Technical Evaluation and Recycling Potential of Polyolefin and Paper Separation in Mixed Waste Material Recovery Facilities

Abstract

1. Introduction

2. Materials and Methods

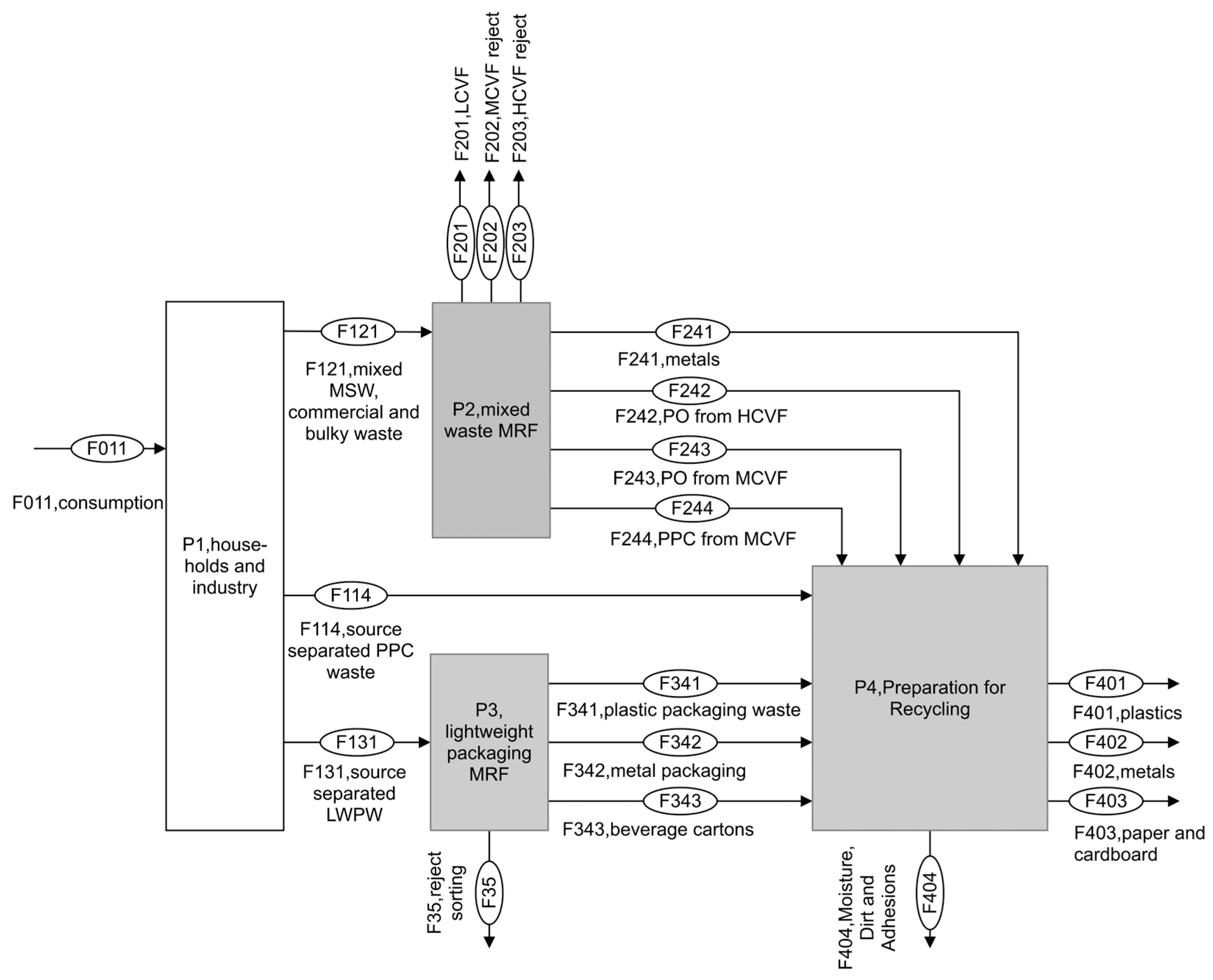

2.1. Investigated MRF for Mixed Waste

2.2. Pilot-Scale Processing Trials

2.2.1. Operational Parameters and General Design

Trial 1: High Calorific Value Fraction

Trial 2: Medium Calorific Value Fraction

2.2.2. Waste Stream Characterisation: Sampling and Sorting

2.2.3. Performance Indicators

2.3. Technical Potential Assessment for Recovery of PO and PPC

2.3.1. Upgrade Scenarios

2.3.2. Lower Heating Values

3. Results and Discussion

3.1. Pilot-Scale Processing Trials

3.1.1. Trial 1 and 2: PO Recovery

3.1.2. Trial 2: PPC Recovery

3.2. Technical Potential Assessment for Recovery of PO and PPC

3.2.1. Implications for PO and PPC Recycling

3.2.2. Implications for Incineration and Refuse-Derived Fuels

3.2.3. Further Economic and Environmental Implications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| EPR | Extended Producer Responsibility |

| ETS | Emissions Trading System |

| HDPE | High-Density Polyethene |

| HCVF | High Calorific Value Fraction |

| LCVF | Low Calorific Value Fraction |

| LDPE | Low-Density Polyethene |

| LHV | Lower Heating Value |

| MCVF | Medium Calorific Value Fraction |

| MFA | Material Flow Analysis |

| MRF | Material Recovery Facility |

| MSW | Municipal Solid Waste |

| NIR | Near-Infrared |

| PE | Polyethene |

| PET | Polyethene Terephthalate |

| PO | Polyolefins |

| PP | Polypropylene |

| PPC | Paper, Paperboard and Cardboard |

| PS | Polystyrene |

| PVC | Polyvinylchloride |

References

- Wilson, D.C. Learning from the Past to Plan for the Future: An Historical Review of the Evolution of Waste and Resource Management 1970–2020 and Reflections on Priorities 2020–2030—The Perspective of an Involved Witness. Waste Manag. Res. 2023, 41, 1754–1813. [Google Scholar] [CrossRef] [PubMed]

- Wilson, D.C. Development Drivers for Waste Management. Waste Manag. Res. 2007, 25, 198–207. [Google Scholar] [CrossRef]

- Karak, T.; Bhagat, R.M.; Bhattacharyya, P. Municipal Solid Waste Generation, Composition, and Management: The World Scenario. Crit. Rev. Environ. Sci. Technol. 2012, 42, 1509–1630. [Google Scholar] [CrossRef]

- Lederer, J.; Bartl, A.; Blasenbauer, D.; Breslmayer, G.; Gritsch, L.; Hofer, S.; Lipp, A.-M.; Mühl, J. A Review of Recent Trends to Increase the Share of Post-Consumer Packaging Waste to Recycling in Europe. Detritus 2022, 19, 3–17. [Google Scholar] [CrossRef]

- Beigl, P. Auswertung der Restmüllzusammensetzung in Österreich 2018/2019 (Analysis of Residual Waste Composition in Austria 2018/2019); Im Auftrag des Bundesministeriums für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Vienna, Austria, 2020. [Google Scholar]

- Lipp, A.-M.; Lederer, J. The Circular Economy of Packaging Waste in Austria: An Evaluation Based on Statistical Entropy and Material Flow Analysis. Resour. Conserv. Recycl. 2025, 217, 108193. [Google Scholar] [CrossRef]

- Mattson, K.R.; Pettersen, J.B.; Brattebø, H. Incineration Economy: Waste Management Policy Failing the Circular Economy Transition in Norway. Resour. Conserv. Recycl. 2024, 210, 107838. [Google Scholar] [CrossRef]

- Pomberger, R.; Sarc, R.; Lorber, K.E. Dynamic Visualisation of Municipal Waste Management Performance in the EU Using Ternary Diagram Method. Waste Manag. 2017, 61, 558–571. [Google Scholar] [CrossRef]

- Feil, A.; Pretz, T.; Jansen, M.; Thoden van Velzen, E.U. Separate Collection of Plastic Waste, Better than Technical Sorting from Municipal Solid Waste? Waste Manag. Res. 2017, 35, 172–180. [Google Scholar] [CrossRef]

- Rousta, K.; Ordoñez, I.; Bolton, K.; Dahlén, L. Support for Designing Waste Sorting Systems: A Mini Review. Waste Manag. Res. 2017, 35, 1099–1111. [Google Scholar] [CrossRef] [PubMed]

- Rousta, K.; Bolton, K.; Lundin, M.; Dahlén, L. Quantitative Assessment of Distance to Collection Point and Improved Sorting Information on Source Separation of Household Waste. Waste Manag. 2015, 40, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Knickmeyer, D. Social Factors Influencing Household Waste Separation: A Literature Review on Good Practices to Improve the Recycling Performance of Urban Areas. J. Clean. Prod. 2020, 245, 118605. [Google Scholar] [CrossRef]

- Schuch, D.; Lederer, J.; Fellner, J.; Scharff, C. Separate Collection Rates for Plastic Packaging in Austria—A Regional Analysis Taking Collection Systems and Urbanization into Account. Waste Manag. 2023, 155, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Seyring, N.; Dollhofer, M.; Weißenbacher, J.; Bakas, I.; McKinnon, D. Assessment of Collection Schemes for Packaging and Other Recyclable Waste in European Union-28 Member States and Capital Cities. Waste Manag. Res. 2016, 34, 947–956. [Google Scholar] [CrossRef] [PubMed]

- Statistik Austria Urban-Rural-Typologie. Stand 2021 (Urban-Rural Typology. Status as of 2021); Bundesanstalt Statistik Österreich: Wien, Austria, 2021. [Google Scholar]

- Foschi, E.; Barbir, J.; Mersico, L.; Stasiskiene, Z. Tourism Intensity and Plastic Waste Management: Insights from European Capital Cities. Discov. Sustain. 2025, 6, 419. [Google Scholar] [CrossRef]

- Obersteiner, G.; Gollnow, S.; Eriksson, M. Carbon Footprint Reduction Potential of Waste Management Strategies in Tourism. Environ. Dev. 2021, 39, 100617. [Google Scholar] [CrossRef]

- Ranieri, E.; Rada, E.C.; Ragazzi, M.; Masi, S.; Montanaro, C. Critical Analysis of the Integration of Residual Municipal Solid Waste Incineration and Selective Collection in Two Italian Tourist Areas. Waste Manag. Res. 2014, 32, 551–555. [Google Scholar] [CrossRef]

- Blasenbauer, D.; Lipp, A.-M.; Fellner, J.; Tischberger-Aldrian, A.; Stipanović, H.; Lederer, J. Recovery of Plastic Packaging from Mixed Municipal Solid Waste. A Case Study from Austria. Waste Manag. 2024, 180, 9–22. [Google Scholar] [CrossRef]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central Sorting and Recovery of MSW Recyclable Materials: A Review of Technological State-of-the-Art, Cases, Practice and Implications for Materials Recycling. J. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef]

- Edo-Alcón, N.; Gallardo, A.; Colomer-Mendoza, F.J.; Lobo, A. Efficiency of Biological and Mechanical-Biological Treatment Plants for MSW: The Case of Spain. Heliyon 2024, 10, e26353. [Google Scholar] [CrossRef]

- Pressley, P.N.; Levis, J.W.; Damgaard, A.; Barlaz, M.A.; DeCarolis, J.F. Analysis of Material Recovery Facilities for Use in Life-Cycle Assessment. Waste Manag. 2015, 35, 307–317. [Google Scholar] [CrossRef] [PubMed]

- (Thanos) Bourtsalas, A.C.; Themelis, N.J. Materials and Energy Recovery at Six European MBT Plants. Waste Manag. 2022, 141, 79–91. [Google Scholar] [CrossRef]

- Ardolino, F.; Berto, C.; Arena, U. Environmental Performances of Different Configurations of a Material Recovery Facility in a Life Cycle Perspective. Waste Manag. 2017, 68, 662–676. [Google Scholar] [CrossRef] [PubMed]

- Cimpan, C.; Maul, A.; Wenzel, H.; Pretz, T. Techno-Economic Assessment of Central Sorting at Material Recovery Facilities—The Case of Lightweight Packaging Waste. J. Clean. Prod. 2016, 112, 4387–4397. [Google Scholar] [CrossRef]

- Montejo, C.; Tonini, D.; del Carmen Márquez, M.; Astrup, T.F. Mechanical-Biological Treatment: Performance and Potentials. An LCA of 8 MBT Plants Including Waste Characterization. J. Environ. Manag. 2013, 128, 661–673. [Google Scholar] [CrossRef]

- Olafasakin, O.; Ma, J.; Bradshaw, S.L.; Aguirre-Villegas, H.A.; Benson, C.; Huber, G.W.; Zavala, V.M.; Mba-Wright, M. Techno-Economic and Life Cycle Assessment of Standalone Single-Stream Material Recovery Facilities in the United States. Waste Manag. 2023, 166, 368–376. [Google Scholar] [CrossRef] [PubMed]

- Edo-Alcón, N.; Gallardo, A.; Colomer-Mendoza, F.J. Characterization of SRF from MBT Plants: Influence of the Input Waste and of the Processing Technologies. Fuel Process. Technol. 2016, 153, 19–27. [Google Scholar] [CrossRef]

- Samolada, M.C.; Zabaniotou, A.A. Energetic Valorization of SRF in Dedicated Plants and Cement Kilns and Guidelines for Application in Greece and Cyprus. Resour. Conserv. Recycl. 2014, 83, 34–43. [Google Scholar] [CrossRef]

- Velis, C.; Wagland, S.; Longhurst, P.; Robson, B.; Sinfield, K.; Wise, S.; Pollard, S. Solid Recovered Fuel: Influence of Waste Stream Composition and Processing on Chlorine Content and Fuel Quality. Environ. Sci. Technol. 2012, 46, 1923–1931. [Google Scholar] [CrossRef]

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J.T. Production and Quality Assurance of Solid Recovered Fuels Using Mechanical—Biological Treatment (MBT) of Waste: A Comprehensive Assessment. Crit. Rev. Environ. Sci. Technol. 2010, 40, 979–1105. [Google Scholar] [CrossRef]

- Gritsch, L.; Breslmayer, G.; Lederer, J. Quantity and Quality of Paper-Based Packaging in Mixed MSW and Separate Paper Collection—A Case Study from Vienna, Austria. Resour. Conserv. Recycl. 2025, 215, 108091. [Google Scholar] [CrossRef]

- Lechleitner, A.; Schwabl, D.; Schubert, T.; Bauer, M.; Lehner, M. Chemisches Recycling von gemischten Kunststoffabfällen als ergänzender Recyclingpfad zur Erhöhung der Recyclingquote. Osterr. Wasser-Abfallwirtsch. 2020, 72, 47–60. [Google Scholar] [CrossRef]

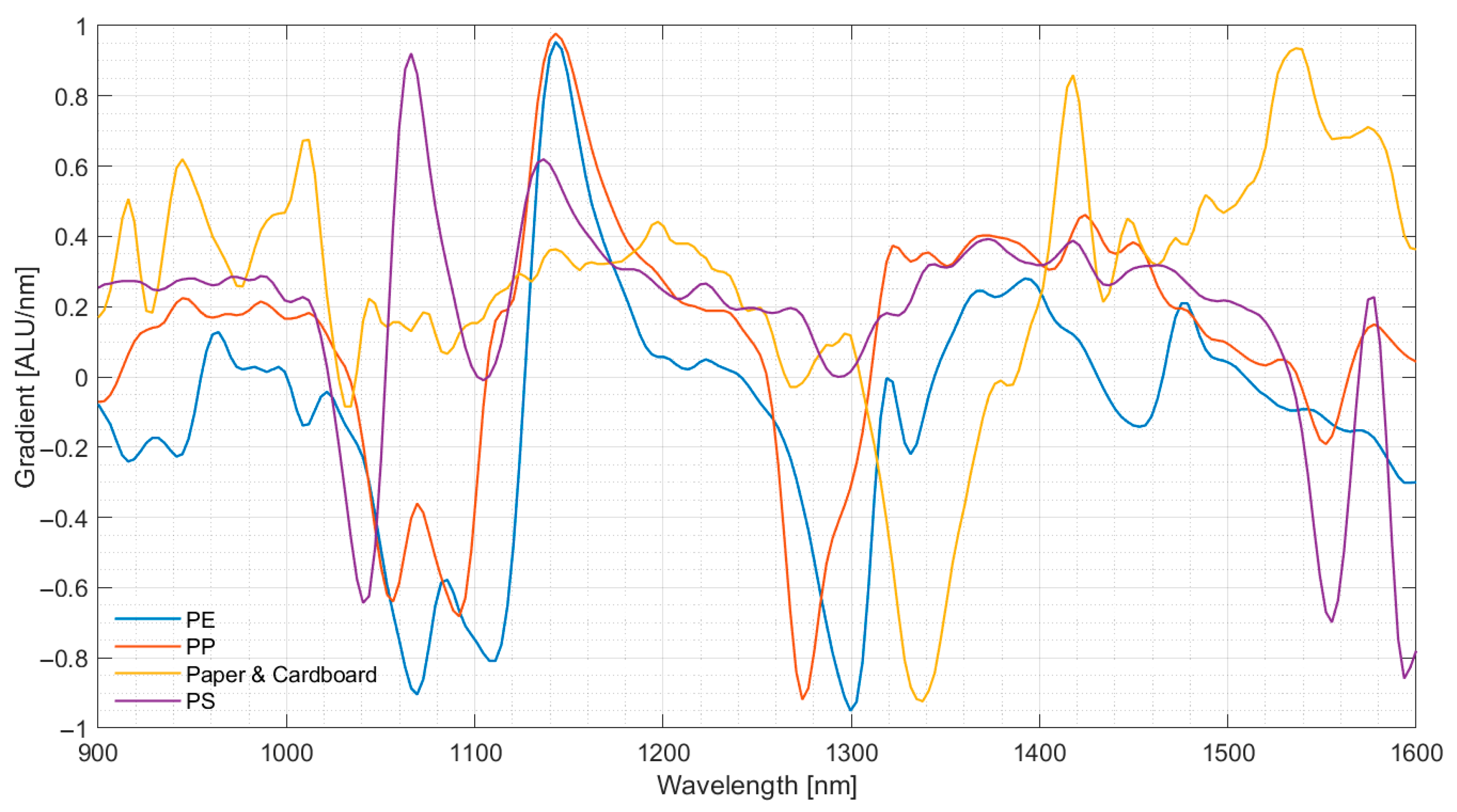

- Stipanovic, H.; Arth, P.; Koinig, G.; Kuhn, N.; Lederer, J.; Blasenbauer, D.; Lipp, A.-M.; Tischberger-Aldrian, A. Influence of Different Measuring Backgrounds on the Classification of Multilayer Polyolefin Films Using a Near-Infrared Handheld Spectrometer. Appl. Spectrosc. 2024, 79, 816–828. [Google Scholar] [CrossRef]

- GeoSphere Austria Klimamonitoringportal. Available online: https://klimaportal.geosphere.at/klimamonitoring (accessed on 26 August 2025).

- tiris—Tiroler Rauminformationssystem Geografische Informationssystem des Landes Tirol. Available online: https://www.tirol.gv.at/statistik-budget/tiris/ (accessed on 27 May 2021).

- Geodateportal Geoland. Available online: https://www.geoland.at/webgisviewer/geoland/map/Geoland_Viewer/Geoland (accessed on 18 May 2022).

- Kandlbauer, L.; Sarc, R.; Pomberger, R. Großtechnische experimentelle Forschung im Digital Waste Research Lab und Digitale Abfallanalytik und -behandlung. Österr. Wasser-Abfallwirtsch. 2024, 76, 32–41. [Google Scholar] [CrossRef]

- Gerlach, R.; Nocerino, J. Guidance for Obtaining Representative Laboratory Analytical Subsamples from Particulate Laboratory Samples; United States Environmental Protection Agency: Washington, DC, USA, 2003. [Google Scholar]

- Skutan, S.; Brunner, P. Metals in RDF and Other High Calorific Value Fractions from Mechanical Treatment of MSW: Analysis and Sampling Errors. Waste Manag. Res. J. Int. Solid Wastes Public Clean. Assoc. ISWA 2012, 30, 645–655. [Google Scholar] [CrossRef]

- Gy, P. Sampling of Heterogeneous and Dynamic Material Systems: Theories of Heterogeneity, Sampling, and Homogenizing; Data Handling in Science and Technology; Elsevier: Amsterdam, The Netherlands; New York, NY, USA, 1992; ISBN 978-1-281-77893-2. [Google Scholar]

- Mika, S.; Mühl, J.; Skutan, S.; Aschenbrenner, P.; Limbeck, A.; Lederer, J. Substance Flows of Heavy Metals in Industrial-Scale Municipal Solid Waste Incineration Bottom Ash Treatment: A Case Study from Austria. Waste Manag. 2025, 195, 240–252. [Google Scholar] [CrossRef] [PubMed]

- Bauernfeind, T. Evaluierung Verschiedener Analyseverfahren zur Bestimmung des Polyolefingehalts von Feedstock für das chemische Recycling (Evaluation of Different Analytical Methods to Determine the Polyolefin Content of Feedstock for Chemical Recycling). Master’s Thesis, TU Wien, Vienna, Austria, 2023. [Google Scholar]

- Feil, A.; Thoden van Velzen, E.U.; Jansen, M.; Vitz, P.; Go, N.; Pretz, T. Technical Assessment of Processing Plants as Exemplified by the Sorting of Beverage Cartons from Lightweight Packaging Wastes. Waste Manag. 2016, 48, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Allesch, A.; Brunner, P.H. Material Flow Analysis as a Decision Support Tool for Waste Management: A Literature Review. J. Ind. Ecol. 2015, 19, 753–764. [Google Scholar] [CrossRef]

- Cencic, O.; Rechberger, H. Material Flow Analysis with Software STAN. J. Environ. Eng. Manag. 2008, 18, 3–7. [Google Scholar]

- Laner, D.; Rechberger, H.; Astrup, T. Systematic Evaluation of Uncertainty in Material Flow Analysis. J. Ind. Ecol. 2014, 18, 859–870. [Google Scholar] [CrossRef]

- Kelly, J.D. A Regularization Approach to the Reconciliation of Constrained Data Sets. Comput. Chem. Eng. 1998, 22, 1771–1788. [Google Scholar] [CrossRef]

- Neubauer, C.; Stoifl, B.; Tesar, M.; Thaler, P. Sortierung und Recycling von Kunststoffabfällen in Österreich: Status 2019. Anhang; Umweltbundesamt: Wien, Austria, 2020. [Google Scholar]

- Kost, T. Brennstofftechnische Charakterisierung von Haushaltsabfällen (Fuel Characterisation of Household Waste). Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2001. [Google Scholar]

- Beckmann, M.; Pohl, M.; Bernhardt, D.; Gebauer, K. Criteria for Solid Recovered Fuels as a Substitute for Fossil Fuels—A Review. Waste Manag. Res. 2012, 30, 354–369. [Google Scholar] [CrossRef]

- Pohl, M.; Gebauer, K.; Beckmann, M. Characterisation of Refuse Derived Fuels in View of the Fuel Technical Properties. In Proceedings of the 8th European Conference on Industrial Furnaces and Boilers (INFUB-8), Vilamoura, Portugal, 25–28 March 2008; CD-ROM. VGB PowerTech e.V.: Essen, Germany, 2008. [Google Scholar]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of Post-Consumer Plastic Packaging Waste in the EU: Recovery Rates, Material Flows, and Barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Kim, Y. The Use of Polyolefins in Industrial and Medical Applications. In Polyolefin Fibres; Ugbolue, S.C.O., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2009; pp. 133–153. ISBN 978-1-84569-207-0. [Google Scholar]

- Ouederni, M. Polyolefins in Textiles and Nonwovens. In Polyolefin Compounds and Materials: Fundamentals and Industrial Applications; Al-Ali AlMa’adeed, M., Krupa, I., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 231–245. ISBN 978-3-319-25982-6. [Google Scholar]

- European Union. EU Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Off. J. Eur. Union 2018, 150, 109–140. [Google Scholar]

- BMSGPK Recycling von Alttextilien: Was in Österreich Gilt. Available online: https://www.konsumentenfragen.at/konsumentenfragen/Aktuelles/Konsumentenfragen/Recycling-von-Alttextilien-Was-in-Oesterreich-gilt.html (accessed on 11 March 2025).

- Kusenberg, M.; Eschenbacher, A.; Delva, L.; De Meester, S.; Delikonstantis, E.; Stefanidis, G.D.; Ragaert, K.; Van Geem, K.M. Towards High-Quality Petrochemical Feedstocks from Mixed Plastic Packaging Waste via Advanced Recycling: The Past, Present and Future. Fuel Process. Technol. 2022, 238, 107474. [Google Scholar] [CrossRef]

- OMV Recycling-Technologien. Available online: https://www.omv.com/de/expertise/chemicals/reoil (accessed on 11 March 2025).

- Schubert, T.; Lehner, M.; Karner, T.; Hofer, W.; Lechleitner, A. Influence of Reaction Pressure on Co-Pyrolysis of LDPE and a Heavy Petroleum Fraction. Fuel Process. Technol. 2019, 193, 204–211. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Bhaskar, T.; Uddin, M.A.; Kaneko, J.; Kusaba, T.; Matsui, T.; Muto, A.; Sakata, Y.; Murata, K. Liquefaction of Mixed Plastics Containing PVC and Dechlorination by Calcium-Based Sorbent. Energy Fuels 2003, 17, 75–80. [Google Scholar] [CrossRef]

- Huysveld, S.; Ragaert, K.; Demets, R.; Nhu, T.T.; Civancik-Uslu, D.; Kusenberg, M.; Van Geem, K.M.; De Meester, S.; Dewulf, J. Technical and Market Substitutability of Recycled Materials: Calculating the Environmental Benefits of Mechanical and Chemical Recycling of Plastic Packaging Waste. Waste Manag. 2022, 152, 69–79. [Google Scholar] [CrossRef]

- Jeswani, H.; Krüger, C.; Russ, M.; Horlacher, M.; Antony, F.; Hann, S.; Azapagic, A. Life Cycle Environmental Impacts of Chemical Recycling via Pyrolysis of Mixed Plastic Waste in Comparison with Mechanical Recycling and Energy Recovery. Sci. Total Environ. 2021, 769, 144483. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Commission Implementing Decision (EU) …/… of XXX Laying down Rules for the Application of Directive (EU) 2019/904 of the European Parliament and of the Council as Regards the Calculation, Verification and Reporting of Data on Recycled Plastic Content in Single-Use Plastic Beverage Bottles and Repealing Commission Implementing Decision (EU) 2023/2683. Ref Ares20255489340 2025, Draft. Available online: https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/13467-Single-use-plastic-beverage-bottles-EU-rules-for-calculating-verifying-and-reporting-on-recycled-plastic-content_en (accessed on 1 September 2025).

- Magrinho, A.; Semiao, V. On the Effect of MSW Moisture Content on Meeting Target Recycling Rates. Waste Manag. 2008, 28, 310–317. [Google Scholar] [CrossRef]

- Spies, A.M.; Kroell, N.; Ludes, A.; Küppers, B.; Raulf, K.; Greiff, K. Assessing the Resource Potential of Paper and Board in Lightweight Packaging Waste Sorting Plants through Manual Analysis and Sensor-Based Material Flow Monitoring. Waste Manag. 2024, 189, 196–210. [Google Scholar] [CrossRef]

- Tischberger-Aldrian, A.; Stipanovic, H.; Kuhn, N.; Bäck, T.; Schwartz, D.; Koinig, G. Automatisierte Textilsortierung—Status quo, Herausforderungen und Perspektiven. Österr. Wasser-Abfallwirtsch. 2024, 76, 63–79. [Google Scholar] [CrossRef]

- Miranda, R.; Monte, M.C.; Blanco, A. Analysis of the Quality of the Recovered Paper from Commingled Collection Systems. Resour. Conserv. Recycl. 2013, 72, 60–66. [Google Scholar] [CrossRef]

- Miranda, R.; Concepcion Monte, M.; Blanco, A. Impact of Increased Collection Rates and the Use of Commingled Collection Systems on the Quality of Recovered Paper. Part 1: Increased Collection Rates. Waste Manag. 2011, 31, 2208–2216. [Google Scholar] [CrossRef]

- ZSVR. UBA Recycling Im Wandel: Gemeinsam Für Qualität Und Quoten! Jahrespressekonferenz 4. Dezember 2023 (Recycling in Transition: Working Together for Quality and Quotas! Annual Press Conference 4 December 2023); Stiftung Zentrale Stelle Verpackungsregister, Umweltbundesamt Deutschland: Dessau-Roßlau, Germany, 2023. [Google Scholar]

- Cabanes, A.; Strangl, M.; Ortner, E.; Fullana, A.; Buettner, A. Odorant Composition of Post-Consumer LDPE Bags Originating from Different Collection Systems. Waste Manag. 2020, 104, 228–238. [Google Scholar] [CrossRef]

- Luijsterburg, B.; Goossens, H. Assessment of Plastic Packaging Waste: Material Origin, Methods, Properties. Resour. Conserv. Recycl. 2014, 85, 88–97. [Google Scholar] [CrossRef]

- Möllnitz, S.; Feuchter, M.; Duretek, I.; Schmidt, G.; Pomberger, R.; Sarc, R. Processability of Different Polymer Fractions Recovered from Mixed Wastes and Determination of Material Properties for Recycling. Polymers 2021, 13, 457. [Google Scholar] [CrossRef] [PubMed]

- Thoden van Velzen, E.U.; Chu, S.; Alvarado Chacon, F.; Brouwer, M.T.; Molenveld, K. The Impact of Impurities on the Mechanical Properties of Recycled Polyethylene. Packag. Technol. Sci. 2021, 34, 219–228. [Google Scholar] [CrossRef]

- Picuno, C.; Van Eygen, E.; Brouwer, M.T.; Kuchta, K.; Thoden van Velzen, E.U. Factors Shaping the Recycling Systems for Plastic Packaging Waste—A Comparison Between Austria, Germany and The Netherlands. Sustainability 2021, 13, 6772. [Google Scholar] [CrossRef]

- Lipp, A.-M.; Schlossnikl, J.; Gentgen, I.; Koch, T.; Archodoulaki, V.; Lederer, J. Recycling Rigid Polypropylene from Mixed Waste: Does the Origin Affect Mechanical Recyclate Quality? Waste Manag. Res. 2025. ahead of print. [Google Scholar] [CrossRef]

- Thoden van Velzen, E.U.; Smeding, I.W.; Brouwer, M.T.; Maaskant, E. Comparison of the Quality of Mechanically Recycled Plastics Made from Separately Collected and Mechanically Recovered Plastic Packaging Waste. In Proceedings of the Conference: Waste to Resources, Hanover, Germany, 20 May 2021. [Google Scholar]

- Golkaram, M.; Mehta, R.; Taveau, M.; Schwarz, A.; Gankema, H.; Urbanus, J.H.; De Simon, L.; Cakir-Benthem, S.; van Harmelen, T. Quality Model for Recycled Plastics (QMRP): An Indicator for Holistic and Consistent Quality Assessment of Recycled Plastics Using Product Functionality and Material Properties. J. Clean. Prod. 2022, 362, 132311. [Google Scholar] [CrossRef]

- Maaskant-Reilink, E.; Thoden van Velzen, E.U.; Smeding, I.W. Moleculaire Verontreiniging in Gerecyclede Kunststoffolie uit Bron-en Nascheiding (Molecular Contamination in Recycled Plastic Film from Source and Post-Separation); Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-Economic Assessment of Mechanical Recycling of Challenging Post-Consumer Plastic Packaging Waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Jiang, X.; Bateer, B. A Systematic Review of Plastic Recycling: Technology, Environmental Impact and Economic Evaluation. Waste Manag. Res. 2025, 43, 1159–1178. [Google Scholar] [CrossRef] [PubMed]

- European Union. EU Regulation (EU) 2025/40 of the European Parliament and of the Council of 19 December 2024 on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC (Text with EEA Relevance). Off. J. Eur. Union 2024, 40, 1–124. [Google Scholar]

- Lahl, U.; Zeschmar-Lahl, B. Material Recycling of Plastics—A Challenge for Sustainability. Sustainability 2024, 16, 6630. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Chemicals Strategy for Sustainability—Towards a Toxic-Free Environment. COM2020 667 Final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52020DC0667 (accessed on 1 May 2025).

- Larrain, M.; Billen, P.; Van Passel, S. The Effect of Plastic Packaging Recycling Policy Interventions as a Complement to Extended Producer Responsibility Schemes: A Partial Equilibrium Model. Waste Manag. 2022, 153, 355–366. [Google Scholar] [CrossRef] [PubMed]

- Burggräf, P.; Steinberg, F.; Sauer, C.R.; Nettesheim, P.; Wigger, M.; Becher, A.; Greiff, K.; Raulf, K.; Spies, A.; Köhler, H.; et al. Boosting the Circular Manufacturing of the Sustainable Paper Industry—A First Approach to Recycle Paper from Unexploited Sources Such as Lightweight Packaging, Residual and Commercial Waste. Procedia CIRP 2023, 120, 505–510. [Google Scholar] [CrossRef]

- CONTAM. Scientific Opinion on Mineral Oil Hydrocarbons in Food. EFSA J. 2012, 10, 2704. [Google Scholar] [CrossRef]

- Pivnenko, K.; Laner, D.; Astrup, T.F. Material Cycles and Chemicals: Dynamic Material Flow Analysis of Contaminants in Paper Recycling. Environ. Sci. Technol. 2016, 50, 12302–12311. [Google Scholar] [CrossRef]

- Pivnenko, K.; Eriksson, E.; Astrup, T.F. Waste Paper for Recycling: Overview and Identification of Potentially Critical Substances. Waste Manag. 2015, 45, 134–142. [Google Scholar] [CrossRef]

- Pivnenko, K.; Olsson, M.E.; Götze, R.; Eriksson, E.; Astrup, T.F. Quantification of Chemical Contaminants in the Paper and Board Fractions of Municipal Solid Waste. Waste Manag. 2016, 51, 43–54. [Google Scholar] [CrossRef]

- Kral, U.; Kellner, K.; Brunner, P.H. Sustainable Resource Use Requires “Clean Cycles” and Safe “Final Sinks. ” Sci. Total Environ. 2013, 461–462, 819–822. [Google Scholar] [CrossRef] [PubMed]

- Ihsanullah, I.; Alam, G.; Jamal, A.; Shaik, F. Recent Advances in Applications of Artificial Intelligence in Solid Waste Management: A Review. Chemosphere 2022, 309, 136631. [Google Scholar] [CrossRef] [PubMed]

- Kuchta, K.; Guo, J.; Woidasky, J.; Auer, M.; Schmidt, J.; Pomberger, R.; Tischberger-Aldrian, A.; Kuhn, N.; Anditsch, A. Vorstudie—Vergleich Innovativer Identifikationsverfahren Für Post-Consumer Leichtverpackungen—Endbericht; Hamburg Institute for Innovation, Climate Protection and Circular Economy GmbH (HiiCCE): Hamburg, Germany, 2023. [Google Scholar]

- Möllnitz, S.; Bauer, M.; Schwabl, D.; Sarc, R. Wet-Mechanical Processing of a Plastic-Rich Two-Dimensional-Fraction from Mixed Wastes for Chemical Recycling. Waste Manag. Res. 2021, 39, 731–743. [Google Scholar] [CrossRef]

- Sarc, R.; Seidler, I.; Kandlbauer, L.; Lorber, K.; Pomberger, R. Design, Quality and Quality Assurance of Solid Recovered Fuels for the Substitution of Fossil Feedstock in the Cement Industry—Update 2019. Waste Manag. Res. 2019, 37, 885–897. [Google Scholar] [CrossRef] [PubMed]

- BMK. Die Bestandsaufnahme Der Abfallwirtschaft in Österreich—Statusbericht 2024 (Referenzjahr 2022) (The Inventory of Waste Management in Austria—Status Report 2024 (Reference Year 2022)); Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Wien, Austria, 2024. [Google Scholar]

- Kranzinger, L.; Schopf, K.; Pomberger, R.; Punesch, E. Case Study: Is the ‘Catch-All-Plastics Bin’ Useful in Unlocking the Hidden Resource Potential in the Residual Waste Collection System? Waste Manag. Res. 2017, 35, 155–162. [Google Scholar] [CrossRef]

- European Commision. Commission Implementing Regulation (EU) 2024/1321 of 8 May 2024 Amending Implementing Regulation (EU) 2018/2067 as Regards the Verification of Data and the Accreditation of Verifiers. 2024. Available online: https://eur-lex.europa.eu/eli/reg_impl/2024/1321/oj/eng (accessed on 30 July 2025).

- European Union. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 Establishing the Framework for Achieving Climate Neutrality and Amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’). 2021. Available online: https://eur-lex.europa.eu/eli/reg/2021/1119/oj/eng (accessed on 30 July 2025).

- DEHst Berichtspflicht Abfallverbrennungsanlagen—Deutsche Emissionshandelsstelle. Available online: https://www.dehst.de/DE/Themen/EU-ETS-1/Stationaere-Anlagen/Abfallverbrennung/abfallverbrennung_node.html#doc327802bodyText3 (accessed on 30 July 2025).

- Zero Waste Europe Zero Waste Europe Urges Comprehensive Inclusion of Waste Incineration in EU Emissions Trading System. Available online: https://zerowasteeurope.eu/press-release/zero-waste-europe-urges-comprehensive-inclusion-of-waste-incineration-in-eu-emissions-trading-system/ (accessed on 30 July 2025).

- Hogg, D. Incineration in the EU-ETS: A Set of Suggestions for Its Inclusion; Equanimator Ltd. for Zero Waste Europe: Bristol, UK, 2024. [Google Scholar]

- Warringa, G.; Manna, K. Waste Incineration Under the EU ETS Assessment of Climate Benefits—Update 2025; CE Delf for Reloop and Zero Waste Europe: Delft, The Netherlands, 2025. [Google Scholar]

- Schmidt, S.; Laner, D. Reducing the Climate Impact of Residual Waste Treatment: A German Case Study on Carbon Management Strategies. Waste Manag. 2025, 198, 137–150. [Google Scholar] [CrossRef]

- Günther, C.; Pahle, M.; Govorukha, K.; Osorio, S.; Fotiou, T. Carbon Prices on the Rise? Shedding Light on the Emerging Second EU Emissions Trading System (EU ETS 2). Clim. Policy 2025, 1–12. [Google Scholar] [CrossRef]

- Hausberger, J. (Abfallwirtschaftsverband Tirol Mitte—ATM, Schwaz, Austria); Lipp, A.-M. (TU Wien, Wien, Austria). Personal Communication, 2024.

- Schuch, D. (Altstoff Recycling Austria—ARA, Wien, Austria); Lipp, A.-M. (TU Wien, Wien, Austria). Personal Communication, 2024.

- Jenewein, S. (Innsbrucker Kommunalbetriebe—IKB, Innsbruck, Austria); Lipp, A.-M. (TU Wien, Wien, Austria). Personal Communication, 2024.

- Leitgeb, D. (Recyclingzentrum Ahrental—RZ Ahrental, Innsbruck, Austria); Lipp, A.-M. (TU Wien, Wien, Austria). Personal Communication, 2024.

- Meirer, M. Physikalische Aufbereitung von Restabfällen Zur Co-Vergärung in Abwasserreinigungsanlagen (Physical Treatment of Residual Waste for Co-Digestion in Wastewater Treatment Plants). Ph.D. Thesis, Leopold-Franzens-Universität Innsbruck, Fakultät für Technische Wissenschaften, Innsbruck, Austria, 2018. [Google Scholar]

- Gritsch, L.; Breslmayer, G.; Rainer, R.; Stipanovic, H.; Tischberger-Aldrian, A.; Lederer, J. Critical Properties of Plastic Packaging Waste for Recycling: A Case Study on Non-Beverage Plastic Bottles in an Urban MSW System in Austria. Waste Manag. 2024, 185, 10–24. [Google Scholar] [CrossRef]

- Wohner, B.; Schwarzinger, N.; Gürlich, U.; Heinrich, V.; Tacker, M. Technical Emptiability of Dairy Product Packaging and Its Environmental Implications in Austria. PeerJ 2019, 7, e7578. [Google Scholar] [CrossRef]

| No. | Name | Description | HCVF Upgrade | MCVF Upgrade | No. of NIR Sorters |

|---|---|---|---|---|---|

| Status quo | Baseline | No Upgrades, only metal separation | - | - | - |

| Scenario I | PO Recovery I | Parameters determined by processing trial 1, see Figure 3b | PO | - | 2 |

| Scenario II | PO Recovery II | Parameters determined by processing trial 2, see Figure 3c | - | PO | 2 |

| Scenario III | PO + PPC Recovery | Parameters determined by processing trial 2, see Figure 3c | - | PO + PPC | 4 |

| Scenario IV | Enhanced PO Recovery | Parameters determined by processing trials 1 and 2, see Figure 3b,c | PO | PO | 4 |

| Scenario V | Intensive Sorting for Maximum Recovery | Parameters determined by processing trials 1 and 2, see Figure 3b,c | PO | PO + PPC | 6 |

| System Mass Recovery in wt. % | Purity in wt. % | System Yield in wt. % | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Trial | Material | ||||||||

| 1 | HCVF | Input | 100 ± 1.1 | 12 ± 1.2 | 15 ± 1.5 | 12 ± 1.2 | 100 ± 14 | 100 ± 14 | 100 ± 14 |

| 1 | HCVF | PO Reject 1 | 83 ± 1.3 | 5.8 ± 0.58 | 5.8 ± 0.58 | 14 ± 1.4 | 41 ± 5.9 | 33 ± 4.8 | 94 ± 13 |

| 1 | HCVF | PO Eject 2 | 17 ± 1.1 | 41 ± 4.1 | 57 ± 5.7 | 4.8 ± 0.48 | 59 ± 8.6 | 67 ± 9.7 | 6.9 ± 1.5 |

| 1 | HCVF | PO Reject 1 | 5.8 ± 1.1 | 11 ± 1.1 | 26 ± 2.6 | 10 ± 1.0 | 5.3 ± 1.3 | 10 ± 1.8 | 5.0 ± 1.0 |

| 1 | HCVF | PO Eject 2 | 11 ± 1.1 | 63 ± 6.3 | 73 ± 7.3 | 1.0 ± 0.10 | 54 ± 1.3 | 57 ± 8.2 | 2.0 ± 0.41 |

| 2 | MCVF | Input | 100 ± 1.2 | 7.8 ± 0.78 | 16 ± 1.6 | 16 ± 1.6 | 100 ± 14 | 100 ± 14 | 100 ± 14 |

| 2 | MCVF | PO Reject 1 | 74 ± 1.4 | 3.5 ± 0.35 | 3.5 ± 0.35 | 18 ± 1.8 | 33 ± 4.9 | 16 ± 2.5 | 88 ± 13 |

| 2 | MCVF | PO Eject 1 | 26 ± 1.2 | 20 ± 2.0 | 54 ± 5.4 | 7.4 ± 0.74 | 67 ± 9.7 | 84 ± 12 | 12 ± 2.2 |

| 2 | MCVF | PO Reject 2 | 11 ± 1.2 | 7.3 ± 1.5 | 7.3 ± 1.5 | 21 ± 4.2 | 10 ± 2.6 | 4.8 ± 0.69 | 6.3 ± 1.1 |

| 2 | MCVF | PO Eject 2 | 15 ± 1.2 | 31 ± 3.1 | 53 ± 5.3 | 6.3 ± 0.63 | 57 ± 2.6 | 80 ± 11.6 | 6.0 ± 1.1 |

| 2 | MCVF | PPC Reject 1 | 46 ± 1.2 | 5.5 ± 1.1 | 5.5 ± 1.1 | 11 ± 2.2 | 33 ± 7.4 | 15 ± 2.5 | 32 ± 4.6 |

| 2 | MCVF | PPC Eject 1 | 28 ± 1.3 | 2.1 ± 0.42 | 2.1 ± 0.42 | 44 ± 8.9 | 0.51 ± 7.4 | 0.24 ± <0.10 | 55 ± 7.9 |

| 2 | MCVF | PPC Reject 2 | 9.1 ± 1.3 | 4.1 ± 0.83 | 4.1 ± 0.83 | 16 ± 3.1 | 0.32 ± 4.7 | 0.15 ± <0.10 | 6.3 ± 0.40 |

| 2 | MCVF | PPC Eject 2 | 19 ± 1.2 | 0.81 ± 0.16 | 0.81 ± 0.16 | 55 ± 11 | 0.19 ± 2.7 | <0.10 ± <0.10 | 49 ± 7.0 |

| HCVF | MCVF | |||

|---|---|---|---|---|

in MJ·kg−1 | in kt·yr−1 | in MJ·kg−1 | in kt·yr−1 | |

| Status Quo | 17.9 ± 1.70 | 10.5 | 13.4 ± 2.11 | 27.3 |

| Scenario I | 17.1 ± 1.67 | 9.4 ± 0.1 | 13.4 ± 2.11 | 27.3 |

| Scenario II | 17.9 ± 1.70 | 10.5 | 12.7 ± 2.00 | 23.2 ± 0.2 |

| Scenario III | 17.9 ± 1.70 | 10.5 | 13.1 ± 2.55 | 18.0 ± 0.2 |

| Scenario IV | 17.1 ± 1.67 | 9.4 ± 0.1 | 12.7 ± 2.00 | 23.2 ± 0.2 |

| Scenario V | 17.1 ± 1.67 | 9.4 ± 0.1 | 13.1 ± 2.55 | 18.0 ± 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lipp, A.-M.; Blasenbauer, D.; Stipanovic, H.; Koinig, G.; Tischberger-Aldrian, A.; Lederer, J. Technical Evaluation and Recycling Potential of Polyolefin and Paper Separation in Mixed Waste Material Recovery Facilities. Recycling 2025, 10, 176. https://doi.org/10.3390/recycling10050176

Lipp A-M, Blasenbauer D, Stipanovic H, Koinig G, Tischberger-Aldrian A, Lederer J. Technical Evaluation and Recycling Potential of Polyolefin and Paper Separation in Mixed Waste Material Recovery Facilities. Recycling. 2025; 10(5):176. https://doi.org/10.3390/recycling10050176

Chicago/Turabian StyleLipp, Anna-Maria, Dominik Blasenbauer, Hana Stipanovic, Gerald Koinig, Alexia Tischberger-Aldrian, and Jakob Lederer. 2025. "Technical Evaluation and Recycling Potential of Polyolefin and Paper Separation in Mixed Waste Material Recovery Facilities" Recycling 10, no. 5: 176. https://doi.org/10.3390/recycling10050176

APA StyleLipp, A.-M., Blasenbauer, D., Stipanovic, H., Koinig, G., Tischberger-Aldrian, A., & Lederer, J. (2025). Technical Evaluation and Recycling Potential of Polyolefin and Paper Separation in Mixed Waste Material Recovery Facilities. Recycling, 10(5), 176. https://doi.org/10.3390/recycling10050176