Organic Material for Clean Production in the Batik Industry: A Case Study of Natural Batik Semarang, Indonesia

Abstract

1. Introduction

2. Results

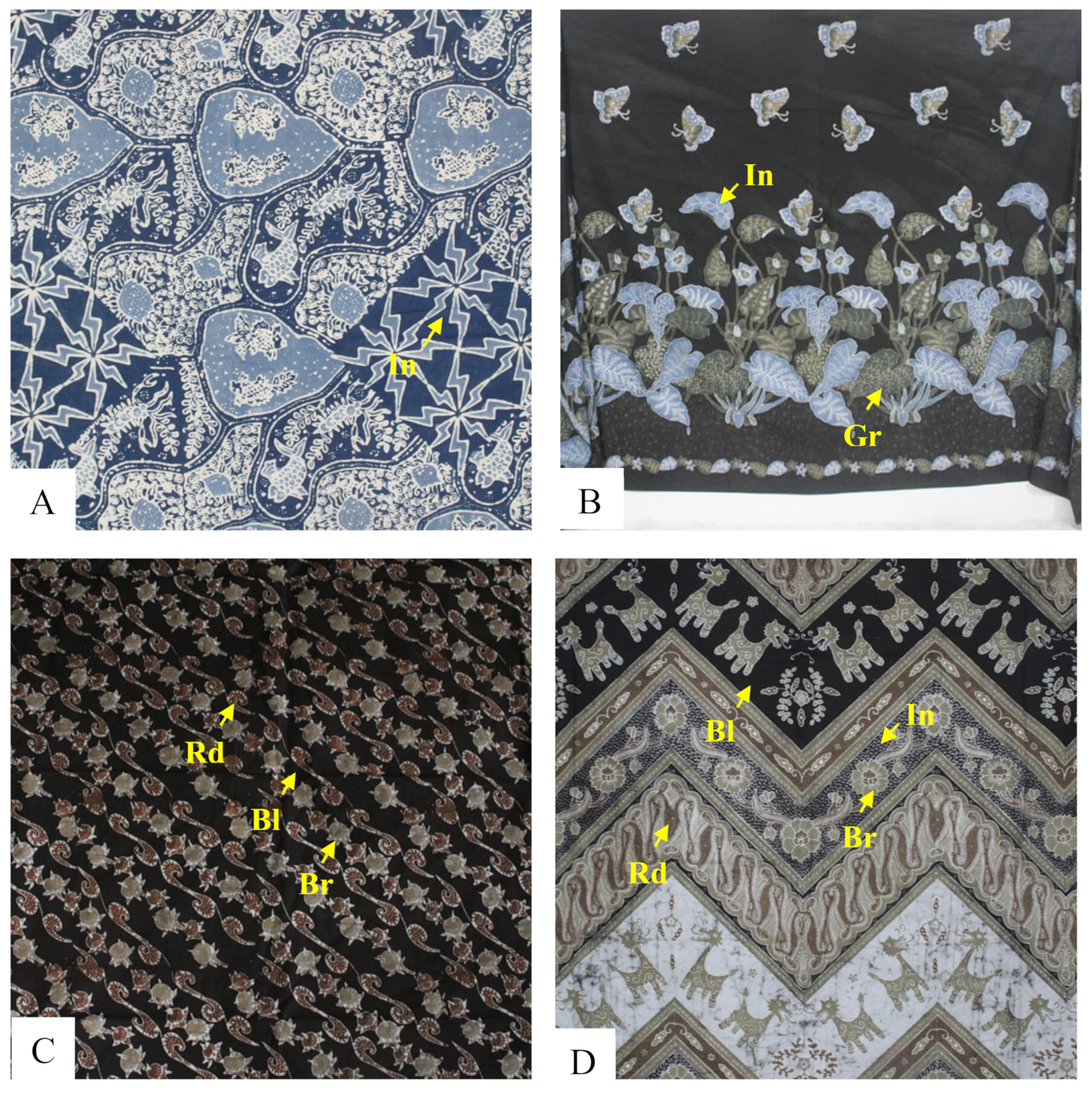

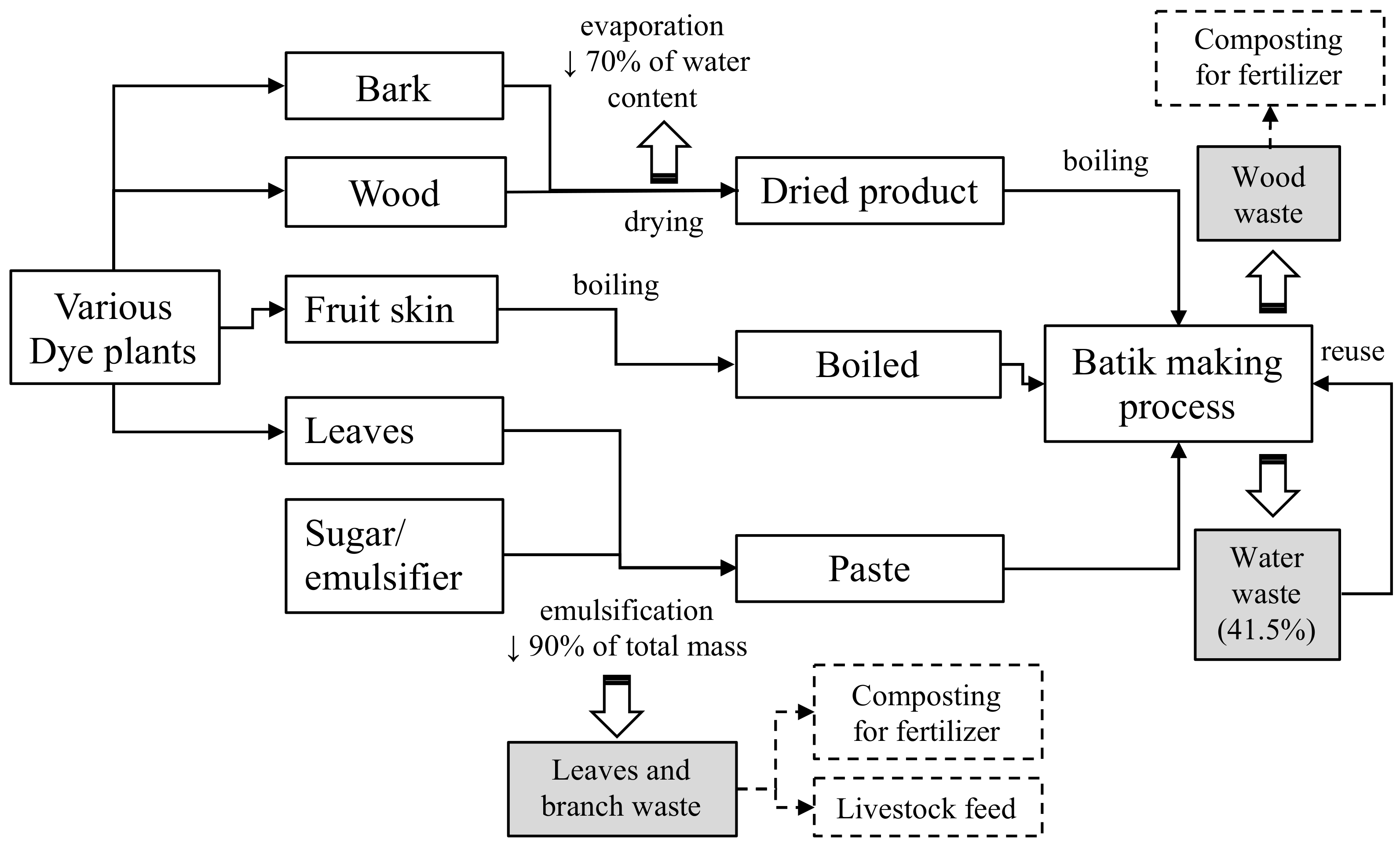

2.1. The Batik Motif and Organic Material for Natural Dye

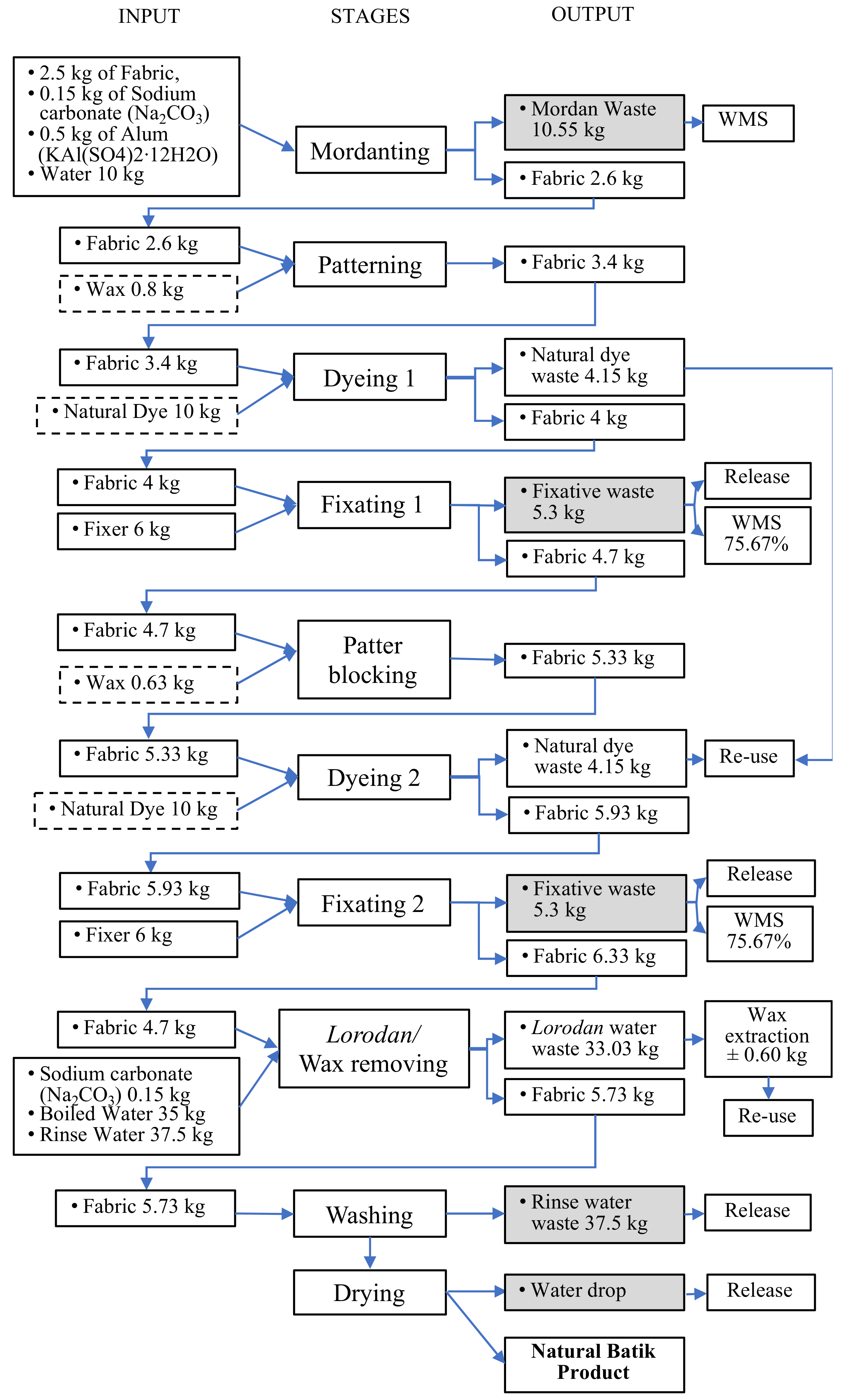

2.2. Clean Production Management Scheme

2.3. Clean Production Improvement Strategy

3. Discussion

4. Materials and Methods

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Steelyana, E.; Batik, A. Beautiful Cultural Heritage that Preserve Culture and Supporteconomic Development in Indonesia. Binus Bus. Rev. 2012, 3, 116. [Google Scholar] [CrossRef]

- Krisnawati, E.; Sunarni, N.; Indrayani, L.M.; Sofyan, A.N.; Nur, T. Identity Exhibition in Batik Motifs of Ebeg and Pataruman. SAGE Open 2019, 9, 2158244019846686. [Google Scholar] [CrossRef]

- Tresnadi, C.; Sachari, A. Identification of Values of Ornaments in Indonesian Batik in Visual Content of Nitiki Game. J. Arts Humanit. 2015, 4, 25–39. [Google Scholar]

- Rudianto, M.; Sulistyati, A.; Rizali, N.; Faizin, A. Batik Sudagaran as Cultural Creation of the Laweyan’s Merchants; Seword Press: Surakarta, Indonesia, 2019. [Google Scholar]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Thiripuranthagan, S.; Rupa, V. Detoxification of Carcinogenic Dyes by Noble Metal (Ag, Au, Pt) Impregnated Titania Photocatalysts. In Gold Nanoparticles-Reaching New Heights; IntechOpen: Rijeka, Croatia, 2019; pp. 1–26. [Google Scholar]

- Chung, K.T. Azo dyes and human health: A review. J. Environ. Sci. Heal. Part C Environ. Carcinog. Ecotoxicol. Rev. 2016, 34, 233–261. [Google Scholar] [CrossRef]

- Budiyanto, S.; Anies; Purnaweni, H.; Sunoko, H.R. Environmental Analysis of the Impacts of Batik Waste Water Polution on the Quality of Dug Well Water in the Batik Industrial Center of Jenggot Pekalongan City. E3S Web Conf. 2018, 31, 09008. [Google Scholar] [CrossRef]

- Naqsyabandi, S.; Riani, E.; Suprihatin, S. Impact of batik wastewater pollution on macrobenthic community in Pekalongan River. AIP Conf. Proc. 2018, 2023, 020128. [Google Scholar]

- Lestari, S.; Sudarmadji; Tandjung, S.D.; Santosa, S.J. Lethal toxicity of Batik waste water bio-sorption results in Tilapia (Oreochromis niloticus). Adv. Sci. Lett. 2017, 23, 2611–2613. [Google Scholar] [CrossRef]

- Syauqiah, I.; Nurandini, D.; Lestari, R. Study of Potential Pollution of Sasirangan Liquid Waste with Biological and Chemical Parameters. BIO Web Conf. 2020, 20, 02003. [Google Scholar] [CrossRef]

- Joko, T.; Dangiran, H.L.; Astorina, N.; Dewanti, Y. The Effectiveness of Plant Pistia Stratiotes Weight to Reduction of Heavy Metal Content Chromium (Cr) Waste at Batik Home Industry in Regency of Pekalongan. Int. J. Sci. Basic Appl. Res. 2015, 24, 45–54. [Google Scholar]

- Arifan, F.; Winarni, S. Analysis of copper and lead on coastal environment a case study of Kaliprau coastal, Pemalang. Adv. Sci. Lett. 2017, 23, 3534–3536. [Google Scholar] [CrossRef]

- Yaacob, M.R.; Ismail, M.; Zakaria, M.N.; Zainol, F.A.; Zain, N.F.M. Environmental Awareness of Batik Entrepreneurs in Kelantan, Malaysia—An Early Insight. Int. J. Acad. Res. Bus. Soc. Sci. 2015, 5, 338–347. [Google Scholar] [CrossRef]

- Rezagama, A.; Sutrisno, E.; Handayani, D.S. Pollution Model of Batik and Domestic Wastewater on River Water Quality. IOP Conf. Ser. Earth Environ. Sci. 2020, 448, 012074. [Google Scholar] [CrossRef]

- Kasiri, M.B.; Safapour, S. Natural dyes and antimicrobials for green treatment of textiles. Environ. Chem. Lett. 2014, 12, 1–13. [Google Scholar] [CrossRef]

- Basak, S.; Senthilkumar, T.; Krishnaprasad, G.; Jagajanantha, P. Sustainable Development in Textile Processing. In Sustainable Green Chemical Processes and their Allied Applications; Inamuddin Asiri, A., Ed.; Springer Nature: Mumbai, India, 2020; pp. 560–571. ISBN 978-3-030-42283-7. [Google Scholar]

- Sinaga, A.S.R. Color-based Segmentation of Batik Using the L*a*b Color Space. SinkrOn 2019, 3, 175–179. [Google Scholar] [CrossRef]

- Fessehaie, J. Leveraging the Services Sector for Inclusive Value Chains in Developing Countries; International Centre for Trade and Sustainable Development (ICTSD): Geneva, Switzerland, 2017. [Google Scholar]

- Nandamudi, S.K.; Sen, A. Landscape Restoration and Community Involvement in Biodiversity Conservation. In Corporate Biodiversity Management for Sustainable Growth; Sharma, R., Watve, A., Pandey, A., Eds.; Springer Nature: Pune, India, 2020; pp. 127–150. ISBN 9783030427023. [Google Scholar]

- Baik, Y.; Park, Y.R. Managing legitimacy through corporate community involvement: The effects of subsidiary ownership and host country experience in China. Asia Pac. J. Manag. 2019, 36, 971–993. [Google Scholar] [CrossRef]

- Zerin, I.; Farzana, N.; Sayem, A.S.M.; Anang, D.M.; Haider, J. Potentials of Natural Dyes for Textile Applications. Encycl. Renew. Sustain. Mater. 2020, 873–883. [Google Scholar] [CrossRef]

- Rahadi, R.A. The Analysis of Consumers’ Preferences for Batik Products in Indonesia. Rev. Integr. Bus. Econ. Res. 2020, 9, 278–287. [Google Scholar]

- Sánchez-Muñoz, S.; Mariano-Silva, G.; Leite, M.O.; Mura, F.B.; Verma, M.L.; Da Silva, S.S.; Chandel, A.K. Production of Fungal and Bacterial Pigments and Their Applications; Elsevier, B.V.: Oxford, UK, 2019; ISBN 9780444643230. [Google Scholar]

- Verma, S.; Gupta, G. Natural dyes and its applications: A brief review. Int. J. Res. Anal. Rev. 2017, 4, 57–60. [Google Scholar]

- Kusumawati, N.; Samik, S.; Kristyanto, A. Quality Improvement of ABBS Hand Writing Batik Production through Standardization of Natural Dyeing using Water Guava and Mango Leaves. Atl. Highlights Chem. Pharm. Sci. 2020, 1, 29–32. [Google Scholar]

- Indrianingsih, A.W.; Darsih, C. Natural Dyes from Plants Extract and Its Applications in Indonesian Textile Small Medium Scale Enterprise. Eksergi 2014, 11, 16. [Google Scholar] [CrossRef][Green Version]

- Bhuiyan, M.A.R.; Islam, A.; Ali, A.; Islam, M.N. Color and chemical constitution of natural dye henna (Lawsonia inermis L) and its application in the coloration of textiles. J. Clean. Prod. 2017, 167, 14–22. [Google Scholar] [CrossRef]

- Hasibuan, S.; Hidayati, J. The Integration of Cleaner Production Innovation and Creativity for Supply Chain Sustainability of Bogor Batik SMEs. Int. J. Ind. Manuf. Eng. 2018, 12, 679–684. [Google Scholar]

- Fatima, A.; Raja, G.K.; Shah, M.A.; Gul, I.; Tabassum, S.; Batool, S.; Ahmed, W.; Ahmad, M.S. Extraction and Evaluation of a Natural Dye From Bistorta Amplexicaule. Pak. J. Sci. 2017, 69, 195. [Google Scholar]

- Najera, F.; Dippold, M.A.; Boy, J.; Seguel, O.; Koester, M.; Stock, S.; Merino, C.; Kuzyakov, Y.; Matus, F. Effects of drying/rewetting on soil aggregate dynamics and implications for organic matter turnover. Biol. Fertil. Soils 2020. [Google Scholar] [CrossRef]

- Alfiyanti, I.L.; Fatoni, R.; Fatimah, S. The Application of Mahagony Bark (Swietenia Mahagony L.) for Natural Dyeing. Adv. Sustain. Sci. Eng. Technol. 2020, 2, 1–7. [Google Scholar]

- Aino, K.; Narihiro, T.; Minamida, K.; Kamagata, Y.; Yoshimune, K.; Yumoto, I. Bacterial community characterization and dynamics of indigo fermentation. FEMS Microbiol. Ecol. 2010, 74, 174–183. [Google Scholar] [CrossRef]

- De Oliveira Rodrigues, P.; Gurgel, L.V.A.; Pasquini, D.; Badotti, F.; Góes-Neto, A.; Baffi, M.A. Lignocellulose-degrading enzymes production by solid-state fermentation through fungal consortium among Ascomycetes and Basidiomycetes. Renew. Energy 2020, 145, 2683–2693. [Google Scholar] [CrossRef]

- Okamoto, T.; Aino, K.; Narihiro, T.; Matsuyama, H.; Yumoto, I. Analysis of microbiota involved in the aged natural fermentation of indigo. World J. Microbiol. Biotechnol. 2017, 33, 1–10. [Google Scholar] [CrossRef]

- Aino, K.; Hirota, K.; Okamoto, T.; Tu, Z.; Matsuyama, H.; Yumoto, I. Microbial communities associated with indigo fermentation that thrive in anaerobic alkaline environments. Front. Microbiol. 2018, 9, 1–16. [Google Scholar] [CrossRef]

- Pattanaik, L.; Duraivadivel, P.; Hariprasad, P.; Naik, S.N. Utilization and re-use of solid and liquid waste generated from the natural indigo dye production process – A zero waste approach. Bioresour. Technol. 2020, 301, 122721. [Google Scholar] [CrossRef]

- Sharma, K.; Garg, V.K. Vermicomposting of Waste; Elsevier, B.V.: Oxford, UK, 2019; ISBN 9780444642004. [Google Scholar]

- Marín, M.; Artola, A.; Sánchez, A. Production of proteases from organic wastes by solid-state fermentation: Downstream and zero waste strategies. 3 Biotech 2018, 8, 205. [Google Scholar] [CrossRef] [PubMed]

- Shabbir, M.; Rather, L.J.; Bukhari, M.N.; Ul-Islam, S.; Shahid, M.; Khan, M.A.; Mohammad, F. Light Fastness and Shade Variability of Tannin Colorant Dyed Wool with the Effect of Mordanting Methods. J. Nat. Fibers 2019, 16, 100–113. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Mondal, M.S.; Hossain, M.N. The Influence of Mordant and Mordanting Techniques on Ecofriendly Dyeing of Cotton Fabric By Extracted Used Tea. J. Eng. Sci. 2018, 9, 111–117. [Google Scholar]

- Manian, A.P.; Paul, R.; Bechtold, T. Metal mordanting in dyeing with natural colourants. Color. Technol. 2016, 132, 107–113. [Google Scholar] [CrossRef]

- Fauzi, A.M.; Defianisa, R.L. Analysis for cleaner production implementation strategy in batik industry in Bogor. IOP Conf. Ser. Earth Environ. Sci. 2019, 325, 012005. [Google Scholar] [CrossRef]

- Handayani, W.; Kristijanto, A.I.; Hunga, A.I.R. A water footprint case study in Jarum village, Klaten, Indonesia: The production of natural-colored batik. Environ. Dev. Sustain. 2019, 21, 1919–1932. [Google Scholar] [CrossRef]

- Jain, M.S.; Daga, M.; Kalamdhad, A.S. Composting physics: A degradation process-determining tool for industrial sludge. Ecol. Eng. 2018, 116, 14–20. [Google Scholar] [CrossRef]

- Musa, H.; Chinniah, M. Malaysian SMEs Development: Future and Challenges on Going Green. Procedia—Soc. Behav. Sci. 2016, 224, 254–262. [Google Scholar] [CrossRef]

- Richards, P.R. Fabric Finishing: Dyeing and Colouring; Elsevier Ltd.: New York, NY, USA, 2015; ISBN 9780857095619. [Google Scholar]

- Indarti Rahayu, I.A.T.; Peng, L.H. Sustainable Batik Production: Review and Research Framework. Adv. Soc. Sci. Educ. Humanit. Res. 2020, 390, 66–72. [Google Scholar]

- Birgani, P.M.; Ranjbar, N.; Abdullah, R.C.; Wong, K.T.; Lee, G.; Ibrahim, S.; Park, C.; Yoon, Y.; Jang, M. An efficient and economical treatment for batik textile wastewater containing high levels of silicate and organic pollutants using a sequential process of acidification, magnesium oxide, and palm shell-based activated carbon application. J. Environ. Manag. 2016, 184, 229–239. [Google Scholar] [CrossRef] [PubMed]

- Sirait, M. Cleaner production options for reducing industrial waste: The case of batik industry in Malang, East Java-Indonesia. Jkt. IOP Conf. Ser. Earth Environ. Sci. 2018, 106, 012069. [Google Scholar] [CrossRef]

- Buthiyappan, A.; Abdul Raman, A.A.; Daud, W.M.A.W. Development of an advanced chemical oxidation wastewater treatment system for the batik industry in Malaysia. RSC Adv. 2016, 6, 25222–25241. [Google Scholar] [CrossRef]

- Harrison, H.; Birks, M.; Franklin, R.; Mills, J. Case study research: Foundations and methodological orientations. Forum Qual. Sozialforsch. 2017, 18. [Google Scholar] [CrossRef]

| Natural Dyes Plant | Vern Name | Colour | Plant Part | Used Product |

|---|---|---|---|---|

| Caesalpinia sappan | Secang | Red | Wood | Dried wood |

| Ceriops candolleana | Tingi | Brown | Fruit skin | Boiled * |

| Maclura cochinchinensis | Tegeran | Yellow | Bark | Dried bark |

| Pelthophorum ferruginum | Soga Jambal | Brown | Bark | Dried bark |

| Indigofera tinctoria | Tarum/Indigo | Blue indigo | Leaves, stem | Paste ** |

| Indigofera arrecta | Indigo | Blue indigo | Leaves, stem | Paste ** |

| Rhizopora spp. | Bakau | Brown | Fruit skin | Boiled * |

| Strobilantes cusia | Indigo | Blue indigo | Leaves | Paste ** |

| Terminalia bellirica | Jelawe | Yellow | Bark | Dried bark |

| Natural Dyes Plant | Sources | Cultivation | By-Product Waste | Waste Management |

|---|---|---|---|---|

| Caesalpinia sappan | Semarang, Central Java | Wide distributed but does not cultivated | Wood shavings | Decomposed or firewood |

| Ceriops candolleana/ C. tagal | Coastal area of Semarang City | - | No waste | - |

| Maclura cochinchinensis | Surakarta, Central Java, originally from Sumatra and Kalimantan | - | Wood pulp | Decomposed |

| Pelthophorum ferruginum * | Surakarta, Central Java | - | - | - |

| Indigofera tinctoria | - | Local farmers | No waste | - |

| Indigofera arecta | - | Local farmers | No waste | - |

| Rhizopora spp. | Coastal area of Semarang City | - | No waste | - |

| Strobilantes cusia | Japan (was introduced in 2016 for dye plant diversification in Malon) | Local farmers | No waste | - |

| Terminalia bellirica | Semarang | - | Wood shavings | Decomposed or timber |

| Step | Problems | Existing Waste Management | Alternative Housekeeping and Waste Management |

|---|---|---|---|

| Mordanting | Wastewater contain Na2CO3 and KAl(SO4)2·12H2O and material of fabric | Reused and deposited in the waste container | Precipitation process to separate solid waste (microfiber) and water purification using a phytoremediation technique |

| Patterning | - | - | - |

| Dyeing 1 and 2 | Natural dye waste | Wood-based dye, the residual product was composted in open areasPaste-based dye was reused until no remaining compound was left | Composting process for wood in a closed and localized place |

| Fixating 1 and 2 | Wastewater contain CaCO3 and FeSO4 | Almost 75% was drained to the environment, and the remaining waste was deposited in the anaerobe-waste container | Streamlining the existing wastewater management installation by increasing the capacity and maintaining the installation |

| Pattern Blocking/waxing | Scattered and evaporated wax | Collected and reused | - |

| Lorodan/Wax removing | Wastewater contain wax | Removing process to collect the wax on the surface, and reused for next pattern blocking/waxing | Draining the remaining wastewater to the wastewater management installation |

| Washing and Drying | Water drop on the floor | Discharged into the environment | Applying a water drain collector |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martuti, N.K.T.; Hidayah, I.; Margunani, M.; Alafima, R.B. Organic Material for Clean Production in the Batik Industry: A Case Study of Natural Batik Semarang, Indonesia. Recycling 2020, 5, 28. https://doi.org/10.3390/recycling5040028

Martuti NKT, Hidayah I, Margunani M, Alafima RB. Organic Material for Clean Production in the Batik Industry: A Case Study of Natural Batik Semarang, Indonesia. Recycling. 2020; 5(4):28. https://doi.org/10.3390/recycling5040028

Chicago/Turabian StyleMartuti, Nana Kariada Tri, Isti Hidayah, Margunani Margunani, and Radhitya Bayu Alafima. 2020. "Organic Material for Clean Production in the Batik Industry: A Case Study of Natural Batik Semarang, Indonesia" Recycling 5, no. 4: 28. https://doi.org/10.3390/recycling5040028

APA StyleMartuti, N. K. T., Hidayah, I., Margunani, M., & Alafima, R. B. (2020). Organic Material for Clean Production in the Batik Industry: A Case Study of Natural Batik Semarang, Indonesia. Recycling, 5(4), 28. https://doi.org/10.3390/recycling5040028