Abstract

Municipal solid waste (MSW) is rising globally, and improper management harms the environment and public health. As a result, there is heightened interest in finding effective solutions, and identifying research trends helps determine the best management and valorization pathways. However, the existing reviews often focus narrowly on specific technologies or regional case studies, lacking a comprehensive analysis of global research trends. This study addresses this significant gap by conducting a large-scale trend analysis based on 15,646 relevant articles screened from 25,068 Scopus-indexed publications from 1904 to 2023 using title, abstract, and keyword analysis. Literature-based comparative assessments were conducted to critically evaluate the pathways through TEE (techno-economic and environmental), SWOT (strengths, weaknesses, opportunities, and threats), and PESTEL (political, economic, social, technological, environmental, and legal) frameworks. Since 1990, article publication has increased by about 10% annually, consistently concentrating on thermochemical conversion and, more recently, on sustainability and circular economy perspectives. Seven distinct pathways for MSW management were identified, with recycling and material recovery, followed by thermochemical conversion for high-calorific waste and biochemical conversion for high-organic waste, showing the most promise. The findings aim to help researchers understand MSW research trends and assist planners in identifying effective management and valorization strategies.

1. Introduction

Urbanization, both in size and number, is expanding globally, and it is predicted that by 2030, three in five humans will live in cities [1]. With the population increase in cities and unplanned settlements, municipal solid waste (MSW) management has become a significant challenge, and improper management has impacted the overall ecosystem [2]. The global waste generation in 2016 was approximately 2.01 billion tonnes, which is predicted to reach 3.40 billion tonnes by 2050. Waste generation in high-income countries accounts for about 34% of the world’s total waste, while low-income countries contribute only 5%. However, it is projected that per capita waste generation in low and middle-income countries will rise by 40%, while in high-income countries, it will increase by 19% by 2050 [3].

Still, about one-third of the world’s waste is being openly dumped and burned [3], which has impacted the surroundings, such as air, water, and soil [4], and resulted in health hazards, environmental deterioration, and a decline in quality of life. The effective management of MSW is crucial for sustainable urban development, which requires coordinated efforts in waste collection, transportation, treatment, valorization, and disposal to minimize adverse effects [5]. However, a lack of appropriate knowledge regarding management and valorization pathways, along with resource constraints, has hindered the effective handling of MSW. Understanding global research trends and current management practices helps in selecting the best pathways. However, adapting to new and advanced technologies is complex and tied to multifaceted sustainability challenges. The methods of MSW management and valorization pathways vary based on quantity and composition, as well as various socio-economic and weather parameters.

Comprehensive analysis helps to understand better the evolution of MSW-related research, which in turn facilitates the identification of suitable MSW management and valorization technologies. Several studies have analyzed the global research trend in MSW [6,7,8,9]. One study [9] assessed the articles from 1993 to 2008, another study [7] from 1997 to 2014, and a third study [8] from 1992 to 2016 to understand global MSW research trends. The study [6] assessed from 1980 to 2019 to investigate the research trend in the economic analysis of MSW management systems. However, the existing studies lack critical analysis of the current management and valorization pathways and require updated analysis. Techno-economic and environmental (TEE) assessment helps to critically analyze the MSW management pathways and find the best route. Few studies have reported conducting TEE for MSW management pathways, but mostly focusing only on the country level and specific pathways [10,11,12]. Similarly, the SWOT (strengths, weaknesses, opportunities, and threats) tool is also used to understand the associated processes and pathways, develop strategies to exploit strengths and weaknesses, address weaknesses, and mitigate threats [13]. Studies have been reported using the SWOT analysis tool for MSW management and valorization; however, as in TEE, most have studied the specific waste and process [13,14,15,16]. In addition, the political, economic, social, technological, environmental, and legal (PESTEL) tool is also used in MSW research [17]. This analysis is a comprehensive method for evaluating the external factors that impact technology and processes and helps make well-informed decisions for strategic planning, market analysis, and risk management. Few studies have reported the PESTEL analysis for MSW research [17,18,19,20]. However, these studies have not employed these tools to critically analyze the various pathways and technologies for MSW management and valorization at the global level.

Therefore, to address this gap, the study first assessed articles published in Scopus-indexed journals up to 2023 to understand global trends in MSW research. Through this analysis, the study identified various pathways for MSW management and valorization. After outlining the pathways, the study critically reviewed each one using TEE, SWOT, and PESTEL based on the literature. The findings offer insights into global research trends and current pathways, highlighting both positive and negative aspects that are useful for researchers designing their studies and for planners selecting the most effective pathway.

2. Methodology

2.1. Research Trend Analysis

The current management and valorization pathways of MSW were reviewed based on the literature and the research trend was assessed. The scholarly documents published in Scopus-indexed journals were assessed by developing a syntax (Table A1) and searching within the document title. A total of 25,068 documents published up to 2023 were found, and further filtration was applied to refine the documents. First, the scope was limited to those published in journals only (19,960) and further limited to articles (17,968). Finally, 15,646 articles published in English were selected for further analysis. To investigate the trend of article publications, trend lines were drawn, indicating a higher R2 in the study. Similarly, country-specific publication numbers were plotted on a global map using the RStudio software (Version 4.3.1). To analyze the research trend, the documents were categorized based on their publication dates: pre-1990, 1990–1999, 2000–2009, 2010–2019, and after 2020. Initial word lists and potential terminology were prepared to assess the trend and were searched within the titles, abstracts, and keywords of the articles, adopting the methodology used in the study [21]. The number of articles referenced in the research regarding each management and valorization pathway, waste and its source, software and tools, and sustainability were analyzed by developing code in RStudio.

2.2. TEE, SWOT, and PESTEL Analyses

The TEE, SWOT, and PESTEL analyses of each pathway were conducted to critically review the MSW management and valorization pathways, mainly based on the literature assessment.

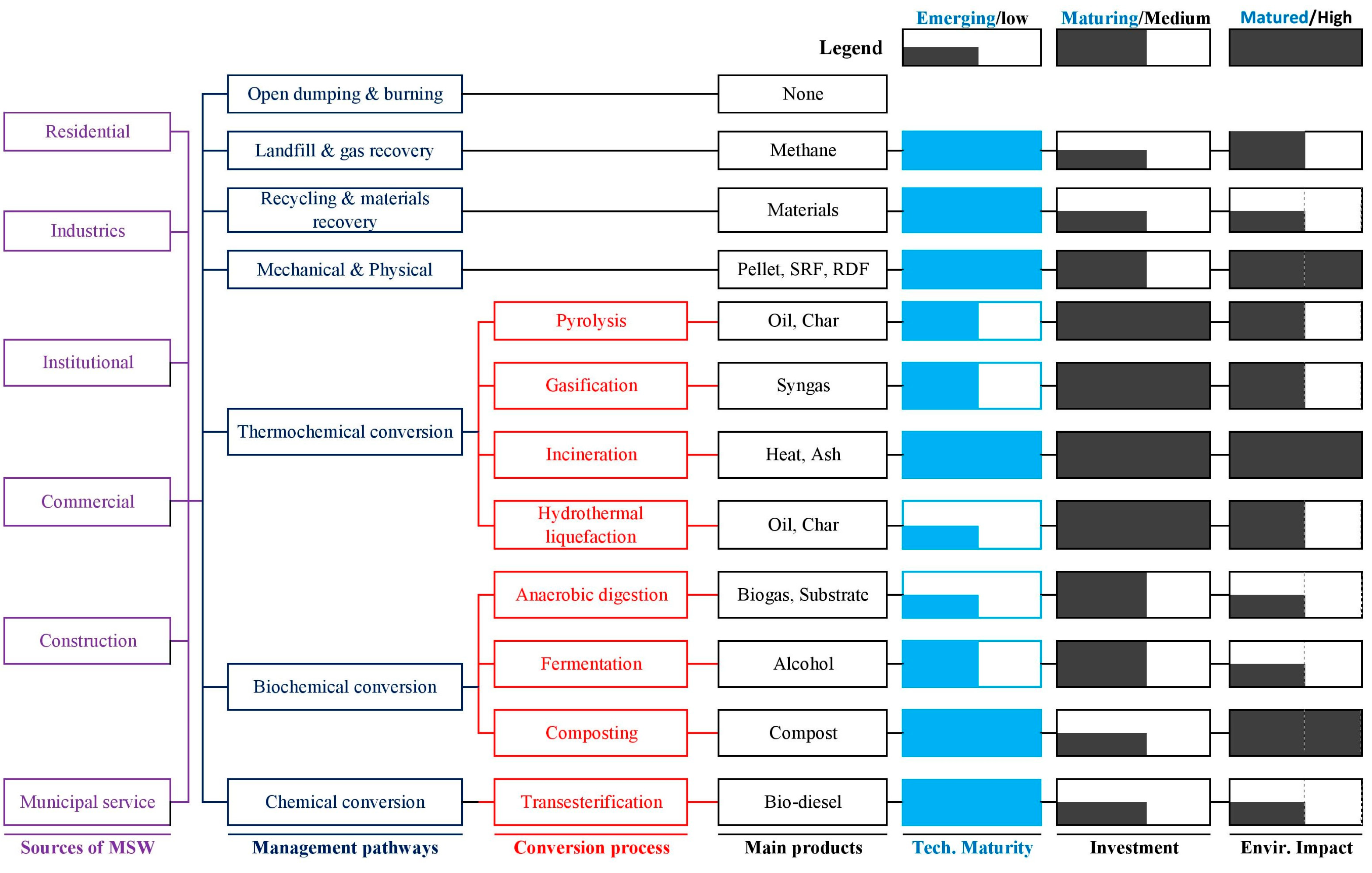

In the TEE analysis, all three aspects are categorized: technology maturity level in emerging, maturing, and mature; economic investment (upfront cost); and environmental impact in low, medium, and high. Technical maturity is categorized as emerging, maturing, and mature based on technology readiness level (TRL). TRL, developed by the National Aeronautics and Space Administration (NASA), has categorized levels from 1 to 9 [22], and for this study, TRL 1–4, TRL 4–8, and TRL 9 are categorized as emerging, maturing, and matured, respectively. Similarly, the International Energy Agency (IEA) has categorized TRL from 1 to 11 [23]. TRL 1–4, 5–10, and TRL 11 are categorized as emerging, maturing, and matured, respectively. Similarly, the economic investment and environmental impacts were analyzed and categorized, comparing the data gathered from the literature. Investment needed to manage waste was considered for economic analysis. Environmental impact was analyzed based on the greenhouse gas (GHG) emissions in kg CO2e/tonne. To convert the various emissions (such as CO2, CH4, and N2O), equivalent data were used from the published document elsewhere [24]. Thermochemical conversion pathways are further specified as pyrolysis, gasification, incineration, and hydrothermal liquefaction, and biochemical conversion processes are specified as anaerobic digestion, fermentation, and composting.

The SWOT and TEE analyses of each pathway were discussed further, specifying the thermochemical and biochemical conversion pathways, while the PESTEL analysis was discussed for major pathways only. For each aspect of PESTEL, both opportunities and challenges were analyzed.

3. Global Research Trend in MSW

3.1. Year- and Country-Wise Publication

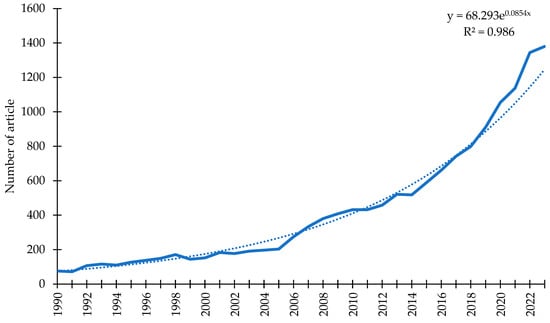

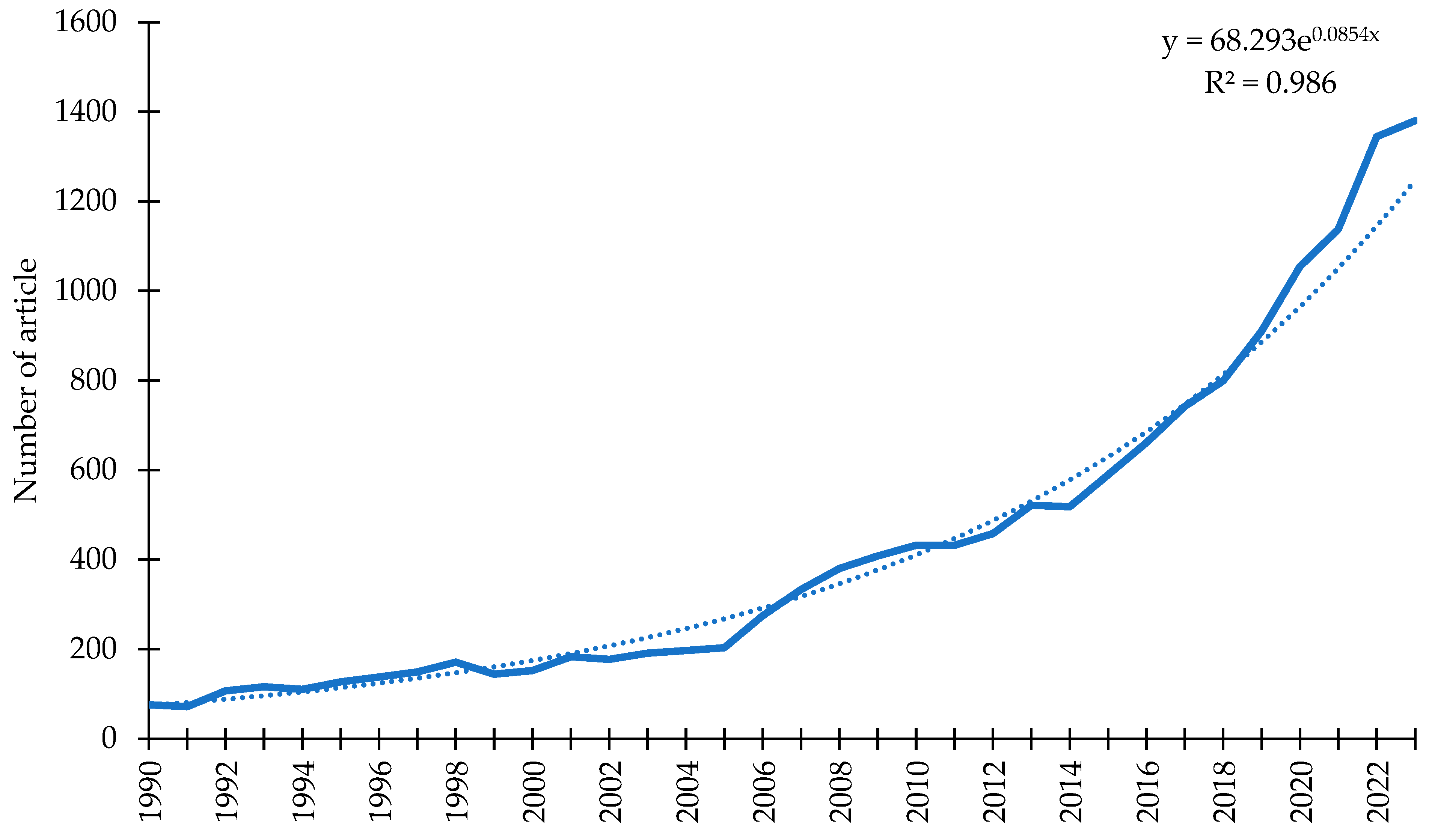

A total of 15,646 articles published in Scopus-indexed journals were assessed between 1904 and 2023. The first article was published more than a century ago, discussing the utilization and disposal of MSW [25]. Overall, there is an increasing trend in the number of articles (Table A2 and Figure A1). From 1904 to 1989, a total of 962 articles were published, averaging about 11 articles per year. This figure rose to 121 articles per year between 1990 and 1999 and increased by tenfold to 1229 articles per year in 2020–2023. The rising number of articles published annually has also impacted the growth rate: it was just 8.6% from 1990 to 1999, increasing to 12.1% from 2000 to 2009, and reaching 14.0% in the years between 2020 and 2022. The trend in article publications between 1990 and 2023 fitted a second-order polynomial and an exponential trend line, demonstrating a good fit with an R2 of 0.986 for the exponential trend line (Figure A1).

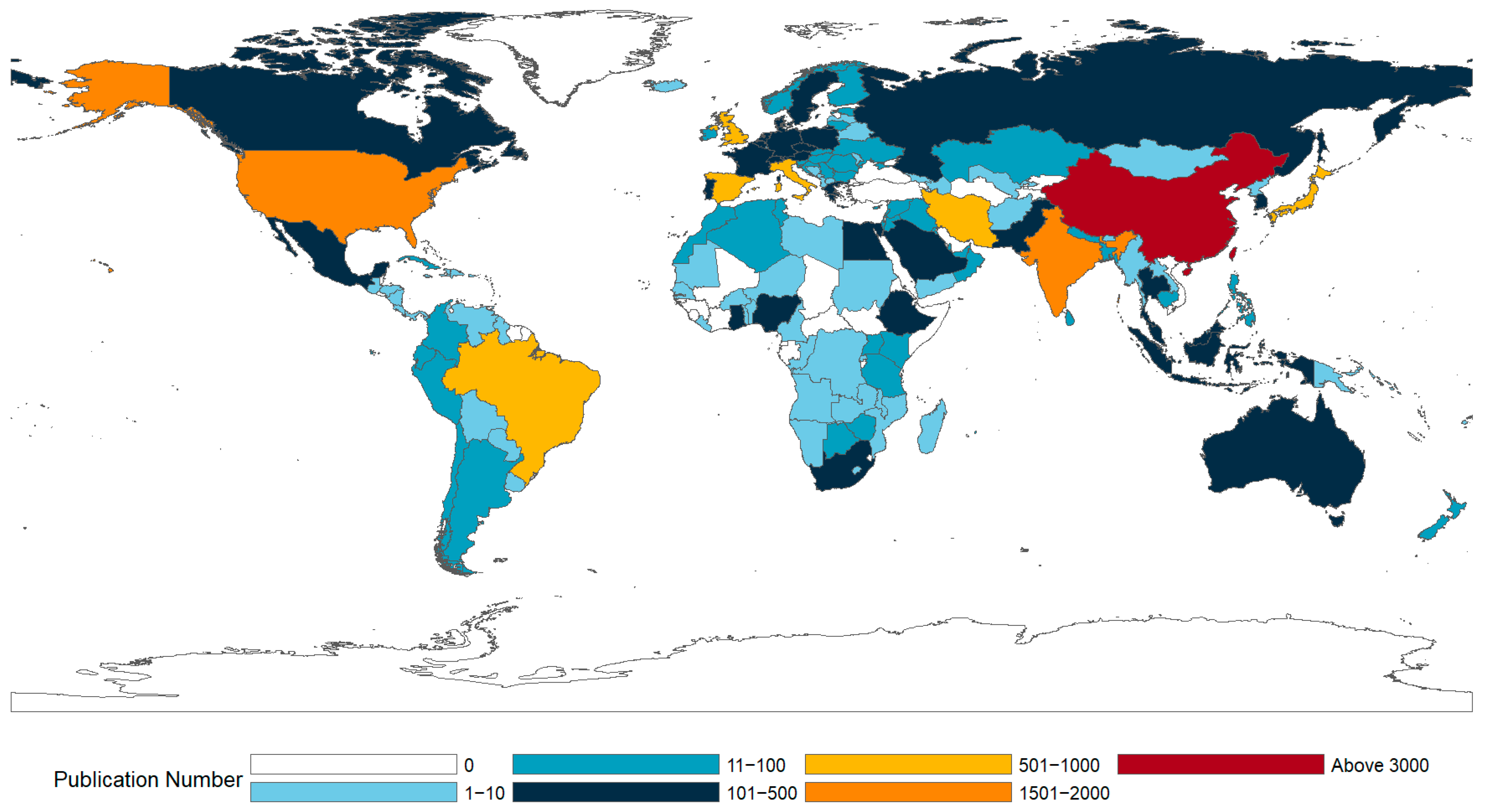

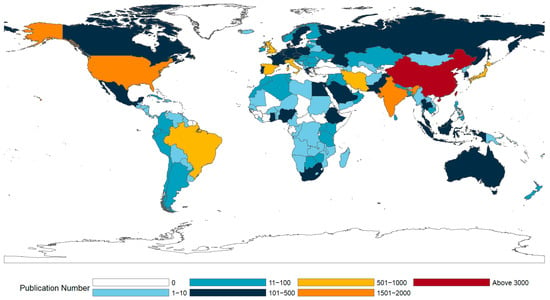

Regarding the number of publications, articles were published from 156 countries. Only one article was published in 25 countries, while over 100 appeared from 39 countries. The variation in publication numbers may stem from each country’s focus on higher education and research, its economy, and its research budget. The USA led in the number of publications until 2000, but India took the lead from 2000 to 2009, and China has led since 2010 (Table A2). From 2020 to 2023, more than a quarter of the published articles came from China, and this trend is likely to continue. Overall, more articles were published from China, followed by the USA and India (Figure 1). The high number of publications from China is attributed to government support for research and publishing [26,27].

Figure 1.

Country-wise publication numbers from 1904 to 2023 show that China has the highest contribution, followed by the USA and India.

3.2. Management and Valorization Pathways

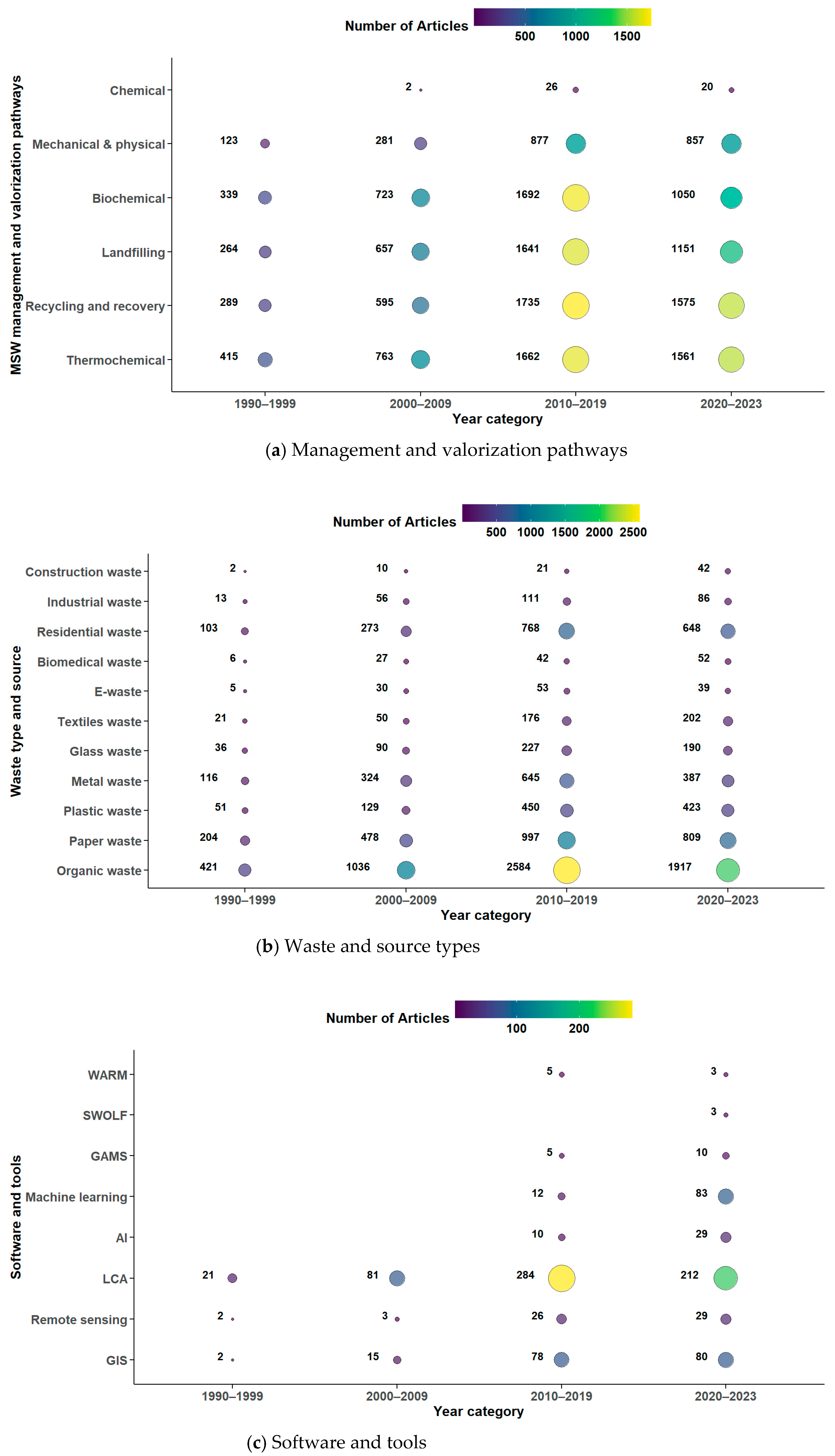

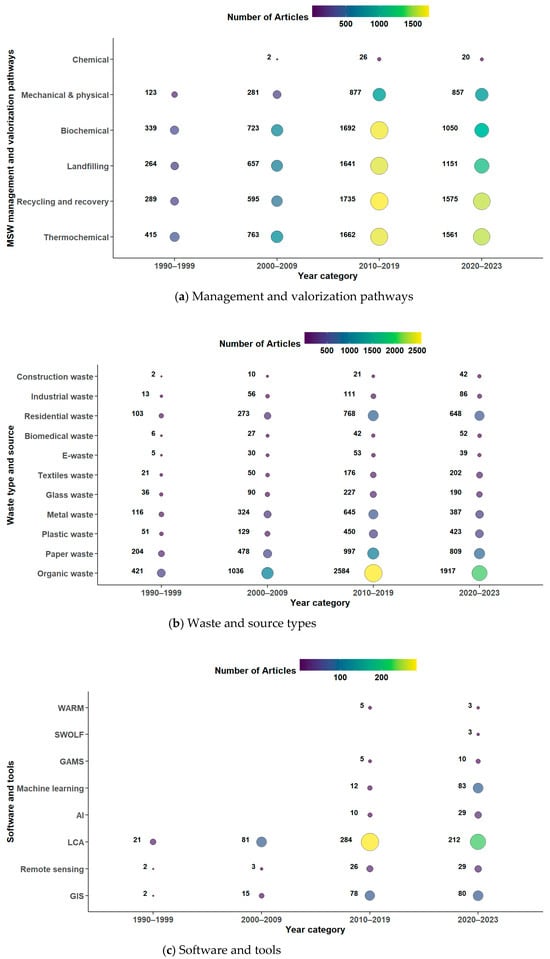

A total of seven distinct pathways for managing MSW are identified globally (Figure 2a). However, open dumping and burning are not considered management pathways. As the number of publications has increased over the years (Figure A1), the overall trend in management and valorization pathways has risen steadily. Thermochemical conversion is, overall, the most studied process for managing and valorizing MSW, mentioned in 7375 studies. This is followed by recycling and recovery, landfilling, biochemical conversion, mechanical and physical processes, and chemical conversion (Figure 2a).

Figure 2.

Research trends of municipal solid waste management: (a) management and valorization pathways-wise, (b) waste and source types-wise, (c) software and tools-wise, and (d) sustainability and circularity research-wise. A total of six distinct pathways have been identified, and the corresponding number of articles is shown.

Overall, 307 studies per year mentioned thermochemical conversion and found an increasing trend: 58 studies per year in 1990–1999 and 653 studies per year in 2020–2023. The reason behind thermochemical conversion being mainly studied could be due to the versatile nature of the process, both in terms of feedstock and products. The process can convert organic and inorganic waste, producing direct heat, syngas, bio-oil, and char. In addition, the process significantly reduces the volume of waste [28,29]. A detailed critical discussion of the management and valorization pathways is performed in Section 4.

3.3. Waste and Source Types of MSW

MSW is composed of various types of waste, both organic and inorganic. The analysis showed that most studies mentioned organic waste, followed by paper, plastic, glass, textiles, biomedical, and e-waste (Figure 2b). A similar trend can be seen for conventional MSW such as household, paper, metal, plastic, glass, and textiles. However, the trend showed an increase in research related to e-waste. This is due to the rise in the use of electronic items, which has created havoc for its management [30]. Such waste contains hazardous materials, such as heavy metals, and is considered high risk for health [31]. Likewise, biomedical waste requires greater attention for management, as it comprises approximately 27% of infectious waste and poses a risk to public health [32]. A rapid surge in studies mentioning biomedical waste can be seen during 2020–2023. This is due to COVID-19 and the rise in the use of protective equipment, such as masks, gloves, gowns, and shields [33].

The waste source-wise trend (Figure 2b) showed a consistent upward trend over the years. The most significant increase in the trend was observed in construction waste, possibly due to rising environmental concerns, scarcity of raw materials, public awareness, and regulatory pressure [34,35].

3.4. Software and Tools Used in MSW Research

Various software and tools have been found to be used in MSW research, such as to assess the environmental impacts and to optimize the process (Figure 2c). The life cycle assessment (LCA) tool, which is used to evaluate the environmental impact associated with the process and product, has been mentioned in 598 studies, and the trend is rising rapidly. This may be a result of heightened awareness and government regulations that mandate an assessment of environmental impacts. It was found that the LCA tool was first mentioned in a study published in 1992 [36] which discussed hospitality solid waste minimization from the LCA perspective.

Similarly, the use of geographic information systems (GIS) and remote sensing has increased in recent years, as these tools enable spatial analysis capabilities necessary for the proper selection of landfills and treatment plants, their monitoring, the analysis of waste generation and distribution sites, and the mapping of waste collection and transportation routes. The first article using remote sensing to study groundwater contamination by MSW was published in 1992 [37]. Similarly, GIS was first used in a 1996 study [38] which studied the MSW potential for Illinois, USA. Both tools were found to be extensively used in studies published after 2010.

High-level algorithm tools, such as artificial intelligence (AI) and machine learning, have been found to be increasingly helpful. It was found that AI was first mentioned in a study published in 1995 [39] and machine learning in 2016 [40].

Similarly, various optimization models and tools were used in MSW research, such as the general algebraic modeling system (GAMS), the solid waste optimization lifecycle framework (SWOLF), and the waste reduction model (WARM). SWOLF and WARM were first mentioned in studies published in 2014 [41,42], while GAMS was found in a study published in 2017 [43]. The study published in 2013 [44] also used the SWOLF model for optimization; however, it was not found as the study search strategy is based only on the title, abstract, and keywords. The GAMS model optimizes complex MSW management processes, such as cost, resource allocation, and logistics [43,45]. The SWOLF model optimizes environmental and economic performance, integrating LCA with optimization [44]. The WARM identifies the most environmentally friendly strategies from various options based on estimating GHG emissions [46]. Such tools and models have been used more frequently in recent years. In addition, research focusing on route optimization has also been found to be growing.

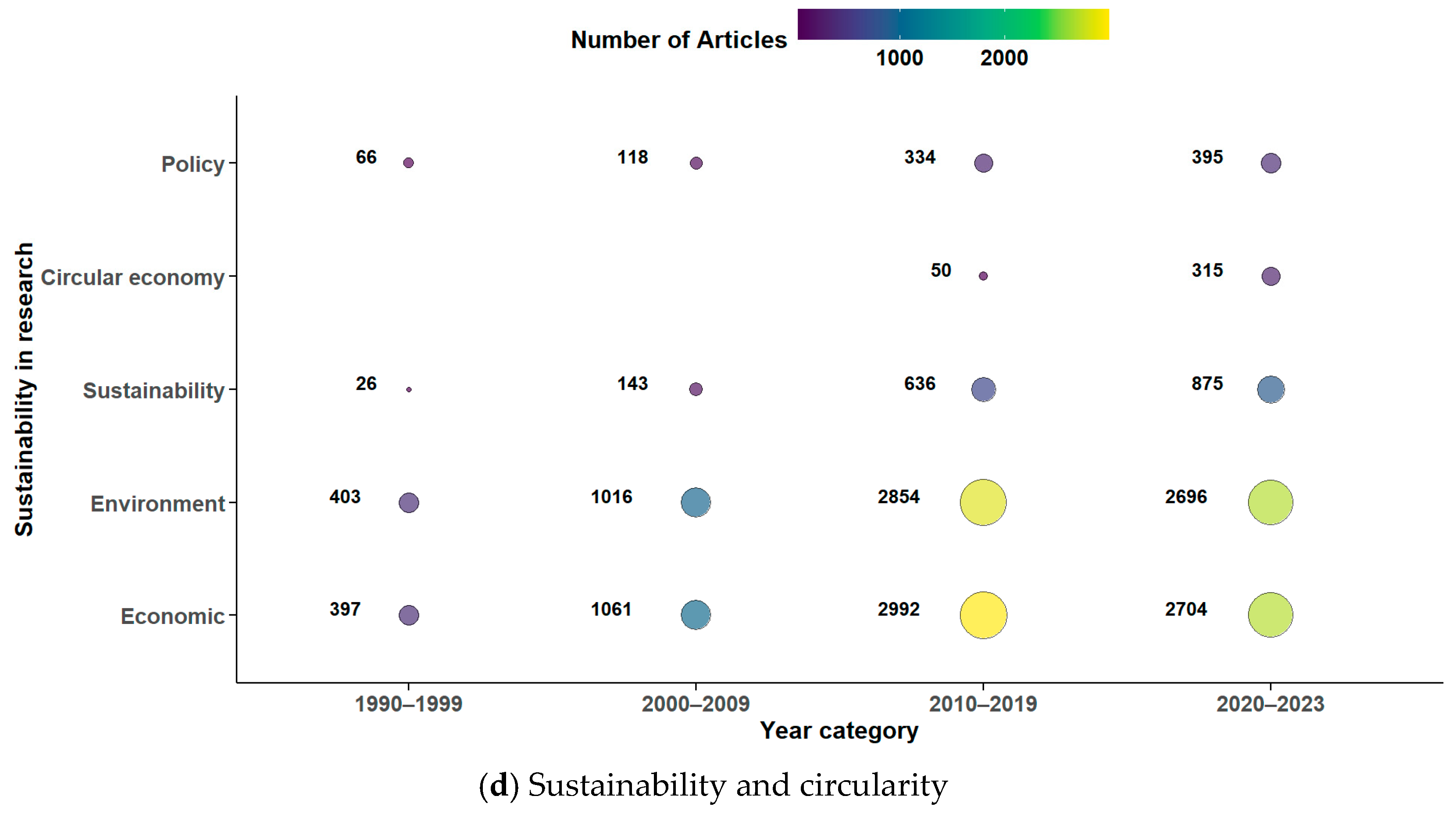

3.5. Sustainability and Circularity in MSW Research

The study showed that research focusing on sustainability, circularity, and policy is increasing (Figure 2d). The economy was the topic most often mentioned in the studies, followed by the environment, sustainability, policy, and circular economy. Before 2010, most studies mentioned the environment, followed by the economy. This demonstrates the growing interest in developing environmentally friendly and economically viable MSW management and valorization technologies. The environment and economy are two pillars of sustainability. Favorable policies are necessary to establish a sustainable system, and similar trends were observed in policy-related studies. The circular economy concept was initially used in a study published in 2012 [47]. Only five articles discussed the circular economy between 2010 and 2019, but this number increased to about 79 between 2020 and 2023. This highlights the growing interest in circular economy-related research in MSW. Such research aims to develop strategies for a sustainable closed-loop system that minimizes environmental impact while maximizing resource recovery and reducing waste generation.

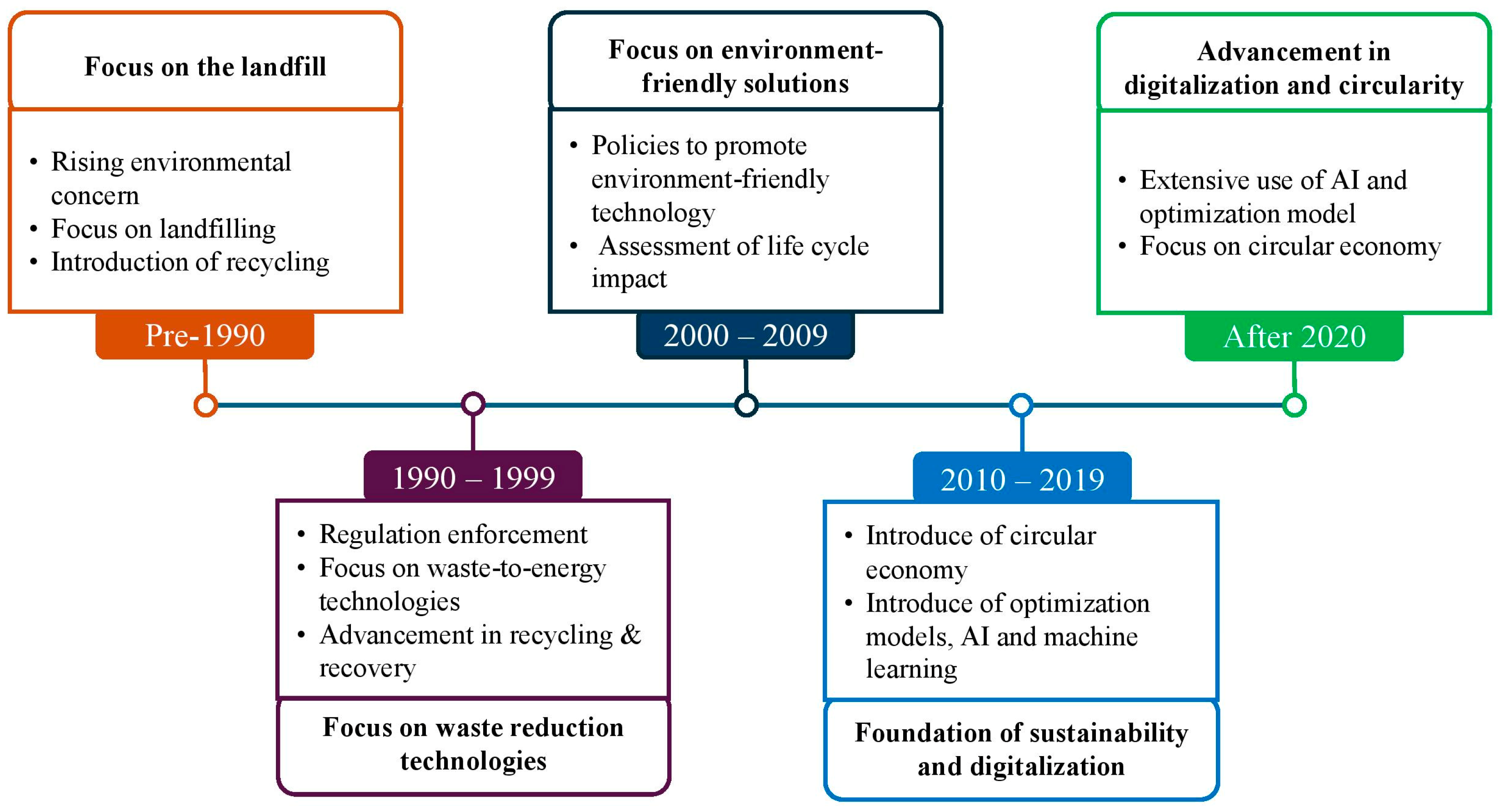

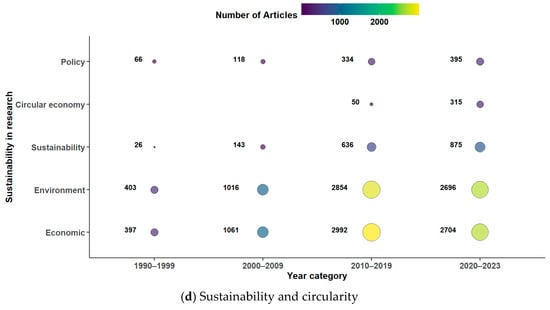

3.6. Global MSW Management Timeline

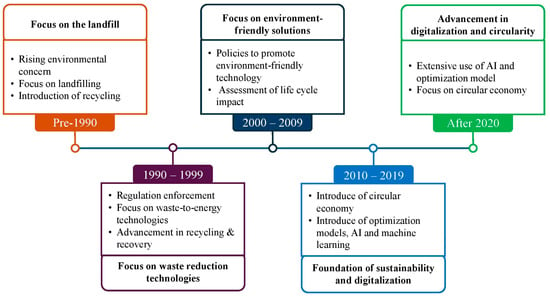

Based on the global MSW research trend analysis considering the management and valorization pathways, software and tools, and sustainability and circularity in research, the study has broadly categorized timeline as era of landfilling (pre-1990), foundation of waste-to-energy technology (1990–1999), advancement and diversification of waste-to-energy technology (2000–2009), foundation of sustainability and digitalization (2010–2019), and advancement in digitalization and circularity (2020–2023) (Figure 3).

Figure 3.

Global MSW management and valorization trend timeline. It is categorized into five phases: focus on landfilling (pre-1990), focus on waste reduction technology (1990–1999), focus on environment-friendly solutions (2000–2009), the foundation of sustainability and digitalization (2010–2019), and advancement in digitalization and circularity (after 2020).

Focus on landfill (Pre-1990): Before 1990, the global focus was on getting rid of city trash. Rapid and unplanned urbanization after the Second World War [48] triggered the rise in MSW. The surge in MSW quantity and its environmental consequences raised concern, which increased the global focus on landfilling. Landfilling technology needs relatively low technical requirements and low cost [49] but is associated with degrading the nearby soil, air, and water [4], and also the loss of resources. Landfilling needs significant land areas and finding new land for increasing MSW is increasingly challenging. It is also a matter of conflict in many cities due to the protests of nearby settlements [50]. Furthermore, landfilling is a loss of resources, which can be recovered by adopting recycling and recovery approaches. Initially, open dumping was practiced with no regulations, but then early sanitary landfills emerged, on which soil is used to cover the waste to reduce odors and pollution [51]. After that, landfills were designed with liners, a system to collect leachate, and gas venting to prevent pollution [52]. Modern landfills use advanced technology to monitor the environment and recover methane, which helps manage the site long-term. The latest innovation is bioreactor landfills, which speed up waste decomposition by controlling moisture and air input [53], promoting sustainability and energy recovery. Consequently, recycling and recovery techniques were introduced for MSW management and valorization.

Focus on waste reduction technologies (1990–1999): In this period, various MSW management, valorization pathways, and different tools were introduced. The recycling and recovery approaches were adopted by countries. The approaches have numerous benefits for environmental protection, economic generation, and resource conservation. Waste reduction strategies focusing on waste-to-energy technologies, such as gasification and pyrolysis, also gained momentum for MSW management and valorization during this period. In addition, studies were found mentioning the chemical conversion process to produce biodiesel from MSW (Figure 2a). During this period, LCA, an environmental impact assessment tool; GIS; and remote sensing were also introduced.

Focus on environment-friendly solutions (2000–2009): During this period, MSW management and valorization technology diversified and advanced, and research was increased to assess the environmental impact of the technology through its life cycle. This is supported by a four-fold increase in LCA research during this period compared to 1990–1999 (Figure 2c). Similarly, the research mentioned the environment had also increased from about 40 articles per year in 1990–1999 to 100 articles per year in this period.

Foundation of sustainability and digitalization (2010–2019): During this period, the circular economy concept was adopted in MSW management and valorization. This approach significantly contributes to sustainability, resource conservation, waste reduction, environmental protection, and economic generation. In the same period, studies investigated optimization in MSW management and valorization, and machine learning and AI were also introduced in the research.

Advancement in digitalization and circularity (After 2020): Research on the circular economy has skyrocketed during this period (Figure 2d). This shows the focus on advancing circularity in MSW. Similarly, the use and advancement of optimization tools have also been found to be increasing (Figure 2c).

Overall, trend analysis showed that future research will continuously increase in focus on reducing MSW by adopting closed-loop systems, such as circular economy concepts and process optimization. Optimization tools, machine learning, and AI will also be extensively used.

4. MSW Management and Valorization Pathways

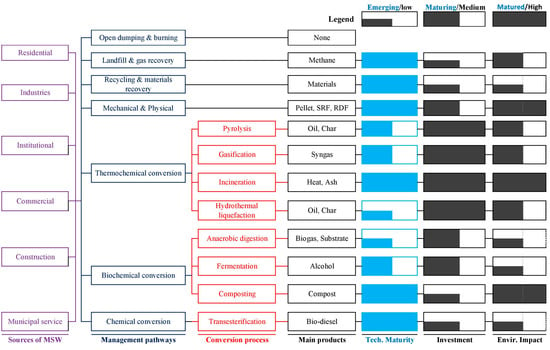

The study showed that MSW is managed mainly through seven major routes: open dumping and burning, recycling and material recovery, landfill and gas recovery, physical conversion, thermochemical conversion, biochemical conversion, and chemical conversion (Figure 4). In this section, critical discussions of each route, along with the TEE (Table 1 and Figure 4), SWOT (Table A3), and PESTEL (Table A4) analyses, are presented except for open dumping and burning.

Figure 4.

Source of MSW, management and conversion pathways and process, main products, and TEE of the associated process. Technology maturity is categorized into emerging, maturing, and matured, while investment and environmental impacts are categorized as low, medium, and high.

Table 1.

Technical maturity, economic (cost), and emissions associated with each management pathway and conversion process of MSW.

4.1. Open Dumping and Burning

Open dumping and burning are prevalent MSW management practices, especially in low-income countries, where the major fraction of waste is handled this way due to weak regulations [3]. While burning methods reduce waste mass and volume by 70–80% and 90%, respectively [69], a study [58] has reported that per tonne of waste generates 580 kg of ash in open burning and 0.444 m³ of untreated leachate in open dumping. Though heat may reduce bioactivity and odors and deter disease vectors, the environmental costs are severe. Regulation varies widely: some areas enforce penalties, while others overlook violations, influenced by socio-economic and seasonal factors. For instance, MSW burning in Delhi, India, ranged from 90 to 1170 kg/km2 in winter and 13 to 1100 kg/km2 in summer, highest in poorer areas [70]. Economically favored for its low cost, it degrades geotechnical soil properties—dry density, California bearing ratio, and cohesion—and increases pH, total dissolved solids, electrical conductivity, and toxic metal content [71,72]. This degradation reduces plant diversity and affects nearby ecosystems [73], harming aquatic life [74], wildlife [75], and humans [76]. Methane emissions from decaying organics contribute to climate change [77]. Among all the methods, open burning causes the most harm to health and the environment [58]. Strong legal frameworks are essential to mitigate these impacts.

4.2. Recycling and Material Recovery

The scientific community initiated recycling documentation in 1972, aiming to reuse plastics from MSW in the USA [78]. Worldwide, around 14% of MSW is recycled, with high-income nations recycling approximately 29%, whereas low-income countries recycle only about 4% [3]. MSW consists of recyclable items like organic waste, plastics, metals, glass, and wood. Efficient waste management is crucial for urban well-being and includes collecting and sorting recyclables at specific separation centers. Recycling generates economic benefits from materials such as plastics, paper, and metals, whereas organic waste can be converted into compost or biogas. For instance, recycling a ton of mobile phones can produce 0.347 kg of gold, which accounts for 80% of the material’s worth [79]. Furthermore, recycling construction waste, such as paper, rubber, plastics, and textiles, into composite materials boosts infrastructure by increasing durability and strength [80].

Recycling and material recovery play a crucial role in managing MSW in developed countries due to advancements in technology. Improvements in sorting and processing techniques, such as automation, have greatly enhanced these operations. While concerns about cross-contamination have mainly been mitigated [81], developing nations still face challenges stemming from technological gaps [82]. In these regions, manual sorting often lacks essential precautions, resulting in health hazards and higher contamination rates [83]. In terms of cost, recycling and recovery are low-cost pathways; studies have reported that it costs around USD 105.8–140.0 per tonne of MSW [62,63]. Significant environmental issues arise from recycling processes, including transportation and machinery usage. However, recycling generally has a lesser impact than landfilling and thermochemical methods. It promotes a waste-based economy, creates job opportunities, conserves energy in production, and protects nature [84].

Advancements in technology and rising demand for recycled materials, influenced by environmental concerns, reinforce recycling and material recovery [81]. Integration with other engineered routes helps lower environmental costs [58]. For example, recycling and biologically processing food waste help ease landfill burdens while recovering energy and generating bio-fertilizers [85]. However, challenges persist, such as limited public awareness and insufficient technology in many low-income nations, alongside high recycling costs [86]. In these areas, encouraging waste reduction and recycling is crucial, particularly for food waste, metal scraps, and plastics. The increasing costs of virgin materials are driving demand for recycled goods, creating significant opportunities in this sector [87]. Still, trade barriers and competition for new resources pose considerable threats to the recycling industry [88]. Additionally, stringent regulations can both promote and impede recycling efforts.

4.3. Landfill and Gas Recovery

Landfills are the oldest and most common waste disposal method, with organized waste burial starting in the 1940s [51]. Sanitary landfills incorporate features such as lined bottoms, leachate collection systems, groundwater monitoring, and gas collection systems, either flared or converted into energy, along with caps [89]. This regulated environment allows MSW to be buried with advanced barriers that safeguard the environment for many years, significantly reducing harmful emissions compared to open dumping. Approximately 37% of the world’s MSW is sent to landfills, with around 8% undergoing processing via gas recovery systems [3]. In contrast to natural geotechnical materials, landfilled MSW experiences biodegradation, which results in leachate and gas production, heat release, waste compression, and deformation. The composition of raw landfill gas includes 50–60% methane, 40–50% carbon dioxide, and nearly 1% trace gases from different components of MSW [90]. The methane generated from organic waste is captured for energy conversion, and studies suggest that landfill methane in Delhi could provide electricity to between 0.8 and 1.8 million households, amounting to 80–183 gigawatt-hours [79]. Furthermore, leachate, a byproduct characterized by high chemical oxygen demand (COD) levels (100–70,900 mg/L) and a biochemical oxygen demand (BOD)/COD ratio of 0.04–0.7, shows lower biodegradability compared to municipal wastewater [91]. Nonetheless, the physicochemical and biological processes occurring within landfills contribute to the breakdown of MSW, making careful site selection crucial due to various influencing factors [84].

Landfill gas recovery is a cost-efficient, scalable method for producing renewable energy and lowering GHG emissions. The costs associated with the technology range between USD 76.3 and 115.7 per tonne of MSW [58,64]. As land becomes scarcer and operational costs rise, the expenses of this process increase. While gas recovery can help reduce pollution and GHG emissions [92], it still contributes significant emissions, estimated at 9855 kg CO2e per tonne of MSW, primarily from methane [67]. Advancements in landfill design and gas capture technology can improve efficiency. However, the presence of hazardous materials in MSW, such as cadmium, zinc, lead, and copper, creates risks by producing trace gases and cancer-causing compounds like benzene and vinyl chloride [90,93,94], which has led to public protests and political protests against landfills. Effective risk management entails the close monitoring of MSW characteristics, chemical components, leachate, gas flow, and material movement [95]. Regular pollution leakage monitoring is crucial at every landfill [96], in both the operating and closure phases, but it incurs extra costs. In addition to this, rising public protests by nearby settlements, increasing costs, and limited land availability are prompting a global shift from landfilling toward alternative waste management strategies [50].

4.4. Mechanical and Physical Conversion

The history of refuse-derived fuels (RDFs) traces back to the late 19th century when MSW was first used as fuel for steam generation [97]. Originating in England, the practice quickly spread to the USA, Germany, and Japan. In the 1890s, New York City innovated a technique that involved handpicking solid waste to recover valuables, using the remaining material as RDF for electricity generation. Following the removal of non-combustible items, MSW with high calorific content can be processed and shredded to create RDF [98], which may subsequently be treated to produce solid recovered fuel (SRF) with uniform specifications. RDF and SRF can be pelletized using mechanical pressing, which helps reduce the volume and storage and transportation costs. SRF and RDF are mainly used in thermal power plants, such as in the cement industry, as coal substitutes [99]. This process minimizes waste disposal demands, mitigates environmental impact, and supports a circular economy. To enhance conversion efficiency, comprehensive waste characterization, technological advancements, and robust waste collection and segregation systems are crucial.

Overall, MSW’s mechanical and physical conversion to RDF and SRF is a mature technology capable of processing a variety of MSW types and potentially replacing traditional fuels such as coal [100]. However, the main challenge in this route is that the product’s properties vary with the feedstock and contain harmful pollutants, such as heavy metals, if not appropriately segregated before feeding to the plant [101]. The capital cost for RDF is reported to be about USD 20,273.7–55,887.2 per tonne of MSW [65]. The reported production cost for RDF is 24 USD/tonne, which is lower than coal with a comparable heating value [102]. Although the process is considered energy-intensive, as it requires significant energy to sort, shred, and compress the MSW, it does not significantly impact the environment during production and reduces the landfill burden. However, when RDF is burned in thermal power plants, it results in significant emissions, although replacing coal with RDF can decrease emissions by about 2.25 kg of CO2/kg of coal [100]. However, the product should adhere to environmental standards. Public awareness and acceptance of waste conversion technologies can influence their adoption, with communities increasingly supporting sustainable waste management solutions.

4.5. Thermochemical Conversion

Thermochemical conversion of MSW utilizes heat treatment and chemical processes to produce energy. Major thermochemical techniques for MSW conversion include pyrolysis, gasification, incineration, and hydrothermal liquefaction. Pyrolysis occurs without oxygen at temperatures between 400 and 700 °C, yielding bio-oil, biochar, and gas [103]. These byproducts of pyrolysis are useful for various applications, such as chemical manufacturing, soil improvement, water purification, and fuel production. Lignocellulosic biomass, the primary renewable feedstock in MSW, has the potential to partially substitute fossil fuels and lessen GHG emissions [104]. Bio-oil composition, derived from carbohydrates and aromatic lignin in biomass, significantly impacts its yield and composition. However, despite emitting lower SOx and NOx than petroleum oil, bio-oil faces challenges as a fuel due to drawbacks like high acid content, oxygenation, low volatility, and elevated water content [105]. Recent advancements in biochar production and functionalization have underscored its significance as a long-term carbon resource for combating climate change [106]. Pyrolysis is preferred over other thermochemical methods because of its favorable processing conditions and lower costs associated with converting biomass to liquids [107]. Despite this preference, biomass pyrolysis remains intricate due to the diversity of lignocellulosic materials, alongside the complexities involved in reaction chemistry and reactor design.

In supplying partial oxygen, MSW can be converted into syngas by a gasification process over 550 °C [108]. Syngas can produce electricity or power internal combustion engines and can be further processed into hydrogen (H2), with promising research and development in this area. However, incineration in lower- and middle-income countries faces challenges due to MSW’s low caloric value, requiring an average of 7 MJ/kg for efficient combustion, influenced by socio-economic and climatic diversity [108]. To overcome such under-colorific value, supplementary fuel is needed, which incurs extra costs. Additionally, incineration produces hazardous pollutants like polychlorinated biphenyls (PCBs), polychlorinated dibenzofurans (PCDFs), and polyaromatic hydrocarbons (PAHs), along with fly ash [109], which pose health and environmental risks. Thus, there is a pressing need for innovative waste-to-energy technologies that consider energy yield, chemical value, byproduct quality, and economic feasibility.

In incineration, MSW is directly burned to produce heat [109], which is used to produce electricity or for other thermal purposes. Due to its capability to achieve substantial volume reduction (up to ∼90%) and mass reduction (up to ∼70%) of waste, incineration has emerged as the most preferred waste disposal method in many major cities around the world [110]. MSW is subjected to enough oxygen for complete combustion in the incineration process. Incinerating for energy recovery has become a well-known and effective MSW management technique, especially in European countries, where strict regulations facilitate operations. Modern waste-to-energy systems are equipped with advanced air pollution control technologies such as electrostatic precipitators, bag filters, and sorbent injection systems [111]. The byproducts of this process include bottom ash, which is typically classified as non-hazardous, and fly ash, which is generally considered hazardous. However, numerous studies have explored the valorization of these residues. For example, vitrified bottom ash is used to produce sintered glass-ceramics [112], and fly ash is incorporated into geopolymer matrices with demonstrated chemical stability [113]. Furthermore, research has shown that artificial aggregates can be created using incineration bottom ash mixed with a low-alkalinity binder, providing a sustainable alternative for use as aggregates in the concrete industry [114]. Some studies reported on the sintering and phase transformation of ceramics derived from pretreated incinerator bottom ash [115] and the use of fly ash as a phosphate adsorbent, showing potential for wastewater management [116]. Furthermore, solidification/stabilization processes such as the Soliroc are employed to immobilize heavy metals within a cementitious matrix [113] further supporting the safe management. These advancements showed the potential for integrating the circular economy into incineration practices through material reuse and energy recovery.

Additionally, MSW can be converted into bio-crude for energy applications using a hydrothermal liquefaction (HTL) process as well, where wet MSW is treated at lower temperatures (300–400 °C) and high pressure (15–20 MPa) [117]. HTL utilizes water as a vital additive, enabling eco-friendly reactions like hydrolysis, condensation, decarboxylation, and dehydration. Okoligwe et al., 2022 [118] highlighted the substantial mass and energy efficiency of biofuel production through HTL with MSW. Despite reaching a maximum biofuel yield of 58% and a maximum energy recovery of 95% [117], precise design considerations are crucial for the optimal operation of this technique. Evaluating parameters such as temperature, reaction time, and waste-to-water ratio becomes imperative for enhancing energy efficiency, which needs more in-depth research for scaling up this system [119].

Comparatively, pyrolysis and hydrothermal liquefaction are emerging technologies for MSW conversion [23,55]. Gasification technology is proven for coal [120] but is still maturing for MSW conversion, mainly due to inconsistency in the feedstock properties and complexity in gas cleanup [23,55]. Incineration is a mature technology [55]; however, due to its high environmental impacts, it is not the preferred route for MSW management. The TRL varies by region; for instance, Renergi Pty Ltd (Perth, Australia)’s gasification technology has a higher TRL than Endeavour’s microwave-assisted technology in Italy [56]. The availability of advanced technologies influences TRL, while customer readiness level (CRL) and societal readiness level (SRL) are also vital for sustainability. Incineration, though mature, shows medium CRL and low SRL [55]. The investment costs for these technologies exceed those of other methods. The reported costs per tonne of MSW include pyrolysis (USD 41,902–304,238), gasification (USD 51,210–742,535), incineration (USD 77,200–697,998), and hydrothermal liquefaction USD 262,450 [59,61]. The high costs necessitate government support and pose a risk for investors. Nevertheless, increasing demand and favorable policies encourage the adoption of waste-to-energy technologies, despite their high initial expenses and negative impacts, which impede growth. Innovations are improving the efficiency of thermochemical processes like gasification and pyrolysis, enhancing their competitiveness. Incorporating emission control technology aids in promoting these solutions. Legally, these facilities must comply with strict environmental regulations to protect public health. Additionally, while these technologies can process diverse waste, design considerations must account for variations in feedstock properties. Overall, the analysis underscores the complex challenges and opportunities in optimizing thermochemical conversion technologies for waste management.

4.6. Biochemical Conversion

MSW contains considerable organic waste, such as food, which can be converted into energy and compost through biochemical processes facilitated by microbes. Key technologies for waste conversion include anaerobic digestion, composting, and fermentation. AD originated in South Asia in the 18th century and spread to Europe as technology advanced, but the biogas generation mechanism from organic decomposition was not understood until 1930 [121]. Converting organic waste into fuel reduces reliance on non-renewable energy sources like natural gas and coal and mitigates environmental impacts by lowering waste volume and capturing potent GHGs such as methane. During AD, bacteria break down organic waste anaerobically, producing biogas (primarily methane) and nutrient-rich substrates [122]. Methane can be utilized for electricity generation, vehicle fuel, or cooking [123]. While the substrate can serve as a bio-fertilizer, care must be taken as it may contain microplastics or heavy metals [124]. Thus, it is crucial to meticulously separate organic waste from non-organic impurities in MSW. Additionally, challenges such as MSW complexity, microbial sensitivity, inhibitory feedstock substances, and the need for pretreatment complicate the anaerobic digestion process [125].

Another promising and low-cost method is composting organic waste in a controlled system using microorganisms, which converts organic waste into compost, which is used as a soil fertilizer and can reduce the dependency on chemical fertilizers [126]. Under controlled circumstances—such as temperature, moisture, and oxygen levels—a microbial community breaks down organic matter, producing heat that accelerates the composting process. Composting methods can be categorized into two types: pre-fermentation, where waste is directly composted, and post-fermentation, where waste is first sorted from non-compostable items [127]. Typically, MSW undergoes post-fermentation decomposition, with the organic content breaking down for 2–4 weeks in the presence of oxygen [128]. The resulting compost is monitored, with unwanted materials removed, and it can undergo additional processing for various uses. Given the simplicity of the process and the fact that organic waste constitutes a significant portion of the waste stream, this method is both widely used and one of the most practical and effective ways to manage waste in developing countries. Nonetheless, composting has its drawbacks, including lengthy decomposition periods, the risk of contamination from hazardous substances such as heavy metals and plastics, and the necessity for substantial space during the composting process.

Another promising method of the utilization of organic waste is by converting it to alcohol, such as ethanol; volatile fatty acids; and hydrogen production through the fermentation process by using microorganisms. The produced alcohol can be used as fuel or further processed to make other valuable products such as plastics and pharmaceuticals [129,130,131]. However, such bioconversion needs various pretreatments as well as purification techniques for the final products. As this is not a fully optimized technology, the cost of production is high, and more research and development are needed to develop new strains of microorganisms for more efficient production and to make the technology viable [132].

Anaerobic digestion and composting are proven routes for MSW management and have high TRL and CRL; however, it has medium SRL [55]. The fermentation is still in the emerging stage [133]. The efficiency of the gas formation in anaerobic digestion varies with feedstock composition and process parameters, such as temperature and pH; therefore, critical consideration is needed while selecting the raw materials and designing the plant. As compared to thermochemical conversion technologies, the biochemical conversion process needs less investment. In biochemical conversion, composting technology needs low economic investment compared to anaerobic digestion and fermentation. The per tonnes of MSW conversion by anaerobic digestion needs USD 10,977.9–109,190.5 [65], while composting technologies need USD 3552.8–54,555.58 [65]. The capital investment reported by developing countries is significantly higher than that of developed countries, primarily due to limited access to technology and reliance on imported materials and equipment, which drives up investment costs [134]. However, composting produces much more environmental emissions (22,505 kg of CO2e/tonnes of MSW) than the other two technologies; anaerobic digestion produces 4106 kg of CO2e/tonnes of MSW [67]. Furthermore, compost and substrate produced from anaerobic digestion may contain hazardous materials, such as heavy metals and microplastic [135], which pose significant risks if used without treatment. In addition, there is a challenge in competing with chemical fertilizers. The viability depends on technology costs and potential revenue from biogas, biofuels, and organic fertilizers. Supportive policies for energy and compost generation from MSW facilitate the adoption of biochemical processes. Public support and awareness of the environmental benefits are crucial, although concerns about local impacts may arise. Overall, this route reduces landfill volume and GHG emissions while promoting sustainability. However, adherence to environmental regulations and safety standards is essential for the sustainability of technology.

4.7. Chemical Conversion

Chemical conversion through esterification is a method of converting the organic fraction of MSW to biodiesel. The production of biodiesel uses a range of feedstocks, comprising first-generation (edible oils), second-generation (non-edible oils, waste cooking oils, animal fats), and third-generation (algal biomass) sources [136]. The production of biodiesel involves the use of various catalysts, including homogeneous, heterogeneous, and enzyme catalysts, all following a common reaction pathway (alcohol + MSW (oil) → biodiesel + glycerin) [137]. The selection of the catalyst is vital for achieving production efficiency. While biodiesel helps lessen environmental effects and decrease dependency on fossil fuels, it faces economic challenges compared to fossil fuels [138]. Optimizing the use of non-edible oils and low-cost materials like waste cooking oil and animal fats can improve its economic feasibility, considering that feedstock expenses represent about 70% of the total biodiesel production costs [139].

Although being a mature technology for producing biodiesel from oil [140], it has several challenges, such as the availability of raw materials, logistical challenges (such as collection and transportation) [141], catalyst development [142], and economic viability [143]. Waste cooking oil and animal fats are the main sources of biodiesel production from MSW, but in most cases, it is not mixed with the MSW. Therefore, there is the challenge of obtaining enough quantity of raw materials for industrial-scale biodiesel production from MSW. The heterogeneous nature of the feedstock also makes the conversion route challenging [144,145]. The challenges must be addressed to make the technology viable.

It has been reported that per tonne of waste cooking oil can be converted to biodiesel with a total manufacturing cost of USD 165–487 [60]. Due to emissions regulations in vehicles, there is a supportive environment for biodiesel consumption, as it is still expensive to use fossil fuels. However, the government subsidiaries’ policies have helped promote clean energy and fuel alternatives. The study has shown that the production and sale of biodiesel produced from MSW at USD 1.47/L is competitive, especially in the USA and Germany [146]. Advancements in process efficiency can reduce the cost of production and, hence, the sustainability of the process.

5. Conclusions and Recommendations

The study revealed that the number of research publications related to MSW management and practices is increasing exponentially each year. The average annual growth rate of 10% has been consistent and has increased in recent years. In terms of publication numbers, the USA led before 2000. However, between 2000 and 2009, more articles were published from India, and since 2010, China has surpassed other countries by a significant margin. The trend analysis has shown that recent global research focuses more on sustainability and the circular economy, utilizing optimization tools. After a comprehensive literature review, seven MSW management and valorization pathways have been identified, including open dumping and burning, which are the most hazardous waste management techniques. Based on the literature-based TEE, PESTEL, and SWOT analyses, the study concluded that recycling and material recovery, followed by thermochemical conversion for high calorific waste and biochemical conversion for high organic waste, seem promising for MSW management and valorization routes.

Identifying the best route is vital for developing sustainable waste management. Each technology’s location-specific TEE, SWOT, and PESTEL assessments are necessary and recommended for further study.

Author Contributions

Conceptualization, S.K. and S.A.; methodology, S.K. and B.K.K.; software, S.K.; validation, S.K.; formal analysis, S.K. and B.K.K.; investigation, S.K. and B.K.K.; resources, S.A.; data curation, S.K.; writing—original draft preparation, S.K., B.K.K., and M.S.; writing—review and editing, S.A.; visualization, S.K.; supervision, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The raw data can be obtained upon request from the corresponding author.

Acknowledgments

S.K. would like to acknowledge Willington Arthur of Auburn University for the voluntary pre-review of this work. Generative AI tools, such as ChatGPT (GPT-3.5) Gemini (2.5 Flash), and Copilot (free version), were used to refine the code for RStudio. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AD | Anaerobic digestion |

| AI | Artificial Intelligence |

| CRL | Customer readiness level |

| CO2e | Carbon dioxide equivalent |

| EC | Electrical conductivity |

| GAMS | General algebraic modeling system |

| GHG | Greenhouse gas |

| GIS | Geographic Information Systems |

| HTL | Hydrothermal liquefaction |

| IEA | International Energy Agency |

| LCA | Life cycle assessment |

| MSW | Municipal solid waste |

| NASA | National Aeronautics and Space Administration |

| PAHs | Polyaromatic hydrocarbons |

| PCBs | Polychlorinated biphenyls |

| PCDFs | Polychlorinated dibenzofurans |

| PESTEL | Political, economic, social, technological, environmental, and legal |

| RDF | Refused derived fuel |

| SRF | Solid recovered fuel |

| SRL | Societal readiness level |

| SWOT | Strengths, weaknesses, opportunities, and threats |

| SWOLF | Solid waste optimization lifecycle framework |

| TDS | Total dissolved solids |

| TEE | Techno-economic and environmental |

| TRL | Technology readiness level |

| USA | United States of America |

| USD | United States Dollar |

| WARM | Waste reduction model |

Appendix A

Table A1.

Search syntax for Scopus database.

Table A1.

Search syntax for Scopus database.

| Syntax | Accessed Date |

|---|---|

| TITLE (“Municipal Waste” OR “Solid Waste” OR “Urban Waste” OR “City Waste”) AND PUBYEAR > 1903 AND PUBYEAR < 2024 AND (LIMIT-TO (SRCTYPE, “j”)) AND (LIMIT-TO (DOCTYPE, “ar”)) AND (LIMIT-TO (LANGUAGE, “English”)) | 21 July 2024 |

Table A2.

Number of articles published, growth rate, and top 5 countries by publication number in each categorized period.

Table A2.

Number of articles published, growth rate, and top 5 countries by publication number in each categorized period.

| Period | Number | Number/Year | Top 5 Countries by Number (Rank) |

|---|---|---|---|

| Before 1990 | 962 | 11 | USA, Canada, Italy, Japan, and UK |

| 1990–1999 | 1210 | 121 | USA, Spain, Italy, Japan, and UK |

| 2000–2009 | 2499 | 250 | India, USA, China, Japan, and Spain |

| 2010–2019 | 6062 | 606 | China, India, USA, Italy, and Spain |

| 2020–2023 | 4913 | 1229 | China, India, USA, Italy, and Iran |

Table A3.

SWOT analysis of MSW management and valorization pathways.

Table A3.

SWOT analysis of MSW management and valorization pathways.

| Management Pathways | Conversion Process | Strength | Weakness | Opportunities | Threats | References |

|---|---|---|---|---|---|---|

| Recycling and materials recovery |

|

|

|

| [81,88] | |

|

|

| ||||

|

| |||||

| Landfill and gas recovery |

|

|

|

| [50,92] | |

|

|

| ||||

| ||||||

| Mechanical and Physical |

|

|

|

| [101] | |

|

|

|

| |||

|

|

| ||||

| Thermochemical | Pyrolysis |

|

|

|

| [147,148] |

|

|

|

| |||

|

| |||||

| Gasification |

|

|

|

| [149,150] | |

|

|

|

| |||

| ||||||

| Incineration |

|

|

|

| [151,152] | |

|

|

| ||||

| Hydrothermal |

|

|

|

| [153,154] | |

| Liquefaction |

|

|

|

| ||

|

| |||||

| Biochemical | Anaerobic digestion |

|

|

|

| [122,124] |

|

|

|

| |||

| Fermentation |

|

|

|

| [129,130] | |

|

| |||||

| Composting |

|

|

|

| [131,155] | |

| Chemical | Esterification |

|

|

|

| [144,156] |

| ||||||

Table A4.

PESTEL analysis of MSW management and valorization pathways.

Table A4.

PESTEL analysis of MSW management and valorization pathways.

| Aspect | Recycling and Materials Recovery | Landfill and Gas Recovery | Mechanical and Physical Processes | Thermochemical Methods | Biological Processes | Chemical Processes |

|---|---|---|---|---|---|---|

| Political |

|

|

|

|

|

|

|

|

|

|

|

| |

| Economic |

|

|

|

|

|

|

|

|

|

|

|

| |

| Social |

|

|

|

|

|

|

|

|

|

|

| ||

| Technological |

|

|

|

|

|

|

|

|

|

|

|

| |

| Environmental |

|

|

|

|

|

|

|

|

|

|

| ||

| Legal |

|

|

|

|

|

|

|

|

|

|

|

| |

| References | [157,158] | [159,160] | [159,161] | [18,162] | [161,163] | [163] |

Figure A1.

Articles published per year between 1990 and 2023. The trend demonstrated a good fit with an R2 of 0.986 for the exponential trend line.

Figure A1.

Articles published per year between 1990 and 2023. The trend demonstrated a good fit with an R2 of 0.986 for the exponential trend line.

References

- UNDESA The World’s Cities in 2018—Data Booklet. United Nations, Dep. Econ. Soc. Aff. Popul. Division (2018). 2018. Available online: https://digitallibrary.un.org/record/3799524/files/the_worlds_cities_in_2018_data_booklet.pdf (accessed on 23 August 2024).

- Khatib, I.A. Municipal solid waste management in developing countries: Future challenges and possible opportunities. In Integrated Waste Management; Kumar, S., Ed.; InTech: London, UK, 2011; Volume 2, pp. 35–48. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018; ISBN 9788578110796. [Google Scholar]

- Gautam, A.; Malla, D.; Thapa, B.; Khatiwada, A.; Kafley, G.; Shah, S.K.; Kafle, S. Effects of Open Dumping Site on Surrounding Air, Soil, and Water: A Case Study of Biratnagar Metropolitan City. Bibechana 2024, 21, 171–179. [Google Scholar] [CrossRef]

- Guerrero, L.A.; Maas, G.; Hogland, W. Solid Waste Management Challenges for Cities in Developing Countries. Waste Manag. 2013, 33, 220–232. [Google Scholar] [CrossRef] [PubMed]

- Medina-mijangos, R.; Seguí-amórtegui, L. Research Trends in the Economic Analysis of Municipal Solid Waste Management Systems: A Bibliometric Analysis from 1980 to 2019. Sustainability 2020, 12, 8509. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, W.; Yang, Y.; Yang, Y.; Man, X. Global Trends of Municipal Solid Waste Research from 1997 to 2014 Using Bibliometric Analysis. J. Air Waste Manag. Assoc. 2015, 65, 1161–1170. [Google Scholar] [CrossRef]

- Li, N.; Han, R.; Lu, X. Bibliometric Analysis of Research Trends on Solid Waste Reuse and Recycling during 1992–2016. Resour. Conserv. Recycl. 2018, 130, 109–117. [Google Scholar] [CrossRef]

- Fu, H.Z.; Ho, Y.S.; Sui, Y.M.; Li, Z.S. A Bibliometric Analysis of Solid Waste Research during the Period 1993–2008. Waste Manag. 2010, 30, 2410–2417. [Google Scholar] [CrossRef]

- Otero Meza, D.D.; Sagastume Gutiérrez, A.; Cabello Eras, J.J.; Salcedo Mendoza, J.; Hernández Ruydíaz, J. Techno-Economic and Environmental Assessment of the Landfill Gas to Energy Potential of Major Colombian Cities. Energy Convers. Manag. 2023, 293, 117522. [Google Scholar] [CrossRef]

- Leme, M.M.V.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Lopes, B.M.; Ferreira, C.H. Techno-Economic Analysis and Environmental Impact Assessment of Energy Recovery from Municipal Solid Waste (MSW) in Brazil. Resour. Conserv. Recycl. 2014, 87, 8–20. [Google Scholar] [CrossRef]

- El Ibrahimi, M.; Khay, I.; El Maakoul, A.; Bakhouya, M. Techno-Economic and Environmental Assessment of Anaerobic Co-Digestion Plants under Different Energy Scenarios: A Case Study in Morocco. Energy Convers. Manag. 2021, 245, 114553. [Google Scholar] [CrossRef]

- Zorpas, A.A. Strategy Development in the Framework of Waste Management. Sci. Total Environ. 2020, 716, 137088. [Google Scholar] [CrossRef]

- Paes, L.A.B.; Bezerra, B.S.; Deus, R.M.; Jugend, D.; Battistelle, R.A.G. Organic Solid Waste Management in a Circular Economy Perspective—A Systematic Review and SWOT Analysis. J. Clean. Prod. 2019, 239, 118086. [Google Scholar] [CrossRef]

- Faisal, F.; Rasul, M.G.; Jahirul, M.I.; Schaller, D. Pyrolytic Conversion of Waste Plastics to Energy Products: A Review on Yields, Properties, and Production Costs. Sci. Total Environ. 2023, 861, 160721. [Google Scholar] [CrossRef]

- Chaher, N.E.H.; Nassour, A.; Nelles, M. Cross-Mediterranean Insights: Governance in Action for Circular Economy and Sustainable Waste Management Solutions in Tunisia’s Tourism. Recycling 2025, 10, 9. [Google Scholar] [CrossRef]

- Thakur, V. Framework for PESTEL Dimensions of Sustainable Healthcare Waste Management: Learnings from COVID-19 Outbreak. J. Clean. Prod. 2021, 287, 125562. [Google Scholar] [CrossRef]

- Song, J.; Sun, Y.; Jin, L. PESTEL Analysis of the Development of the Waste-to-Energy Incineration Industry in China. Renew. Sustain. Energy Rev. 2017, 80, 276–289. [Google Scholar] [CrossRef]

- Kumarasiri, B.; Dissanayake, P. Barriers to Implementing Waste-to-Energy Projects in Sri Lanka: A PESTEL Analysis. Built Environ. Proj. Asset Manag. 2021, 11, 544–558. [Google Scholar] [CrossRef]

- Turkyilmaz, A.; Guney, M.; Karaca, F.; Bagdatkyzy, Z.; Sandybayeva, A.; Sirenova, G. A Comprehensive Construction and Demolition Waste Management Model Using PESTEL and 3R for Construction Companies Operating in Central Asia. Sustainability 2019, 11, 1593. [Google Scholar] [CrossRef]

- Kafle, S.; Sapkota, S.; Higgins, B.T.; Adhikari, S. Research Trends in Life Cycle Assessment of Hydrogen Production: Methodological Review on Thermochemical Conversion Processes. Int. J. Hydrog. Energy 2025, 106, 432–443. [Google Scholar] [CrossRef]

- Catherine, G. Manning Technology Readiness Levels. Available online: https://www.nasa.gov/directorates/somd/space-communications-navigation-program/technology-readiness-levels/ (accessed on 8 September 2024).

- IEA. ETP Clean Energy Technology Guide. Available online: https://www.iea.org/data-and-statistics/data-tools/etp-clean-energy-technology-guide (accessed on 8 September 2024).

- Brander, M.; Greenhouse Gases, CO2, CO2e, and Carbon: What Do All These Terms Mean? Econometrica, White Papers. 2012, 2–3. Available online: https://bluemangrove.fund/wp-content/uploads/2021/03/Glossary-on-different-CO2-terms.pdf (accessed on 8 September 2024).

- William, F. Morse The Utilization and Disposal of Municipal Waste. J. Frankl. Inst. 1904, 79, 401–423. [Google Scholar] [CrossRef]

- Rhoads, R.A.; Wang, X.; Shi, X.; Chang, Y. China’s Rising Research Universities: A New Era of Global Ambition; JHU Press: Baltimore, MD, USA, 2014; ISBN 1421414546. [Google Scholar]

- Owens, B.B. China Seeks to Showcase Research Clout by Building Its Own Publishing Realm. Nature 2023, 630, 5–7. [Google Scholar]

- Paudel, P.P.; Kafle, S.; Park, S.; Kim, S.J.; Cho, L.; Kim, D.H. Advancements in Sustainable Thermochemical Conversion of Agricultural Crop Residues: A Systematic Review of Technical Progress, Applications, Perspectives, and Challenges. Renew. Sustain. Energy Rev. 2024, 202, 114723. [Google Scholar] [CrossRef]

- Nandhini, R.; Berslin, D.; Sivaprakash, B.; Rajamohan, N.; Vo, D.V.N. Thermochemical Conversion of Municipal Solid Waste into Energy and Hydrogen: A Review. Environ. Chem. Lett. 2022, 20, 1645–1669. [Google Scholar] [CrossRef]

- Tansel, B. From Electronic Consumer Products to E-Wastes: Global Outlook, Waste Quantities, Recycling Challenges. Environ. Int. 2017, 98, 35–45. [Google Scholar] [CrossRef]

- Abubakar, A.; Zangina, A.S.; Maigari, A.I.; Badamasi, M.M.; Ishak, M.Y.; Abdullahi, A.S.; Haruna, J.A. Pollution of Heavy Metal Threat Posed by E-Waste Burning and Its Assessment of Human Health Risk. Environ. Sci. Pollut. Res. 2022, 29, 61065–61079. [Google Scholar] [CrossRef]

- Singh, N.; Ogunseitan, O.A.; Tang, Y. Technology Medical Waste: Current Challenges and Future Opportunities for Sustainable Management Medical Waste: Current Challenges and Future. Crit. Rev. Environ. Sci. Technol. 2022, 52, 2000–2022. [Google Scholar] [CrossRef]

- Jacob, M.; Jacob, M.; Basile, N.S.; Munjal, S. Bio-Medical Waste and COVID-19 Pandemic. In Pandemic. In Pandemic Perspectives: Praxis, Policy and Pedagogies; Taylor & Francis: New York, NY, USA, 2024; p. 133. [Google Scholar]

- Tafesse, S.; Girma, Y.E.; Dessalegn, E. Analysis of the Socio-Economic and Environmental Impacts of Construction Waste and Management Practices. Heliyon 2022, 8, e09169. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O. Policy Imperatives for Diverting Construction Waste from Landfill: Experts’ Recommendations for UK Policy Expansion. J. Clean. Prod. 2017, 147, 57–65. [Google Scholar] [CrossRef]

- Cummings, L.E. Hospitality Solid Waste Minimization: A Global Frame. Int. J. Hosp. Manag. 1992, 11, 255–267. [Google Scholar] [CrossRef]

- David, J.E. Groundwater Exploitation and Recharge, and Contamination by Industry, Agriculture and Municipal Waste. Int. J. Ecol. Environ. Sci. 1992, 18, 179–193. [Google Scholar]

- Callas, M.D.; Kerzee, R.G.; Bing-Canar, J.; Mensah, E.K.; Croke, K.G.; Swager, R.R. An Indicator of Solid Waste Generation Potential for Illinois Using Principal Components Analysis and Geographic Information Systems. J. Air Waste Manag. Assoc. 1996, 46, 414–421. [Google Scholar] [CrossRef]

- Basri, H.B.; Stentiford, E.I. Expert Systems in Solid Waste Management. Waste Manag. Res. 1995, 13, 67–89. [Google Scholar] [CrossRef]

- Abbasi, M.; El Hanandeh, A. Forecasting Municipal Solid Waste Generation Using Artificial Intelligence Modelling Approaches. Waste Manag. 2016, 56, 13–22. [Google Scholar] [CrossRef] [PubMed]

- Mahmoudkhani, R.; Valizadeh, B.; Khastoo, H. Greenhouse Gases Life Cycle Assessment (GHGLCA) as a Decision Support Tool for Municipal Solid Waste Management in Iran. J. Environ. Health Sci. Eng. 2014, 12, 71. [Google Scholar] [CrossRef] [PubMed]

- Levis, J.W.; Barlaz, M.A.; Decarolis, J.F.; Ranjithan, S.R. Systematic Exploration of Efficient Strategies to Manage Solid Waste in U.S Municipalities: Perspectives from the Solid Waste Optimization Life-Cycle Framework (SWOLF). Environ. Sci. Technol. 2014, 48, 3625–3631. [Google Scholar] [CrossRef] [PubMed]

- Asefi, H.; Lim, S. A Novel Multi-Dimensional Modeling Approach to Integrated Municipal Solid Waste Management. J. Clean. Prod. 2017, 166, 1131–1143. [Google Scholar] [CrossRef]

- Levis, J.W.; Barlaz, M.A.; DeCarolis, J.F.; Ranjithan, S.R. A Generalized Multistage Optimization Modeling Framework for Life Cycle Assessment-Based Integrated Solid Waste Management. Environ. Model. Softw. 2013, 50, 51–65. [Google Scholar] [CrossRef]

- Ooi, J.K.; Woon, K.S. Simultaneous Greenhouse Gas Reduction and Cost Optimisation of Municipal Solid Waste Management System in Malaysia. Chem. Eng. Trans. 2021, 83, 487–492. [Google Scholar] [CrossRef]

- de Medeiros Engelmann, P.; dos Santos, V.H.J.M.; da Rocha, P.R.; dos Santos, G.H.A.; Lourega, R.V.; de Lima, J.E.A.; Pires, M.J.R. Analysis of Solid Waste Management Scenarios Using the WARM Model: Case Study. J. Clean. Prod. 2022, 345, 130687. [Google Scholar] [CrossRef]

- Jian, C.; Ya, C.; Yu, J.; Miaoyi, C. Application of EPR System on Solid Waste Management in Advanced Economies and Its Enlightenment to Mainland China. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2012, 30, 999–1006. [Google Scholar]

- Meier zu Selhausen, F. Growing Cities: Urbanization in Africa; African Economic History Network (AEHN): Roma, Lesotho, 2020; ISBN 9789464476521. Available online: https://www.aehnetwork.org/wp-content/uploads/2016/01/Meier-zu-Selhausen.Growing-Cities.pdf (accessed on 18 November 2024).

- Vaverková, M.D. Landfill Impacts on the Environment—Review. Geosciences 2019, 9, 431. [Google Scholar] [CrossRef]

- Martus, E. Municipal Solid Waste Management in Russia: Protest, Policy, and Politics. Russ. Anal. Dig. 2020, 23, 2–6. [Google Scholar] [CrossRef]

- Bell, J.M. Sanitary Landfill Method of Solid Waste Disposal. Engng Bull. Purdue Univ. Ext. Ser. 1973, 141, 110–130. [Google Scholar]

- Haxo, H.E.; White, R.M.; Haxo, P.D.; Fong, M.A. Liner Materials Exposed to Municipal Solid Waste Leachate. Waste Manag. Res. 1985, 3, 41–54. [Google Scholar] [CrossRef]

- Slezak, R.; Krzystek, L.; Ledakowicz, S. Degradation of Municipal Solid Waste in Simulated Landfill Bioreactors under Aerobic Conditions. Waste Manag. 2015, 43, 293–299. [Google Scholar] [CrossRef]

- Themelis, N.J.; Reshadi, S. Potential for Reducing the Capital Costs of WTE Facilities. In Proceedings of the 17th Annual North American Waste-to-Energy Conference NAWTEC 17, Chantilly, VA, USA, 18–20 May 2009; pp. 245–251. [Google Scholar] [CrossRef]

- Munir, M.T.; Mohaddespour, A.; Nasr, A.T.; Carter, S. Municipal Solid Waste-to-Energy Processing for a Circular Economy in New Zealand. Renew. Sustain. Energy Rev. 2021, 145, 111080. [Google Scholar] [CrossRef]

- Jafri, Y.; Waldheim, L.; Lundgren, J. Emerging Gasification Technologies for Waste & Biomass; IEA Bioenergy Task 33: Paris, France, 2020; ISBN 978-1-910154-84-7. Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/02/Emerging-Gasification-Technologies_final.pdf (accessed on 8 November 2024).

- Kowalski, Z.; Kulczycka, J.; Verhé, R.; Desender, L.; De Clercq, G.; Makara, A.; Generowicz, N.; Harazin, P. Second-Generation Biofuel Production from the Organic Fraction of Municipal Solid Waste. Front. Energy Res. 2022, 10, 919415. [Google Scholar] [CrossRef]

- Prateep Na Talang, R.; Sirivithayapakorn, S. Environmental and Financial Assessments of Open Burning, Open Dumping and Integrated Municipal Solid Waste Disposal Schemes among Different Income Groups. J. Clean. Prod. 2021, 312, 127761. [Google Scholar] [CrossRef]

- Satiada, M.A.; Calderon, A. Comparative Analysis of Existing Waste-to-Energy Reference Plants for Municipal Solid Waste. Clean. Environ. Syst. 2021, 3, 100063. [Google Scholar] [CrossRef]

- Esmaeili, H. A Critical Review on the Economic Aspects and Life Cycle Assessment of Biodiesel Production Using Heterogeneous Nanocatalysts. Fuel Process. Technol. 2022, 230, 107224. [Google Scholar] [CrossRef]

- Rahman, W.-U.; Patel, M.; Kurian, V.; Kumar, A. A Comparative Techno-Economic Assessment of Fast Pyrolysis, Hydrothermal Liquefaction, and Intermediate Pyrolysis of Municipal Solid Waste for Liquid Transportation Fuels Production. Energy Convers. Manag. 2022, 267, 115877. [Google Scholar] [CrossRef]

- Lavee, D. Is Municipal Solid Waste Recycling Economically Efficient? Environ. Manag. 2007, 40, 926–943. [Google Scholar] [CrossRef]

- LeMoult, C.; The Cost of Recycling Hits Budgets in Massachusetts Cities and Towns. GBH 2020. Available online: https://www.wgbh.org/news/local/2020-03-09/the-cost-of-recycling-hits-budgets-in-massachusetts-cities-and-towns (accessed on 30 May 2025).

- EPA. Full Cost Accounting for Municipal Solid Waste Management: A Handbook; U.S. Environmental Protection Agency [Office of] Solid Waste and Emergency Response: Washington, DC, USA, 1997. [Google Scholar]

- Aleluia, J.; Ferrão, P. Assessing the Costs of Municipal Solid Waste Treatment Technologies in Developing Asian Countries. Waste Manag. 2017, 69, 592–608. [Google Scholar] [CrossRef]

- Verma, R.L.; Borongan, G. Emissions of Greenhouse Gases from Municipal Solid Waste Management System in Ho Chi Minh City of Viet Nam. Urban Sci. 2022, 6, 78. [Google Scholar] [CrossRef]

- Kristanto, G.A.; Koven, W. Estimating Greenhouse Gas Emissions from Municipal Solid Waste Management in Depok, Indonesia. City Environ. Interact. 2019, 4, 100027. [Google Scholar] [CrossRef]

- Hu, Z.; Shen, J.; Tan, P.; Lou, D. Life Cycle Carbon Footprint of Biodiesel Production from Waste Cooking Oil Based on Survey Data in Shanghai, China. Energy 2025, 320, 135318. [Google Scholar] [CrossRef]

- Hjelmar, O.; Johnson, A.; Comans, R. Incineration: Solid Residues. In Solid Waste Technology & Management; Wiley: Hoboken, NJ, USA, 2010; pp. 430–462. ISBN 9780470666883. [Google Scholar]

- Nagpure, A.S.; Ramaswami, A.; Russell, A. Characterizing the Spatial and Temporal Patterns of Open Burning of Municipal Solid Waste (MSW) in Indian Cities. Environ. Sci. Technol. 2015, 49, 12911–12912. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Gupta, A.K.; Ganguly, R. Impact of Open Dumping of Municipal Solid Waste on Soil Properties in Mountainous Region. J. Rock Mech. Geotech. Eng. 2018, 10, 725–739. [Google Scholar] [CrossRef]

- Ali, S.M.; Pervaiz, A.; Afzal, B.; Hamid, N.; Yasmin, A. Open Dumping of Municipal Solid Waste and Its Hazardous Impacts on Soil and Vegetation Diversity at Waste Dumping Sites of Islamabad City. J. King Saud Univ. Sci. 2014, 26, 59–65. [Google Scholar] [CrossRef]

- Lamasanu, A.; Mihai, F.C. The Illegal Dumping of Waste in Forest Areas—Evidence from Rural Territory. In Proceedings of the International Conference Integrated Management of Environmental Resources, Suceava, Romania, 4–6 November 2011; Horodnic, S.A., Duduman, M.L., Palaghianu, C., Eds.; Stefan cel Mare University Press: Suceava, Romania, 2012; Volume 46, pp. 46–50. [Google Scholar]

- Phoonaploy, U.; Tengjaroenkul, B.; Neeratanaphan, L. Effect of Heavy Metals from an Electronic Waste Open Dumping Area on the Cytotoxicity of Climbing Perch (Anabas Testudineus). Int. J. Environ. Stud. 2020, 77, 983–997. [Google Scholar] [CrossRef]

- Malekian, M.; Hadi, M.; Tarkesh, M. Landscape Features Affecting Bird Diversity and Abundance at an Urban Landfill Site: A Case Study in Central Iran. Bird Study 2021, 68, 21–29. [Google Scholar] [CrossRef]

- Tocoloa, A.; Martinho, A.P.; Vaz-Fernandes, P. Epidemiological Risk Perceptions of People Living Close to Open Dumps in Nampula, Mozambique: A Case Study Control. In The Informal Sector and the Environment; Routledge: London, UK, 2022; pp. 150–168. [Google Scholar] [CrossRef]

- Kaushal, A.; Sharma, M.P. Methane Emission from Panki Open Dump Site of Kanpur, India. Procedia Environ. Sci. 2016, 35, 337–347. [Google Scholar] [CrossRef]

- Paul, D.R.; Vinson, C.E.; Locke, C.E. The Potential for Reuse of Plastics Recovered from Solid Wastes. Polym. Eng. Sci. 1972, 12, 157–166. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.S. Recycling Municipal, Agricultural and Industrial Waste into Energy, Fertilizers, Food and Construction Materials, and Economic Feasibility: A Review; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; Volume 21, ISBN 1031102201551. [Google Scholar]

- Goli, V.S.N.S.; Singh, D.N.; Baser, T. A Critical Review on Thermal Treatment Technologies of Combustible Fractions from Mechanical Biological Treatment Plants. J. Environ. Chem. Eng. 2021, 9, 105643. [Google Scholar] [CrossRef]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central Sorting and Recovery of MSW Recyclable Materials: A Review of Technological State-of-the-Art, Cases, Practice and Implications for Materials Recycling. J. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, Z.; Zhang, J.; Liu, Y.; Chen, L.; Yang, M.; Osman, A.I.; Farghali, M.; Liu, E.; Hassan, D.; et al. Municipal Solid Waste Management Challenges in Developing Regions: A Comprehensive Review and Future Perspectives for Asia and Africa. Sci. Total Environ. 2024, 930, 172794. [Google Scholar] [CrossRef] [PubMed]

- Gundupalli, S.P.; Hait, S.; Thakur, A. A Review on Automated Sorting of Source-Separated Municipal Solid Waste for Recycling. Waste Manag. 2017, 60, 56–74. [Google Scholar] [CrossRef]

- Deselnicu, D.C.; Militaru, G.; Deselnicu, V.; Zăinescu, G.; Albu, L. Towards a Circular Economy—A Zero Waste Programme for Europe. In Proceedings of the 7th International Conference on Advanced Materials and Systems, 18–20 October 2018; pp. 563–568. [Google Scholar] [CrossRef]

- Iqbal, A.; Liu, X.; Chen, G.H. Municipal Solid Waste: Review of Best Practices in Application of Life Cycle Assessment and Sustainable Management Techniques. Sci. Total Environ. 2020, 729, 138622. [Google Scholar] [CrossRef]

- Kurniawan, K.; Soefihara, M.D.A.; Nababan, D.C.; Kim, S. Current Status of the Recycling of E-Waste in Indonesia. Geosystem Eng. 2022, 25, 83–94. [Google Scholar] [CrossRef]

- Van Beukering, P.J.H.; Bouman, M.N. Empirical Evidence on Recycling and Trade of Paper and Lead in Developed and Developing Countries. World Dev. 2001, 29, 1717–1737. [Google Scholar] [CrossRef]

- OECD. International Trade and the Transition to a More Resource Efficient and Circular Economy; Organisation for Economic Co-operation and Development: Paris, France, 2018; Available online: https://www.oecd.org/en/publications/international-trade-and-the-transition-to-a-more-resource-efficient-and-circular-economy_847feb24-en.html (accessed on 25 November 2024).

- Kale, C.; Gökçek, M. A Techno-Economic Assessment of Landfill Gas Emissions and Energy Recovery Potential of Different Landfill Areas in Turkey. J. Clean. Prod. 2020, 275, 122946. [Google Scholar] [CrossRef]

- Duan, Z.; Scheutz, C.; Kjeldsen, P. Trace Gas Emissions from Municipal Solid Waste Landfills: A Review. Waste Manag. 2021, 119, 39–62. [Google Scholar] [CrossRef]

- Teng, C.; Zhou, K.; Peng, C.; Chen, W. Characterization and Treatment of Landfill Leachate: A Review. Water Res. 2021, 203, 117525. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A.; Alamoudı, R.H.; Ahmad, W.; Sheıkh, M.H. Optimization of Municipal Solid Waste (MSW) Disposal in Saudi Arabia. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 1929–1937. [Google Scholar] [CrossRef]

- Scott, J.; Beydoun, D.; Amal, R.; Low, G.; Cattle, J. Landfill Management, Leachate Generation, and Leach Testing of Solid Wastes in Australia and Overseas. Crit. Rev. Environ. Sci. Technol. 2005, 35, 239–332. [Google Scholar] [CrossRef]

- Slack, R.J.; Gronow, J.R.; Voulvoulis, N. Household Hazardous Waste in Municipal Landfills: Contaminants in Leachate. Sci. Total Environ. 2005, 337, 119–137. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.F.; Feng, S.J. Comprehensive Overview of Numerical Modeling of Coupled Landfill Processes. Waste Manag. 2020, 118, 161–179. [Google Scholar] [CrossRef]

- Wang, X.; Jia, M.; Chen, X.; Xu, Y.; Lin, X.; Kao, C.M.; Chen, S. Greenhouse Gas Emissions from Landfill Leachate Treatment Plants: A Comparison of Young and Aged Landfill. Waste Manag. 2014, 34, 1156–1164. [Google Scholar] [CrossRef]

- Alter, H. The History of Refuse-Derived Fuels. Resour. Conserv. 1987, 15, 251–275. [Google Scholar] [CrossRef]

- Mateus, M.M.; Cecílio, D.; Fernandes, M.C.; Neiva Correia, M.J. Refuse Derived Fuels as an Immediate Strategy for the Energy Transition, Circular Economy, and Sustainability. Bus. Strateg. Environ. 2023, 32, 3915–3926. [Google Scholar] [CrossRef]

- Martignon, P. Trends on Use of Solid Recovered Fuels; Johansson, I., Edo, M., Eds.; IEA Bioenergy: Paris, France, 2020; ISBN 9781910154724. [Google Scholar]