Effect of Solvent Pre-Treatment on the Leaching of Copper During Printed Circuit Board Recycling

Abstract

1. Introduction

2. Results and Discussion

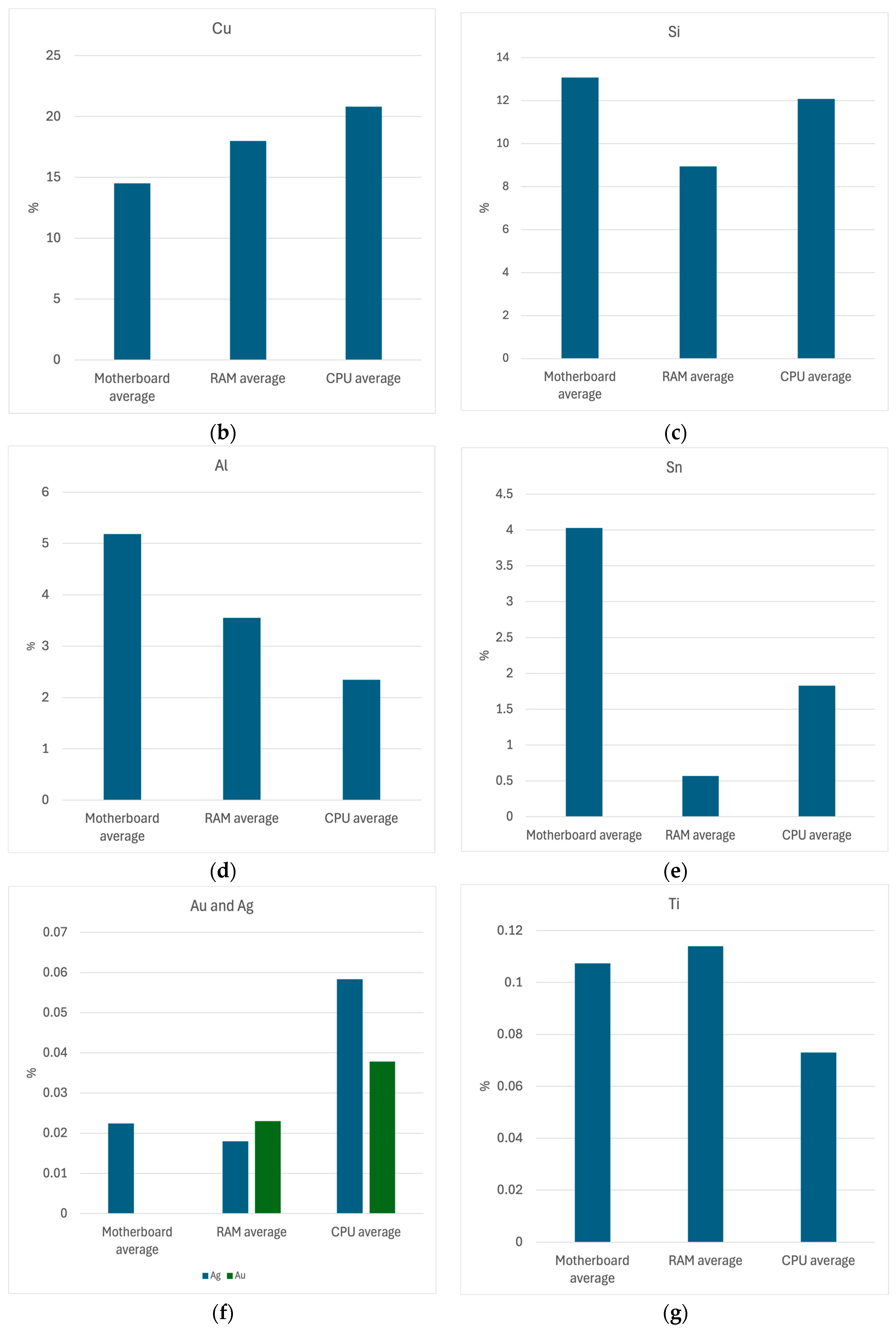

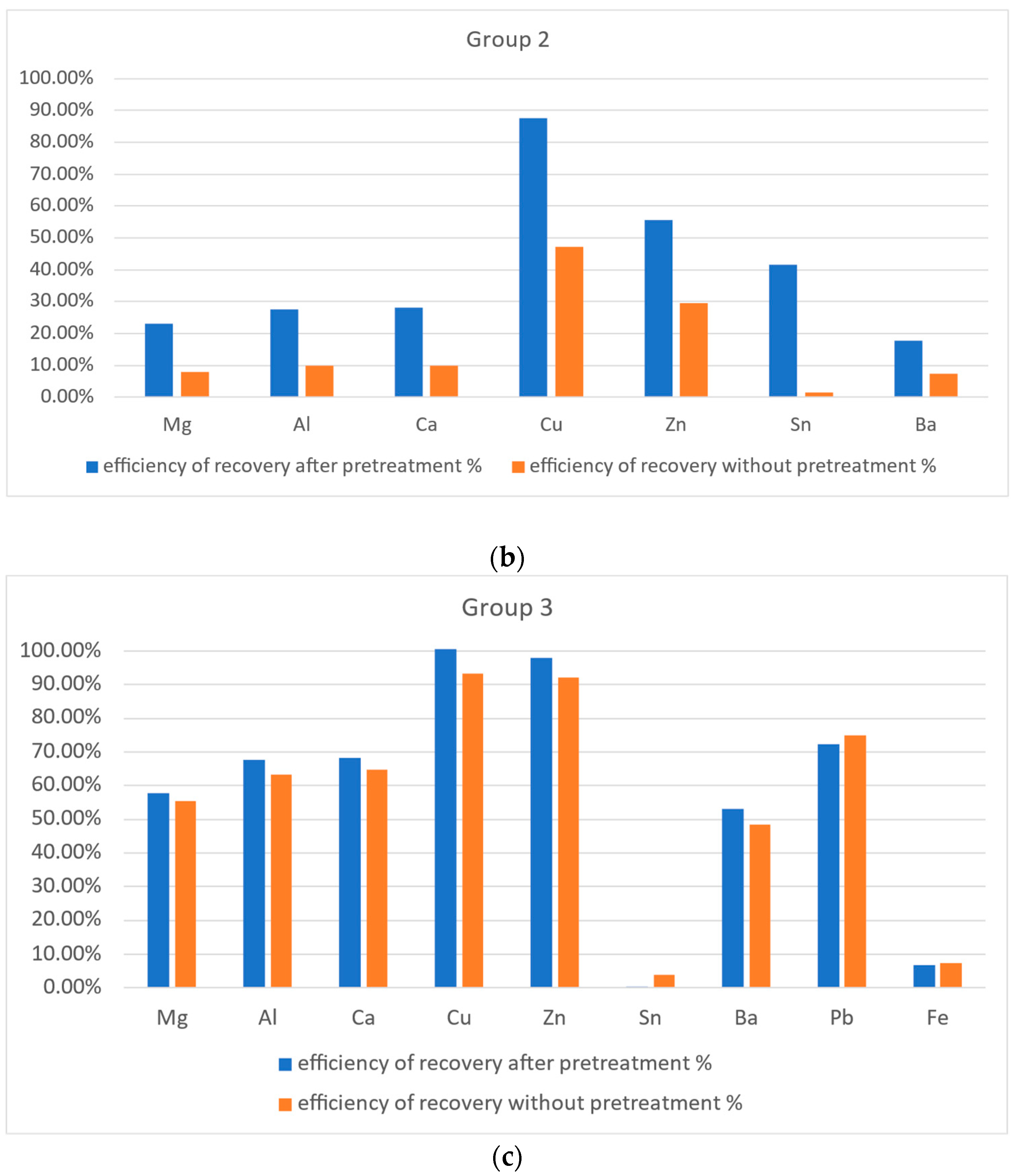

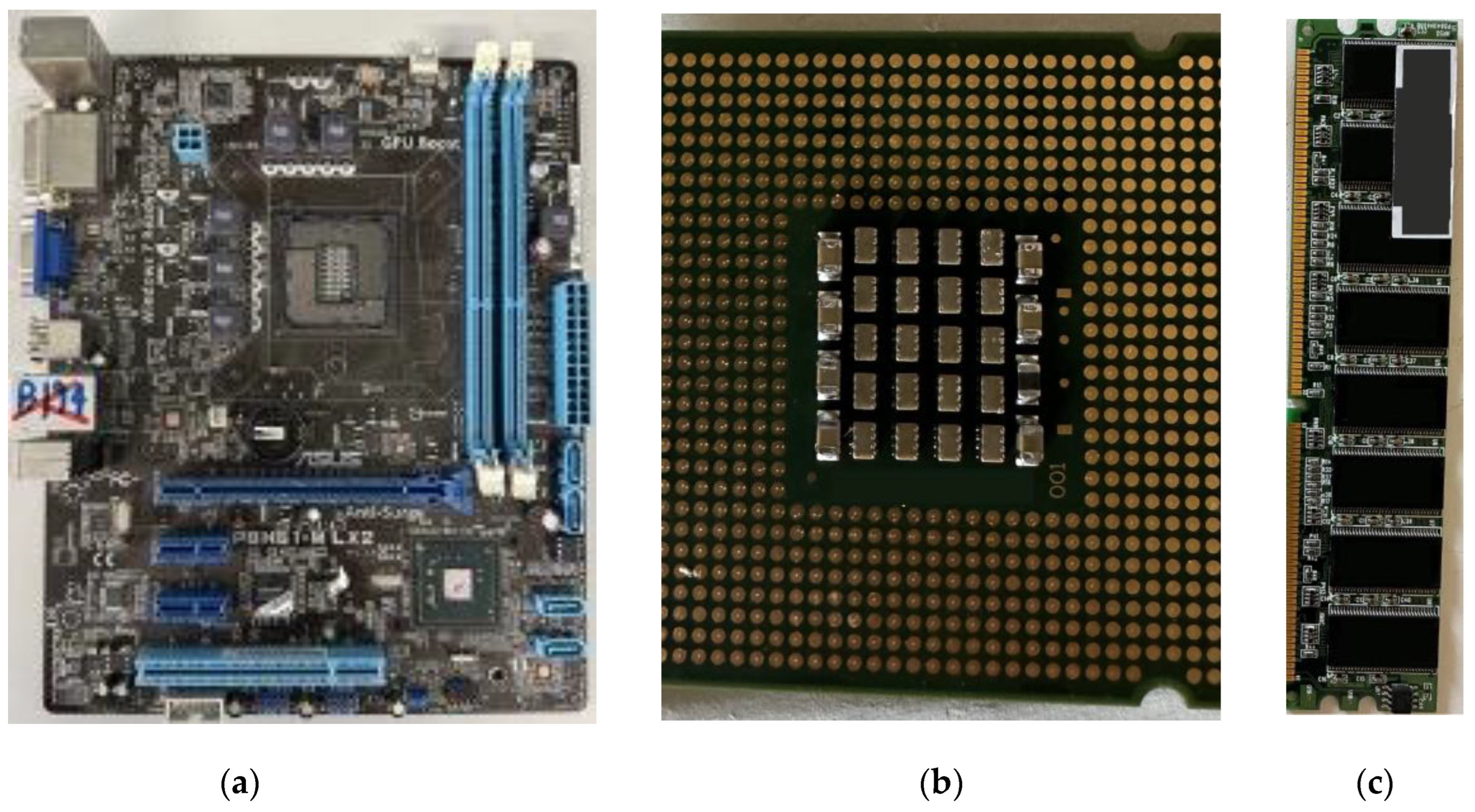

2.1. Characterization of the Various Categories of PCBs

2.2. Effect of Solvent Pretreatment of Waste PCBs Using DMSO

2.2.1. Effect of Pretreatment on the Organic Element

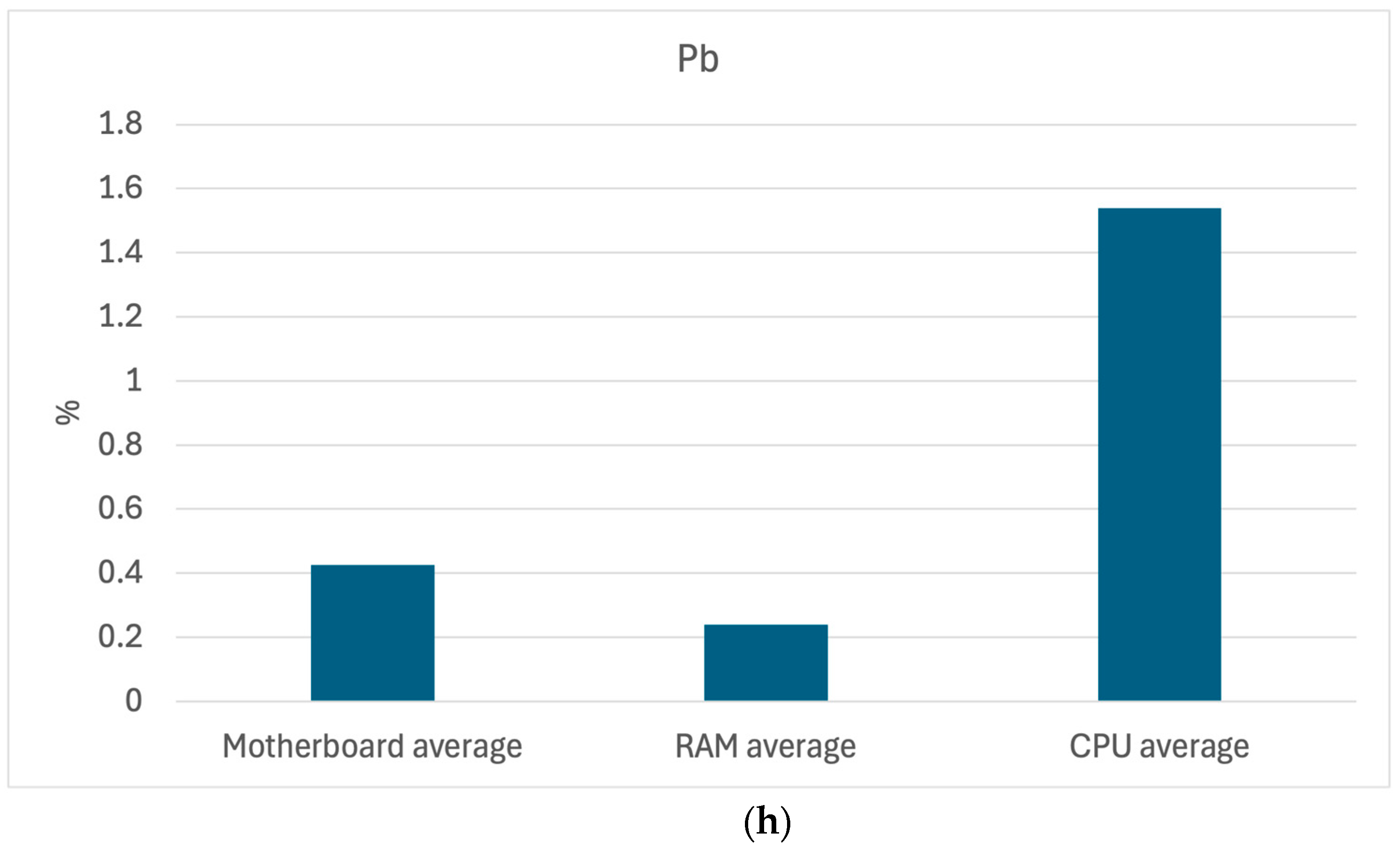

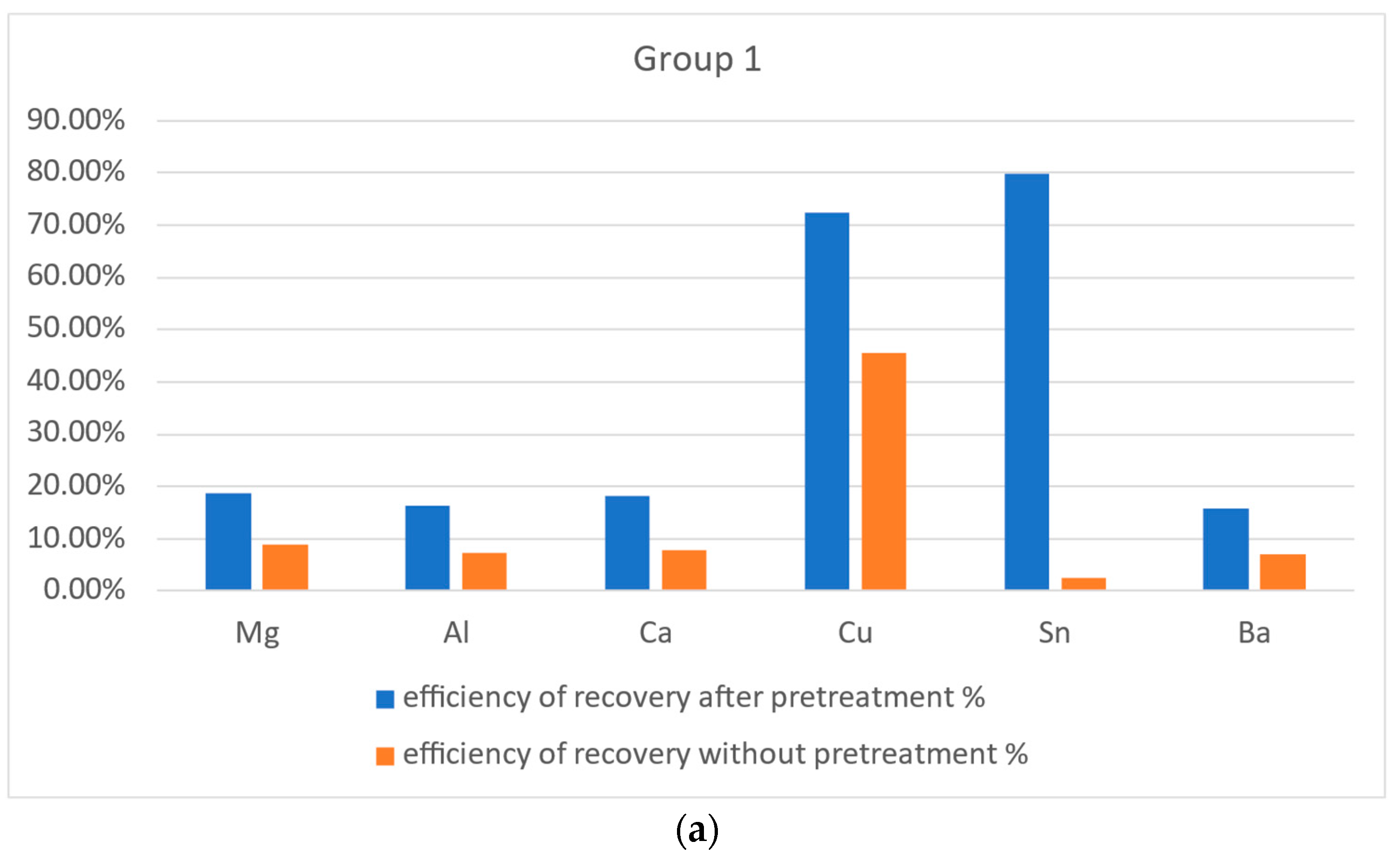

2.2.2. Effect of Pretreatment on Copper Extraction Efficiency During Leaching

3. Materials and Methods

3.1. Materials Collection and Preparation

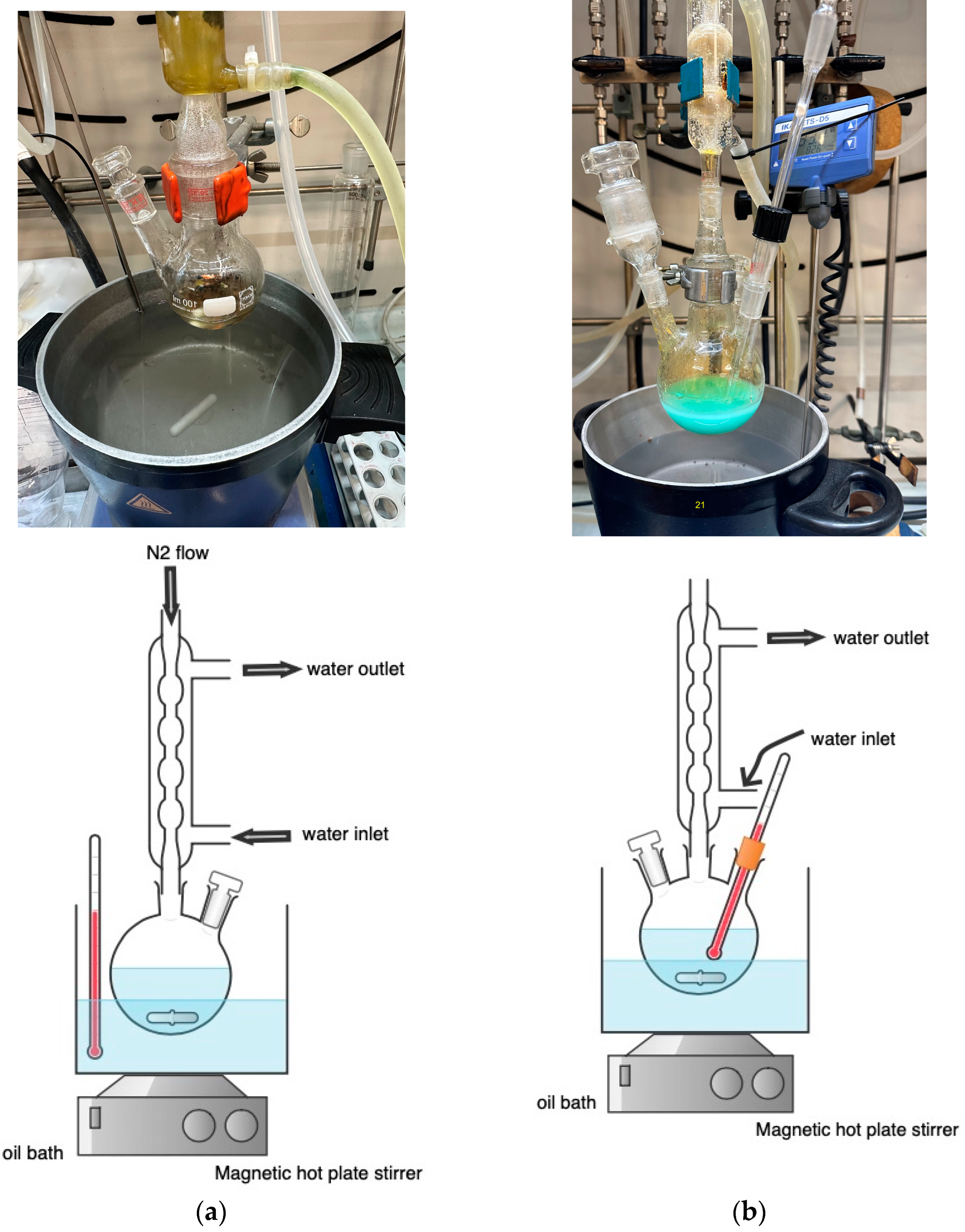

3.2. Pre-Treatment and Leaching Method

3.3. Analytical Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CPU | Central Processing Unit |

| DMA | Dimethylacetamide |

| DMF | Dimethylformamide |

| DMSO | Dimethyl sulfoxide |

| ICP-MS | Inductively Coupled Plasma Mass Spectrometry |

| ICP-OES | Inductively Coupled Plasma Optical Emission Spectrometry |

| NMP | N-methyl-2-pyrrolidone |

| PBDE | Polybromodiphenylethers |

| PC | Personal computer |

| PCB | Printed circuit Boards |

| RAM | Random Access Memory |

| REM | Rare-earth metals |

| TBBPA | Tetrabromobisphenol A |

| WEEE | Waste Electrical and Electronic Equipment |

| XRF | X-ray fluorescence spectroscopy |

References

- Kumar, A.; Holuszko, M.; Crocce, D.; Espinosa, R. E-waste: An overview on generation, collection, legislation and recycling practices. Resour. Conserv. Recycl. 2017, 122, 32–42. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, L. Metallurgical recovery of metals from electronic waste: A review. J. Hazard. Mater. 2008, 158, 228–256. [Google Scholar] [CrossRef] [PubMed]

- Hall, W.J.; Williams, P.T. Separation and recovery of materials from scrap printed circuit boards. Resour. Conserv. Recycl. 2007, 51, 691–709. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 5 November 2024).

- European Commission. Critical Raw Materials. Available online: https://single-market-economy.ec.europa.eu/sectors/raw-materials/areas-specific-interest/critical-raw-materials_en (accessed on 29 October 2024).

- European Parliament. Directive 2012/19/EU on Waste Electrical and Electronic Equipment (WEEE); European Parliament: Brussels, Belgium, 2012; pp. 38–71. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32012L0019 (accessed on 2 July 2024).

- Priya, A. Management of Electronic Waste: Resource Recovery, Technology and Regulation; Wiley: Hoboken, NJ, USA, 2023; Available online: https://www.wiley.com/en-us/Management+of+Electronic+Waste%3A+Resource+Recovery%2C+Technology+and+Regulation-p-9781119894339 (accessed on 16 January 2024).

- Oke, E.A.; Potgieter, H. Recent chemical methods for metals recovery from printed circuit boards: A review. J. Mater. Cycles Waste Manag. 2024, 26, 1349–1368. [Google Scholar] [CrossRef]

- Trinh, H.B.; Kim, S.; Lee, J. Selective Copper Recovery by Acid Leaching from Printed Circuit Board Waste Sludge. Metals 2020, 10, 293. [Google Scholar] [CrossRef]

- Liu, J.C.; Kao, T.-H. Extraction of Cu and Pb from printed circuit board sludge using ammonia solutions. Water Sci. Technol. 2003, 47, 167–172. [Google Scholar] [CrossRef]

- Kumar, M.; Lee, J.-C.; Kim, M.-S.; Jeong, J.; Yoo, K. Leaching of metals from waste printed circuit boards (WPCBs) using sulfuric and nitric acids. Environ. Eng. Manag. J. (EEMJ) 2014, 13, 2601–2607. [Google Scholar] [CrossRef]

- Ilyas, S.; Anwar, M.A.; Niazi, S.B.; Afzal Ghauri, M. Bioleaching of metals from electronic scrap by moderately thermophilic acidophilic bacteria. Hydrometallurgy 2007, 88, 180–188. [Google Scholar] [CrossRef]

- Birloaga, I.; De Michelis, I.; Ferella, F.; Buzatu, M.; Vegliò, F. Study on the influence of various factors in the hydrometallurgical processing of waste printed circuit boards for copper and gold recovery. Waste Manag. 2013, 33, 935–941. [Google Scholar] [CrossRef]

- Tuncuk, A.; Stazi, V.; Akcil, A.; Yazici, E.Y.; Deveci, H. Aqueous metal recovery techniques from e-scrap: Hydrometallurgy in recycling. Miner. Eng. 2012, 25, 28–37. [Google Scholar] [CrossRef]

- Oke, E.A.; Potgieter, H. Discarded e-waste/printed circuit boards: A review of their recent methods of disassembly, sorting and environmental implications. J. Mater. Cycles Waste Manag. 2024, 26, 1277–1293. [Google Scholar] [CrossRef]

- Cui, J.; Forssberg, E. Mechanical recycling of waste electric and electronic equipment: A review. J. Hazard. Mater. 2003, 99, 243–263. [Google Scholar] [CrossRef]

- Charitopoulou, M.A.; Papadopoulou, L.; Achilias, D.S. Removal of Bromine from Polymer Blends with a Composition Simulating That Found in Waste Electric and Electronic Equipment through a Facile and Environmentally Friendly Method. Polymers 2023, 15, 709. [Google Scholar] [CrossRef]

- Guo, X.; Peng, S.; Jiang, L.; Mo, X.; Zhu, Y.; Liu, Y.; Cai, K.; Song, Q. Removal of polybrominated diphenyl ethers in high impact polystyrene (HIPS) from waste TV sets. Environ. Sci. Pollut. Res. 2022, 29, 59317–59327. [Google Scholar] [CrossRef]

- Schlummer, M.; Popp, L.; Trautmann, F.; Zimmermann, D.; Maurer, A. Recovery of bromine and antimony from WEEE plastics. In Proceedings of the 2016 Electronics Goes Green 2016+ (EGG), Berlin, Germany, 6–9 September 2016; IEEE: Piscataway Township, NJ, USA; pp. 1–5. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, Y.; Wang, L.Y.; Zhou, M.; Zhou, J. The separation of waste printed circuit board by dissolving bromine epoxy resin using organic solvent. Waste Manag. 2012, 33, 484–488. [Google Scholar] [CrossRef] [PubMed]

- Council, B.; Haarman, A.; Fedato, S.; Holt, A. Brominated Flame Retardants and the Circular Economy of WEEE Plastics State of Play. 2023. Available online: https://www.bsef.com/wp-content/uploads/2023/09/Brominated-Flame-Retardants-and-the-Circular-Economy-of-WEEE-Plastics.pdf (accessed on 19 January 2024).

- Wath, S.B.; Katariya, M.N.; Singh, S.K.; Kanade, G.S.; Vaidya, A.N. Separation of WPCBs by dissolution of brominated epoxy resins using DMSO and NMP: A comparative study. Chem. Eng. J. 2015, 280, 391–398. [Google Scholar] [CrossRef]

- Verma, H.R.; Singh, K.K.; Mankhand, T.R. Dissolution and separation of brominated epoxy resin of waste printed circuit boards by using di-methyl formamide. J. Clean. Prod. 2016, 139, 586–596. [Google Scholar] [CrossRef]

- Verma, H.R.; Singh, K.K.; Mankhand, T.R. Delamination mechanism study of large size waste printed circuit boards by using dimethylacetamide. Waste Manag. 2017, 65, 139–146. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, Y.; Wang, L.; Qian, G.; Zhang, W.; Zhou, M.; Zhou, J. Dissolution of Brominated Epoxy Resins by Dimethyl Sulfoxide To Separate Waste Printed Circuit Boards. Environ. Sci. Technol. 2013, 47, 2654–2660. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, Y.; Wang, L.Y.; Qian, G.R.; Zhou, M.; Zhou, J. A novel approach to separation of waste printed circuit boards using dimethyl sulfoxide. Int. J. Environ. Sci. Technol. 2013, 10, 175–180. [Google Scholar] [CrossRef]

- Kang, K.D.; Ilankoon, I.; Chong, M.N.; Wu, T.Y. Exfoliation of coarse printed circuit boards using dimethylacetamide: Production of copper concentrates. Miner. Eng. 2023, 191, 107963. [Google Scholar] [CrossRef]

- Preetam, A.; Modak, A.; Jadhao, R.; Naik, S.N.; Pant, K.K.; Kumar, V. A comprehensive study on the extraction of transition metals from waste random access memory using acetic acid as a chelating solvent. J. Environ. Chem. Eng. 2022, 10, 2213–3437. [Google Scholar] [CrossRef]

- Calgaro, C.O.; Schlemmer, D.F.; Bassaco, M.M.; Dotto, G.L.; Tanabe, E.H.; Bertuol, D.A. Supercritical extraction of polymers from printed circuit boards using CO2 and ethanol. J. CO2 Util. 2017, 22, 307–316. [Google Scholar] [CrossRef]

- Sanyal, S.; Ke, Q.; Zhang, Y.; Ngo, T.; Carrell, J.; Zhang, H.; Dai, L.L. Understanding and optimizing delamination/recycling of printed circuit boards using a supercritical carbon dioxide process. J. Clean. Prod. 2013, 41, 174–178. [Google Scholar] [CrossRef]

- de Souza, G.B.M.; Pereira, M.B.; dos Santos, L.F.; Alonso, C.G.; Jegatheesan, V.; Cardozo-Filho, L. Management of waste printed circuit boards via supercritical water technology. J. Clean. Prod. 2022, 368, 133198. [Google Scholar] [CrossRef]

- Suslavich, B.T.; Das, A.; Young, C.A. Chemical Liberation of Waste Printed Circuit Boards. WO2022178235A1, 25 August 2022. Available online: https://patents.google.com/patent/WO2022178235A1/en (accessed on 23 September 2024).

- Kaifua, su. Method for Non-Incineration and Non-Cyanation Treatment of Waste Printed Circuit Boards. JP5766305B2, 19 August 2015. Available online: https://patents.google.com/patent/JP5766305B2/en (accessed on 23 September 2024).

- Torres Marques, A.; Da Silva Monteiro Bastos, M.M.; Marques Martelo, L.; Soares De Sousa, P.M.; Relvas Vieira Dias, A.C.; Guerreiro Alves Arroja, L.M. Eco-Friendly Method for Recycling Electronic Waste. WO2022123438A1, 16 June 2022. Available online: https://patents.google.com/patent/WO2022123438A1/en (accessed on 23 September 2024).

- Ma, L.; Shi, Y.; Wang, Q.; Liang, X.; Li, Z.; Liu, L. Method for Harmless Treatment and Resource Comprehensive Recovery of Circuit Board. CN103084369A, 8 May 2013. Available online: https://patents.google.com/patent/CN103084369A/en (accessed on 23 September 2024).

- Dutta, D.; Panda, R.; Kumari, A.; Goel, S.; Jha, M.K. Sustainable recycling process for metals recovery from used printed circuit boards (PCBs). Sustain. Mater. Technol. 2018, 17, e00066. [Google Scholar] [CrossRef]

- Vijayaram, R.; Nesakumar, D.; Chandramohan, K. Copper Extraction from the Discarded Printed Circuit Board by Leaching. Res. J. Eng. Sci. 2013, 2, 11–14. Available online: https://www.isca.in (accessed on 29 November 2023).

- Sethurajan, M.; van Hullebusch, E.D. Leaching and Selective Recovery of Cu from Printed Circuit Boards. Metals 2019, 9, 1034. [Google Scholar] [CrossRef]

- Silvas, F.P.C.; Jiménez Correa, M.M.; Caldas, M.P.K.; de Moraes, V.T.; Espinosa, D.C.R.; Tenório, J.A.S. Printed circuit board recycling: Physical processing and copper extraction by selective leaching. Waste Manag. 2015, 46, 503–510. [Google Scholar] [CrossRef]

- Kang, K.D.; Ilankoon, I.M.S.K.; Dushyantha, N.; Chong, M.N. Assessment of Pre-Treatment Techniques for Coarse Printed Circuit Boards (PCBs) Recycling. Minerals 2021, 11, 1134. [Google Scholar] [CrossRef]

- Priya, A.; Hait, S. Characterization of particle size-based deportment of metals in various waste printed circuit boards towards metal recovery. Clean. Mater. 2021, 1, 100013. [Google Scholar] [CrossRef]

- Priya, A.; Hait, S. Qualitative and quantitative metals liberation assessment for characterization of various waste printed circuit boards for recycling. Environ. Sci. Pollut. Res. 2017, 24, 27445–27456. [Google Scholar] [CrossRef] [PubMed]

- Baldé, C.P.; Kuehr, R.; Yamamoto, T.; McDonald, R.; D’Angelo, E.; Althaf, S.; Bel, G.; Deubzer, O.; Fernandez-Cubillo, E.; Forti, V.; et al. “The Global E-waste Monitor 2024”, Geneva/Bonn. 2024. Available online: https://www.itu.int/itu-d/sites/environment (accessed on 16 October 2024).

- The European Parliament, Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011 on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Text with EEA Relevance. 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011L0065 (accessed on 8 September 2018).

| Method Used | Type of WEEE | Particle Size | Temperature | Duration | Solid-To-Liquid Ratio | Reference |

|---|---|---|---|---|---|---|

| DMSO | PC-Motherboard | 16 mm2 | 145 °C | 60 min | 1:7 | Zhu et al. [20] |

| DMSO | PC-Motherboard | 1–1.5 cm2 | 90 °C | 60 min | 1:2 | Zhu et al. [25] |

| DMSO | PC-Motherboard | 1–1.5 cm2 | 135 °C | 10 min | 1:2 | Zhu et al. [25] |

| DMSO | PC-Motherboard | 2–3 cm2 | 90 °C | 90 min | 1:2 | Zhu et al. [25] |

| DMSO | PC-Motherboard | 2–3 cm2 | 135 °C | 20 min | 1:2 | Zhu et al. [25] |

| DMSO | PC-Motherboard | 15–20 mm2 | 170 °C | 30 min | 1:2 | Zhu et al. [26] |

| DMSO | PC motherboard | 6 mm | 90 °C | 90 min | 1:2 | Wath et al. [22] |

| DMA | PC-Motherboard | 1 cm2 | 160 °C | 75 min | 1:10 | Dean Kang et al. [27] |

| DMA | PC-Motherboard | 1 cm2 | 160 °C | 150 min | 3:10 | Verma et al. [24] |

| DMA | PC-Motherboard | 16 cm2 | 160 °C | 420 min | 3:10 | Verma et al. [24] |

| DMF | Mix PCBs | 1 cm2 | 135 °C | 240 min | 300 g/L | Verma et al. [23] |

| NMP | PC motherboard | 8 mm sieve | 100 °C | 90 min | 1:5 | Wath et al. [22] |

| Supercritical ethanol | RAM PCB | 10–20 mm | 300 °C | 60 min | 1:20 | Preetam et al. [28] |

| Material | Al | Ba | Br | Ca | Cu | Fe | Mg | Na | Pb | S | Si | Sn | Sr | Ti | Zn | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight % | 4.6 | 0.6 | 0.1 | 9.5 | 12.7 | 0.1 | 0.2 | 0.2 | 0.5 | 0.2 | 13.3 | 3.2 | 0.1 | 0.2 | 0.03 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, A.T.I.; Schimperna, G.; Cantoni, G.; Demichelis, F.; Fino, D.; Perucchini, S.; Rubertelli, F.; Laviano, F. Effect of Solvent Pre-Treatment on the Leaching of Copper During Printed Circuit Board Recycling. Recycling 2025, 10, 80. https://doi.org/10.3390/recycling10030080

Mohamed ATI, Schimperna G, Cantoni G, Demichelis F, Fino D, Perucchini S, Rubertelli F, Laviano F. Effect of Solvent Pre-Treatment on the Leaching of Copper During Printed Circuit Board Recycling. Recycling. 2025; 10(3):80. https://doi.org/10.3390/recycling10030080

Chicago/Turabian StyleMohamed, Ahmed Tarek Ismail, Giuliana Schimperna, Gianluca Cantoni, Francesca Demichelis, Debora Fino, Sara Perucchini, Francesca Rubertelli, and Francesco Laviano. 2025. "Effect of Solvent Pre-Treatment on the Leaching of Copper During Printed Circuit Board Recycling" Recycling 10, no. 3: 80. https://doi.org/10.3390/recycling10030080

APA StyleMohamed, A. T. I., Schimperna, G., Cantoni, G., Demichelis, F., Fino, D., Perucchini, S., Rubertelli, F., & Laviano, F. (2025). Effect of Solvent Pre-Treatment on the Leaching of Copper During Printed Circuit Board Recycling. Recycling, 10(3), 80. https://doi.org/10.3390/recycling10030080