Abstract

This literature review critically examines the incorporation of mineral wool waste (MWW), a byproduct of insulation materials, into new construction materials as a sustainable recycling strategy. Covering research published between 2000 and 2025, the review focuses on the effects of MWW on various material properties and performance, including concrete, mortar, alkali-activated materials (AAMs), geopolymers (GPs), building ceramics, and asphalt. Experimental evidence demonstrates that MWW can enhance or alter the performance of these materials, offering promising opportunities for waste valorization. The review also identifies challenges related to optimizing material compositions and production methods, and highlights the need for further research to facilitate the industrial-scale application of MWW-recycled construction materials. By synthesizing current knowledge, this work aims to inform sustainable development and circular economy practices in the construction sector.

1. Introduction

Construction and demolition waste (CDW) represents a substantial portion of the total waste produced on Earth, accounting for around 36% [1]. Although three-quarters of CDW has potential for recovery, a significant amount is still disposed of in landfills, resulting in a serious threat to the environment [2,3]. Based on a projection of the 3 billion tons of CDW produced annually worldwide, it is estimated that about one-third or roughly 1 billion tons per year end up in landfills, with China, the USA, EU, and India being the greatest contributors to this pollution [4]. As CDW continues to pose significant challenges due to its growing volume and environmental impacts, the effective management and recycling of CDW streams is needed to reduce landfill use and economize the use of natural resources [5].

The recycling of waste is gaining attention as industries and governments strive to support circular economy principles. There has been noticeable progress in research on both CDW recycling and in recycling different industrial wastes into innovative construction materials such as geopolymers (GPs) [6], alkali-activated materials (AAMs) [7], and engineered cementitious composites [8]. Despite this progress, mineral wool waste (MWW), a prevalent byproduct of insulation manufacturing, remains underexplored [9]. The reason for this might be challenging material compositions, limited processing infrastructure, or the common perception of the material’s non-recyclability [10,11].

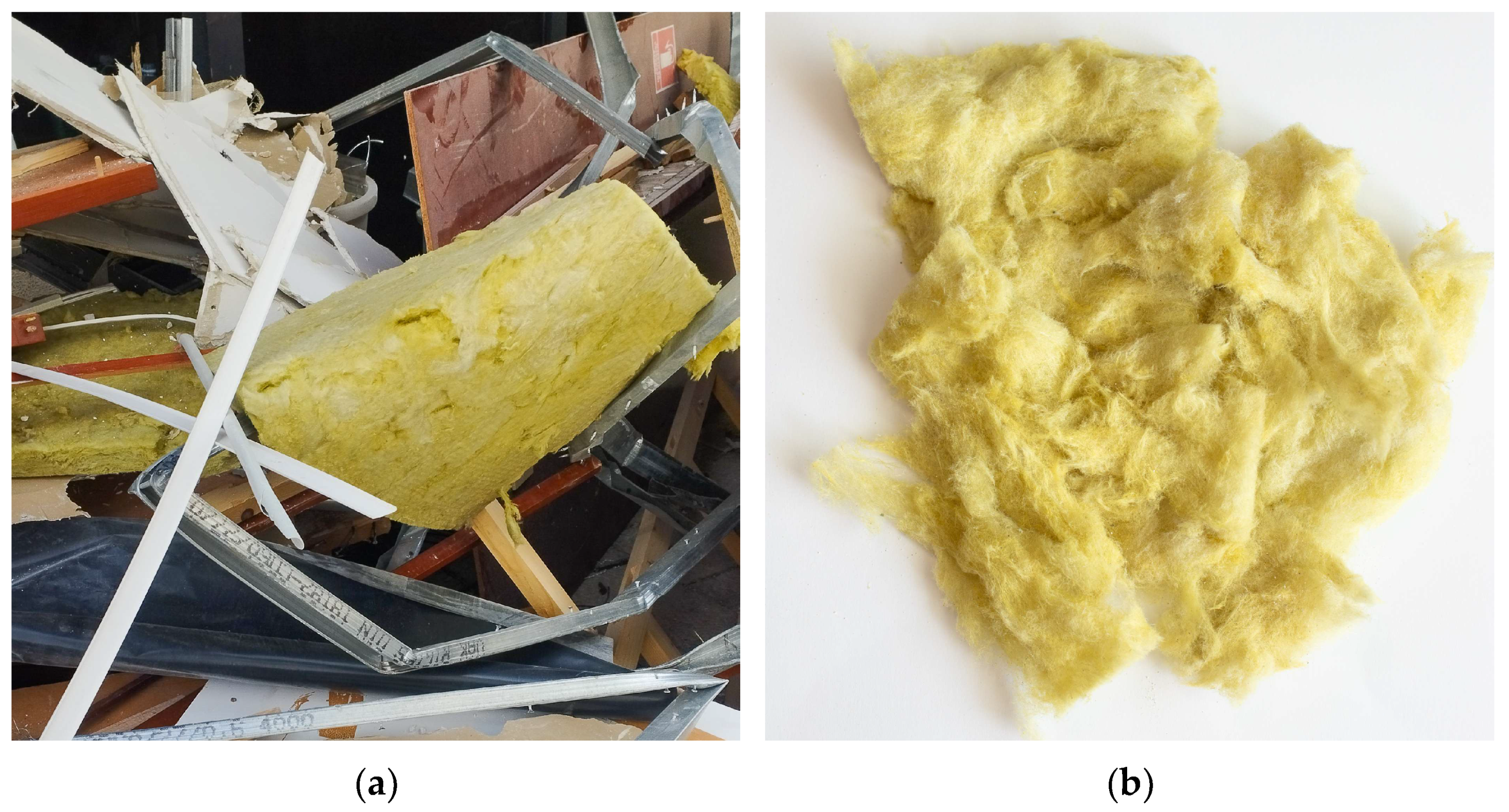

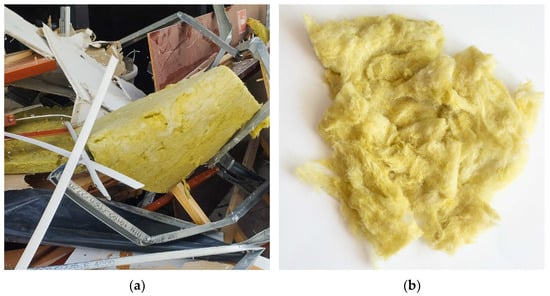

MWW (Figure 1) is an important material flow in CDW because of its widespread use as an insulating material in construction. The term mineral wool refers to various insulation materials made of rock wool (RW), glass wool (GW), or slag wool. Mineral wool is used for thermal, acoustic, and fire protection in construction and other sectors [12]. The production of mineral wool begins with the melting of raw materials such as basalt and diabase (in the case of RW), or sand and limestone (for GW), along with secondary materials, at high temperatures—usually between 1300 and 1500 °C [13,14]. The subsequent production steps include fiberization through high-speed spinning, the injection of binders, curing, and shaping. The final product has a low density and high porosity, resulting in efficient insulation properties [15].

Figure 1.

MWW: (a) Mixed CDW accumulation during the renovation project; (b) Close-up of a MWW from the CDW pile.

RW and GW are by far the most used insulation materials in the world [10,11]. In the European Union, mineral wool represents 58% of the total thermal insulation market [16]. This prevalence is not surprising, as mineral wool insulation is recognized as one of the most efficient solutions for cost-effective and energy-efficient thermal management in buildings [17]. As a consequence of the growing demand for energy-efficient buildings, the consumption of mineral wool products is also increasing, resulting in significant quantities of MWW [18]. To illustrate this, the estimated production of MWW in Europe alone was over 2.5 million tons in 2020, but this quantity is expected to grow at a predicted annual growth rate of 1.2% [19,20]. Although MWW does not constitute a large mass proportion of the total CDW, it occupies a large volume due to its low density (the bulk density varies between 20 and 200 kg/ and the true density can be up to 3000 kg/), resulting in increased transportation and disposal costs [10,18].

The majority of this waste is still landfilled [17,21], despite the fact that it might possess unknown and environmentally hazardous properties. Dust and fine fibers from landfilled or dumped MWW could eventually find their way into the ecosystem, resembling the behavior of microplastics, while the contaminants from MWW could be transported into groundwater via infiltration [22]. Moreover, the landfill disposal of MWW demands a substantial area and incurs high logistical costs [23]. As the landfilled quantities have steeply risen in the last decade [24], the research and development of appropriate management practices for MWW are urgently needed.

Although previous research has emphasized the importance of reusing MWW, it remains crucial to advance existing knowledge through an analysis of recent findings and applications. Motivated by the global environmental challenge of CDW management and the growing supply of MWW from future renovation and demolition activities, we conducted a literature review on MWW utilization in construction materials, focusing on recent advancements. Our aim is to explore MWW’s potential as a raw material for new construction products, and therefore to contribute to the research domain through an in-depth analysis of material properties and structural performance in concrete, mortars, and other building materials incorporating recycled MWW.

2. Literature Review Methodology

This review provides a comprehensive overview of the incorporation of MWW into various construction materials. The initial search was guided by the primary research question “How has MWW been utilized in construction materials from 2000 to 2025?”. Additional guiding questions included:

- Which construction materials incorporate MWW, and how does its inclusion affect their properties and performance?

- What opportunities and challenges are associated with the recycling of MWW in construction materials?

- What future research directions could address current gaps in the valorization of MWW?

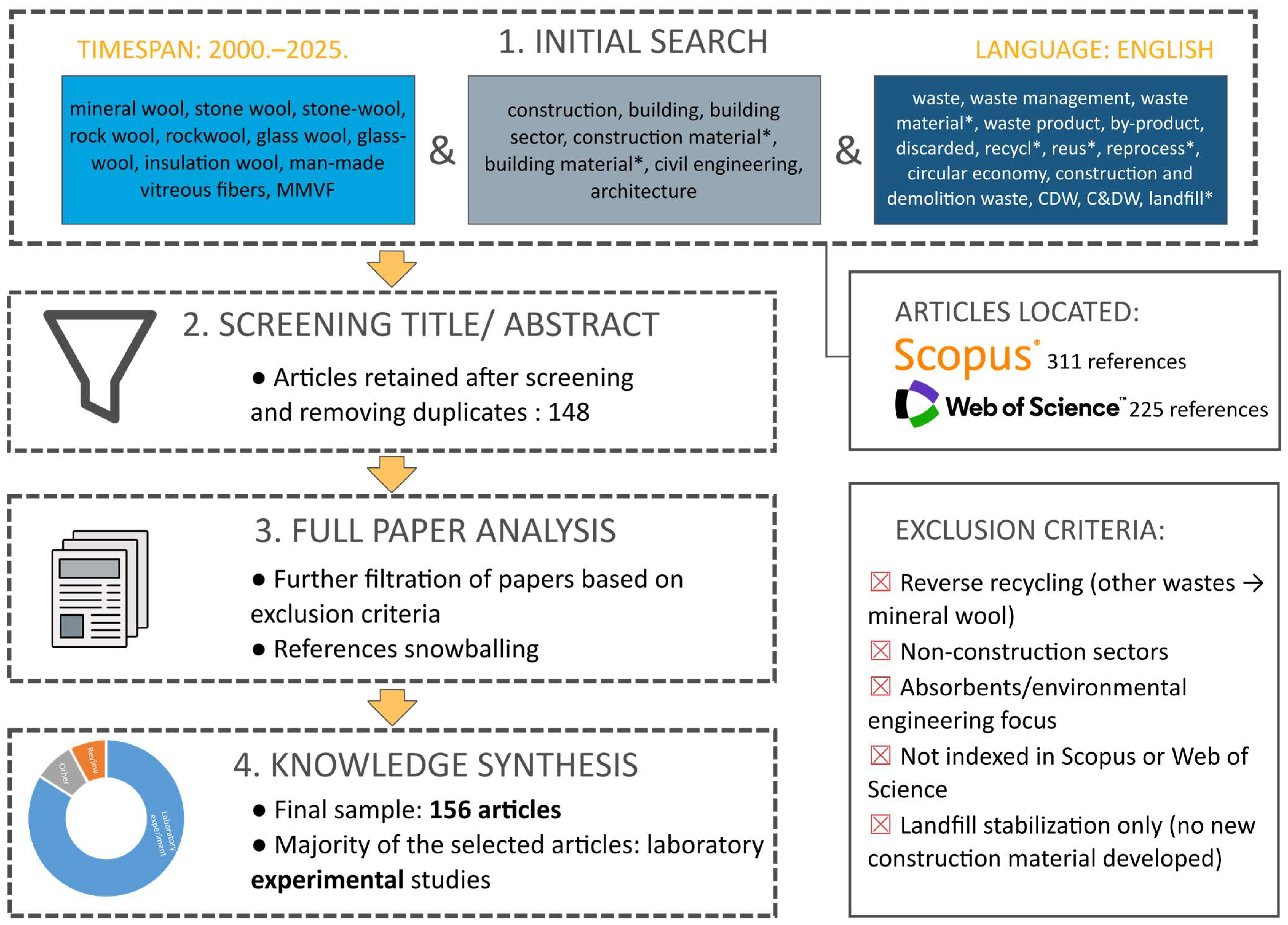

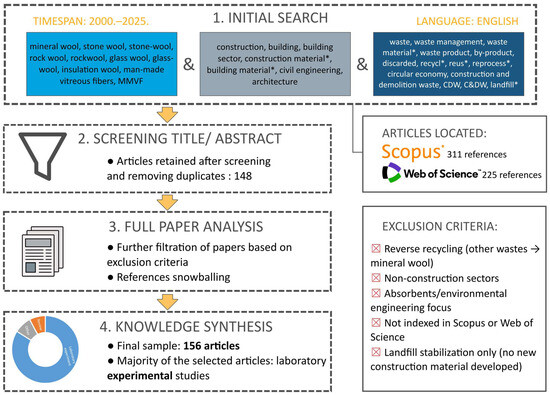

Therefore, we conducted a systematic literature review in four main stages (Figure 2). First, we selected two well-established scientific databases for the literature review: Scopus and Web of Science. In each database, we formulated queries to identify research papers that addressed the intersection of three main concepts—mineral wool, construction industry, and waste material—in their titles, keywords, or abstracts. Synonyms for each concept were also considered to ensure comprehensive coverage. The search was limited to articles published in English between 2000 and 2025. The initial query yielded 311 records from Scopus and 225 articles from Web of Science.

Figure 2.

Summary of the literature review methodology.

The titles and abstracts of articles were then screened based on the predefined research questions, and the duplicates from two databases were removed. This process resulted in 148 articles, which were then fully analyzed in the third step of the review process. Their reference lists were also checked to identify additional relevant studies. To determine whether a publication was within the scope of our analysis, we applied several exclusion criteria. For example, we excluded studies where mineral wool or MWW was not the input, but rather the output—that is, studies in which other waste streams were used to produce mineral wool. We also focused exclusively on applications in the construction sector, excluding studies related to other industries such as shipbuilding or automotive manufacturing. Additionally, we excluded research that reported the development of absorbents for environmental engineering. During the snowballing process, all newly identified references were only included if they were indexed in Scopus or Web of Science; otherwise, they were excluded. Lastly, we excluded studies that discuss MWW landfill stabilization without the development of new construction materials.

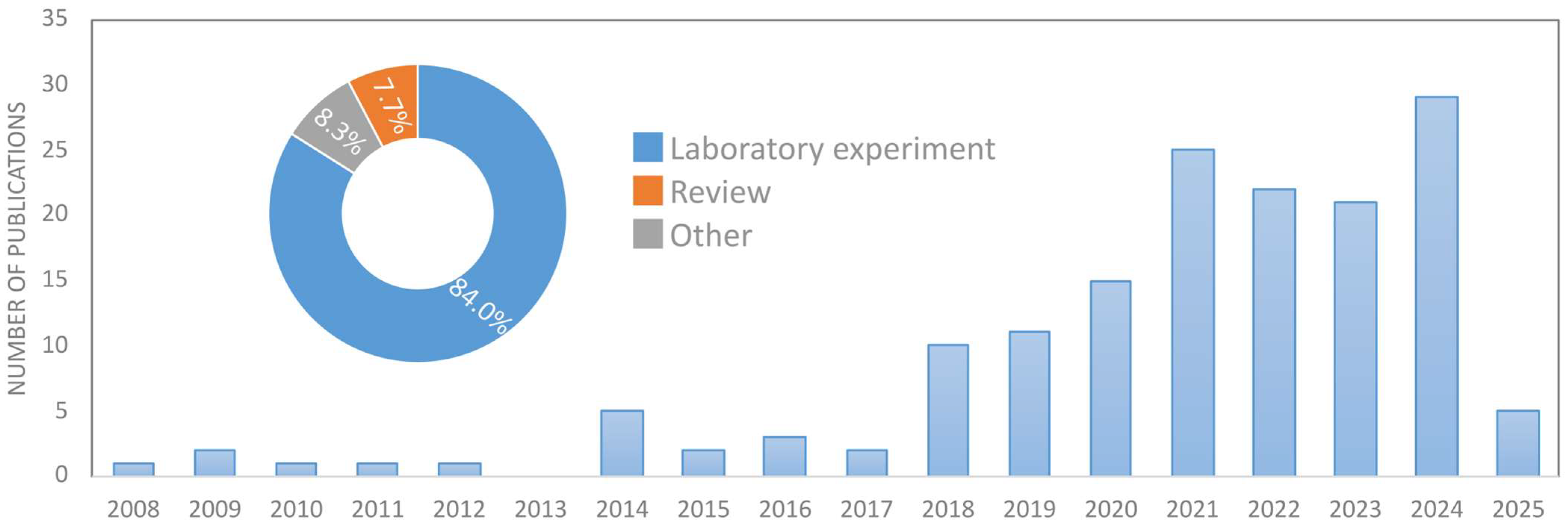

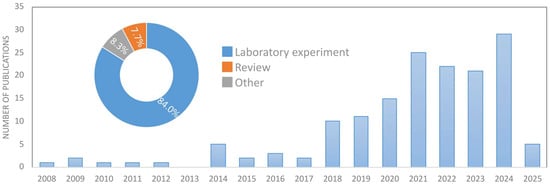

The final step of the literature review involved synthesizing knowledge from the 156 research articles selected for our database. Notably, the majority of these papers were published from 2018 onwards (Figure 3), reflecting growing environmental awareness and policy-driven pressures. No relevant articles were identified for the period 2000–2007. The review reveals that most studies (84%; Figure 3) focus on the laboratory testing of newly developed materials.

Figure 3.

The number of publications in the final database (Retrieved date: 21 June 2025).

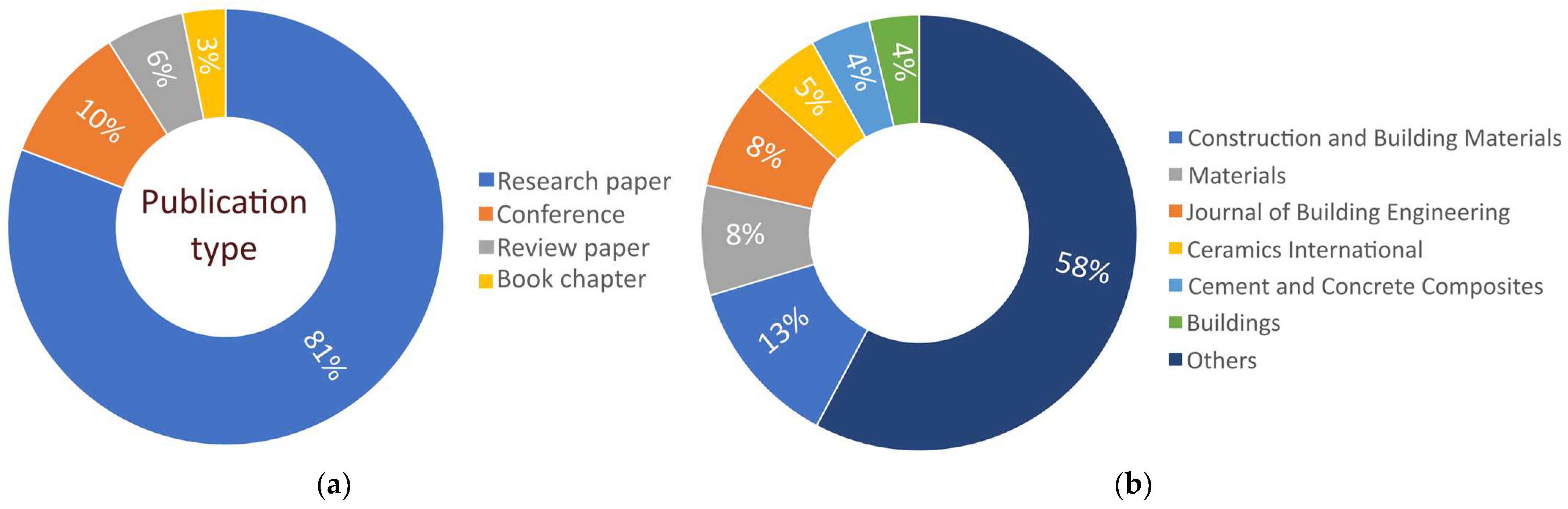

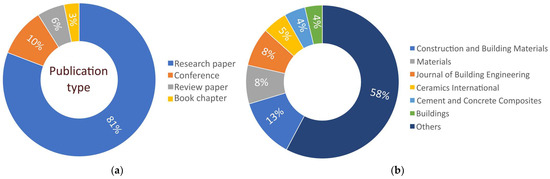

Additionally, only a small number of previously published review articles and studies from related domains—such as life cycle assessment (LCA) and economic analyzes [25,26,27,28], methodological frameworks for supply chain optimization [29], and applied method validations [30]—were identified. In terms of publication type, most of the selected studies (126 out of 156 studies) appeared in research journals, with Construction and Building Materials emerging as the most frequent publication source (Figure 4).

Figure 4.

Publications overview: (a) publication type; (b) distribution of selected papers by journal.

Several review articles have addressed various aspects of MWW reutilization (Table 1). However, these reviews primarily focused on specific applications or locations and did not provide an in-depth analysis of the key research questions that are central to our study. To address this gap, our review systematically examines the use of MWW, its effects, barriers, benefits, and future prospects, providing new insights and a more focused perspective on MWW reutilization in new construction materials.

Table 1.

Summary of previous review articles and the context in which MWW was discussed.

In summary, the systematic and multi-stage review methodology was applied to define the comprehensive database of relevant literature. This approach provides a solid foundation for synthesizing current knowledge and identifying research gaps related to the incorporation of MWW in construction materials such as cementitious materials, AAMs, GPs, mortars, and others.

3. Mineral Wool Waste: Characterization, Challenges and Opportunities

3.1. Classification and Sources of MWW

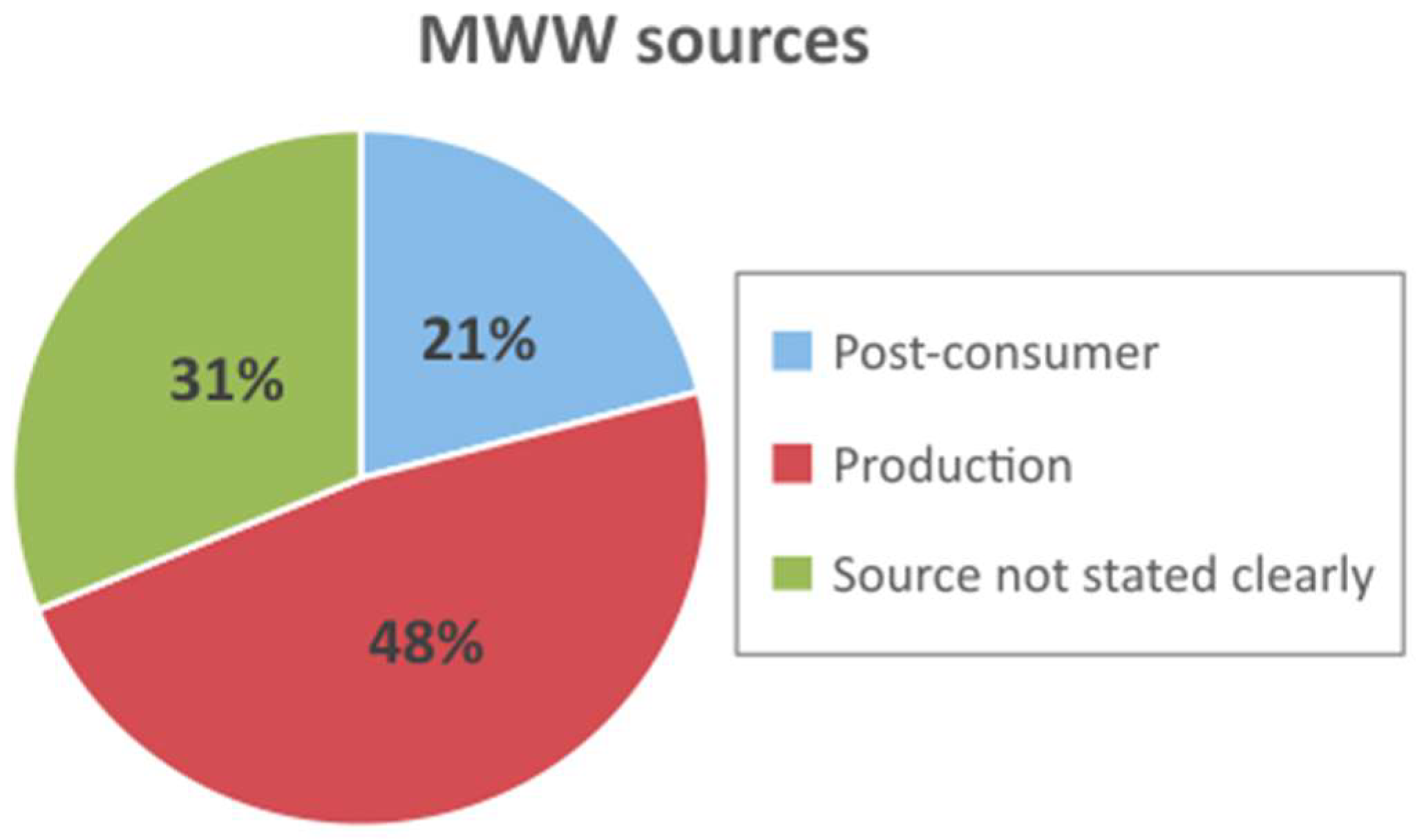

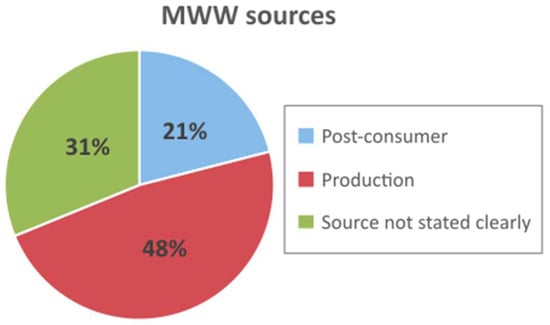

MWW can be categorized as either manufacturing (production) waste or post-consumer waste [15]. While manufacturing offcuts represent a minority of MWW, the majority originates from the CDW streams [10]. However, from the conducted literature review, it is apparent that less than a quarter of selected studies focus on processing MWW from landfills, i.e., post-consumer MWW (Figure 5). This observation aligns with previous findings in the literature [38], and the approach can be justified because MWW from the production is less contaminated, allowing laboratory experiments to be conducted under controlled conditions. Nevertheless, it is essential to analyze MWW from CDW streams, as it constitutes the predominant fraction of this waste material.

Figure 5.

Origin of MWW in selected research.

3.2. Challenges in Recycling

Unfortunately, MWW is sometimes perceived as an unrecyclable material [11,20,39,40,41] and therefore often disposed of at landfills and left exposed to further contamination. Due to its bulkiness and the great difference in Young’s modulus between mineral wool and general CDW, managing the safe handling of MWW in landfills is challenging. MWW has a significantly different density than the majority of the common CDW; thus, mixing MWW with general CDW can lead to landfill instability. According to Sattler et al. [42], Young’s modulus of stabilized and cement-supported briquetted MWW ranges from 7.5 MPa to 111 MPa, which, despite this improvement, remains approximately three orders of magnitude lower than that of common CDW. This represents a safety risk, and accidents involving overturned machinery in landfills have already been reported [42]. Apart from its challenging mechanical properties, another major concern is the chemical composition of the MWW. Although previous research suggests that MWW generally has homogenous properties, variations in the waste material properties can still influence the production of new materials. It is essential to pay special attention to the analysis and processing of resin binders in raw MWW, as they can significantly affect the processes and reactions involved in recycling.

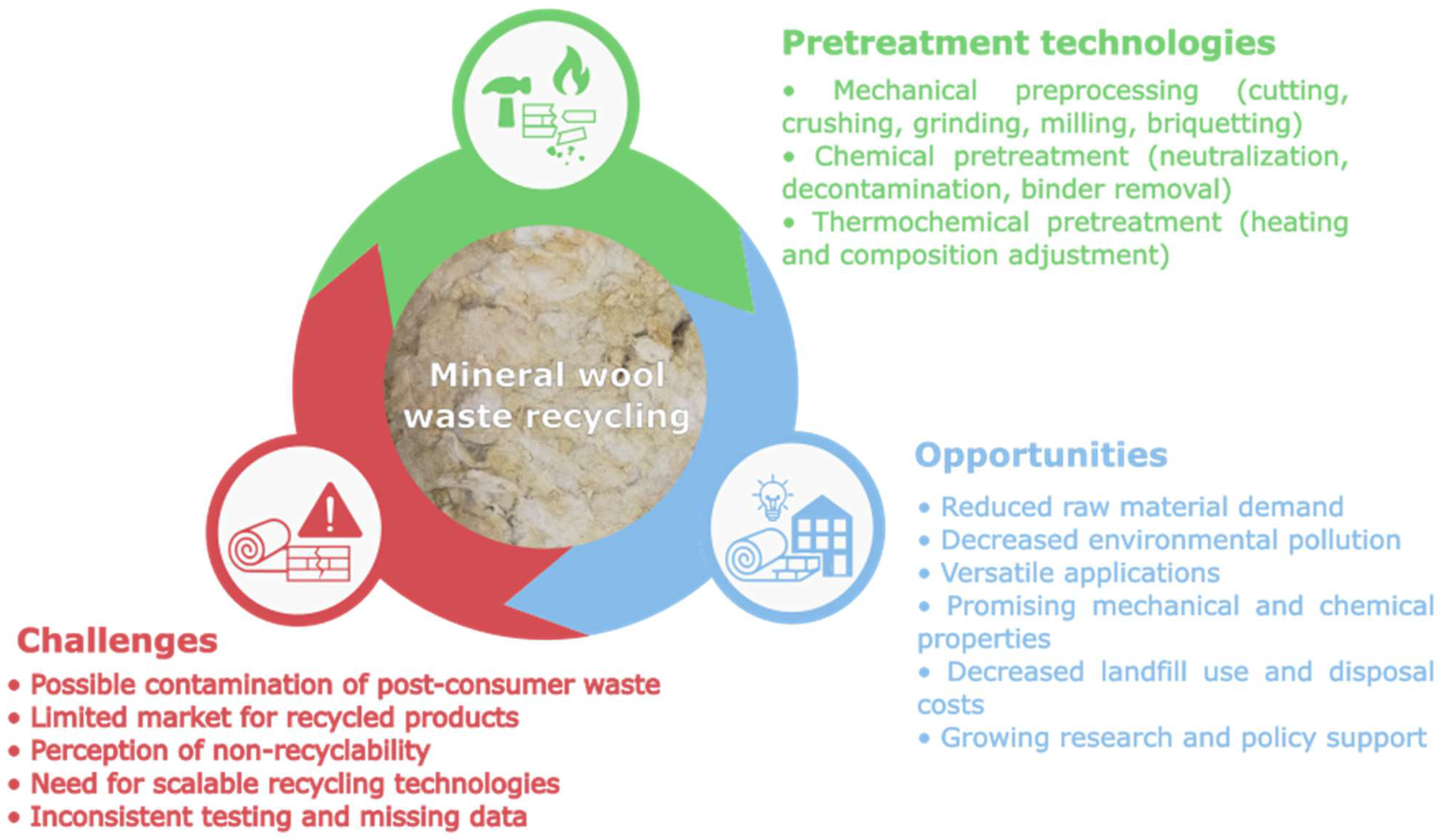

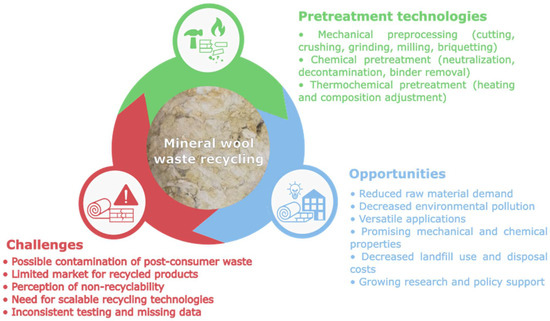

The closed-loop recycling of mineral wool remains in its early stages, primarily due to technological limitations, the lack of established supply chains, and high associated costs [43]. These barriers contribute to a limited market for recycled mineral wool products, as concerns about quality, availability, and price competitiveness often lead manufacturers and consumers to prefer virgin materials, further restricting demand and market growth. The majority of studies have focused on laboratory-scale experiments, underscoring the necessity for recycling technologies that are scalable, stable, and efficient. Progress in this field requires moving beyond isolated trials toward the development of functional systems that are suitable for real-world application. During this review, it was observed that many studies assess only selected properties—such as mechanical strength, fire behavior, or durability—reflecting a lack of comprehensive testing and standardized guidelines. The incomplete reporting of material compositions and experimental details further complicates the advancement of MWW recycling. As a result of the conducted literature review, the main opportunities, obstacles, and pretreatment technologies in recycling MWW are summarized in Figure 6.

Figure 6.

Key opportunities, challenges, and pretreatment technologies associated with recycling MWW into new construction materials.

3.3. Pretreatment Technologies

Pretreatment technologies are essential in MWW recycling for construction applications, as they help to remove contaminants and impurities, adjust physical properties, and improve compatibility with cementitious or other matrices. The literature reports a range of pretreatment strategies, which are predominantly mechanical, but also include chemical and thermochemical methods.

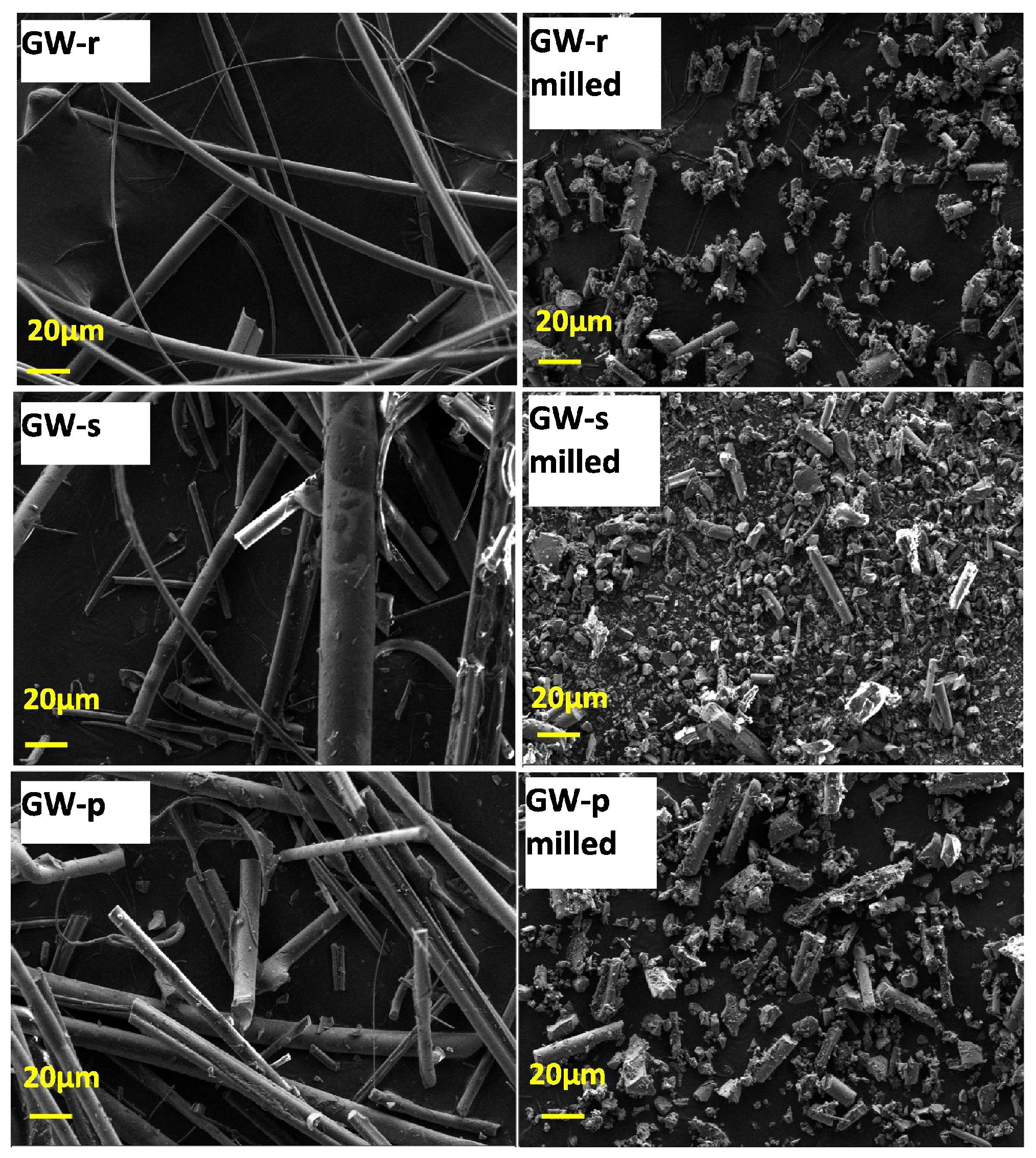

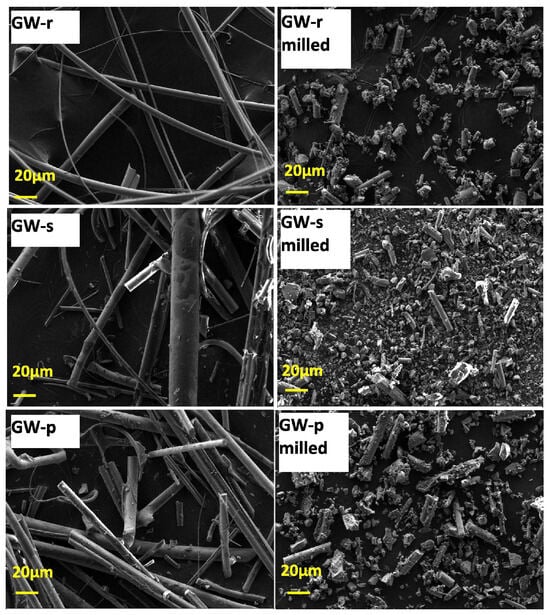

Mechanical pretreatment typically involves crushing, grinding, milling, or cutting to reduce the fiber size and adapt the material for reuse. These steps are essential not only for improving the mixing properties, but also for enhancing the reactivity and performance of the recycled material. For instance, fine milling of a GW has been shown to enhance its reactivity during sintering of porous ceramics by promoting more homogeneous mixing in the green body stage [44]. Fine particles provide a larger surface area, which can have a positive effect on the densification of a final product. This morphological transformation is illustrated in Figure 7, which shows scanning electron microscopy (SEM) images comparing raw and milled GW particles [45]. The milled sample exhibits significantly smaller, fractured fibers and a granular morphology, indicating improved surface accessibility and reactivity. Yliniemi et al. [10] investigated different comminution methods for mineral wools and their effects on the final physical characteristics. Compression-based methods, specifically the vibratory disk milling and hydraulic pressing, were found to completely break down mineral wools’ fibrousness and transform it into powder form. The vibratory disk mill was notably superior in reducing fiber length, making it ideal for applications requiring a powder, such as GPs and cement additives. In contrast, methods based on high cutting speeds, such as rotating knife granulator, high-frequency dispergator, and fine impact mill, only moderately affected the material’s bulk density and fiber length. Crucially, the study found that the comminution methods did not decrease fiber width but rather truncated fibers, with results remaining consistent regardless of the mineral wool type, indicating similar behavior for all glassy mineral wools. The compression and abrasion-based mills are suggested as the most promising solutions for converting this MWW into a usable resource.

Figure 7.

SEM images of the milled GW: samples include fibers without resin (GW-r); with sugar resin (GW-s); and with phenolic resin (GW-p). Reprinted from [45], with permission from publisher.

Chemical pretreatment is primarily used to neutralize the hazardous materials present in mineral wool binders. Potentially hazardous coatings are used as weak binders in the manufacture of mineral wool. Traditionally, phenol–formaldehyde–urea binders have been used in the manufacture of mineral wool, although the industry is moving towards binder technologies that minimize or even eliminate formaldehyde emissions due to carcinogenicity [46]. In an effort to address these issues, the invention of alternative, more environmentally friendly binder systems based on non-toxic biopolymers has been researched [47], but not yet accepted industrially. Therefore, several chemical processes for the reprocessing of MWW have been used in research. Phenol can be completely neutralized using an aqueous solution of hydrogen peroxide with ferrous sulfate as a catalyst to oxygenate it and convert it into phenoxyl radicals, while formaldehyde can be treated with a solution of diammonium hydrogen phosphate and carbamide, forming stable and non-toxic compounds. In a series of studies by Lithuanian researchers [48,49,50], a neutralization process in which these reagent solutions were sprayed onto MWW for safe utilization in the manufacture of ceramic products was used. These chemical reactions reduce health and environmental risks and enable the safer processing of MWW in subsequent uses.

Thermochemical pretreatment combines high-temperature processing with chemical modification to alter the structural and compositional properties of mineral wool. The process often involves incorporating corrective additives materials such as CaO [51], SiO2, and MgO [52], or by-products such as fly ash from paper production [51], dolomite slurry, and corundum dust [52] to target the modification of the mineral wool chemical composition at high temperatures (e.g., 1400 °C [51]). The treated material is then rapidly cooled, resulting in an amorphous phase, which is crucial for its hydraulic reactivity. The thermochemically treated MWW can then be used as a supplementary cementitious material (SCM) [51], or in the production of regenerated, non-hazardous new mineral wool [52]. A further example of thermochemical processing is presented in a study by Dhamale et al. [22], where plasma treatment was applied to melt and vitrify mineral wool at extremely high temperatures. This treatment decomposed the organic binder and transformed the fibrous microstructure into a glassy solid, demonstrating the capacity for both detoxification and material valorization.

Overall, pretreatment technologies play a crucial role in enhancing the physico-chemical characteristics necessary for the successful incorporation of MWW into new construction materials. Among the examined studies, mechanical pretreatment is the most commonly employed method, as it reduces fiber length and increases surface area, thereby enhancing the reactivity and performance of the recycled product. Although chemical and thermochemical pretreatments have been shown to neutralize hazardous binder materials, their application remains largely confined to research settings. Further work is needed to standardize these approaches and assess their economic and environmental feasibility on a large scale.

3.4. Opportunities for Utilization

Although most MWW is currently landfilled, some countries are introducing legal regulations to encourage urgent solutions enabling large-scale recycling. Austria is leading this change with a legally binding landfill ban effective from 2027 [51,52]. To the best of our knowledge, no other countries have confirmed similar legislation yet. Nevertheless, the global trend toward reducing the landfilling of MWW is supported by the UN 2030 Sustainable Development Goals (SDGs), the EU’s Green Deal, and the Landfill Directive, all of which highlight the need to develop viable recycling and reuse pathways for recyclable waste streams.

Innovative recycling or reuse could preserve the valuable landfill space, and at the same time reduce the risk of environmental pollution. Reusing and recycling MWW presents a significant opportunity to reduce landfill use and avoid the disposal costs associated with landfilling. Moreover, reclaiming construction materials from waste reduces the exploitation of raw materials [18]. Therefore, diverting the MWW from landfills not only reduces the negative impact on the environment but also prevents the further contamination of MWW, facilitating the recycling process. This literature review has identified diverse potential applications of MWW in construction materials, with the most prominent being its use in concrete and cement, AAMs, GPs, mortars, and building ceramics, among others. These applications will be discussed in more detail in the following chapter.

4. Mineral Wool Waste in Production of Construction Materials

This section provides an overview of the utilization of MWW in the development of sustainable construction products. The discussion is organized into the following key application areas: Portland-type cement-based concrete, AAMs (including GPs), mortars, and other applications, such as building ceramics and asphalt mixtures.

4.1. MWW in Concrete Production

One of the principal objectives of the concrete industry is to reduce the amount of cement used in concrete mixtures [53]. This goal is driven by the rapid growth of Portland cement (PC) production, which is associated with high material consumption, substantial energy demands, and significant greenhouse gas (GHG) emissions. Addressing these challenges requires the adoption of strategies to enhance the sustainability of PC production. Implementing innovative technologies, improving energy efficiency, and incorporating alternative materials are effective medium-term measures that could contribute to achieving carbon neutrality by 2050 [54].

4.1.1. MWW Types, Processing, and Dosage

According to the literature review, the use of MWW as a substitute material in Portland-type cement-based concrete has been explored through several main approaches. Specifically, MWW has been tested as an aggregate replacement, a cementitious material, a fiber reinforcement, and a filler (Table 2). The reviewed studies utilize both post-consumer and production MWW, including GW, RW, and mineral dust. This diversity highlights the potential to use different waste streams in the production of blended PC concrete composites.

Waste mineral streams are usually mechanically processed (crushing, grinding, milling) with particles that range from fine powders (<63 µm) to coarse aggregates (50 mm). The degree of processing directly affects the role MWW can play, where coarse fibers are suited to aggregate replacement or fiber reinforcement, while fine powders are more appropriate as cement replacements, SCMs, or fillers. Dosages are typically low for fiber reinforcement (0.5–2.0 wt% of cement), reflecting the need to balance the improved flexural strength with workability challenges. For the aggregate and cementitious replacements, dosages vary more widely, from as low as 0.5 wt% of cement [55] to as high as 21.7 wt% of cement [56]. Leber et al. [57] explore the feasibility of very high filler replacement levels (10–100%), suggesting that MWW can serve as a major component in certain mix designs, for example, in the case of thin vibro-pressed concrete blocks.

The addition of MWW generally reduces the workability of concrete mixes. This decrease is more pronounced as the dosage of MWW increases. As reported by Lim et al. [58], adding more than 2% of MWW by cement weight requires compensation to balance the corresponding increase in adhesion. Therefore, adjustments in water content or the use of superplasticizers are recommended to ensure the proper handling and placement of the mix, especially at the higher dosages of MWW addition.

Table 2.

Comparative overview of studies investigating MWW in PC concrete.

Table 2.

Comparative overview of studies investigating MWW in PC concrete.

| Waste Type and Source | Processing Method/Output | Replacement Form | Dosage | Reference |

|---|---|---|---|---|

| GW and RW (post-consumer) | N/A | Fiber reinforcement | 0.5, 1.0, and 2.0 wt% of cement | [58] |

| RW waste obtained from thermal insulation materials | Crushed and ground, size distribution from 17 to 250 µm | Aggregate replacement; supplementary binding material when particles < 75 µm | 2.0, 5.0, 7.0, and 10.0 vol% of concrete | [59] |

| Post-consumer mineral fibers | Grinding, fiber length < 2 mm | Cement replacement or additive replacing limestone | 0.5 wt% of cement | [55] |

| Post-consumer mineral wool | Crushed and ground in a rotor cutting mill to mean fiber length 0.03–0.15 mm | Fiber reinforcement | 0.5, 1.0, 1.5, and 2.0 wt% of cement | [60] |

| RW residue, source not clearly stated | Grinding | SCM | 1.24, 2.83, and 4.42 vol% of concrete | [61] |

| Mineral dust from RW manufacturing | 90% of the dust particles < 216.55 µm | Cement replacement | 2.5, 5.0, and 7.5 wt% of cement | [53] |

| Recycled glass and RW insulation | Irregular shape, max. size 50 mm | Partial aggregate/filler replacement | 21.7 wt% of cement | [56] |

| Waste material from mineral wool production | Separation of fine-grained particles | Filler replacement | 10–100% filler replacement | [57] |

4.1.2. Mechanical Properties

Table 3 gives an overview of the mechanical performance in the reviewed studies, where the peak strengths (compressive, flexural, and tensile) are reported, and the percentage of improvement (Δ) is compared to the reference case. Most studies report either slight reductions or modest increases in compressive strength when MWW is incorporated at low to moderate dosages (typically ≤5 wt% of cement or ≤10 vol% of concrete). Cheng et al. [59] reported the best results, obtaining compressive strengths for samples with 10 vol% RW addition that were about 3%, 5%, 15%, and 18% higher than the reference sample at 7, 14, 28, and 56 days, respectively. The authors explain these improvements by the high fineness of MWW, which improves the pozzolanic activity and packing density within the cement matrix. Conversely, higher MWW dosages can significantly reduce compressive strength, as observed by Štefan et al. [56], who reported an 80.2% reduction in compressive strength when MWW was added at a dosage of 21.7 wt% of cement. However, in this particular study, there are significant differences in the w/c ratio (0.39 and 0.5 for the reference and MWW addition, respectively), as well as in the cement content between the compared specimens, so the observed decrease in compressive strength is not solely due to the addition of mineral wool insulation shreds. Furthermore, it should be noted that the peak strength values and the percent differences (Δ%) cannot be attributed solely to MWW due to the variability of the experimental parameters in the studies summarized in Table 3. Therefore, this table should be considered as a summary of relevant research rather than a direct comparison of results.

Table 3.

Summary of the strength enhancements compared to the reference concrete.

Where reported, the improvements in flexural strength are consistently positive and often substantial, with increases ranging from +16.7% [55] to +34.4% [60]. This suggests that MWW, especially in fibrous form, can significantly improve the ductility and crack resistance of concrete. Limited data are available for tensile strength, but the studies that report it [55,59,61] show notable improvements (+6.2% to +33%), further supporting the beneficial role of MWW fibers in enhancing tensile-related properties. As observed, fiber reinforcement at low dosages (0.5–2.0 wt%) is particularly effective in improving flexural and tensile strength.

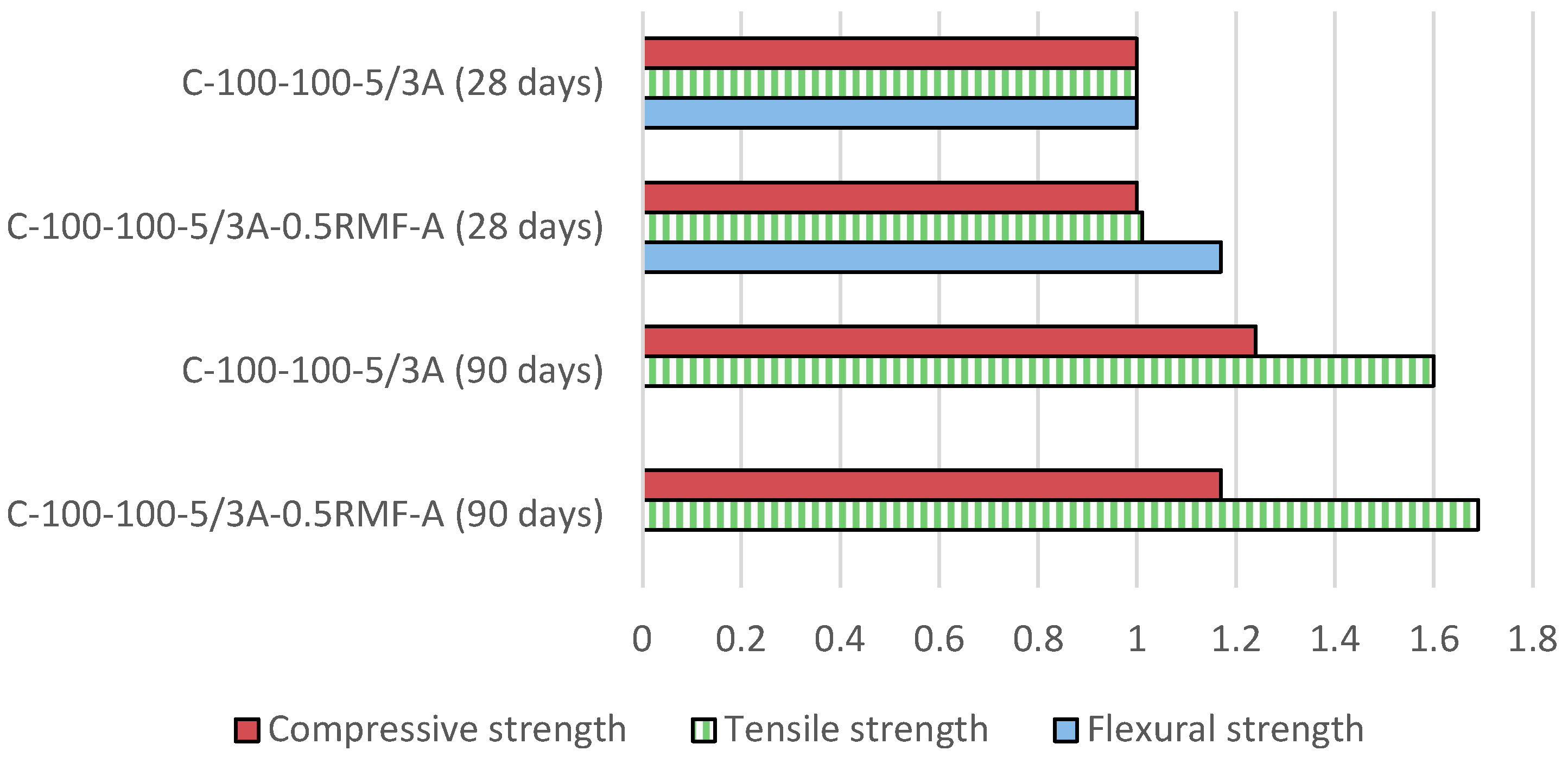

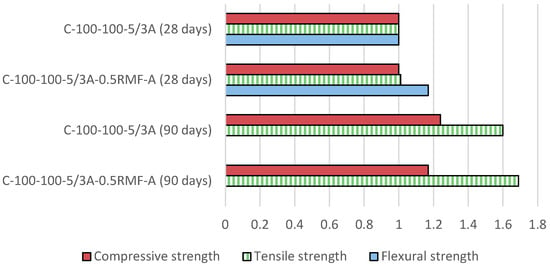

The use of MWW has been evaluated not only in conventional concrete mixtures but also in advanced, sustainable concrete composites incorporating recycled aggregates. Gebremariam et al. [55] incorporated ground insulation material at a dosage of 0,5% of the cement weight, which represents a considerable volume in the concrete mixture due to the low bulk density of MWW. The authors have developed a sustainable concrete mixture made of recycled coarse, fine, and ultrafine particles retrieved from demolition sites (C-100-100-5/3A) and compared the compressive, tensile, and flexural strength of reference specimens to those of sustainable concrete with the addition of MWW (C-100-100-5/3A-0.5RMF-A). The results of this study (Figure 8) show increased flexural strength with the addition of MWW and an improvement in tensile strength at 90 days in cured specimens. On the contrary, compressive strength was lower than the tested reference, but still met the structural criteria. This demonstrates that MWW is a versatile material, and it has a growing importance in the development of environmentally responsible concrete-based materials.

Figure 8.

Relative experimental results for sustainable concrete with the addition of MWW, based on data from [55]; figure created by the authors.

Table 4 summarizes the range of experimental tests and material properties evaluated in recent studies on concrete incorporating MWW. While most studies focused on mechanical properties, only a subset addressed long-term durability indicators such as freeze–thaw resistance, chloride ion resistance, carbonation resistance, and related properties. This limited focus highlights a gap in the systematic evaluation of durability for concretes containing MWW. Although the evidence base for durability remains limited, the results reported in these select studies allow for some important observations regarding the effects of MWW on concrete’s long-term behavior.

Table 4.

Test methods and performance indicators across selected concrete studies.

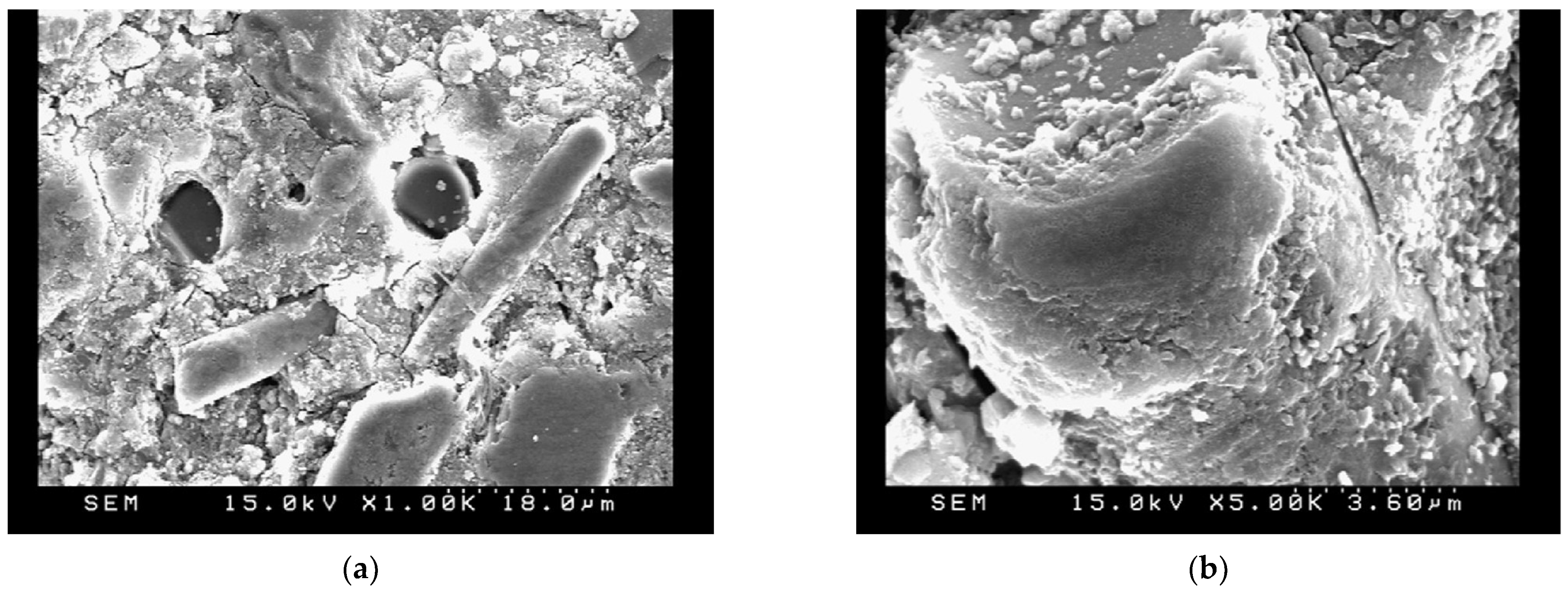

4.1.3. Durability

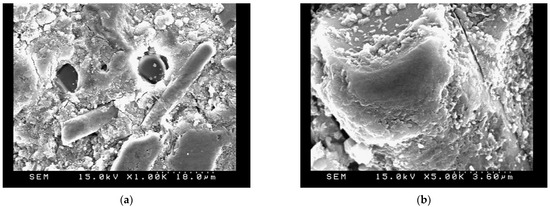

Concrete specimens with very fine MWW (particle size <250 μm) show a significant reduction in water absorption compared to control mixes. For example, Cheng et al. [59] reported that the addition of 10% RW waste measured by volume of concrete reduced water absorption by 33% (w/cm = 0.55) and 28% (w/cm = 0.65) relative to the control samples. The reduction is attributed to the pozzolanic activity and the filler effect of fine mineral wool, which densifies the microstructure and decreases the capillary pore volume [53,59]. Micrographs reveal the compact texture of concrete samples with the addition of MWW, which affects their physico-mechanical properties (Figure 9). On the other hand, in a low-carbon concrete study by Soldado et al. [61], MWW as an SCM generally resulted in higher water absorption than fly ash at the same replacement rates, but all mixes still fell within the “high-quality” concrete range for water absorption.

Figure 9.

SEM micrograph of the cement-based sample with the addition of MWW, showing a compact texture. Reprinted from [59], with permission from publisher: (a) Effect of MWW on restricting crack propagation in cement-based specimens; (b) Hydration and pozzolanic reaction products of MWW.

Durability enhancements resulting from the incorporation of MWW have also been demonstrated through freeze–thaw resistance testing. In the study by Nagrockiene et al. [53], the addition of MWW led to increased frost resistance, attributed to a higher proportion of closed pores and a reduction in open pores within the concrete matrix. Similarly, Lim et al. [58] reported improved freeze–thaw resistance with the use of waste GW. However, the author cautions that, for other types of mineral wool, careful optimization of the addition rate is necessary to achieve the desired durability benefits.

The chloride ion penetration test showed divergent results for the total charge passed with MWW addition. This discrepancy could be attributed to differences in particle size, dosage, processing, mix design, and curing conditions. Fine, well-processed MWW at low to moderate dosages and with proper curing can significantly improve chloride resistance, as demonstrated in the work of Cheng et al. [59] who obtained a 70% lower total charge passed for samples with 10 vol% MWW. On the other hand, coarser, poorly dispersed, or high-dosage MWW may increase permeability and worsen results. For example, Lim et al. [58] found an increase in the total charge passed in the range from +1.3% up to +32.8%.

Overall, it appears that studies using fine, ground MWW at moderate dosages of approximately less than 5 wt% cement replacement, coupled with good curing, consistently report improved durability properties compared to reference concrete. For example, Nagrockiene et al. [53] recommend replacing up to 5% weight of the cement with mineral dust, while Cheng et al. [59] obtained improved durability results by adding RW waste up to 10 vol% of concrete. On the other hand, when MWW is used in coarse or fibrous form at higher dosages—such as 25% or 100% filler replacement—the results often show increased water absorption and higher charge passed in chloride permeability tests, compared to the control sample. This is typically due to poor fiber dispersion or insufficient matrix densification.

The reviewed data demonstrate that MWW can be effectively utilized in concrete to enhance flexural and tensile strength, while the effect on compressive strength depends on the dosage, processing, and replacement form. Careful optimization and processing are essential to fully exploit the benefits of MWW in sustainable concrete production. The consistent improvement in certain durability metrics, although based on a small dataset, points to the potential of MWW as a beneficial addition to concrete. In this manner, the use of primary raw materials can be reduced, and the environmental impact of solid waste disposal can be avoided while maintaining or even improving the mechanical and durability properties of alternative concrete products.

4.2. MWW in Mortar Production

Mortar is a building material primarily composed of a mixture of binder, sand, and water. The binders used in mortar are predominantly inorganic, such as cement and lime, although organic binders can also be employed in specialized applications. Similar to concrete and other construction materials, as well as the construction sector in general, efforts are underway to incorporate circular economy principles into mortar production. CDW represents a significant source of raw materials for building projects, enabling the repurposing of materials such as MWW.

4.2.1. Material Characteristics and Testing Approaches for Mortars with MWW

Mortar serves multiple functions in construction, primarily as a binding agent, filler, and sealant in masonry and surface finishing applications. Its performance requirements include adhesion, surface hardness, mechanical strength, water permeability, water vapor permeability, certain thermal properties, and durability. The composition of the mortar significantly influences these characteristics. Table 5 summarizes studies where MWW was incorporated into mortar—either as a replacement for sand or cement, as reinforcement, or as an additive. To extend the data, Table 6 lists the test methods used in these studies. The most commonly assessed properties include compressive and flexural strength, thermal conductivity, microstructural features, fire resistance, and durability indicators such as capillary absorption, freeze–thaw resistance, and salt crystallization.

Table 5.

Comparative overview of studies investigating MWW in mortars.

Table 6.

Test methods and performance indicators across selected mortar studies.

According to Table 5, mineral wool is added to the mortar in varying quantities, with its proportion ranging from very low (e.g., 0.17 wt% of cement) to high—such as 50 vol% of sand—within the total mortar volume. Waste mineral wool is typically subjected to mechanical processing methods such as manual cutting, shredding, crushing, and grinding, resulting in fibers ranging from 0 to 12,000 µm.

In some studies, such as [75], the use of technogenic fibrous MWW as a cement replacement positively influences the packing density of the composite’s newly formed matrix while also providing a micro-reinforcing effect. On the other hand, in specimens containing RW, fiberglass wool, or mixed mineral wool fibers with lengths of 500–1000 µm, the structure, chemical composition, and microstructure of the fiber-reinforced mortars were similar to those of the reference mortar. However, minor increases in porosity and slight decreases in density were observed. These changes may contribute to a reduction in mechanical properties but an improvement in insulating performance [24].

The SEM analysis of the tested specimens indicates different results. From one perspective, clusters of MWW fibers are observed within the mortar, which indicates inhomogeneity in the samples [73]. In contrast, another study [69] reports that the incorporation of RW fibers significantly improved the microstructure of lightweight mortars by enhancing their compactness.

The workability of mortars containing MWW is slightly reduced compared to the reference mixtures [71]. This variation depends on the quantity and form of the MWW, as well as on the water absorption capacity of the raw materials used [72]. According to [76], the fiber morphology of waste RW is interlaced, forming a three-dimensional network that enhances resistance to flow.

4.2.2. Mechanical Properties

The mechanical properties depend on multiple factors, including the amount of water, the type of binder (cement, lime), additives, the type of MWW, and their proportions. Table 7 provides an overview of the mechanical performance reported in the reviewed studies, detailing the peak compressive and flexural strengths of mixtures containing MWW, along with the percentage change (Δ) compared to the reference mixtures. According to Table 7, the addition of MWW may result in either a decrease or an increase in compressive strength, while generally enhancing flexural strength.

Table 7.

Summary of strength enhancements compared to reference mortar/material.

Due to its high SiO2 and Al2O3 content and amorphous structure, MWW can participate in pozzolanic reactions, generating additional cementitious hydrates that fill the pore system and improve the space-filling capacity of the mortar matrix [69]. Several studies have examined how various parameters affect the properties of mortar, particularly by varying the type of aggregate and the addition of MWW. To evaluate the impact of MWW addition on mortar properties, this paper highlights the differences between the reference mixture presented in the observational study and a comparable mixture. The reference mixture is considered to be an initial mixture (e.g., with natural sand as the fine aggregate), while a comparable mixture differs in composition from a reference mixture (e.g., natural sand is partially replaced with a lightweight aggregate). However, the comparable mixture shares the same composition as the observed mortar with MWW, except for MWW fibers, making it more appropriate for comparison purposes.

For example, the incorporation of RW in lightweight mortar increased the compressive strength by 56.6% relative to the comparable mortar with the same lightweight aggregate. However, when compared to a mixture marked here as the reference mixture, the compressive strength decreased by approximately 28% [69]. Conversely, in [67], mortar mixtures containing MWW fibers 12 mm in length and natural aggregate achieved a compressive strength 84.4% higher than the reference plaster mixture (without aggregate), yet showed a slight decrease (−1.8%) relative to the comparable mortar with the same aggregate type.

In the same study [67], the addition of mineral wool residue enhanced the flexural strength by 48.7% for the reference plaster and by 11.5% for the comparable mortar, confirming the beneficial effect of fiber incorporation on improving ductility and deformation capacity. The positive influence of MWW fibers on flexural strength is also reported in [72]. However, the same study observed a reduction in the compressive strength of fiber-reinforced mortar, possibly due to fiber overlapping, creating voids that lead to failure during testing.

Additionally, using basalt MWW as a multifunctional micro-aggregate in plaster mortar significantly decreased compressive strength by 30.6% to over 60% compared to the reference mortar, although the flexural strength increased at the lowest MWW content [65].

4.2.3. Durability

After undergoing freeze–thaw cycles and salt crystallization tests, lime mortars incorporating MWW generally exhibited good stability and greater resistance to accelerated aging compared to traditional mortars [66]. The visual inspection of specimens from one study showed that mortars with MWW appeared unchanged after freeze–thaw cycling, with no signs of damage, indicating good frost resistance [63]. However, due to increased porosity, these mortars had weaker resistance to salt crystallization [63]. In another study by Khongova et al. [74], when recycled aggregate was combined with waste mineral fibers, the resulting mixtures after 100 cycles of frost and thaw demonstrated better frost resistance than those made with standard sand. This improved performance is attributed to the pozzolanic activity of MWW, which densifies the mortar structure and fills capillary pores, preventing critical water saturation.

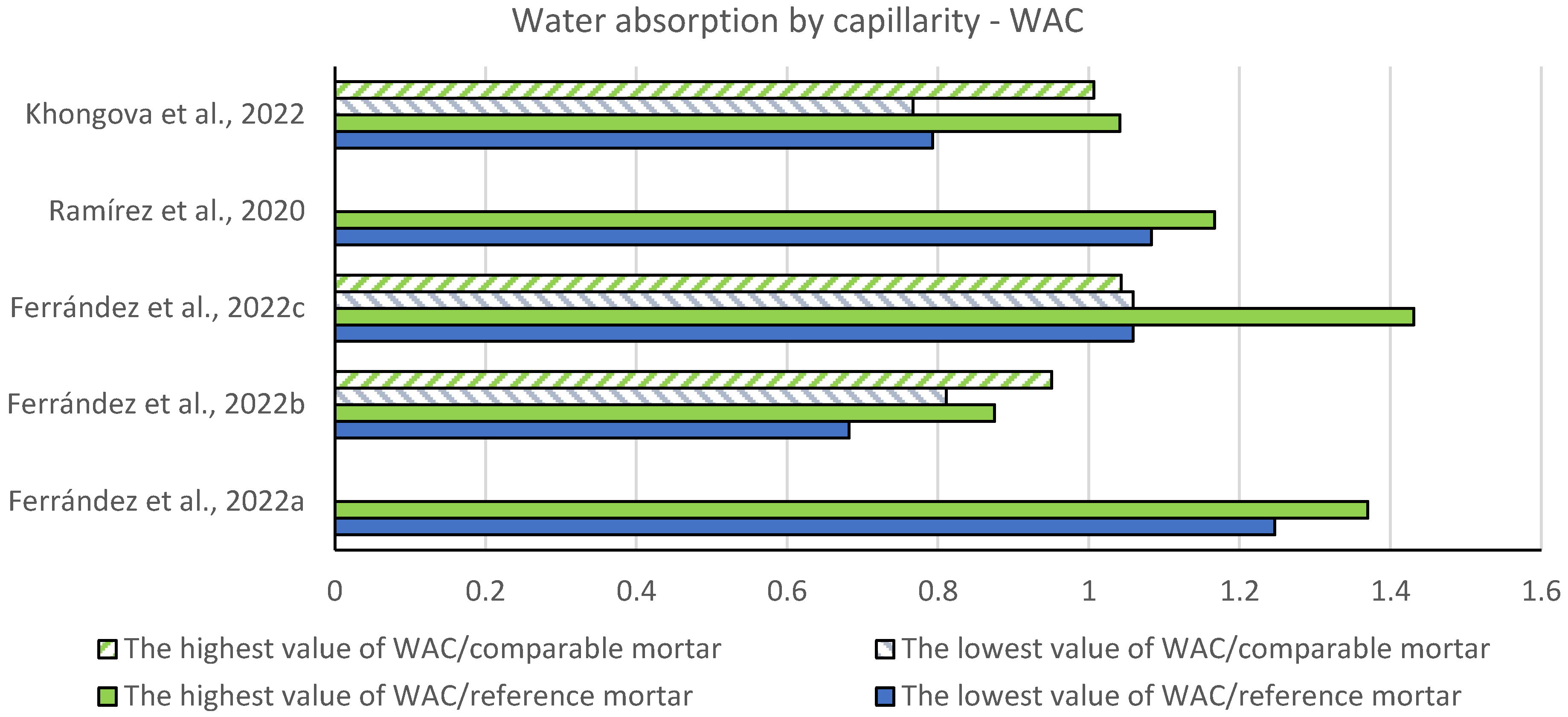

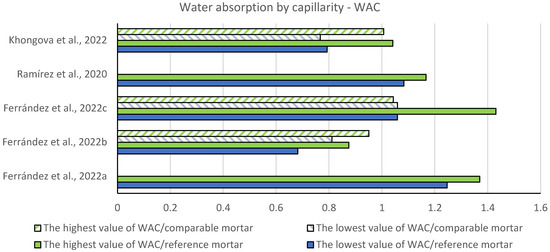

Figure 10 shows the relative relationships between the measured highest and lowest water absorption by capillarity on specimens with MWW addition in relation to the reference mixture and the comparable mixture. A positive MWW contribution is present if this ratio is less than 1. Khongova et al. [74] obtained an improved mixture compared to both the reference mixture and the comparable mixture. The addition of MWW fibers reduced capillary water absorption in all plaster mortars compared to the reference and comparable mortars in a study by Ferrández [67]. However, other studies [66,68,71] found that higher proportions of MWW led to increased capillary water absorption. The increase is significantly higher compared to the reference mortar (from 6 to 43%) than compared to the comparable mortar (from 3 to 4%), which was influenced by the replacement of aggregates [68]. Thus, the effects of MWW on water absorption depend on its dosage and the specific composition of the mixture.

Figure 10.

Relative ratios of water absorption by capillarity, based on data compiled from literature sources: Ferrández et al., 2022a, [66]; Ferrández et al., 2022b, [67]; Ferrández et al., 2022c, [68]; Ramírez et al., 2020, [71]; Khongova et al., 2022, [74].

4.2.4. Thermal Conductivity

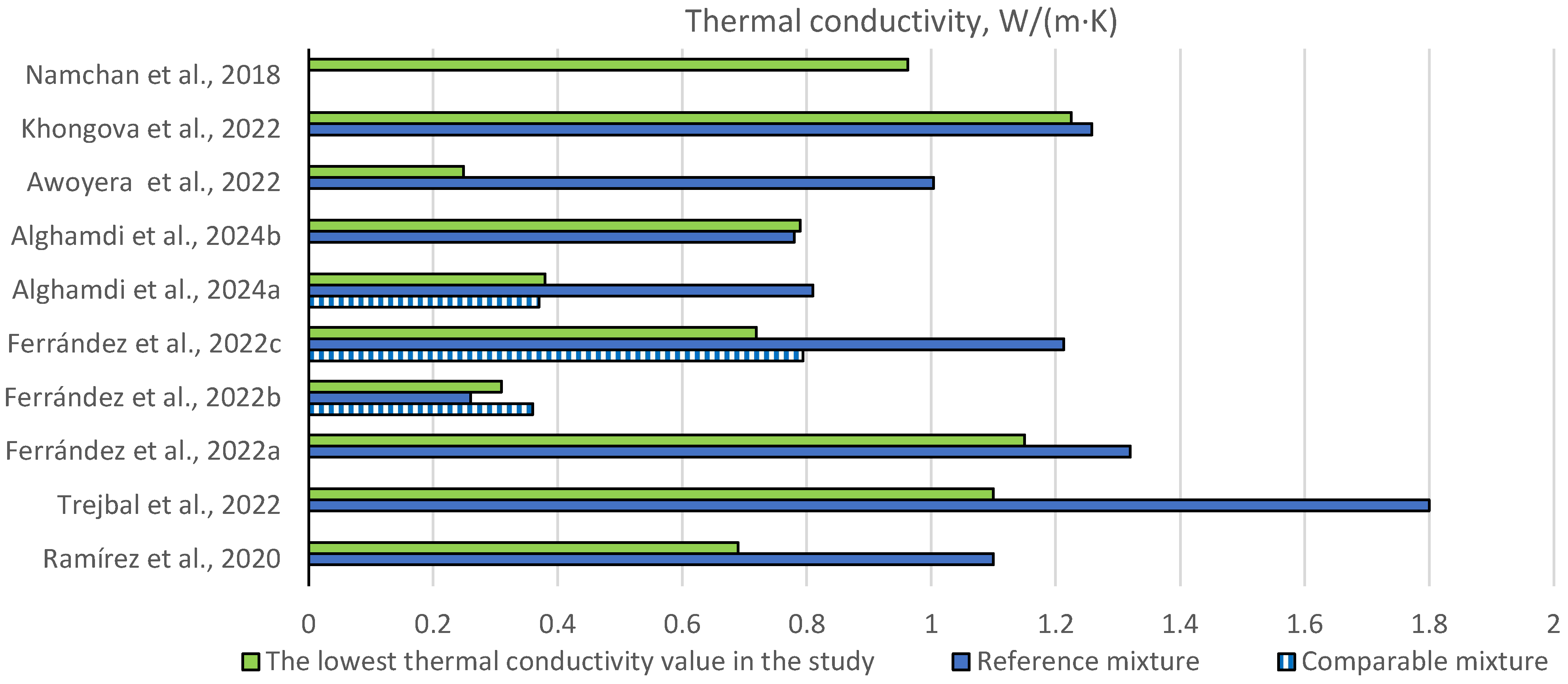

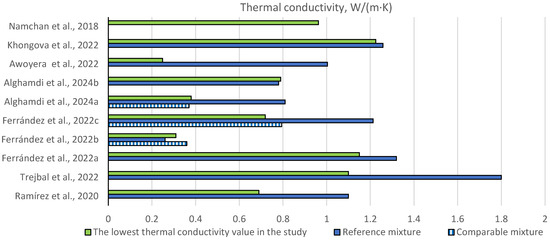

The average thermal conductivity of mineral wool typically ranges between 0.03 and 0.04 W/m·K. These materials are characterized by low thermal conductivity, non-flammability, and high resistance to moisture damage [79]. In contrast, conventional fine aggregates exhibit a much higher thermal conductivity, approximately 2 W/m·K. Therefore, replacing sand with MWW reduces the aggregate’s ability to conduct heat [77]. The effect of incorporating MWW into cement or lime mortars on their thermal conductivity is illustrated in Figure 11, which compares the values for a reference mortar and the specimen with MWW addition with the lowest thermal conductivity.

Figure 11.

Thermal conductivity of mortars with MWW addition, based on data compiled from literature sources: Ramírez et al., 2020, [62]; Trejbal et al., 2022, [65]; Ferrández et al., 2022a, [66]; Ferrández et al., 2022b, [67]; Ferrández et al., 2022c, [68]; Alghamdi et al., 2024a, [69]; Alghamdi et al., 2024b, [70]; Awoyera et al., 2022, [73]; Khongova et al., 2022, [74]; Namchan et al., 2018, [77].

According to Figure 11, the specimen from study [73] achieved the greatest reduction, lowering the thermal conductivity of the reference mixture by 75.2%. This particular mortar mixture contains mineral wool and rice straw as a combined total replacement of 30 wt%. Other studies [62,65,68,69] also reported substantial reductions in thermal conductivity—ranging from 37% to 53% compared to their respective reference mixtures—as summarized in Figure 11. It should be noted, however, that some studies distinguish between reference samples containing natural aggregates and those with alternative aggregates, such as recycled aggregates. In these cases [67,68,69], the relative reduction attributable to MWW alone is significantly lower. Furthermore, studies measuring mortar density have confirmed that specimens with lower density generally exhibit lower thermal conductivity, indicating improved thermal insulation properties [74].

4.2.5. Fire Resistance

Cement mortars incorporating mineral wool residues demonstrate considerable potential to improve fire resistance while maintaining low thermal conductivity after exposure to elevated temperatures. A study by Ramírez et al. [62] investigated mortars with partial sand replacement (up to 50 vol% of the sand) by MWW fibers, and reported the reduced deterioration of flexural strength after exposure to temperatures up to 700 °C, compared to control mixtures without MWW. Exposure to fire had almost no effect on the surface hardness value, while the compressive strength decreased compared to the strength before the fire. This suggests that mineral wool fibers act to partially preserve mechanical integrity under thermal stress. Furthermore, the addition of RW in moderate proportions (3–5 wt% relative to binder content) enhances residual strength and mitigates cracking, likely attributable to its inherent non-combustibility and reinforcing effect on the mortar microstructure [69,70]. Altogether, these findings underscore the efficacy of MWW, particularly RW, in improving the thermal resilience and structural stability of mortar composites under fire exposure.

4.3. MWW in AAMs and GPs

4.3.1. MWW as Precursor for AAMs and GPs

AAMs and GPs have proven to be promising and sustainable alternatives for the utilization of various industrial wastes in cementitious binders, which have a significantly lower carbon footprint compared to OPC [80,81]. These binders are synthesized by the chemical activation of amorphous aluminosilicate precursors using alkali solutions (NaOH, KOH, Na2SiO3, K2SiO3), where the precursor dissolves in a high pH environment and forms aluminosilicate gels through the subsequent polycondensation and reorganization of the aluminosilicate network, which hardens and densifies into solid material [82].

In alkali-activated systems, the physico-chemical characteristics of the solid aluminosilicate source (referred to as precursor) are a prioritizing parameter, with MWW being highly suitable as a precursor due to its high specific surface area and favorable chemical and mineralogical composition. The intrinsic chemical composition of RW and GW with their high SiO2 content and the addition of Al2O3 fulfills the fundamental requirements of precursors for the synthesis of AAMs and GPs [83,84]. In addition, their predominantly amorphous nature contributes to high reactivity and ready availability for dissolution in alkaline solutions [85]. The chemical composition of the precursor significantly influences the characteristics of the resulting AAMs and GPs. A key distinction lies in the alumina content, with GW exhibiting a substantially lower Al2O3 concentration than RW (Table 8). Due to this alumina deficiency, the mix design for GW requires the incorporation of secondary precursors with a higher alumina content, such as bauxite residues [86] or slags [87], to achieve the desired material properties. Furthermore, RW is characterized by a CaO content, often exceeding 15 wt%, which promotes the formation of calcium–alumina–silicate hydrate (C-A-S-H) gels as the primary reaction products in AAMs. This distinguishes RW-based AAMs from GPs, in which sodium–alumina–silicate hydrate (N-A-S-H) gels serve as the dominant binding phases [88]. The predominant Na2O in GW can contribute to the overall alkalinity of the system and must be carefully considered when designing the mixture [89,90] by adjusting the dosage of external alkaline activators. Typically, the amount of alkali added to sodium-rich precursors must be reduced to maintain optimal molar ratios [91], to avoid too much free, unreacted alkali and the possible formation of efflorescence in the final product [92]. The dissolution kinetics of mineral wool under high alkaline conditions at various liquid-to-solid ratios was studied by Ramaswamy et al. [93]. Their study demonstrated that at a lower liquid-to-solid ratio of 50, RW and GW resulted in a similar dissolution rate. In contrast, at a high ratio of 1000, RW dissolves faster than GW, where RW forms surface precipitates that affect the transport of ions.

Horvat and Ducman [94] investigated the influence of the precursor particle size in AAMs, where it was concluded that finer particles lead to better mechanical properties due to the larger reactive surface area and higher reaction rate. Although MWW fibers have a desirable mean diameter of 3–10 μm [95], the high-speed spinning-disk process also generates rounded, incompletely fiberized round particles (so-called “shots”) with diameters up to 60 μm, introducing a coarser fraction into the product. No article specifically addresses the different fractions of MWW, although some types of mineral wool may contain up to 40 wt% [95] of coarser incompletely fiberized particles, where particle size can influence the reactivity of the precursor. The MWW used in studies is usually pre-treated by grinding and sieving to homogenize the material and increase the reactivity in AAMs and GPs. It has been reported that the grinding process of MWW is improved by the addition of electrocorundum, where such an addition can have a dual benefit: it intensifies mechanical activation, producing a finer particle size with a higher specific surface area to have more reactive precursor, and introduces additional alumina, thereby compensating for the Al deficiency of co-milled GW in the production of GP binders [96].

Table 8.

The typical chemical composition of MWW expressed as major oxides, according to Yliniemi et al. [18], and their role in alkali activation and geopolymerization.

Table 8.

The typical chemical composition of MWW expressed as major oxides, according to Yliniemi et al. [18], and their role in alkali activation and geopolymerization.

| Oxide/Property | RW (Approx. wt%) [18] | GW (Approx. wt%) [18] | Significance for AAMs or GPs |

|---|---|---|---|

| SiO2 | 40–43 | 59–64 | Primary precursor for Si-Al network, fundamental network formers [82,97]; higher content in GW |

| Al2O3 | 14–18 | 1–5 | Essential for Al-O tetrahedra formation [98]; often deficient in GW, requiring mixing with more alumina dominant precursor |

| CaO | 14–23 | 8–10 | Source of Ca for C-A-S-H gels in AAMs systems [99] |

| Fe2O3 | 6–9 | 0–2 | Contributes to chemical complexity, possible layered double hydroxide formation [93,100]; higher in RW |

| MgO | 8–14 | 2–3 | Might forms carbonation phases like hydrotalcite or layered double hydroxide phases in activated systems [93,101,102] |

| Na2O | 1–3 | 15–18 | Present in GW; contributes to pH of system, can influence activator dosage |

| Amorphous phase | >95 | >90 | High reactivity in alkaline media, crucial for dissolution |

4.3.2. Mechanical Properties

Research indicates that the compressive strength of mineral wool-based GPs varies considerably depending on the type of MWW used and the specific formulation. Łaźniewska-Piekarczyk et al. [103] demonstrated the robust compressive strengths of mineral wool-based GPs, with reported values averaging approximately 62 MPa. Due to the low Al content in GW, the addition of 15 wt% ground bauxite or pure Al2O3 powder was used to create an appropriate ratio of Si and Al for geopolymerization. It was observed that samples of GP mortar without the inclusion of aggregates were characterized by cracking and deformation. Similarly, Yliniemi et al. [104] reported the incorporation of MWW in AAM systems using sodium aluminate solution, instead of the commonly used sodium silicate, due to the lack of Al to optimize the mix design according to the optimum Si/Al molar ratio. The final compressive strengths ranged from 30 MPa to 49 MPa after 28 days, with the RW specimens breaking into several pieces under compressive loading, while the GW specimens deformed in one piece. In a study with alkali-activated hybrid cements made from MWW containing 15 and 30% OPC, the unconfined compressive strength (12 MPa) was almost doubled compared to pure AAM cement (7 MPa) [101]. A consistent trend observed in various studies is an inverse correlation between porosity and compressive strength [105], whereby increasing the admixture of MWW could lead to high porosity and facilitate cracking [85].

A notable advantage of incorporating MWW fibers is the significant improvement in flexural strength. Studies have consistently shown that the addition of fibers can significantly improve the flexural strength of GPs, with ratios of compressive strength to flexural strength reaching up to 26.3% for MWW-based formulations [96]. This improvement is largely attributed to the fibrous structure of the MWW, which acts as an effective reinforcement within the GP matrix, distributing stress and counteracting crack propagation. In some studies, such as Hossein et al. [106], it was observed that the partial substitution of the main aluminosilicate precursor by MWW up to 12 wt% improves the flexural properties, while the compressive strength decreases.

Comprehensive studies of dissolution and reaction kinetics mechanisms are essential for AAMs and GPs to clarify how these processes influence microstructural evolution, physical properties, and the optimization of mix design for diverse construction applications. Ramaswamy et al. [93] investigated MWW in highly alkaline media and identified distinct precipitation products as well as dissolution–precipitation mechanisms governed by the liquid-to-solid ratio and material chemistry, which are relevant for understanding MWW incorporation into alkali-activated matrices. GW and RW showed different dissolution kinetics in alkaline media, with surface precipitates playing a critical role in controlling ion transport and induction periods. Two main types of precipitation products were observed: Mg–Al–Fe layered double hydroxides (LDH) and C–N–(A-)S–H. The incorporation of Al depended on the liquid-to-solid ratio: at lower ratios, Al was preferentially incorporated into dense C–N–(A)–S–H gels, whereas at higher ratios it tended to partition into LDH phases rather than into C–N–(A)–S–H, leaving a more porous and weaker C–N–S–H (Al-depleted phase) [93]. Similarly, the incorporation of Al into LDH secondary phases was shown to reduce the degree of Al incorporation into the main binding C–A–S–H gels in slag-based AAMs, while its role in MWW-based AAMs remains less understood [107], particularly in relation to durability and final mechanical properties. Further systematic investigations are required to clarify the relationships between reaction kinetics, gel chemistry, and the resulting macroscopic performance parameters of AAMs.

4.3.3. Thermal Properties

While raw mineral wool has exceptional thermal insulation properties characterized by low thermal conductivity, this property is primarily due to its low density and high porosity, which traps air and impedes heat transfer [15]. However, incorporating MWW into a denser GP or AAM binder changes these properties significantly. Compared to the raw fibers (0.037 W/(m·K) for RW), MWW-based GPs have significantly higher thermal conductivity coefficients, typically between 0.953 W/(m·K) and 1.053 W/(m·K) [96]. This is primarily attributed to the geopolymerization process, which reduces the total porosity and increases the density, thereby reducing the number and effectiveness of the insulating air pockets. Nevertheless, its thermal conductivity remains superior to that of reinforced concrete (1.7 W/(m·K) [96]).

In order to achieve thermal insulation properties closer to those of raw mineral wool, a switch to foamed GP production technologies is proposed, even if this may come at the expense of a certain mechanical strength. Gas-forming additives such as hydrogen peroxide [108], aluminum powder, silicon dust, zinc powder [109], sodium hypochlorite, and sodium perborate [110] can be dispersed in the fresh AAM or GP paste and form in situ porosity. Pavlin et al. [111] developed foamed alkali-activated RW by incorporating hydrogen peroxide H2O2 as a foaming agent along with a surface stabilizing agent. Increasing the concentration of H2O2 led to reduced material density and increased porosity. As a result of the formation of interconnected pore networks, the thermal conductivity decreased significantly, reaching as low as 0.09 W/(m·K).

Furthermore, high porosity and favorable thermal conductivity can be achieved without the use of additional additives, enhancing the cost-effectiveness of MWW-based products. One of the easily adaptable approaches involves the mechanical processing and granulation of waste materials into lightweight aggregates [112]. Koh et al. [113] demonstrated the pelletization of RW into lightweight aggregates by alkali activation, with the final porous structures exhibiting a thermal conductivity of 0.075 to 0.094 W/(m·K). Although the development of such lightweight AAM aggregates with incorporated MWW is encouraging, it remains under-researched. While fine particles often lead to good pelletization [114,115], the role of the fibrous MWW particle morphology on the efficiency of disk or shear pelletization, structural stability, and porosity of aggregates is unclear.

4.3.4. Durability

AAMs and GPs generally exhibit superior durability characteristics when compared to conventional OPC. They demonstrate excellent resistance to high temperatures, retaining substantial residual strength even at temperatures of up to 800 °C [116]. This property is related to their stable hydration products and microstructure, which are less susceptible to chipping and cracking under thermal stress. Alkali-activated 3D-printed products made of MWW and co-binders exhibited chemical and mineralogical stability up to 700 °C, with 3D-printed samples showing less shrinkage and a lower degree of expansion compared to molded samples [117]. In addition, GPs are known for their robust resistance to aggressive chemical environments, including strong acids and sulfates, and exhibit lower chloride ion permeability, which improves their long-term performance under corrosive conditions [118]. Only limited studies have been published on the freeze–thaw resistance of MWW-based GPs and AAMs, with some results showing excellent resistance for RW, while GW, in contrast, has poor resistance [39]. The mechanisms behind this need to be further investigated as they remain unclear. A comparative study of MWW-slag AAMs on one-part mixtures, prepared by adding water to a dry blend of precursor and solid activator, and on two-part mixtures, in which a liquid alkaline solution serves as the activator, revealed that similar reaction products [119] are formed. However, the one-part system has a shorter setting time and exhibits better resistance to sulfate attack than the two-part mix AAMs.

4.3.5. Challenges and Future Prospects for Research of MWW Utilization in AAM and GP

Unlike conventional construction materials such as cement systems, AAMs and GPs still operate under a patchwork of emerging guidelines rather than under a unified code base and standards. National bodies are beginning to close this gap, with some countries having already published guidelines for alternative materials. Australia has issued SA TS 199:2023 [120], a full structural design specification for GPs and AAM concretes. More recently, guidelines are being produced for more performance-based standardization and the introduction of new products to the market, with the UK’s fast-track BSI Flex 350 v2.0 [121] setting out a performance-based route for the certification of all concretes with alternative binder systems, including AAMs. AAMs and GPs represent a huge group of materials with diverse applications, so instead of fixed chemistries, initiatives point to a future where the quality control of AAMs focuses on measured durability for specific construction applications and life cycle carbon metrics.

In addition to the existing, well-researched precursors for AAMs and GPs, such as fly ash, metakaolin, and ground granulated blast furnace slag, there is a need to include new waste-derived precursors, where MWW has a place. The terms of reaction kinetics and final properties of MWW-based AAMs and GPs remain under researched, where tools and modeling to predict the MWW material properties are required. Most studies compare MWW alternative binder materials with conventional cement and concrete products only in terms of mechanical performance, neglecting cost efficiency and embodied CO2 metrics, areas where the waste valorization of MWW could offer major advantages.

Mineral wool usually contains a small amount of organic binders, often phenol-formaldehyde or urea resins, ranging from 1 to 10 wt%, whereby these components can release toxic volatile compounds such as ammonia, phenol, and formaldehyde when heated or in contact with strongly alkaline solutions, such as in the design of AAMs. Possible solutions, such as pre-treatment methods, including thermal decomposition or multi-step chemical dissolution, to remove or neutralize these organic components prior to alkali activation, are required.

Another general challenge in the production of AAMs and GPs is the alkaline activators, which represent the greatest environmental impact hotspots in the LCA [81]. The potentially high cost and environmental impacts associated with the commercially produced activator solutions detract from the overall sustainability benefits. For construction-oriented AAM and GP applications, high-purity reagent-grade alkaline activators are not always essential. Instead, making AAM and GP technology more adaptable lies in quantifying trace impurities in the activator or MWW and employing lower-purity, cost-effective, and sustainable alkali sources, which can alter reaction pathways and end-properties. Different types of glasses, including MWW, have been recognized as potentially suitable for the production of alternative silicate solutions [84,122]. Further research on the techniques of preparation and economic evaluation is required, with MWW being particularly suitable due to its high reactivity and chemical composition.

The MWW residues, such as RW with amorphous Ca- and Mg-silicates, are suitable for enhanced mineral carbonation, an accelerated reaction that binds gaseous CO2 into a stable Ca/Mg carbonate. Besides the sustainability benefit of carbon sequestration, it could potentially improve the mechanical and durability performance of the final AAMs due to pore refinement and the densification of material. Although no peer-reviewed study has yet investigated the potential of RW carbonation and RW-based AAMs, research on other industrial Ca/Mg wastes such as ashes and slags [123,124,125] shows promising avenues and is of great interest to the industry for net-zero construction. The ex situ carbonation of MWW for low-carbon fillers and the in situ carbonation–curing of precast elements should be explored. Methodologies for CO2 sequestration as a function of the chemical and mineralogical composition of MWW could benefit wider valorization potential in net-zero construction materials.

4.4. Other Applications of MWW in Construction Materials

4.4.1. Building Ceramics

MWW, derived from various industrial processes, is recognized as an active component that can enhance the properties of building ceramics. Due to its chemical similarity to clay minerals and its fluxing properties, MWW serves as a valuable substitute for natural sand and other additives. Recent studies have demonstrated that incorporating MWW at levels of 10–20 wt% of the mixture can significantly improve the compressive strength and densification of ceramics. For instance, Kiznievič [48] used centrifugation waste containing 70–80% unfiberized melt particles and 20–30% fibers and beads, achieving compressive strengths of 60–80 MPa, shrinkage below 2.5%, and water absorption between 7.1 and 12.5%. Similarly, Pranckeviciene and Pundiene [126] reported that 20 wt% MWW increased density by 3.3%, compressive strength by circa 19%, and shrinkage by 16.1%, while it decreased water absorption by a factor of three. Porous ceramics produced from spodumene tailings and waste GW have also shown promising results, with optimal compressive strength achieved at 10 wt% GW (particle size <100 µm) [44].

Table 9 shows a great variation in the obtained results, influenced by GW pretreatment, its content, the composition of the mixture, and the sintering temperature. Overall, these data highlight both the performance benefits and the need for careful optimization to mitigate potential drawbacks, such as excessive shrinkage, low compressive strength, or high water absorption.

Table 9.

Summary of key parameters across the reviewed studies on MWW in building ceramics.

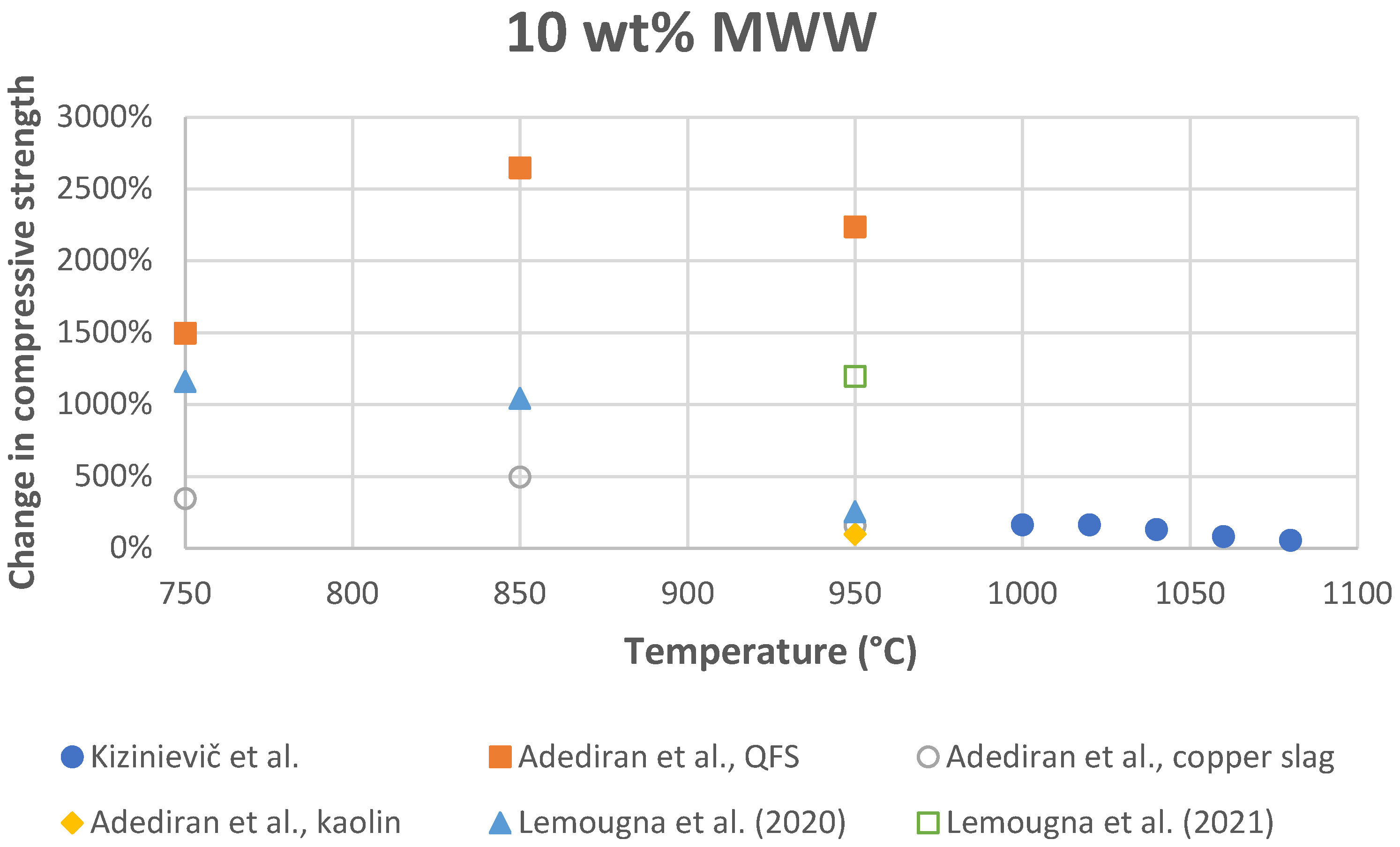

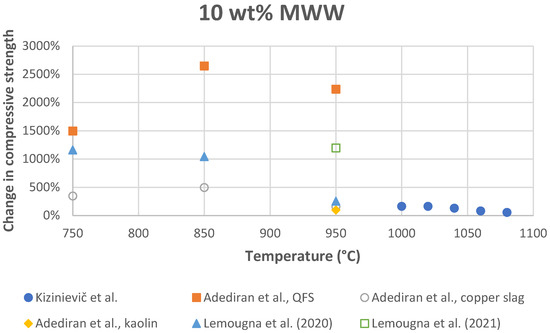

The impact of incorporating 10 wt% MWW into ceramic matrices on compressive strength is presented in Figure 12. This effect is expressed as the percentage change relative to reference samples over a range of sintering temperatures. A significant enhancement in compressive strength was reported by Adediran et al. [129], who observed an increase from 5 MPa to 117 Mpa, corresponding to an improvement of more than 2000%, when comparing a reference sample composed of pure quartz–feldspar (QFS) to a sample containing 10 wt% MWW. The most pronounced improvement was observed in the temperature range of 850–950 °C, whereas the increase in compressive strength became more modest beyond the temperature plateau at 1000 °C. However, considerable variation exists between studies; some, particularly those utilizing QFS, have achieved substantially higher gains than others. These discrepancies highlight the necessity of optimizing both material formulation and processing conditions.

Figure 12.

Relative change in compressive strength (%) of building ceramic samples with 10 wt% MWW addition compared to reference samples, based on data compiled from literature sources [44,50,129,132].

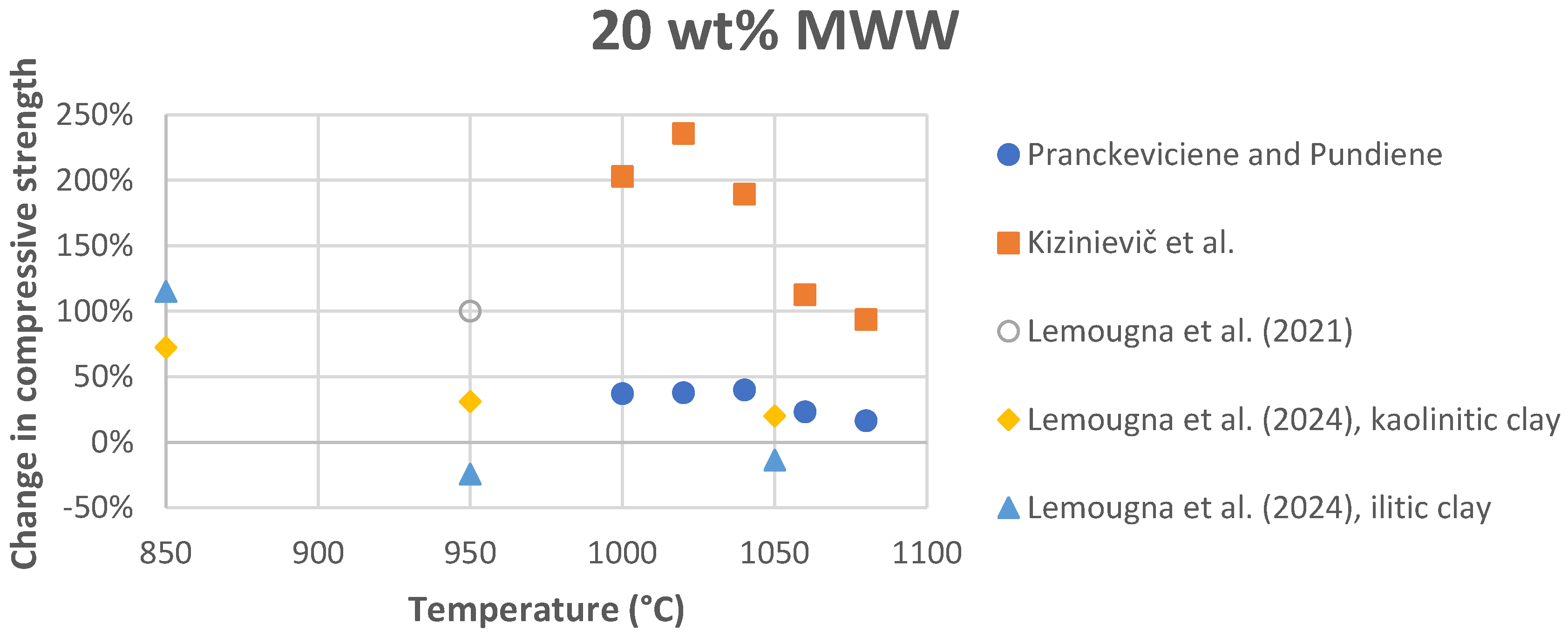

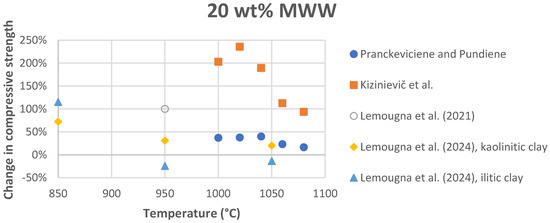

As shown in Figure 13, when 20 wt% MWW was incorporated into the mixture, the improvements in compressive strength were generally more modest compared to those obtained with 10 wt% MWW, with increases typically up to 100%. Two exceptions to this trend are reported by Kiznievič et al. [50] and Lemougna et al. [131] (the case of illitic clay). While Kiznievič et al. observed a significant improvement of up to 235%, particularly in the temperature range of 1000–1050 °C, the compressive strength of the samples produced with illitic clay studied by Lemougna et al. was even reduced at certain temperatures.

Figure 13.

Relative change in compressive strength (%) of building ceramic samples with 20 wt% MWW addition compared to reference samples, based on data compiled from literature sources [44,50,126,131].

Overall, these findings underscore the versatility of MWW in both clay-based and waste-based ceramics, supporting its potential role in circular economy strategies. Moreover, MWW can be tailored for use in both dense and porous ceramic applications, further broadening its utility. However, the precise composition of the mixture must be carefully developed, with close attention paid to the processing conditions.

4.4.2. Asphalt Mixtures

Research has demonstrated that MWW can be incorporated into asphalt mixtures primarily in two forms: as a finely ground powder replacing conventional mineral filler, or as fibers added to the mix. The proportion of mineral wool added ranges between 0.2% and 4% by weight of the asphalt mixture. Incorporating mineral wool has been shown to enhance asphalt mixture performance by improving tensile strength and rutting resistance, increasing fatigue life, and reducing permanent deformation. These benefits have been confirmed through laboratory tests such as the indirect tensile strength test, stiffness modulus measurement, fatigue testing, and dynamic creep analysis [133,134].

However, these experiments were conducted using samples obtained directly from factory production, or the source of the mineral wool was not stated clearly. For this reason, additional research is required to evaluate the influence of resin content and other impurities present in waste mineral wool on asphalt mixture performance. Moreover, the addition of mineral wool fibers has been observed to increase asphalt binder absorption [134]. As such, optimal dosages and processing methods should be further investigated to elucidate the mechanisms and effects of different MWW fiber characteristics on asphalt mixtures. [134,135].

Initial investigations into the environmental and economic impacts of incorporating MWW into asphalt mixtures have been reported [135]. Nevertheless, a comprehensive LCA is needed to provide more reliable data. Future research should also include durability analyses to assess the long-term effects of adding MWW to asphalt mixtures.

5. Conclusions

This literature review demonstrates that the recycling of MWW in construction materials has gained increasing research attention over recent decades. Most studies focus primarily on the mechanical performance of MWW-incorporated materials, commonly comparing them against reference samples without MWW additions. Results regarding compressive strength are inconsistent across different material types, underscoring the need for a deeper investigation into the microstructural and chemical mechanisms that govern these variations. Conversely, flexural strength generally shows consistent improvement with MWW incorporation.

Durability assessments also yield variable outcomes, and it is noteworthy that not all studies include such evaluations, highlighting a critical gap in the current research landscape. This gap suggests the necessity for standardized guidelines and protocols to direct future investigations on durability-related properties. However, the results suggest that using finely ground and preprocessed MWW at moderate dosages improves the mechanical and durability properties of the tested samples.

Given the intrinsic characteristics of mineral wool—namely its favorable thermal insulation and fire resistance properties—it is important to further explore these aspects in the development of innovative construction composites. Additionally, the amorphous structure and chemical composition of MWW facilitate pozzolanic activity, which may be further harnessed to enhance material performance.

The majority of research studies analyze MWW from the production streams, even though the greatest part of MWW comes from the construction and renovation activities. Future research should investigate the potential of processing and utilizing waste from landfills and construction sites in more detail. Additionally, further work should also provide economic and environmental assessments of pretreatment technologies to enhance the raw MWW for incorporation into new construction materials.

In light of these considerations, the most promising pathways for MWW recycling may lie in non-structural, insulation-oriented composite materials rather than purely load-bearing applications. Nonetheless, comprehensive research is required to elucidate both mechanical and durability properties more thoroughly. Future work should also transition from isolated laboratory-scale experiments toward real-world applications, including the optimization of supply chains, economic feasibility studies, and life-cycle assessments. There is growing focus on expanding applications beyond traditional cement-based composites to include AAMs and GPs.

Moreover, advancing MWW utilization must incorporate considerations of cost efficiency and embodied carbon emissions. Exploring carbon sequestration methodologies for MWW could significantly increase its valorization potential within net-zero construction paradigms. With evolving environmental policies aimed at sustainability, minimizing landfilling and promoting the recycling of MWW will become increasingly essential. These trends highlight the evolving multidisciplinary efforts aimed at maximizing the valorization potential of MWW in construction materials.

Author Contributions

Conceptualization, M.M., S.J., N.O.-Š. and A.T.; methodology, M.M., S.J., N.O.-Š. and A.T.; software, M.M. and S.J.; validation, M.M., S.J., N.O.-Š. and A.T.; formal analysis, M.M., S.J., N.O.-Š. and A.T.; investigation, M.M., S.J., N.O.-Š. and A.T.; resources, M.M., S.J., N.O.-Š. and A.T.; data curation, M.M., S.J., N.O.-Š. and A.T.; writing—original draft preparation, M.M., S.J., N.O.-Š. and A.T.; writing—review and editing, M.M., S.J., N.O.-Š. and A.T.; visualization, M.M., S.J., N.O.-Š. and A.T.; supervision, M.M.; project administration, M.M.; funding acquisition, M.M. and S.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research is partially supported through project KK.01.1.1.02.0027, a project co-financed by the Croatian Government and the European Union through the European Regional Development Fund—the Competitiveness and Cohesion Operational Programme. Tesovnik is supported by the ARIS Program Group P2-0273.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to thank ROCKWOOL Adriatic for providing a guided tour of their facilities. This visit greatly contributed to our understanding of the production process and informed the development of this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AAMs | Alkali-activated materials |

| CDW | Construction and demolition waste |

| GHG | Greenhouse gas emissions |

| GPs | Geopolymers |

| LCA | Life cycle assessment |

| MWW | Mineral wool waste |

| RW | Rock wool |

| GW | Glass wool |

| OPC | Ordinary Portland cement |

| SCM | Supplementary cementitious material |

| SEM | Scanning electron microscopy |

References

- De Andrade Salgado, F.; De Andrade Silva, F. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and Demolition Waste Management Contributing Factors Coupled with Reduce, Reuse, and Recycle Strategies for Effective Waste Management: A Review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The Circular Economy in the Construction and Demolition Waste Management: A Comparative Analysis in Emerging and Developed Countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Sai Trivedi, S.; Snehal, K.; Das, B.B.; Barbhuiya, S. A Comprehensive Review towards Sustainable Approaches on the Processing and Treatment of Construction and Demolition Waste. Constr. Build. Mater. 2023, 393, 132125. [Google Scholar] [CrossRef]

- Bedeković, G.; Kovačević Zelić, B.; Sobota, I. Construction and Demolition Waste Management in Croatia with Recycling Overview. Detritus 2018, 4, 122–128. [Google Scholar] [CrossRef]

- Huang, B.-T.; Xi, H.; Ma, R.-Y.; Zhang, Z.-L.; Lao, J.-C.; Zhang, H.; Shen, Y.-N.; Shi, D.-D.; Xu, L.-Y. Ultra-High-Strength Engineered Geopolymer Composites (UHS-EGC) with Mineral Processing Waste: Probabilistic Modeling of Cracking Behavior. Theor. Appl. Fract. Mech. 2025, 140, 105138. [Google Scholar] [CrossRef]

- Oubaha, S.; El Machi, A.; Mabroum, S.; Taha, Y.; Benzaazoua, M.; Hakkou, R. Recycling of Phosphogypsum and Clay By-Products from Phosphate Mines for Sustainable Alkali-Activated Construction Materials. Constr. Build. Mater. 2024, 411, 134262. [Google Scholar] [CrossRef]

- Nodehi, M.; Taghvaee, V.M. Applying Circular Economy to Construction Industry through Use of Waste Materials: A Review of Supplementary Cementitious Materials, Plastics, and Ceramics. Circ. Econ. Sustain. 2022, 2, 987–1020. [Google Scholar] [CrossRef]

- Mastali, M.; Zahra, A.; Hugo, K.; Faraz, R. Utilization of Mineral Wools in Production of Alkali Activated Materials. Constr. Build. Mater. 2021, 283, 122790. [Google Scholar] [CrossRef]

- Yliniemi, J.; Laitinen, O.; Kinnunen, P.; Illikainen, M. Pulverization of Fibrous Mineral Wool Waste. J. Mater. Cycles Waste Manag. 2018, 20, 1248–1256. [Google Scholar] [CrossRef]

- Kinnunen, P.; Yliniemi, J.; Talling, B.; Illikainen, M. Rockwool Waste in Fly Ash Geopolymer Composites. J. Mater. Cycles Waste Manag. 2017, 19, 1220–1227. [Google Scholar] [CrossRef]

- Mobley, R.K. Plant Engineer’s Handbook; Butterworth-Heinemann: Boston, MA, USA, 2001; ISBN 978-0-7506-7328-0. [Google Scholar]

- Li, Y.; Ren, S. Building Decorative Materials; Woodhead Publishing in Materials; Woodhead Publishing: Oxford, UK, 2011; ISBN 978-0-85709-257-1. [Google Scholar]

- Hall, M.R.; Allinson, D. Materials for Energy Efficiency and Thermal Comfort in Buildings; Woodhead Publishing Series in Energy; Hall, M.R., Ed.; Woodhead Publishing: Cambridge, UK, 2010; ISBN 978-1-84569-927-7. [Google Scholar]