A Biowaste Treatment Technology Assessment in Malawi

Abstract

1. Introduction

2. Materials and Methods

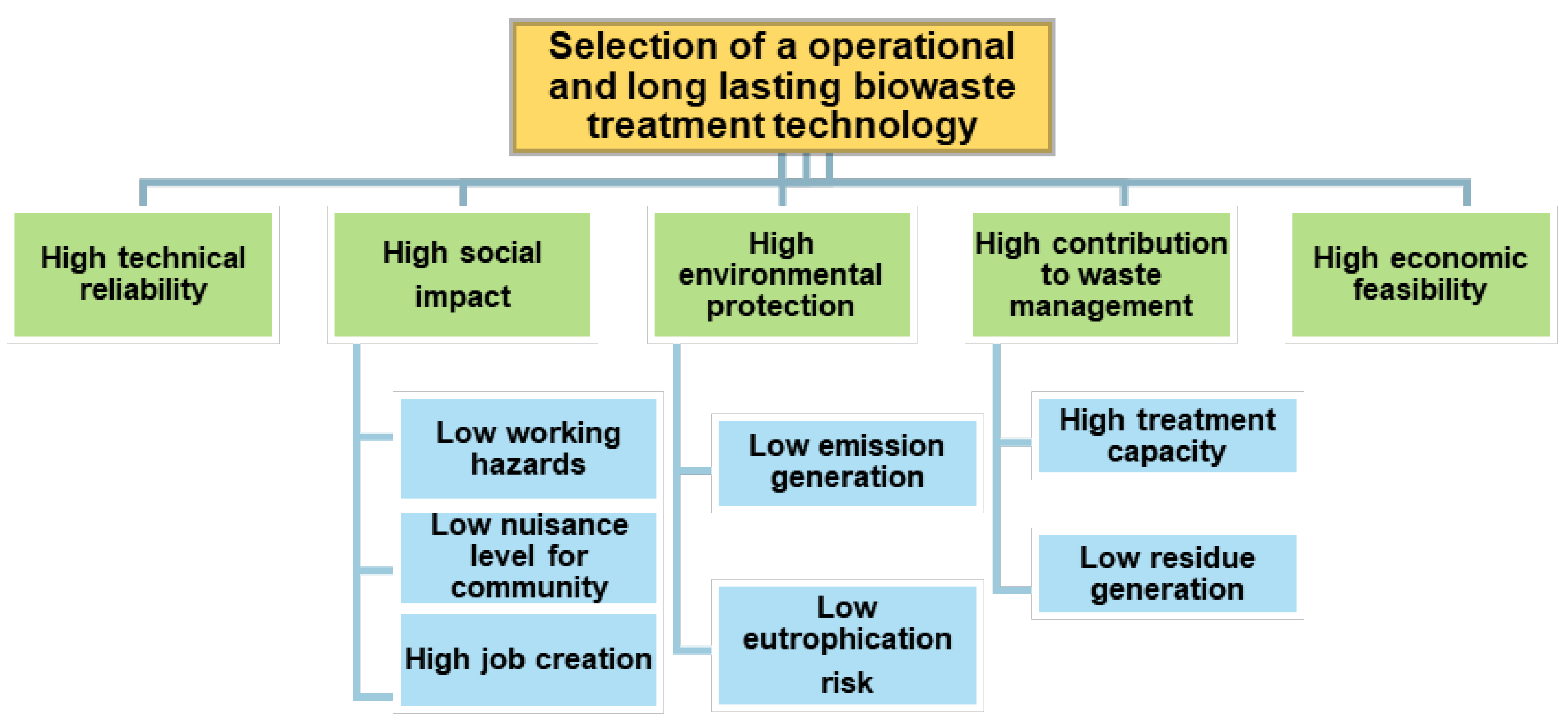

2.1. SOWATT Approach

2.2. Study Area

2.3. Biowaste Technology Options

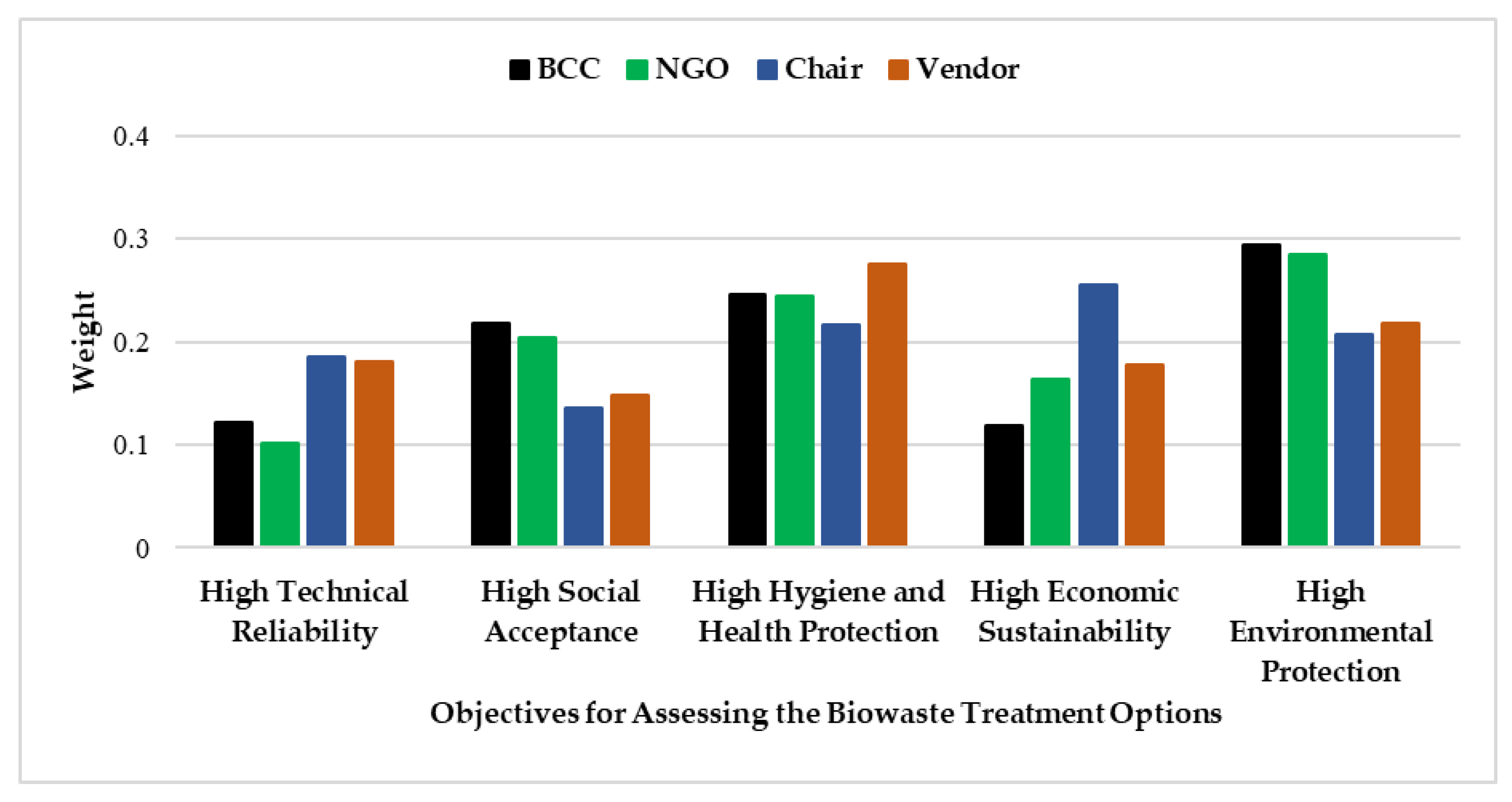

2.4. Stakeholders and Preferences

- : weight of objective or sub-objective x;

- : points given during the swing (in Equation (1)) or the reverse swing (in Equation (2)) method by the stakeholder to objective x; and

- m: number of objectives to be considered: 5 main objectives, 4 sub-objectives for “social acceptance”, 2 sub-objectives for “hygiene and health protection” and 2 sub-objectives for “environmental protection”.

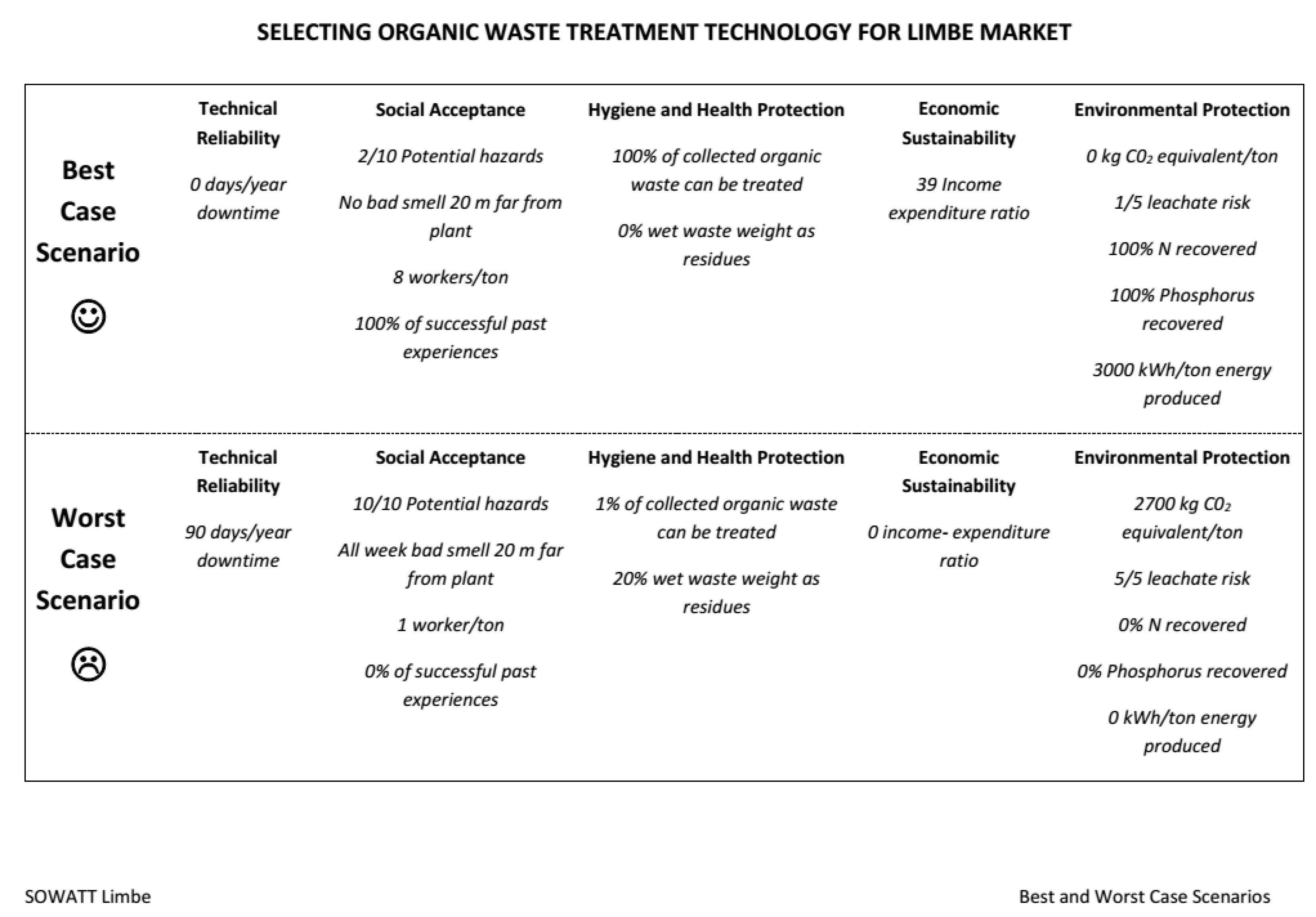

2.5. Technology Scoring

- : normalized value of the estimated performance of technology option Y for objective X;

- : the estimated performance of technology option Y for objective X;

- : minimum value considered for objective X among all technology options; and

- : maximum value considered for objective X among all technology options.

- : value (score) of the technology alternative A;

- : weight of objective r;

- : normalized value of the performance of technology alternative A for objective r; and

- : number of objectives.

- : normalized value of the performance of alternative A for objective r;

- : weight of sub-objective x;

- nx: normalized value of the performance of alternative A for sub-objective x; and

- m: number of sub-objectives.

3. Results

3.1. Stakeholder Preferences

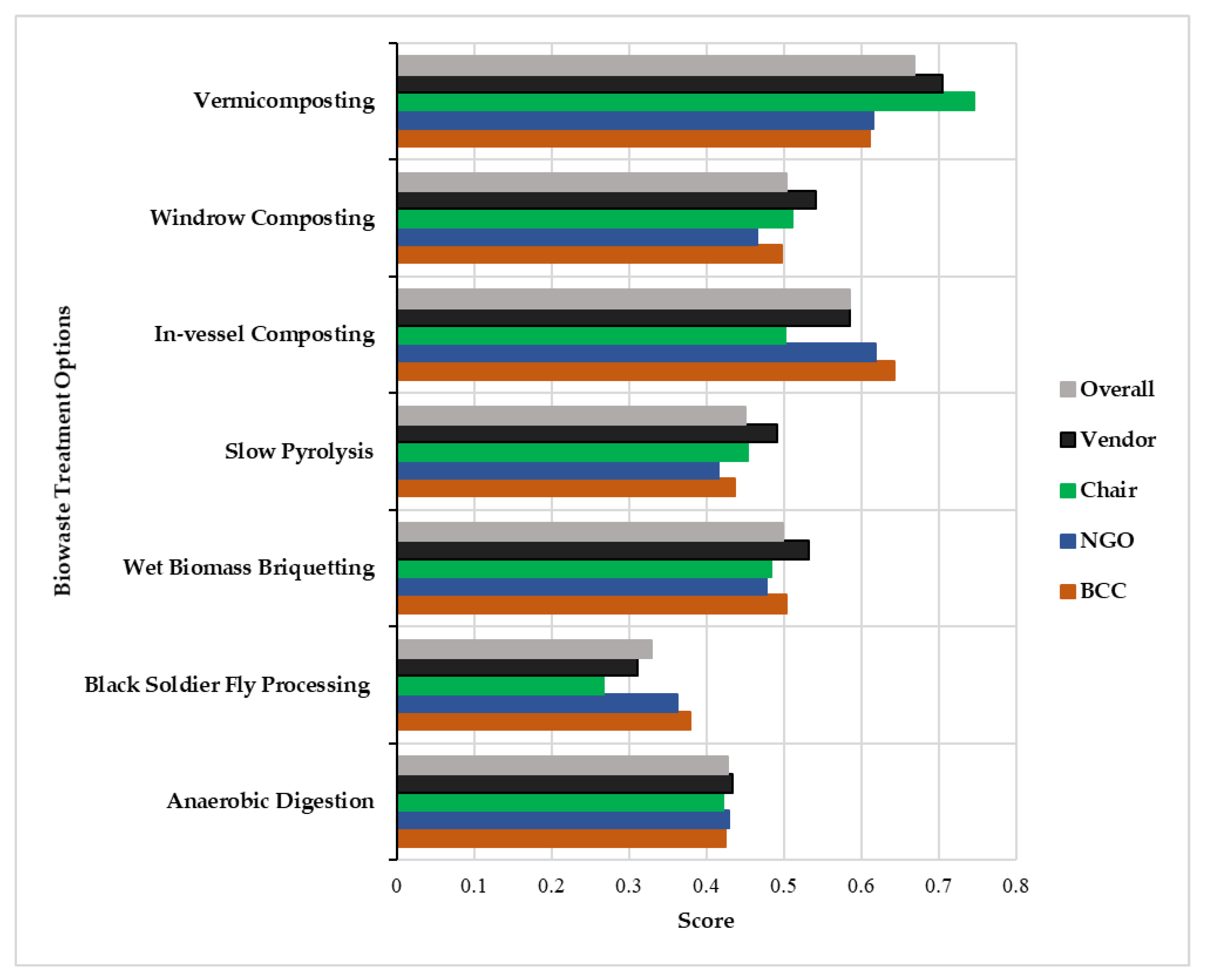

3.2. Technology Scores

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid waste management challenges for cities in developing countries. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef] [PubMed]

- Wilson, D.C.; Rodic, L.; Scheinberg, A.; Velis, C.A.; Alabaster, G. Comparative analysis of solid waste management in 20 cities. Waste Manag. Res. 2012, 30, 237–254. [Google Scholar] [CrossRef] [PubMed]

- Reddy, P.S.; Nandini, N. Leachate characterization and assessment of groundwater pollution near municipal solid waste landfill site. Nat. Environ. Pollut. Technol. 2011, 10, 415–418. [Google Scholar]

- National Statistical Office. Malawi in Figures 2016; Government Press: Zomba, Malawi, 2016; p. 2.

- Kasinja, C.; Tilley, E. Formalization of Informal Waste Pickers’ Cooperatives in Blantyre, Malawi: A Feasibility Assessment. Sustainability 2018, 10, 1149. [Google Scholar] [CrossRef]

- Lohri, C.R.; Diener, S.; Zabaleta, I.; Mertenat, A.; Zurbrügg, C. Treatment technologies for urban solid biowaste to create value products: A review with focus on low- and middle-income settings. Rev. Environ. Sci. Biotechnol. 2017, 2017 16, 81–130. [Google Scholar] [CrossRef]

- Zurbrügg, C. Assessment methods for waste management decision-support in developing countries. Ph.D. Thesis, Università degli Studi di Brescia, Brescia, Italy, 2013. [Google Scholar]

- Van de Klundert, A.; Anschütz, J. Integrated Sustainable Waste Management–The Concept. Waste Consultants: Gouda, The Netherlands, 2001; ISBN 9076639027. [Google Scholar]

- Wilson, D.C.; Rodic, L.; Cowing, M.J.; Velis, C.A.; Whiteman, A.D.; Scheinberg, A.; Vilches, R.; Masterson, D.; Stretz, J.; Oelz, B. ‘Wasteaware’ benchmark indicators for integrated sustainable waste management in cities. Waste Manag. 2015, 35, 329–342. [Google Scholar] [CrossRef] [PubMed]

- Karmperis, A.C.; Aravossis, K.; Tatsiopoulos, I.P.; Sotirchos, A. Decision support models for solid waste management: Review and game-theoretic approaches. Waste Manag. 2013, 2013. 33, 1290–1301. [Google Scholar] [CrossRef]

- Fiorucci, P.; Minciardi, R.; Robba, M.; Sacile, R. Solid waste management in urban areas: Development and application of a decision support system. Resour. Conserv. Recycl. 2003, 37, 301–328. [Google Scholar] [CrossRef]

- Güereca, L.P.; Gassó, S.; Baldasano, J.M.; Jiménez-Guerrero, P. Life cycle assessment of two biowaste management systems for Barcelona, Spain. Resour. Conserv. Recycl. 2006, 49, 32–48. [Google Scholar] [CrossRef]

- Zabaleta, I.; Scholten, L.; Zurbrügg, C. Selecting Appropriate Organic Waste Treatment Options in the Philippines. Sandec News 2015, 16, 4–5. [Google Scholar]

- Mertenat, A.; Zabaleta, I.; Zurbrügg, C. Appropriate Biowaste Treatment Technology for Aquitania, Colombia. Sandec News 2016, 17, 6–7. [Google Scholar]

- Eisenführ, F.; Weber, M.; Langer, T. Rational Decision Making; Springer: Berlin, Germany, 2010. [Google Scholar]

- Gregory, R.; Failing, L.; Harstone, M.; Long, G.; McDaniels, T.; Ohlson, D. Structured Decision Making. A Practical Guide to Environmental Management Choices. Wiley-Blackwell: Hoboken, NJ, USA, 2012; ISBN 978-1-4443-3341-1. [Google Scholar]

- Reichert, P.; Langhans, S.D.; Lienert, J.; Schuwirth, N. The conceptual foundation of environmental decision support. J. Environ. Manage. 2015, 154, 316–332. [Google Scholar] [CrossRef] [PubMed]

- Schuwirth, N.; Reichert, P.; Lienert, J. Methodological aspects of multi-criteria decision analysis for policy support: A case study on pharmaceutical removal from hospital wastewater. Eur. J. Oper. Res. 2012, 220, 472–483. [Google Scholar] [CrossRef]

- Scholten, L.; Scheidegger, A.; Reichert, P.; Mauer, M.; Lienert, J. Strategic rehabilitation planning of piped water networks using multi-criteria decision analysis. Water Res. 2014, 49, 124–143. [Google Scholar] [CrossRef] [PubMed]

- Cooperband, L. The Art and Science of Composting – A Resource for Farmers and Compost Producers. University of Wisconsin-Madison, Center for Integrated Agricultural Systems: Madison, WI, USA, 2002. [Google Scholar]

- Rothenberger, S.; Zurbrügg, C.; Enayetullah, I.; Sinha, A. Decentralized Composting for Cities of Low- And Middle-Income Countries—A User’s Manua; l. Swiss Federal Institute of Aquatic Science and Technology (Eawag), Dübendorf, Switzerland and Waste Concern: Dhaka, Bangladesh, 2006. [Google Scholar]

- Vögeli, Y.; Lohri, C.; Gallardo, A.; Diener, S.; Zurbrügg, C. Anaerobic Digestion of Biowaste in Developing Countries—Practical Information and Case Studies; Swiss Federal Institute of Aquatic Science and Technology (Eawag): Dübendorf, Switzerland, 2014. [Google Scholar]

- Munroe, G. Manual of On-Farm Vermicomposting and Vermiculture; Organic Agriculture Centre of Canada: Nova Scotia, Canada, 2007. [Google Scholar]

- Ali, U.; Sajid, N.; Khalid, A.; Riaz, L.; Rabbani, M.M.; Syed, J.H.; Malik, R.N. A review on vermicomposting of organic wastes. Environ Prog Sustain Energy 2015, 34, 1050–1062. [Google Scholar] [CrossRef]

- Dortmans, B.M.A.; Diener, S.; Verstappen, B.M.; Zurbrügg, C. Black Soldier Fly Biowaste Processing—A Step-by-Step Guide; Eawag-Swiss Federal Institute of Aquatic Science and Technology. Department of Sanitation, Water and Solid Waste for Development (Sandec): Dübendorf, Switzerland, 2017. [Google Scholar]

- Zheng, J.; Lienert, J. Stakeholder interviews with two MAVT preference elicitation philosophies in a Swiss water infrastructure decision: Aggregation using SWING-weighting and disaggregation using UTAGMS. Eur. J. Oper. Res. 2018, 267, 273–287. [Google Scholar] [CrossRef]

| Objectives | Objective Description | Attribute | Attribute Description |

|---|---|---|---|

| High technical reliability | The technology operates with as little downtime (technology breakdown or not working for whatever reason) as possible | Maximum number of consecutive days of downtime per year (days/year) The lower this attribute, the higher is the technical reliability | Estimated while considering a list of influencing factors that included affordability of materials for maintenance, time required to get maintenance materials from supplier, and affordability of maintenance personnel |

| High social acceptance | The technology is accepted by the community from a socio-cultural perspective, which is defined by four sub-objectives: (1) ‘high job creation’, (2) ‘high working safety’, (3) ‘low smell impact’, and (4) ‘high trust in technology’ | ||

| High job creation | The technology generates employment and therefore increases social acceptance | Number of workers for each ton of biowaste treated (workers/ton) | Estimated for each technology based on similar local experiences with the technology or from literature |

| High working safety | The technology ensures safe working conditions, thereby increasing social acceptance | Value from 1–10. 1 is low potential of hazards (safe) and 10 is high potential of hazards (unsafe) | Estimated considering the possible risks that the technology poses to the workers |

| Low smell impact | The technology does not create nuisance by smell, thereby increasing social acceptance | Number of hours per week of bad smell 20 meters away from the installation (h/week) | Estimated based on literature |

| High trust in technology | Past success of a technology creates a level of trust that increases social acceptance | Percentage of past experiences for each technology that are still working (%) | Estimated by dividing the number of existing installations by the total number of installations (past and current) |

| High environmental pollution | The technology is environmentally friendly, whereby environmental friendliness is defined by two sub-objectives: (1) ‘low environmental pollution’ and (2) ‘high resource recovery’ | ||

| Low environmental pollution | The technology generates less pollution to the atmosphere (gases) and to groundwater (leachate), which contributes to environmental protection | CO2 equivalents emitted to the atmosphere for each ton of biowaste treated. Leachate risk (from 1 to 5) 1 being low leachate risk and 5 being high leachate risk | Estimated based on literature |

| High resource recovery | The technology contributes to recovering as much phosphorus and nitrogen as possible and/or generates renewable energy from biowaste, which contributes to environmental protection | Percentage (%) of nitrogen (N) in biowaste recovered in the end-product Percentage (%) of phosphorus (P) in biowaste recovered in the end-product Energy generated, in Kilowatt hours (kWh), from each ton of waste (kWh/ton) | Estimated based on literature |

| High hygiene and health protection of the community | The technology contributes highly to reducing health risks and improving hygiene in the community. This objective is described by two sub-objectives: (1) ‘high treatment capacity’ and (2) ‘low residue generation’ | ||

| High treatment capacity | The technology is able to treat a lot of the collected waste, which contributes to protection of the health of the community | Percentage (%) of the collected waste that the technology can treat | Estimated based on local experiences of the technology |

| Low residue generation | The technology generates less residual waste, which contributes to protection of the health of the community | Percentage (%) of the input waste that is converted into a non-marketable residue | Estimated based on local experiences and literature |

| High economic sustainability | The income obtained with the technology enables one to at least cover its cost and, if possible, make profit | Ratio of revenues and expenditure (dimensionless value) The higher this ratio (value) is, the higher the economic sustainability of the technology | Estimated by dividing the revenues and expenditures over the lifespan of the installation. Estimation based on local experiences and literature |

| Objectives | Unit | AD | BSF (NT) | BSF (HT) | WBB | SP (NT) | SP (HT) | IC (NT) | IC (HT) | WC | VC |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sub-Objectives | |||||||||||

| Attributes | |||||||||||

| High technical reliability | |||||||||||

| Downtime | days/ year | 90 | 90 | 90 | 7 | 14 | 14 | 30–90 | 30–90 | 0–7 | 0 |

| High social acceptance | |||||||||||

| High job creation | |||||||||||

| Labour productivity | workers/ton/day | 1.25–2.5 | 2.5–5 | 2.5–5 | 3–5 | 3.75–7.5 | 3.75–7.5 | 1.5 | 1.5 | 2.5–5 | 2.5–5 |

| High working safety | |||||||||||

| Level of potential hazards | Scale of 1–10 | 7 | 4 | 4 | 7 | 9 | 9 | 3 | 3 | 4 | 2 |

| Low smell impact | |||||||||||

| Smell emissions at 20 meters distance | h/week | 0 | 168 | 168 | 0–168 | 56 | 56 | 0 | 0 | 84 | 0–168 |

| High trust in technology | |||||||||||

| Percentage of projects still operational | % | 20–50 | 0 | 100 | 25 | 0 | 100 | 0 | 100 | 14–57 | 100 |

| High environmental protection | |||||||||||

| Low environmental pollution | |||||||||||

| CO2 emission | kg CO2 eq./ton | 170–690 | 200–300 | 200–300 | 0–5 | 1600–2700 | 1600–2700 | 23–33 | 23–33 | 325–390 | 325–390 |

| Leachate-risk level | Scale 1–5 | 4 | 2 | 2 | 2 | 1 | 1 | 1 | 1 | 5 | 5 |

| High resource recovery | |||||||||||

| Nitrogen recovered | % N | 90–100 | 43 | 43 | 0 | 0 | 0 | 62.5–91 | 62.5–91 | 25–91 | 40–91 |

| Phosphorus recovered | % P | 95–100 | 67 | 67 | 0 | 0 | 0 | 85–99 | 85–99 | 62–99 | 40–99 |

| Energy recovered | kWh/ton | 600–900 | 0 | 0 | 500–3000 | 2000–3000 | 2000–3000 | 0 | 0 | 0 | 0 |

| High hygiene and community health protection | |||||||||||

| Low residue generation | |||||||||||

| Residue output | % | 0 | 0–20 | 0–20 | 0–5 | 0 | 0 | 0 | 0 | 0 | 0 |

| High treatment capacity | |||||||||||

| Applicability to biowaste collected | % | 10–30 | 10–60 | 10–60 | 20–70 | 0–10 | 0–10 | 75–100 | 75–100 | 75–100 | 50–85 |

| High economic sustainability | |||||||||||

| Financial Performance | Cost-Revenue Ratio | 13.31 | 0.17 | 0.17 | 1.69 | 0.04 | 0.04 | 0.94 | 0.94 | 2.86 | 38.2 |

| BCC Cluster | NGO Cluster | Chair Cluster | Vendor Cluster |

|---|---|---|---|

|

|

| 16 randomly selected vendors from the produce section of the market |

| Objectives | Swing Method | Reverse Swing | Average | Rank | |||

|---|---|---|---|---|---|---|---|

| Point | Weight | Point | Weight | ||||

| Main Objectives | Technical Reliability | 80 | 0.242 | 20 | 0.242 | 0.242 | 2 |

| Social Acceptance | 50 | 0.152 | 50 | 0.152 | 0.151 | 4 | |

| Hygiene and Health Protection | 100 | 0.303 | 0 | 0.303 | 0.303 | 1 | |

| Economic Sustainability | 40 | 0.121 | 60 | 0.121 | 0.121 | 5 | |

| Environmental Protection | 60 | 0.182 | 40 | 0.182 | 0.182 | 3 | |

| Social Acceptance | Working Safety | 100 | 0.333 | 0 | 0.370 | 0.352 | 1 |

| Smell Impact | 70 | 0.233 | 50 | 0.185 | 0.209 | 3 | |

| Job Creation | 80 | 0.267 | 20 | 0.296 | 0.281 | 2 | |

| Trust in Technology | 50 | 0.167 | 60 | 0.148 | 0.157 | 4 | |

| Hygiene and Health Protection | Treatment Capacity | 100 | 0.556 | 0 | 0.833 | 0.694 | 1 |

| Residue Generation | 80 | 0.444 | 80 | 0.1667 | 0.306 | 2 | |

| Environmental Protection | Environmental Pollution | 100 | 0.556 | 0 | 0.667 | 0.611 | 1 |

| Resource Recovery | 80 | 0.444 | 50 | 0.333 | 0.389 | 2 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mpanang’ombe, W.; Tilley, E.; Zabaleta, I.; Zurbrügg, C. A Biowaste Treatment Technology Assessment in Malawi. Recycling 2018, 3, 55. https://doi.org/10.3390/recycling3040055

Mpanang’ombe W, Tilley E, Zabaleta I, Zurbrügg C. A Biowaste Treatment Technology Assessment in Malawi. Recycling. 2018; 3(4):55. https://doi.org/10.3390/recycling3040055

Chicago/Turabian StyleMpanang’ombe, Wrixon, Elizabeth Tilley, Imanol Zabaleta, and Christian Zurbrügg. 2018. "A Biowaste Treatment Technology Assessment in Malawi" Recycling 3, no. 4: 55. https://doi.org/10.3390/recycling3040055

APA StyleMpanang’ombe, W., Tilley, E., Zabaleta, I., & Zurbrügg, C. (2018). A Biowaste Treatment Technology Assessment in Malawi. Recycling, 3(4), 55. https://doi.org/10.3390/recycling3040055