Abstract

The main environmental issue associated with compost production is the production of a liquid leachate. Leachate from municipal wastes contains carbon, nitrogen, phosphorus, potassium and trace elements that can be used as nutrients by plants. The advantages of the use of organic wastes such as compost leachate as fertilizers are evident. Their use would reduce the consumption of commercial fertilizers, which need, with their production, high cost and energy. This work aims to determine the physical and chemical properties of a specific leachate with a variable composition, collected from the composting line of a mechanical and biological treatment facility. The goal is to assess if the leachates can be used as a potential source for fertilizers, and thus develop and design a sequence of processes which could effectively convert the leachates to commercial fertilizers according to the requirements of the proposal of regulation of the European Parliament of 2016 for fertilizers. Preliminary results show that the leachate samples qualitatively meet the requirements established for the composition of commercial fertilizers, especially organo-mineral fertilizers. Furthermore, there is no production cost of leachate as a raw material. The results show that the leachate is characterized by manageable concentrations of heavy metals which can be removed by adsorption processes, and it presents suitable amounts of organic carbon after a water removal procedure. However, the establishment of the conditions for suitable conversion processes are still under investigation considering the high composition variability due to factors like storage and environmental conditions.

Keywords:

leachate; fertilizers; waste valorization; treatment plant; nutrients; organic carbon; heavy metals 1. Introduction

Disposal of municipal waste is a major environmental problem. Increased urbanization and industrialization, especially in developing countries, requires municipal authorities to handle larger amounts of municipal waste than in the past [1,2,3].

To avoid the deposition of the organic fraction of municipal solid waste on landfill, new treatments and also new application to the leachate must be developed [4,5,6]. The main pollution issue associated with this compost treatment is the production of a liquid leachate that is characterized by high levels of salts and NH4-N and high organic load that depend on many parameters such as the materials treated and the specific processes used for the treatment [7].

Although the handling and disposal of municipal waste compost leachate is one of the major problems of compost production, it may be considered as a source of nutrients and water. Compost leachate from municipal wastes may contain carbon, nitrogen, phosphorus, potassium and trace elements that can be used as nutrients by plants [8].

Their use would reduce the consumption of commercial fertilizers, characterized by high production and energy costs [9]. Leachate is a waste product, which means that no direct production costs are associated; instead, it implies expensive treatment processes to be discarded. The use of leachate in agriculture also means that the costs at waste treatment plants can be reduced, since processes for nitrogen, phosphorus and other substances removal would not be necessary.

However, due to the nature of the leachates, they may contain, in addition to elements of interest, heavy metals, phytotoxic substances such as ammonia, organic compounds of low molecular weight and/or high salt content [10,11].

Several studies concerning the valorization of different types of leachates have been developed during the years. Justin and Zupancic [12] proposed the use of combined purification of the leachate in constructed wetland with subsequent reuse for irrigation of grass and willows. The wastewater presented a good effect in plants growth, but it kept high concentrations of pollutants. Sheets et al. [13] analyzed several emerging methods for the efficient treatment and reuse of nutrient-rich effluents from anaerobic digestion processes, and highlighted technologies like algae cultures or struvite crystallization as promising solutions for the valorization of the liquid fractions. However, the main disadvantages associated with the referred technologies were pathogen regrowth and prevalence of emerging organic micro-pollutants. Prazeres et al. [14] studied the use of cheese whey wastewater treated by NaOH precipitation for tomato production. It was concluded that NaOH precipitation is a viable physicochemical process to pretreat cheese whey wastewater using a combination of aerobic digestion, sedimentation and centrifugation, achieving a sludge volume reduction of 80% and simultaneously producing an effluent with organic matter depletion of around 40%. However, the effluent produced was viable to be used only for a few species of tomato that could handle its high salinity content. On the other hand, Postacchini et al. [15] studied the environmental impacts generated by the use of polyaluminum chloride (PAC) as a coagulant chemical agent and sodium hydroxide as a pH control chemical agent, in the processing of a leachate resulting from an Italian wastewater treatment plant. The study proposed the use of alternatives, namely the substitution of sodium hydroxide by calcium hydroxide and of PAC by ferric chloride.

While some leachate samples exhibit pH values around 8, with conductivity values of 8.3 mS/cm, dissolved carbon of 429 mg/L, chemical oxygen demand of 1508 mg/L, total nitrogen of 398 mg/L, and total phosphorous of 2.37 mg/L [12], other leachate samples are reported with significantly different values, like those presented by Postacchini et al. [15] for a leachate stream that exhibits a chemical oxygen demand of 4128 mg/L, total nitrogen of 1414 mg/L, and total phosphorous of 10 mg/L. These are two examples that show that leachate streams do not display typical composition values. The content of organic carbon, nutrients and contaminants depends on the nature of the raw material, the conversion processes applied, the operational conditions, etc.

The ultimate aim of this work is the development and design of a sequence of processes to convert a specific leachate with a variable composition, collected from the composting line of a mechanical and biological treatment facility, into commercial fertilizers which fit the composition requirements of the European Legislation. However, to effectively design these processes, it is necessary to assess the typical composition of the liquid leachate and to predict its possible variability, for the evaluation of the composition alteration needs. Therefore, in the present work, the data gathered for the characterization of the leachate is presented and discussed, and a simplified flowsheet for the conversion sequence of processes is proposed.

2. Materials and Methods

The samples were obtained from the leachate storage tank at the company Resíduos do Nordeste, EIM (Mirandela, Portugal). This leachate stream is produced and recovered from a composting line of a mechanical and biological treatment plant of organic wastes. The samples were collected in October 2017 and June 2018, and then were stored at 4 °C in 5 L polyethylene terephthalate bottles.

The sample concentration procedure was performed using a simple distillation equipment: 900 mL of the original sample was heated until 100 °C, the water was evaporated, condensed and collected in a flask. The ratio between the initial and final volume is given as the concentration factor and this factor is used for identification of each sample.

pH and conductivity measurements were done using a pH-electrode SenTix 41 (±0.001) from WTW (WTW, Weilheim, Germany) and a conductivity cell TetraCon 325 from WTW (±0.01 mS/cm) [8,11,16].

Total Organic Carbon (TOC) analysis was performed with 1:1000 dilution, in a Shimadzu TOC-L 5000A equipment (Shimadzu, Duisburg, Germany) while density assessment was done using 5 and 10 mL pycnometers dried for 24 h, using a precision weighing balance (±0.0001 g) [8,11,16].

The statistical correlation between TOC and Density was assessed by Pearson correlation, which produces a sample correlation coefficient, r (see Equation (1)), which measures the strength and direction of linear relationships between pairs of continuous variables (X and Y), and varies between −1 and +1, where 0 represents no correlation. By extension, the Pearson Correlation allows the evaluation of the statistical evidence for a linear relationship among the same pairs of variables in the population [17]:

Dry mass percentage was obtained using an oven from Scientific Series 9000 (Scientific, Randburg, South Africa) at 105 °C for 48 h while Ash percentage was performed at 450 °C until constant mass was reached in a precision balance (±0.0001 g) [11].

Heavy metals quantification was performed by digesting the samples with HNO3/HCl during 48 h at 60 °C, filtration using a 0.2 µm syringe filter in a 50 mL volumetric flask, completed with a 5% HNO3 solution, with subsequent analysis by atomic absorption spectroscopy Varian SpectrAA 220 (Varian, Steinhausen, Switzerland) [8,11].

Total Kjeldhal Nitrogen (TKN) analysis was based in BS EN 15604 (European Committee for Standardization, Brussels, Belgium) and performed by digesting the sample with concentrated H2SO4 and Kjeldhal catalyst for 30 min after a colorless solution forms; then 50 mL of water was added and 50 mL of a 40% NaOH solution, and the solution was subsequently distillated. The distillate was collected using boric acid solution at 4% and a mix indicator, then titrated using hydrochloric acid 0.0978 M previously standardized. Ammoniacal Nitrogen quantification procedure was based in BS EN 15475 through the distillation of the initial sample. The distillate was again collected using boric acid solution at 4% and a mixed indicator, which was then titrated using a previously standardized solution of hydrochloric acid 0.0978 M. Organic Nitrogen was calculated through the difference between Total and Ammoniacal Nitrogen [8,11,16].

Phosphorous analysis was based in the BS EN 13650 procedure and performed by digesting the sample with HNO3 for 45 min and then with HClO4 for 1 h until a colorless solution is formed. This solution was transferred to a 250 mL volumetric flask, which was filled. Afterwards, it was filtered, and 85 mL of the filtered solution was mixed with 15 mL of vanadate molybdate solution. The solution was left to rest for 10 min. The 500 ppm standard solution was prepared using 0.9640 g of 40% purity KH2PO4, dried for 2 h at 105 °C, in a 1000 mL volumetric flask. The standards solutions used for calibration were produced from the 500 ppm solution by adding aliquots containing 2.0, 2.5, 3.0, 4.0 and 5.0 mL of the previously prepared KH2PO4 solution, 20 mL of distilled water and 15 mL of vanadate molybdate solution in 50 mL volumetric flasks, where the volume was completed. These solutions contain 20, 25, 30, 40 and 50 ppm of P2O5, respectively. The standard solutions were produced with concentrations of 20, 25, 30 and 40 ppm, respectively. They stand for 10 min to complete color development and determination of the absorbance of the solutions was carried out at 400 nm using as a blank the solution containing 20 ppm of P2O5. From the obtained data, the calibration equation was constructed. The percentage of P2O5 is calculated using Equation (2), where C is concentration in ppm of P2O5 in the sample, A is volume of the aliquot taken from the extract, in mL, for this analysis, 85 mL, and G is initial mass of the sample, in grams [8,11,16]:

3. Results and Discussion

Chemical properties of original and concentrated leachates are summarized in Table 1 for samples collected in October 2017 and June 2018, respectively, from the compost leachate storage facility. The 45× concentration factor was tested in duplicate for the October 2017 sample to verify the consistence of the data in each analysis. Both 45× samples show similar values for TOC, Density and Heavy metals content.

Table 1.

Chemical properties of original and concentrated leachates (October 2017 and June 2018).

The original leachate obtained at June 2018 showed a TOC concentration 10 times greater than the leachate obtained at October 2017, which makes evident the high heterogeneity of the leachate produced. Its composition may depend strongly on various factors, such as the composition of the biomass at the entrance of the composting line, and/or weather conditions or organic and inorganic external contaminations, since the leachate is stored in an open, non-stirred vessel, for relatively large periods of time (from days to weeks) before it is sent (together with the leachate stream from the landfill) to the treatment process. However, both original leachate samples must be concentrated to satisfy the requirements of the EU fertilizers legislation [8] to reach 3% of TOC for liquid organo-mineral fertilizers, which is the lower value of organic carbon requirements in legislation for liquid fertilizers.

The concentration procedure was carried out by simple distillation, to remove the great excess of water in the samples and fulfill the minimum requirements. While samples from October 2017 needed a stronger concentration process to reach the TOC legislation specification and required being concentrated to 1/30 of the initial volume, the samples from June 2018 reached the proposed TOC values with concentration volume ratios of around 1/3.

Sample density, pH and conductivity were measured, and present high variations between the original and the concentrated samples as presented in Table 1. The distillation process, due to the water removal, promotes also the concentration of the inorganic carbon content, as carbonates, which must be corrected to a neutral pH before a possible use as fertilizer. This feature can be noticed in the Table 2, where the Total (TC), Inorganic (IC) and Total Organic Carbon (TOC) content is presented.

Table 2.

Carbon content properties of original and concentrated leachates (October 2017 and June 2018).

The original leachate dry mass and ash percentage showed a greater content of organic and inorganic material in the sample from June 2018 compared with October 2017 samples, which is in accordance with the TOC analysis. The IC analysis represents the content of carbonates and bicarbonates, which explain the greater value in pH for concentrated leachates from October 2017. TOC is defined as the difference between TC and IC.

However, from a qualitative point of view, it is notorious that the original leachate from October 2017 and its concentrated samples present higher contents of solid material in suspension. However, these samples also require greater water removal in order to reach the TOC requirements. On the other hand, it is visible that the original sample from June 2018 presents lower material in suspension, but needs less water removal, which results in less agglutination and, consequently, lower densities and dry mass contents. Therefore, the original sample from June 2018 showed a higher content of dry mass and ashes compared to the original sample from October 2017. As said before, the concentration procedure was less intense (approximately 10 times lower concentration factors) for June 2018 samples, which means less water removal, but overall the concentrated samples from June 2018 are more diluted compared to the concentrated samples from October 2017, which could explain why the concentrated samples from October 2017 present similar content of organic carbon, but considerably higher dry mass and ashes contents compared to June 2018 concentrated samples.

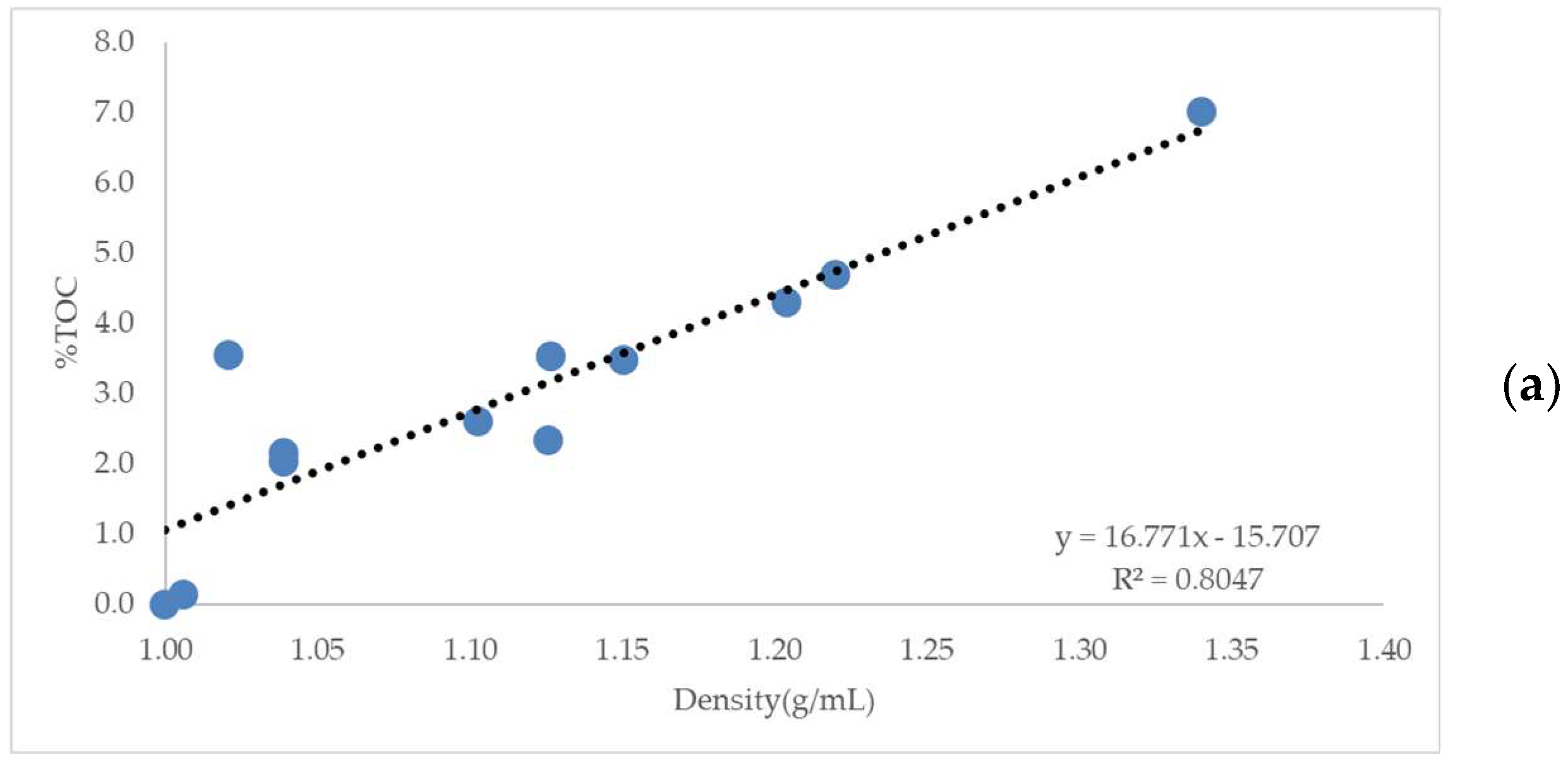

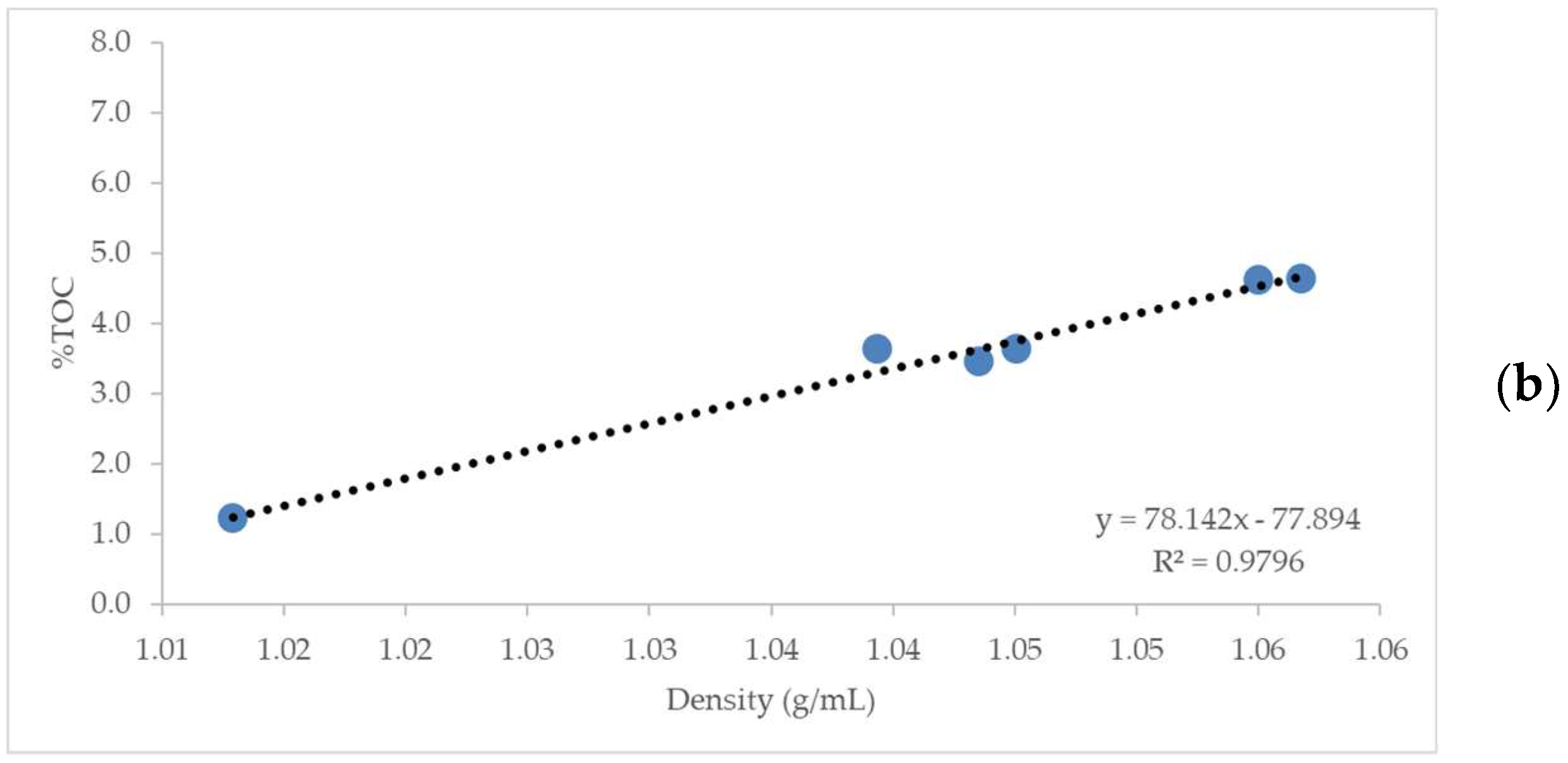

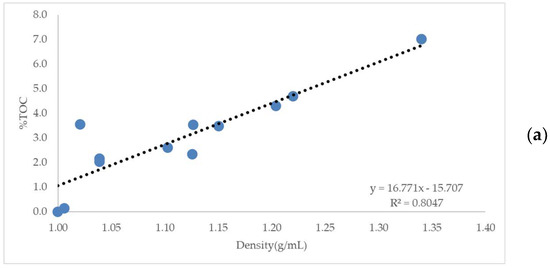

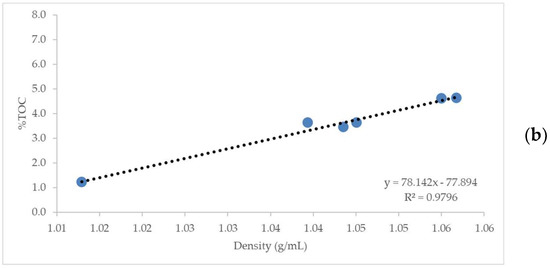

It is observed that the organic carbon content has a strong influence on the final density of the concentrate obtained. Thus, some statistical analysis can now be used to verify the correlation between bulk density and TOC for sample from October 2017 and June 2018, as shown in Figure 1a,b that presents how density is affected by the TOC in each sample.

Figure 1.

Correlation between Density and TOC. (a) October 2017; (b) June 2018.

A significance test using Pearson’s correlation coefficient was carried out. A correlation coefficient r of 0.9 was obtained for October 2017 samples, while a value of r = 0.99 was estimated for June 2018 samples. Thus, it can be stated that the correlation between density and TOC values is statistically significant for a 99% confidence interval, in both cases.

The procedure for the characterization of organic nitrogen was carried out to obtain the parameters for the leachate, which could be compared with in the legislation specifications. The results obtained through the difference of values between the total and ammoniacal nitrogen are shown in Table 3. This analysis was only applied to the original leachates which present the maximum value possible for the leachate. The concentrated samples were not analyzed because, with the distillation process, some amount of volatile nitrogen is lost due to the heating process. Therefore, the N content for the concentrated leachate samples should be underestimated.

Table 3.

Concentration of total, ammoniacal and organic nitrogen.

Following the same features presented for TOC characterization, the original leachate obtained at June 2018 showed a nitrogen concentration 10 times greater than the leachate obtained in October 2017.

According to European Union legislation [8], to be considered a liquid organo-mineral fertilizer, the product must contain at least one of the following declared nutrients in the minimum quantities: 2% by weight of total nitrogen, of which 0.5% by mass of the fertilizer product must be organic nitrogen; 2% by weight of total phosphorus pentoxide (P2O5); and 2% by mass of total potassium oxide (K2O). Therefore, the nitrogen values do not fit the requirements in the legislation; it is necessary to carry out the Phosphorus and Potassium analyses, using the concentrated leachates, to verify possible conformances in at least one of the required nutrients.

For the characterization of total phosphorus, the samples were characterized in sequence, following the same conditions applied to the standards. In Table 4, data referring to absorbance, concentration in ppm and %w/w of each sample is presented, in addition to the minimum concentrations required by the legislation.

Table 4.

Content of P2O5 in concentrated leachates.

The values obtained are below the minimum required by the legislation, even in more concentrated samples. These values denote a low concentration of P2O5 in the sample collected from the supernatant residue in the storage tank. More concentrated samples, such as the solids decanted in this storage tank, may present higher phosphorus levels without the need for further concentration processes.

The heavy metals concentration is presented in Table 5, and it was determined only in the concentrated samples because the original sample did not reach the analysis detection limit.

Table 5.

Concentration of heavy metals in the concentrated leachates.

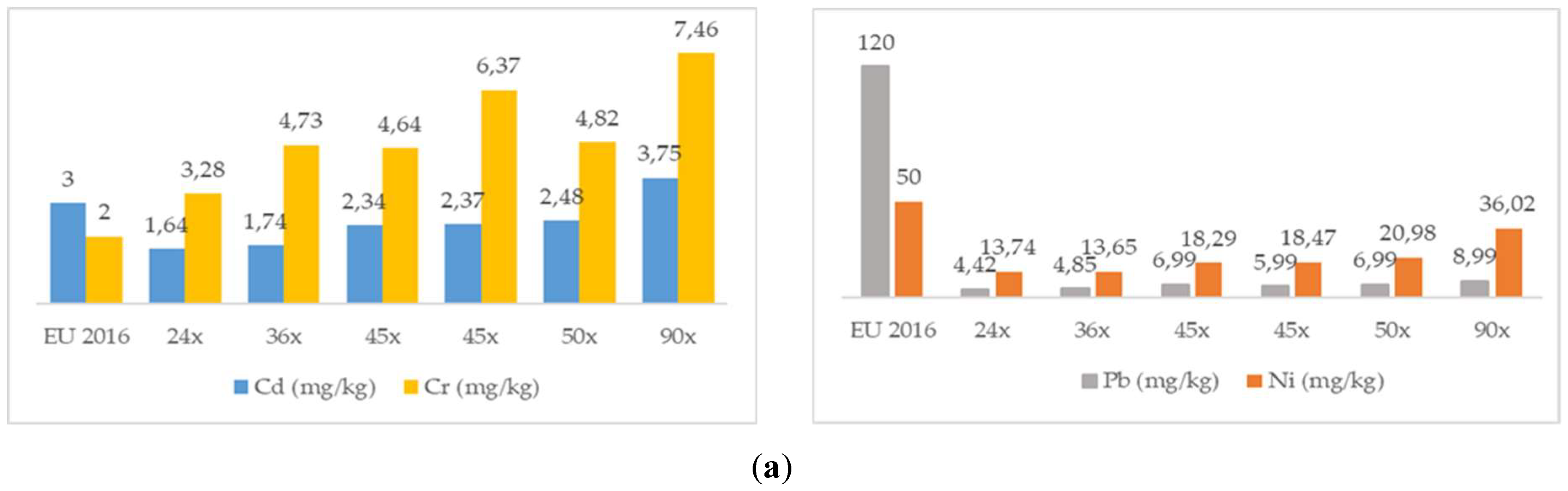

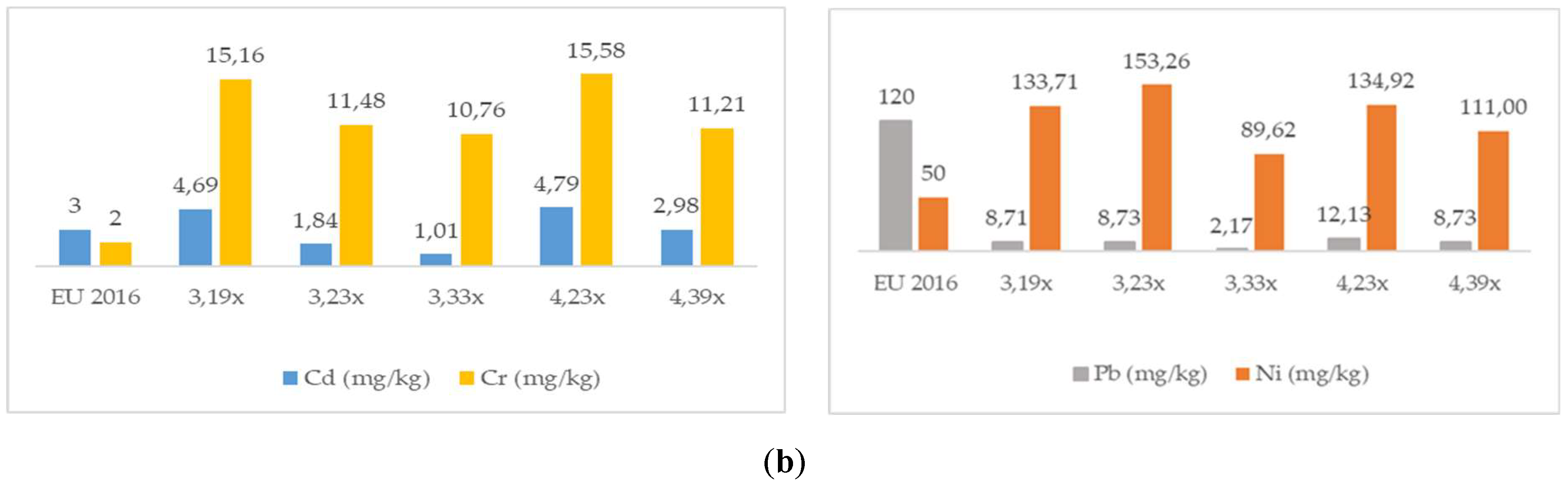

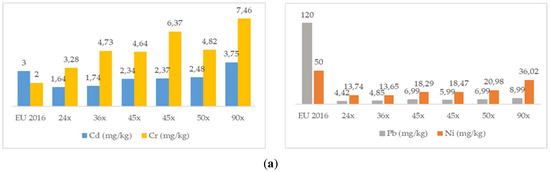

Table 5 shows that the concentration of each heavy metal varies in each concentrated sample according to the original sample and the level of sample concentration. Higher water removal should mean higher heavy metal concentration. Nevertheless, it can be verified from the analysis of Table 5 that, especially for the samples of June 2018, a direct relationship between the concentration process and its effect in the heavy metals content is not observable, probably due to the heterogeneous characteristics of the colloidal samples. Figure 2a,b show a comparison between the EU legislation and the content of heavy metals in the samples.

Figure 2.

Concentration of heavy metals in the concentrated leachates. (a) from October 2017; (b) from June 2018.

As shown in Figure 2a,b, the content of Pb fulfills the requirements of the EU legislation in all concentrated samples produced. However, Cd, Cr and Ni must be removed to achieve the fertilizer requirements.

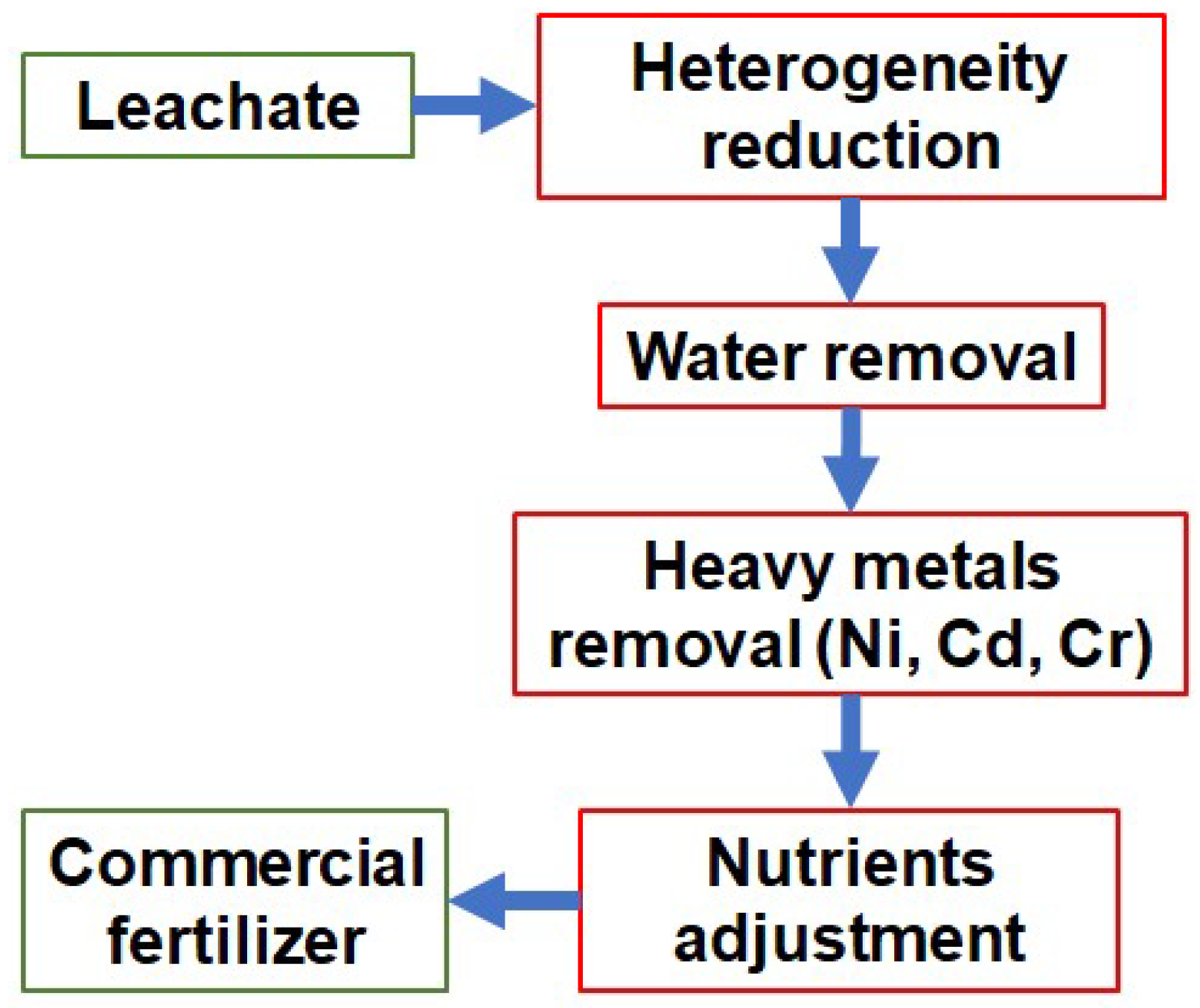

From the analysis of original and concentrated leachate samples, a simplified flowsheet for a sequence of composition adjustments for the leachate can now be proposed, as presented in Figure 3.

Figure 3.

Proposed simplified flowsheet for a conversion process of the leachate to commercial fertilizers.

This flowsheet represents a proposal for the main operations that the leachate must pass through to reach the minimum legislation requirements for commercial fertilizers. The specific processes for each conversion step must be selected and designed, considering the general composition of the liquid leachate and its possible variation.

4. Conclusions

The concentrated leachate samples cannot be used, at this point, as commercial fertilizers because they do not fit all the legislation requirements, but they still display potential to be used after simple processing. It shows high concentration of total organic carbon (TOC) and low levels of heavy metals. However, some adjustments must be made to tune the concentration of these components.

Seasonal factors lead to difficulties in the characterization of the wastes due to the variation of the composition of the material, which is exposed to weather conditions and external contaminants. However, the specific conditions applied will depend on the leachate characteristics to fit its composition to the legislation requirements for organo-mineral fertilizers. Samples taken from a close, well-stirred tank instead of the storage open tank where the effluent is collected may show higher levels of organic carbon and nutrients without requiring an initial concentration process. The introduction of these changes in the leachate storage facility can also contribute to a significant reduction in the content variations observed for the different leachate samples.

The Nitrogen and Phosphorous nutrients are present in low levels even after the concentration procedure, mainly due to the composition of the sample used, which is characterized by almost 99% content in water. However, ultrafiltration or reverse osmosis could be viable solutions to remove the excess of water without affecting significantly the content of the product in other compounds, especially nutrients.

The content of heavy metals in the concentrated samples must be reduced to fit the legislation requirements, especially for Ni, Cd and Cr. The adsorptive process using activated carbon, zeolites, or other adsorbents could be a solution to reduce the concentration of those metals without affecting the TOC.

Other characterizations like Potassium determination remain to be carried out to evaluate the content of this nutrient and if it fits the legislation specification because only one of the three nutrients NPK must be present in the minimum requirements.

However, the potential for the use of these wastes as fertilizers is great, especially because it promotes the use of liquid wastes with high organic carbon content for agricultural applications with the possibility of producing a high value-added material. In addition, it promotes the recycling of wastes that are currently treated only as pollutants, with a more useful destination than simply waste treatment and disposal.

Author Contributions

Conceptualization, H.T.G.; Formal analysis, J.C.; Investigation, J.C. and P.B.; Project administration, H.T.G.; Supervision, P.B. and H.T.G.; Writing—original draft, J.C.; Writing—review & editing, P.B.

Funding

This work was financially supported by Project VALORCOMP, funded by FEDER through Program INTERREG V-A Spain–Portugal (POCTEP) 2014–2020.

Acknowledgments

This work was assisted by Resíduos do Nordeste, an EIM company that provided the leachate samples.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hue, N.V. Residual effects of sewage-sludge application on plant and soil-profile chemical composition. Commun. Soil Sci. Plant Anal. 1988, 19, 1633–1643. [Google Scholar] [CrossRef]

- Nyamangara, J.; Mzezewa, J. The effect of long-term sewage sludge application on Zn, Cu, Ni and Pb levels in a clay loam soil under pasture grass in Zimbabwe. Agric. Ecosyst. Environ. 1999, 73, 199–204. [Google Scholar] [CrossRef]

- Khoshgoftarmanesh, A.H.; Kalbasi, M. Effect of municipal waste leachate on soil properties and growth and yield of rice. Commun. Soil Sci. Plant Anal. 2002, 33, 2011–2020. [Google Scholar] [CrossRef]

- Hyde, K.; Smith, A.; Smith, M.; Henningsson, S. The challenge of waste minimisation in the food and drink industry: A demonstration project in East Anglia, UK. J. Clean. Prod. 2001, 9, 57–64. [Google Scholar] [CrossRef]

- Henningsson, S.; Hyde, K.; Smith, A.; Campbell, M. The value of resource efficiency in the food industry: A waste minimisation project in East Anglia, UK. J. Clean. Prod. 2004, 12, 505–512. [Google Scholar] [CrossRef]

- Usón, A.A.; Ferreira, G.; Vásquez, D.Z.; Bribián, I.Z.; Sastresa, E.L. Estimation of the energy content of the residual fraction refused by MBT plants: A case study in Zaragoza’s MBT plant. J. Clean. Prod. 2012, 20, 38–46. [Google Scholar] [CrossRef]

- Moreno, R.; García, T.; Storch, J.M.; Arellano, E. Fertilization and correction of agricultural soils with organic products. Use of organic waste and by-products as fertilizers. Characterization of leachates. In Proceedings of the CONAMA10: Congreso Nacional de Medio Ambiente, Madrid, Spain, 22–26 November 2010; pp. 1–10. [Google Scholar]

- European Comission. European Parliament and European Council Proposal for the Regulation of Fertilizers Products with the CE Marking and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009; European Comission: Brussels, Belgium, 1069. [Google Scholar]

- Romero, C.; Ramos, P.; Costa, C.; Carmen Márquez, M. Raw and digested municipal waste compost leachate as potential fertilizer: Comparison with a commercial fertilizer. J. Clean. Prod. 2013, 59, 73–78. [Google Scholar] [CrossRef]

- Zhang, T.; Ding, L.; Ren, H. Pretreatment of ammonium removal from landfill leachate by chemical precipitation. J. Hazard. Mater. 2009, 166, 911–915. [Google Scholar] [CrossRef] [PubMed]

- Ministério da Economia de Portugal. Ministério da economia—Decreto-Lei n.° 103/2015; Ministério da Economia de Portugal: Lisboa, Portugal, 2015; pp. 3756–3788. [Google Scholar]

- Zupanc, M. Combined purification and reuse of landfill leachate by constructed wetland and irrigation of grass and willows. Desalination 2009, 246, 157–168. [Google Scholar]

- Sheets, J.P.; Yang, L.; Ge, X.; Wang, Z.; Li, Y. Beyond land application: Emerging technologies for the treatment and reuse of anaerobically digested agricultural and food waste. WASTE Manag. 2015, 44, 94–115. [Google Scholar] [CrossRef] [PubMed]

- Prazeres, A.R.; Rivas, J.; Adelaide, M.; Patanita, M.; Dôres, J.; Carvalho, F. Agricultural reuse of cheese whey wastewater treated by NaOH precipitation for tomato production under several saline conditions and sludge management. Agric. Water Manag. 2016, 167, 62–74. [Google Scholar] [CrossRef]

- Postacchini, L.; Ciarapica, F.E.; Bevilacqua, M. Environmental assessment of a land fi ll leachate treatment plant: Impacts and research for more sustainable chemical alternatives. J. Clean. Prod. 2018, 183, 1021–1033. [Google Scholar] [CrossRef]

- Clescerl, L.S.; Greenber, A.E.; Eaton, A.D. (Eds.) Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington, DC, USA, 1999. [Google Scholar]

- Lee, J.; Nicewander, W.A. Thirteen Ways to Look at the Correlation Coefficient. Am. Stat. 2012, 42, 59–66. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).