinen, M.; Mänttäri, M. Green solvents in recovery of aluminium and plastic from waste pharmaceutical blister packaging. Waste Manag. 2020, 107, 20–27. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, M.Z.; Park, Y.K.; Kang, Y.; Watanabe, A.; Kim, S.; Kim, Y.M. Effective use of aluminum-plastic laminate as a feedstock for catalytic pyrolysis over micro and mesoporous catalysts. J. Clean. Prod. 2019, 229, 1093–1101. [Google Scholar] [CrossRef]

- Yin, S.; Rajarao, R.; Gong, B.; Wang, Y.; Kong, C.; Sahajwalla, V. Thermodelamination of metallised composite plastic: An innovative approach to generate aluminium from packaging plastic waste. J. Clean. Prod. 2019, 211, 321–329. [Google Scholar] [CrossRef]

- Dave, P.N.; Joshi, A.K. Plasma pyrolysis and gasification of plastics waste—A review. J. Sci. Ind. Res. 2010, 69, 177–179. [Google Scholar]

- Hepworth, M.T.; Tylko, J.K.; Han, H. Treatment of electric arc furnace dust with a sustained shockwave plasma reactor. Waste Manag. Res. 1993, 11, 415–427. [Google Scholar] [CrossRef]

- European Commission. LIFE Program—Project CLEAN: Converting Laminates into Energy and Aluminium for the Benefit of Nature, LIFE06 ENV/E/000010. 2010. Available online: https://ec.europa.eu/environment/life/project/Projects/index.cfm?fuseaction=home.getProjects&themeID=70&projectList (accessed on 17 December 2020).

- Ludlow-Palafox, C.; Chase, H.A. Microwave-induced pyrolysis of plastic wastes. Ind. Eng. Chem. Res. 2001, 40, 4749–4756. [Google Scholar] [CrossRef]

- Ludlow-Palafox, C.; Chase, H.A. Microwave Induced Pyrolysis Reactor and Method. U.S. Patent 7951270 B2, 31 May 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Robertson, G.L. Recycling of Aseptic Beverage Cartons: A Review. Recycling 2021, 6, 20. https://doi.org/10.3390/recycling6010020

Robertson GL. Recycling of Aseptic Beverage Cartons: A Review. Recycling. 2021; 6(1):20. https://doi.org/10.3390/recycling6010020

Chicago/Turabian StyleRobertson, Gordon L. 2021. "Recycling of Aseptic Beverage Cartons: A Review" Recycling 6, no. 1: 20. https://doi.org/10.3390/recycling6010020

APA StyleRobertson, G. L. (2021). Recycling of Aseptic Beverage Cartons: A Review. Recycling, 6(1), 20. https://doi.org/10.3390/recycling6010020