Genetic Algorithm and Taguchi Method: An Approach for Better Li-Ion Cell Model Parameter Identification

Abstract

1. Introduction

- Provide an easy-to-implement, robust, and systematic approach to the characterization of a Li-ion cell from experimentation, to modeling, to validation.

- The parameters used for setting the GA have been justified using the Taguchi method and proven to make the algorithm more efficient in terms of computation time and model fitting.

- The GA parameter optimization method could be generalized and used for other characterization techniques (e.g., particle swarm optimization).

- A real-word household power consumption profile was used to parametrize the cell model; therefore, this study is a solid basis for further investigation on the use of second-life Li-ion batteries in solar home storage systems.

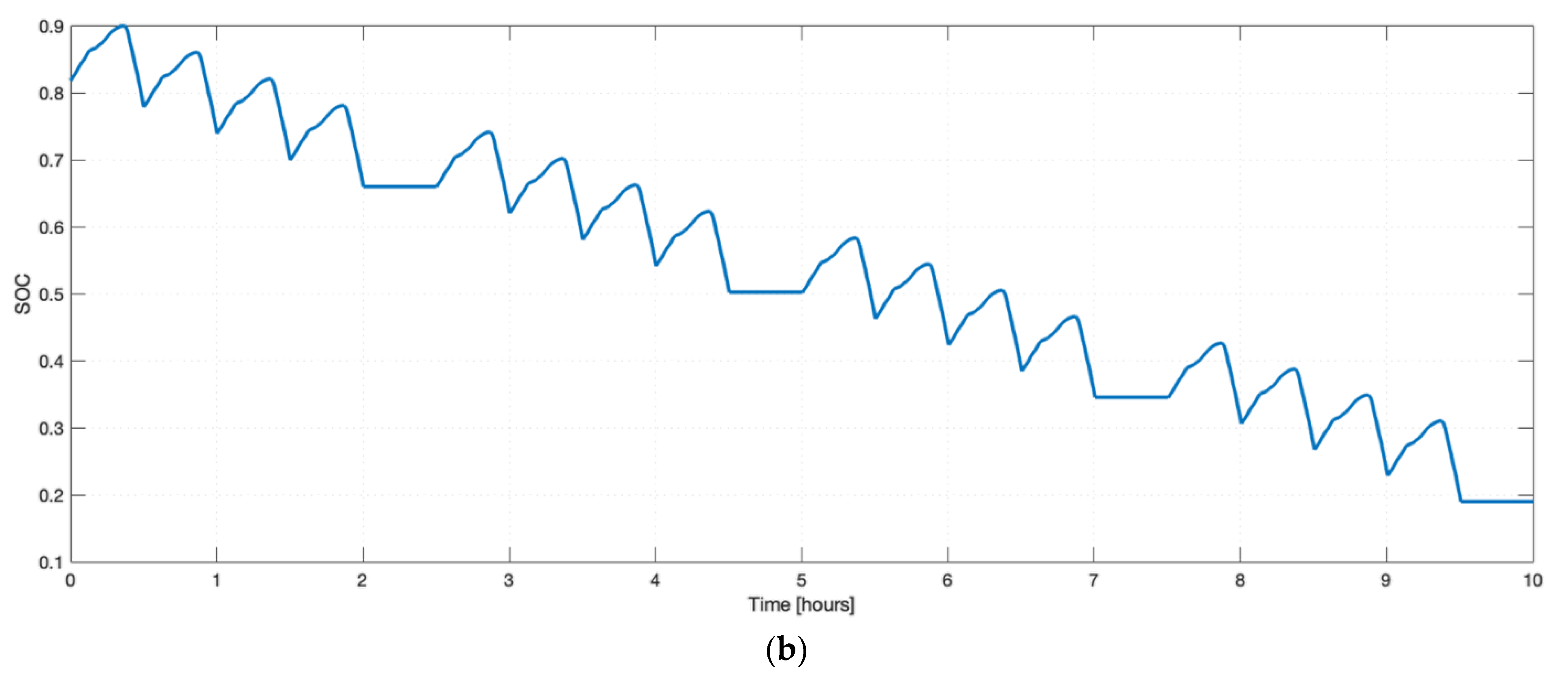

2. Brief Introduction of Collected Dataset

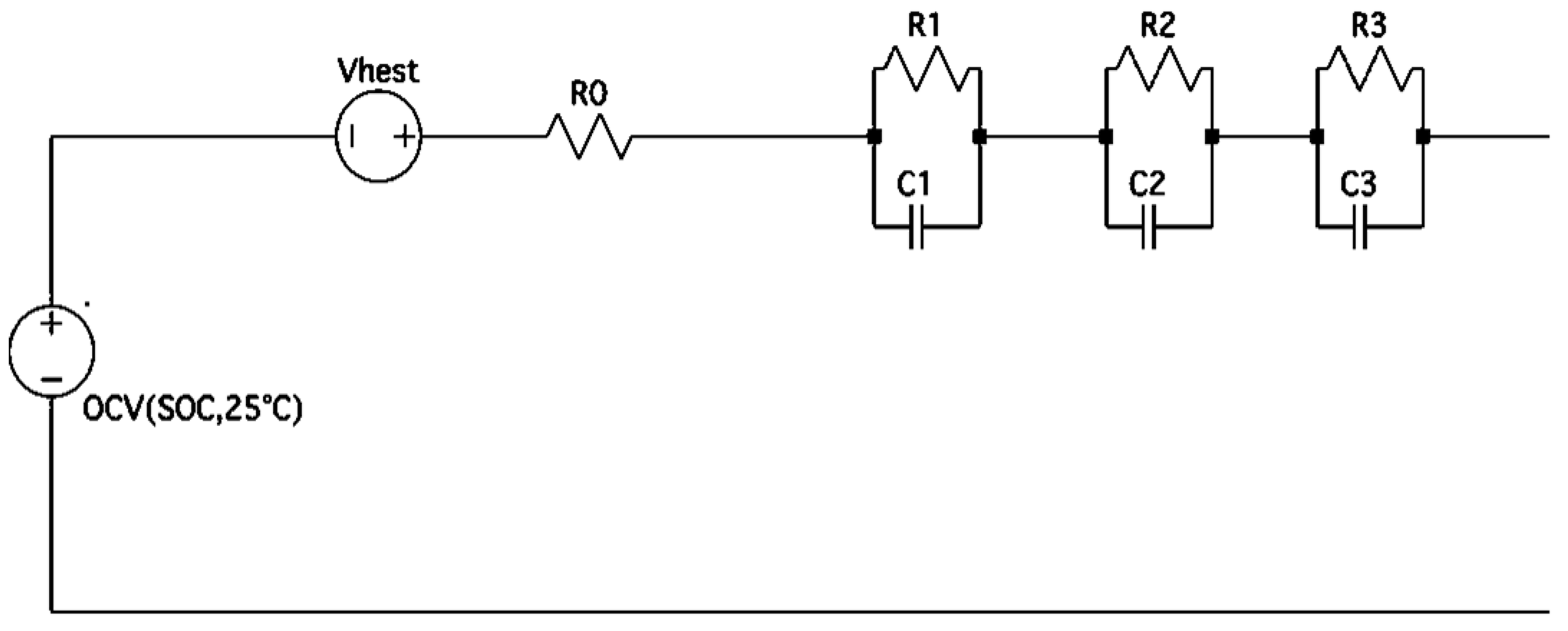

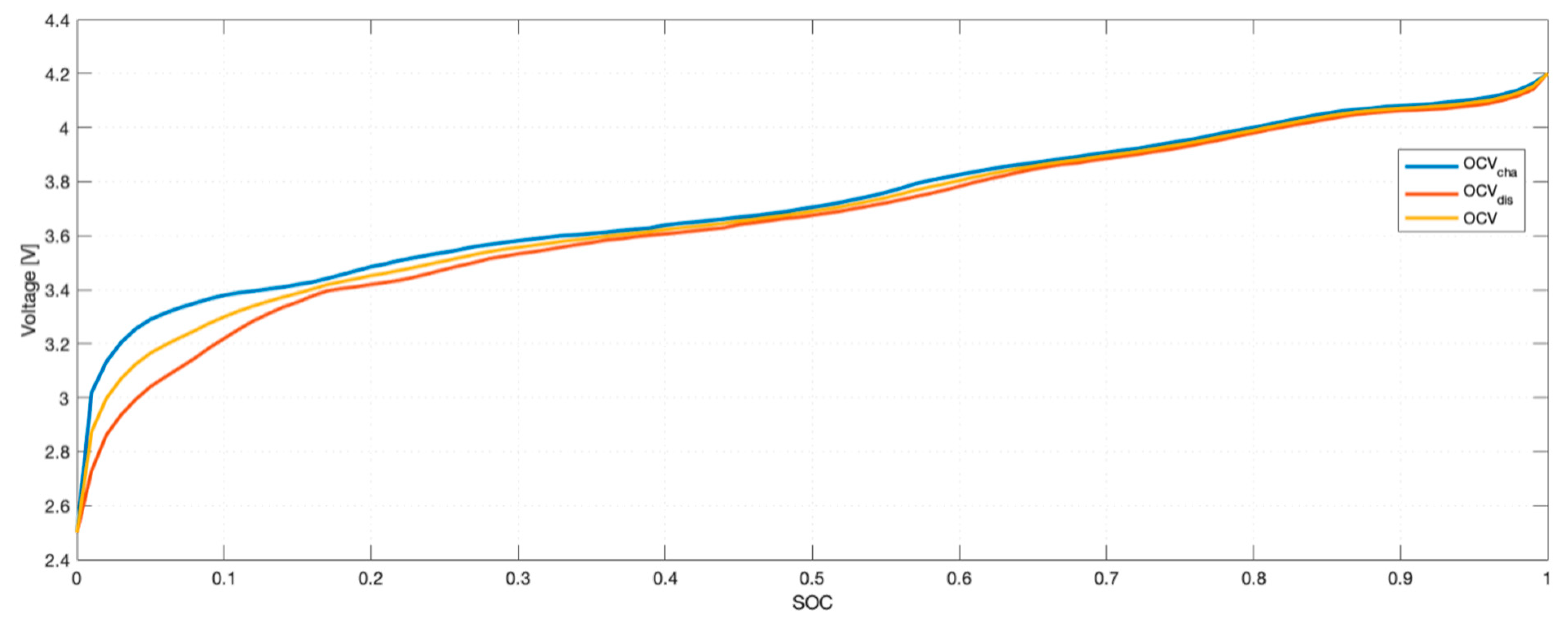

3. Lithium-Ion Cell Modelling

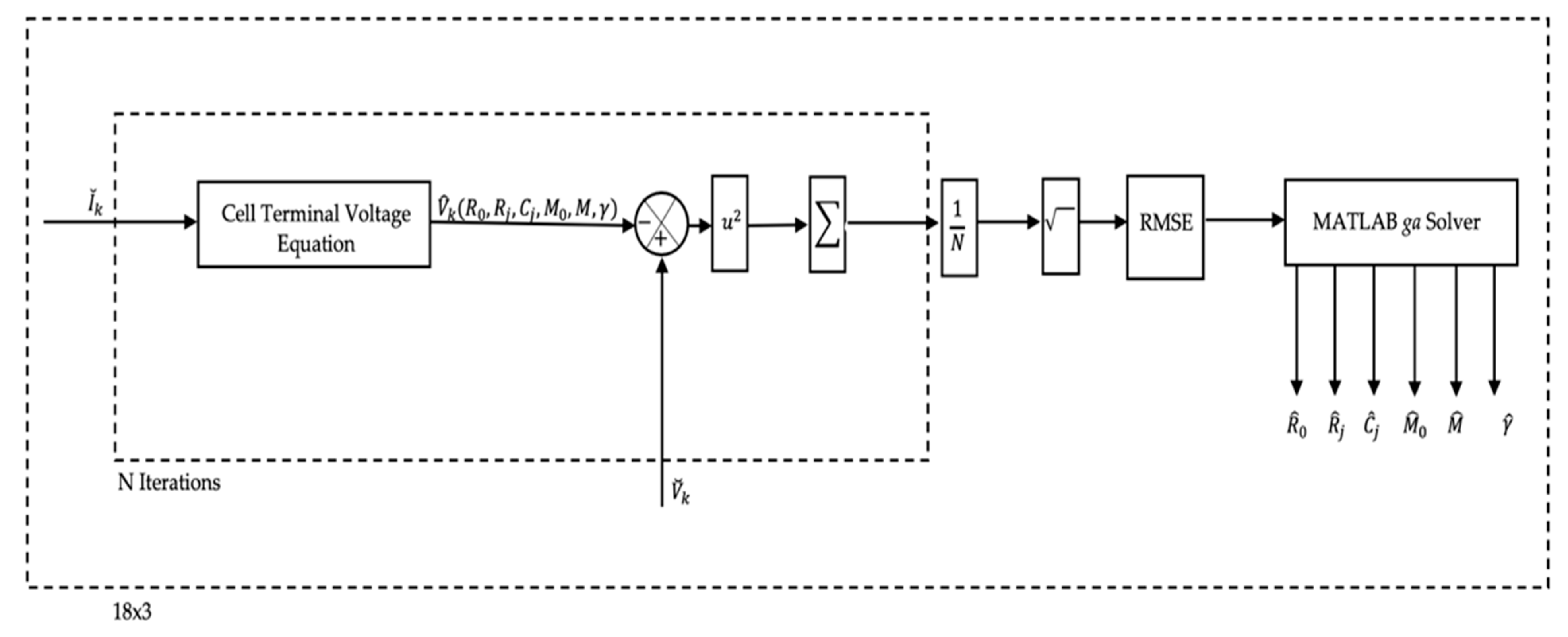

4. EECM Parameter Identification Approach

4.1. Genetic Algorithm

- Create a population of random chromosomes (potential solutions);

- Score each chromosome in the population for fitness, and ‘usually’ select individuals with better fitness values as parents;

- Create a new generation through crossover and mutation;

- Repeat until some criteria is reached (e.g., max number of generations, max amount of time running);

- Emit the fittest chromosome as the solution.

4.2. Systematic Approach Based on Taguchi Experimental Design

4.2.1. Generating Taguchi Experimental Design

4.2.2. Conducting the Experiments

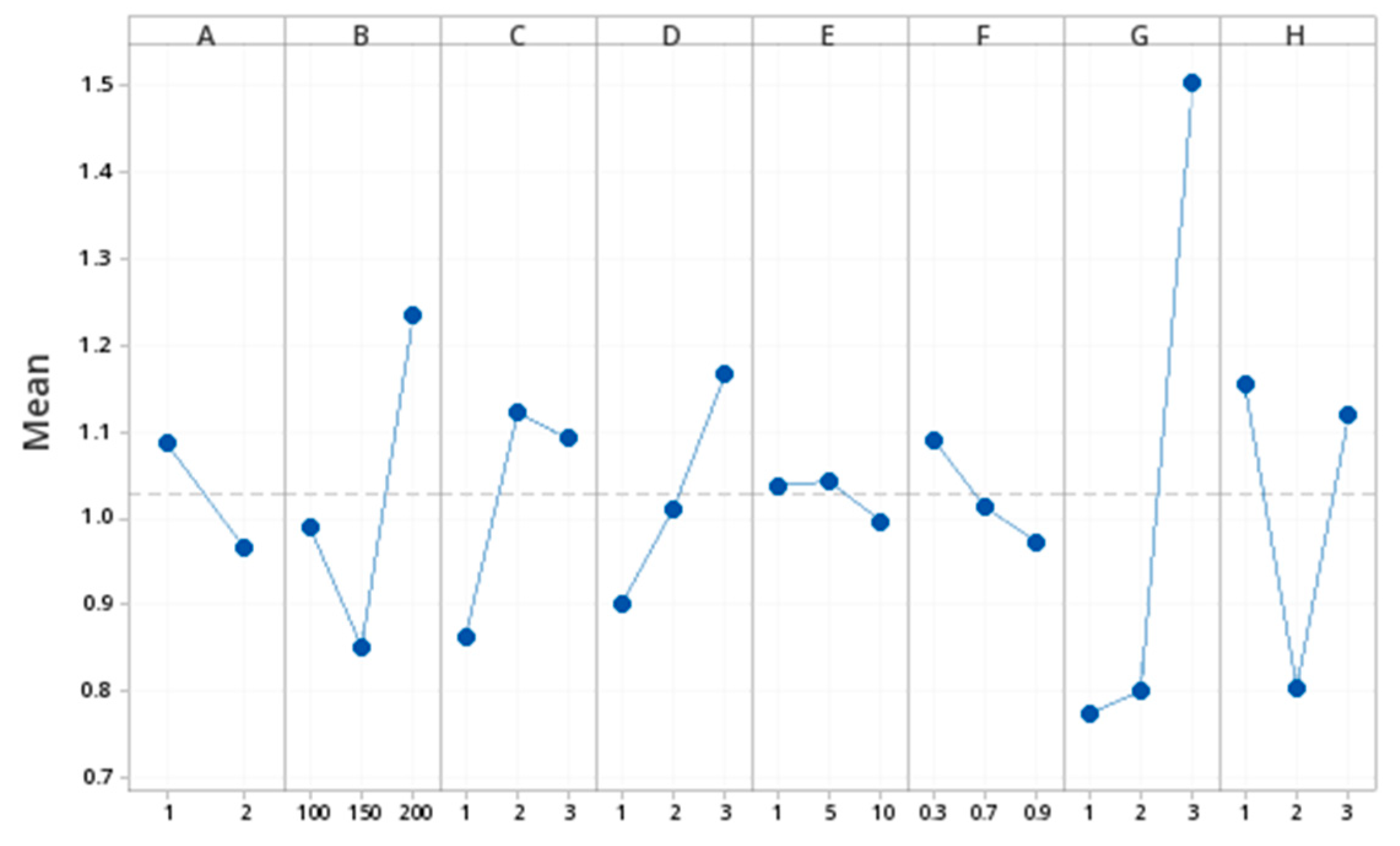

4.2.3. Analyzing Data

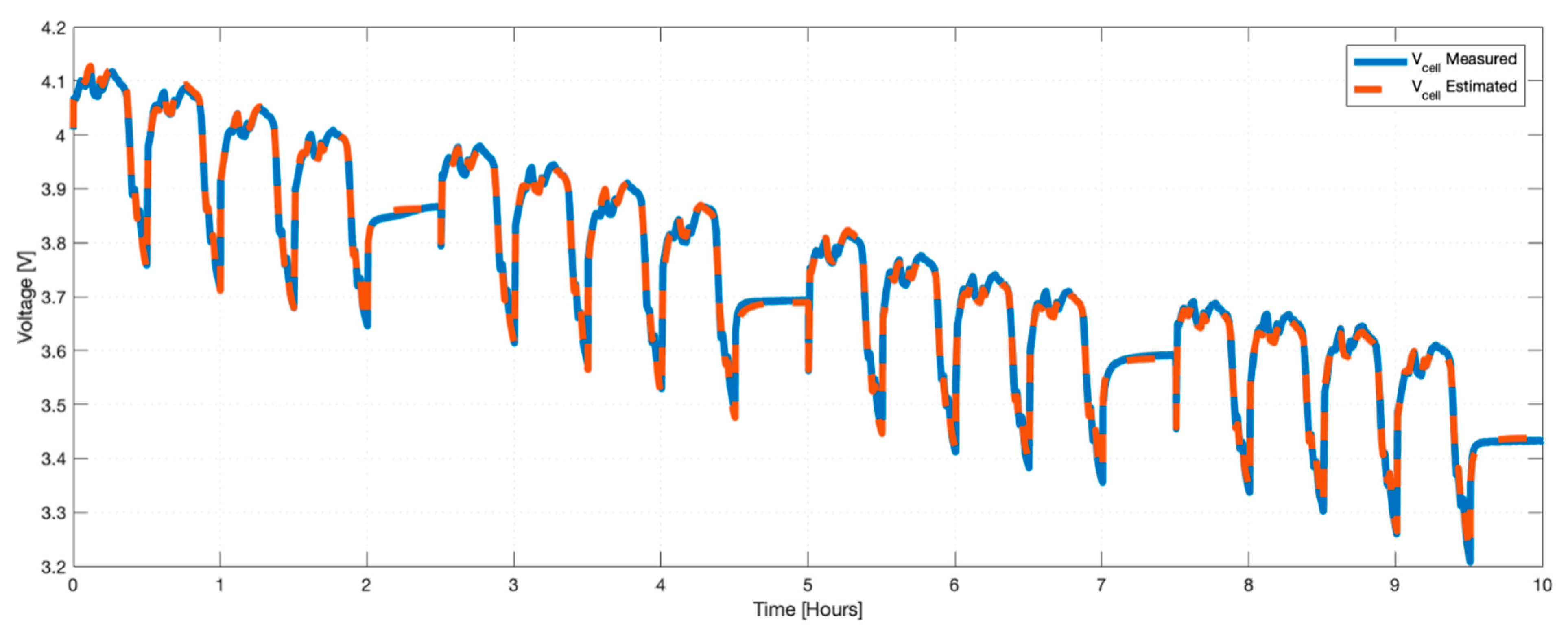

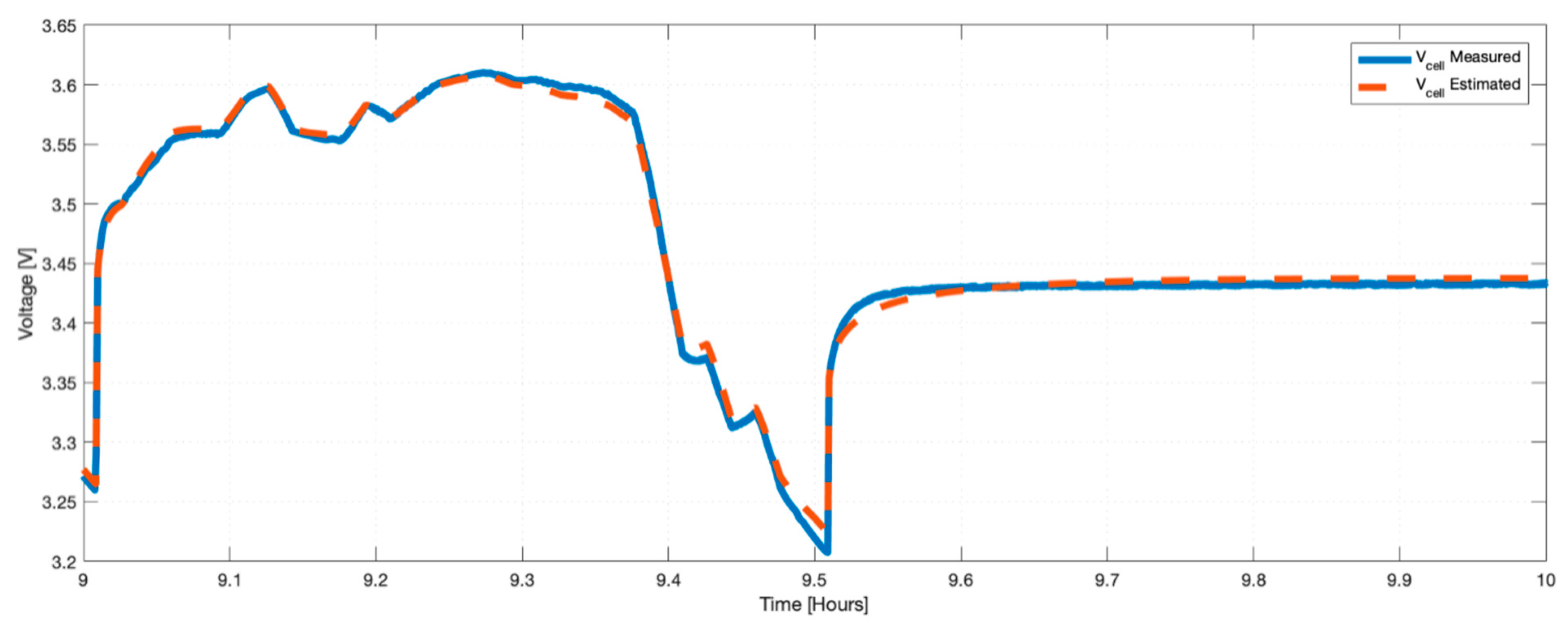

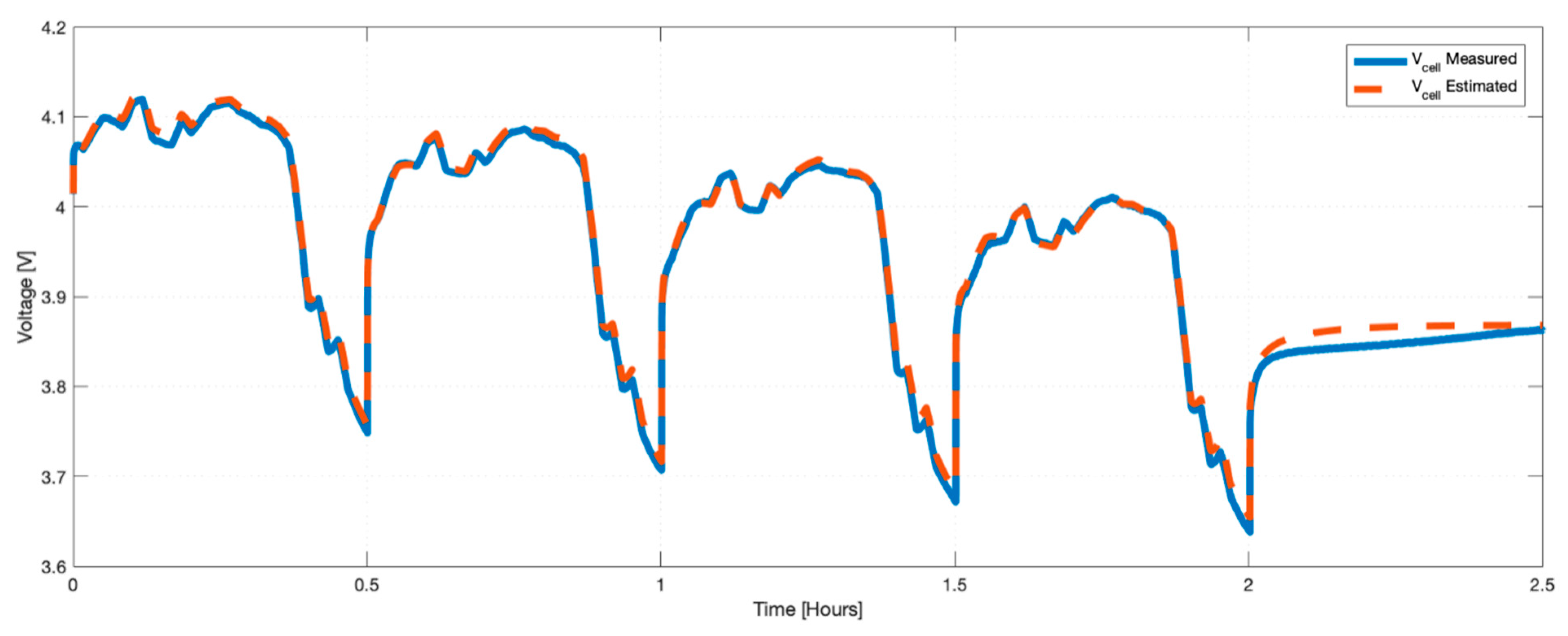

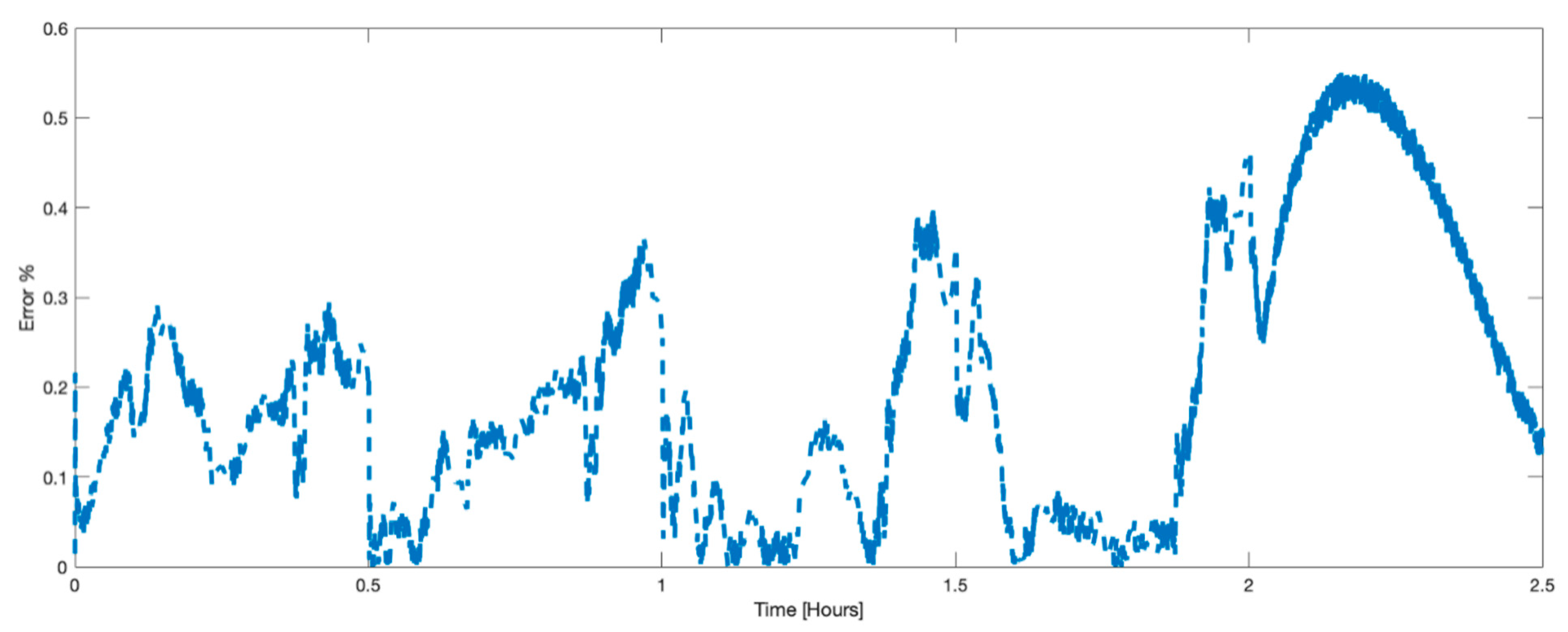

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of Utilising Second Life EV Batteries: Applications, Lifespan, Economics, Environmental Impact, Assessment, and Challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Electric Vehicles, Second Life Batteries, and Their Effect on the Power Sector|McKinsey. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/second-life-ev-batteries-the-newest-value-pool-in-energy-storage (accessed on 22 August 2022).

- Bagalini, V.; Zhao, B.Y.; Wang, R.Z.; Desideri, U. Solar PV-Battery-Electric Grid-Based Energy System for Residential Applications: System Configuration and Viability. Research 2019, 2019, 3838603. [Google Scholar] [CrossRef] [PubMed]

- Chaianong, A.; Bangviwat, A.; Menke, C.; Breitschopf, B.; Eichhammer, W. Customer Economics of Residential PV–Battery Systems in Thailand. Renew. Energy 2020, 146, 297–308. [Google Scholar] [CrossRef]

- Faessler, B. Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review. Energies 2021, 14, 2335. [Google Scholar] [CrossRef]

- Tabusse, R.; Bouquain, D.; Jemei, S.; Chrenko, D. Battery Aging Test Design during First and Second Life. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 18 November–16 December 2020; pp. 1–6. [Google Scholar]

- Kumar, P.; Balasingam, B.; Rankin, G.; Pattipati, K.R. Battery Thermal Model Identification and Surface Temperature Prediction. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; pp. 1–6. [Google Scholar]

- Tran, M.-K.; Mathew, M.; Janhunen, S.; Panchal, S.; Raahemifar, K.; Fraser, R.; Fowler, M. A Comprehensive Equivalent Circuit Model for Lithium-Ion Batteries, Incorporating the Effects of State of Health, State of Charge, and Temperature on Model Parameters. J. Energy Storage 2021, 43, 103252. [Google Scholar] [CrossRef]

- Pizarro-Carmona, V.; Castano-Solís, S.; Cortés-Carmona, M.; Fraile-Ardanuy, J.; Jimenez-Bermejo, D. GA-Based Approach to Optimize an Equivalent Electric Circuit Model of a Li-Ion Battery-Pack. Expert Syst. Appl. 2021, 172, 114647. [Google Scholar] [CrossRef]

- Vaidya, S.; Depernet, D.; Chrenko, D.; Laghrouche, S. Experimental Development of Embedded Online Impedance Spectroscopy of Lithium-Ion Batteries—Proof of Concept and Validation. In Proceedings of the Electrimacs 2022, Nancy, France, 16–19 May 2022; 8p. [Google Scholar]

- Baronti, F.; Zamboni, W.; Roncella, R.; Saletti, R.; Spagnuolo, G. Open-Circuit Voltage Measurement of Lithium-Iron-Phosphate Batteries. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Pisa, Italy, 11–14 May 2015; pp. 1711–1716. [Google Scholar]

- Guo, S. The Application of Genetic Algorithms to Parameter Estimation in Lead-Acid Battery Equivalent Circuit Models. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2010. [Google Scholar]

- Heenan, T.M.M.; Jnawali, A.; Kok, M.D.R.; Tranter, T.G.; Tan, C.; Dimitrijevic, A.; Jervis, R.; Brett, D.J.L.; Shearing, P.R. An Advanced Microstructural and Electrochemical Datasheet on 18650 Li-Ion Batteries with Nickel-Rich NMC811 Cathodes and Graphite-Silicon Anodes. J. Electrochem. Soc. 2020, 167, 140530. [Google Scholar] [CrossRef]

- Klass, A.; Wilson, E. Remaking Energy: The Critical Role of Energy Consumption Data. Calif. Law Rev. 2016, 104, 1095. [Google Scholar]

- Alahmed, A.; Almuhaini, M. Hybrid Top-Down and Bottom-Up Approach for Investigating Residential Load Compositions and Load Percentages. arXiv 2020, arXiv:2004.12940. [Google Scholar]

- Vogt, Y. Top–down Energy Modeling. Strateg. Plan. Energy Environ. 2003, 22, 64–79. [Google Scholar] [CrossRef]

- Index of /Ml/Machine-Learning-Databases/00235. Available online: https://archive.ics.uci.edu/ml/machine-learning-databases/00235/ (accessed on 22 August 2022).

- Quoilin, S.; Kavvadias, K.; Mercier, A.; Pappone, I.; Zucker, A. Quantifying Self-Consumption Linked to Solar Home Battery Systems: Statistical Analysis and Economic Assessment. Appl. Energy 2016, 182, 58–67. [Google Scholar] [CrossRef]

- Parate, A.; Bhoite, S. Individual Household Electric Power Consumption Forecasting Using Machine Learning Algorithms. Int. J. Comput. Appl. Technol. Res. 2019, 8, 371–376. [Google Scholar] [CrossRef]

- He, Y.; He, R.; Guo, B.; Zhang, Z.; Yang, S.; Liu, X.; Zhao, X.; Pan, Y.; Yan, X.; Li, S. Modeling of Dynamic Hysteresis Characters for the Lithium-Ion Battery. J. Electrochem. Soc. 2020, 167, 090532. [Google Scholar] [CrossRef]

- Lu, B.; Song, Y.; Zhang, Q.; Pan, J.; Cheng, Y.-T.; Zhang, J. Voltage Hysteresis of Lithium Ion Batteries Caused by Mechanical Stress. Phys. Chem. Chem. Phys. 2016, 18, 4721–4727. [Google Scholar] [CrossRef]

- Graells, C.P.; Trimboli, M.S.; Plett, G.L. Differential Hysteresis Models for a Silicon-Anode Li-Ion Battery Cell. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020; pp. 175–180. [Google Scholar]

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. A Study on the Open Circuit Voltage and State of Charge Characterization of High Capacity Lithium-Ion Battery Under Different Temperature. Energies 2018, 11, 2408. [Google Scholar] [CrossRef]

- Zahid, T.; Li, W. A Comparative Study Based on the Least Square Parameter Identification Method for State of Charge Estimation of a LiFePO4 Battery Pack Using Three Model-Based Algorithms for Electric Vehicles. Energies 2016, 9, 720. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Zhao, P.; Kang, J.; Yan, F.; Du, C. Correlation between the Model Accuracy and Model-Based SOC Estimation. Electrochim. Acta 2017, 228, 146–159. [Google Scholar] [CrossRef]

- Rahimi Eichi, H.; Chow, M.-Y. Modeling and Analysis of Battery Hysteresis Effects. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012; pp. 4479–4486. [Google Scholar]

- Chrenko, D.; Fernandez Montejano, M.; Vaidya, S.; Tabusse, R. Aging Study of In-Use Lithium-Ion Battery Packs to Predict End of Life Using Black Box Model. Appl. Sci. 2022, 12, 6557. [Google Scholar] [CrossRef]

- Dao, S.; Abhary, K.; Marian, R. Maximising Performance of Genetic Algorithm Solver in Matlab. Eng. Lett. 2016, 24, 75–83. [Google Scholar]

- 14.1: Design of Experiments via Taguchi Methods—Orthogonal Arrays. Available online: https://eng.libretexts.org/Bookshelves/Industrial_and_Systems_Engineering/Book%3A_Chemical_Process_Dynamics_and_Con-trols_(Woolf)/14%3A_Design_of_Experiments/14.01%3A_Design_of_Experiments_via_Taguchi_Methods_-_Orthogonal_Arrays (accessed on 28 November 2022).

- Bower, K.M. Analysis of Variance (ANOVA) Using Minitab. Sci. Comput. Instrum. 2000, 17, 64–65. [Google Scholar]

- Schlasza, C.; Ostertag, P.; Chrenko, D.; Kriesten, R.; Bouquain, D. Review on the Aging Mechanisms in Li-Ion Batteries for Electric Vehicles Based on the FMEA Method. In Proceedings of the 2014 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 15–18 June 2014; pp. 1–6. [Google Scholar]

- Azis, N.A.; Joelianto, E.; Widyotriatmo, A. State of Charge (SoC) and State of Health (SoH) Estimation of Lithium-Ion Battery Using Dual Extended Kalman Filter Based on Polynomial Battery Model. In Proceedings of the 2019 6th International Conference on Instrumentation, Control, and Automation (ICA), Bandung, Indonesia, 31 July–2 August 2019; pp. 88–93. [Google Scholar]

- Obeid, H.; Petrone, R.; Chaoui, H.; Gualous, H. Higher Order Sliding-Mode Observers for State-of-Charge and State-of-Health Estimation of Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2022, 1–11. [Google Scholar] [CrossRef]

| No. | Parameters | Code | Level | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| 1 | Migration Direction | A | Forward | Both | - |

| 2 | Population Size | B | 100 | 150 | 200 |

| 3 | Fitness Scaling Function | C | Proportional | Rank | Top |

| 4 | Selection Function | D | Remainder | Tournament | Roulette |

| 5 | Elite Count | E | 1 | 5 | 10 |

| 6 | Crossover Fraction | F | 0.3 | 0.7 | 0.9 |

| 9 | Crossover Function | G | Two Point | Scattered | Arithmetic |

| 8 | Mutation Function | H | Adaptive xsqFeasible | Uniform | Gaussian |

| Experiment | Parameters of ga Solver | |||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | |

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 |

| 3 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 |

| 4 | 1 | 2 | 1 | 1 | 2 | 2 | 3 | 3 |

| 5 | 1 | 2 | 2 | 2 | 3 | 3 | 1 | 1 |

| 6 | 1 | 2 | 3 | 3 | 1 | 1 | 2 | 2 |

| 7 | 1 | 3 | 1 | 2 | 1 | 3 | 2 | 3 |

| 8 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 1 |

| 9 | 1 | 3 | 3 | 1 | 3 | 2 | 1 | 2 |

| 10 | 2 | 1 | 1 | 3 | 3 | 2 | 2 | 1 |

| 11 | 2 | 1 | 2 | 1 | 1 | 3 | 3 | 2 |

| 12 | 2 | 1 | 3 | 2 | 2 | 1 | 1 | 3 |

| 13 | 2 | 2 | 1 | 2 | 3 | 1 | 3 | 2 |

| 14 | 2 | 2 | 2 | 3 | 1 | 2 | 1 | 3 |

| 15 | 2 | 2 | 3 | 1 | 2 | 3 | 2 | 1 |

| 16 | 2 | 3 | 1 | 3 | 2 | 3 | 1 | 2 |

| 17 | 2 | 3 | 2 | 1 | 3 | 1 | 2 | 3 |

| 18 | 2 | 3 | 3 | 2 | 1 | 2 | 3 | 1 |

| Experiment | Parameters of ga Solver | RMSE % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | Run 1 | Run 2 | Run 3 | |

| 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0.945 | 0.812 | 0.797 |

| 2 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 0.615 | 0.784 | 0.698 |

| 3 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 1.410 | 1.841 | 0.816 |

| 4 | 1 | 2 | 1 | 1 | 2 | 2 | 3 | 3 | 0.989 | 1.162 | 1.526 |

| 5 | 1 | 2 | 2 | 2 | 3 | 3 | 1 | 1 | 0.706 | 0.752 | 0.674 |

| 6 | 1 | 2 | 3 | 3 | 1 | 1 | 2 | 2 | 0.699 | 0.715 | 0.650 |

| 7 | 1 | 3 | 1 | 2 | 1 | 3 | 2 | 3 | 0.744 | 0.889 | 0.829 |

| 8 | 1 | 3 | 2 | 3 | 2 | 1 | 3 | 1 | 0.793 | 2.161 | 1.265 |

| 9 | 1 | 3 | 3 | 1 | 3 | 2 | 1 | 2 | 0.634 | 0.665 | 0.621 |

| 10 | 2 | 1 | 1 | 3 | 3 | 2 | 2 | 1 | 0.642 | 0.675 | 0.842 |

| 11 | 2 | 1 | 2 | 1 | 1 | 3 | 3 | 2 | 1.131 | 1.022 | 0.990 |

| 12 | 2 | 1 | 3 | 2 | 2 | 1 | 1 | 3 | 0.632 | 0.811 | 0.7889 |

| 13 | 2 | 2 | 1 | 2 | 3 | 1 | 3 | 2 | 0.791 | 0.944 | 0.800 |

| 14 | 2 | 2 | 2 | 3 | 1 | 2 | 1 | 3 | 0.657 | 0.905 | 0.614 |

| 15 | 2 | 2 | 3 | 1 | 2 | 3 | 2 | 1 | 0.642 | 0.636 | 0.6390 |

| 16 | 2 | 3 | 1 | 3 | 2 | 3 | 1 | 2 | 0.766 | 0.703 | 0.7802 |

| 17 | 2 | 3 | 2 | 1 | 3 | 1 | 2 | 3 | 0.978 | 1.109 | 0.917 |

| 18 | 2 | 3 | 3 | 2 | 1 | 2 | 3 | 1 | 1.456 | 1.890 | 0.891 |

| Source | DF | Adj SS | Adj MS | F | p |

|---|---|---|---|---|---|

| A | 1 | 0.06578 | 0.06578 | 0.92 | 0.381 |

| B | 2 | 0.18040 | 0.18040 | 2.53 | 0.173 |

| C | 2 | 0.23933 | 0.11966 | 1.68 | 0.277 |

| D | 2 | 0.21353 | 0.10677 | 1.50 | 0.309 |

| E | 2 | 0.00555 | 0.00555 | 0.08 | 0.791 |

| F | 2 | 0.04346 | 0.04346 | 0.61 | 0.470 |

| G | 2 | 2.04866 | 1.02433 | 14.36 | 0.008 |

| H | 2 | 0.44251 | 0.22125 | 3.10 | 0.133 |

| Error | 2 | 0.35666 | 0.07133 | ||

| Total | 17 | 3.59588 |

| A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|

| Both | 150 | Proportional | Remainder | 10 | 0.9 | Two Point | Uniform |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Rafei, T.; Yousfi Steiner, N.; Chrenko, D. Genetic Algorithm and Taguchi Method: An Approach for Better Li-Ion Cell Model Parameter Identification. Batteries 2023, 9, 72. https://doi.org/10.3390/batteries9020072

Al Rafei T, Yousfi Steiner N, Chrenko D. Genetic Algorithm and Taguchi Method: An Approach for Better Li-Ion Cell Model Parameter Identification. Batteries. 2023; 9(2):72. https://doi.org/10.3390/batteries9020072

Chicago/Turabian StyleAl Rafei, Taha, Nadia Yousfi Steiner, and Daniela Chrenko. 2023. "Genetic Algorithm and Taguchi Method: An Approach for Better Li-Ion Cell Model Parameter Identification" Batteries 9, no. 2: 72. https://doi.org/10.3390/batteries9020072

APA StyleAl Rafei, T., Yousfi Steiner, N., & Chrenko, D. (2023). Genetic Algorithm and Taguchi Method: An Approach for Better Li-Ion Cell Model Parameter Identification. Batteries, 9(2), 72. https://doi.org/10.3390/batteries9020072