Integrated Circuits from Lighting Equipment: Presence and Characterisation of Precious Metals (Ag, Au, Pd, and Pt)

Abstract

1. Introduction

1.1. WEEE Recycling

1.2. Driver Structure

1.2.1. Valuable and Precious Metals in Drivers

1.2.2. Drivers’ Recycling

1.3. Integrated Circuits

The Literature Review

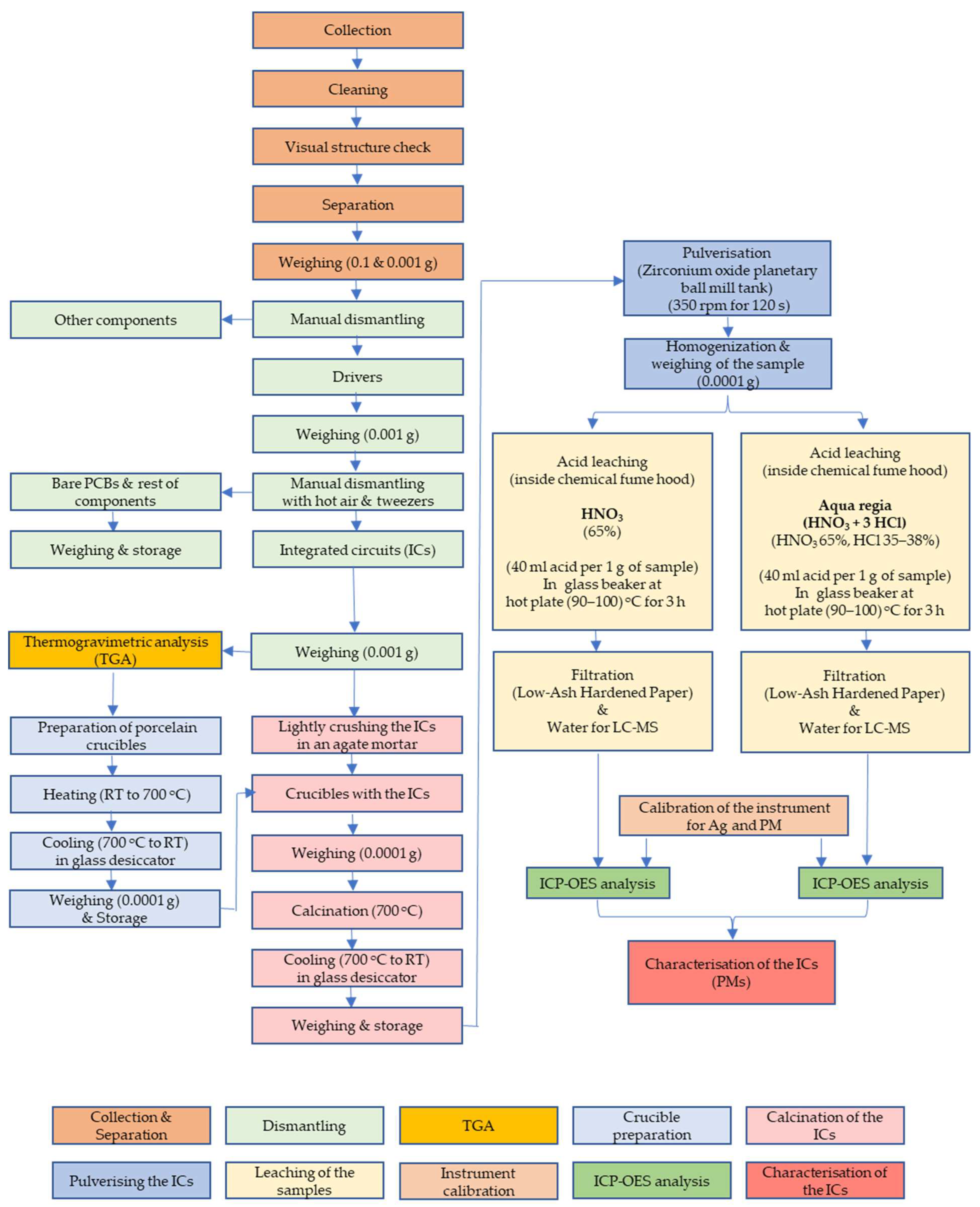

2. Materials and Methods

2.1. Collection and Separation

2.2. Select Unique LE Units

2.3. Dismantling and Separation

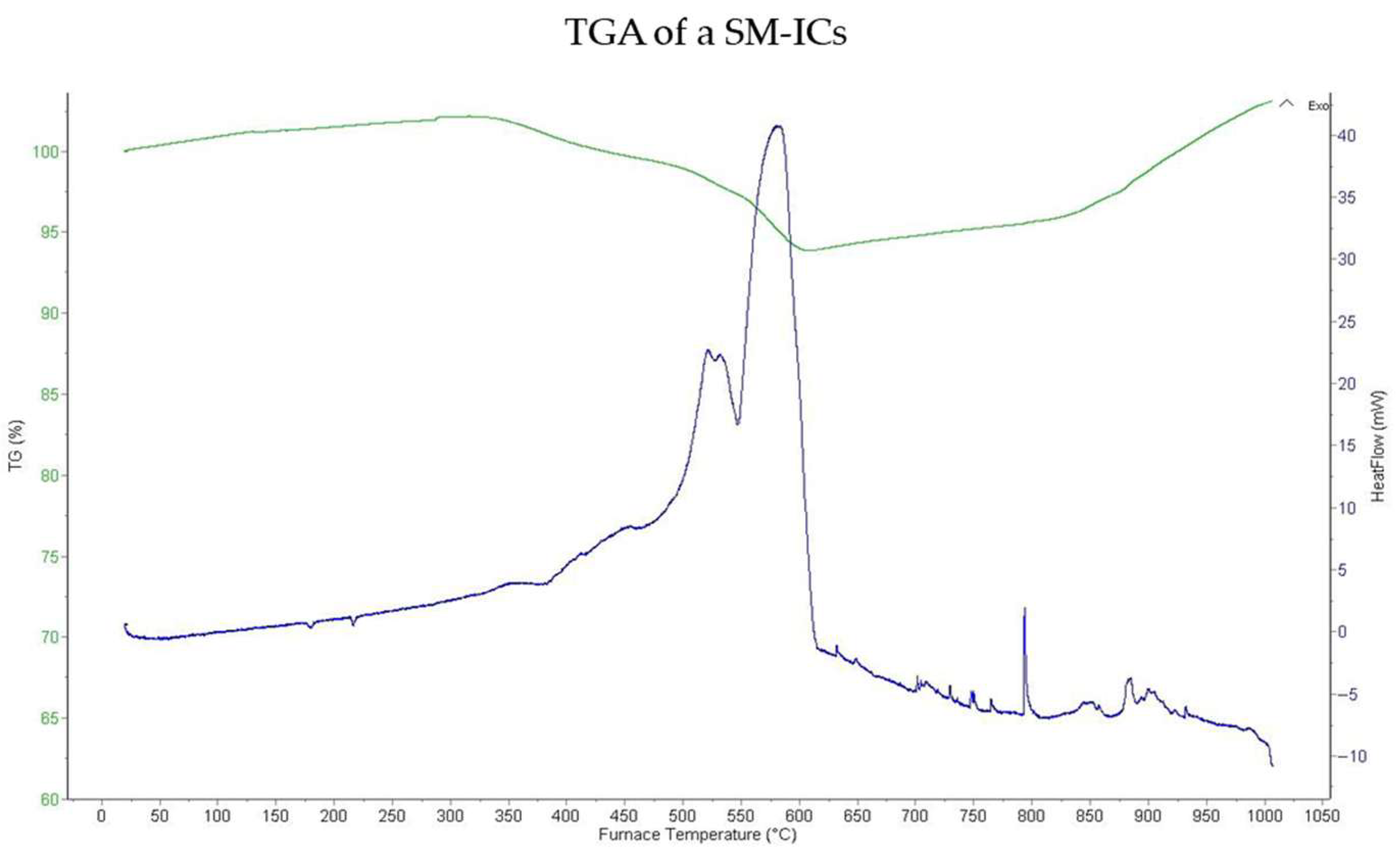

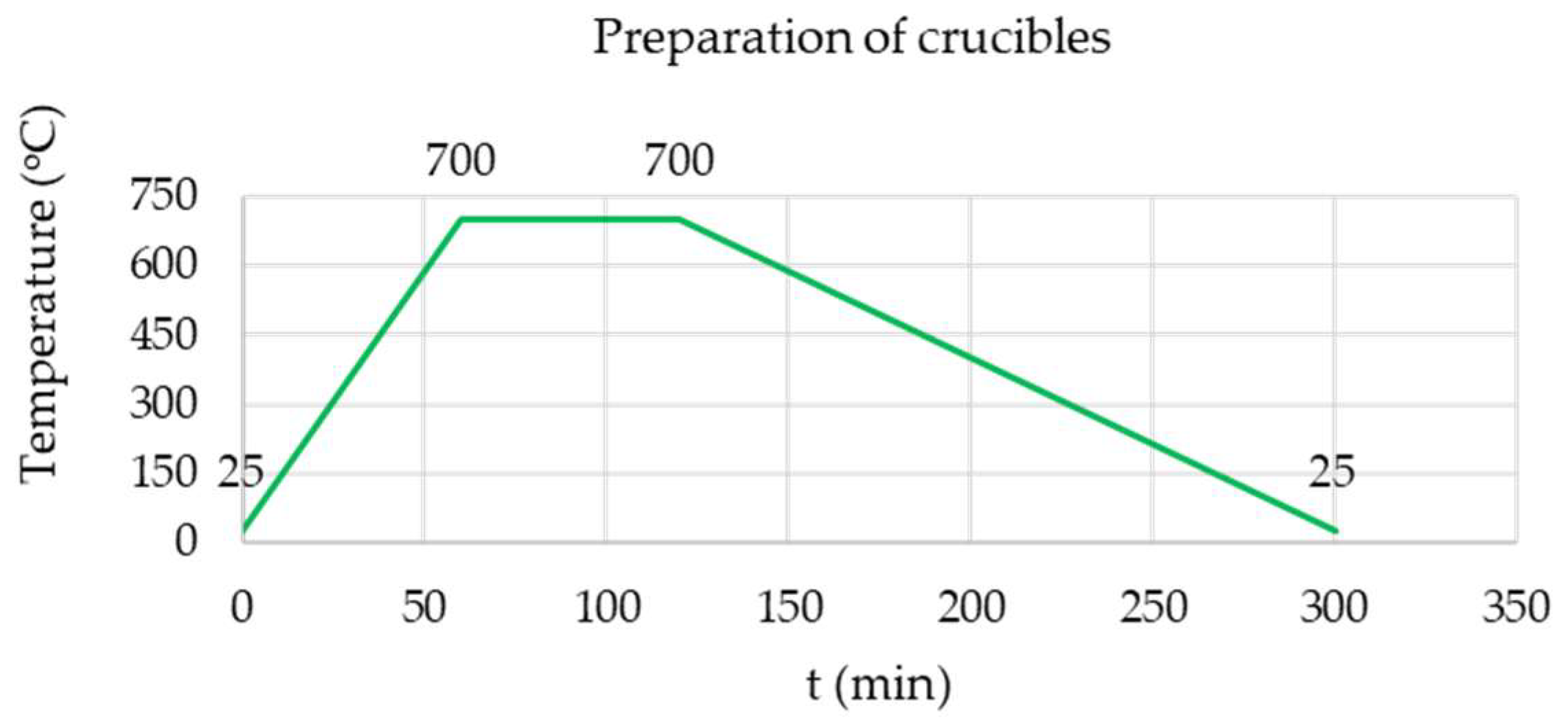

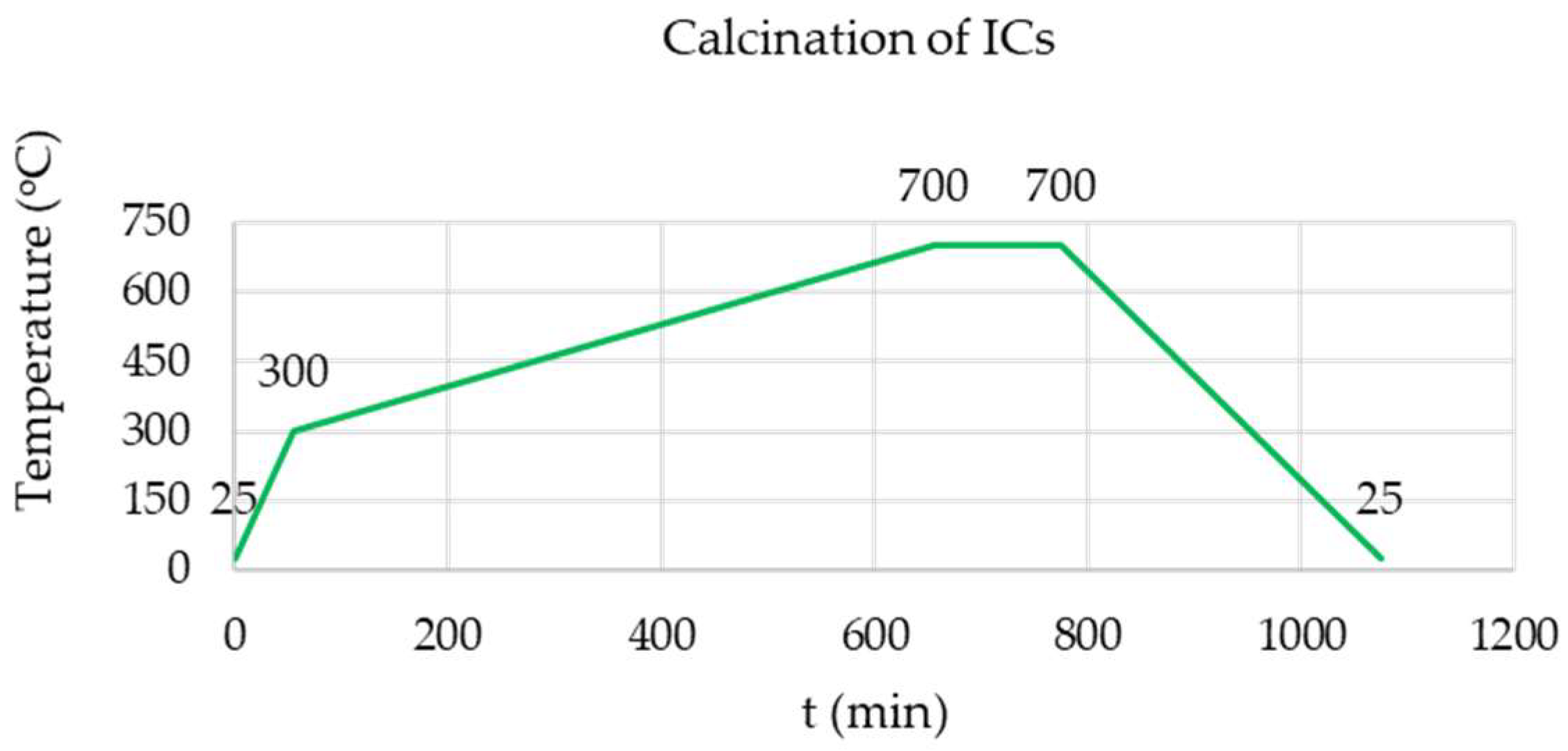

2.4. Preparing Porcelain Crucibles and Calcination of ICs

2.5. Creation of Laboratory Samples

2.6. Dissolution of Samples

2.7. ICP-OES Analysis

3. Results and Discussion

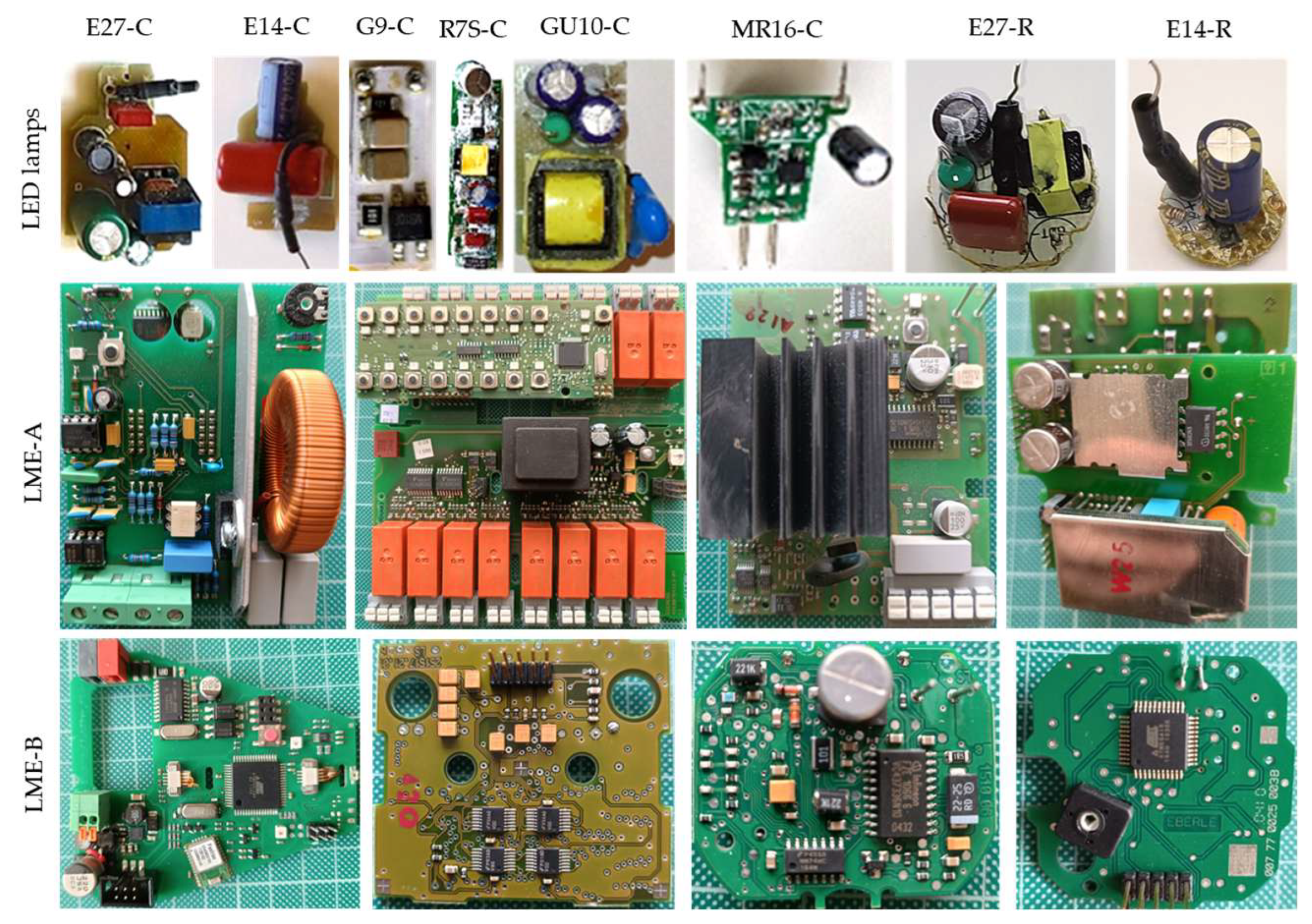

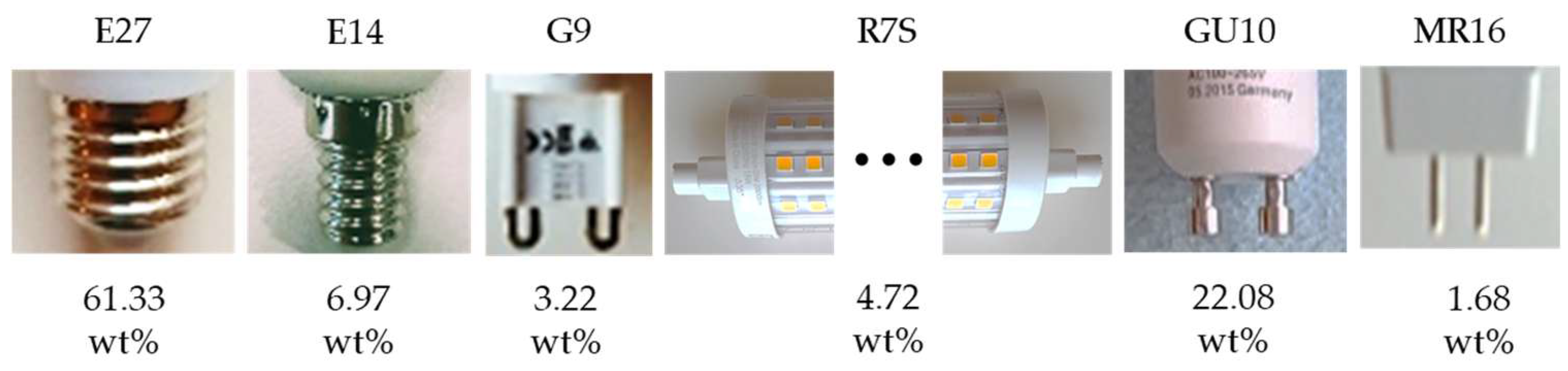

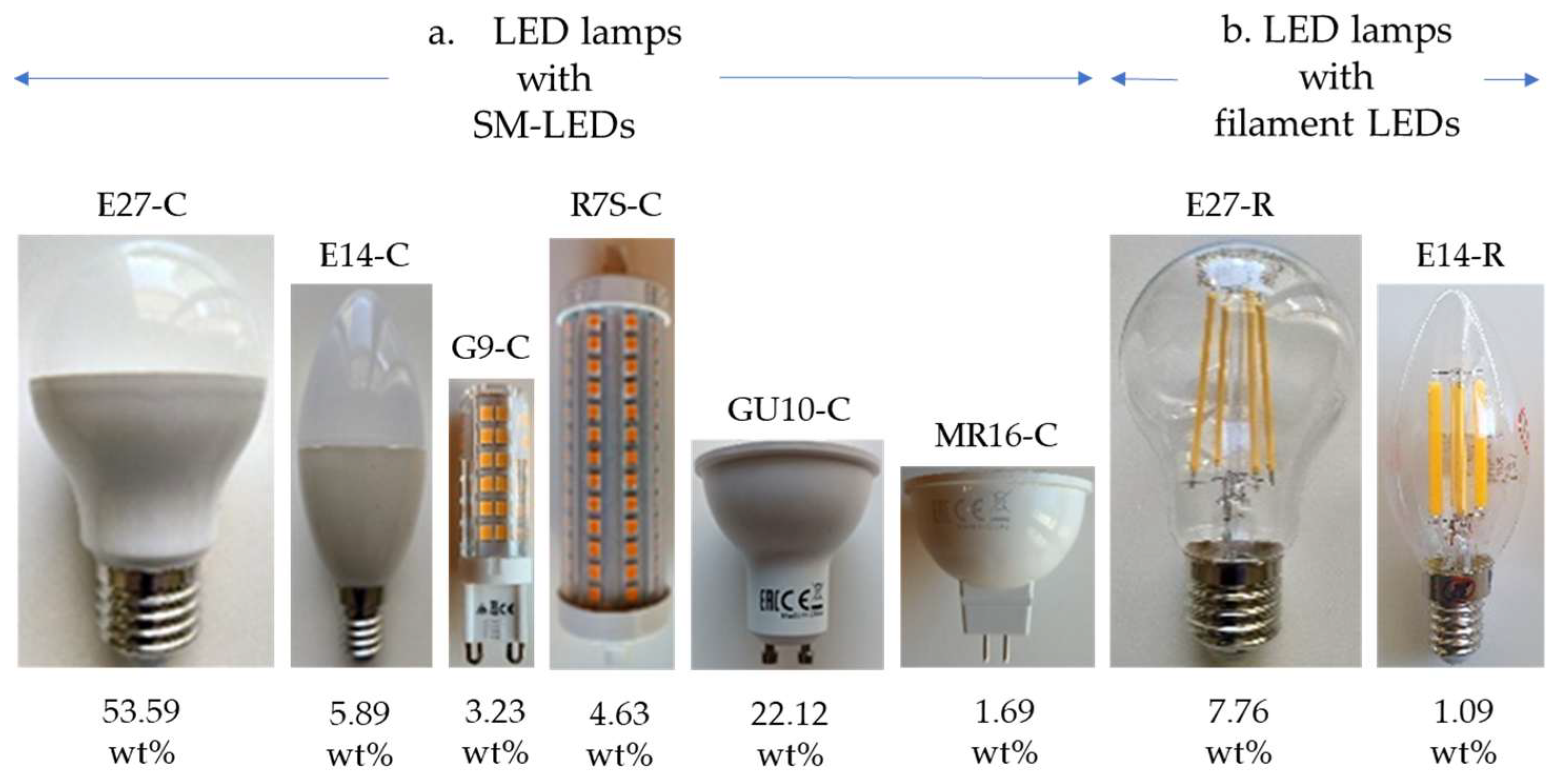

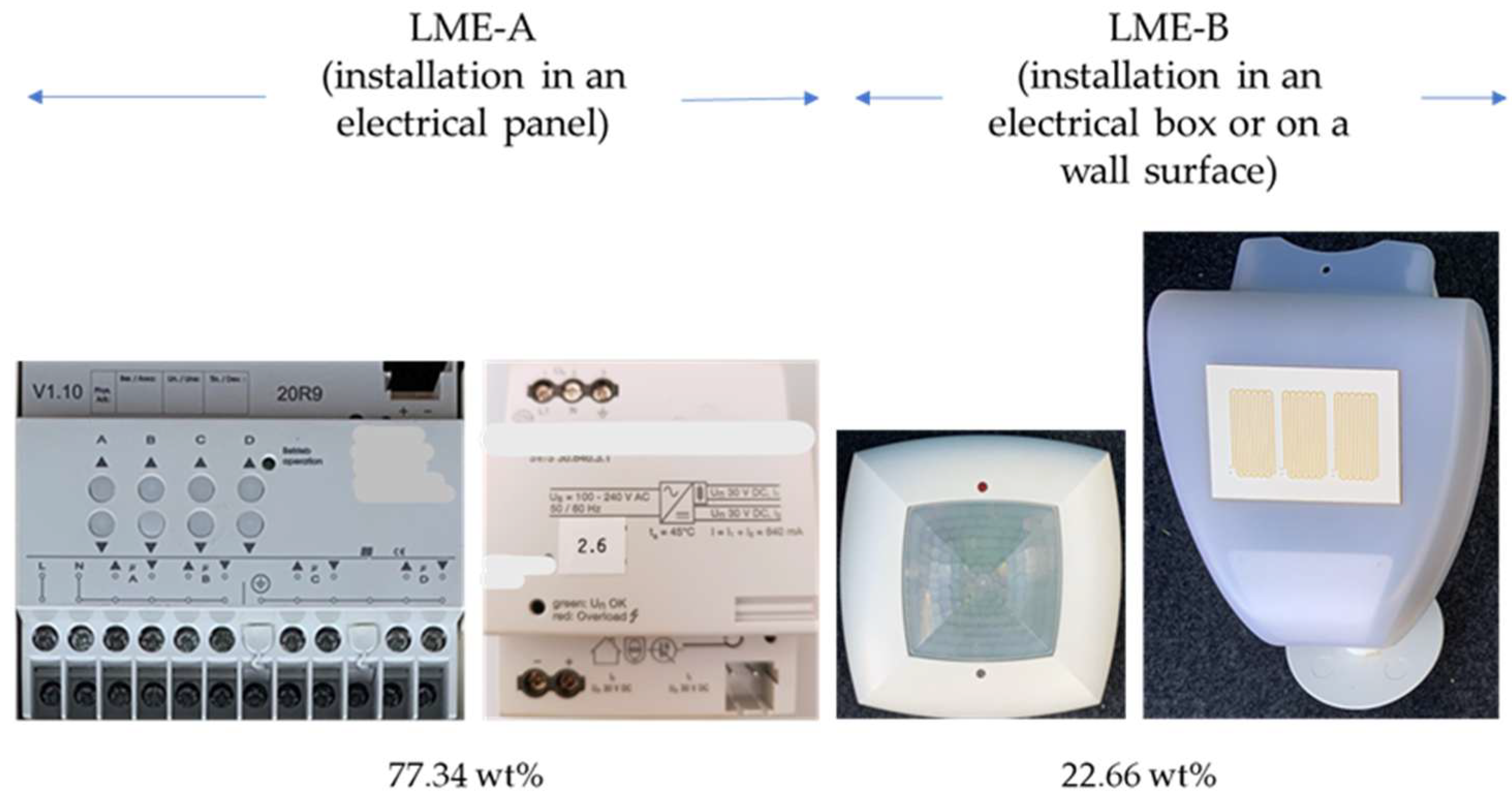

3.1. Separation and Participation of LE

3.2. Selection of Lighting Equipment with Unique Technical Features

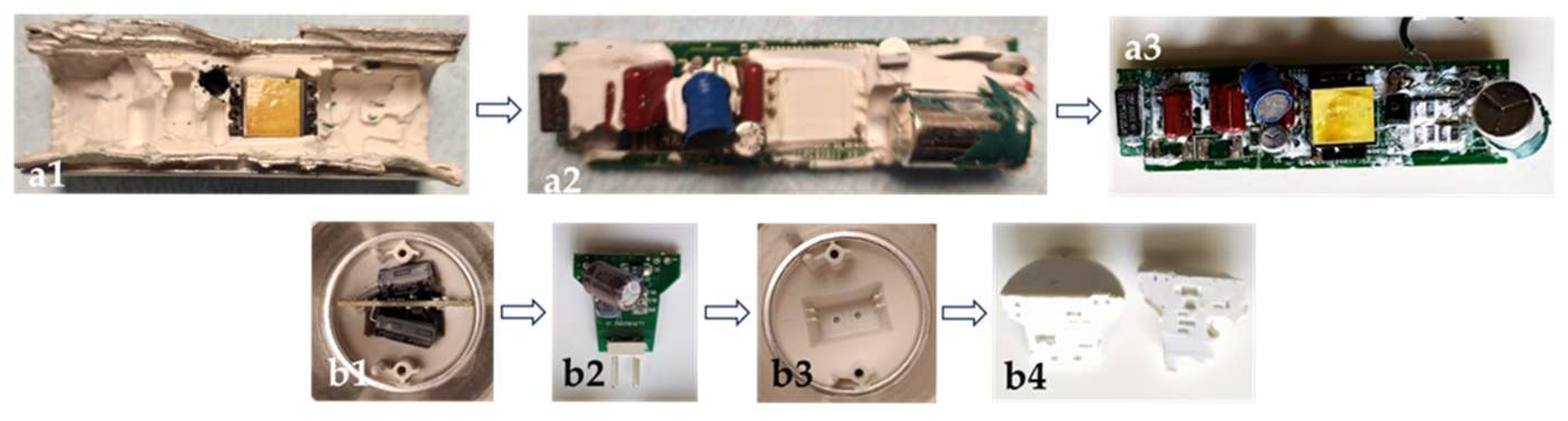

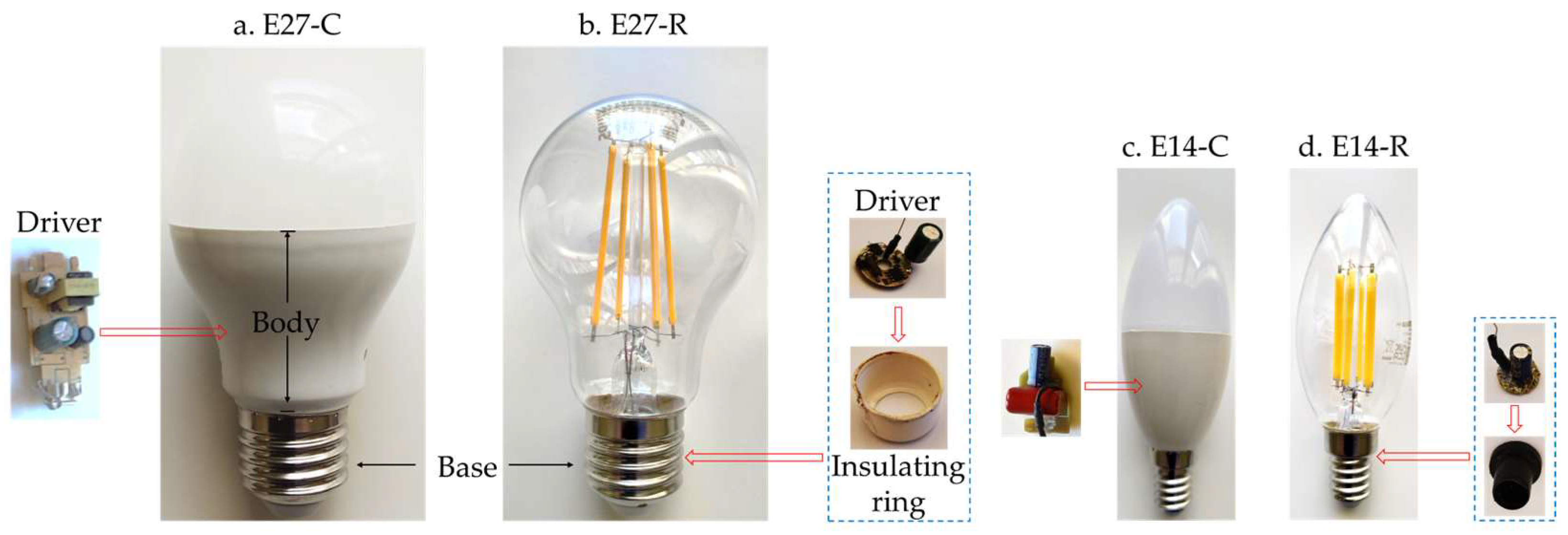

3.3. Individual Structures of LE

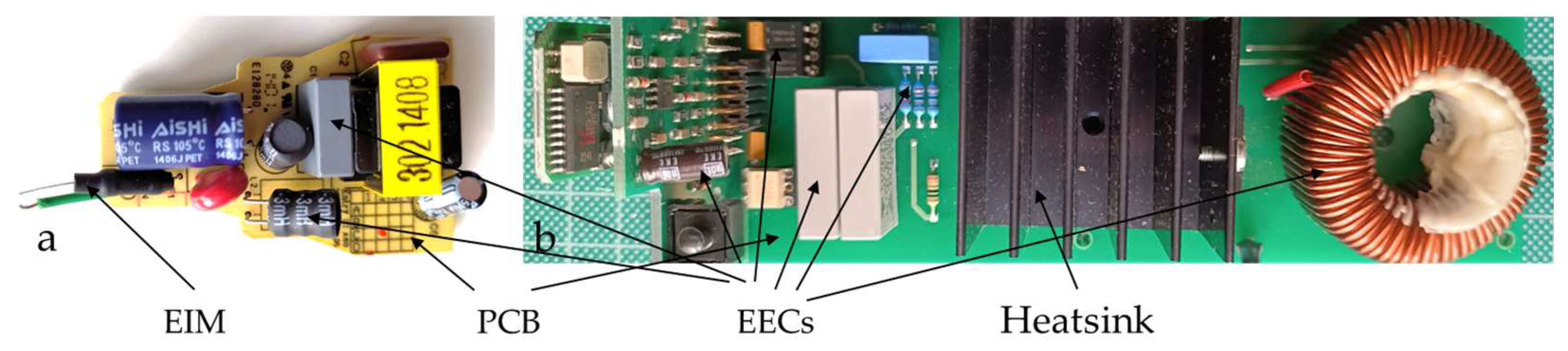

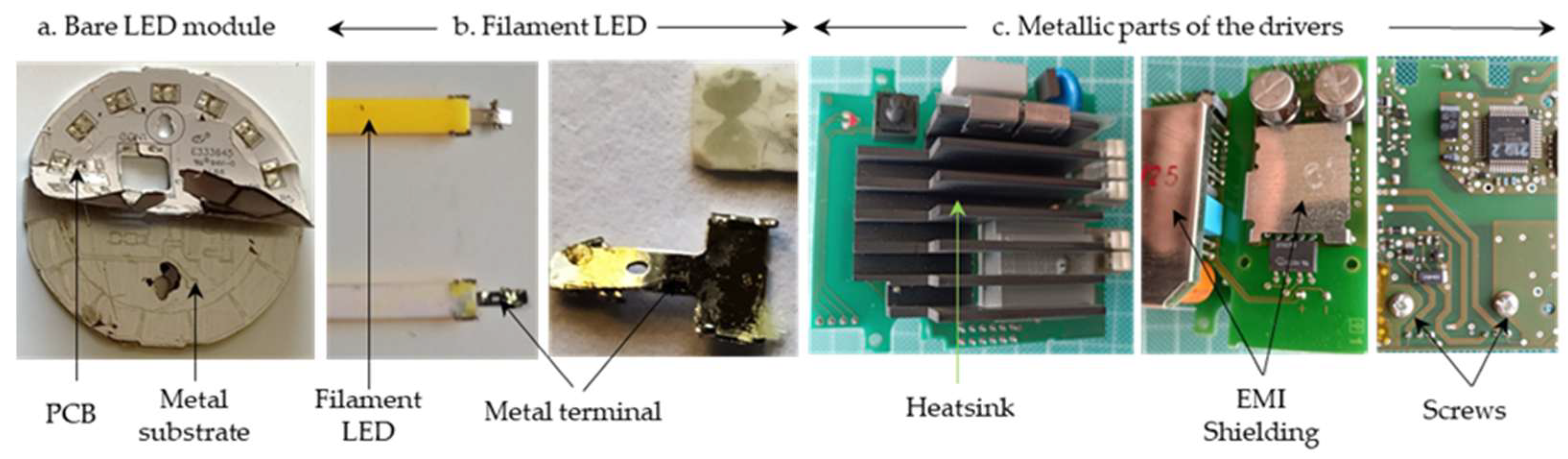

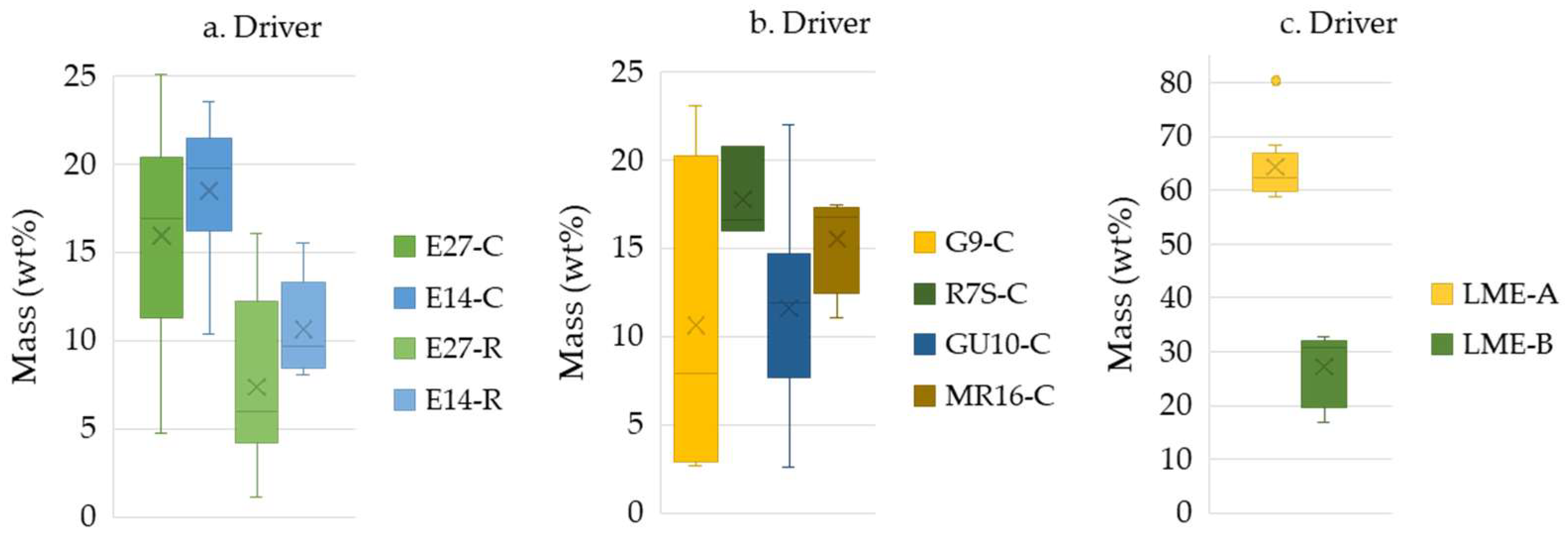

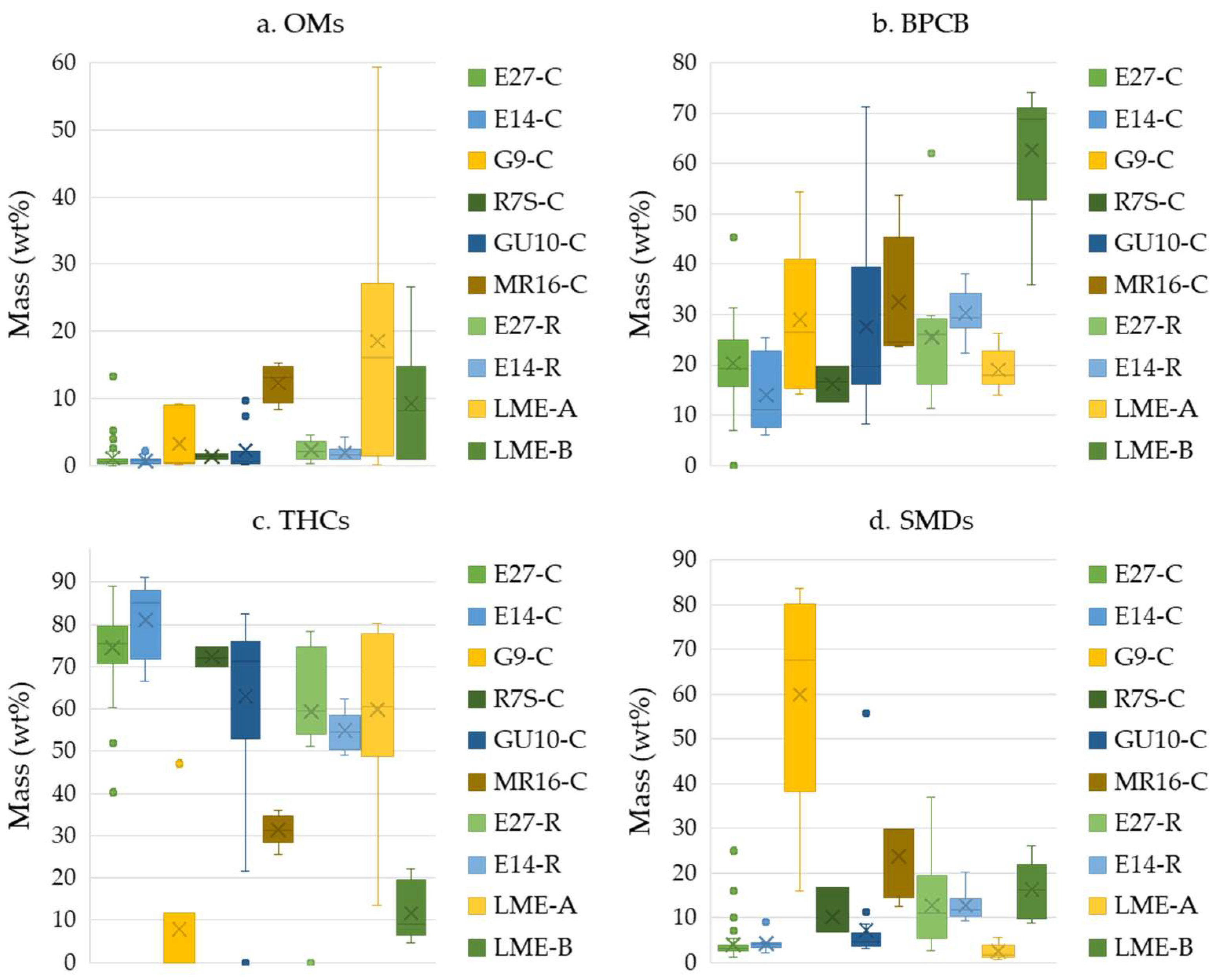

3.4. Driver

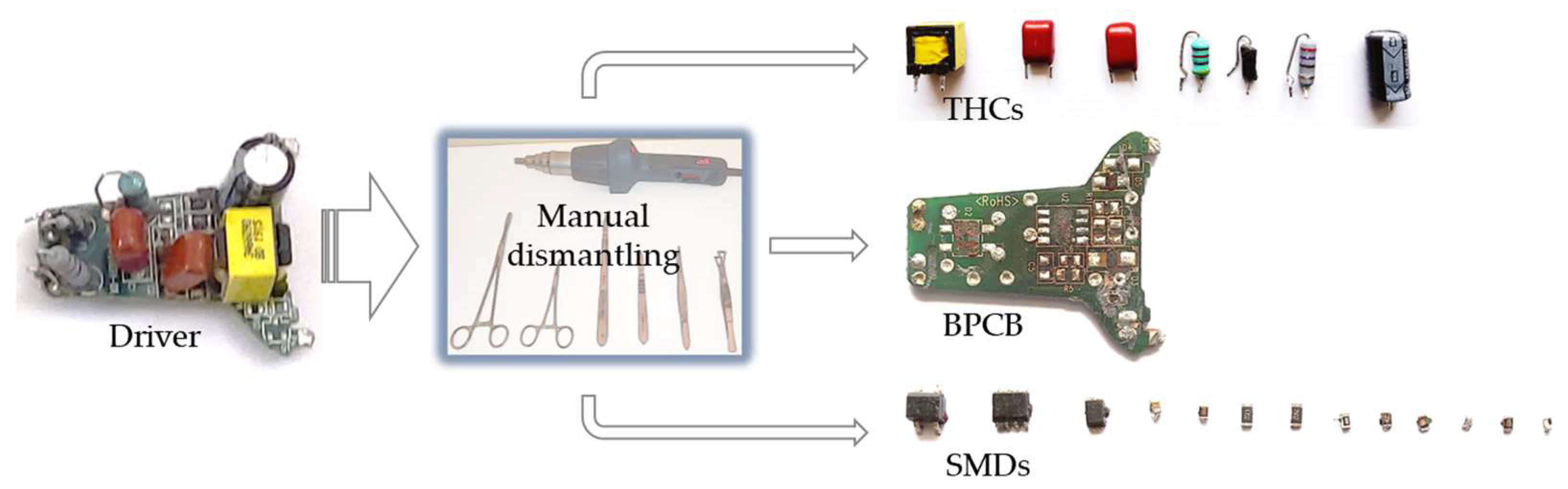

3.4.1. Dismantling of Drivers

3.4.2. Integrated Circuits (ICs)

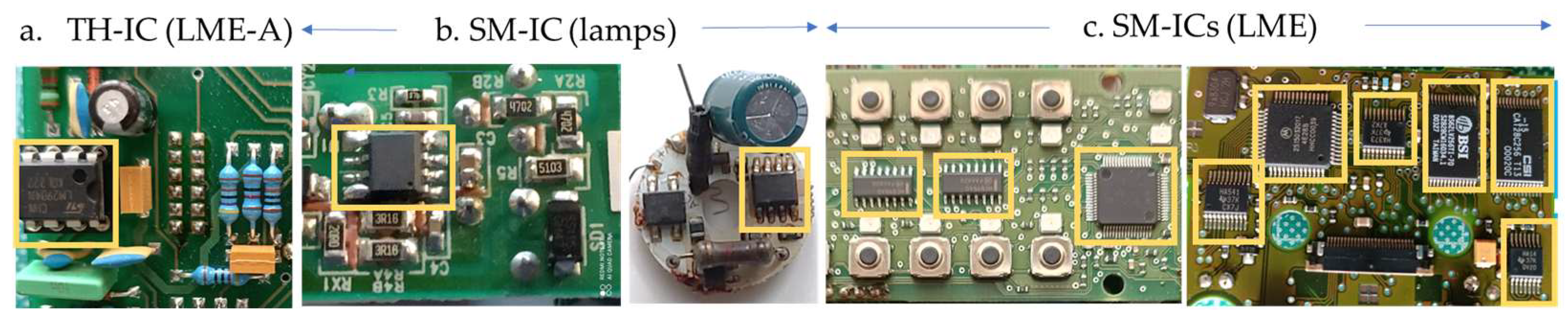

Through-Hole Integrated Circuits (TH-ICs)

Surface Mount Integrated Circuits (SM-ICs)

3.5. Characterisation of ICs from LE via ICP-OES Analysis

3.5.1. Presence per Element

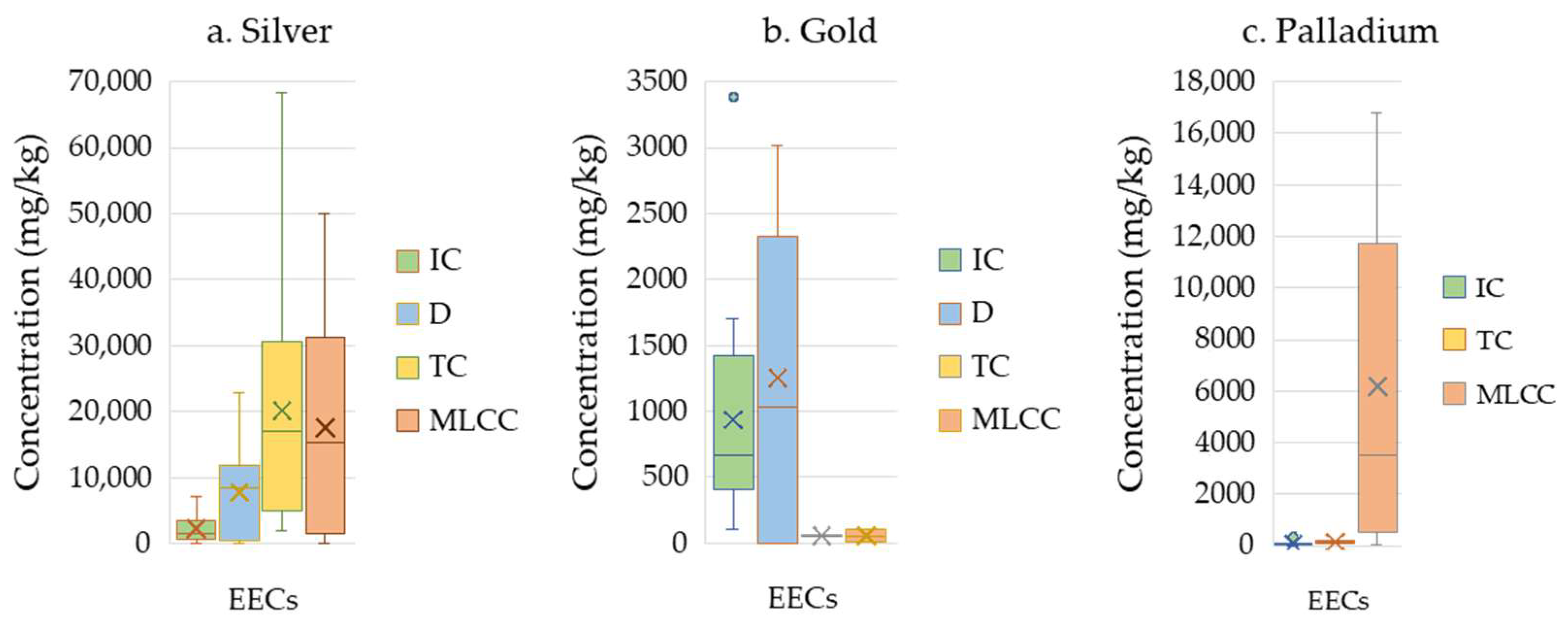

Silver (Ag)

Gold (Au)

Palladium (Pd)

Platinum (Pt)

3.5.2. Targeted Recycling

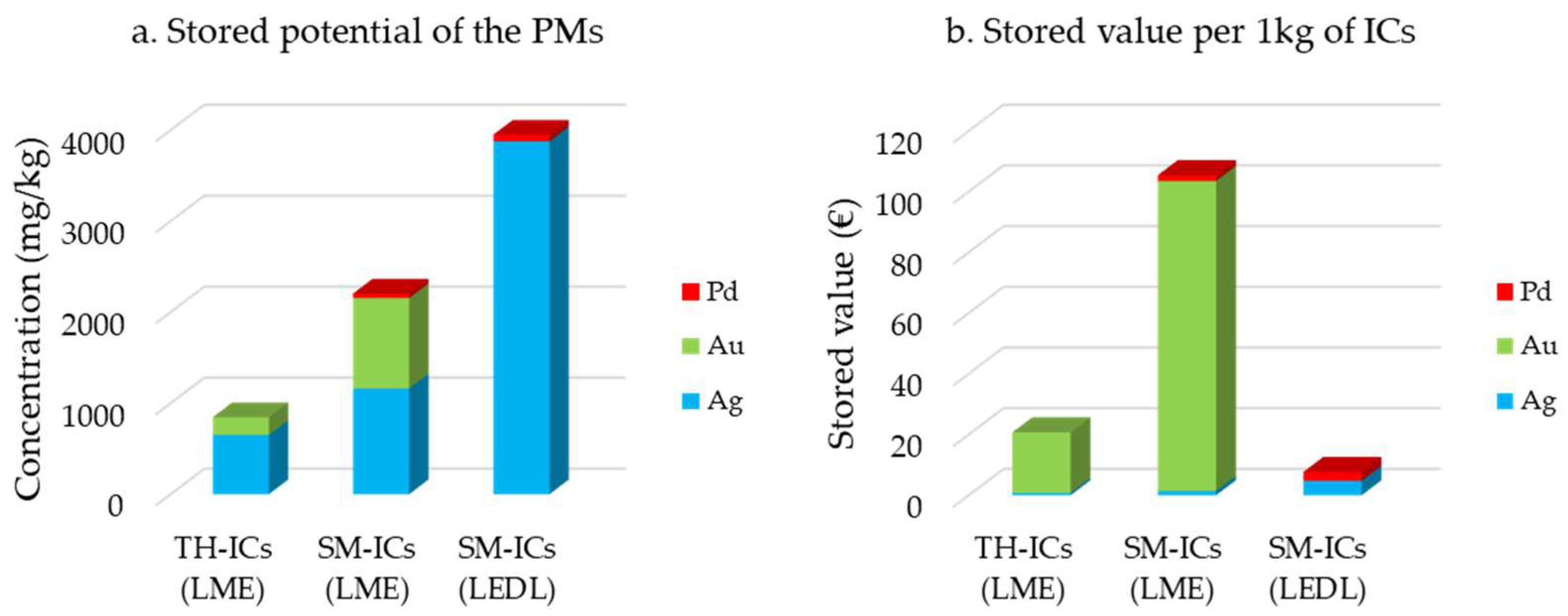

3.5.3. The Presence and Stored Value of PMs in ICs

3.5.4. The Stored Potential of PMs in EEE

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAS | Atomic absorption spectrometry |

| ADT | Additional technical details |

| BPCBs | Bare printed circuit boards |

| BT | Base type |

| CC | Corresponding case |

| D | Diodes |

| DA | Data adaption |

| EECs | Electrical and electronic components |

| EEE | Electrical and electronic equipment |

| EIMs | Electrical insulation materials |

| EU | European Union |

| ICs | Integrated circuits |

| ICP-AES | Inductively coupled plasma atomic emission spectrometry |

| ICP-MS | Inductively coupled plasma mass spectrometry |

| ICP-OES | Inductively coupled plasma optical emission spectroscopy |

| LE | Lighting equipment |

| LED | Light-emitting diode |

| LEDL | Light-emitting diode lamps |

| LME | Lighting management equipment |

| MC | Mass comparison |

| MF | Metal fraction |

| MLCCs | Multi-layer ceramic capacitors |

| n/a | Not available |

| ND | Not detected |

| OMs | Other materials |

| OoQL | Out of quantification limit |

| PC | Personal computer |

| PCB | Printed circuit board |

| PMs | Precious metals |

| PS | Present study |

| SM | Surface mount |

| SMD | Surface mount devices |

| SM-LEDs | Surface mount light-emitting diodes |

| SM-ICs | Surface mount integrated circuits |

| SO | Sample origin |

| TCs | Tantalum capacitors |

| TH | Trough-hole |

| THCs | Through-hole components |

| TH-ICs | Through-hole integrated circuits |

| WEEE | Waste electrical and electronic equipment |

Appendix A

| THC | E27-C | Ε14-C | G9-C | R7S-C | GU10-C | MR16-C | Ε27-R | Ε14-R | LME-A | LME-B |

|---|---|---|---|---|---|---|---|---|---|---|

| TF | (x) | (x) | (x) | (x) | (x) | (x) | ||||

| Coil | (x) | (x) | (x) | (x) | (x) | (x) | ||||

| AEC | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) |

| MPFC | (x) | (x) | (x) | (x) | (x) | (x) | ||||

| CC | (x) | |||||||||

| TRs | (x) | |||||||||

| RES | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | ||

| FWBR | (x) | (x) | ||||||||

| RoCs | (x) | |||||||||

| CONN | (x) | (x) | (x) | (x) | (x) | |||||

| Relay | (x) | |||||||||

| TB | (x) | |||||||||

| Button | (x) | (x) | ||||||||

| PFC | (x) | |||||||||

| P-TR | (x) | |||||||||

| Varistor | (x) | |||||||||

| Diode | (x) | |||||||||

| IC | (x) |

| SMD | E27-C | Ε14-C | G9-C | R7S-C | GU10-C | MR16-C | Ε27-R | Ε14-R | LME-A | LME-B |

|---|---|---|---|---|---|---|---|---|---|---|

| IC | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) |

| FWBR | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) |

| Resistor | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) |

| Diode | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | |

| TR | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | |

| Inductor | (x) | (x) | (x) | (x) | ||||||

| MLCC | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) | (x) |

| TC | (x) | (x) | ||||||||

| Z-diode | (x) | (x) | ||||||||

| LED | (x) | (x) | ||||||||

| Button | (x) | (x) |

References

- Oh, S.T.; Lim, J.H. Natural light adaptive context lighting system that provides a lighting environment tailored to the User’s objectives. Heliyon 2025, 11, e42064. [Google Scholar] [CrossRef]

- Lee, S.H.; Oh, S.T.; Lim, J.H. Fade Lighting Control Method for Visual Comfort and Energy Saving. Proc. Eng. Technol. Innov. 2023, 25, 54–62. [Google Scholar] [CrossRef]

- Işıldar, A.; Rene, E.R.; van Hullebusch, E.D.; Lens, P.N.L. Electronic waste as a secondary source of critical metals: Management and recovery technologies. Resour. Conserv. Recycl. 2018, 135, 296–312. [Google Scholar] [CrossRef]

- Bookhagen, B.; Bastian, D.; Buchholz, P.; Faulstich, M.; Opper, C.; Irrgeher, J.; Prohaska, T.; Koeberl, C. Metallic resources in smartphones. Resour. Policy 2020, 68, 101750. [Google Scholar] [CrossRef]

- Diaz, F.; Florez, S.; Friedrich, B. Mass Flow Analysis and Metal Losses by the Degradation Process of Organic-Containing WEEE Scraps. Chem. Ing. Tech. 2015, 87, 1599–1608. [Google Scholar] [CrossRef]

- Dias, P.; Palomero, J.; Cenci, M.P.; Scarazzato, T.; Bernardes, A.M. Electronic waste in Brazil: Generation, collection, recycling and the covid pandemic. Clean. Waste Syst. 2022, 3, 100022. [Google Scholar] [CrossRef]

- Holgersson, S.; Steenari, B.M.; Björkman, M.; Cullbrand, K. Analysis of the metal content of small-size Waste Electric and Electronic Equipment (WEEE) printed circuit boards—Part 1: Internet routers, mobile phones and smartphones. Resour. Conserv. Recycl. 2018, 133, 300–308. [Google Scholar] [CrossRef]

- Nieberl, M.; Hornung, A.; Sajdak, M.; Majewski, A.J.; Ouadi, M. Application and recycling of tantalum from waste electric and electronic equipment—A review. Resour. Conserv. Recycl. 2023, 190, 106866. [Google Scholar] [CrossRef]

- Sahan, M.; Kucuker, M.A.; Demirel, B.; Kuchta, K.; Hursthouse, A. Determination of metal content of waste mobile phones and estimation of their recovery potential in Turkey. Int. J. Environ. Res. Public Health 2019, 16, 887. [Google Scholar] [CrossRef]

- Liu, W.; Ford, P.; Uvegi, H.; Margarido, F.; Santos, E.; Ferrão, P.; Olivetti, E. Economics of materials in mobile phone preprocessing, focus on non-printed circuit board materials. Waste Manag. 2019, 87, 78–85. [Google Scholar] [CrossRef]

- Andooz, A.; Eqbalpour, M.; Kowsari, E.; Ramakrishna, S.; Cheshmeh, Z.A. A comprehensive review on pyrolysis of E-waste and its sustainability. J. Clean. Prod. 2022, 333, 130191. [Google Scholar] [CrossRef]

- Cayumil, R.; Khanna, R.; Rajarao, R.; Mukherjee, P.S.; Sahajwalla, V. Concentration of precious metals during their recovery from electronic waste. Waste Manag. 2016, 57, 121–130. [Google Scholar] [CrossRef]

- Alim, M.A.; Abdullah, M.Z.; Aziz, M.S.A.; Kamarudin, R. Die attachment, wire bonding, and encapsulation process in LED packaging: A review. Sens. Actuators A Phys. 2021, 329, 112817. [Google Scholar] [CrossRef]

- Chen, K.J.; Hung, F.Y.; Chang, C.Y. A study of the sulfidation behavior on palladium-coated copper wire with a flash-gold layer (Pca) after wire bonding. Electronics 2019, 8, 792. [Google Scholar] [CrossRef]

- Xia, L.; Liu, Y.; Xu, Z. Simultaneous utilization of copper and non-metals from waste integrated circuits for precious metal melting capture and organics thermal detoxification. J. Hazard. Mater. 2024, 479, 135689. [Google Scholar] [CrossRef] [PubMed]

- An, B.; Zhou, H.; Cao, J.; Ming, P.; Persic, J.; Yao, J.; Chang, A. A Review of Silver Wire Bonding Techniques. Micromachines 2023, 14, 2129. [Google Scholar] [CrossRef] [PubMed]

- Muß, D.; Koch, R. Bonding wire characterization using non-destructive X-ray imaging. Microelectron. Reliab. 2023, 148, 115177. [Google Scholar] [CrossRef]

- Akcil, A.; Erust, C.; Gahan, C.S.; Ozgun, M.; Sahin, M.; Tuncuk, A. Precious metal recovery from waste printed circuit boards using cyanide and non-cyanide lixiviants—A review. Waste Manag. 2015, 45, 258–271. [Google Scholar] [CrossRef]

- Sideris, K.M.; Fragoulis, D.; Stathopoulos, V.N.; Sinioros, P. Multi-Layer Ceramic Capacitors in Lighting Equipment: Presence and Characterisation of Rare Earth Elements and Precious Metals. Recycling 2023, 8, 97. [Google Scholar] [CrossRef]

- Sideris, K.M.; Katsiris, I.; Fragkoulis, D.; Stathopoulos, V.N.; Sinioros, P. Waste SMD LEDs from End-of-Life Residential LED Lamps: Presence and Characterisation of Rare Earth Elements and Precious Metals as a Function of Correlated Colour Temperature. Recycling 2024, 9, 128. [Google Scholar] [CrossRef]

- Oke, E.A.; Potgieter, H. Discarded e-waste/printed circuit boards: A review of their recent methods of disassembly, sorting and environmental implications. J. Mater. Cycles Waste Manag. 2024, 26, 1277–1293. [Google Scholar] [CrossRef]

- Li, H.; Eksteen, J.; Oraby, E. Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): Current status and perspectives—A review. Resour. Conserv. Recycl. 2018, 139, 122–139. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, Z. Precious metals recovery from waste printed circuit boards: A review for current status and perspective. Resour. Conserv. Recycl. 2016, 113, 28–39. [Google Scholar] [CrossRef]

- Debnath, B.; Roychowdhury, P.; Kundu, R. Electronic Components (EC) Reuse and Recycling—A New Approach towards WEEE Management. Procedia Environ. Sci. 2016, 35, 656–668. [Google Scholar] [CrossRef]

- Martinez-Ballesteros, G.; Valenzuela-García, J.L.; Gómez-Alvarez, A.; Encinas-Romero, M.A.; Mejía-Zamudio, F.A.; de Jesús Rosas-Durazo, A.; Valenzuela-Frisby, R. Recovery of ag, au, and pt from printed circuit boards by pressure leaching. Recycling 2021, 6, 67. [Google Scholar] [CrossRef]

- Fazari, J.; Hossain, M.Z.; Charpentier, P. A review on metal extraction from waste printed circuit boards (wPCBs). J. Mater. Sci. 2024, 59, 12257–12284. [Google Scholar] [CrossRef]

- Kaya, M. Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef]

- D’Adamo, I.; Rosa, P.; Terzi, S. Challenges in waste electrical and electronic equipment management: A profitability assessment in three European countries. Sustainability 2016, 8, 633. [Google Scholar] [CrossRef]

- Hadi, P.; Xu, M.; Lin, C.S.K.; Hui, C.W.; McKay, G. Waste printed circuit board recycling techniques and product utilization. J. Hazard. Mater. 2015, 283, 234–243. [Google Scholar] [CrossRef] [PubMed]

- Priya, A.; Hait, S. Comprehensive characterization of printed circuit boards of various end-of-life electrical and electronic equipment for beneficiation investigation. Waste Manag. 2018, 75, 103–123. [Google Scholar] [CrossRef] [PubMed]

- Kumari, A.; Jha, M.K.; Lee, J.C.; Singh, R.P. Clean process for recovery of metals and recycling of acid from the leach liquor of PCBs. J. Clean. Prod. 2016, 112, 4826–4834. [Google Scholar] [CrossRef]

- Szalatkiewicz, J. Metals recovery from artificial ore in case of printed circuit boards, using plasmatron plasma reactor. Materials 2016, 9, 683. [Google Scholar] [CrossRef]

- Oliveira, J.S.S.; Hacha, R.R.; D’almeida, F.S.; Almeida, C.A.; Moura, F.J.; Brocchi, E.A.; Souza, R.F.M. Electronic waste low-temperature processing: An alternative thermochemical pretreatment to improve component separation. Materials 2021, 14, 6228. [Google Scholar] [CrossRef] [PubMed]

- Paola, M. Recycling of Printed Circuit Boards. In Integrated Waste Management—Volume II; IntechOpen: London, UK, 2011. [Google Scholar] [CrossRef][Green Version]

- Cesaro, A.; Gallo, M.; Moreschi, L.; Del Borghi, A. The hydrometallurgical recovery of critical and valuable elements from WEEE shredding dust: Process effectiveness in a life cycle perspective. Resour. Conserv. Recycl. 2024, 206, 107609. [Google Scholar] [CrossRef]

- Silva, L.H.d.S.; Júnior, A.A.F.; Azevedo, G.O.A.; Oliveira, S.C.; Fernandes, B.J.T. Estimating recycling return of integrated circuits using computer vision on printed circuit boards. Appl. Sci. 2021, 11, 2808. [Google Scholar] [CrossRef]

- Zhao, W.; Xu, J.; Fei, W.; Liu, Z.; He, W.; Li, G. The reuse of electronic components from waste printed circuit boards: A critical review. Environ. Sci. Adv. 2023, 2, 196–214. [Google Scholar] [CrossRef]

- Xia, D.; Lee, C.; Charpentier, N.M.; Deng, Y.; Yan, Q.; Gabriel, J.C.P. Drivers and Pathways for the Recovery of Critical Metals from Waste-Printed Circuit Boards. Adv. Sci. 2024, 11, e2309635. [Google Scholar] [CrossRef] [PubMed]

- Monneron-Enaud, B.; Wiche, O.; Schlömann, M. Biodismantling, a Novel Application of Bioleaching in Recycling of Electronic Wastes. Recycling 2020, 5, 22. [Google Scholar] [CrossRef]

- Wu, C.; Awasthi, A.K.; Qin, W.; Liu, W.; Yang, C. Recycling value materials from waste PCBs focus on electronic components: Technologies, obstruction and prospects. J. Environ. Chem. Eng. 2022, 10, 108516. [Google Scholar] [CrossRef]

- Hadi, P.; Ning, C.; Ouyang, W.; Xu, M.; Lin, C.S.K.; McKay, G. Toward environmentally-benign utilization of nonmetallic fraction of waste printed circuit boards as modifier and precursor. Waste Manag. 2015, 35, 236–246. [Google Scholar] [CrossRef]

- Hao, J.; Wang, Y.; Wu, Y.; Guo, F. Metal recovery from waste printed circuit boards: A review for current status and perspectives. Resour. Conserv. Recycl. 2020, 157, 104787. [Google Scholar] [CrossRef]

- Maurice, A.A.; Dinh, K.N.; Charpentier, N.M.; Brambilla, A.; Gabriel, J.C.P. Dismantling of printed circuit boards enabling electronic components sorting and their subsequent treatment open improved elemental sustainability opportunities. Sustainability 2021, 13, 10357. [Google Scholar] [CrossRef]

- Huang, C.M.; Romero, J.A.; Osterman, M.; Das, D.; Pecht, M. Life cycle trends of electronic materials, processes and components. Microelectron. Reliab. 2019, 99, 262–276. [Google Scholar] [CrossRef]

- Mori de Oliveira, C.; Bellopede, R.; Tori, A.; Marini, P. Study of Metal Recovery from Printed Circuit Boards by Physical-Mechanical Treatment Processes. Mater. Proc. 2021, 5, 121. [Google Scholar] [CrossRef]

- Canal Marques, A.; Cabrera, J.-M.; de Fraga Malfatti, C. Printed circuit boards: A review on the perspective of sustainability. J. Environ. Manag. 2013, 131, 298–306. [Google Scholar] [CrossRef]

- Agrawal, M.; Singh, R.; Ranitović, M.; Kamberovic, Z.; Ekberg, C.; Singh, K.K. Global market trends of tantalum and recycling methods from Waste Tantalum Capacitors: A review. Sustain. Mater. Technol. 2021, 29, e00323. [Google Scholar] [CrossRef]

- Yin, Y.; Yang, Y. Sustainable Transition of the Global Semiconductor Industry: Challenges, Strategies, and Future Directions. Sustainability 2025, 17, 3160. [Google Scholar] [CrossRef]

- Delfini, M.; Ferrini, M.; Manni, A.; Massacci, P.; Piga, L.; Scoppettuolo, A. Optimization of Precious Metal Recovery from Waste Electrical and Electronic Equipment Boards. J. Environ. Prot. 2011, 2, 675–682. [Google Scholar] [CrossRef]

- Jung, M.; Yoo, K.; Alorro, R.D. Dismantling of electric and electronic components from waste printed circuit boards by hydrochloric acid leaching with stannic ions. Mater. Trans. 2017, 58, 1076–1080. [Google Scholar] [CrossRef]

- Charles, R.G.; Douglas, P.; Dowling, M.; Liversage, G.; Davies, M.L. Towards Increased Recovery of Critical Raw Materials from WEEE–evaluation of CRMs at a component level and pre-processing methods for interface optimisation with recovery processes. Resour. Conserv. Recycl. 2020, 161, 104923. [Google Scholar] [CrossRef]

- Vermeşan, H.; Tiuc, A.-E.; Purcar, M. Advanced recovery techniques for waste materials from IT and telecommunication equipment printed circuit boards. Sustainability 2020, 12, 74. [Google Scholar] [CrossRef]

- Panda, R.; Dinkar, O.S.; Kumari, A.; Gupta, R.; Jha, M.K.; Pathak, D.D. Hydrometallurgical processing of waste integrated circuits (ICs) to recover Ag and generate mix concentrate of Au, Pd and Pt. J. Ind. Eng. Chem. 2021, 93, 315–321. [Google Scholar] [CrossRef]

- Sheel, A.; Pant, D. Recovery of gold from electronic waste using chemical assisted microbial biosorption (hybrid) technique. Bioresour. Technol. 2018, 247, 1189–1192. [Google Scholar] [CrossRef]

- Liu, Y.; Li, K.; Guo, J.; Xu, Z. Impact of the operating conditions on the derived products and the reaction mechanism in vacuum pyrolysis treatment of the organic material in waste integrated circuits. J. Clean. Prod. 2018, 197, 1488–1497. [Google Scholar] [CrossRef]

- Datta, M. Manufacturing processes for fabrication of flip-chip micro-bumps used in microelectronic packaging: An overview. J. Micromanufacturing 2020, 3, 69–83. [Google Scholar] [CrossRef]

- Qazi, J.; Ikeda, M. Failure Analysis of Capacitors and Inductors. In Microelectronics Failure Analysis: Desk Reference; ASM International: Almere, The Netherlands, 2019; pp. 587–602. [Google Scholar] [CrossRef]

- Pina, C.; Elduque, D.; Gómez, P.; Sarasa, J.; Javierre, C. Influence of the Material Composition SMD Diodes on Their Environmental Impact. Electronics 2021, 10, 1033. [Google Scholar] [CrossRef]

- Niu, B.; Xu, Z. From Waste Metallized Film Capacitors to Valuable Materials: Hexagonal Flake-Like Micron Zinc Powder, Copper-Iron Electrodes, and an Energy Resource. ACS Sustain. Chem. Eng. 2018, 6, 12281–12290. [Google Scholar] [CrossRef]

- Niu, B.; Chen, Z.; Xu, Z. Method for recycling tantalum from waste tantalum capacitors by chloride metallurgy. ACS Sustain. Chem. Eng. 2017, 5, 1376–1381. [Google Scholar] [CrossRef]

- Niu, B.; Chen, Z.; Xu, Z. Application of pyrolysis to recycling organics from waste tantalum capacitors. J. Hazard. Mater. 2017, 335, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Niu, B.; Chen, Z.; Xu, Z. Recovery of Valuable Materials from Waste Tantalum Capacitors by Vacuum Pyrolysis Combined with Mechanical-Physical Separation. ACS Sustain. Chem. Eng. 2017, 5, 2639–2647. [Google Scholar] [CrossRef]

- Chen, Z.; Niu, B.; Zhang, L.; Xu, Z. Vacuum pyrolysis characteristics and parameter optimization of recycling organic materials from waste tantalum capacitors. J. Hazard. Mater. 2018, 342, 192–200. [Google Scholar] [CrossRef]

- Sikander, A.; Kelly, S.; Kuchta, K.; Sievers, A.; Willner, T.; Hursthouse, A.S. Chemical and Microbial Leaching of Valuable Metals from PCBs and Tantalum Capacitors of Spent Mobile Phones. Int. J. Environ. Res. Public Health 2022, 19, 10006. [Google Scholar] [CrossRef]

- Choi, B.; Domínguez, B.; D’Souza, A.; Khadse, H.; Kunkel, A.; Nagarajan, S.; Necke, T.; Peche, R.; Revello, M.; Rossa, J.; et al. Sustainable recycling process for tantalum recovery from printed circuit boards. Resour. Conserv. Recycl. 2023, 198, 107201. [Google Scholar] [CrossRef]

- Prabaharan, G.; Barik, S.P.; Kumar, B. A hydrometallurgical process for recovering total metal values from waste monolithic ceramic capacitors. Waste Manag. 2016, 52, 302–308. [Google Scholar] [CrossRef]

- Niu, B.; Xu, Z. Application of Chloride Metallurgy and Corona Electrostatic Separation for Recycling Waste Multilayer Ceramic Capacitors. ACS Sustain. Chem. Eng. 2017, 5, 8390–8395. [Google Scholar] [CrossRef]

- Niu, B.; Xu, Z. Innovating e-waste recycling: From waste multi-layer ceramic capacitors to Nb–Pb codoped and ag-Pd-Sn-Ni loaded BaTiO3 nano-photocatalyst through one-step ball milling process. Sustain. Mater. Technol. 2019, 21, e00101. [Google Scholar] [CrossRef]

- Panda, R.; Dinkar, O.S.; Jha, M.K.; Pathak, D.D. Hydrometallurgical processing of waste multilayer ceramic capacitors (MLCCs) to recover silver and palladium. Hydrometallurgy 2020, 197, 105476. [Google Scholar] [CrossRef]

- Liu, Y.; Song, Q.; Zhang, L.; Xu, Z. Behavior of enrichment and migration path of Cu–Ag–Pd–Bi–Pb in the recovery of waste multilayer ceramic capacitors by eutectic capture of copper. J. Clean. Prod. 2021, 287, 125469. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Song, Q.; Xu, Z. Recovery of palladium and silver from waste multilayer ceramic capacitors by eutectic capture process of copper and mechanism analysis. J. Hazard. Mater. 2020, 388, 122008. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Song, Q.; Zhang, L.; Xu, Z. Separation of metals from Ni-Cu-Ag-Pd-Bi-Sn multi-metal system of e-waste by leaching and stepwise potential-controlled electrodeposition. J. Hazard. Mater. 2021, 408, 124772. [Google Scholar] [CrossRef]

- Liu, Y.; Song, Q.; Zhang, L.; Xu, Z. Novel approach of in-situ nickel capture technology to recycle silver and palladium from waste nickel-rich multilayer ceramic capacitors. J. Clean. Prod. 2021, 290, 125650. [Google Scholar] [CrossRef]

- Lee, C.H.; Tang, L.W.; Popuri, S.R. A study on the recycling of scrap integrated circuits by leaching. Waste Manag. Res. 2011, 29, 677–685. [Google Scholar] [CrossRef] [PubMed]

- Mir, S.; Dhawan, N. Investigation of Pyrolysis Followed by Leaching for Metal Recovery from Integrated Circuits. JOM 2023, 75, 3467–3479. [Google Scholar] [CrossRef]

- Li, K.; Zhang, L.; Xu, Z. Decomposition behavior and mechanism of epoxy resin from waste integrated circuits under supercritical water condition. J. Hazard. Mater. 2019, 374, 356–364. [Google Scholar] [CrossRef]

- Drawell. Available online: https://www.drawellanalytical.com/ (accessed on 28 August 2025).

- Barua, S.; Rahman, I.M.M.; Miyaguchi, M.; Mashio, A.S.; Maki, T.; Hasegawa, H. On-site analysis of gold, palladium, or platinum in acidic aqueous matrix using liquid electrode plasma-optical emission spectrometry combined with ion-selective preconcentration. Sens. Actuators B Chem. 2018, 272, 91–99. [Google Scholar] [CrossRef]

- Birloaga, I.; Coman, V.; Kopacek, B.; Vegliò, F. An advanced study on the hydrometallurgical processing of waste computer printed circuit boards to extract their valuable content of metals. Waste Manag. 2014, 34, 2581–2586. [Google Scholar] [CrossRef]

- Zamprogno Rebello, R.; Lima, M.T.W.D.C.; Yamane, L.H.; Siman, R.R. Characterization of end-of-life LED lamps for the recovery of precious metals and rare earth elements. Resour. Conserv. Recycl. 2020, 153, 104557. [Google Scholar] [CrossRef]

- Cenci, M.P.; Berto, F.C.D.; Schneider, E.L.; Veit, H.M. Assessment of LED lamps components and materials for a recycling perspective. Waste Manag. 2020, 107, 285–293. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Qiao, Q.; Cao, J.; Li, H.; Bian, Z. Precious metal recovery. Joule 2021, 5, 3097–3115. [Google Scholar] [CrossRef]

- Mizanur Rahman, S.M.; Kim, J.; Lerondel, G.; Bouzidi, Y.; Clerget, L. Value retention options in circular economy: Issues and challenges of LED lamp preprocessing. Sustainability 2019, 11, 4723. [Google Scholar] [CrossRef]

- Benmamas, L.; Bouzidi, Y.; Houset, G.; Nomenyo, K.; Bru, K.; Beaulieu, M.; Leclere, P.; Clerget, L.; Lerondel, G. Selective separation of plastic LED lamp components using electrodynamic fragmentation for material recovery. Waste Manag. 2022, 144, 210–220. [Google Scholar] [CrossRef] [PubMed]

- Wehbie, M.; Semetey, V. Characterization of end-of-life LED lamps: Evaluation of reuse, repair and recycling potential. Waste Manag. 2022, 141, 202–207. [Google Scholar] [CrossRef] [PubMed]

- Dzombak, R.; Padon, J.; Salsbury, J.; Dillon, H. Assessment of end-of-life design in solid-state lighting. Environ. Res. Lett. 2017, 12, 084013. [Google Scholar] [CrossRef]

- Tuenge, J.R.; Hollomon, B.; Dillon, H.E.; Snowden-Swan, L.J. Life-Cycle Assessment of Energy and Environmental Impacts of LED Lighting Products, Part 3: LED Environmental Testing; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA, 2013. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Bhakar, V.; Naik, S.; Andrat, S.N. Life cycle assessment of incandescent, fluorescent, compact fluorescent and light emitting diode lamps in an Indian scenario. Procedia CIRP 2014, 15, 467–472. [Google Scholar] [CrossRef]

- Cenci, M.P.; Berto, F.C.D.; Castillo, B.W.; Veit, H.M. Precious and critical metals from wasted LED lamps: Characterization and evaluation. Environ. Technol. 2020, 43, 1870–1881. [Google Scholar] [CrossRef]

- Dodbiba, G.; Oshikawa, H.; Ponou, J.; Kim, Y.; Haga, K.; Shibayama, A.; Fujita, T. Treatment of Spent LED Light Bulbs for Recycling of Its Components: A Combined Assessment in the Context of LCA and Cost-Benefit Analysis. Resour. Process. 2019, 66, 15–28. [Google Scholar] [CrossRef]

- Martins, T.R.; Tanabe, E.H.; Bertuol, D.A. Innovative method for the recycling of end-of-life LED bulbs by mechanical processing. Resour. Conserv. Recycl. 2020, 161, 104875. [Google Scholar] [CrossRef]

- Balinski, A.; Recksiek, V.; Stoll, M.; Christesen, C.; Stelter, M. Liberation and Separation of Valuable Components from LED Modules: Presentation of Two Innovative Approaches. Recycling 2022, 7, 26. [Google Scholar] [CrossRef]

- Mir, S.; Dhawan, N. A comprehensive review on the recycling of discarded printed circuit boards for resource recovery. Resour. Conserv. Recycl. 2022, 178, 106027. [Google Scholar] [CrossRef]

- Panda, R.; Dinkar, O.S.; Jha, M.K.; Pathak, D.D. Recycling of gold from waste electronic components of devices. Korean J. Chem. Eng. 2020, 37, 111–119. [Google Scholar] [CrossRef]

- Marwede, M.; Chancerel, P.; Deubzer, O.; Jordan, R.; Nils, F. Mass Flows of Selected Target Materials in LED Products Project Introduction—Cycling Resources Embedded in Systems Containing Light-emitting Diodes (CycLED). In Electronics Goes Green 2012+; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2012. [Google Scholar]

- Laurent, A. Commodities at a Glance: Special Issue on Rare Earths; United Nations (UN): New York, NY, USA; Geneva, Switzerland, 2014; p. 48p. [Google Scholar]

- Mazloum-Nejadari, A.; Khatibi, G.; Czerny, B.; Lederer, M.; Nicolics, J.; Weiss, L. Reliability of Cu wire bonds in microelectronic packages. Microelectron. Reliab. 2017, 74, 147–154. [Google Scholar] [CrossRef]

- SHINKO. Available online: https://www.shinko.co.jp/english/ (accessed on 4 June 2025).

- TEXAS INSTRUMENT. Available online: https://www.ti.com/ (accessed on 23 March 2025).

- AZO MATERIALS. Available online: https://www.azom.com/ (accessed on 13 February 2025).

- ThermoFisher SCIENTIFIC. Available online: https://jobs.thermofisher.com/global/en (accessed on 25 April 2025).

- Umicore. Available online: https://pmm.umicore.com/en/prices/ (accessed on 18 July 2025).

- Granados-Fernández, R.; Montiel, M.A.; Díaz-Abad, S.; Rodrigo, M.A.; Lobato, J. Platinum recovery techniques for a circular economy. Catalysts 2021, 11, 937. [Google Scholar] [CrossRef]

- Smith, L.; Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M. Life cycle assessment and environmental profile evaluations of high volumetric efficiency capacitors. Appl. Energy 2018, 220, 496–513. [Google Scholar] [CrossRef]

- Bourgeois, D.; Lacanau, V.; Mastretta, R.; Contino-Pépin, C.; Meyer, D. A simple process for the recovery of palladium from wastes of printed circuit boards. Hydrometallurgy 2020, 191, 105241. [Google Scholar] [CrossRef]

- Andrade, D.F.; Castro, J.P.; Garcia, J.A.; Machado, R.C.; Pereira-Filho, E.R.; Amarasiriwardena, D. Analytical and reclamation technologies for identification and recycling of precious materials from waste computer and mobile phones. Chemosphere 2022, 286, 131739. [Google Scholar] [CrossRef] [PubMed]

| Literature Review | Present Study | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Driver Mass (wt%) | Driver Mass (wt%) | MC | ||||||||||

| LE | BT | ATD | Variation | Avg. | Ref. | CC | Variation | Avg. | ATD | L | C | H |

| Mix | (a) | 13 | [80] | n/a | ||||||||

| Lamps | 8.02–22.43 | [83] | DA | 2.58–25.09 | 15.32 | (g) | (x) | |||||

| ″ | E27 | 5–6.9 | 6.1 | [87] | 4.77–25.09 | 15.93 | (x) | |||||

| ″ | ″ | 18.84 | [88] | ″ | ″ | (x) | ||||||

| ″ | ″ | 9.36 | [81] | ″ | ″ | (x) | ||||||

| ″ | ″ | 12.97–22.7 | 16.71 | [89] | ″ | ″ | (x) | (x) | ||||

| ″ | ″ | 12 | [84] | ″ | ″ | (x) | ||||||

| ″ | ″ | (b) | 13 | [90] | n/a | |||||||

| ″ | ″ | (c) | 16.02 | [91] | DA | 4.64–25.09 | 17.02 | (h) | (x) | |||

| ″ | E14–E27 | (d) | 19 | [92] | ″ | 4.77–25.09 | 16.37 | (x) | ||||

| ″ | E27 | (e), (f) | 10.61–49.96 | 28.92 | [86] | 28.51–55.59 | 47.14 | (x) | (x) | |||

| IC Type | SO | AT | Ag | Au | Pd | Pt | Ref. |

|---|---|---|---|---|---|---|---|

| n/a | PC | ICP-OES | 701 | 18 | [49] | ||

| ″ | Monitor | ″ | 154 | 14 | [49] | ||

| ″ | TV | ″ | 315 | 12 | [49] | ||

| ″ | n/a | AAS | 868 | 289 | [74] | ||

| ″ | ″ | ″ | 1494 | 1365 | [74] | ||

| ″ | ″ | ″ | 6590 | 1435 | [74] | ||

| ″ | ″ | ″ | 1830 | 1317 | [74] | ||

| ″ | ″ | ″ | 3410 | 414 | [74] | ||

| ″ | ″ | ″ | 353 | 199 | [74] | ||

| ″ | ″ | ″ | 471 | 101 | [74] | ||

| ″ | ″ | ″ | 1304 | 490 | [74] | ||

| ″ | ″ | ″ | 870 | 407 | [74] | ||

| ″ | ″ | ″ | 2980 | 1393 | [74] | ||

| ″ | ″ | ″ | 2645 | 1247 | [74] | ||

| ″ | ″ | ″ | 4188 | 3386 | [74] | ||

| ″ | ″ | ″ | 1036 | 1678 | [74] | ||

| ″ | ″ | ″ | 656 | 504 | [74] | ||

| ″ | ″ | ″ | 617 | 636 | [74] | ||

| ″ | ″ | ″ | 2067 | 1525 | [74] | ||

| ″ | ″ | ″ | 533 | 560 | [74] | ||

| ″ | ″ | ″ | 514 | 496 | [74] | ||

| ″ | ″ | ″ | 4325 | 844 | [74] | ||

| ″ | ″ | ″ | 1828 | 1546 | [74] | ||

| ″ | ″ | ″ | 3167 | 581 | [74] | ||

| ″ | ″ | ″ | 2558 | 1699 | [74] | ||

| ″ | Memory | ICP-OES | 850 | 1640 | [50] | ||

| ″ | n/a | ICP-MS | 7200 | [55] | |||

| ″ | PC | ″ | 7200 | [76] | |||

| Small | Medical | ″ | 211 | 339 | [39] | ||

| Big | ″ | ″ | 35 | 1 | [39] | ||

| n/a | n/a | ICP-AES ICP-MS | 5200 | 179 | [15] | ||

| TH | LME | ICP-OES | 652 | 194 | BLOQ | ND | PS |

| SM | ″ | ″ | 1162 | 993 | 49 | ″ | ″ |

| ″ | LED lamps | ″ | 3876 | BLOQ | 74 | BLOQ | ″ |

| MF | SO | AT | Ag | Au | Pd | Pt | Ref. |

|---|---|---|---|---|---|---|---|

| SM-ICs | PC | AAS ICP-OES | 7480 | 5880 | 110 | 4 | [53] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sideris, K.M.; Liogas, K.A.; Fragkoulis, D.; Stathopoulos, V.N.; Sinioros, P. Integrated Circuits from Lighting Equipment: Presence and Characterisation of Precious Metals (Ag, Au, Pd, and Pt). Recycling 2025, 10, 175. https://doi.org/10.3390/recycling10050175

Sideris KM, Liogas KA, Fragkoulis D, Stathopoulos VN, Sinioros P. Integrated Circuits from Lighting Equipment: Presence and Characterisation of Precious Metals (Ag, Au, Pd, and Pt). Recycling. 2025; 10(5):175. https://doi.org/10.3390/recycling10050175

Chicago/Turabian StyleSideris, Konstantinos M., Konstantinos A. Liogas, Dimitrios Fragkoulis, Vassilis N. Stathopoulos, and Panagiotis Sinioros. 2025. "Integrated Circuits from Lighting Equipment: Presence and Characterisation of Precious Metals (Ag, Au, Pd, and Pt)" Recycling 10, no. 5: 175. https://doi.org/10.3390/recycling10050175

APA StyleSideris, K. M., Liogas, K. A., Fragkoulis, D., Stathopoulos, V. N., & Sinioros, P. (2025). Integrated Circuits from Lighting Equipment: Presence and Characterisation of Precious Metals (Ag, Au, Pd, and Pt). Recycling, 10(5), 175. https://doi.org/10.3390/recycling10050175