Abstract

In this work, recycling of post-consumer carpets into structural composites using a modified vacuum assisted resin transfer molding process has been demonstrated. Fabrication of carpet composites addressed the problem related to the environmental effect of waste carpet. Application of the recycled carpet composite as the noise barrier structure has been studied in terms of noise absorption coefficient. Results show that the carpet composite absorbs noise better than conventional noise barrier at a wide spectrum of frequency. Effect of weather exposure on the carpet composite showed the degradation in the mechanical properties. Nanoclay films are also used on the carpet composite and show no change in the noise absorption ability.

1. Introduction

For sustainable development, the materials recovery and recycling industry have to deliver marketable products which are based on cost-effective technologies and have a positive life cycle environmental impact [1,2]. As the carpet is a petroleum-based material, recycling of the carpet can save around 700,000 barrels of oil per year, hence conserving 4.4 trillion BTUs of energy [3]. Carpet waste is both an environmental and economic problem because of the cost involved in the disposal of waste carpet. The cost also involves the discarding of valuable raw materials like Nylon 6,6, polyester, polyvinyl chloride (PVC), polypropylene (PP), other olefins, etc., going to landfills apart from the cost of transporting the waste to landfills. In the present, the use of the post-consumer carpet as the landfilling material is causing several environmental issues as the carpet fibers are non-biodegradable [4,5,6]. Hence, recycling of the carpet in the form of structural composites serves as a motivation to address the problem of recycling of waste carpet.

Most of the manufactured carpets today consist of nylon, olefin, polyester, cotton, and wool fibers—the major structural components of carpet face fiber, backing, binder, and filler. Nylon has attained greater popularity and is utilized in 65% of the carpet sold in the US market [7]. It has excellent performance characteristics and is very durable, especially in heavy foot traffic conditions. Nylon-based carpets have either the nylon 6 face fibers or the premium nylon 6, 6 face fibers. However, these carpets fail to perform after their shelf life of 11 years and are either incinerated or sent to landfills after their useful service [8,9,10,11,12].

Recycling carpet, however, is difficult because three of its major components are chemically and physically diverse. Most carpets contain 20–50% weight face fiber, the remaining being backing materials, commonly polypropylene, and an adhesive that attaches the carpet fiber to the backing material. The adhesive typically consists of carboxylated styrene-butadiene (XSB) latex copolymer and an inorganic filler like calcium carbonate [13]. Current recycling techniques for nylon-based carpet either include physical shearing and separation of carpet fibers to aid in the production of new nylon-based carpets, focus on recovery of nylon from carpet waste or chemical recycling of carpets [14,15]. Physical shearing of carpets involves intensive labor and thereby is highly uneconomical. The chemical recycling techniques of carpet recycling fail to deliver in sustainable product development due to their characteristic requirement of high-energy inputs. Hence, a novel recycling technique that makes use of the three-dimensional fibers architecture of carpets and converts into structural laminates using a resin matrix is both highly superior and desirable [16,17,18,19].

Impact of increasing automobile noise pollution is creating significant environmental and health concern. People have used conventional materials such as concrete and wood as the noise barrier. However, these conventional materials have limitations as a noise barrier component. With the advancement of new materials, researchers have started using different kinds of nanomaterial such as nanofiber [20], carbon nanotube [21,22], granular material [23], and metal nanoparticles [24]. These materials have significant effects on the noise barrier capability of the material. The influence of the nanomaterial on the acoustic properties on the composites motivated this work to characterize the influence of organic nanoclay in noise barrier capability.

The vacuum-assisted resin transfer molding (VARTM) technique is a simple fabrication technique used to infuse resins into materials to get products that are essentially made up of more than one material. Therefore, the resulting product is multifunctional due to the combined essence of both of the material properties. In this study, nylon 6, 6-based carpet fibers were infused with epoxy, polyester, and vinyl ester resins to yield carpet composites with improved properties by using a modified VARTM fabrication process.

In the present study, recycling of post-consumer carpets into composite materials with improved mechanical and sound barrier properties that will meet the needs of infrastructure, transportation, and sound barrier walls from recycled nylon-based carpet and low-cost constituents like nanoclay. It is also necessary that this is achieved without separation of the ingredients.

2. Experimentation

2.1. Materials and Reagents

In the present investigation, nylon 66 based cut loop type of carpet (Orange Cool Aid by Shaw Industries was selected). The carpets of size 60 cm × 144 cm were procured from Georgia Carpet Industries Inc., Atlanta, and then pieces of sizes 28 cm × 28 cm, 30 cm × 30 cm and 65 cm × 30 cm were prepared for the samples. Three types of resins were used in this study: Epoxy 2000, Polyester (PE), and Vinylester (VE). The resins, Epoxy 2000 (hardener Epoxy Hardener 2120), Polyester, and Vinylester (with hardener: methyl-ethyl-ketone-peroxide) (MEKP) were procured from Sigma Aldrich (St. Louis, MO, USA).

2.2. Resin Preparation

The Epoxy 2000 mixed with hardener in a weight ratio of 27/100 (hardener/epoxy), the epoxy cured at 121 °C for 6 h. The polyester resin was prepared by adding hardener MEKP in the weight ratio of 1/100 (MEKP/PE), and Vinyl Ester resin MEKP was added in the weight ratio of 1.25/100 (MEKP/VE). A curing time of 24 h was maintained for all the resin type to ensure complete curing.

2.3. Addition of Nanoclay Film

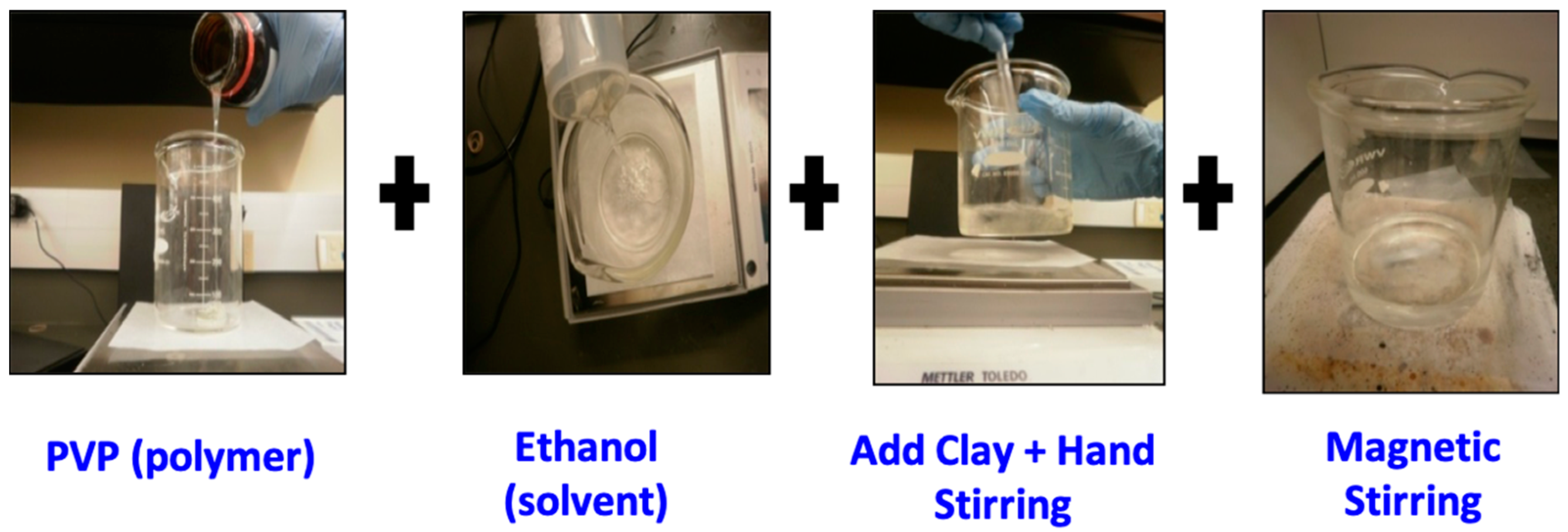

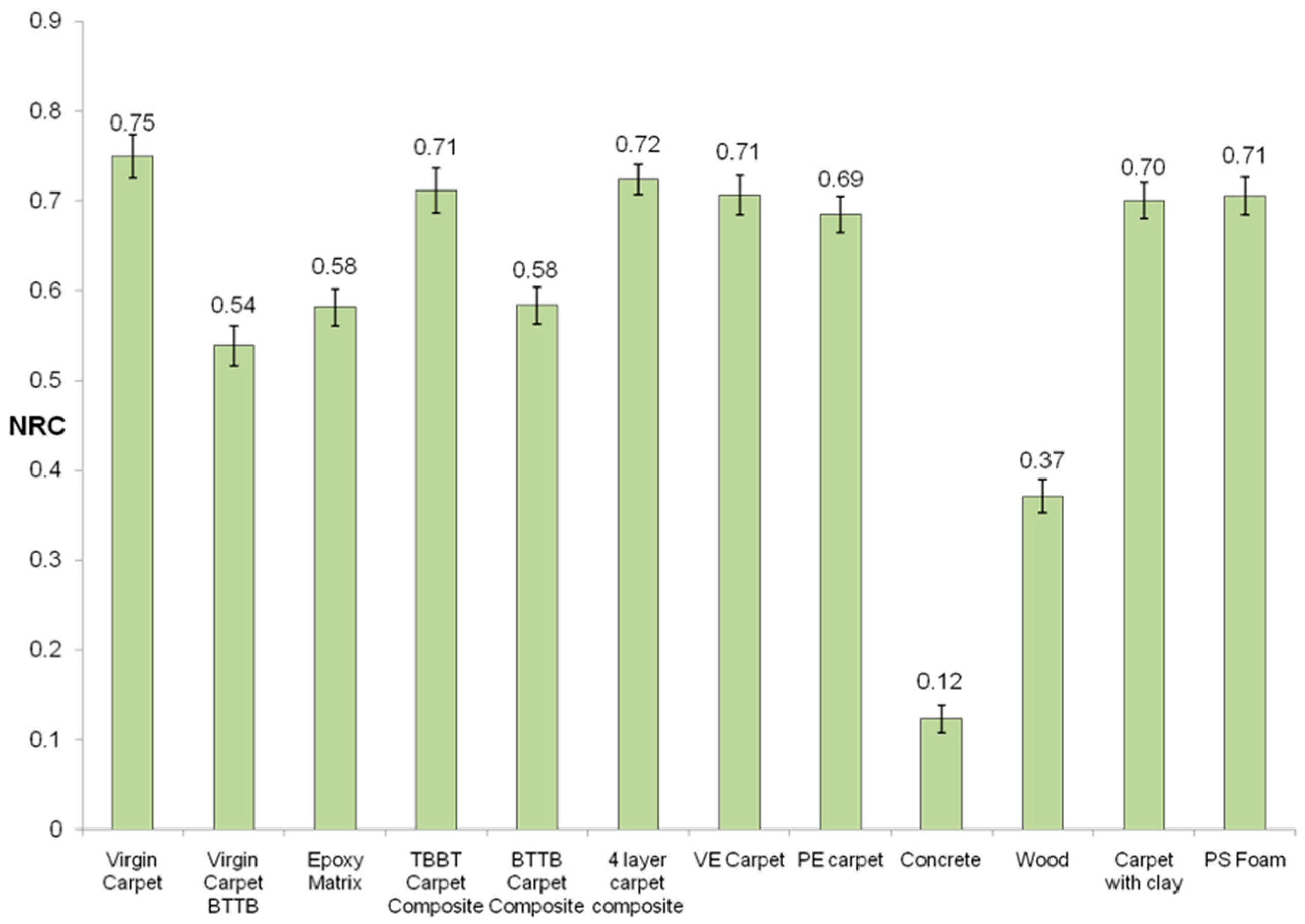

Ten percent of pure PVP K-60 of molecular weight 160 kDa (Sigma Aldrich Co., St. Louis, MO, USA) was mixed with reagent ethanol (obtained from VWR Inc. Radnor, PA, USA) by hand stirring for 15 min and later stirring on a magnetic stirrer for 45 min. Organically modified montmorillonite clay (OMMT) (Sigma Aldrich, St. Louis, MO, USA) was used as organic filler in this study with 0.3, and 30 wt.% nanoclay added to the PVP. The mixture was stirred in a magnetic stirrer for 2 h. Sonication can also be used instead of magnetic stirring. However, sonication made the films brittle after the evaporation of the solvent. The film solution was poured into a boundary of about 0.12 m × 0.12 m made by tacky tape on a clean glass plate and left for drying for 24 h in fume-hood. The solid films were later dried at 90 °C for 8 h under vacuum and stored in a desiccator until used. Figure 1 illustrates the materials used in the fabrication of PVP clay nanocomposite films.

Figure 1.

Polyvinylpyrrolidone (PVP)-clay films made using Solution Induced Intercalation method.

2.4. Fabrication Process

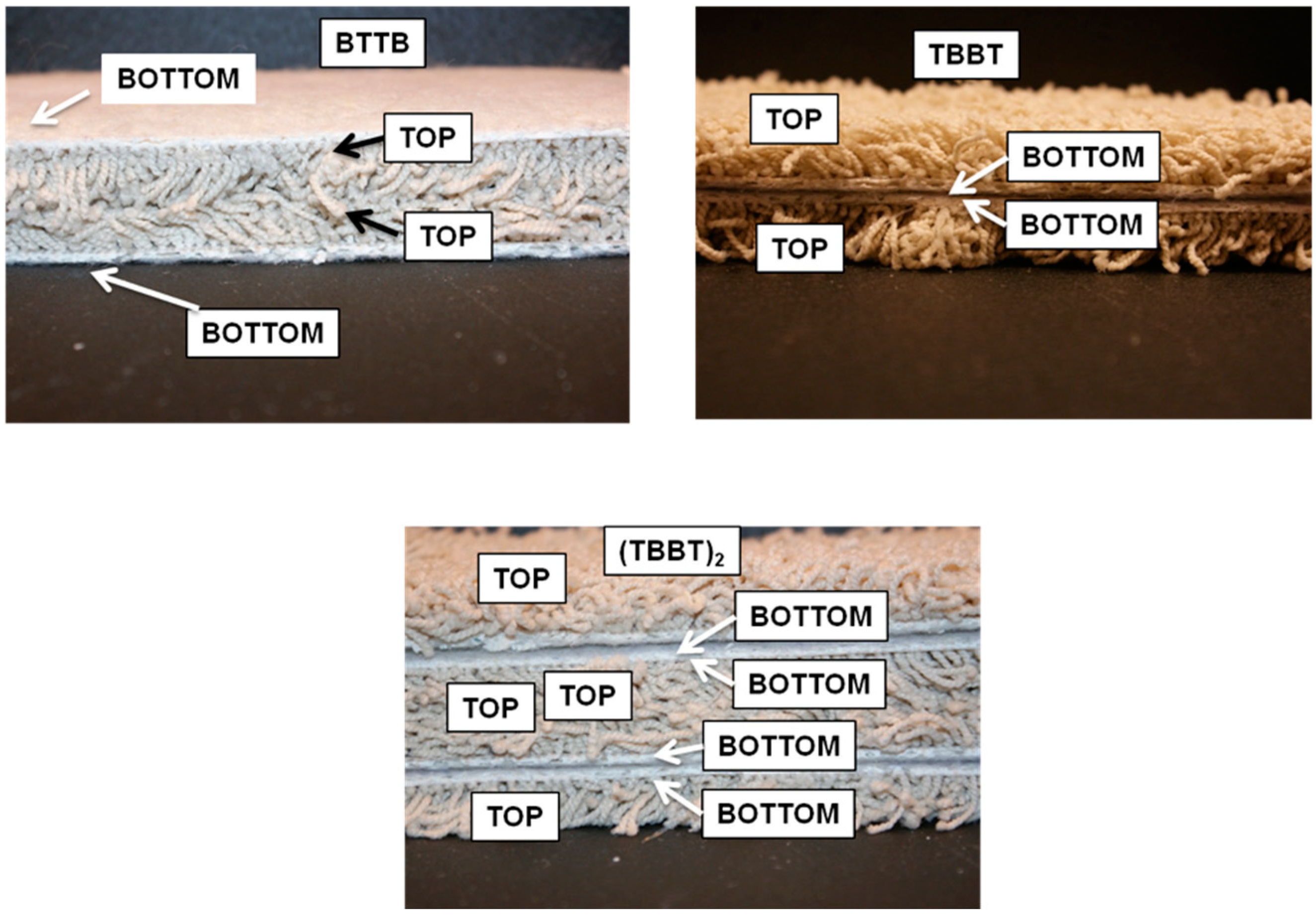

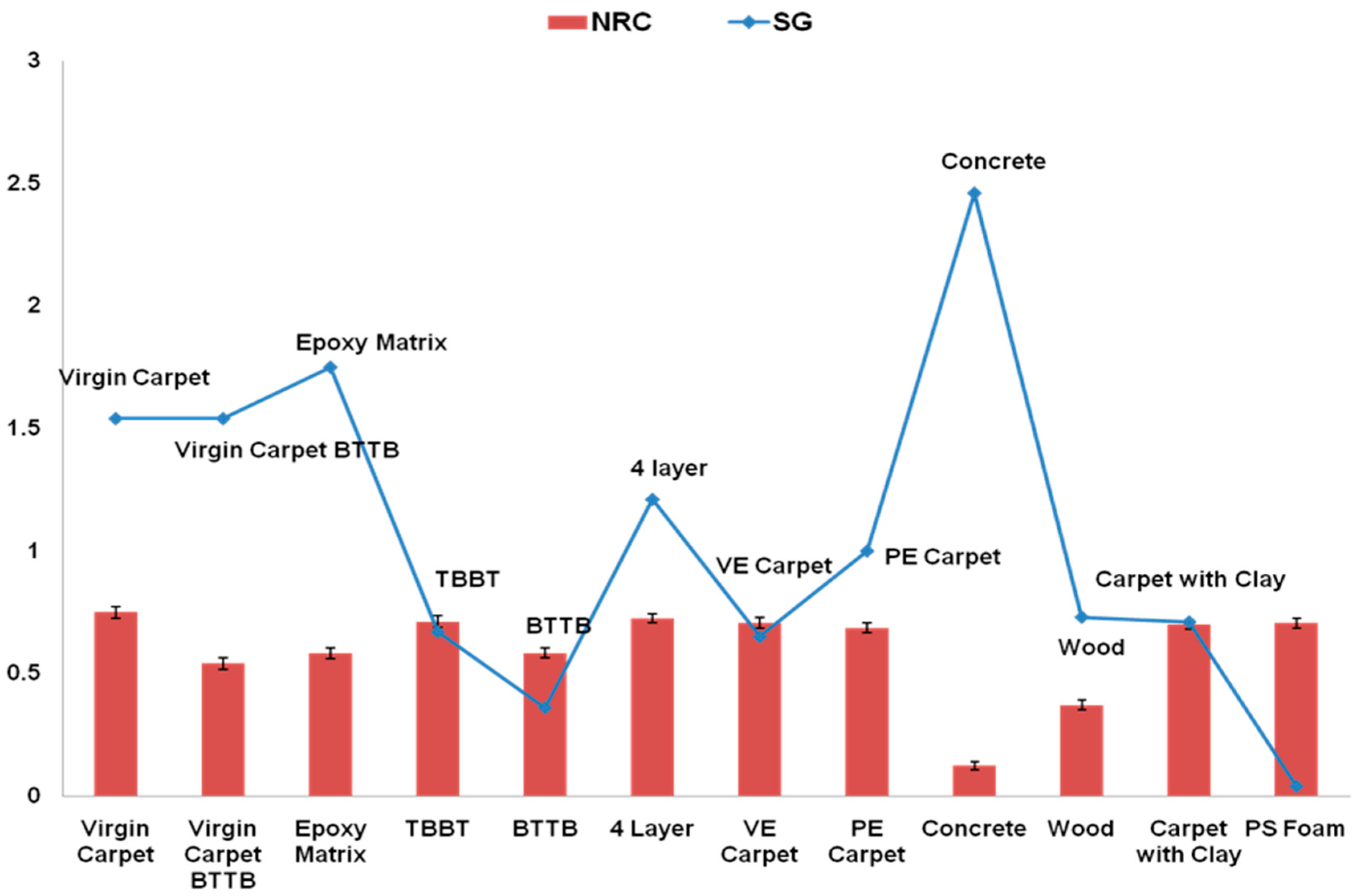

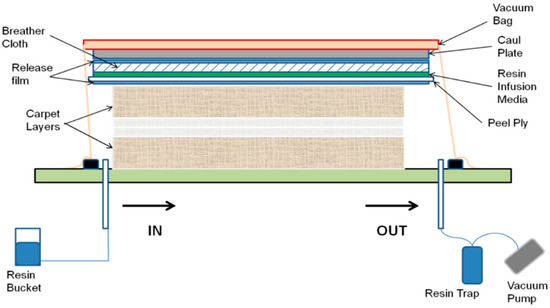

Samples were prepared using a vacuum assisted resin transfer molding technique in three different combinations of layers, Top-Bottom-Bottom-Top (TBBT), Bottom-Top-Top-Bottom (BTTB), and (Top-Bottom-Bottom-Top)2 (TBBT2) also known as 4-layers as shown in Figure 2. The carpet fiber side is the top, and the carpet backing side is the bottom. In the modified VARTM fabrication process usage of caul plates and green mesh cloth are an addition.

Figure 2.

Images of carpet configurations used for Vacuum assisted resin transfer molding (VARTM).

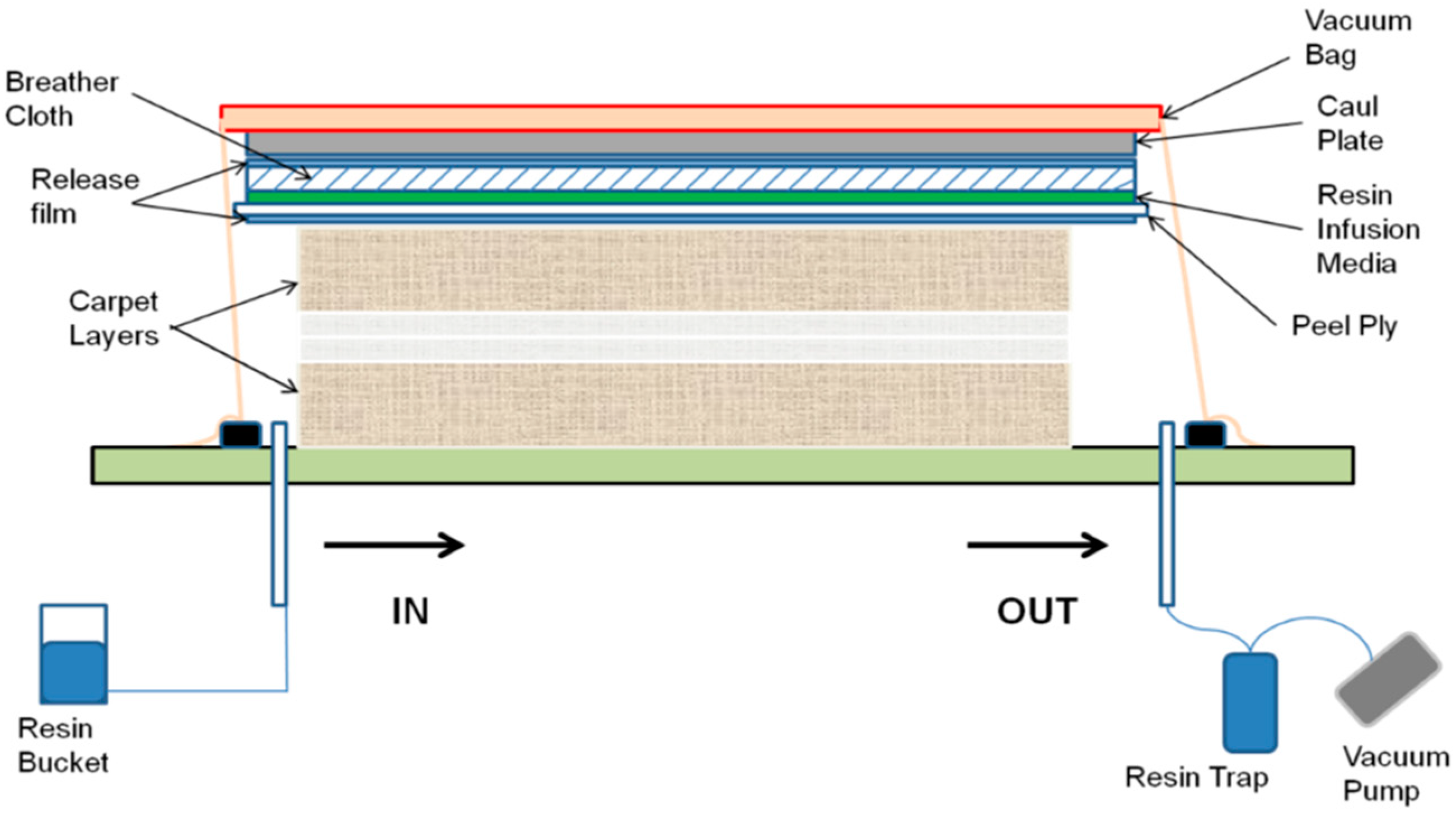

The required size of nylon bagging material (Airtech International Inc, Chino, CA, USA), tacky tape, and connecting tubes (Fiberglast, Brookville, OH, USA) are cut initially. The modified VARTM fabrication process involves the usage of a thin release sheet placed over the carpet for minimum resin usage. Thin pores on the sheet make sure that excess resin flowed out of the pores and was carried to the next level of mesh which creates the local stress points inside the vacuum bag so that the resin ran through the carpet configuration and reached the other end.

In the VARTM, nylon bag is used to enclose the setup, with attention paid to avoiding air pockets at any end. In the modified VARTM process, the same procedure is used but over a sheet of aluminum which is placed over the breather cloth layer (thereby sandwiching the entire carpet sample assembly) as shown in Figure 3. Clay film was used only on BTTB configuration for comparison only.

Figure 3.

An illustrative schematic of the scaled-up VARTM process (elevation view).

3. Characterization

3.1. XRD

XRD tests were used in this study to investigate the structure of clay formed in the final composite was conducted on a CuKα source (λ = 1.5418 Å), an X-Ray generator of Bruker Discover operated at 40 kV and 40 mA.

3.2. Synergistic Water and UV Exposure

Composite degradation was carried out by exposing BTTB carpet composites to an alternate cycle of 8 h of UV and 4 h of moisture in an accelerated weather chamber (Q-labs, Westlake, OH, USA) for 400 h.

3.3. Flexural Experiment

To understand the effect of weather degradation on the carpet composites, flexural tests were carried out. The flexural test was carried out for comparative purpose only. Hence, a very wide sample (25.4 cm × 12.7 cm × 10.1 cm) was used and tested on the universal testing machine (Instron 5567, Norwood, MA, USA). The experiments were designed in the following ways: The first consisted of unexposed samples without any exposure to weather degradation and were tested as reference samples. Another configuration was to place the weather degradation exposed sample to the compression side while the third configuration of the sample was to place the UV exposed sample on the tension face.

3.4. Acoustic Characterization

Friction between the automobile body and the air developed the change in a gradient of the air pressure. This change in the gradient of air pressure causes the noise. Noise is also created due to the engine, the exhaust of the vehicle, and the contact of tires on pavement surfaces. The noise develops a spectrum of multiple frequencies (within the range of 250 Hz and 4000 Hz) that can create a problem [25,26,27,28,29,30].

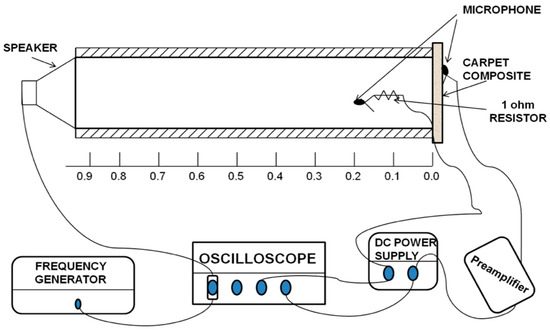

The noise absorption coefficients (NAC) of carpet composites were measured using the impedance tube method (ASTM C 384-04) to evaluate their feasibility as noise barriers. The noise absorption coefficient is the most critical parameter in the acoustic characterization of a material. When a material is exposed to the sound wave, some percentage of the wave bounced back, and some get absorbed. The value of NAC lies between 0 (means completely reflected) and 1 (means completely absorbed).

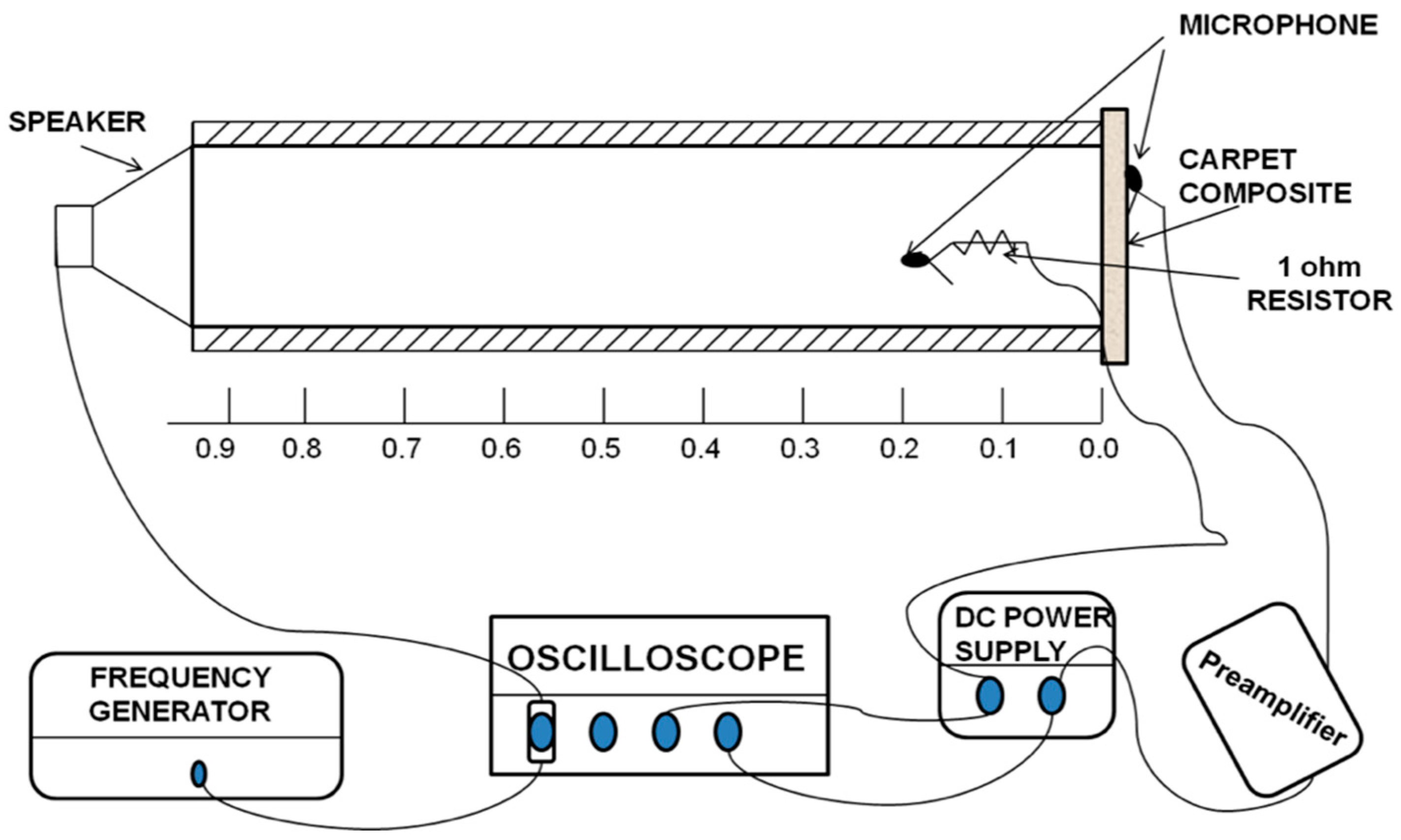

The standing wave apparatus used for this investigation requires an impedance tube, two microphones, an oscilloscope, and measurement of complex pressures from the speaker with input from the frequency generator as shown in Figure 4 below.

Figure 4.

A schematic diagram to show the apparatus used for the acoustic test based on ASTM C–384.

A rectangular aluminum tube used as an impedance tube, of cross section 0.0762 m × 0.0762 m, with polished inner ends. Tube attenuation and velocity of sound are calculated using the equation as per ASTM standard.

The microphone voltage should be at least 10 times more than the voltage of the background noise to ensure that the noise level would be at least 10 dB more than the noise level of background noise. The sound waves of various frequencies are generated by changing the placement of the microphone at a different distance from the specimen.

The standing wave ratio (SWR) is calculated using the extrapolation method by measuring the voltages (corresponding to the pressure levels) at different frequencies and distances as given in the equation below.

In this experiment, the voltage has been correlated to the change in pressure level, and hence the SWR can also be given as,

where Pmax, Pmin is the maximum and minimum sound pressures in the impedance tube.

SWR (0) is determined by extrapolation of the maximum and minimum voltages measured in the tube.

The pressure reflection coefficient (PRC) can be calculated from SWR (0) using the following equation:

The noise absorption coefficient related to the pressure reflection coefficient by the following equation:

4. Results

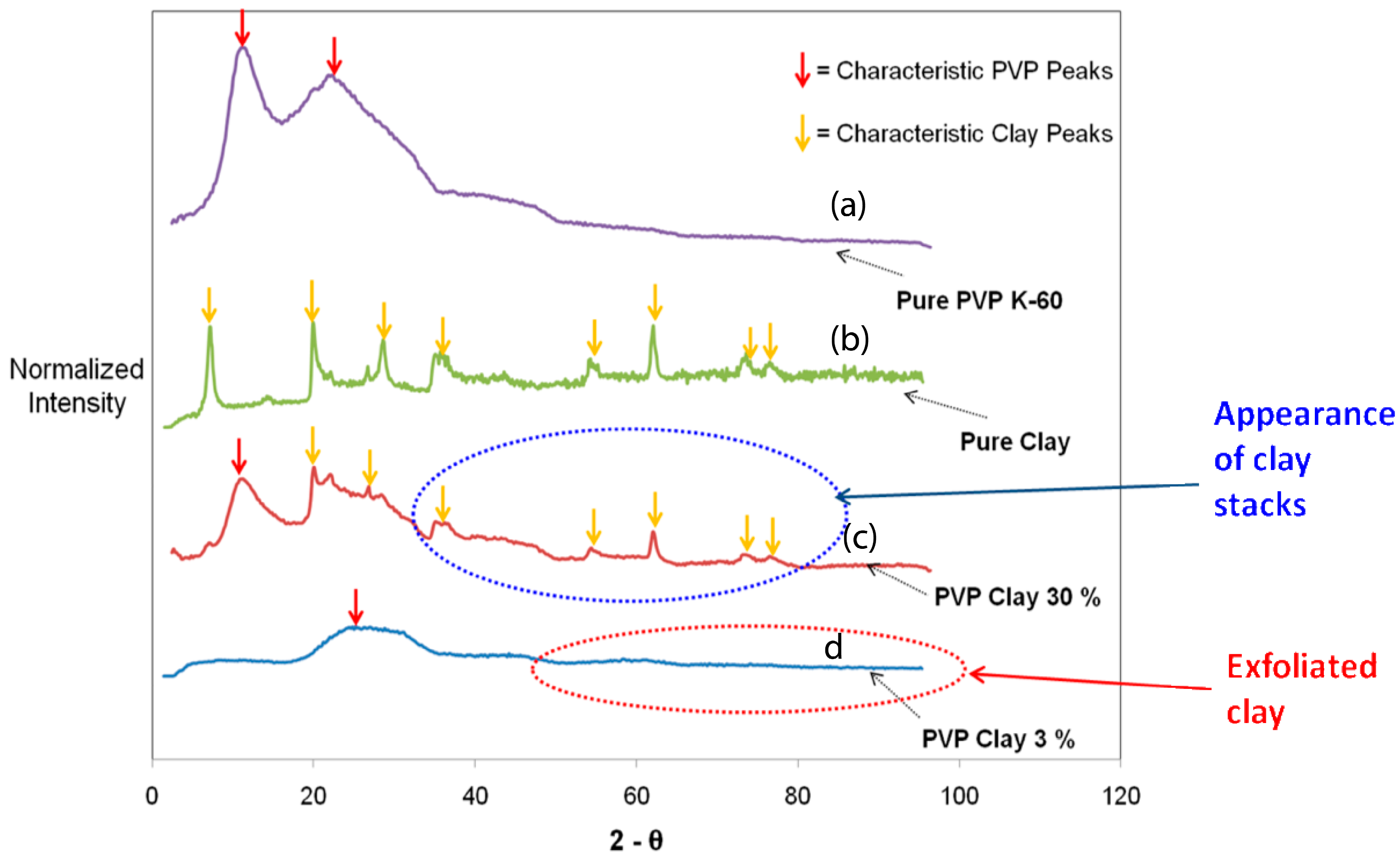

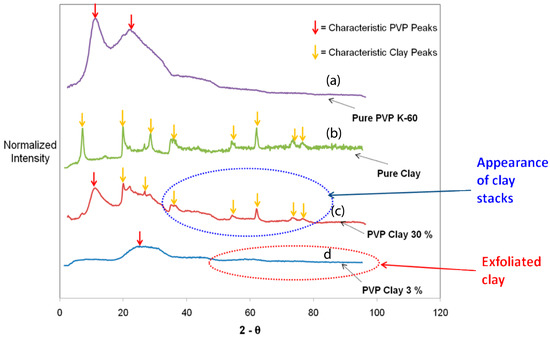

The diffraction spectra of Figure 5a represent the peaks that indicate the characteristic amorphous nature of PVP. Figure 5b represents the diffraction spectra for the pure OMMT clay powder with some sharp peaks indicating the crystalline nature of nanoclay. These sharp peaks are characteristic peaks of nanoclay.

Figure 5.

XRD spectra.

This phenomenon of reduction of amorphous nature due to the addition of nanoclay was observed in Figure 5c, as shown in the case of 30 wt.% clay addition in the PVP. Addition of nanoclay to PVP is expected to reduce the amorphous nature of the PVP polymer matrix. This would result in a reduction of the area under the amorphous hump displayed by the characteristic PVP peaks. On addition of clay to PVP, a shift in the position of clay peaks would indicate an increase in the spacing between the layers suggesting the intercalation.

The diminishing peak of 3 wt.% clay (Figure 5d) PVP suggests the exfoliation of the layers resulting from the better dispersion of clay particles in the PVP. Considering the XRD result, we have used only 3 wt.% clay-PVP film in this study.

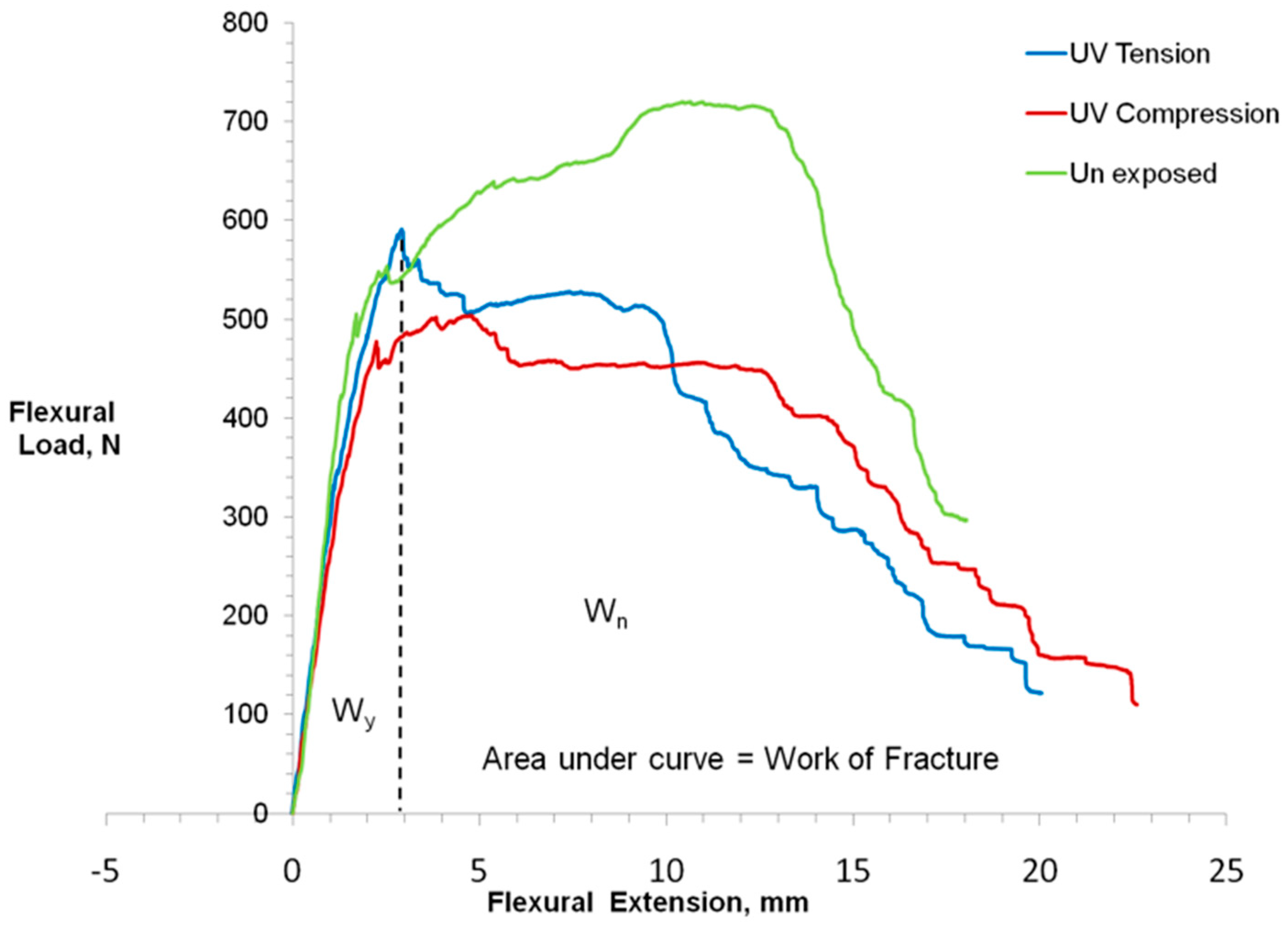

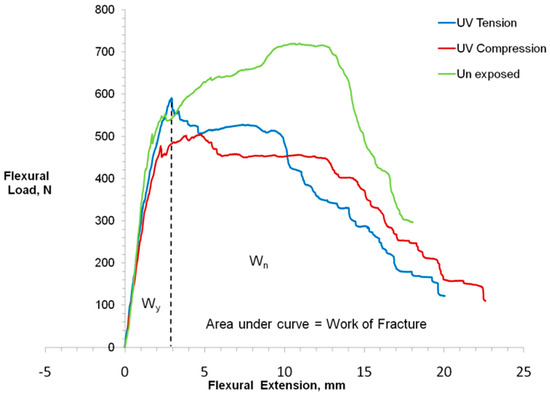

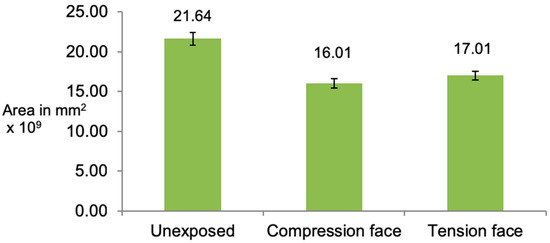

Figure 6 presents the results obtained from the three-point bend test performed on the BTTB carpet composite. It can be observed the failure of samples exposed to UV and moisture in comparison to the unexposed sample show that the carpet composite exhibits the brittle failure. The area under the curve of a force-extension plot is the work of fracture of the composite (Wf). The work of fracture is a sum of work due to yielding (Wy) and work due to plasticization (Wn).

Figure 6.

Preliminary results of the three-point bend tests conducted on the UV exposed samples indicating brittleness induced in the samples.

Wn has decreased drastically due to exposure of the composites to UV and moisture suggested degradation of the composite. The area under the curve of load-displacement data would give a much better understanding of the magnitude of reduction in the work of fracture of the unexposed and UV-Moisture exposed carpet composite.

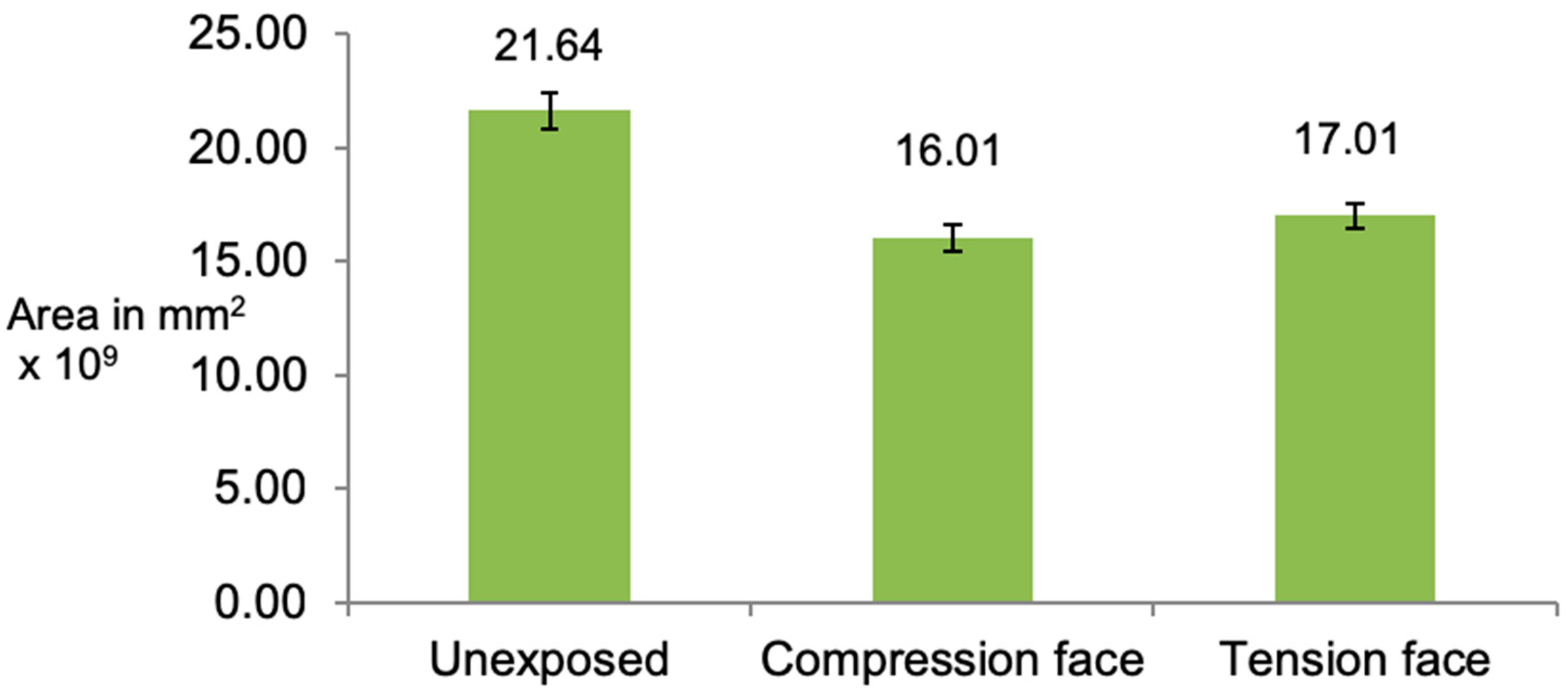

The values for the area under the curve of Figure 6 were calculated using the trapezoidal rule. Figure 7 exhibits that the area under the curve is at its highest for the clay-based carpet composite without any exposure to UV. A decrease in area under the curve for the exposed samples indicates a decrease in work fracture which in turn implies a degradation of the carpet composites on exposure to UV and moisture.

Figure 7.

Values of the area under curve calculated using the trapezoidal rule.

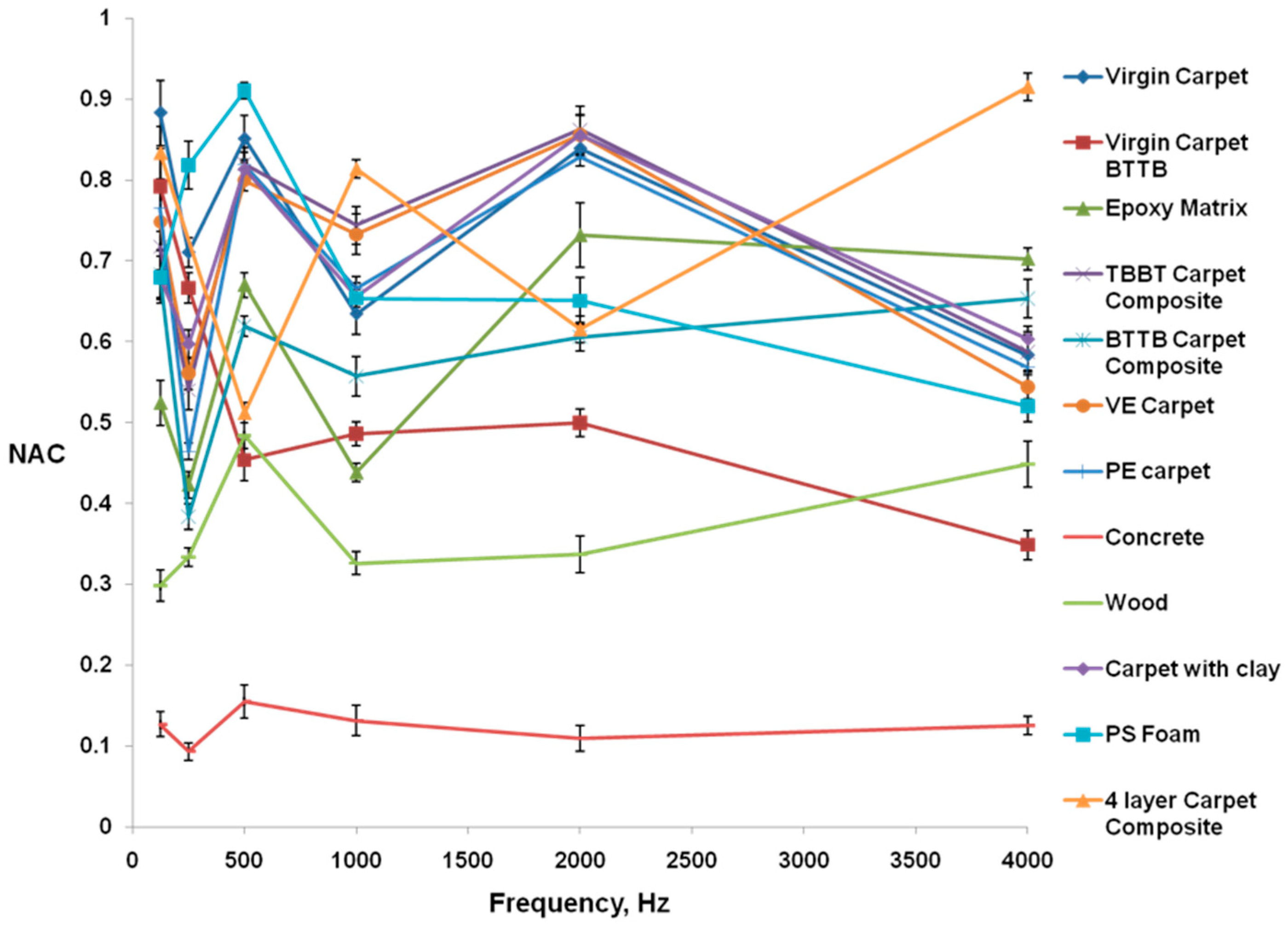

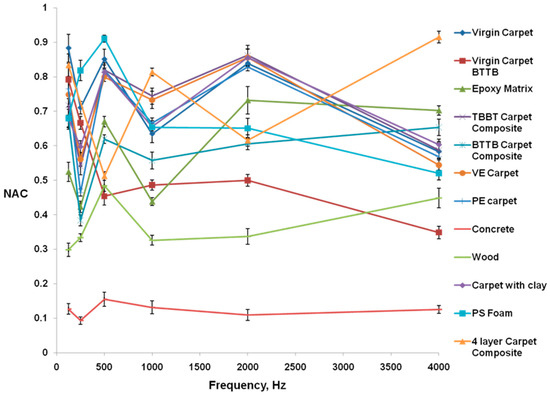

The NAC measurements were conducted as per ASTM C-384 at the 3rd-octave band frequency range from 125 Hz to 4000 Hz. The 3rd-octave band frequencies chosen for this test were—125 Hz, 250 Hz, 500 Hz, 1000 Hz, 2000 Hz, and 4000 Hz.

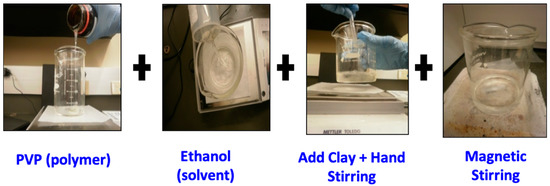

Figure 8 shows the result obtained for 12 different materials tested for noise absorption coefficient (NAC).

Figure 8.

Noise absorption coefficients of various noise absorbing materials calculated at the third-octave band range of frequencies using ASTM C 384-04.

The following detailed observations were made on the results of NAC obtained at different frequencies.

As a result, the study indicates that the virgin carpet (single layer-no resin) has the highest NAC at low frequencies of 125 Hz however, at the frequency range from 250–500 Hz the NAC value reduces. Polystyrene (PS) foam shows better sound absorption ability in the frequency range of 250–500 Hz, however, at a frequency above 500 Hz the NAC value of PS foam reduces.

The sound absorption ability of the four-layer carpet composite exhibited exceptionally good in the frequency range from 1000 Hz to 4000 Hz. As a result indicates, 4-layer carpet composite performs better than both the virgin carpet and the epoxy matrix at higher frequencies which is more related to the frequency of highway noise hence, four-layer carpet composite material was best suited for a highway noise barrier.

To compare the effect of carpet backing, Virgin carpet BTTB was also tested. The lower value of NAC indicates that due to the porosity of the back surface, the sound absorption ability of the material reduces. The NAC of BTTB Carpet composite is lesser than epoxy matrix in the third-octave band range of frequencies suggest that porosity play is a dominating role at the higher frequency. TBBT composite shows higher NAC values than BTTB composite which indicates that the porosity of backing dominates even after resin treatment of the carpet.

Concrete shows a significantly lower value of NAC compared to other materials. Addition of clay to the composites does not affect the noise absorption properties of the carpet composites.

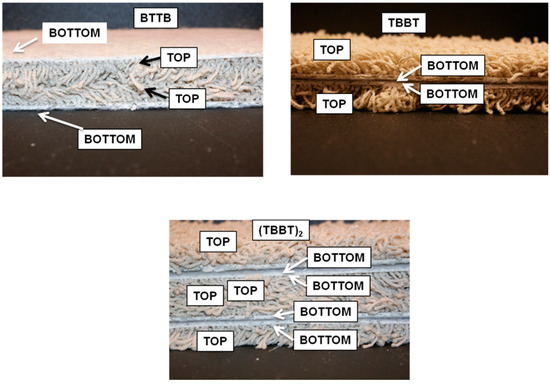

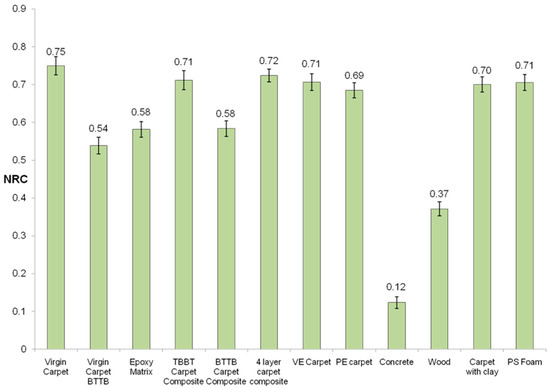

Noise reduction coefficient (NRC) represents the average of the value of NAC of the material at the different frequencies. NRC was calculated, from NAC, for all the materials. Figure 9 illustrates the NRC’s for all the 12 materials.

Figure 9.

Noise reduction coefficients of all the materials calculated at the third-octave band range of frequencies using ASTM C 384-04.

NRC of virgin carpet is the highest and concrete is the lowest. The NRC value of BTTB carpet composite is close the epoxy matrix suggests no influence of backing on the sound absorption ability. The NRC of virgin carpet is high, but the low mechanical properties limit the use of the virgin carpet as the highway barrier. Hence, the 4-layer carpet composite with the second highest value of NRC can be proposed as a good highway noise barrier.

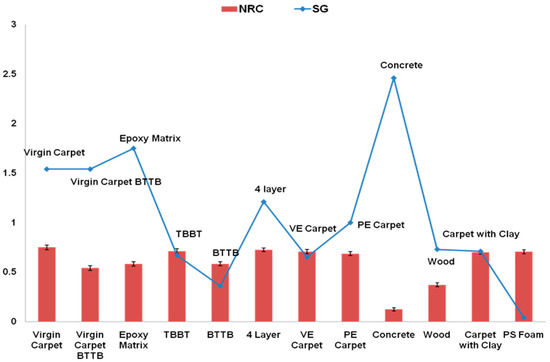

We have also investigated the relation between acoustic properties and density of the material. We have obtained the specific gravity of the materials using Archimedes’ principle as shown in Table 1. Among all the materials tested, PS foam has the lowest value of SG 0.4167 and concrete, has the highest SG of 24.61 The 4-layer carpet composite has the specific gravity (SG) of 1.21 which is highest among carpet composites. Whereas, BTTB carpet composite has lowest value SG (0.36). The TBBT carpet composite has an SG value of 0.67 while the TBBT carpet with clay configuration has an SG of 7.143, which indicates that the use of clay increases the specific gravity of the composite.

Table 1.

Twelve sound absorbing materials and their surface properties.

As shown in Figure 10, most of the materials with lower specific gravity exhibits the higher acoustic properties.

Figure 10.

Correlation of noise reduction coefficients (NRC) with specific gravity (SG).

5. Conclusions

In this work, vacuum assisted resin transfer molding was used to fabricate engineered composite materials from post-consumer carpet waste. The carpet composite shows excellent noise absorption ability at the wide spectrum of frequency. The 4-layer carpet composite shows the best noise absorbing ability compared to other carpet composite configuration. The application of nanoclay does not have any influence on the absorbing noise coefficient. Weather exposure of the composite exhibit degradation in the mechanical properties. Further study on the effect the clay infused carpet composite on the mechanical properties is required.

Author Contributions

K.M. performed the experimental study and writing of the manuscript. R.K.V. conceptualized the study, performed writing and reviewing as well as administrated the project.

Funding

This research was funded by the Oklahoma Center for Advancement of Science and Technology for the funding of this project ONAP 09-20.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leigh, J. Beyond Peak Oil in Post Globalization Civilization Clash. Open Geogr. J. 2008, 1, 15–24. [Google Scholar] [CrossRef]

- Daniels, E.J. Advanced Process Research and Development to Enhance Materials Recycling. Polym. Plast. Technol. Eng. 1999, 38, 569–579. [Google Scholar] [CrossRef]

- Mihut, C.; Dinyar, K.C.; Francis, G.M.; Amiridis, M.D. Review: Recycling of Nylon From Carpet Waste. Polym. Eng. Sci. 2001, 41, 1457–1470. [Google Scholar] [CrossRef]

- Carpet and Rug Institute. Board Meeting—Agenda Item 10 in the California Integrated Waste Management Board; Carpet and Rug Institute: Dalton, GA, USA, 2004. [Google Scholar]

- Fishbein, B.K. Carpet Take-Back: EPR American Style. Environ. Qual. Manag. 2000, 10, 25–36. [Google Scholar] [CrossRef]

- Bartl, H.A.; Hackl, A.; Mihalyi, B.; Wistuba, M.; Marini, I. Recycling of Fibre Materials. Process Saf. Environ. Protect. 2005, 83, 351–358. [Google Scholar] [CrossRef]

- Sifniades, S.; Levy, A.B.; Hendrix, J.A. Process for the Depolymerizing Nylon-Containing Whole Carpet to Form Caprolactam. U.S. Patent 5,929,234, 21 May 1998. [Google Scholar]

- Sifniades, S.; Levy, A.B.; Hendrix, J.A. Process for Depolymerizing Nylon-Containing Waste to Form Caprolactum. U.S. Patent 5,932,724, 16 April 1997. [Google Scholar]

- Mayer, R.E.; Crescentini, L.; Jenczewski, T.J. Process for the Purification of Caprolactam Obtained from the Depolymerization of Polyamide-Containing Carpet. U.S. Patent 6,187,917, 29 October 1999. [Google Scholar]

- Hendrix, J.A.; Booij, M.; Frentzen, Y.H. Depolymerization of Polyamides. U.S. Patent 5,668,277, 15 April 1996. [Google Scholar]

- Jenczewski, T.J.; Crescentini, L.; Mayer, R.E. Monomer Recovery from Multi-Component Materials. U.S. Patent 5,656,757, 10 August 1995. [Google Scholar]

- Frentzen, Y.H.; Thijert, M.P.; Zwart, R.L. Process for the Recovery of Caprolactam from Waste Containing Nylon. U.S. Patent 6,111,099, 12 January 1998. [Google Scholar]

- Corbin, T.F.; Handermann, A.C.; Kotek, R.; Porter, W.D.; Dellinger, J.A.; Davis, E.A. Reclaiming Epsilon-Caprolactam from Nylon 6 Carpet. U.S. Patent 5,977,193, 11 September 1992. [Google Scholar]

- Santos, E.D.; Mettvier, P.; Gubelmann, M. Process for Treating a Material Comprising a Polymer by Hydrolysis. U.S. Patent 5,905,168, 25 July 1995. [Google Scholar]

- Moens, L. Purification of Caprolactam from Recycled Nylon. U.S. Patent 5,919,927, 9 April 1998. [Google Scholar]

- Bockhorn, H.; Donner, S.; Gernsbeck, M.; Hornung, A.; Hornung, U. Pyrolysis of polyamide 6 under catalytic conditions and its application to reutilization of carpets. J. Anal. Appl. Pyrolysis 2001, 58–59, 79–94. [Google Scholar] [CrossRef]

- Roberts, C.B.; Griffith, T. Process for Recovering Polymers from Commingled Materials. U.S. Patent 5,994,417, 4 June 1997. [Google Scholar]

- Costello, M.R.; Keller, B.R. Process for Separation and Recovery of Waste Carpet Components. U.S. Patent 5,722,603, 28 November 1998. [Google Scholar]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2007, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Bihola, D.V.; Amin, H.N.; Shah, V.D. Application of Nano Material to Enhance Acoustic Properties. Int. J. Eng. Sci. Futur. Technol. 2015, 12, 001–009. [Google Scholar]

- Ayub, M.; Zander, A.C.; Howard, C.Q.; Cazzolato, B.S.; Huang, D.M.; Shanov, V.N.; Alvarez, N.T. Normal incidence acoustic absorption characteristics of a carbon nanotube forest. Appl. Acoust. 2017, 127, 223–239. [Google Scholar] [CrossRef]

- Ayub, M.; Zander, A.C.; Howard, C.Q.; Cazzolato, B.S.; Shanov, V.N.; Alvarez, N.T. Acoustic absorption behavior of carbon nanotube arrays. In Proceedings of the 43rd International Congress on Noise Control Engineering (Inter-Noise 2014), Melbourne, Australia, 16–19 November 2014; Volume 249, pp. 929–938. [Google Scholar]

- Attenborough, K. Models for the acoustical characteristics of air filled granular materials. Acta Acust. 1993, 1, 213–226. [Google Scholar]

- Chen, M.; Cai, F.; Wang, C.; Wang, Z.; Meng, L.; Li, F.; Zhang, P.; Liu, X.; Zheng, H. Observation of metal nanoparticles for acoustic manipulation. Adv. Sci. 2017, 4, 1600447. [Google Scholar] [CrossRef] [PubMed]

- Yamaguchi, N.H.; Mizuno, M.T. Sound absorption mechanism of porous asphalt pavement. J. Acoust. Soc. Jpn. E 1999, 20, 29–43. [Google Scholar] [CrossRef]

- Meiarashi, S.; Ishida, M.; Nakashiba, F.; Niimi, H.; Hasebe, M.; Nakatsuji, T. Improvement in the effect of drainage asphalt road surface on noise reduction. Appl. Acoust. 1996, 47, 189–204. [Google Scholar] [CrossRef]

- Oshino, Y.; Mikami, T.; Ohnishi, H.; Tachibana, H. Investigation into road vehicle noise reduction by drainage asphalt pavement. J. Acoust. Soc. Jpn. E 1999, 20, 75–84. [Google Scholar] [CrossRef]

- Tiwari, V.; Shukla, A.; Bose, A. Acoustic properties of cenosphere reinforced cement and asphalt concrete. Appl. Acoust. 2004, 65, 263–275. [Google Scholar] [CrossRef]

- May, D.N. The optimum weight of highway noise barriers. J. Sound Vib. 1980, 68, 1–13. [Google Scholar] [CrossRef]

- ASTM C-384-04. Standard Test Method for Impedance and Absorption of Acoustical Materials by Impedance Tube Method; ASTM: West Conshohocken, PA, USA, 2004. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).