Impact of Particle Size on Properties of 100% Recycled End-of-Life Tire Rubber Sheets from Calendering

Abstract

1. Introduction

2. Results

2.1. Leaching Test

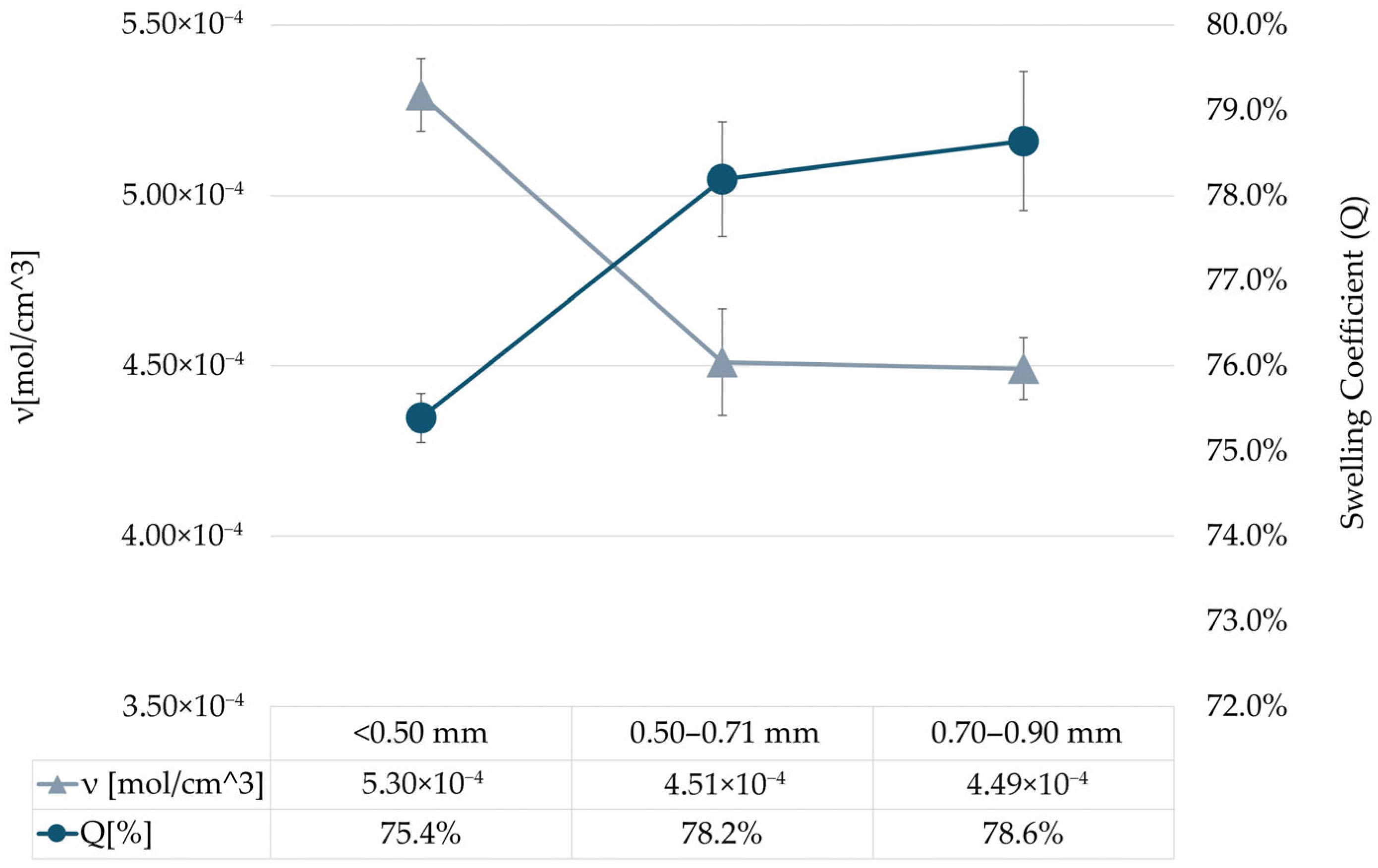

2.2. Crosslink Density

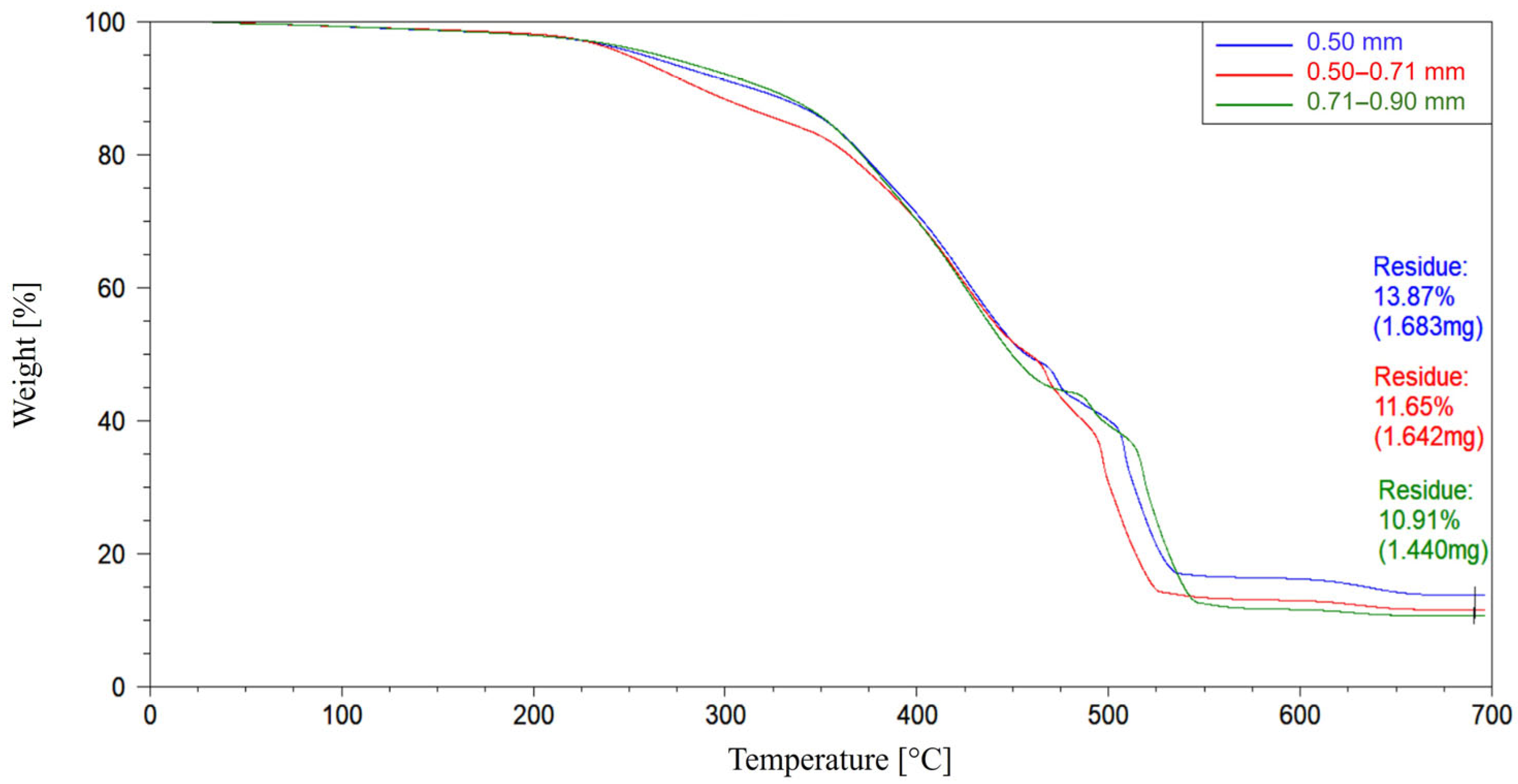

2.3. Thermogravimetric Analysis

2.4. Mechanical Tests

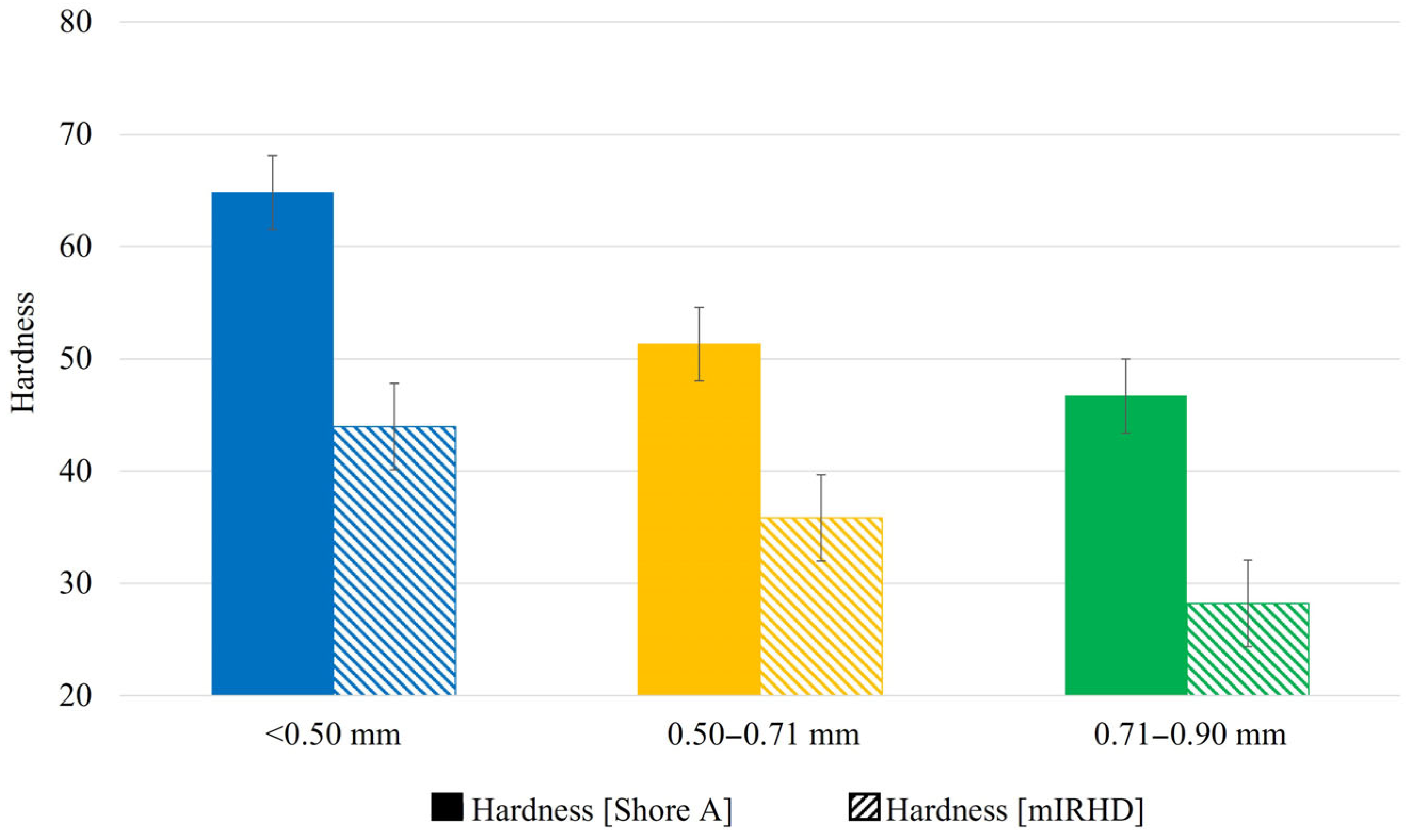

2.4.1. Hardness Test

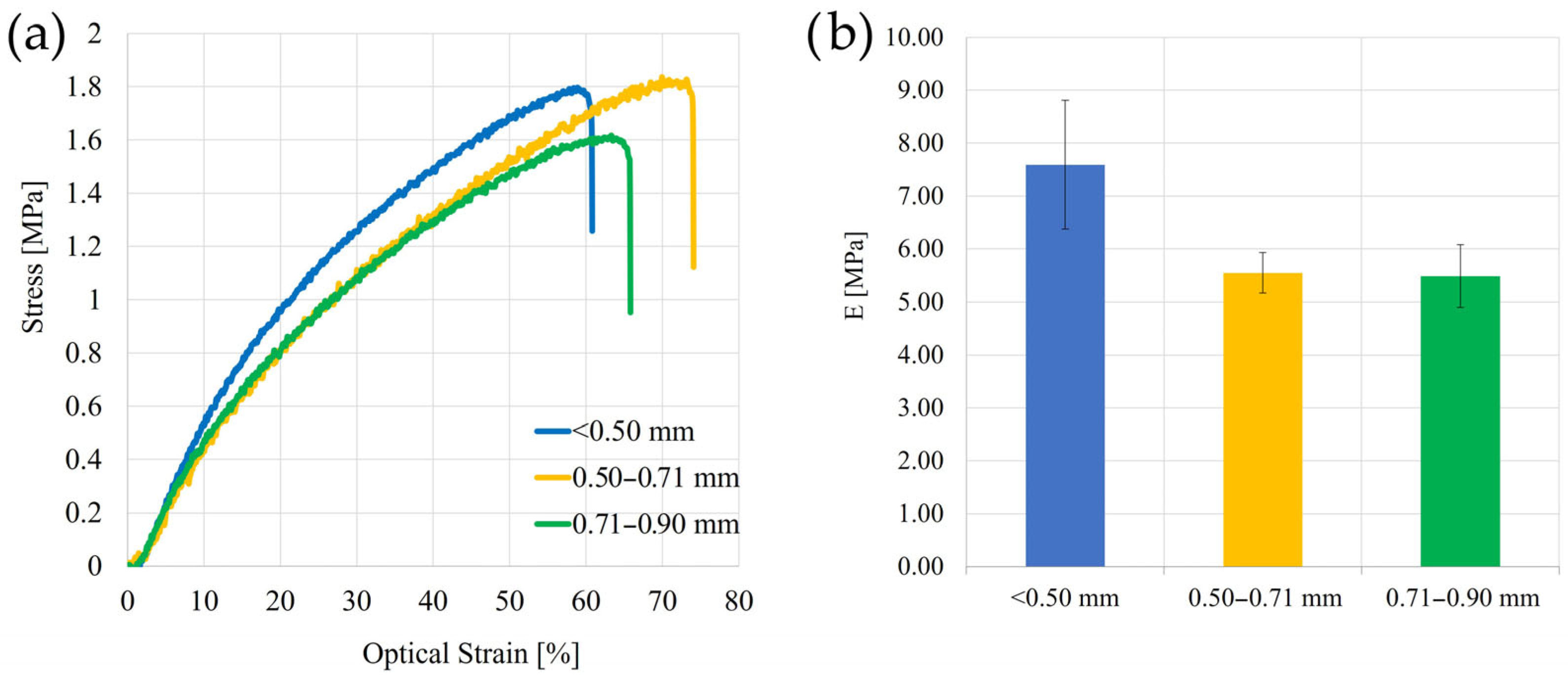

2.4.2. Tensile Test

3. Discussion

4. Materials and Methods

- Vulcanized rubber matrix: primarily styrene-butadiene rubber (SBR) and natural rubber (NR) blends with residual sulfur crosslinks

- Carbon black reinforcement: approximately 20–30 wt% retained within the rubber matrix

- Inorganic fillers: including silica, zinc oxide, and calcium carbonate

- Residual additives: processing oils, antioxidants, and vulcanization accelerators

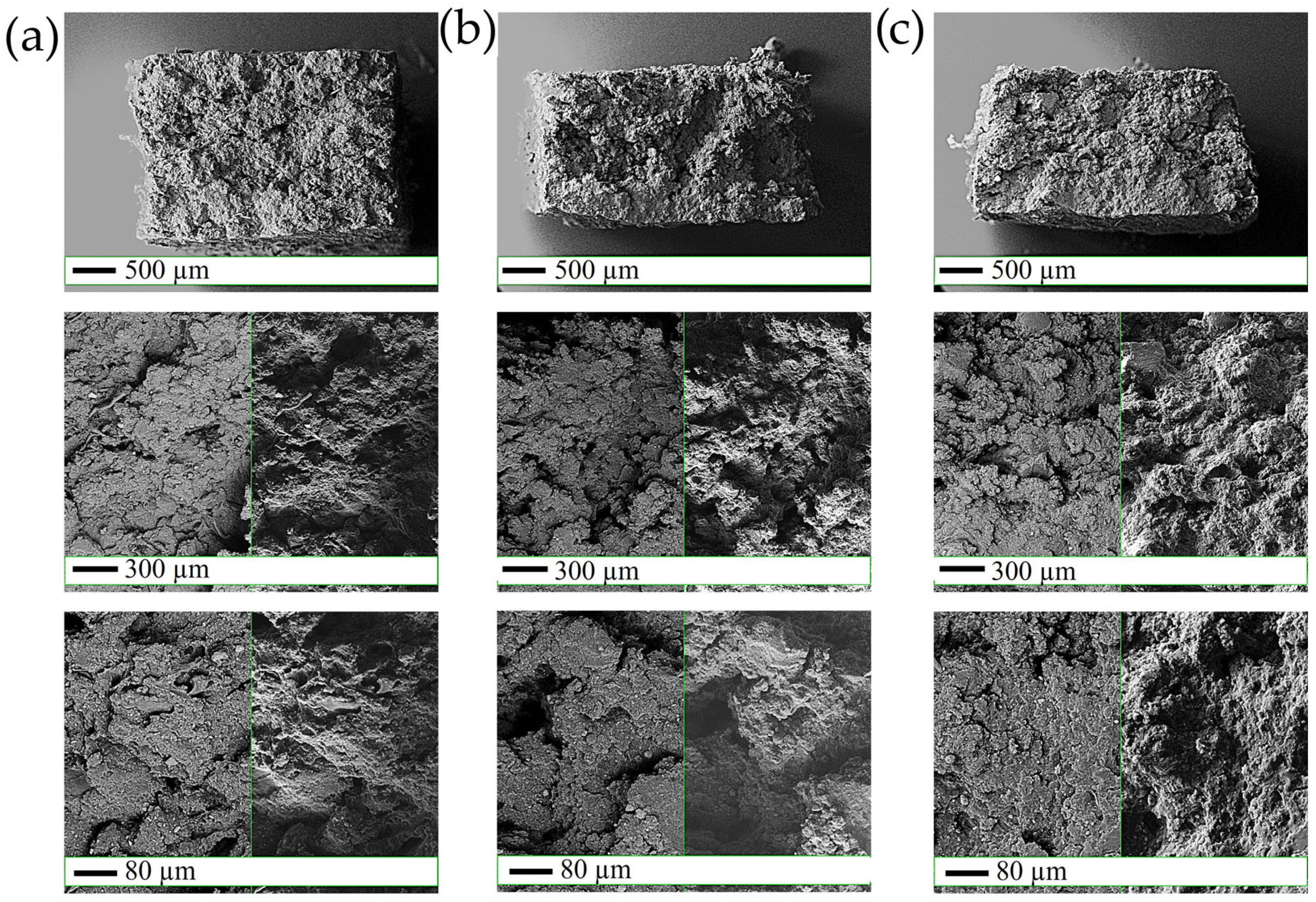

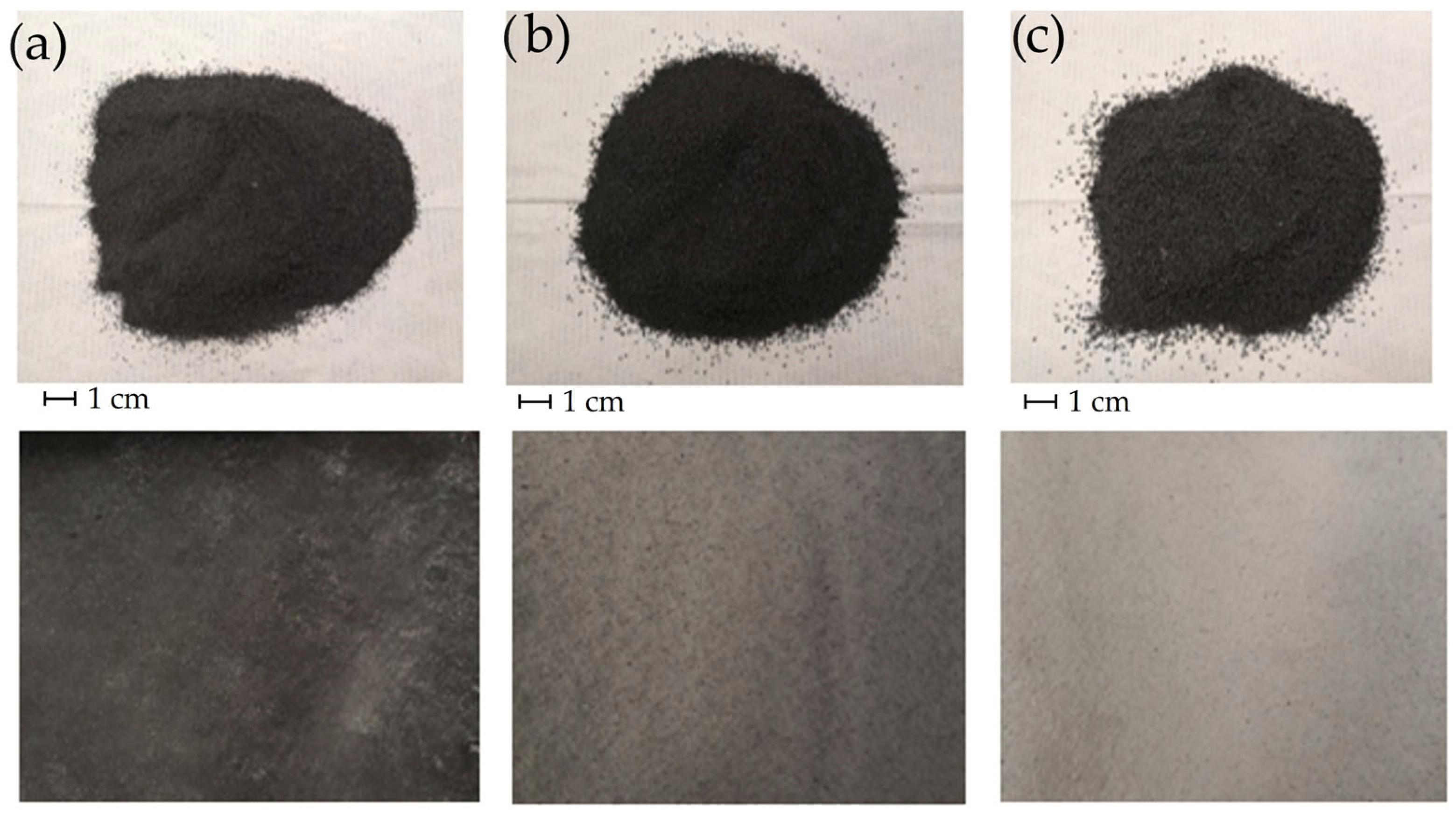

- Fine fraction: <0.50 mm

- Medium fraction: 0.50–0.71 mm

- Coarse fraction: 0.71–0.90 mm

- Roll gap (nip): 0.05 mm

- Front-roll linear speed: 8 m·min−1

- Speed ratio (friction ratio): 1:1.2 between front and back rolls, generating the shear forces

- Motor power: 7.5 kW

- Processing time: approximately 40 min per batch (150 g)

- Number of passes: approximately 450–500 passes (one pass every ~5 s)

5. Conclusions

- The additive-free, low-energy process converts ELT powders into cohesive sheets without external heating or virgin binders, relying solely on friction-induced temperature rise.

- Finer powder fractions (<0.5 mm) retain the highest crosslink density (5.30 × 10−4 mol·cm−3, ~18% higher than coarser powders), resulting in increased hardness and modulus.

- The recycled sheets exhibit tensile strengths of 1.6–1.8 MPa and elongation at break of 60–75%, positioning the material between low-temperature compression-molded and high-pressure sintered GTRs. Compared with sintering, calendering provides a favorable balance between mechanical performance and energy demand, while preserving 100% recycled content.

- The transformation from particulate rubber to a monolithic structure addresses the EU microplastic regulation (2023/2055), as the calendered sheets prevent direct particle dispersion. However, microplastic formation may still occur under severe abrasion.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ELT | End-of-Life Tires |

References

- Battista, M.; Gobetti, A.; Agnelli, S.; Ramorino, G. Post-Consumer Tires as a Valuable Resource: Review of Different Types of Material Recovery. Environ. Technol. Rev. 2020, 10, 1–25. [Google Scholar] [CrossRef]

- European Tyre and Rubber Manufacturers’ Association, E. End-of-Life Tyres in a Circular Economy: ETRMA’s Perspective on a Competitive Recycling Sector. Available online: https://tyreseurope.org/ (accessed on 29 July 2025).

- Gobetti, A.; Cornacchia, G.; Ramorino, G. Transforming Waste into Valuable Resources: Recycled Nitrile-Butadiene Rubber Scraps Filled with Electric Arc Furnace Slag. Clean. Eng. Technol. 2024, 23, 100823. [Google Scholar] [CrossRef]

- Gobetti, A.; Ramorino, G.; Gelfi, M.; Depero, L.E.; Zacco, A.; Fenotti, M.; Cornacchia, G. Innovative Application of Steelmaking Slag from Ladle Furnace as Filler for Recycled Nitrile Butadiene Rubber Industrial Scrap. J. Environ. Chem. Eng. 2025, 13, 119511. [Google Scholar] [CrossRef]

- Blume, A.; Kiesewetter, J. Determination of the Crosslink Density of Tire Tread Compounds by Different Analytical Methods. KGK Kautsch. Gummi Kunststoffe 2019, 72, 33–42. [Google Scholar]

- Gobetti, A.; Marchesi, C.; Depero, L.E.; Ramorino, G. Characterization of Recycled Nitrile Butadiene Rubber Industrial Scraps. J. Mater. Cycles Waste Manag. 2024, 26, 1761–1775. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in Used Tyres Management in the European Union: A Review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Formela, K. Sustainable Development of Waste Tires Recycling Technologies—Recent Advances, Challenges and Future Trends. Adv. Ind. Eng. Polym. Res. 2021, 4, 209–222. [Google Scholar] [CrossRef]

- Gobetti, A.; Cornacchia, G.; Agnelli, S.; Ramini, M.; Ramorino, G. A Novel and Sustainable Rubber Composite Prepared from Electric Arc Furnace Slag as Carbon Black Replacement. Carbon Resour. Convers. 2024, 7, 100230. [Google Scholar] [CrossRef]

- Williams, P.T. Pyrolysis of Waste Tyres: A Review. Waste Manag. 2013, 33, 1714–1728. [Google Scholar] [CrossRef]

- Lahijani, P.; Zainal, Z.A. Gasification of Palm Empty Fruit Bunch in a Bubbling Fluidized Bed: A Performance and Agglomeration Study. Bioresour. Technol. 2011, 102, 2068–2076. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste Tyre Pyrolysis—A Review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Roy, C.; Chaala, A.; Darmstadt, H. Vacuum Pyrolysis of Used Tires End-Uses for Oil and Carbon Black Products. J. Anal. Appl. Pyrolysis 1999, 51, 201–221. [Google Scholar] [CrossRef]

- Formela, K.; Cysewska, M.; Haponiuk, J.T. Thermomechanical Reclaiming of Ground Tire Rubber via Extrusion at Low Temperature: Efficiency and Limits. J. Vinyl Addit. Technol. 2016, 22, 213–221. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Cannone Falchetto, A.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the Unexplored Potential of European Waste Materials for Road Construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and Recycling of Waste Rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.T.; Chuah, A.L.; Rashmi, W. Waste Tire Rubber in Polymer Blends: A Review on the Evolution, Properties and Future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Kumar, C.R.; Fuhrmann, I.; Karger-Kocsis, J. LDPE-Based Thermoplastic Elastomers Containing Ground Tire Rubber with and without Dynamic Curing. Polym. Degrad. Stab. 2002, 76, 137–144. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Lis, M.J. Acoustic and Mechanical Properties of Recycled Polyvinyl Chloride/Ground Tyre Rubber Composites. J. Compos. Mater. 2014, 48, 1061–1069. [Google Scholar] [CrossRef]

- De, D.; Maiti, S.; Adhikari, B. Reclaiming of Rubber by a Renewable Resource Material (RRM). III. Evaluation of Properties of NR Reclaim. J. Appl. Polym. Sci. 2000, 75, 1493–1502. [Google Scholar] [CrossRef]

- Asaro, L.; Gratton, M.; Seghar, S.; Aït Hocine, N. Recycling of Rubber Wastes by Devulcanization. Resour. Conserv. Recycl. 2018, 133, 250–262. [Google Scholar] [CrossRef]

- Kalbe, U.; Krüger, O.; Wachtendorf, V.; Berger, W.; Hally, S. Development of Leaching Procedures for Synthetic Turf Systems Containing Scrap Tyre Granules. Waste Biomass Valorization 2013, 4, 745–757. [Google Scholar] [CrossRef]

- European Commission Commission Regulation (EU) 2023/2055—Restriction of Microplastics Intentionally Added to Products. Available online: https://single-market-economy.ec.europa.eu/sectors/chemicals/reach/restrictions/commission-regulation-eu-20232055-restriction-microplastics-intentionally-added-products_en#:~:text=added to products-,Commission Regulation (EU) 2023/2055—Restriction of mi (accessed on 30 July 2025).

- EU Commission Bans Crumb Rubber Infill. Available online: https://scraptirenews.com/2023/11/03/eu-commission-bans-crumb-rubber-infill/#:~:text=Image 49For crumb rubber,the Council raised any objections (accessed on 30 July 2025).

- Marín-Genescà, M.; García-Amorós, J.; Mujal-Rosas, R.; Vidal, L.M.; Arroyo, J.B.; Fajula, X.C. Ground Tire Rubber Recycling in Applications as Insulators in Polymeric Compounds, According to Spanish Une Standards. Recycling 2020, 5, 16. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling Waste Tires into Ground Tire Rubber (Gtr)/Rubber Compounds: A Review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Toncheva, A.; Brison, L.; Dubois, P.; Laoutid, F. Recycled Tire Rubber in Additive Manufacturing: Selective Laser Sintering for Polymer-Ground Rubber Composites. Appl. Sci. 2021, 11, 8778. [Google Scholar] [CrossRef]

- Bocca, B.; Forte, G.; Petrucci, F.; Costantini, S.; Izzo, P. Metals Contained and Leached from Rubber Granulates Used in Synthetic Turf Areas. Sci. Total Environ. 2009, 407, 2183–2190. [Google Scholar] [CrossRef] [PubMed]

- Van Der Sloot, H.A.; Comans, R.N.J.; Hjelmar, O. Similarities in the Leaching Behaviour of Trace Contaminants from Waste, Stabilized Waste, Construction Materials and Soils. Sci. Total Environ. 1996, 178, 111–126. [Google Scholar] [CrossRef]

- DIN 18035-7:2002-06; Sports Grounds Part 7; Synthetic Turf Areas Determination of Environmental Compatibility. Deutsches Institut fuer Normung: Berlin, Germany, 2002; pp. 6–8.

- Park, J.K.; Edil, T.B.; Kim, J.Y.; Huh, M.; Lee, S.H.; Lee, J.J. Suitability of Shredded Tyres as a Subsitute for a Landfill Leachate Collection Medium. Waste Manag. Res. 2003, 21, 278–289. [Google Scholar] [CrossRef]

- Supplemento Ordinario Alla Gazzetta Ufficiale 16 Aprile 1998 n. 88 Individuazione Dei Rifiuti Non Pericolosi Sottoposti Alle Procedure Semplificate Di Recupero Ai Sensi Degli Articoli 31 e 33 Del Decreto Legislativo 5 Febbraio 1997, n. 22. 1998. Available online: https://www.gazzettaufficiale.it/eli/id/1998/04/16/098A3052/sg%20 (accessed on 29 July 2025).

- Ministero dell'Ambiente e della Tutela del Territorio e del Mare. Ministero Dell’ambiente e Della Tutela del Territorio e del Mare Gazzetta Ufficiale Del 31 Marzo 2020, n.78; Gazzetta Ufficiale: Rome, Italy, 2005; Available online: https://www.gazzettaufficiale.it/eli/id/2020/07/21/20G00094/sg (accessed on 29 July 2025).

- UNI EN 12457-2 Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/Kg for Materials with Particle Size Below 4 Mm (Without or with Size R). 2004. Available online: https://www.scribd.com/document/511437969/BS-EN-12457-2-2002 (accessed on 29 July 2025).

- Bilgili, E.; Dybek, A.; Arastoopour, H.; Bernstein, B. A New Recycling Technology: Compression Molding of Pulverized Rubber Waste in the Absence of Virgin Rubber. J. Elastomers Plast. 2003, 35, 235–256. [Google Scholar] [CrossRef]

- Morin, J.E.; Williams, D.E.; Farris, R.J. A Novel Method to Recycle Scrap Tires: High-Pressure High-Temperature Sintering. Rubber Chem. Technol. 2002, 75, 955–968. [Google Scholar] [CrossRef]

- Quadrini, F.; Bellisario, D.; Santo, L.; Hren, I. Direct Moulding of Rubber Granules and Powders from Tyre Recycling. Appl. Mech. Mater. 2013, 371, 315–319. [Google Scholar] [CrossRef]

- Quadrini, F.; Santo, L.; Musacchi, E. A Sustainable Molding Process for New Rubber Products from Tire Recycling. Prog. Rubber Plast. Recycl. Technol. 2018, 35, 41–55. [Google Scholar] [CrossRef]

- Lucignano, C.; Gugliemotti, A.; Quadrini, F. Compression Moulding of Rubber Powder from Exhausted Tyres. Polym.-Plast. Technol. Eng. 2012, 51, 340–344. [Google Scholar] [CrossRef]

- Gobetti, A.; Tomasoni, G.; Cornacchia, G.; Ramorino, G. Steel Slag as a Low-Impact Filler in Rubber Compounds for Environmental Sustainability. Mater. Manuf. Process. 2024, 39, 1830–1841. [Google Scholar] [CrossRef]

- Formela, K.; Cysewska, M.; Haponiuk, J. The Influence of Screw Configuration and Screw Speed of Co-Rotating Twin Screw Extruder on the Properties of Products Obtained by Thermomechanical Reclaiming of Ground Tire Rubber. Polimery/Polymers 2014, 59, 170–177. [Google Scholar] [CrossRef]

- Swapna, V.P.; Stephen, R.; Greeshma, T.; Sharan Dev, C.; Sreekala, M.S. Mechanical and Swelling Behavior of Green Nanocomposites of Natural Rubber Latex and Tubular Shaped Halloysite Nano Clay. Polym. Compos. 2016, 37, 602–611. [Google Scholar] [CrossRef]

- ISO 48-4; Rubber, Vulcanized or Thermoplastic—Determination of Hardness—Part 4: Indentation Hardness by Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2018.

- ISO 37; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2017.

| Materials | Zn (mg/L) | Cd (mg/L) | Cr_tot (mg/L) | Pb (mg/L) | Sn (mg/L) |

|---|---|---|---|---|---|

| 0.71–0.90 mm | 51.500 | <0.00025 | <0.0025 | 0.00200 | <0.02 |

| 0.50–0.71 mm | 37.750 | <0.00025 | <0.0025 | <0.00125 | <0.02 |

| <0.50 mm | 55.250 | 0.00050 | <0.0025 | <0.00125 | <0.02 |

| 0.8–2.5 mm | 0.3 | <0.00025 | <0.0025 | <0.00125 | <0.002 |

| Synthetic Turf Areas: Determination of Environmental Compatibility (DIN 18035-7) [30] | 0.5 | 0.005 | 0.05 | 0.04 | 0.05 |

| Limit for reuse (Italian Ministerial decree 5 February 1998) [32] | 3 | 5 | 0.5 | 0.05 | - |

| Limit for disposal as Inert waste (Italian Ministerial decree 30 August 2005) [33] | 0.4 | 4 | 0.5 | 0.05 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gobetti, A.; Cornacchia, G.; Dey, K.; Ramorino, G. Impact of Particle Size on Properties of 100% Recycled End-of-Life Tire Rubber Sheets from Calendering. Recycling 2025, 10, 207. https://doi.org/10.3390/recycling10060207

Gobetti A, Cornacchia G, Dey K, Ramorino G. Impact of Particle Size on Properties of 100% Recycled End-of-Life Tire Rubber Sheets from Calendering. Recycling. 2025; 10(6):207. https://doi.org/10.3390/recycling10060207

Chicago/Turabian StyleGobetti, Anna, Giovanna Cornacchia, Kamol Dey, and Giorgio Ramorino. 2025. "Impact of Particle Size on Properties of 100% Recycled End-of-Life Tire Rubber Sheets from Calendering" Recycling 10, no. 6: 207. https://doi.org/10.3390/recycling10060207

APA StyleGobetti, A., Cornacchia, G., Dey, K., & Ramorino, G. (2025). Impact of Particle Size on Properties of 100% Recycled End-of-Life Tire Rubber Sheets from Calendering. Recycling, 10(6), 207. https://doi.org/10.3390/recycling10060207