1. Introduction

The current energy scenario is dominated by fossil fuels, which account for about 82% of global energy consumption [

1]. This dependence not only raises concerns about energy security due to the finite nature of these resources but also contributes significantly to greenhouse gas emissions [

2]. The growing global demand for energy and the pressure to reduce greenhouse gas emissions have spurred the search for more sustainable energy sources [

3,

4]. In this context, Colombia faces the particular challenge of meeting an ever-increasing demand for energy, while at the same time trying to move towards a more sustainable and environmentally friendly energy model [

5].

For this reason, biomass has emerged as a viable alternative to fossil fuels due to its renewable nature and its potential to reduce carbon emissions [

6,

7,

8,

9,

10]. However, direct biomass combustion presents technical and economic challenges, which has led to the exploration of strategies such as co-firing with coal [

11,

12]. This approach allows for the use of existing power generation infrastructures while reducing the dependence on coal, thus optimising the environmental and economic balance of the process [

13,

14].

The Department of Córdoba is emerging as a strategic region for the implementation of biomass-based energy alternatives, supported by its significant agricultural potential, which reached 1.28 million tonnes of crops in 2021 [

15]. The privileged geographical and climatic conditions of the Sinú and San Jorge valleys, characterised by a balanced alternation between rainy and dry seasons, have favoured a significant production of strategic crops for biomass production [

16]. The region produces approximately 700,000 coconuts per year on 233 hectares in the Balsal area, generating a significant amount of usable waste, 87% of which could be used for energy purposes. At the same time, the 2114 hectares dedicated to rice production generate an annual production of 16,134 tonnes, of which approximately 3200 tonnes correspond to rice husks, a waste with high potential for use as biomass [

17].

In this context, the co-firing of agricultural residues, specifically coconut and rice husks, together with bituminous coal, represents a promising technological option that could not only contribute to the diversification of the energy matrix but also provide a solution for the sustainable management of agricultural residues [

18]. This process has been extensively studied in terms of thermal efficiency and emission reduction, but its comprehensive environmental impact requires a detailed analysis that considers all stages of the life cycle. In this context, life cycle assessment (LCA) has emerged as a key methodological tool to assess the environmental impact of different fuel mixes [

19,

20,

21]. This approach allows for the quantification of CO

2-equivalent emissions, natural resource consumption, and other environmental impacts such as acidification, eutrophication, and photochemical smog formation, thus providing a holistic view of the sustainability of the process [

22,

23,

24].

Several studies have analysed the environmental impact of burning biomass and coal separately, highlighting that biomass can significantly reduce net carbon emissions due to its renewable origin [

25,

26,

27,

28]. Previous research has shown that co-firing of agro-industrial waste is a viable alternative to reduce the environmental footprint of energy production [

29,

30]. However, results vary depending on factors such as the proportion of biomass in the mix, combustion conditions, and the origin of the energy input [

31,

32,

33]. In this regard, specific studies assessing realistic co-firing scenarios and their impact on the life cycle of the energy system are essential.

This study focuses on the LCA of co-firing coconut residues, rice husks, and bituminous coal, with the aim of quantifying and comparing the environmental impacts of different blending scenarios. Several environmental impact categories are assessed using the ReCiPe 2016 methodology, using primary emissions data and secondary databases such as Ecoinvent. The influence of input transport on the overall impact of the system is also considered, as the distance between biomass sources and generation plants can significantly affect the environmental viability of co-firing.

In addition to reducing emissions and utilising local resources, co-firing creates synergistic effects that improve the overall performance of the combustion process. Blending biomass with coal can complement differences in volatile content, moisture, and ash composition, improving combustion efficiency, stabilising flame characteristics, and reducing harmful emissions beyond what would be expected from the fuels individually. These interactions can also mitigate operational issues such as slagging, fouling, and corrosion, which are commonly associated with the combustion of high percentages of biomass, while maintaining the energy density and predictability of coal. Therefore, the co-firing approach supports circular economy principles and introduces operational and environmental synergies, making it a technically attractive option for the energy transition.

These results will provide relevant information for decision-making in energy planning, allowing for the identification of the most sustainable and environmentally efficient fuel mixes. Furthermore, this analysis will contribute to the scientific literature on co-firing by providing an LCA-based approach to assess the feasibility of integrating waste biomass into the energy matrix in a context where decarbonisation of the energy sector is a global priority.

Background and Objective of This Study

The transition towards sustainable energy systems has intensified research efforts to reduce the environmental impact of conventional fossil fuels. Among these transitional technologies, the use of biomass in coal-fired power stations has emerged as a promising alternative to coal, utilising agro-industrial residues and minimising greenhouse gas emissions. This approach reduces dependence on non-renewable resources and valorises biomass waste, supporting the principles of the circular economy.

Several studies have addressed the technical and environmental feasibility of co-firing. For example, Dzikuć and Łasiński [

11] evaluated the economic and emission implications of adding biomass to coal-fired boilers and confirmed reductions in SO_x and CO

2 emissions. Xu et al. reviewed the current status of coal–biomass co-firing technology, highlighting its potential to reduce the environmental impact of coal-based energy generation. VasileIadou [

29] quantified the renewable and non-renewable CO

2 emissions per unit of energy in lignite–biomass blends, demonstrating the substantial environmental benefits of incorporating biomass. More recent work by Millinger et al. explored how biomass pathways could help to meet emissions targets in European energy systems. However, most of these assessments have been conducted in developed contexts and have limited applicability to regional or developing settings, such as Colombia, where agro-industrial residues are abundant but underutilised.

In the Colombian context, recent studies have begun to explore the integration of biomass energy. For example, Sofán-Germán et al. [

5] assessed the performance of hybrid biomass–coal briquettes during combustion, and Sagastume Gutiérrez et al. [

7] evaluated the potential of using biomass waste to replace firewood in rural households. Despite these efforts, a comprehensive life cycle assessment (LCA) that quantifies the environmental impact of different co-firing configurations using local biomass sources is still lacking.

This study aims to conduct an LCA of co-firing bituminous coal with agro-industrial waste biomass—specifically coconut husk and rice husk—under various fuel mix scenarios. The analysis considers cradle-to-gate system boundaries and assesses environmental indicators such as global warming potential, eutrophication, acidification, and photochemical smog formation, using the ReCiPe 2016 method. Additionally, a sensitivity analysis is included to evaluate the influence of combustion efficiency and transport distance. The aim is to identify fuel mix configurations offering the lowest environmental impact and to inform evidence-based decision-making for the transition to sustainable energy systems in agro-industrial regions such as Córdoba in Colombia.

2. Results and Discussion

2.1. Environmental Impact

2.1.1. Raw Material Extraction Emissions

Figure 1 illustrates the environmental impacts associated with extracting raw materials (bituminous coal, coconut husk, and rice husk), with a focus on CO

2, SO

2, and NOx emissions per tonne of material extracted. The data show that coal extraction results in the highest emissions, particularly of CO

2, at nearly 20 kg per tonne. This is primarily due to the energy-intensive nature of underground and open-pit mining, which requires heavy machinery, explosives, and diesel-powered equipment. In contrast, biomass residues such as rice husks and coconut shells are by-products of agricultural activities and require no dedicated extraction processes. Accordingly, they are assigned minimal upstream emissions in accordance with LCA standards. Studies such as those by Vasileiadou [

29] and Curran [

34] highlight that raw coal substantially contributes to upstream greenhouse gas emissions, due to its embedded carbon and the fossil energy used in its extraction and processing.

By contrast, emissions from biomass extraction (from coconut and rice husks) are significantly lower. This aligns with the findings of Dzikuć and Łasiński [

11], who discovered that biomass residues typically require minimal processing, thereby reducing their environmental impact. Furthermore, the concept of carbon neutrality for biomass, whereby the CO

2 emitted during combustion is offset by the CO

2 absorbed by the plant during its growth, is supported by IPCC methodology and reflected in the lower impact values observed.

Of the two types of biomass, rice husk shows slightly lower emissions than coconut husk, particularly for NOx. This could be due to differences in their nitrogen content. According to Sofán-Germán et al. [

5], rice husk generally has a lower nitrogen and sulphur content than coconut husk, which can affect emission profiles during combustion and processing.

These results reinforce the importance of promoting the partial substitution of bituminous coal by agro-industrial waste biomass as a viable strategy to reduce greenhouse gas emissions and other local pollutants associated with raw material extraction. In addition, this approach contributes to better use of waste that might otherwise be underutilised or cause additional environmental problems, such as inappropriate disposal.

Evidence suggests that the transition to a higher share of biomass in fuel mixes could play an important role in decarbonising the energy sector, especially in agro-industrial regions such as the department of Córdoba, Colombia, where there is ample potential for waste biomass generation.

2.1.2. Transportation Impacts

Figure 2 shows the emissions generated by transporting each raw material. As expected, bituminous coal generates the highest transport-related CO

2 emissions due to its longer transport distances (456–611 km) and greater density. This aligns with the observations of Sugiyono et al. [

30], who emphasised that coal logistics contribute significantly to its life cycle impact, particularly when it is sourced from remote mines.

Conversely, biomass transport generates lower emissions thanks to shorter distances and lighter loads. Nevertheless, transport emissions remain a significant factor, particularly in Scenario G, where the biomass content is high and the distances are long. These findings support the conclusions of Millinger et al. [

28], who emphasised that proximity of biomass sources to power generation sites is crucial for achieving net environmental benefits in co-firing systems.

Additionally, the greater bulk density and total mass of coal transported, combined with longer transport distances of 456–611 km, amplifies CO

2 emissions from logistics. In contrast, biomass residues often originate closer to the combustion site, which reduces their environmental impact during transport. The relationship between transport distance and emissions has been documented by Sugiyono et al. [

30].

2.1.3. Waste Management Impacts

Figure 3 shows the emissions associated with waste management. Once again, coal has the greatest impact, particularly in terms of CO

2 and SO

2 emissions. This is primarily due to the handling and disposal of ash following coal combustion, which contains hazardous heavy metals and requires specific treatment procedures [

29].

On the other hand, coconut and rice husk residues generate significantly lower waste emissions. Their ash is often non-hazardous and can be repurposed as fertiliser or a construction material [

11]. Furthermore, their biodegradability reduces their long-term environmental impact, a benefit recognised by El-Araby [

10], who advocated integrating agro-waste into circular economy strategies.

2.1.4. Emissions from Co-Firing Scenarios

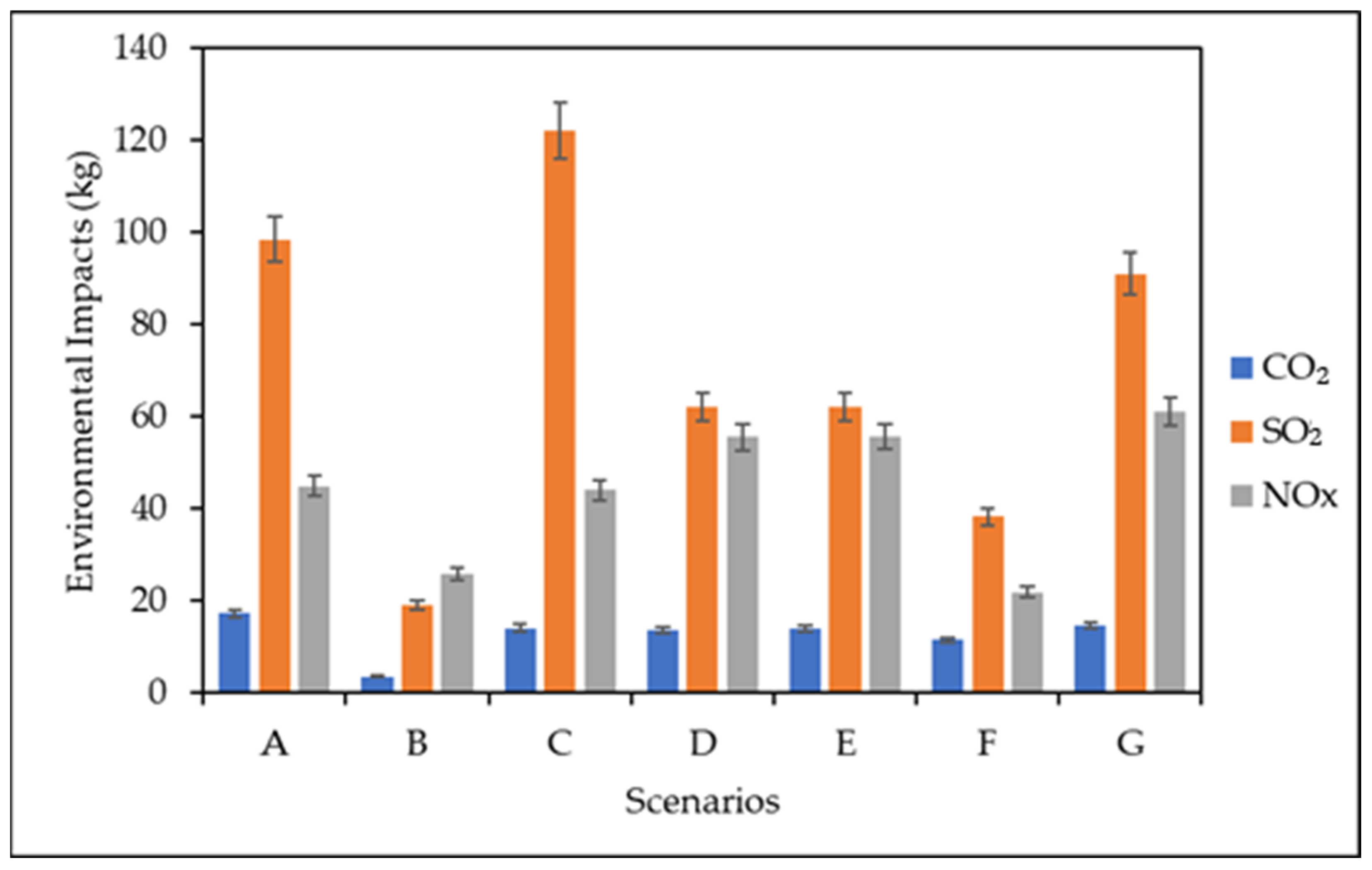

The results obtained in

Figure 4 and

Figure 5 and

Table 1 reflect a detailed assessment of CO

2, SO

2, and NOx emissions in different scenarios (A–G), as well as the overall impact in terms of global warming expressed in kg CO

2 equivalent.

Scenario B (100% rice husk) results in the lowest GWP (300 kg CO

2 eq) and overall emissions. This is due to the low natural content of carbon, sulphur, and nitrogen in rice husk, and its classification as carbon neutral. These results align with those of studies by Vasileiadou [

29] and Sofán-Germán et al. [

5], which demonstrated that rice husk combustion emits significantly fewer pollutants than coal.

Scenario C (100% coal) performs the worst across all categories, with a global warming potential (GWP) of 1200 kg CO

2 equivalent (CO

2 eq), which is over four times higher than that of Scenario B. This confirms coal’s high fossil carbon content, which aligns with the findings of Xu et al. [

13], who reported similar increases in emissions for pure coal systems.

Scenarios D to G show a progressive reduction in emissions as the biomass content increases. For example, Scenario F (15% biomass) achieves a 58% reduction in SO

2 emissions compared to Scenario C, which supports the findings of Dzikuć and Łasiński [

11] that even small amounts of biomass in the fuel mix can lead to substantial emission reductions.

Interestingly, Scenario G (20% biomass) shows a slight increase in CO

2 emissions compared to Scenario F, which could be due to increased transport impacts or operational inefficiencies in the higher-biomass blend. These nuances highlight the importance of balancing fuel composition with logistics and combustion performance, as emphasised by Nunes et al. [

12].

These results confirm that co-firing biomass and coal reduces pollutant emissions and global warming compared to coal alone. The higher biomass content in briquettes contributes significantly to the improved environmental performance, underlining the importance of promoting biomass as a sustainable alternative for power generation and climate change mitigation.

It is important to note that the combustion emissions assessed in this study were based on a prototype-scale reactor. These may differ from those of industrial-scale systems in terms of combustion efficiency, emission control technologies, and fuel handling systems. While the prototype provided accurate primary data under controlled conditions, scaling up could affect emission intensity and energy recovery performance. For example, industrial plants usually use flue gas treatment systems (e.g., electrostatic precipitators and desulphurisation units), which could significantly reduce NO_x and SO2 emissions compared to the prototype level. However, secondary datasets from Ecoinvent, representative of standard industrial operations, were integrated to complement the inventory and improve the external validity of the results. Future studies should consider using direct industrial measurements or validated scaling models to refine life cycle profiles for large-scale applications.

2.1.5. Impact Categories: Acidification, Eutrophication, and Smog Formation

In terms of acidification (kg SO

2 eq), Scenario C shows the worst performance again (164.08 kg), followed by Scenario G. Scenario B (100% rice husk) shows the lowest acidification value (41.83 kg), probably due to the minimal sulphur content of rice husks. Similar trends were observed by Doria Oviedo et al. [

14], who noted that biomass mixtures significantly reduce acidifying emissions.

Surprisingly, Scenario G has the highest eutrophication potential (10.405 kg PO

4 eq) in terms of eutrophication. This may be due to the release of nutrients from biomass ash, particularly in high-biomass blends. This finding is consistent with that of Amir et al. [

24], who observed that phosphorus-containing compounds in biomass residues can increase eutrophication potential if not managed properly. Scenario B performs best again, demonstrating that rice husk may have a more favourable nutrient profile.

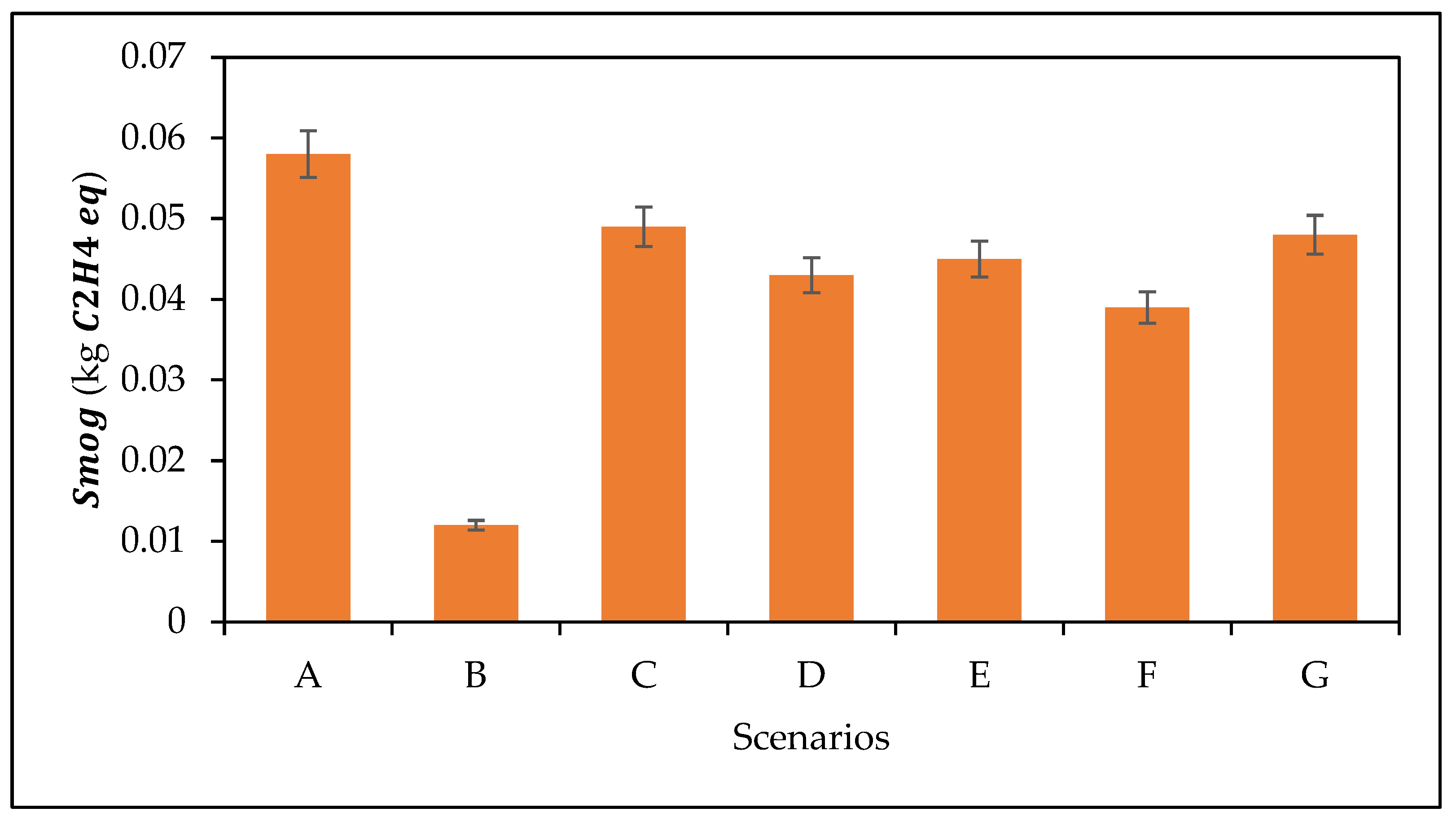

Finally, with regard to photochemical smog, Scenario A (100% coconut shell) has the highest value (0.058 kg C

2H

4 eq), while Scenario B has the lowest (0.012 kg C

2H

4 eq). This is due to the higher content of volatile organic compounds (VOCs) in coconut shell combustion. These results align with previous studies, including that of Qaisrani et al. [

26], which found that the type of biomass significantly affects the formation of smog precursors.

In general, increasing biomass content improves performance in most impact categories. However, biomass selection is important, particularly when balancing acidification versus eutrophication or smog formation. This underlines the importance of assessments that are specific to the feedstock, as emphasised by Millinger et al. [

28].

2.2. Sensitivity Analysis

The sensitivity analysis carried out in this study has now made it possible to assess how variations in two key parameters—combustion efficiency and transport distance—affect the overall environmental impact of the co-firing system.

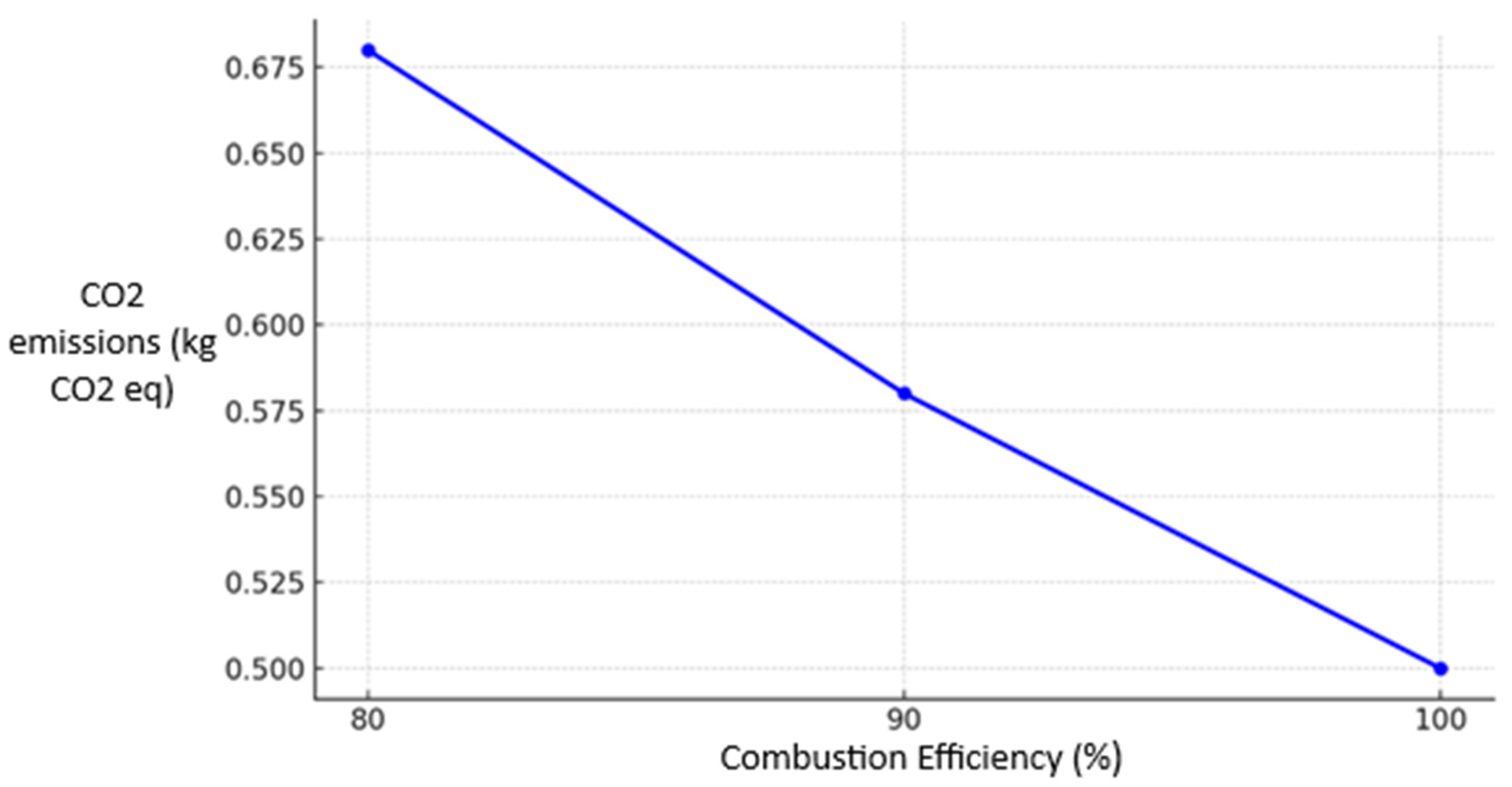

Combustion efficiency is a key determinant of the amount of energy recovered and emissions produced.

Figure 9 shows how CO

2 emissions vary according to three efficiency levels: 100% (variant X), 90% (variant Y), and 80% (variant Z).

With respect to variant X (100% efficiency), this scenario assumes almost complete combustion, with minimal generation of solid waste and gaseous emissions. It can be observed that this level of efficiency generates the lowest CO

2 emissions, reflecting a more efficient use of the energy contained in biomass and coal. Similarly, variant Y (90% efficiency) shows a slight increase in CO

2 emissions due to moderately incomplete combustion. And variant Z (80% efficiency), in this case with low efficiency, shows a significant increase in emissions due to a higher proportion of unburned fuels and the generation of residual solids. These results show that a 10% increase in combustion efficiency can reduce total CO

2 emissions by up to 15%, highlighting the importance of optimising combustion conditions to maximise the environmental sustainability of the process. Similar conclusions were drawn by Curran [

34], who emphasised that inefficient combustion leads to incomplete fuel oxidation and higher emissions.

However, the transport distance of biomass and coal has a significant impact on the climate change impact category due to the emissions generated by land transport.

Figure 10 shows how CO

2 emissions vary according to three evaluated distances: 100 km (variant A), 456 km (variant B), and 611 km (variant C).

Compared to variant A (≤100 km), this scenario, which assumes close proximity between the biomass source and the combustion plant, generates the lowest CO2 emissions per t-km. For variant B (456 km), emissions increase with increasing distance, but only moderately. Finally, for variant C (611 km), this long transport scenario has the highest impact on climate change due to the high amount of CO2 emitted during the transport of biomass and coal.

These results highlight the critical importance of biomass localisation, consistent with the conclusions of Sugiyono et al. [

30], who emphasised the carbon penalty of long-haul biomass transport in Indonesia’s energy systems. This further supports the idea that regional biomass utilisation—such as coconut and rice husks sourced locally in Córdoba—is vital for optimising co-firing sustainability.

Although a full statistical uncertainty analysis was not conducted, the combination of scenario-based sensitivity analysis and qualitative data evaluation provides a preliminary understanding of robustness. Considering the typical variation ranges reported in the literature and in LCA databases, key impact categories such as GWP could vary by approximately ±10–15%. Despite these margins, the relative differences between scenarios remain stable, particularly the superior environmental performance of Scenario B and the poor performance of Scenario C.

This suggests that the conclusions drawn from the comparative LCA are robust under reasonable uncertainty bounds, thereby reinforcing the environmental advantages of biomass co-firing, particularly when using rice husk. Future extensions to this study could involve implementing Monte Carlo simulations to quantify probabilistic confidence intervals.

Regional Limitations and Guidelines for Transferability

Although this study focuses on the Córdoba region, its conclusions may be relevant to other agro-industrial zones. However, direct extrapolation is limited by the specific biomass types (rice husk and coconut shell), transport distances (456–611 km), and regional energy infrastructure (e.g., small-scale co-firing setups).

To facilitate transferability, the following general guidelines are proposed:

Identify locally available biomass residues with comparable energy content, moisture levels, and ash composition.

Adapt the transport impact based on actual distances and logistics efficiencies (e.g., truck vs. rail).

Assess the compatibility of biomass blends with existing combustion technologies.

Consider the regulatory and environmental contexts that may affect the feasibility of co-firing, such as emission limits and waste classification.

These recommendations aim to help replicate the LCA framework in other regions while acknowledging variability in the availability of biomass resources, infrastructure, and policy environments at a local level.

2.3. Circular Economy Considerations

Although the present analysis focuses on replacing bituminous coal with agro-industrial biomass residues, the broader circular economy (CE) framework includes additional strategies that warrant consideration. The circular economy is not only about replacing virgin materials, but also about maintaining resource value within the system for as long as possible, minimising waste generation and creating closed material loops. This framework promotes achieving measurable outcomes, such as increasing resource recovery rates and material reuse, as well as reducing the amount of waste sent to landfills. These are all indicators that are increasingly being used to quantify circular performance.

One relevant opportunity is that the valorisation of combustion ash, particularly that from rice and coconut husks, contains significant levels of silica and potassium, enabling its recovery as a secondary raw material. This practice avoids landfill disposal and supports CE indicators such as material recovery rate and avoided virgin material extraction [

10,

11].

Another option is the production of biochar, which is a stable, carbon-rich solid created from biomass in the presence of limited oxygen. Biochar offers multiple circular benefits, including soil enhancement, carbon sequestration, and waste valorisation, all of which align closely with CE goals. While not included in the scenarios of this study, future work could compare the life cycle assessment (LCA) of biochar production with that of direct biomass combustion.

Furthermore, locally sourcing and utilising biomass enhances regional self-sufficiency, reduces transport emissions, and supports rural economies—core elements of territorial circularity. Implementing closed-loop logistics, whereby biomass is collected, processed, and utilised within the same agro-industrial region (e.g., Córdoba), would minimise reliance on long-distance transportation and enhance the environmental performance of the energy system.

Incorporating these additional circular strategies into the system boundaries of future LCAs would provide a more comprehensive understanding of how biomass co-firing contributes to a truly circular energy transition.

Furthermore, integrating agro-industrial residues into the energy mix diverts materials from traditional disposal routes. Based on regional production data, reusing 3200 tonnes of rice husk and around 600 tonnes of coconut shells each year could prevent over 3800 tonnes of biomass from reaching landfill sites. This improves CE performance by quantifying avoided landfill input and promoting biological resource cycling. Future studies could include explicit circularity indicators, such as the Material Circularity Indicator (MCI) or resource recovery efficiency, to further improve CE assessments.

3. Materials and Methods

3.1. Goal, Delimitation, and Assumptions

This study presents a case study of the department of Córdoba, Colombia, which is characterised as an agro-industrial region due to its high crop production, and where there is a high generation of waste resulting from this practice [

5]. Life cycle assessment (LCA) is a standardised methodology that assesses the environmental impacts associated with a product, process, or service throughout its life cycle, from the extraction of raw materials to final disposal (‘cradle to grave’) [

34]. This study applies a partial cradle-to-grave LCA approach to analyse the environmental impacts of co-firing agro-industrial waste (coconut husk and rice husk) and bituminous coal in a combustion reactor at a prototype level, considering all stages from extraction and transport of inputs to thermal energy generation and waste management.

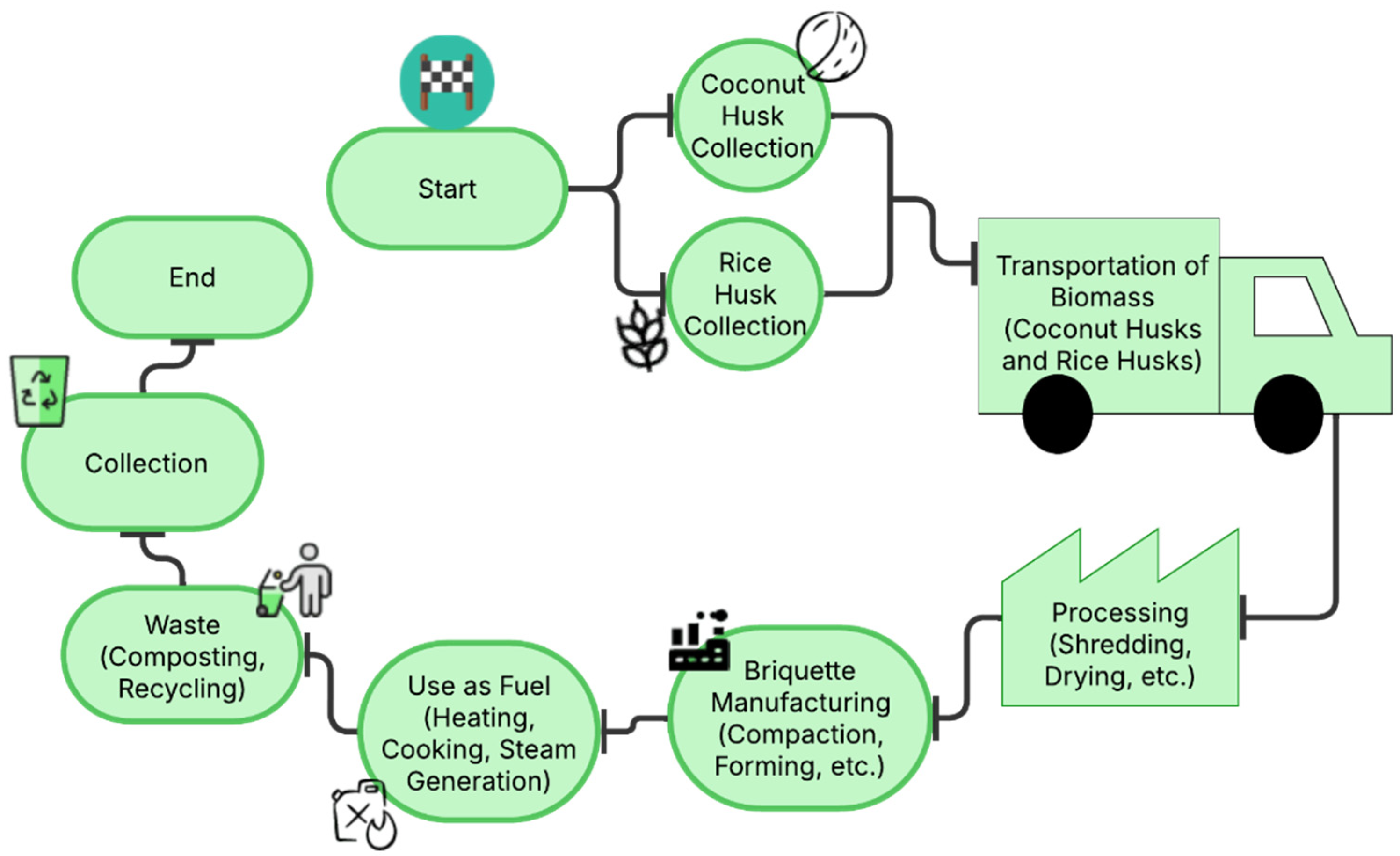

An illustration in

Figure 11 provides a detailed description of the system boundaries, clearly delineating the cradle-to-gate processes included in this analysis.

The system boundary includes the following key stages: the extraction and transport of energy inputs, including both biomass (agro-industrial waste) and bituminous coal; the processing and blending of the fuels in different proportions prior to combustion; the co-firing process in industrial boilers, which includes the monitoring of gaseous emissions and the generation of solid waste such as ash; and the management of emissions and treatment of by-products from the process.

The functional unit chosen for this study is the production of 1 MJ of thermal energy in the co-firing system. This choice is intended to standardise comparisons between the different biomass and coal mix scenarios, ensure methodological consistency, and facilitate the interpretation of results in line with best practice in life cycle assessment (LCA).

The analysis is based on the following key assumptions: The biomass used is an agro-industrial by-product without additional pre-treatment; the transport distances considered are 611 km (Ocaña–Montería) and 456 km (Medellín–Montería), depending on the origin of the agro-industrial waste and the bituminous coal; emissions and effluents, such as CO2, NOx, SOx, particulates, and ash, are assumed to be measured directly in the combustion reactor and supplemented with secondary data from databases such as Ecoinvent; and the average thermal efficiency of the process is included, using a mass-based attribution approach to allocate environmental impacts in the fuel mixes.

In order to assess how the environmental impact varies according to the proportion of biomass and coal in the mix, seven scenarios have been defined, as shown in

Table 3.

The scope of the system excludes post-combustion processes such as off-site final ash disposal, by-product refining, or industrial wastewater management. These processes have been excluded due to their small relative contribution to the overall environmental impact of the energy system assessed. In addition, the analysis considers the energy consumption of auxiliary processes at the incinerator, such as ventilation, gas filtration systems, and environmental monitoring. Continuous operation of the plant is assumed for a standard annual period of 252 days, with a working day of 8 h per day.

Although post-combustion processes such as off-site ash disposal and flue gas treatment are excluded from the main system boundary, their omission is justified on the basis of several considerations. First, this study focuses on a prototype-scale system where post-combustion treatment is limited and not representative of industrial-scale technologies. Second, multiple studies have shown that the relative contribution of ash management and flue gas treatment to the overall life cycle impact of co-firing systems is generally low compared to upstream stages such as fuel extraction and combustion [

28,

34].

Nonetheless, to assess the potential influence of these excluded processes, a qualitative sensitivity estimation was performed based on emission control data from comparable LCA studies. For instance, flue gas treatment in coal-fired systems has been reported to contribute up to 5–8% of total GWP impacts, while ash disposal contributes less than 2% under most operational scenarios [

13,

30]. Therefore, even if included, the expected variation in total environmental impact would likely remain within a margin of ±10%. This reinforces the robustness of this study’s conclusions, while acknowledging the importance of these processes in full-scale systems.

Future work could incorporate a detailed inventory of post-combustion systems, especially when scaling up to commercial implementations, to further refine the environmental profile of biomass–coal co-firing.

3.2. Evaluated Scenarios and Sensitivity Analysis

This study evaluates the co-firing process using a combustion reactor where waste biomass is used together with bituminous coal in different scenarios. The evaluation of co-firing in this study focuses on analysing how the proportions of waste biomass (coconut husk and rice husk) and bituminous coal influence the environmental impacts. Based on the scenarios previously defined in

Table 1, this part of the analysis includes a number of technological variants and a sensitivity analysis to identify potential environmental hotspots and to assess the robustness of the results to changes in key parameters.

Sensitivity analysis is an important tool in environmental and engineering studies, designed to assess how variations in key parameters can affect the overall outcomes of the system under analysis [

35]. Its main purpose is to understand and quantify the extent to which changes in process efficiency, energy recovery, and input transport distance can alter the environmental impacts associated with a particular process or technology. First, process efficiency plays a central role as it determines the ability of the system to recover valuable materials and energy during the different stages of treatment or recycling. If this efficiency is high, the system can maximise the recovery of reusable secondary materials, such as metals or critical compounds, reducing the reliance on virgin raw materials and thus reducing the amount of waste sent to landfill. This efficient recovery helps to mitigate environmental problems such as soil and air pollution and reduces the impacts associated with the extraction and processing of natural resources. Conversely, a decrease in efficiency would lead to an increase in the amount of waste generated, increasing the negative environmental impacts and limiting the benefits of recycling.

In addition, the sensitivity analysis examines how energy recovery affects the environmental performance of the system. Efficient energy recovery from processes such as waste incineration or energy recovery can significantly reduce the overall carbon footprint by reducing the need for energy from fossil sources. This is particularly relevant in scenarios where the recovered energy can be used directly in the system itself, closing cycles and promoting a circular economy approach. On the other hand, if the energy recovery efficiency is low, the system will require more external energy input, which would increase greenhouse gas emissions and other pollutants associated with fossil energy consumption.

Another critical factor that the sensitivity analysis seeks to assess is the impact of input transport distance on the environmental performance of the system. Transporting materials, especially over long distances, can significantly increase emissions of carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM), exacerbating the system’s contribution to climate change and air pollution. Varying transport distances can therefore have a significant impact on the environmental balance, especially if efficient means of transport are not used or if journeys involve high fossil fuel consumption.

Sensitivity analysis then identifies which of these parameters have the greatest influence on environmental impact and how they could be optimised to improve overall system performance. By providing this critical information, the analysis guides decision-making to maximise the sustainability and efficiency of the process being assessed. It also allows for researchers and process designers to anticipate possible future scenarios, evaluate impact mitigation strategies and prioritise the most environmentally effective improvements. Finally, this tool is particularly valuable in a context of uncertainty, as it helps to assess the robustness of the results obtained and to determine whether the conclusions of the study remain consistent in the face of variations in the parameters analysed. Overall, sensitivity analysis is an essential component in designing more sustainable, efficient, and resilient systems in the face of possible variations in operating conditions or the external environment.

3.2.1. Sensitivity Analysis 1 (SA1): Co-Firing Efficiency

Combustion efficiency is a critical factor affecting the amount of energy recovered and the emissions produced during the process. This analysis includes three technology variants that assess the impact of efficiency on environmental sustainability:

Variant X: High efficiency (100%), assuming almost complete combustion with maximum energy recovery and minimum emissions and ash.

Variant Y: Moderate efficiency (90%) with slightly lower energy recovery and moderate increase in NOx, SOx, and CO2 emissions.

Variant Z: Low efficiency (80%) resulting in higher gaseous emissions and residual solids due to incomplete combustion.

This analysis identifies the sensitivity of the system to variations in operating efficiency and highlights the potential for improvement by optimising combustion conditions.

Co-firing bituminous coal with agro-industrial biomass directly affects combustion efficiency and pollutant emissions. Biomass typically has a higher volatile content and lower sulphur concentration than coal, which can increase the burnout rate and reduce SO2 and CO2 emissions. However, if not properly controlled, the high moisture content and lower energy density of biomass may reduce flame temperature, potentially lowering overall thermal efficiency and increasing the production of incomplete combustion by-products (e.g., CO and unburned hydrocarbons). These changes in combustion behaviour can also affect NO_x generation, as this is sensitive to temperature and oxygen availability.

Furthermore, co-firing can lead to heterogeneous fuel mixing, impacting residence time and flame stability, particularly at higher biomass fractions (>20%). These effects were observed in Scenario G, which showed a slight increase in CO2 emissions possibly linked to combustion inefficiencies. Although industrial facilities often deploy flue gas treatment systems (e.g., SCR and ESP), such post-treatment processes were excluded from the LCA due to the prototype scale and limited operational scope of this study. Nevertheless, the results suggest that, even with modest biomass fractions (10–15%), co-firing can reduce key pollutants while maintaining acceptable efficiency, particularly when combustion parameters are optimised.

3.2.2. Sensitivity Analysis 2 (AS2): Transport Distance

The transport of biomass and coal from their point of origin to the co-firing plant has a significant impact on the carbon footprint of the system. This sensitivity analysis assesses how the environmental results vary when transport distances are modified, considering the following cases:

Variant A: Short transport (≤100 km), which assumes that the biomass source is close to the combustion plant.

Variant B: Medium transport (456 km), which is the approximate distance between Medellín and Montería.

Variant C: Long transport (611 km), corresponding to the distance between Ocaña and Montería.

This assessment highlights the impact of transport on the life cycle of the energy system and the need to consider the location of biomass sources in order to maximise the environmental benefits of co-firing.

3.2.3. Constraints and Optimistic Scenarios

The scenarios and variants analysed in this study assume optimistic conditions that maximise energy efficiency and minimise emissions. This approach allows for an upper limit to be placed on the potential environmental benefits of co-firing biomass and coal. However, it is important to recognise that under actual conditions, efficiencies could be lower and emissions higher, which could affect the overall environmental results.

The sensitivity analysis complements this optimistic assessment by showing how specific adjustments to key parameters (such as efficiency and transport distance) can significantly affect the environmental performance of the system.

3.3. Life Cycle Assessment Approach

The life cycle analysis was carried out using a gate-to-gate approach using SimaPro software version 9.5.0.0.0 and the Ecoinvent 3.9 database under the cut-off approach. This approach considers only the stages from extraction and transport of inputs to the co-combustion phase, excluding post-combustion processes such as final ash disposal or wastewater treatment.

To assess the environmental impact, the ReCiPe 2016 method was used in its hierarchical version (H), which allows for the analysis of key categories such as climate change, freshwater eutrophication, and mineral and metal resource use.

3.3.1. Environmental Impact Categories—EICs

The selected environmental impact categories focus on assessing the key impacts of co-firing in terms of climate change, eutrophication, and depletion of mineral and metal resources. These categories were chosen for their relevance to the sustainability of the energy system under consideration and their alignment with regulatory and industry priorities.

3.3.2. Climate Change

To assess climate change impacts, the Intergovernmental Panel on Climate Change (IPCC) characterisation model was used, which calculates the 100-year global warming potential (GWP100), expressed in kilograms of carbon dioxide equivalent (kg CO2 eq). This indicator measures direct emissions to the atmosphere and their impact on global warming, taking into account emissions to different compartments such as ground-level urban air, the lower stratosphere, and the upper troposphere.

3.3.3. Freshwater Eutrophication

Eutrophication of freshwater ecosystems measures the degree of nutrient over-enrichment, mainly due to emissions of phosphorus-containing compounds. This process is related to the effects of excess macronutrients in air, water, and soil and quantifies the impact of these emissions in freshwater bodies where phosphorus is a limiting factor.

3.3.4. Resource Use: Minerals and Metals

This category assesses the use of non-fossil natural resources, specifically minerals and metals. The impact is measured using the Abiotic Depletion Factor (ADF), which calculates the relative depletion of each resource based on its concentration in reserves and its extraction rate, expressed in kilograms of antimony equivalent (kg Sb eq).

3.4. Inventory Data and Process Modelling

The processes included in the LCA were carefully selected to accurately represent the material flows, energy inputs, and emissions specific to the system under study. The modelling is based on primary data collected at the co-firing plant and secondary data from the Ecoinvent 3.9 database. These processes have been adapted to reflect the specific conditions of this study and to ensure methodological consistency. The processes selected from the LCA were modelled to accurately reflect the inputs and outputs of the system under study.

Table 4 shows the main processes extracted from the Ecoinvent 3.9 database and used in the LCA.

3.5. Data Quality and Uncertainty Considerations

This study uses both primary and secondary data sources to model the co-firing system. Primary data were obtained from combustion experiments and emission monitoring in a pilot-scale reactor, while secondary data were sourced from the Ecoinvent 3.9 database on the SimaPro 9.5 platform. While these secondary datasets are widely recognised and peer-reviewed, they do include inherent variability in geographical, technological, and temporal representativeness.

To address potential concerns regarding the quality of the data, a qualitative uncertainty assessment was conducted based on literature values and metadata provided by Ecoinvent. Key contributors to uncertainty include the following:

Variability in the measurement of gaseous emissions (CO2, NOx, and SOx).

Assumptions regarding transport distances and vehicle types.

Estimation of combustion efficiency based on typical ranges from technical literature.

Process allocation choices and the age of data in secondary sources.

Probabilistic uncertainty modelling (e.g., Monte Carlo simulation) was not applied in this study due to constraints in scope and data availability. However, a scenario-based sensitivity analysis (see

Section 3.2) was conducted to evaluate the impact of key parameters on environmental outcomes. Further studies could enhance robustness by integrating full statistical uncertainty analysis or pedigree-based scoring to assess data reliability.

4. Conclusions

This study used a life cycle assessment (LCA) approach to assess the environmental performance of co-firing bituminous coal with agro-industrial biomass waste (coconut husk and rice husk). Seven scenarios with varying biomass-to-coal ratios were evaluated under cradle-to-gate boundaries using the ReCiPe 2016 method. The key conclusions are as follows:

Scenario B (100% rice husk) achieved the best overall environmental performance, with the lowest values for global warming potential (300 kg CO2 eq), eutrophication (4.742 kg PO4 eq), and photochemical smog formation (0.012 kg C2H4 eq).

Scenario F (15% biomass blend) recorded the lowest acidification potential (57.39 kg SO2 eq), demonstrating that even partial substitution can yield significant environmental benefits.

In contrast, Scenario C (100% coal) exhibited the highest impacts in all categories, confirming the environmental burden of coal combustion.

The sensitivity analysis showed that increasing combustion efficiency by 10% could reduce CO2 emissions by up to 15%, and that transport distances significantly influence the carbon footprint. This reinforces the importance of sourcing biomass locally.

While this study focused on input substitution, additional circular economy strategies, such as ash reuse and closed-loop logistics, offer further potential to enhance system sustainability.

Overall, the results confirm that co-firing agro-industrial biomass with coal can effectively reduce environmental impacts and support the transition towards circular, low-carbon energy systems, particularly in regions with abundant biomass residues, such as Córdoba in Colombia.

These findings provide decision-makers with a scientific basis on which to consider co-firing as a viable strategy for cleaner energy production, while promoting the valorisation of agricultural waste and enhancing regional sustainability.