Sustainability and Innovation: Incorporating Waste from Ophthalmic Lenses into Natural Rubber Composites

Abstract

1. Introduction

2. Results and Discussion

2.1. Evaluation of Rheometric Properties

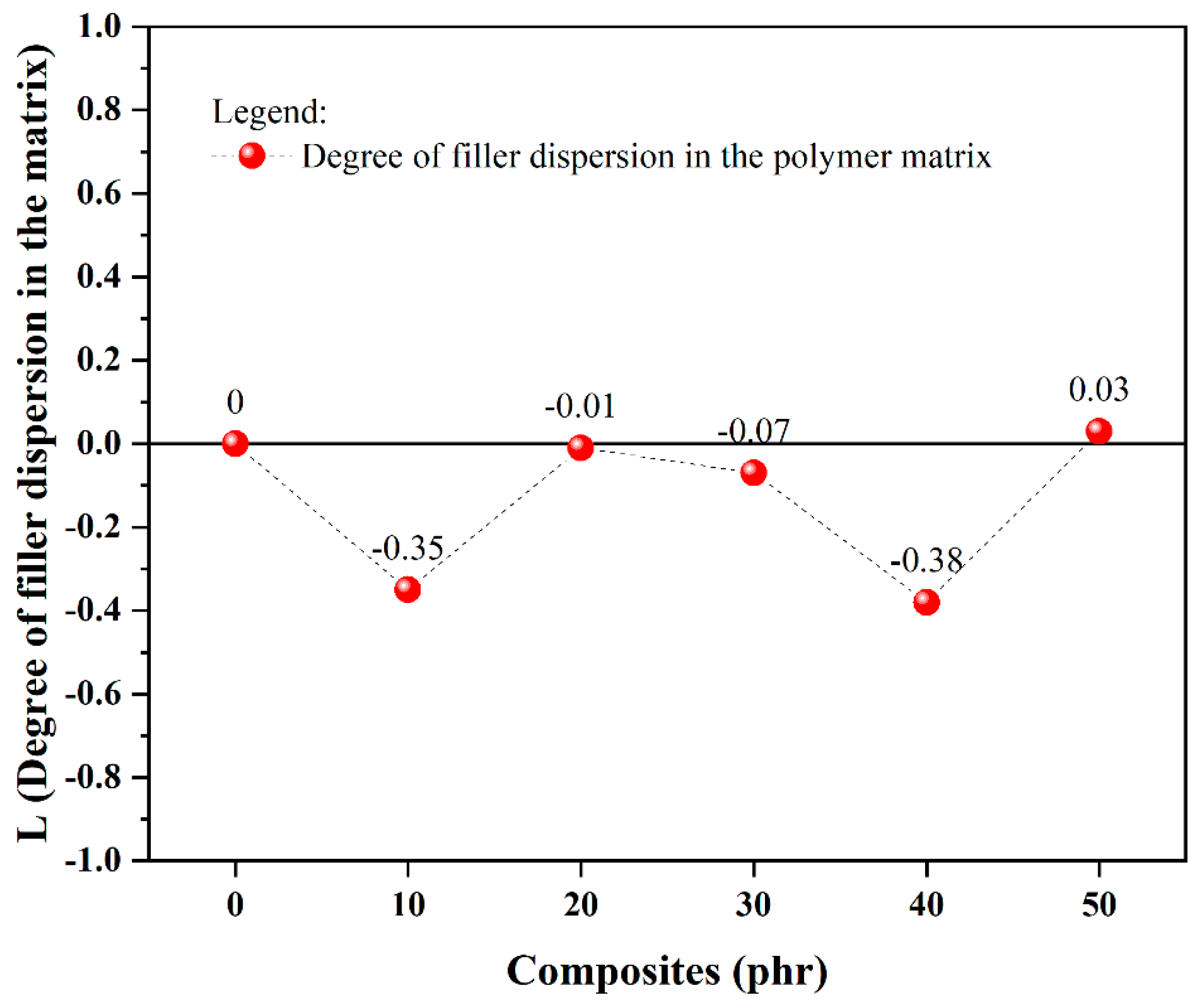

2.2. Analysis of the Dispersion Degree of OLW Fillers in the NR Matrix

2.3. Analysis of Scanning Electron Microscopy (SEM)

2.4. Evaluation of XRF Data for the Ophthalmic Lens Residue

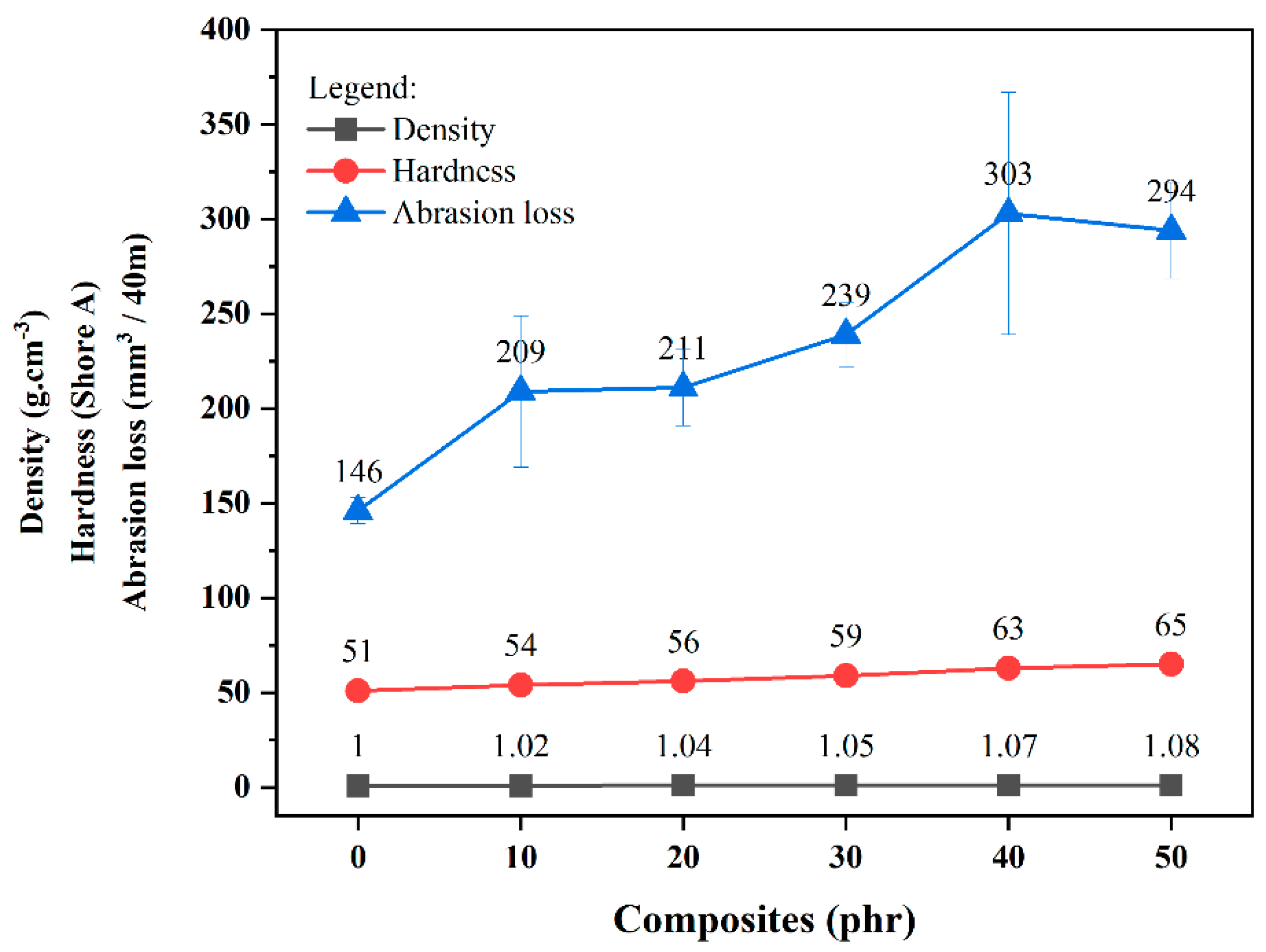

2.5. Analysis of the Density, Hardness, and Abrasion Loss of NR/OLW Composites

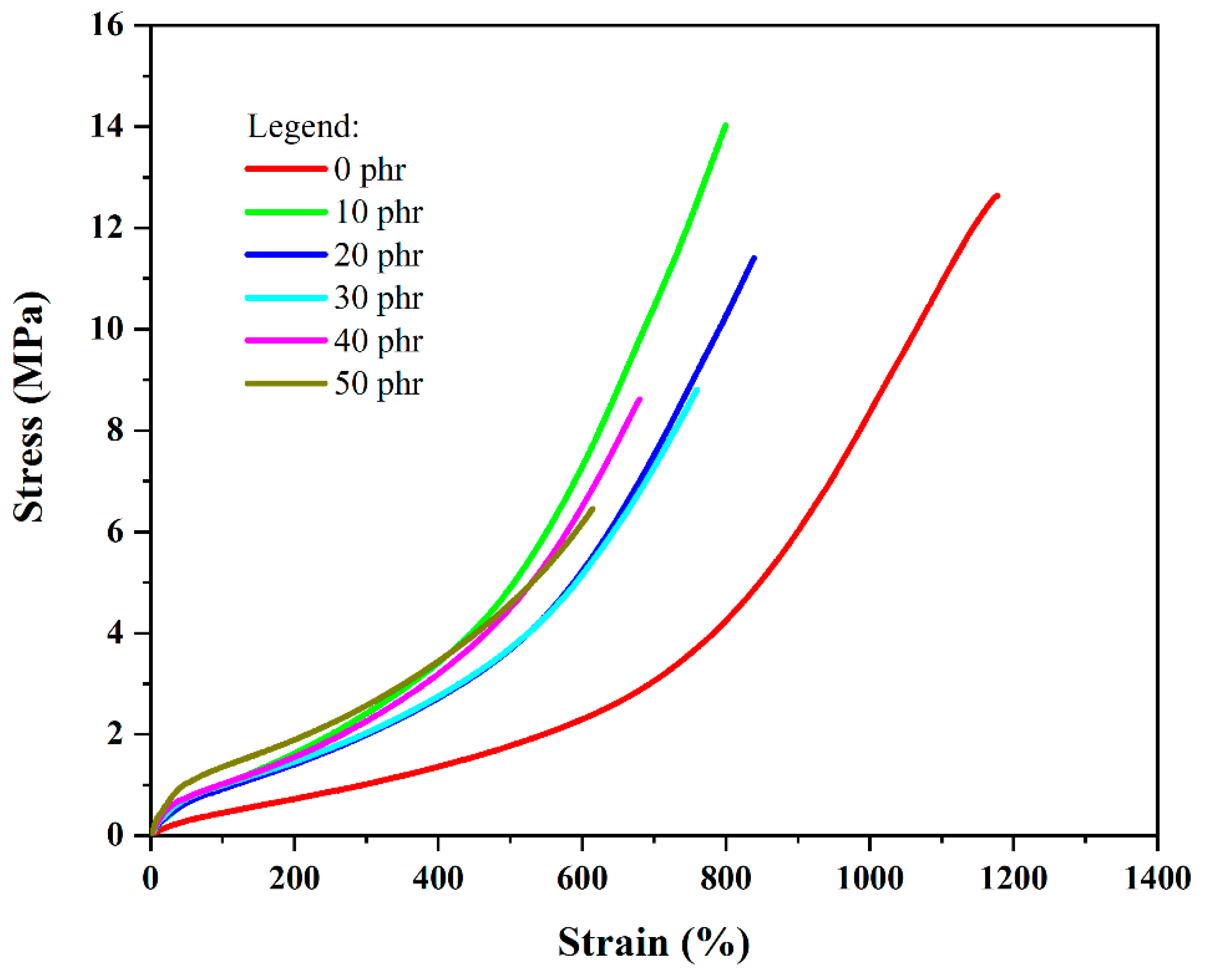

2.6. Assessment of the Mechanical Behavior Under Tension of NR/OLW Composites

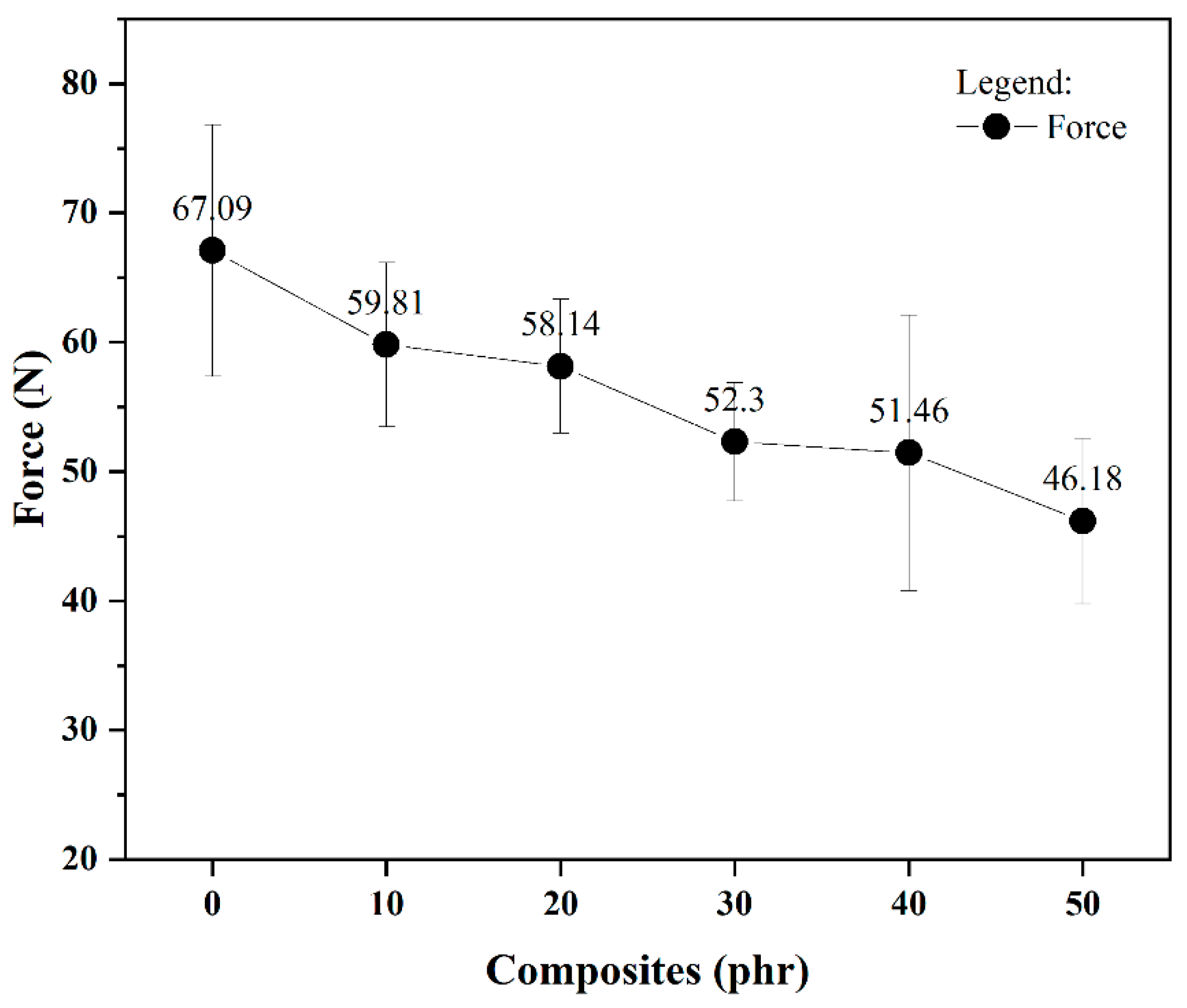

2.7. Assessment of the Tear Strength in NR/OLW Formulations

2.8. Determination of Network Chain Density via Swelling in Organic Medium—Flory–Rehner Approach

2.9. Determination of Crosslink Density Through Tensile Strength Tests—Mooney–Rivlin Approach

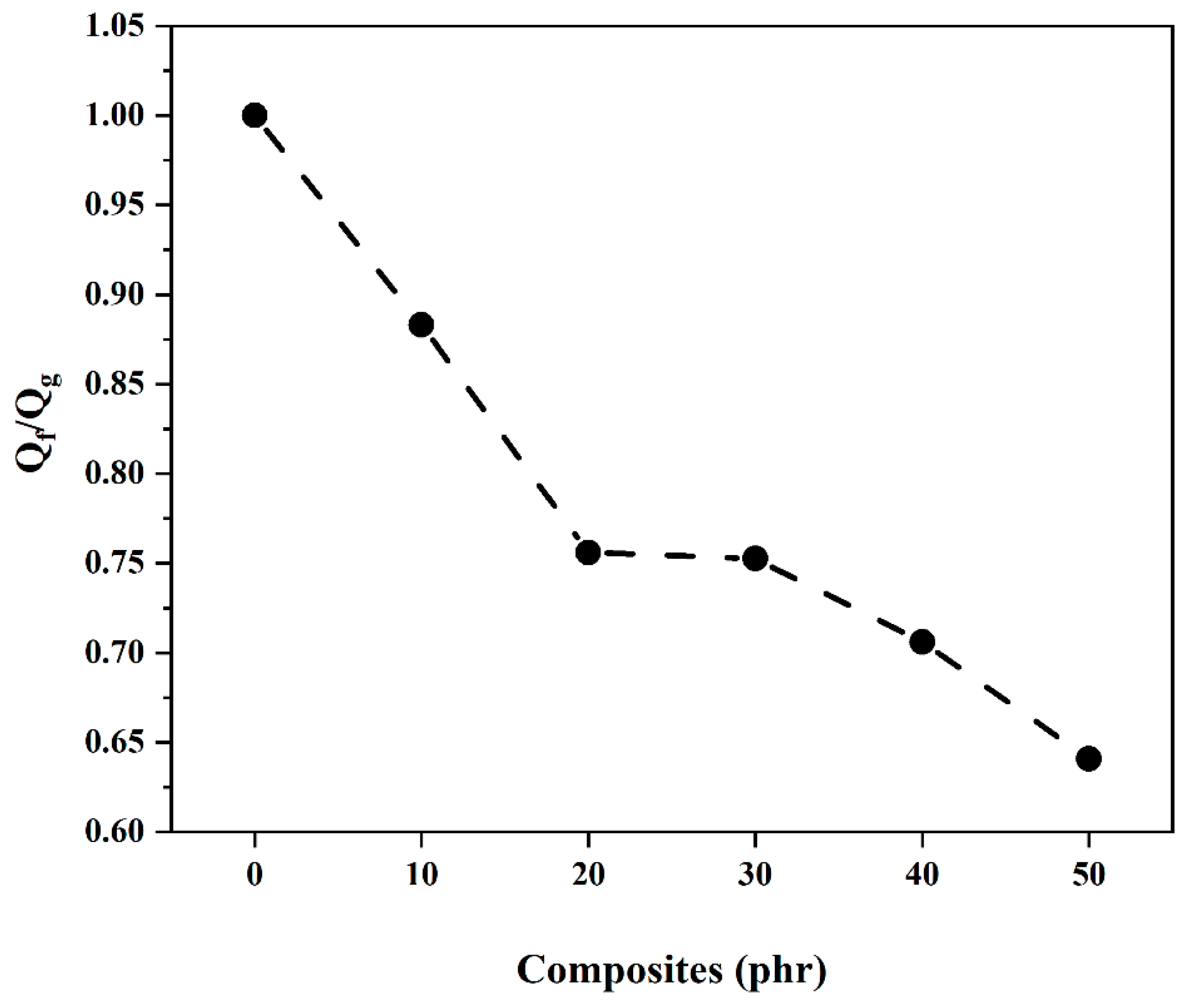

2.10. Investigation of Interfacial Interaction Using the Lorenz–Parks Approach

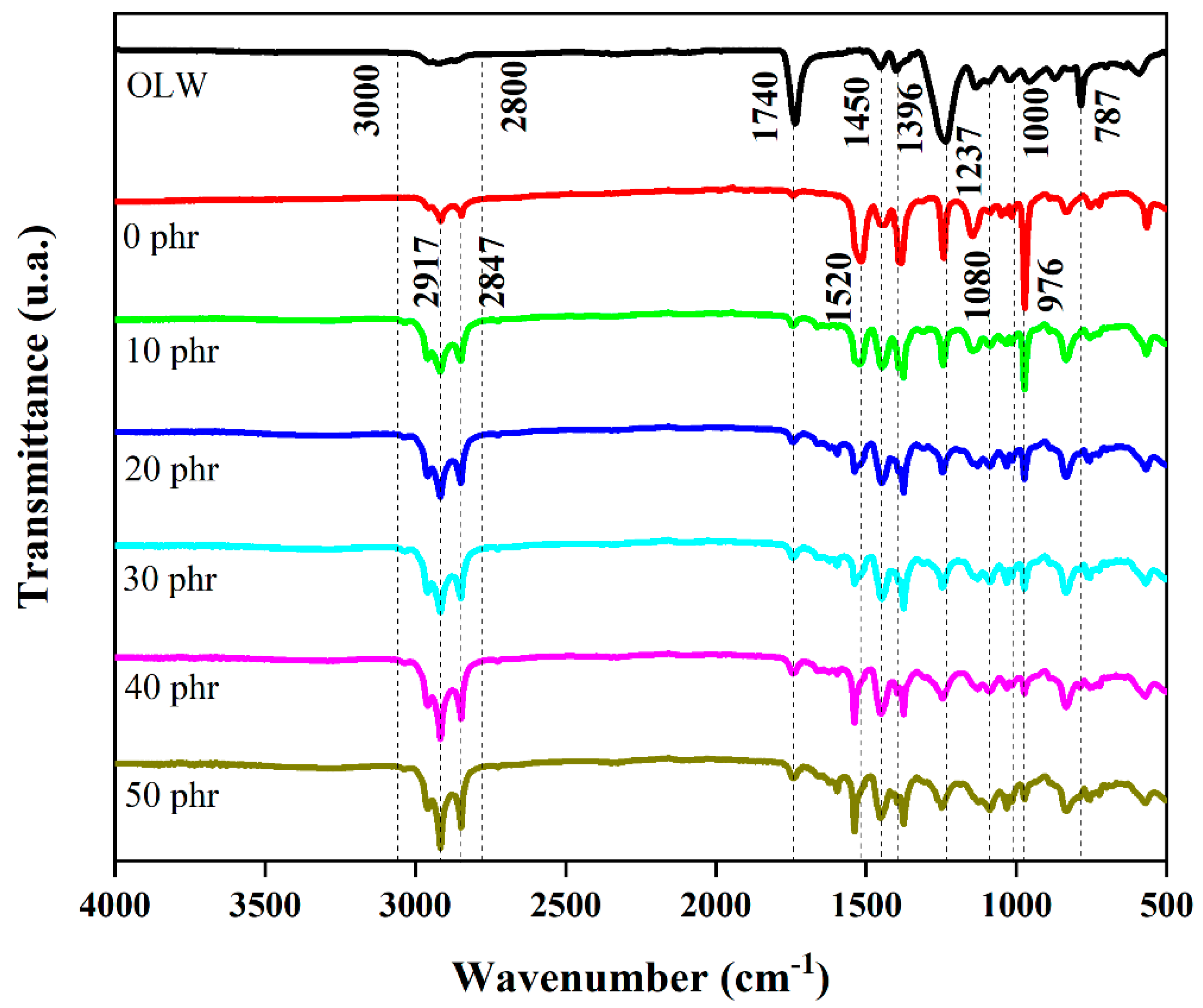

2.11. Analysis of Fourier-Transform Infrared Spectra in ATR Mode

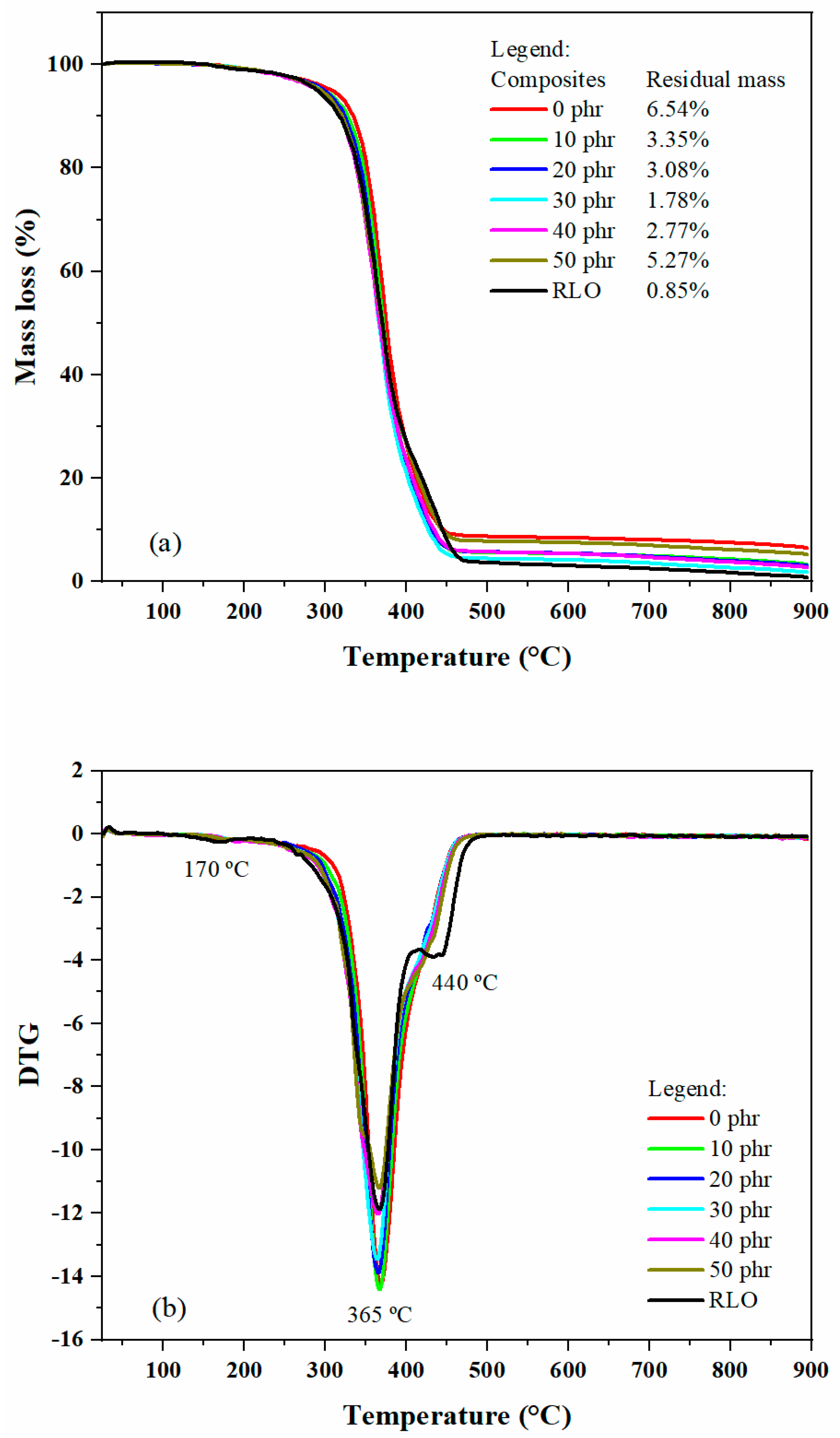

2.12. Analysis of Mass Loss by Thermogravimetry (TGA)

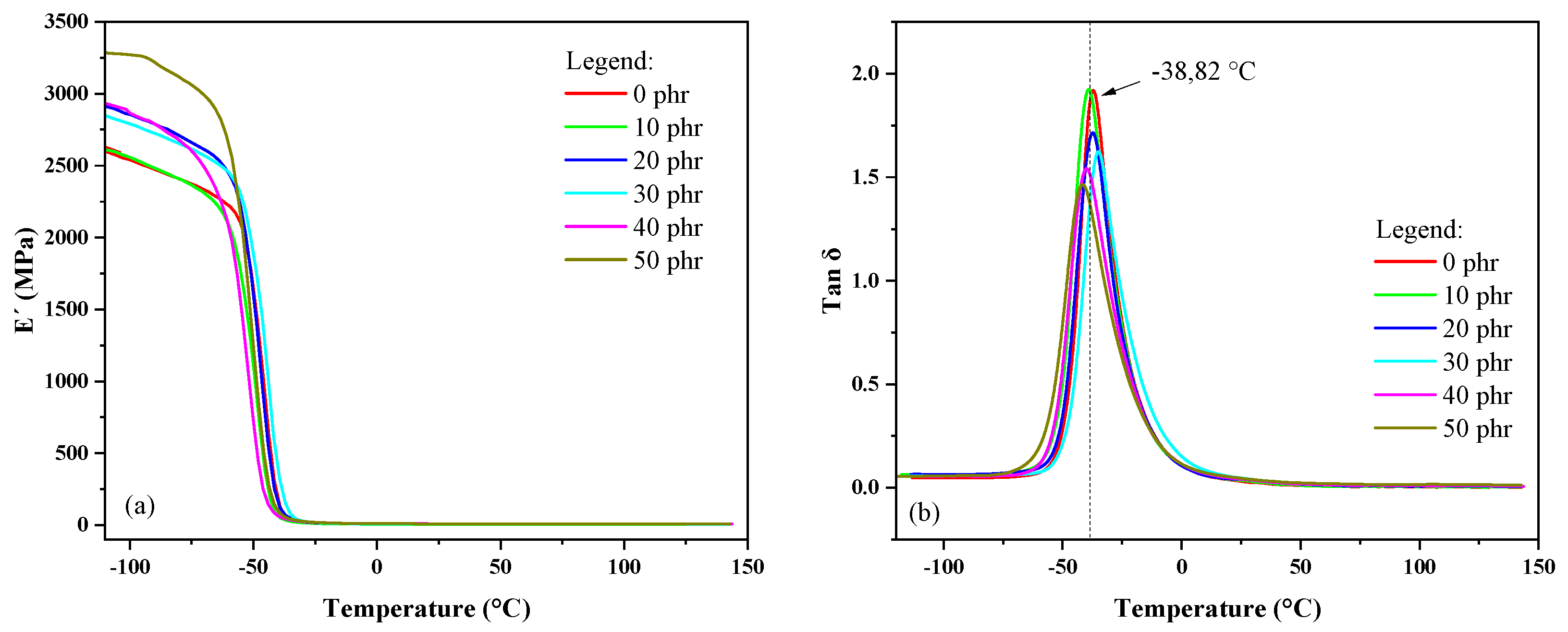

2.13. Dynamic Mechanical Analysis (DMA)

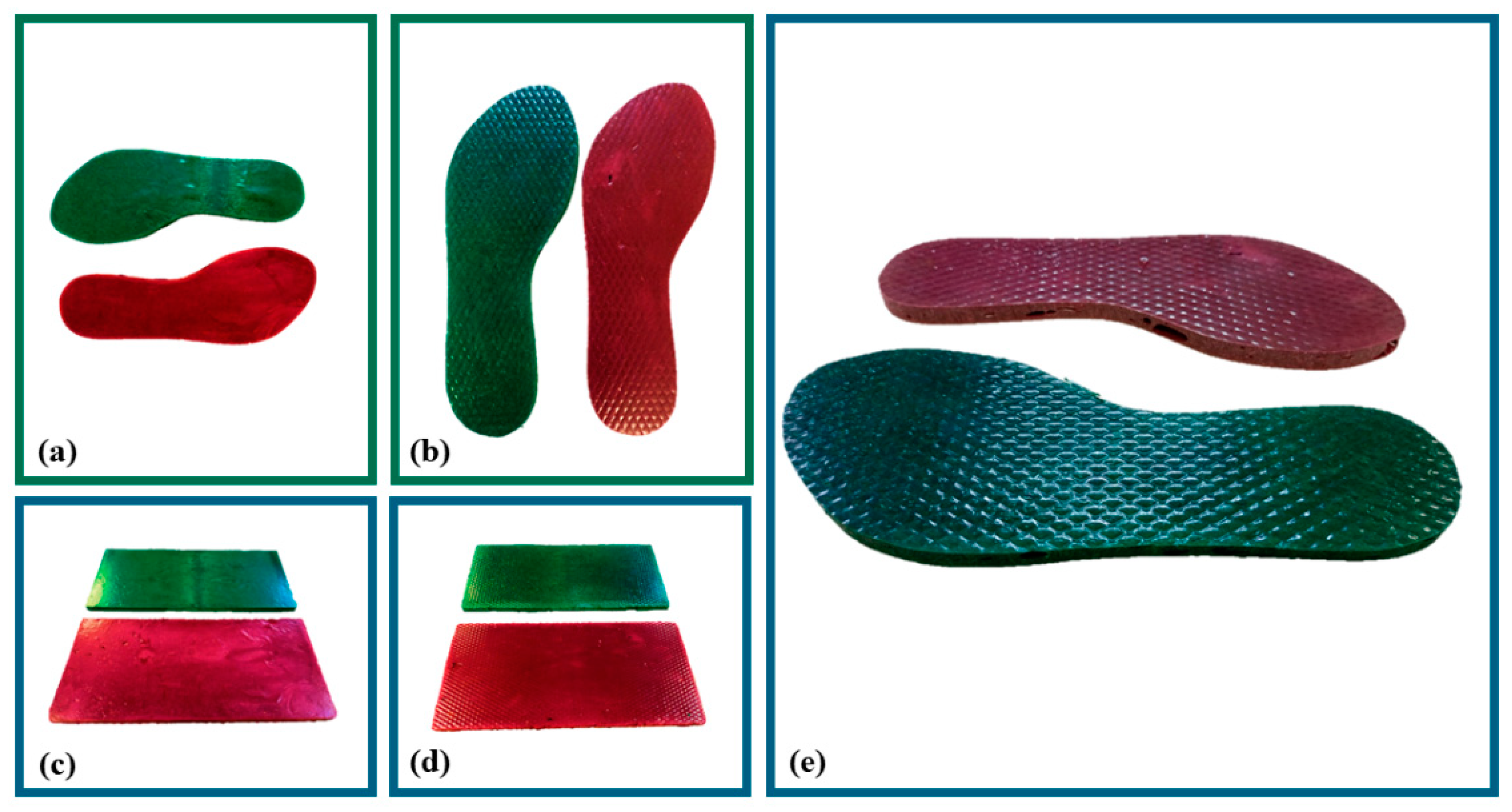

3. Application of the New NR/OLW Composite

4. Experimental Section

4.1. Material

Development of the Composites

4.2. Methodology for Characterization of the Composites

4.2.1. Characterization of Rheological Parameters

4.2.2. Analysis of the Degree of Dispersion of Fillers in Natural Rubber

4.2.3. Analysis by Scanning Electron Microscopy (SEM)

4.2.4. Measurement of Composite Density

4.2.5. Analysis of Crosslink Density in the Composites

4.2.6. Study of X-Ray Fluorescence of the Composites

4.2.7. Infrared Spectroscopy with Fourier Transform (FTIR) Examination

4.2.8. Tensile and Tear Strength Testing of the Composites

4.2.9. Hardness Evaluation of the Composite

4.2.10. Evaluation of Frictional Resistance of the Composites

4.2.11. Investigation of the Compatibility Between Natural Rubber and Ophthalmic Lens Waste Based on the Lorenz–Parks Approach

4.2.12. Thermogravimetric Study (TGA) of the Composites

4.2.13. Study of Dynamic Mechanical Analysis (DMA)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber composites filled with crop residues as an alternative to vulcanizates with common fillers. Polymers 2019, 11, 972. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, R.J.; Agostini, D.L.d.S.; Cabrera, F.C.; dos Reis, E.A.P.; Ruiz, M.R.; Budemberg, E.R.; Teixeira, S.R.; Job, A.E. Sugarcane bagasse ash: New filler to natural rubber composite. Polímeros 2014, 24, 646–653. [Google Scholar] [CrossRef]

- Bacarin, G.B.; Dognani, G.; dos Santos, R.J.; Meirelles, M.G.; Rodrigues, T.F.; Klauck, C.R.; Rodrigues, M.A.S.; Jahno, V.D.; Cabrera, F.C.; Job, A.E. Natural rubber composites with Grits waste from cellulose industry. J. Mater. Cycles Waste Manag. 2020, 22, 1126–1139. [Google Scholar] [CrossRef]

- Sareena, C.; Ramesan, M.T.; Purushothaman, E. Utilization of peanut shell powder as a novel filler in natural rubber. J. Appl. Polym. Sci. 2012, 125, 2322–2334. [Google Scholar] [CrossRef]

- Sowińska-Baranowska, A.; Maciejewska, M. Potential Utilization of Ground Eggshells as a Biofiller for Natural Rubber Biocomposites. Materials 2023, 16, 2988. [Google Scholar] [CrossRef] [PubMed]

- Batista, S.S.; de Souza, L.G.M.; Bezerra, D.M.d.L.; Neto, R.V.P. Viabilities for obtaining, manufacturing and applying composites using bamboo powders and ophthalmic lens waste. Res. Soc. Dev. 2020, 9, e775997455. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Gennaro, E.M.; de Souza, G.H.B.; Souza, D.d.S.; Kawall, S.A.; Hiranobe, M.F.; Salmazo, L.O.; Pérez, M.A.R.; Gil, A.L.; Nascimento, E.S.; et al. Green Rubber Technology: The Potential of Ophthalmic Lens Waste as a Filler in Styrene–Butadiene Rubber-Based Composites. Materials 2025, 18, 1842. [Google Scholar] [CrossRef]

- Najam, M.; Hussain, M.; Ali, Z.; Maafa, I.M.; Akhter, P.; Majeed, K.; Ahmed, A.; Shehzad, N. Influence of silica materials on synthesis of elastomer nanocomposites: A review. J. Elastomers Plast. 2020, 52, 747–771. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the crosslink characteristics and mechanical properties of natural rubber compound via accelerators and reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef] [PubMed]

- Hiranobe, C.T.; Ribeiro, G.D.; Torres, G.B.; dos Reis, E.A.P.; Cabrera, F.C.; Job, A.E.; Paim, L.L.; dos Santos, R.J. Cross-linked density determination of natural rubber compounds by different analytical techniques. Mater. Res. 2021, 24, e20210041. [Google Scholar] [CrossRef]

- Rooj, S.; Das, A.; Heinrich, G. Tube-like natural halloysite/fluoroelastomer nanocomposites with simultaneous enhanced mechanical, dynamic mechanical and thermal properties. Eur. Polym. J. 2011, 47, 1746–1755. [Google Scholar] [CrossRef]

- Schieppati, J.; Schrittesser, B.; Wondracek, A.; Robin, S.; Holzner, A.; Pinter, G. Temperature impact on the mechanical and fatigue behavior of a non-crystallizing rubber. Int. J. Fatigue 2021, 144, 106050. [Google Scholar] [CrossRef]

- He, S.; Hu, J.; Zhang, C.; Wang, J.; Chen, L.; Bian, X.; Lin, J.; Du, X. Performance improvement in nano-alumina filled silicone rubber composites by using vinyl tri-methoxysilane. Polym. Test. 2018, 67, 295–301. [Google Scholar] [CrossRef]

- Santos, R.J.; Hiranobe, C.T.; Dognani, G.; Silva, M.J.; Paim, L.L.; Cabrera, F.C.; Torres, G.B.; Job, A.E. Using the Lorenz–Park, Mooney–Rivlin, and dynamic mechanical analysis relationship on natural rubber/leather shavings composites. J. Appl. Polym. Sci. 2022, 139, 51880. [Google Scholar] [CrossRef]

- Al-HarbI, F.A.; Abdel-Halim, M.S.; Gad, M.M.; Fouda, S.M.; Baba, N.Z.; AlRumaih, H.S.; Akhtar, S. Effect of nanodiamond addition on flexural strength, impact strength, and surface roughness of PMMA denture base. J. Prosthodont. 2019, 28, e417–e425. [Google Scholar] [CrossRef]

- Kaur, J.; Sharma, J.P.; Singh, N.; Pathak, D.; Guleria, N.; Singh, P.K.; Sharma, P.K. Improvement in optical absorption and emission characteristics of polymethyl methacrylate in solution cast polymethyl methacrylate/polyvinyl carbazole polyblends. J. Thermoplast. Compos. Mater. 2023, 36, 3260–3269. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Waesateh, K.; Masa, A.; Ismail, H. Halloysite nanotubes filled natural rubber composites: Functionality, crystallinity and thermal studies. J. Eng. Sci. 2019, 15, 1–10. [Google Scholar] [CrossRef]

- Rolere, S.; Liengprayoon, S.; Vaysse, L.; Sainte-Beuve, J.; Bonfils, F. Investigating natural rubber composition with Fourier Transform Infrared (FT-IR) spectroscopy: A rapid and non-destructive method to determine both protein and lipid contents simultaneously. Polym. Test. 2015, 43, 83–93. [Google Scholar] [CrossRef]

- Nikolaidis, A.K.; Achilias, D.S. Thermal degradation kinetics and viscoelastic behavior of poly (methyl methacrylate)/organomodified montmorillonite nanocomposites prepared via in situ bulk radical polymerization. Polymers 2018, 10, 491. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Inaba, A.; Brown, J.E.; Hatada, K.; Kitayama, T.; Masuda, E. Effects of weak linkages on the thermal and oxidative degradation of poly (methyl methacrylates). Macromolecules 1986, 19, 2160–2168. [Google Scholar] [CrossRef]

- Sui, G.; Zhong, W.H.; Yang, X.P.; Yu, Y.H.; Zhao, S.H. Preparation and properties of natural rubber composites reinforced with pretreated carbon nanotubes. Polym. Adv. Technol. 2008, 19, 1543–1549. [Google Scholar] [CrossRef]

- De Paiva, F.F.G.; de Maria, V.P.K.; Torres, G.B.; Dognani, G.; dos Santos, R.J.; Cabrera, F.C.; Job, A.E. Sugarcane bagasse fiber as semi-reinforcement filler in natural rubber composite sandals. J. Mater. Cycles Waste Manag. 2019, 21, 326–335. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Tolosa, G.R.; Santos, G.T.d.A.; de Oliveira, J.P.J.; Budemberg, E.R.; da Silva, M.J.; Cabrera, F.C.; Job, A.E.; Paim, L.L.; Torres, G.B.; et al. Recycling waste polyurethane from the refrigeration industry as filler in SBR/NR composites for industrial applications. J. Appl. Polym. Sci. 2023, 140, e53709. [Google Scholar] [CrossRef]

- Okafor, C.E.; Okpe, D.U.; Ani, O.I.; Okonkwo, U.C. Development of carbonized wood/silicon dioxide composite tailored for single-density shoe sole manufacturing. Mater. Today Commun. 2022, 32, 104184. [Google Scholar] [CrossRef]

- ASTM D3182-21a; Standard Practice for Rubber—Materials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard Vulcanized Sheets. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D2084-19a; Standard Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter. ASTM: West Conshohocken, PA, USA, 2019.

- Lee, B.L. Reinforcement of uncured and cured rubber composites and its relationship to dispersive mixing—An interpretation of cure meter rheographs of carbon black loaded SBR and cis-polybutadiene compounds. Rubber Chem. Technol. 1979, 52, 1019–1029. [Google Scholar] [CrossRef]

- ASTM D297-21; Standard Test Methods for Rubber Products—Chemical Analysis. ASTM: West Conshohocken, PA, USA, 2022.

- Flory, J.; Rehner, J. Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Mooney, M. A theory of large elastic deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Gruendken, M.; Koda, D.; Dryzek, J.; Blume, A. Low molecular weight ‘liquid’ polymer extended compounds, impact on free volume and crosslink density studied by positron lifetime spectroscopy and stress-strain analysis according to Mooney-Rivlin. Polym. Test. 2021, 100, 107239. [Google Scholar] [CrossRef]

- Sombatsompop, N. Practical use of the Mooney-Rivlin equation for determination of degree of crosslinking of swollen nr vulcanisates. J. Sci. Soc. Thail. 1998, 24, 199–204. [Google Scholar] [CrossRef]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D624-00; Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D5963-22; Standard Test Method for Rubber Property—Abrasion Resistance (Rotary Drum Abrader). ASTM: West Conshohocken, PA, USA, 2019.

- Lorenz, O.; Park, C.R. The crosslinking efficiency of some vulcanizing agents in natural rubber. J. Polym. Sci. 1961, 50, 299–312. [Google Scholar] [CrossRef]

- ASTM D6370-99; Standard Test Method for Rubber—Compositional Analysis by Thermogravimetry (TGA). ASTM: West Conshohocken, PA, USA, 2019.

| Composites NR/OLW | ML (dNm) | MH (dNm) | ΔM = (MH − ML) (dNm) | ts (min) | t90 (min) |

|---|---|---|---|---|---|

| 0 phr | 3.42 | 27.48 | 24.07 | 1.70 | 2.71 |

| 10 phr | 2.51 | 29.69 | 27.09 | 1.59 | 2.52 |

| 20 phr | 3.81 | 30.82 | 27.00 | 1.26 | 2.32 |

| 30 phr | 3.90 | 33.19 | 29.29 | 1.30 | 2.34 |

| 40 phr | 3.30 | 37.03 | 33.73 | 1.38 | 2.38 |

| 50 phr | 4.87 | 38.22 | 33.35 | 1.46 | 2.57 |

| Composites | M 100% (MPa) | M 300% (MPa) | Stress at Rupture (Mpa) | Strain at Rupture (%) |

|---|---|---|---|---|

| NR/OLW0 | 0.45 | 1.01 | 12.58 ± 0.81 | 1149.86 ± 53.28 |

| NR/OLW10 | 0.99 | 2.41 | 13.81 ± 0.93 | 849.36 ± 57.43 |

| NR/OLW20 | 0.92 | 1.99 | 11.33 ± 0.67 | 854.72 ± 22.60 |

| NR/OLW30 | 0.99 | 2.03 | 8.80 ± 1.70 | 738.60 ± 47.89 |

| NR/OLW40 | 1.01 | 2.25 | 8.24 ± 0.71 | 698.67 ± 40.92 |

| NR/OLW50 | 1.36 | 2.56 | 6.24 ± 0.99 | 607.21 ± 31.65 |

| Composites | Flory–Rehner |

|---|---|

| ν × 10−4 (mol·cm−3) | |

| NR/OLW0 | 1.91 |

| NR/OLW10 | 1.91 |

| NR/OLW20 | 1.93 |

| NR/OLW30 | 1.94 |

| NR/OLW40 | 2.18 |

| NR/OLW50 | 2.24 |

| Composites | Mooney–Rivlin | ||

|---|---|---|---|

| η ∗ 10−4 (mol·cm−3) | C1 | C2 | |

| NR/OLW0 | 2.31 | 0.43 | 0.14 |

| NR/OLW10 | 5.67 | 0.88 | 0.52 |

| NR/OLW20 | 6.09 | 0.63 | 0.88 |

| NR/OLW30 | 7.33 | 0.51 | 1.30 |

| NR/OLW40 | 9.88 | 0.50 | 1.95 |

| NR/OLW50 | 11.81 | 0.34 | 2.58 |

| Material | Degradation Event | Temperature (°C) | Mass Loss (%) | Residual Mass (%) | Observations |

|---|---|---|---|---|---|

| OLW (PMMA) | Phase 1 (H–H bonds) | ~170 | 0.85 | - | Degradation of weak H–H bonds in PMMA. |

| Phase 2 (Depolymerization) | ~365 | 77.62 | - | Degradation of the vinyl group. | |

| Phase 3 (Oligomers) | ~440 | 20.68 | 0.85 | Degradation of oligomers; inorganic residue (SiO2, Bi, Sn, etc.). | |

| NR pure (0 phr OLW) | Degradation of organic compounds | ~365 | ~93.46 | 6.54 | Degradation of isoprene; inorganic residue (vulcanization ingredients). |

| NR/OLW (10–50 phr) | single degradation event | ~365 | Varies with %OLW | - | Similar behavior to pure NR, but with a tendency toward lower thermal stability. |

| Constituent Elements | Constituents in Parts per Hundred Rubber | |||||

|---|---|---|---|---|---|---|

| NR/OLW0 | NR/OLW10 | NR/OLW20 | NR/OLW30 | NR/OLW40 | NR/OLW50 | |

| NR SVR CV60 | 100 | 100 | 100 | 100 | 100 | 100 |

| Zinc oxide | 4 | 4 | 4 | 4 | 4 | 4 |

| Stearic acid | 2 | 2 | 2 | 2 | 2 | 2 |

| PEG 4000 | 3 | 3 | 3 | 3 | 3 | 3 |

| Chartwell® | 2 | 2 | 2 | 2 | 2 | 2 |

| Naphthenic oil | 5 | 5 | 5 | 5 | 5 | 5 |

| Ophthalmic lens waste | 0 | 10 | 20 | 30 | 40 | 50 |

| Sulfur | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 |

| MBTS accelerator | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| TMTD accelerator | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Total | 119.8 | 129.8 | 139.8 | 149.8 | 159.8 | 169.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rocha, J.A.; Hiranobe, C.T.; Souza, D.d.S.; Araújo, S.d.S.; Hiranobe, M.F.; de Souza, G.H.B.; Gennaro, E.M.; Cabrera, F.C.; Cardim, G.P.; da Silva, M.J.; et al. Sustainability and Innovation: Incorporating Waste from Ophthalmic Lenses into Natural Rubber Composites. Recycling 2025, 10, 90. https://doi.org/10.3390/recycling10030090

Rocha JA, Hiranobe CT, Souza DdS, Araújo SdS, Hiranobe MF, de Souza GHB, Gennaro EM, Cabrera FC, Cardim GP, da Silva MJ, et al. Sustainability and Innovation: Incorporating Waste from Ophthalmic Lenses into Natural Rubber Composites. Recycling. 2025; 10(3):90. https://doi.org/10.3390/recycling10030090

Chicago/Turabian StyleRocha, José Afonso, Carlos Toshiyuki Hiranobe, Dener da Silva Souza, Samara da Silva Araújo, Márcia Ferreira Hiranobe, Guilherme Henrique Barros de Souza, Elmer Mateus Gennaro, Flávio Camargo Cabrera, Guilherme Pina Cardim, Michael Jones da Silva, and et al. 2025. "Sustainability and Innovation: Incorporating Waste from Ophthalmic Lenses into Natural Rubber Composites" Recycling 10, no. 3: 90. https://doi.org/10.3390/recycling10030090

APA StyleRocha, J. A., Hiranobe, C. T., Souza, D. d. S., Araújo, S. d. S., Hiranobe, M. F., de Souza, G. H. B., Gennaro, E. M., Cabrera, F. C., Cardim, G. P., da Silva, M. J., da Silva, E. A., da Silva, J. F. R., & dos Santos, R. J. (2025). Sustainability and Innovation: Incorporating Waste from Ophthalmic Lenses into Natural Rubber Composites. Recycling, 10(3), 90. https://doi.org/10.3390/recycling10030090