Recycling Volcanic Lapillus as a Supplementary Cementitious Material in Sustainable Mortars

Abstract

1. Introduction

2. Results

2.1. Spreading Test

2.2. Bulk and True Density

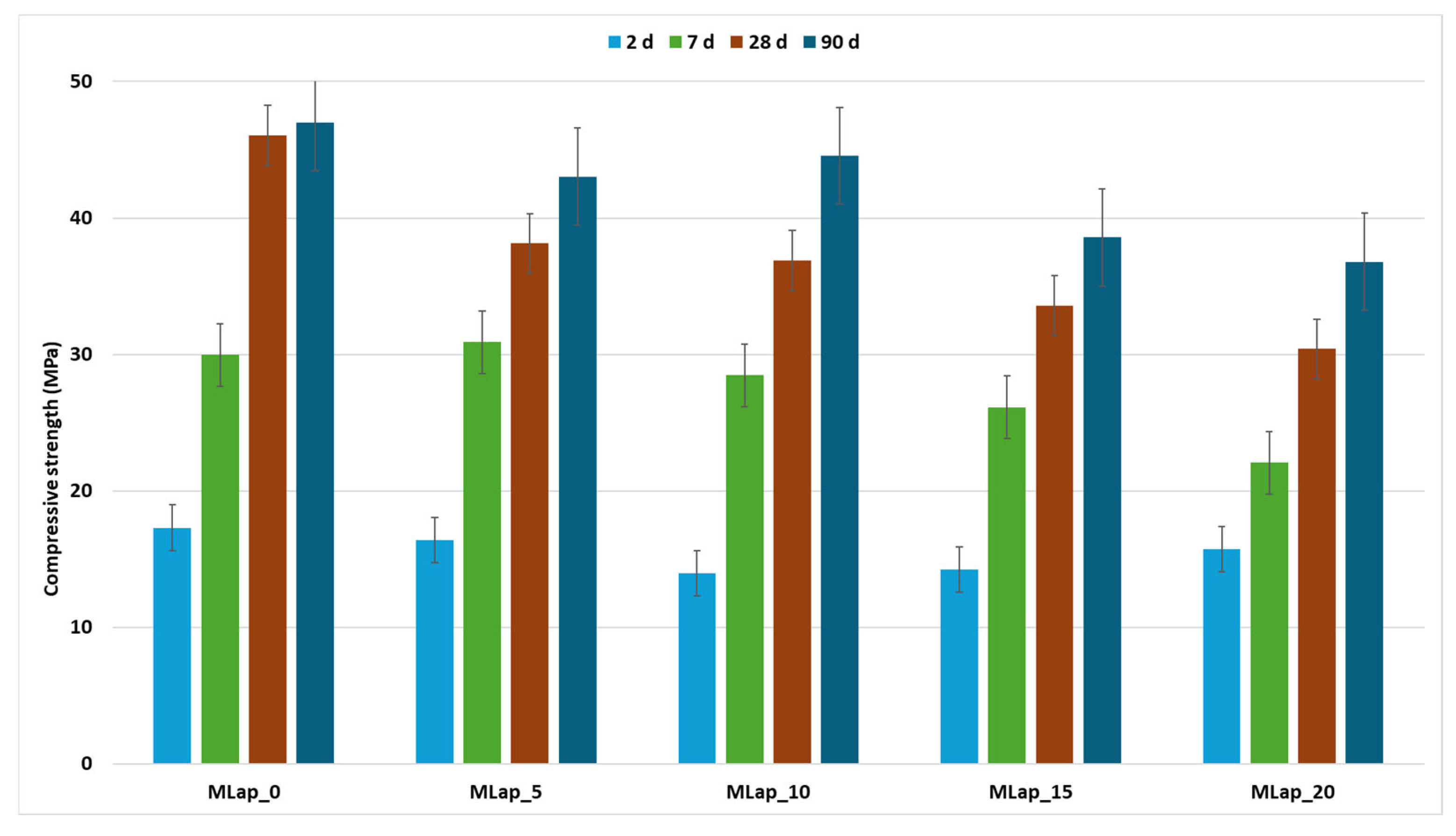

2.3. Compressive Strength

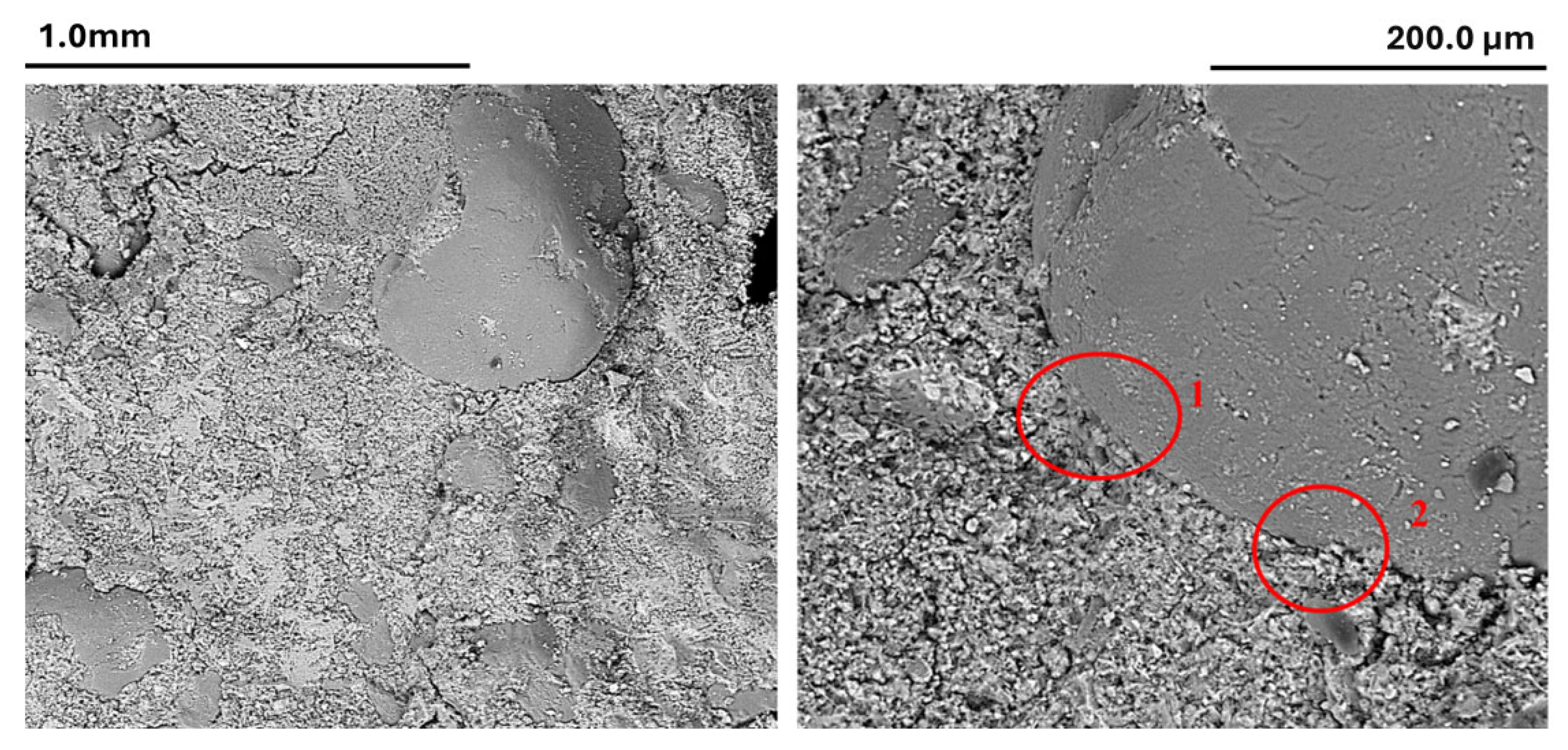

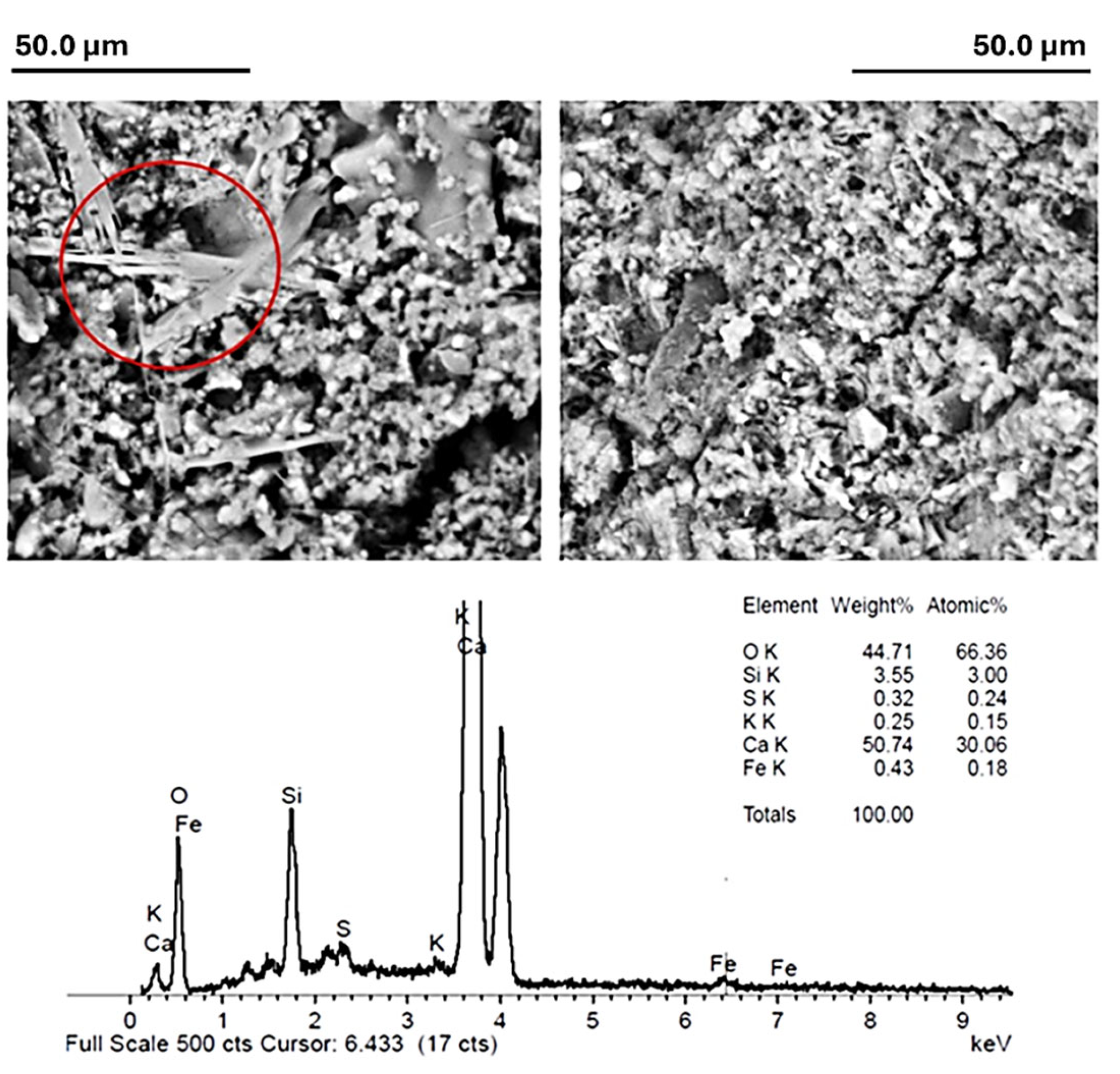

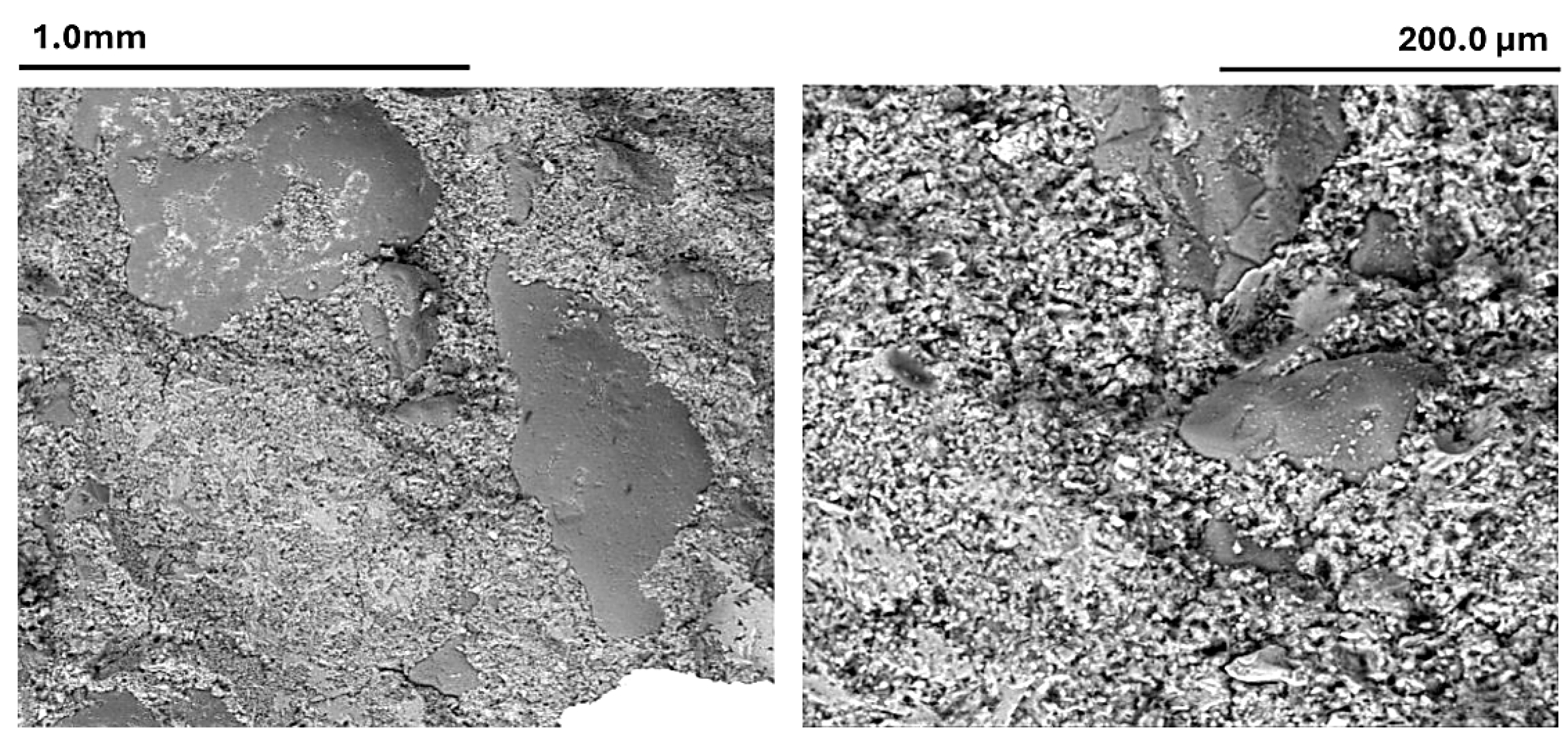

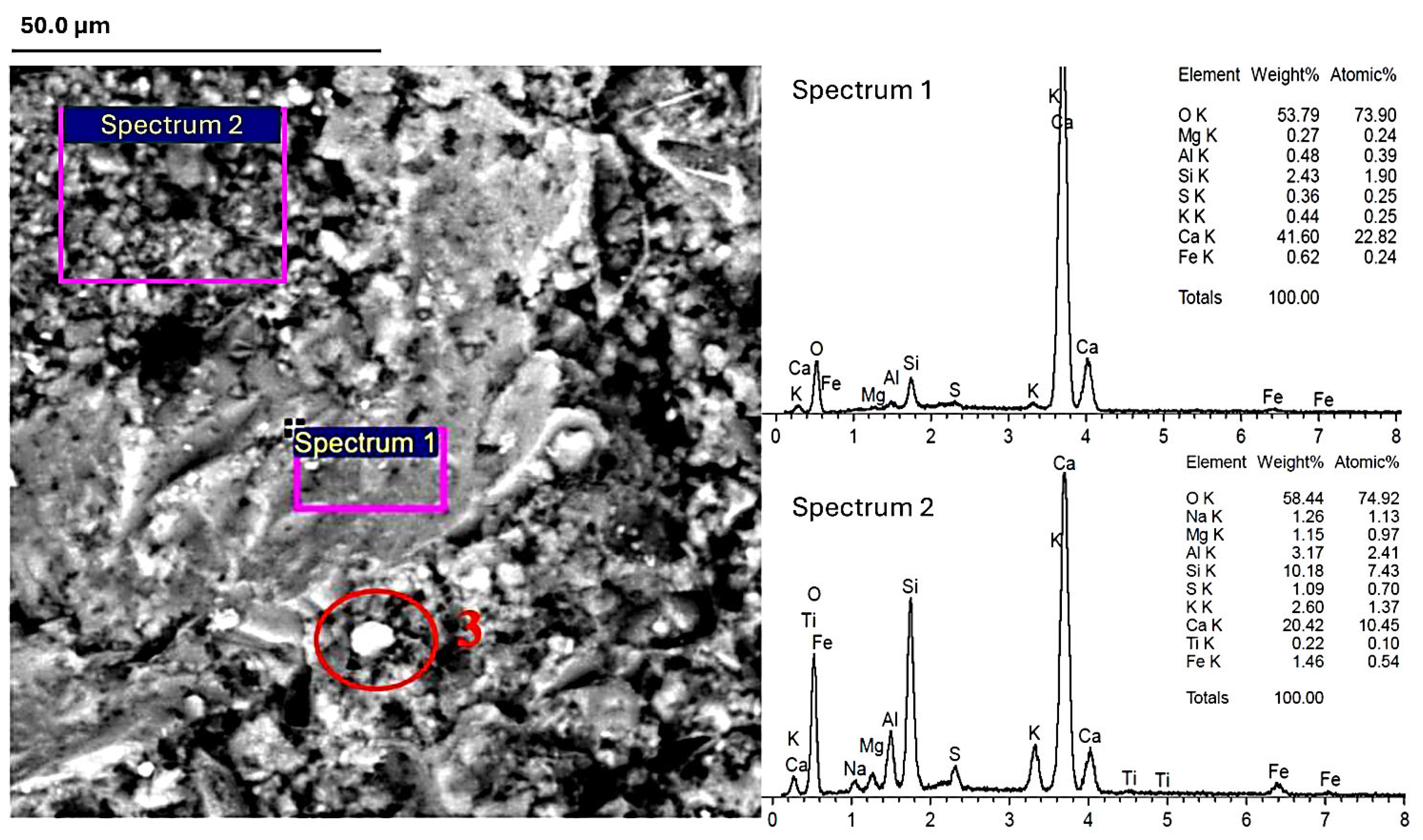

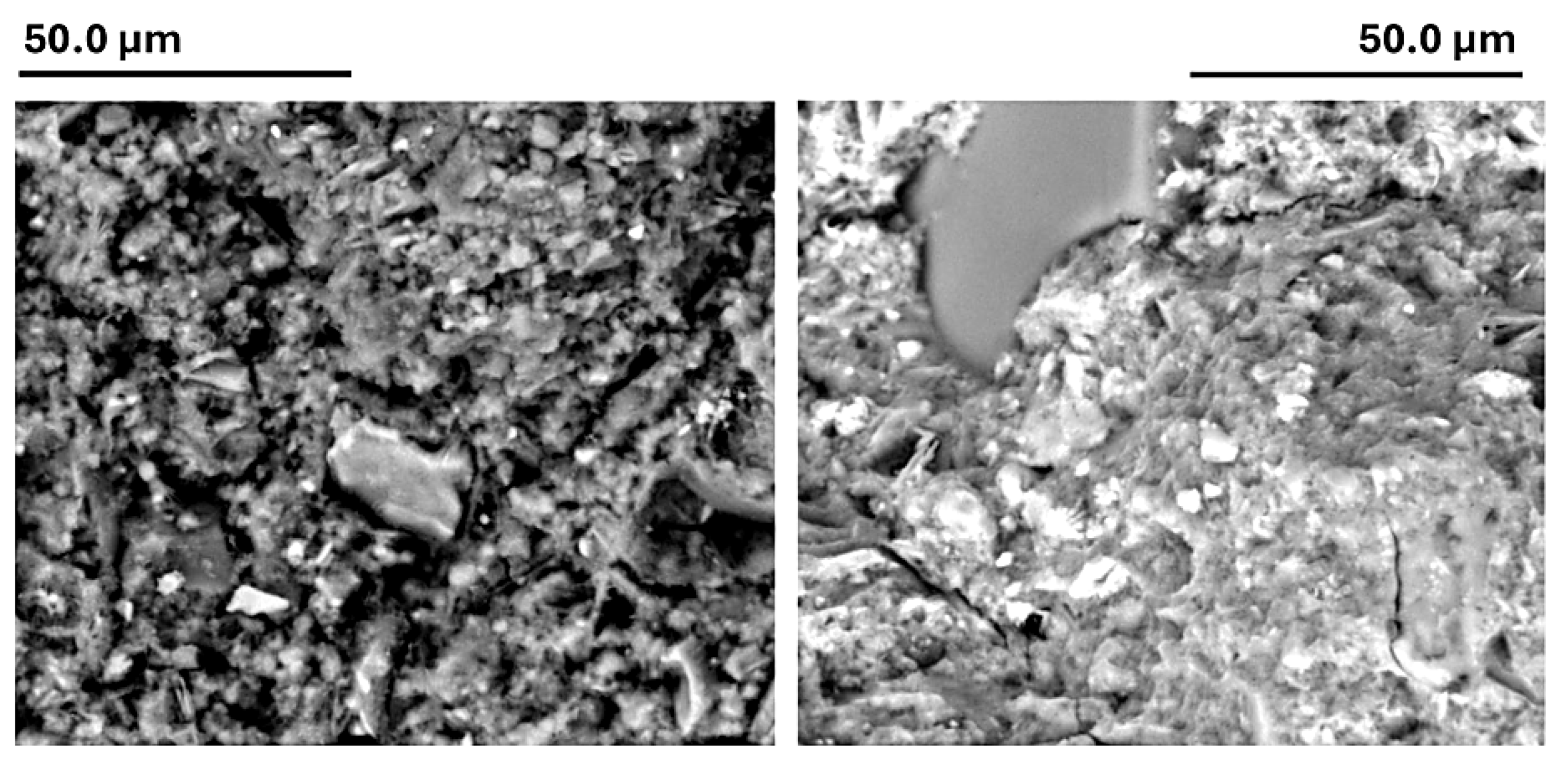

2.4. Scanning Electron Microscopy

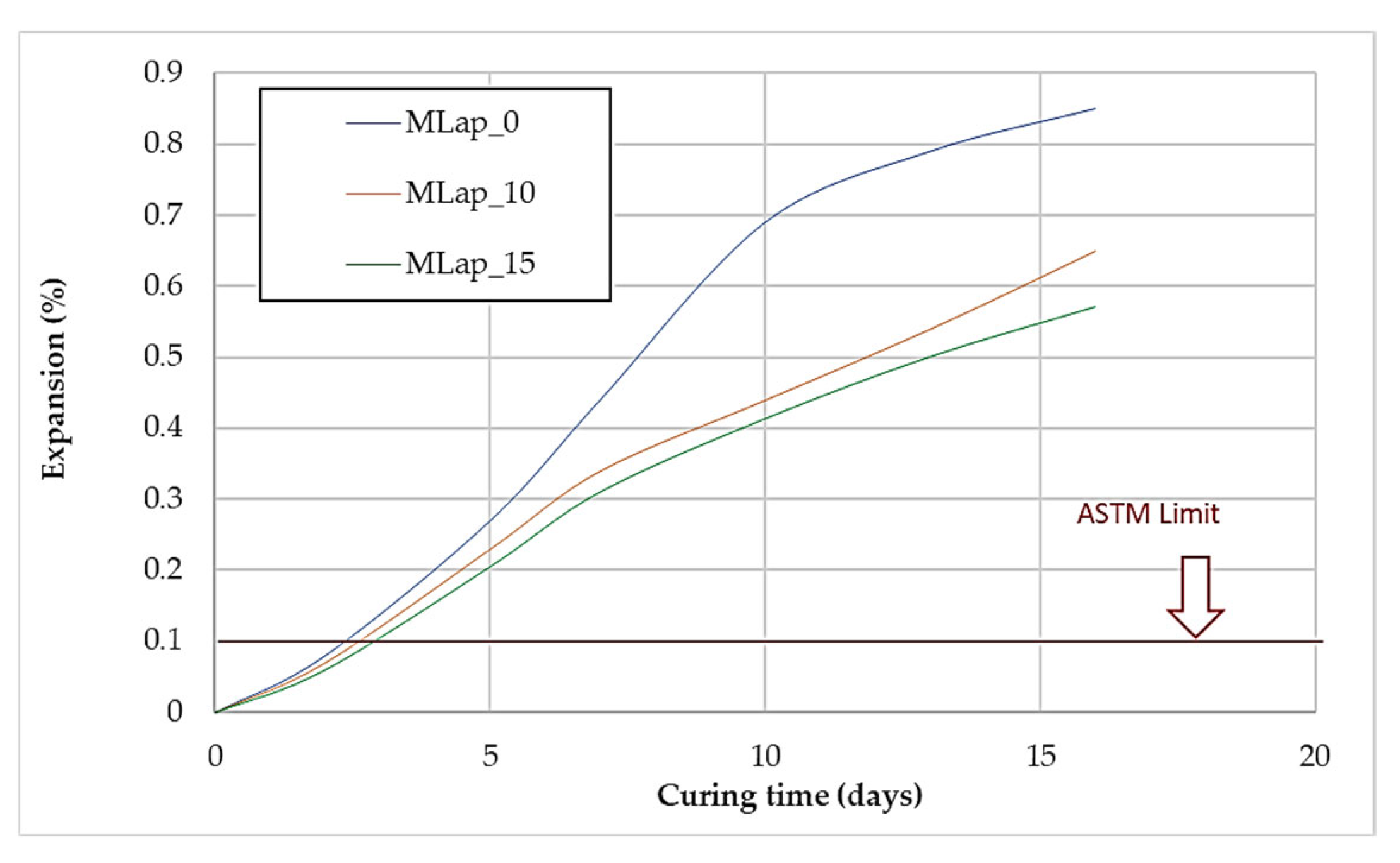

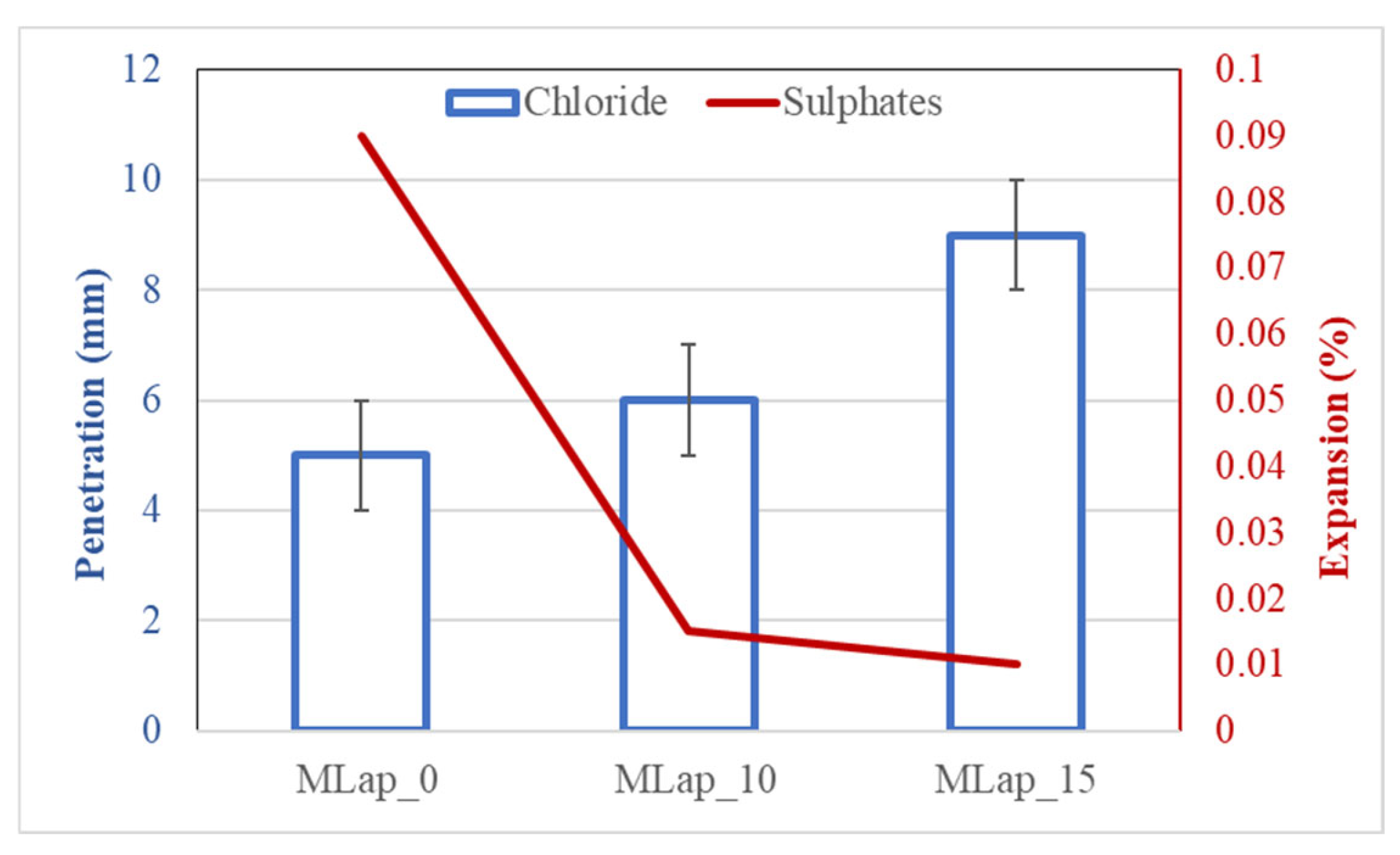

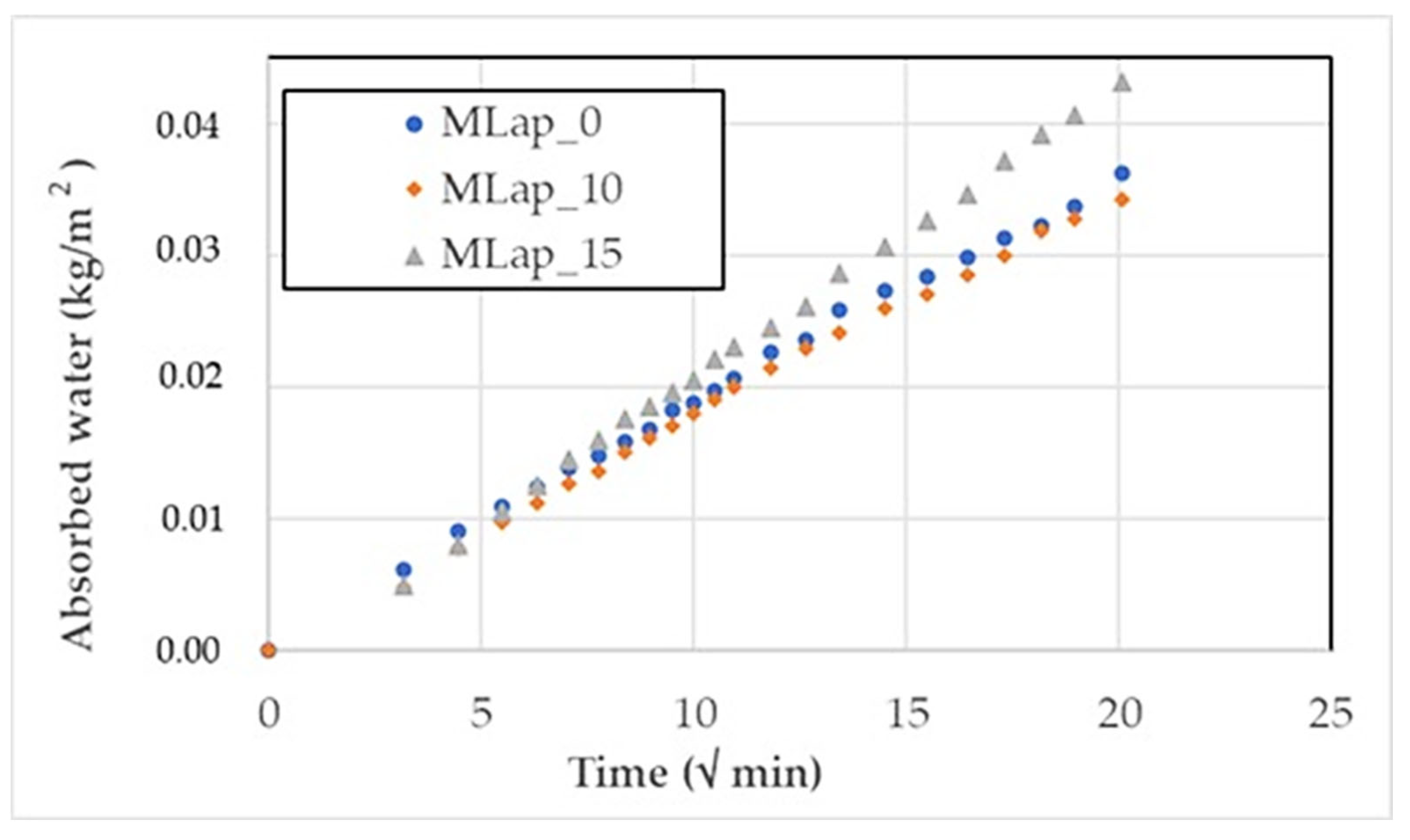

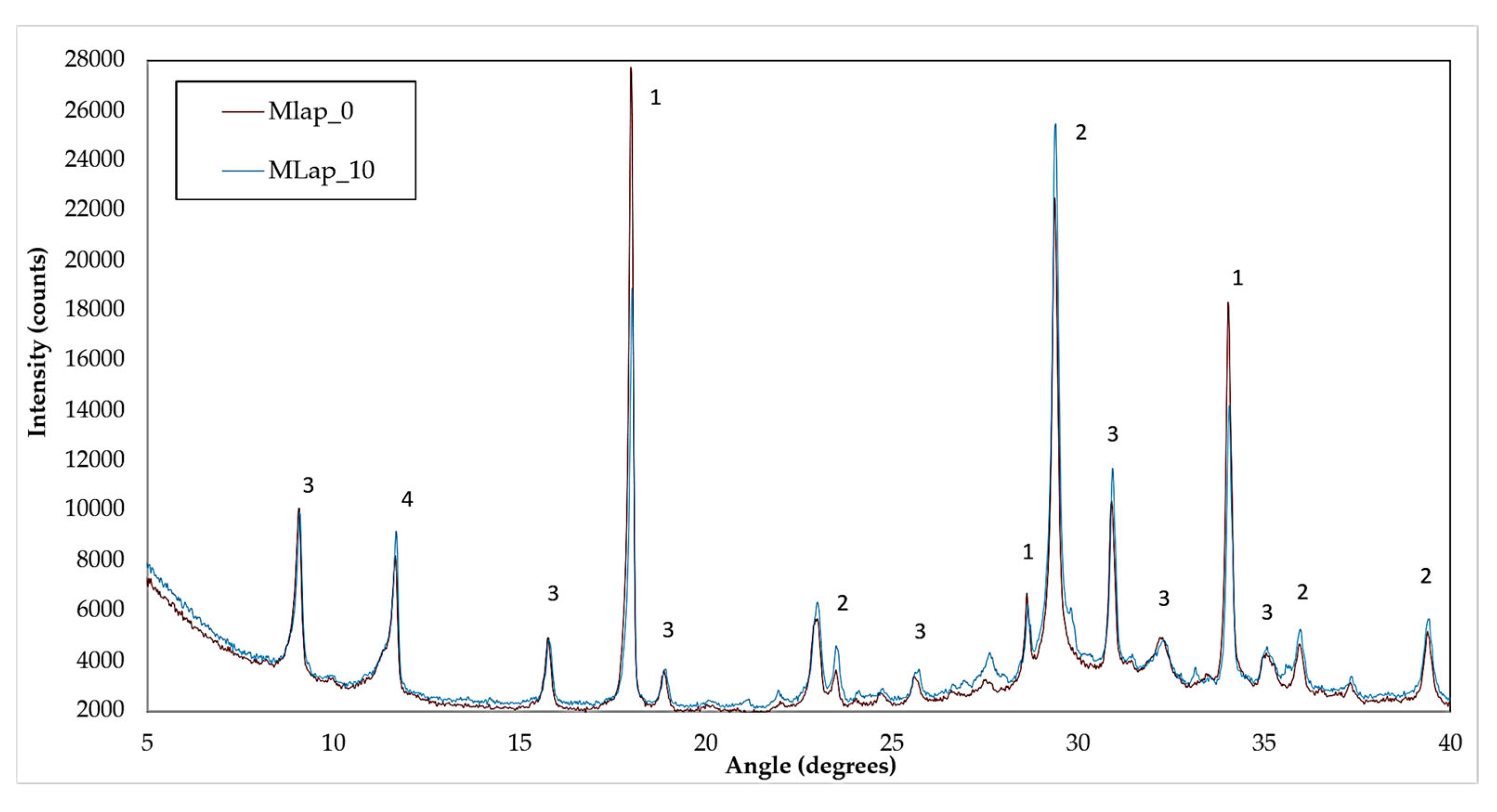

2.5. ASR Reactivity, Chloride and Sulfate Penetration, Water Absorption by Capillarity, and Calcium Hydroxide Content by Thermogravimetric Analysis

3. Discussion

3.1. Spreading Test

3.2. Bulk and True Density

3.3. Compressive Strength

3.4. Scanning Electron Microscopy

3.5. ASR Reactivity, Chloride and Sulfate Penetration, Water Absorption by Capillarity, and Calcium Hydroxide Content by Thermogravimetric Analysis

4. Materials and Methods

4.1. Raw Materials and Samples Preparation

- Limestone Portland cement (CEM II/B-LL 42.5, ECOPlanetIIB4, Holcim Ltd., Zug, Switzerland).

- CEN certified, EN196-1 and ISO 679:2009 compliant normalized sand.

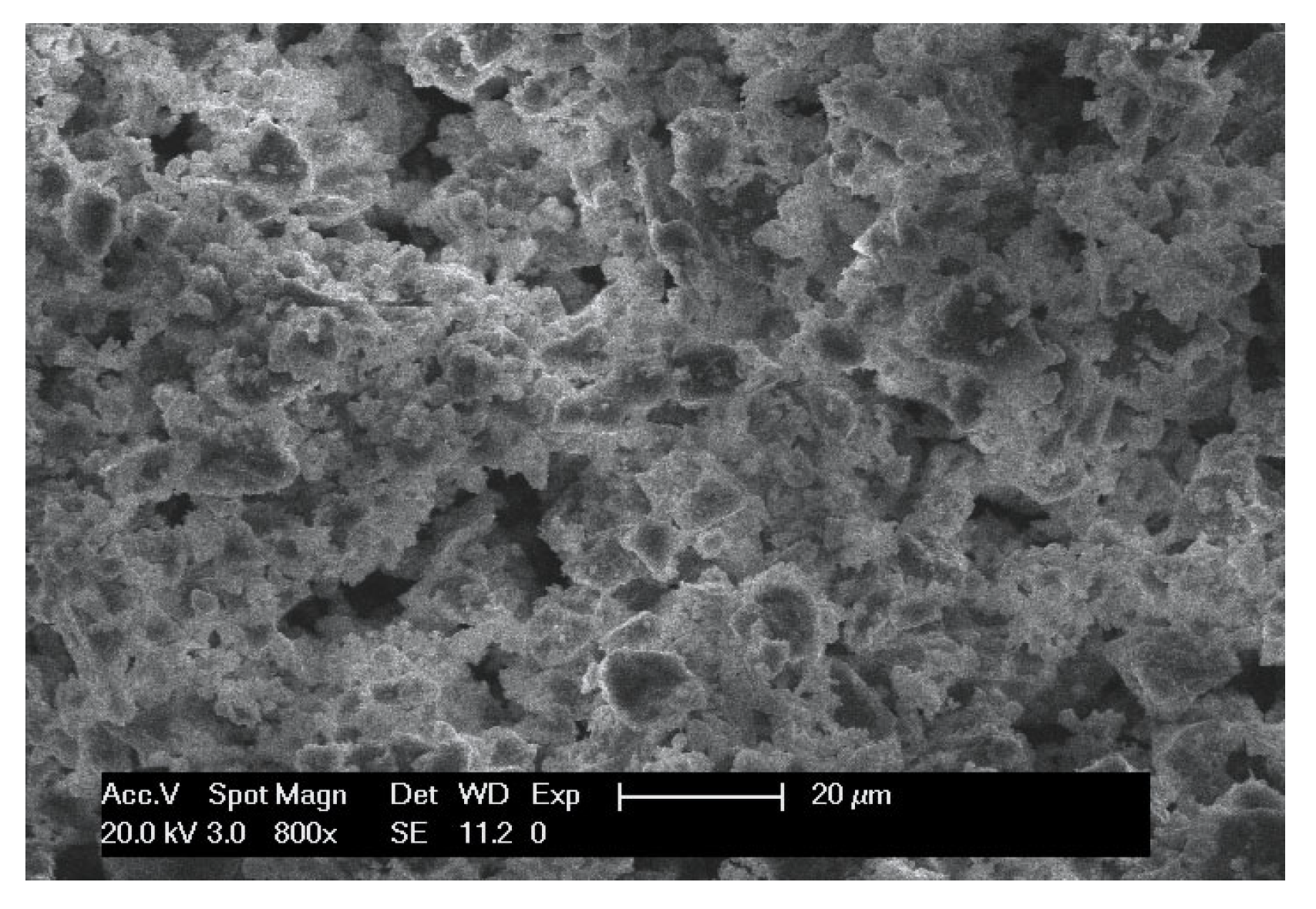

- Volcanic lapillus scrap, effusive magmatic material (Pleistocene Vulsine volcanite) from quarries located in the province of Viterbo (Latium, Italy) naturally calcined at a high temperature, resulting from explosive volcanic eruptions that occurred as a result of the expansion of dissolved gases into acidic lavas [43]. Chemical analysis of the lapillus showed SiO2 and Al2O3 contents of 49.1% and 18.3%, respectively, as well as CaO content of 9.27% and Fe2O3 content of 9.15%, while MgO, Na2O, and K2O contents were 4.25%, 2.35%, and 3.66%, respectively [39,58,59]. Lapillus scraps, which were initially less than 3 mm in diameter, were ground in ball-miller (MMS, Nonantola (MO), Italy) for 5 min in order to obtain an average particle diameter of less than 100 μm in order to increase their reactivity and compatibility with clinker and also to homogenize the waste. The dimensional distribution is D10 = 2.1 µm, D50 = 19.8 µm, and D90 = 60.1 µm. Figure 16 shows the morphology of the powders obtained by scanning electron microscopy (ESEM-Quanta 200, FEI).

4.2. Spreading Test

4.3. Bulk and True Density

4.4. Compressive Strength

4.5. Scanning Electron Microscopy

4.6. Alkali–Silica Reactivity (ASR) Test

4.7. Chloride and Sulfate Penetration

4.8. Water Absorption by Capillarity

4.9. Calcium Hydroxide Content by Thermogravimetric Analysis (TGA)

5. Conclusions

- Workability and density: Workability slightly decreased with higher lapillus content due to its porous nature, but the bulk density reduction suggests potential applications in lightweight construction.

- Mechanical properties: At short curing times, up to 10% replacement mortars showed a limited reduction in compressive strength (MLap_0 = 46.06 MPa and MLap_10 = 36.89 MPa at 28 days of curing), while higher replacement levels (15–20%) led to a more noticeable decrease (at 28 day of curing MLap_15 = 33.57 MPa and MLap_20 = 30.40 MPa). At 90 days of curing, however, up to a 10% substitution, the compressive strength matches the one of the reference mortar (MLap_0 = 47.00 MPa and MLap_10 = 44.57 MPa).

- Pozzolanic activity: It was observed through thermogravimetric analysis (TGA) and X-ray, which showed reduced calcium hydroxide content over time.

- Microstructural analysis: SEM analysis confirmed the formation of a continuous and sound transition zone between the aggregates and the developing matrix in all the investigated mortars.

- Durability improvements: The presence of volcanic lapillus improved resistance to expanding reactions caused by sulfate penetration, as well as those deriving from alkali–silica reactions reducing the expansion by a 30% at 15% substitution, thus mitigating degradation risks.

- Chloride penetration and water absorption: While chloride diffusion increased slightly in the higher replaced samples, capillary water absorption remained similar to the control at 10%, slightly increasing at higher lapillus content.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- CEMBUREAU. World Statistical Review 2004–2014; European Cement Association: Bruxelles, Belgium, 2017. [Google Scholar]

- CEMBUREAU. Activity Report 2023, Bruxelles. Available online: https://cembureau.eu/media/dnbf4xzc/activity-report-2023-for-web.pdf (accessed on 15 April 2025).

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2021, 281, 123558. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2017, 10, 2213–2239. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Nováková, I.; Gjerløw, E. A Review on emerging cementitious materials, reactivity evaluation and treatment methods. Buildings 2023, 13, 526. [Google Scholar] [CrossRef]

- Gartner, E.; Sui, T. Alternative cement clinkers. Cem. Concr. Res. 2018, 114, 27–39. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2025, 78, 71–80. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Hu, Y.; Li, K.; Zheng, L.; Han, B. Fly ash and slag as partial replacement of cement for the synthesis of low carbon cementitious materials. J. Renew. Mater. 2023, 11, 2491–2511. [Google Scholar] [CrossRef]

- Abbas, A.; Sanjaya, E.; Fimbres Weihs, G.A.; Cao, Y.; Samrani, P. Effect of fly ash and ground waste glass as cement replacement in concrete 3D-Printing for sustainable construction. Front. Built Environ. 2024, 10, 1420174. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Dobson, J. Effect of fly ash on compressive strength and chloride binding of seawater-mixed mortars. J. Sustain. Cem.-Based Mater. 2019, 8, 275–289. [Google Scholar] [CrossRef]

- Jun, Y.; Hilario, J.H.P.; Kim, J.H. Hydration characteristics and hydration products of calcium sulfoaluminate cement and fly ash blended pastes. J. Sustain. Cem.-Based Mater. 2024, 13, 1470–1482. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A Comprehensive review on the Ground Granulated Blast Furnace Slag (GGBS) in concrete production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Siddique, R.; Bennacer, R. Use of iron and steel industry by-product (GGBS) in cement paste and mortar. Resour. Conserv. Recycl. 2012, 69, 29–34. [Google Scholar] [CrossRef]

- Majhi, R.K.; Nayak, A.N.; Mukharjee, B.B. Development of sustainable concrete using recycled coarse aggregate and ground granulated blast furnace slag. Constr. Build. Mater. 2018, 159, 417–430. [Google Scholar] [CrossRef]

- Sharmila, P.; Dhinakaran, G. Compressive strength, porosity and sorptivity of ultrafine slag based high strength concrete. Constr. Build. Mater. 2016, 120, 48–53. [Google Scholar] [CrossRef]

- Escalante-Garcia, J.I.; Cabrera-Luna, K.; Castillo-Sanchez, Y.B. Blast furnace slag supersulfated cements: Composition optimization, microstructures, and environmental impact. J. Sustain. Cem.-Based Mater. 2024, 14, 145–166. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Aburumman, M.O.; Al Diseet, M.M.; Taha, R.; Abdel-Jaber, M.; Senouci, A.; Abu Taqa, A. Fly Ash and natural pozzolana impacts on sustainable concrete permeability and mechanical properties. Buildings 2023, 13, 1927. [Google Scholar] [CrossRef]

- Frias, M.; Garcia, R.; de la Villa, R.V.; Martinez Ramirez, S. Coal mining waste as a future eco-efficient supplementary cementing material: Scientific aspect. Recycling 2016, 1, 232–241. [Google Scholar] [CrossRef]

- Saccani, A.; Sandrolini, F.; Andreola, F.; Barbieri, L.; Bignozzi, M. Influence of the pozzolanic fraction obtained from vitrified bottom-ashes from MSWI on the properties of cementitious composites. Mater. Struct. 2005, 38, 367–371. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Zito, S.V.; Irassar, E.; Rahal, V.F. Recycled Construction and Demolition Waste as supplementary cementing materials in eco-friendly concrete. Recycling 2023, 8, 54. [Google Scholar] [CrossRef]

- Presa, L.; Rosado, S.; Peña, C.; Martín, D.A.; Costafreda, J.L.; Astudillo, B.; Parra, J.L. Volcanic ash from the island of La Palma, Spain: An experimental study to establish their properties as pozzolans. Processes 2023, 11, 657. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Frías, M.; Monasterio, M.; García-Giménez, R.; Vigil de la Villa, R.; Álamo, M. Volcanic ash from La Palma (Canary Islands, Spain) as Portland cement constituent. J. Build. Eng. 2023, 78, 107641. [Google Scholar] [CrossRef]

- Ulusu, H.; Aruntaş, H.-Y.; Gültekin, A.B.; Mustafa Day, M.; Çavuş, M.; Kaplan, G. Mechanical, durability and microstructural characteristics of Portland pozzolan cement (PPC): Cleaner and sustainable cement development. Constr. Build. Mater. 2023, 78, 131070. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Effect of pumice and fly ash incorporation on high temperature resistance of cement based mortars. Cem. Concr. Res. 2007, 37, 988–995. [Google Scholar] [CrossRef]

- Qin, L.; Zhou, M.; Yan, J.; Duan, P.; Zhu, Y.; Chen, W.; Zhang, Z.; Wang, A. Hydration characteristics and mechanical properties of cement-based materials modified by calcined zeolite and montmorillonite. J. Renew. Mater. 2023, 11, 2191–2207. [Google Scholar] [CrossRef]

- Wu, C.R.; Hong, Z.Q.; Zhan, B.J.; Cui, S.C.; Kou, S.C. Pozzolanic activity of calcinated low-grade natural sepiolite and its influence on the hydration of cement. Constr. Build. Mater. 2021, 309, 125076. [Google Scholar] [CrossRef]

- Kuo, W.Y.; Huang, J.S.; Lin, C.H. Effects of organo-modified montmorillonite on strengths and permeability of cement mortars. Cem. Concr. Res. 2006, 36, 886–895. [Google Scholar] [CrossRef]

- Limestone Calcined Clay Cement. Available online: https://lc3.ch/ (accessed on 11 November 2024).

- Avet, F.; Scrivener, K. Investigation of the calcined kaolinite content on the hydration of Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 124–135. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Nepal, J.; Bhusan Das, B. Properties, compatibility, environmental benefits and future directions of limestone calcined clay cement (LC3) concrete: A review. J. Build. Eng. 2023, 79, 107794. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Muzenda, T.R.; Hou, P.; Kawashima, S.; Sui, T.; Cheng, X. The role of limestone and calcined clay on the rheological properties of LC3. Cem. Concr. Compos. 2020, 107, 103516. [Google Scholar] [CrossRef]

- Blasi, E.; Di Bella, C.; Choorackal, E.; Maqbool, Q.; Tittarelli, F.; Garufi, D.; Schmidt, T. Use of low-grade kaolinite clays in the production of limestone calcined clay cement. J. Sustain. Cem.-Based Mater. 2024, 14, 209–221. [Google Scholar] [CrossRef]

- Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. Effect of Processed Volcanic Ash as active mineral addition for cement manufacture. Materials 2022, 15, 6305. [Google Scholar] [CrossRef] [PubMed]

- al-Swaidani, A.; Khwies, W. Applicability of artificial neural networks to predict mechanical and permeability properties of volcanic scoria-based concrete. Adv. Civ. Eng. 2018, 2018, 5207962. [Google Scholar] [CrossRef]

- Bilardi, S.; Calabrò, P.; Moraci, N. Optimal design of zvi/lapillus mixtures for nickel removal in permeable reactive barriers. Jpn. Geotech. Soc. Spec. Publ. 2021, 9, 313–318. [Google Scholar] [CrossRef]

- Barbieri, L.; Altimari, F.; Andreola, F.; Maggi, B.; Lancellotti, I. Characterization of volcano-sedimentary rocks and related scraps for design of sustainable materials. Materials 2023, 16, 3408. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Alaibani, A.; Abdulsalam, M.; Mao, C.; Bumajdad, A.; Palkovic, S. Microstructure of cement paste with natural pozzolanic volcanic ash and portland cement at different stages of curing. Constr. Build. Mater. 2016, 113, 423–441. [Google Scholar] [CrossRef]

- Fernea, R.; Tămaș-Gavrea, D.; Manea, D. Experimental investigations on the performances of composite building materials based on industrial crops and volcanic rocks. Crystals 2020, 10, 102. [Google Scholar] [CrossRef]

- al-Swaidani, A. Efficiency of nano-volcanic scoria in the concrete binder. SN Appl. Sci. 2019, 1, 980. [Google Scholar] [CrossRef]

- Available online: https://www.europomice.it/ (accessed on 15 April 2025).

- Jaber, H. Effect of glass wool addition on some properties of cement mortar. Eng. Technol. J. 2016, 34, 2685–2691. [Google Scholar] [CrossRef]

- Khurram, N.; Khan, K.; Saleem, M.; Amin, M.; Akmal, U. Effect of elevated temperatures on mortar with naturally occurring volcanic ash and its blend with electric arc furnace slag. Adv. Mater. Sci. Eng. 2018, 2018, 5324036. [Google Scholar] [CrossRef]

- Aziz, M.; Moundi, A.; Dawaï, D.; Ntiéche, B.; Koungang, B.; Michel, F. Effect of the use of volcanic pozzolan from Mbepit Massif (West-Cameroon) on the mechanical properties of mortar and composite cements production. Eng. Res. Express 2021, 3, 015034. [Google Scholar] [CrossRef]

- Ulusu, H.; Aruntas, H.Y.; Gencel, O. Investigation on characteristics of blended cements containing pumice. Constr. Build. Mater. 2016, 118, 11–19. [Google Scholar] [CrossRef]

- Lemma, R.; Zito, S.; Locati, F.; Castellano, C.C.; Bonavetti, V.L.; Irassar, E.F.; Marfil, S.; Rahhal, V.F. Natural pozzolan with different volcanic glass and zeolite content: Effect on the performance of blended cement. Constr. Build. Mater. 2024, 451, 138821. [Google Scholar] [CrossRef]

- Tang, H.; Xu, L.; Xue, K.; Tian, J.; Yang, J.; Wang, D.; Shu, K.; Zuo, A.; Wu, H. Effect of mechanical activation on hydration properties of natural volcanic rock towards partially replacing cement in composite cementitious materials. J. Build. Eng. 2024, 83, 108427. [Google Scholar] [CrossRef]

- Erdogmus, E.; Erdoğan, Y.; Gencel, O.; Targan, S.; Avciata, U. Influence of colemanite admixture on Portland cement durability. Adv. Cem. Res. 2012, 24, 155–164. [Google Scholar] [CrossRef]

- Gongalves, B.; Exposito, C.; Ishikawa, T.T.; Koga, G.Y. X-ray diffraction study of the early hydration of Portland cements containing calcium carbonate by in-situ and ex-situ approaches. Constr. Build. Mater. 2023, 365, 129947. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, X.; Xue, Q.; Shen, X. New perspective to improve the sulfate attack resistance of mortar by coral sand. J. Build. Eng. 2023, 71, 106483. [Google Scholar] [CrossRef]

- Sotiriadis, K.; Mácová, P.; Mazur, A.S.; Viani, A.; Tolstoy, P.M.; Tsivilis, S. Long-term thaumasite sulfate attack on Portland-limestone cement concrete: A multi-technique analytical approach for assessing phase assemblage. Cem. Concr. Res. 2020, 130, 105995. [Google Scholar] [CrossRef]

- Hossack, A.M.; Thomas, M.D.A. The effect of temperature on the rate of sulfate attack of Portland cement blended mortars in Na2SO4 solution. Cem. Concr. Res. 2015, 73, 136–142. [Google Scholar] [CrossRef]

- Figueira, R.B.; Sousa, R.; Coelho, L.; Azhena, M.; de Almeida, J.M.; Jorge, P.A.S.; Silva, C.J.R. Alkali-silica reaction in concrete: Mechanisms, mitigation and test methods. Cem. Concr. Res 2019, 222, 903–931. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.N.N.; Sarker, P.K.; Shaikh, F.A.; Pramanik, A. The ASR mechanism of reactive aggregates in concrete and its mitigation by fly ash: A critical review. Cem. Concr. Res 2018, 171, 743–758. [Google Scholar] [CrossRef]

- Fanijo, E.O.; Kassem, E.; Ibrahim, A. ASR mitigation using binary and ternary blends with waste glass powder. Cem.Concr. Res. 2021, 280, 122425. [Google Scholar] [CrossRef]

- Altimari, F.; Lancellotti, I.; Leonelli, C.; Andreola, F.; Elsayed, H.; Bernardo, E.; Barbieri, L. Green materials for construction industry from Italian volcanic quarry scraps. Mater. Lett. 2023, 333, 133615. [Google Scholar] [CrossRef]

- Altimari, F. Volcano-Sedimentary Rocks for Green Transition: Valorization and Recovery for the Design of Sustainable Materials. Ph.D. Thesis, University of Modena and Reggio Emilia, Modena, Italy, 10 May 2025. Available online: https://iris.unimore.it/handle/11380/1377869 (accessed on 14 May 2025).

- Saccani, A.; Bignozzi, M.; Barbieri, L.; Lancellotti, I.; Bursi, E. Effect of the chemical composition of different types of recycled glass used as aggregates on the ASR performance of cement mortars. Constr. Build. Mater. 2017, 154, 804–809. [Google Scholar] [CrossRef]

| Mineralogical Phase (wt%) | Lapillus |

|---|---|

| Amorphous | 16.1 |

| Sanidine (K,Na)(Si,Al)4O8 | 19.8 |

| Anorthite (CaAl2Si2O8) | 26.4 |

| Analcime (NaAlSi2O6∙H2O) | 6.1 |

| Diopside (CaMgSi2O6) | 19.0 |

| Hematite (Fe2O3) | 4.9 |

| Plagioclase (Na,Ca)(Si,Al)4O8 | 5.8 |

| Mica X2Y4-6Z8O20(OH,F)4 | 1.9 |

| Code | Water (g) | Cement (g) | Sand (g) | Lapillus (g) | % Replacement |

|---|---|---|---|---|---|

| MLap_0 | 225 | 450.0 | 1350 | 0.0 | 0 |

| MLap_5 | 225 | 427.5 | 1350 | 22.5 | 5 |

| MLap_10 | 225 | 405.0 | 1350 | 45.0 | 10 |

| MLap_15 | 225 | 382.5 | 1350 | 67.5 | 15 |

| MLap_20 | 225 | 360.0 | 1350 | 90.0 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altimari, F.; Barbieri, L.; Saccani, A.; Lancellotti, I. Recycling Volcanic Lapillus as a Supplementary Cementitious Material in Sustainable Mortars. Recycling 2025, 10, 153. https://doi.org/10.3390/recycling10040153

Altimari F, Barbieri L, Saccani A, Lancellotti I. Recycling Volcanic Lapillus as a Supplementary Cementitious Material in Sustainable Mortars. Recycling. 2025; 10(4):153. https://doi.org/10.3390/recycling10040153

Chicago/Turabian StyleAltimari, Fabiana, Luisa Barbieri, Andrea Saccani, and Isabella Lancellotti. 2025. "Recycling Volcanic Lapillus as a Supplementary Cementitious Material in Sustainable Mortars" Recycling 10, no. 4: 153. https://doi.org/10.3390/recycling10040153

APA StyleAltimari, F., Barbieri, L., Saccani, A., & Lancellotti, I. (2025). Recycling Volcanic Lapillus as a Supplementary Cementitious Material in Sustainable Mortars. Recycling, 10(4), 153. https://doi.org/10.3390/recycling10040153