Abstract

Using batteries after their first life in an Electric Vehicle (EV) represents an opportunity to reduce the environmental impact and increase the economic benefits before recycling the battery. Many different second life applications have been proposed, each with multiple criteria that have to be taken into consideration when deciding the most suitable course of action. In this article, a battery assessment procedure is proposed that consolidates and expands upon the approaches in the literature, and facilitates the decision-making process for a battery after it has reached the end of its first life. The procedure is composed of three stages, including an evaluation of the state of the battery, an evaluation of the technical viability and an economic evaluation. Options for battery configurations are explored (pack direct use, stack of battery packs, module direct use, pack refurbish with modules, pack refurbish with cells). By comparing these configurations with the technical requirements for second life applications, a reader can rapidly understand the tradeoffs and practical strategies for how best to implement second life batteries for their specific application. Lastly, an economic evaluation process is developed to determine the cost of implementing various second life battery configurations and the revenue for different end use applications. An example of the battery assessment procedure is included to demonstrate how it could be carried out.

1. Introduction

The goal to mitigate global climate change has resulted in strong policies aimed at reducing greenhouse gas emissions, decoupling economic growth from resource use and more equitable distribution of cost and impacts related to energy. This has been galvanized with large investments to support these objectives including through the EU Green Deal [1] and the recovery plan for Europe, which includes large public investment to aid in the substitution of combustion vehicles for the electric vehicle [2].

With rapid growth in battery markets, particularly the EV market, reductions in the cost and environmental impact of batteries can greatly improve their ability to help achieve energy and environmental goals. The use of batteries in second life applications after reaching the end of life for their initial use is one way to reduce environmental impacts and the costs of storing energy.

The use of batteries in second life applications is starting to gain traction, with several companies commercializing second life storage systems; however, the decision-making process for transitioning from primary, first life applications to second life applications is not well understood. Several studies have been performed that consider the benefits of reusing EV batteries before recycling in various applications [3,4,5,6]. There are some studies and standards that propose tests to evaluate the state of the battery after its first life [7,8]. Two other studies establish the stages between first life and second life, but do not consider the different possibilities of end of life and the different possible configurations [9,10]. Lastly, there is one study that, while it does propose a general process for assessing the second life of batteries, focuses on the disassembly process and does not explore the implications for use in various end-use applications [11].

Uncertainties related with the state of the battery, the different ways and requirements for adapting the battery to a new application, and difficulties in analyzing the economic and environmental benefit, complicates the transition from the first life to the second life. There are multiple potential pathways for the batteries when they reach their end of life (EOL). The more common pathway nowadays is to build a refurbished battery from used modules to perform, for instance, time shifting in an industry [12] or to stack used EV battery packs to provide services at the utility scale [13]. The above-mentioned uncertainties represent a barrier to the replicability and scalability of the implementation of second life batteries.

The aim of this work is several fold: (1) to consolidate and expand upon the battery assessment approaches in the literature by developing a framework for assessing the suitability of battery second life applications. This framework should be well-structured and complete enough to use today, but flexible enough to accommodate evolutions in battery chemistry, topology, regulations, etc. (2) While general frameworks for a second life transition assessment has been developed previously, there are many specific considerations that are not considered, but which are essential to perform a functional assessment. As such, this paper develops a table of specific advantages and disadvantages to consider during the transition process that will guide the user’s decision-making, thereby enabling a more practical and actionable assessment to be performed. (3) This work brings together several layers of the battery evaluation process including an assessment of the state of the battery, a technical viability assessment considering potential second life applications, and an economic assessment. This process can be integrated into the life cycle of the battery and can start as early as the design stage of the battery pack. Additionally, based on the battery assessment process presented, there is the possibility that part of the assessment can be automatized to further accelerate the process of transitioning to second life applications.

Ultimately, the goal of this work is to streamline the decision-making process used to assess EV batteries after their first life with a detailed and actionable assessment tool. This can enable a more rapid, replicable and scalable transition of batteries from first life to second life.

This article is organized as follows: Section 2 summarizes the overall framework of the battery assessment, with Section 3, Section 4 and Section 5 providing a detailed description of the three main steps in the battery assessment including “Evaluation of the State of the Battery”, “Technical viability of different solutions,” and “Economic evaluation of each potential solution”, respectively. Section 6 provides an example of the proposed battery assessment procedure. Section 7 contains a concluding discussion and a description of future work.

2. Framework for the Battery Assessment after First Life

The total vehicle stock of EVs on the market is projected to increase through 2050 [14]. Now, each manufacturer designs their own battery pack so the number of different models with a variety of characteristics, management, controls, and thermal management systems will continue to increase. This issue will affect the second life analyses, since the preferred second life strategies depend on the specific characteristics of the EV battery. This is further complicated by variations of the degradation levels derived from the first life use, that results in batteries reaching EOL with different aging conditions. In addition, the battery state at EOL must be matched to the most suitable and/or profitable second life end use application considering duty cycle, size requirements, market size and revenue potential.

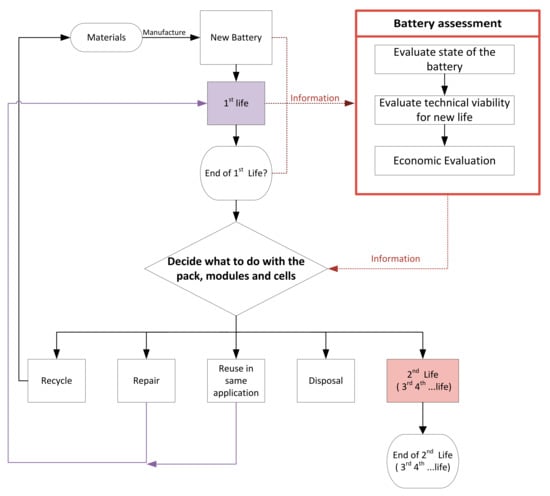

In order to analyze and evaluate these uncertainties, a procedure is proposed to aid in the decision-making process regarding battery reuse (depicted in Figure 1). The battery assessment procedure is placed inside a simplified scheme of the battery life cycle. This assessment is recommended to be performed during the first life, even before removing the battery from the vehicle. This is to avoid incurring unnecessary expenses if a second life solution is not recommended as an output of the analysis. To this end, the assessment is proposed in a way that it can be used by any battery manufacturer, EV manufacturer, distributor, specialist workshop or the vehicle owner. It is comprised by three stages that should be performed.

Figure 1.

The proposed battery assessment as part of a simplified battery life cycle.

- Battery state evaluation: The degradation conditions of the battery (energy, power, external wear) are analyzed.

- Technical viability of different solutions: Requirements for different applications and possible configurations of the EV batteries are analyzed.

- Economic evaluation: The economic viability of the possible solutions is analyzed.

With the structure proposed for the battery assessment, it could be possible to automatize part of the assessment to even further accelerate the decision process after first life. The feedback of the assessment could be saved in the battery passport that the EU dictates for future batteries [15].

Depending on the information available, after each stage of the battery assessment there is an opportunity to determine what should be done with the battery. The available options include the following:

- Recycle/disposal: If the battery is not repairable, it can be recycled or disposed of. If the technology is not available, there is not sufficient recycling capacity or there is no obligation to recycle the battery, and a second life is not possible, disposal immediately after the first life is a potential option.

- Repair/reuse: Depending on the battery architecture and financial considerations, the battery pack or individual modules can be repaired and continue first life in the same vehicle or in another.

- Study second life: If the battery is still in good condition or can be repaired but does not have enough remaining life to meet its first life requirements, the battery assessment can be performed to explore potential options for second life applications.

3. Evaluation of the State of the Battery

The first stage of battery assessment is to not only analyze the health conditions of the battery, but also the accessibility and veracity of the information needed for the following stages. This stage can begin before the battery reaches its EOL, if desired. Batteries will reach EOL at different states since they have undergone different degradation conditions including temperature, C-rates, average state of charge (SoCm), and depth of discharge (DoD) and there may be several reasons for reaching EOL. This step is the first filter to decide what to do with the battery (repair, recycle, disposal or analyze for second life).

To begin this evaluation, the information available about the battery should be collected. Some information may come from the cell manufacturer which may include cell format, chemistry, operating conditions for voltage and current, capacity, expected number of cycles. Datasheets from the pack manufacturer or assembler may include the number of modules, number of cells, internal pack design, warranty, other pack properties and operating conditions. A battery assessment can be performed with a subset of this data; however, the inclusion of limited data will affect the accuracy of the results. Available data can be supplemented with open source [16] or private databases.

The next step is to obtain indicators of the battery health or data that helps to calculate the life in the new possible application. Two different categories are identified:

- 1.

- Continual estimation of battery health:Either on-board or through the cloud, relevant health indicators can be calculated throughout the first life of the battery. These can be direct measurements of important factors including the distance driven, age of the battery, ambient temperature, depth of discharge, battery charging and discharging rate, or more sophisticated calculations such as the State of Health (SOH).The accuracy of the SOH is dependent on the algorithm or process implemented. A variety of different solutions have been developed to estimate SOH [17,18,19,20,21,22,23,24,25], so specific techniques will not be addressed in this paper. However, generally, the use of data to develop the SOH estimation could be based only on a subset of data (periodic health estimates) or even recording of the full life of the battery in the cloud, as some manufacturers are starting to do [26,27]. Additionally, the SOH can be based on data from an individual vehicle or multiple vehicles. In the case that these data are shared, it could make second life rollout and also vehicle-to-grid (V2G) technology more effective [18,28].

- 2.

- Testing of the battery pack: Obtaining indicators of the battery health after the first EOL is currently the most common technique for advising second life decisions. The typical tests performed are capacity and internal resistance. These tests may last 2 days and can be carried out at the pack level, module level or cell level [29]. There are standards that can be followed during the test process, for example, UL 1974 [7]. There is also the chance that the testing of the battery is performed periodically during the first life of the battery as part of the maintenance of the vehicle, which might make the data available for consideration during second life. Also, some strategies to estimate the remaining useful life (RUL) can be use with the data obtained by the tests [30].

The last step of the evaluation stage is to ascertain the reason for reaching the EOL. In general, EOL can be defined as the point in the time when the battery can no longer provide enough power or energy to safely accomplish its intended function [31], which depends on the application and the resulting battery requirements [32]. In EVs, the EOL is commonly established when the discharge capacity drops to a certain value relative to its initial value [33]—typically fixed at 80% [34,35] or 70% [36,37]. There are also some other cases where the EOL is defined by the relative internal resistance instead of the relative capacity. In these cases, the EOL is typically set to 200% of the initial internal resistance of the battery [38,39]. The relative capacity is commonly linked to high-energy EV applications and the relative resistance threshold is normally related to high-power EV applications [10]. However, these definitions do not cover all scenarios that may lead to the EOL of a battery. In general, there are three main reasons for reaching EOL:

- Vehicle reaches EOL: In this case, the vehicle is reaching its EOL while the battery is still functional. For example, the vehicle is retired or damaged either with or without damage to the battery. Depending on the condition and health of the battery, the battery can be used directly as a pack or disassembled into modules or cells along with the accompanying balance of plant to proceed to the next step in its lifecycle, as depicted in Figure 1.

- Battery reaches EOL: There are a broad set of reasons that a battery can reach EOL—most notably, the battery can no longer meet the needs of the driver. This could be because the driver’s needs have changed, or because the battery has degraded rendering it unable to achieve the same level of performance as it once could. This scenario is the most common when the battery cannot fulfill the requirements of the driver in terms of range or power due to a decrease of the energy capacity or an increase of the internal resistance, respectively. Additionally, there could be a failure in the battery pack that prevents its use, while the rest of the vehicle systems are still functional.

- Warranty or legal limitation: There can also be reasons outside of the owner’s control that affect the ability to operate the vehicle. For instance, there can be stipulations in the warranty that require certain actions for the vehicle or the battery pack at a specific age or mileage. Lastly, there could be laws passed in a given country or region that limit usage of vehicles that achieve certain milestones (e.g., age, or mileage). This has been done in many cities in the European Union to limit emissions, by encouraging vehicle stock turnover and movement to more efficient and less polluting vehicles.

4. Technical Viability of Different Solutions

Following the first stage of the assessment, the battery now enters the technical evaluation stage. This stage is focused on exploring requirements for different end use applications and the battery configurations necessary to meet those requirements.

4.1. Second Life Applications: Requirements

Batteries, and storage systems in general, can be used in a broad number of applications. The most discussed applications for second life batteries are: time-shifting (energy arbitrage) [40], peak shaving [41], grid services [42], renewables integration [43], support EV charging stations [44], capacity reserve, personal e-mobility [45] and small electronic devices. The above-mentioned applications require different characteristics for the battery and can vary, even within the same application. That is why, for each specific case, the following requirements should be analyzed:

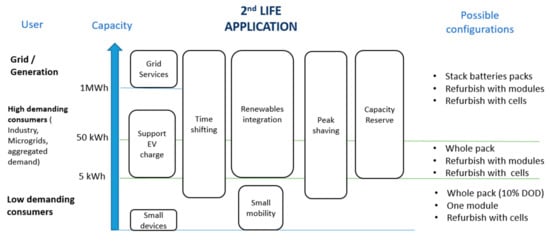

- Capacity: The maximum energy storage capacity to be installed in each application is limited by several factors such as maximum initial investment, energy demand or desired power. Some applications have to follow regulations or consumer requirements to choose the most suitable capacity. The future income of the installation is dependent on the installed capacity, so an economic study is needed to optimize the sizing. If future degradation is taken into consideration during the optimization, it can affect the sizing of the system as well as its economic feasibility. In Figure 2, the identified second life applications are classified in terms of capacity and are matched with the end user of the installation.

Figure 2. Possible configurations and applications depending on the desire capacity.

Figure 2. Possible configurations and applications depending on the desire capacity. - Max power: This depends on the maximum C-rate that the battery can deliver. For Li-ion batteries, it typically varies from 0.5C (Energy Cells) to 5C (Power Cells). Moreover, higher C-rates (25C) can be delivered in small pulses (a few seconds) [46]. Despite that, battery energy storage systems (BESS) oftentimes offer max C-rates of 1C [47,48,49]. Because of the battery design, the power requirement is often interrelated with choosing the most suitable capacity.

- Weight: To obtain the same capacity with second life cells (80% SoH) as with first life cells, 25% more cells are needed and therefore, 25% more net weight of cells will be installed. In stationary applications this does not influence the performance. However, in mobile applications, the weight affects the power and the range of the vehicle. Despite this, in small mobility applications the performance reduction does not appear to be significant. For example, the difference in performance between a scooter with first life batteries (2 kg [45]) and one with second-life batteries (2.5 kg) is equivalent to the difference between the performance of a scooter driven by a 75 kg person and another driven by a 75.5 kg person, that is negligible for the final customer.

- Volume limitations: In mobility applications and small electronic devices, volume is always a limiting factor. For example, the design of the vehicle or the device is greatly affected by the volume and shape of the battery, and therefore it affects the final quality of the product. In contrast, for stationary applications the volume occupied by the battery has a much less significant effect on the capacity installed. However, there are some exceptions such as industries, buildings, or individual houses where the space available may not be enough to install the desired capacity.

- Energy Management system (EMS): The EMS is in charge of controlling the flow of energy in the installation between the different components. The complexity depends on the optimization algorithms included. For example, algorithms to improve the life of the elements of the system, or algorithms to optimize the revenue of the system. It is worthwhile to highlight that the EMS is different from the Battery Management System (BMS), which has the unique objective of ensuring that the battery functions safely. Depending on the new second life application, a new EMS has to be implemented. The communication between the BMS of the old battery or the power converter should be addressed, and may be an impediment as discussed in Section 4.2.

- Thermal management: There are different ways of managing the temperature of the batteries. There are passive techniques and active techniques. The most common active techniques to maintain temperatures in the optimal range are forced air and liquid refrigeration. Depending on the ambient temperature and the working conditions, an appropriate thermal system should be chosen and the degradation of the batteries will be reduced. The decision to include thermal management in the possible second life application should consider the economics of the alternatives (e.g., the ability to reuse a pack or module thermal system, the cost of purchasing a new system, and the performance reduction from not including a thermal management system).

- Possible configurations: Depending on the design of the EV battery pack, it could be adapted to second life applications through different configurations. The main configurations identified in this document are: stacking battery packs, refurbishing used modules and refurbishing used cells. In Figure 2, second life applications are matched with different possible configurations vs capacity. For stationary applications, the three configurations are possible. For low-capacity applications, due to the form factor and capacity requirements, the only practical configuration is to use refurbished cells. This will be explained in detail in the next subsection.

4.2. Second Life Applications: Potential Configurations

Consideration of different battery configurations when deciding on the appropriate second life application is an important part of the battery assessment process. Many battery packs are not designed for a potential reuse; however, more manufacturers are beginning to integrate concepts of eco-design for their battery packs that will aid in the reuse and refurbishing processes—thus lowering costs and complexity [50]. In this section, the possible configurations are analyzed, including the advantages and disadvantages, which are summarized in Table 1.

Table 1.

Summary of main advantages and drawbacks of the second life application configurations.

4.2.1. Stacking Used EV Battery Packs

Stacking battery packs consists of connecting battery packs with the least possible modifications. Combining battery packs can be useful for applications where the energy required is greater than that offered by a single battery pack. Interoperability between battery packs from the same and different manufacturers presents challenges, because EV batteries are not designed with the idea of stacking batteries for second life applications.

Due to the high voltages of the EV battery packs, the connection between them may be done in parallel to avoid isolation problems. This has the advantage of allowing the disconnection of one battery pack in case of failure while maintaining system operation (with lower capacity and power capabilities). On the other hand, when connecting batteries in parallel, some unexpected current flows may develop between batteries with different voltages. To solve this problem, in most of the projects with second life batteries, a power converter is added to the battery. This solution raises the cost, as the DC/DC power converters usually have to be designed especially for each battery type and project [51]. Moreover, if the BMS of the battery pack is not able to communicate with the power converter, a specific gateway has to be developed [52]. EV battery packs with similar characteristics (e.g., capacity, voltage, internal resistance) facilitate the implementation of this type of configuration [51,53].

4.2.2. Refurbished Battery Made from Used Modules

This configuration requires disassembly of the battery pack to the module level. It requires assessing the exterior of the modules, performing characterization tests, certifying that the modules meet the second-life standard, and lastly, integration to form a new battery pack that fits the new application [54]. For applications with high-energy demands, this is an alternative to stacking batteries packs. Similar to the configuration of stacking battery packs, modules with similar characteristics that are able to communicate with a superior BMS should be used in this type of configuration.

4.2.3. Refurbished Modules Made from Used Cells

Refurbishing used cells is similar to refurbishing modules, but the battery pack is disassembled to the cell level. The cells are then packed into new modules and new battery systems. This is particularly valuable when pack or module dimensions are not suitable for the application. Based on the required energy capacity and dimensions, some small mobility and small electronic devices are only able to use cylindrical cells, meaning that if the battery pack is made using prismatic or pouch cells, then the owner can immediately remove these second life applications as potential options.

The outcome of the technical evaluation stage of the battery assessment is to identify suitable end use applications and pack configurations, based on the design and state of the battery pack being assessed.

5. Economic Evaluation of Each Potential Solution

From the technical evaluation, several eligible solutions may have emerged. Each solution is a match to the possible configuration of the battery and the final application. The third stage of the battery assessment is to perform an economic evaluation to find the most profitable application.

The economic evaluation requires an estimation of costs and potential revenues. In subsequent subchapters, important considerations for making this assessment will be described. An example of data from the literature has been provided; however, it is recommended that battery-specific and application-specific data be gathered when performing this analysis.

5.1. Cost of Each Potential Solution

The cost of each solution can be divided into two categories: the cost of the battery, including disassembly, and the cost of the installation into the possible application.

The cost of second life batteries varies widely depending on the configuration chosen. Stacking used EV battery packs or using a whole pack will always have a lower cost than refurbishing modules from used cells. The more it is disassembled, the higher the associated costs. This is due to, on one hand, the cost related with disassembling and, on the other hand, the costs associated with the new equipment needed that can increase the cost around 30% with non-cell related materials (connectors, BMS, case, etc.) [55].

Not all batteries packs have the same internal design, and that makes the cost of disassembly different for each battery. There are different methodologies [56,57,58,59] that can be followed to estimate the cost before disassembling the battery. These methodologies provide deeper insights into which disassembly tasks are the most time-consuming, and provide feedback on how the battery design could be improved to facilitate faster and lower cost disassembly [60].

In [11], the costs associated with removing a battery from the vehicle and disassembling it to the module level and cell level were evaluated. In Table 2, these costs are shown as a reference for manually disassembling a battery pack. This cost will decrease with economies of scale and the use of automatic methods like robots.

Table 2.

Cost of disassembling battery packs. Reprinted from Ref. [11].

Table 2 only considers the disassembly cost. The cost of the second life battery acquisition should also be included, which ranges from 40 to 165 €/kWh [61]. The cost of the battery acquisition varies, depending on remaining life and how much disassembly and testing has been done after the first life.

The cost of the battery is not the only cost of the new second life application that needs to be evaluated. For grid services, the installation is usually called a Battery Energy Storage System (BESS). In Table 3, a brief summary of the costs associated with the installation of BESSs are shown. These costs can be used as a reference, but using data specific to the installation that is being studied will improve reliability of the results of the assessment.

Table 3.

Cost associated with the installation of a BESS.

In summary, the total cost to prepare a battery for second life includes acquisition of the battery, disassembly, possible refurbishing and installation of the new system. Representative costs have been provided for each of these items.

5.2. Revenues

The revenue obtained in consumer-orientated applications (e.g., scooters) comes directly from the price of selling the replacement battery, but in most applications, the amount of revenue obtained depends on how the battery is used during the new life (e.g., time shifting).

For the applications whose source of revenue depends on the use, an optimization algorithm is needed for both analyzing the viability of the project and during the execution of the project to provide operational support (with an EMS). Depending on the quality of this algorithm, the profits of the application can be increased [6]. One of the biggest challenges with developing accurate optimization algorithms is the consideration of battery degradation during the optimization process. The battery degradation is nonlinear, depending on one or more independent variables, and some variables are very difficult to calculate in the same time domain as the other variables of the application. For example, battery degradation is highly affected by the DOD which has to be calculated when the discharge ends, and it is possible that the discharge continues in different periods. This issue makes it difficult to compute the degradation for a single period and the profitability of discharging the battery in that period.

Different authors have proposed many solutions to obtain the optimal use of the battery in different applications and calculate possible revenues. Some of them completely ignore battery degradation [65,66,67] and, in others, the degradation is calculated post-optimization [3]. As a result, the operation strategy is shortsighted and does not consider the battery as a time-limited and costly resource [68]. However, two other approaches do consider battery degradation:

- The constraint-based approach [69,70]: one or more of the following variables are constrained: power, DOD, number of cycles per day, and maximum and minimum state of charge SOC. Such approaches that do not model the degradation behaviour at all return non-optimal results [71].

- The objective-based approach [72,73]: the cost of battery degradation is included as an economic cost in the objective function. The degradation can be expressed using the Ah throughput method [73,74] that assumes that the battery can deliver a certain amount of energy before its end of life without considering the working conditions. Another way of expressing the degradation of the battery is using the number of cycles vs DOD power functions [69,72], where it is assumed that the number of cycles that a battery can perform is inversely proportional to the amplitude of DOD given by a simple power function [71].

Revenue potential for energy storage systems in the U.S. was analyzed in detail by Balducci et al. in 2018 [75]. The minimum, mean and maximum values for each application is presented in Table 4. The highest mean values were registered for frequency regulation ($123/kW-year), capacity or resource adequacy benefits ($106/kW-year), and demand charge reduction ($104/kW-year). Additionally, there is the potential to participate in multiple markets, thereby allowing for stacking of revenues [54].

Table 4.

Minimum, mean and maximum values of different applications in the US markets. Reproduced from Ref. [75].

The high variability of the values is due to the inclusion of different markets, different years, and different ways of implementing the battery. In [5], the following factors are identified as sources of uncertainty when the revenue of an application is calculated: (i) Revenue streams: target market, rate structures, electricity prices and ancillary service payment structures, etc. (ii) Technical parameters: second life battery lifetime, power and energy capabilities, efficiency, heterogeneity, etc. (iii) Policies and market-specific conditions: environmental initiatives, subsidies, legal requirements, etc.

Moreover, apart from the great uncertainties of each application, the market size also needs to be considered. Many applications have a limited market size that can become saturated. Frequency regulation markets are particularly susceptible due to their relatively high value and limited size [76,77,78].

Additionally, there may be other factors that can affect the profitability of second life applications including incentives for battery reuse, or credits for greenhouse gas emissions reductions through a carbon market.

If none of the possible applications and configurations are profitable, the owner should consider recycling or disposing of the battery after this assessment.

6. Example Battery Assessment

In order to show the functionality of the battery assessment procedure, an application example is shown in this chapter. For this, realistic assumptions will be used to observe how the extracted information is analyzed and used to find the optimal pathway for a particular battery.

To begin with, it is assumed that the evaluation is carried out by the car manufacturer. This is a convenient situation as it is the one with extensive knowledge of the battery. It is also a realistic assumption, as European regulations require that the vehicle OEM or battery manufacturers cover expenses related to battery collection and recycling.

The example deals with a vehicle that is no longer capable of fulfilling the driver’s requirements.

6.1. Evaluate State of the Battery

The first step is to assess the condition of the battery. Several pieces of information are needed to evaluate the state of the battery. In the procedure, two options are mentioned: continual estimation of the battery health through vehicle monitoring or through battery tests. This example begins by compiling the available information that does not require any special operation. It will be assumed that the following battery information is available (Table 5):

Table 5.

Information available for assessing the condition of the battery.

In the case of the study, a lifetime battery model is not available to predict the possible estimated life for other applications. However, with the mileage of the vehicle, some calculations (Equations (1) and (2)) can be made to aid in a lifetime estimation.

It is assumed that 1 cycle of the battery is equivalent to the range of the vehicle, by dividing the total km by the range; an estimated value of the total full equivalent cycles (FEC) of the battery can be obtained:

Another assumption is that the life of the vehicle can be linearized [79] and a similar degradation rate can be establish for the second life application, as shown in Equation (2).

With these values, the battery assessment can be continued without the need to carry out any test or removal of the battery pack from the vehicle. Moreover, after this first stage, it is known that the battery works correctly, so it could be used without requiring any repair in a second life application.

6.2. Technical Viability

The objective of the technical feasibility study phase is to check if the battery pack can have a second life, and in what type of configuration it would be. To do this, the necessary information is compiled based on Section 4 (see Table 6).

Table 6.

Information available for the technical feasibility part of the case study.

Looking at the available information in Table 6, the following possible solutions can be assessed:

- Stacking battery packs: This configuration is viable and can be implemented easily using power converters. In this case, only one battery pack is available, so it would be a standalone battery pack application.

- Refurbished battery pack made from used modules: a new battery pack or rack of modules should be built with a BMS available to communicate with the module control units (MCU) of the modules. It is unable to work alone.

- Refurbished modules made from used cells: the battery pack can be dismantled to the cell level so it is possible to refurbish a new pack/module using the used cells. The inconvenience is that in order to use the cells with a new BMS, they should be characterized and a minimum of cells should be wasted in some previous tests.

After analyzing the technical viability of the different configurations, all of these options are possible. However, a priori, refurbished modules made from used cells, and refurbish battery packs made from used modules implies more tasks than using the battery pack directly.

At this point in the battery assessment, a decision must be made from the different options for the purpose of economic analysis. The following options shown in the Table 7 will be explored:

Table 7.

Options to be explored in the economic analysis, based on the information identified in the technical feasibility and battery evaluation steps of the battery assessment.

6.3. Economic Analysis

For the economic analysis of this example, the costs and revenues shown in Section 5 will be used as a reference. A simplified example is shown here, but a more detailed economic analysis should be carried out when making a financial decision.

Several applications are possible. Table 4 contains reference revenue values. For this exercise, it will be assumed that the mean revenue is 50 €/kW-year for energy arbitrage.

To estimate the duration of the battery, we can assume the end of life of the second life application at 50% SOH [80]. This means that 750 FECs can be performed with the battery. Assuming that the battery is cycled every day, the lifetime of the battery before reaching end of life would be around 2 years. Table 8 contains the example assessment of the cost of installation of the second life battery pack.

Table 8.

Example cost assessment of the battery’s transition to second life.

The results for the economic analysis are shown in Table 9.

Table 9.

Results of the economic analysis for the example battery assessment.

6.4. Decision

With the analysis done, a second life application seems viable. When this analysis is done before the battery has been removed from the vehicle, the following steps can be decided (dismantling, transport to the place of installation, etc.) and the calendar ageing due to the storage of the battery is avoided.

The following list contains considerations for improvement that should be taken into account based on the presented example:

- The scrap value (i.e., the price that must be paid to the old owner) of the battery pack has to be subtracted from the mentioned revenues.

- The operation predicts a relatively short lifetime (i.e., two years), after which a new battery would need to be acquired to continue operation.

- Real costs of the required power converter and other equipment should be used, as opposed to the general cost items identified from the literature.

- A deeper analysis of the revenues and optimization of the battery use could be done, to consider the potential for stacked values and the opportunity for enhancing operation decisions by internalizing degradation into the optimization. The assumption that the battery will have a linear degradation until 50% SOH is unlikely if the battery reaches a point of rapid increase in degradation before the 50% SOH level (i.e., the ageing knee).

7. Conclusions and Future Work

This article develops a procedure for the assessment of batteries when transitioning from first life to second life applications. First, the framework for the battery assessment is established with the main uncertainties and challenges identified. The procedure is divided into three stages including: state of the battery, technical viability to transition to a new end-use application, and economic viability.

The first stage gathers information to understand the condition and expectation of performance for the battery. The second stage explores various end use applications, their requirements and using the information gathered in the first stage. It also explores the benefits and weaknesses of different battery configurations to meet those requirements. The third and final stage of the battery assessment outlines the development of an economic evaluation to compare the revenue from different end uses with the cost of implementing the battery configurations outlined in the second stage. The main goal is to establish combinations of second life applications and battery configurations that are profitable.

The main highlights from this work are summarized below:

- This work develops a framework for assessing the suitability of battery second life applications that can be used today, and which has the ability to evolve with changes in the future. Some of the changes envisioned are related to an increase in the volume of recorded data points, advancements in battery modeling and digital twins, as well as improvements to the optimization algorithms in energy management systems to internalize degradation in their objective functions.

- Building on the previous literature, the paper discusses the reasons for transitioning to EOL, the decisions that must be made, and identifies a quantifiable process for determining the most suitable use for batteries as they reach EOL (including repair, reuse, recycle, or disposal).

- This paper explores options for battery configurations (direct use of pack, stack of packs, direct use of modules, refurbish with modules, and refurbish with cells). Uniquely, by comparing those configurations to the technical requirements for second life applications, a reader can rapidly understand the tradeoffs and gain practical knowledge on how best to implement second life batteries for their specific application. This discussion includes a table of advantages and disadvantages to guide the decision process.

- This work develops a method for evaluating the economic impacts of reusing second life batteries compared to purchasing a new battery pack. There are provided default values for costs and revenues. However, with limited data available, it is acknowledged that there is high variability in these data. It is therefore recommended that additional studies need to be performed that capture the cost of transitioning batteries into second life applications.

- Minimizing the costs, accurately predicting battery health and remaining lifetime, and proper sizing for the application are the keys to maximizing the profit from second life batteries.

The next step to consolidate this procedure is to apply it for the assessment of second life batteries in relevant EU projects. Several candidates include the Albatross, COBRA, MARBEL, and HELIOS projects.

Author Contributions

Conceptualization, T.M., M.E.-S., J.E., L.T., V.J.F., C.C.; methodology, T.M., M.E.-S., J.E., V.J.F.; data curation, T.M.; writing—original draft preparation, T.M.; writing—review and editing, T.M., M.E.-S., J.E., V.J.F., L.T., C.C.; visualization, T.M.; supervision, C.C.; project administration, J.E.; funding acquisition, L.T., C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No. 963540 and No. 963580. This funding includes funds to support research work and open-access publications.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data used in this paper is available upon request.

Acknowledgments

Cristina Corchero is a Serra Hunter Fellow.

Conflicts of Interest

The authors declare no conflict of interest, and the funding agencies had no role in the design, execution, interpretation, or writing of the study.

References

- A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 13 May 2022).

- Recovery Plan for Europe. Available online: https://ec.europa.eu/info/strategy/recovery-plan-europe_en (accessed on 13 May 2022).

- Rallo, H.; Canals Casals, L.; De La Torre, D.; Reinhardt, R.; Marchante, C.; Amante, B. Lithium-Ion Battery 2nd Life Used as a Stationary Energy Storage System: Ageing and Economic Analysis in Two Real Cases. J. Clean. Prod. 2020, 272, 122584. [Google Scholar] [CrossRef]

- Canals Casals, L.; Amante García, B. Second-Life Batteries on a Gas Turbine Power Plant to Provide Area Regulation Services. Batteries 2017, 3, 10. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.-I.; Swierczynski, M.; Goikoetxea, A. Battery Second Life: Hype, Hope or Reality? A Critical Review of the State of the Art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Mathews, I.; Xu, B.; He, W.; Barreto, V.; Buonassisi, T.; Peters, I.M. Technoeconomic Model of Second-Life Batteries for Utility-Scale Solar Considering Calendar and Cycle Aging. Appl. Energy 2020, 269, 115127. [Google Scholar] [CrossRef]

- Laboratories, U. UL 1974—Standard for Evaluation for Repurposing Batteries. 2018. Available online: https://standardscatalog.ul.com/ProductDetail.aspx?productId=UL1974 (accessed on 20 April 2022).

- Liao, Q.; Mu, M.; Zhao, S.; Zhang, L.; Jiang, T.; Ye, J.; Shen, X.; Zhou, G. Performance Assessment and Classification of Retired Lithium Ion Battery from Electric Vehicles for Energy Storage. Int. J. Hydrogen Energy 2017, 42, 18817–18823. [Google Scholar] [CrossRef]

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of Utilising Second Life EV Batteries: Applications, Lifespan, Economics, Environmental Impact, Assessment, and Challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Warner, J. Second Life and Recycling of Lithium-Ion Batteries. In The Handbook of Lithium-Ion Battery Pack Design; Elsevier: Amsterdam, The Netherlands, 2015; pp. 169–176. ISBN 978-0-12-801456-1. [Google Scholar]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic Analysis of the Disassembling Activities to the Reuse of Electric Vehicles Li-Ion Batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Lee Sooi Joo, S.; Sing Yang, C.; Yi, R.; Luo Yuanhong, J.; Srinivasan, M. Repurposing of Lithium-Ion Batteries; Singapore Battery Consortium: Singapore, 2021. [Google Scholar]

- Janota, L.; Králík, T.; Knápek, J. Second Life Batteries Used in Energy Storage for Frequency Containment Reserve Service. Energies 2020, 13, 6396. [Google Scholar] [CrossRef]

- Nalley, S.; LaRose, A. International Energy Outlook 2021; U.S. Department of Energy: Washington, DC, USA, 2021. [Google Scholar]

- Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020; European Commission: Brussels, Belgium, 2020.

- BatteryArchive.Org. Available online: https://www.batteryarchive.org/ (accessed on 1 June 2022).

- Wang, S.; Jin, S.; Bai, D.; Fan, Y.; Shi, H.; Fernandez, C. A Critical Review of Improved Deep Learning Methods for the Remaining Useful Life Prediction of Lithium-Ion Batteries. Energy Rep. 2021, 7, 5562–5574. [Google Scholar] [CrossRef]

- Song, L.; Zhang, K.; Liang, T.; Han, X.; Zhang, Y. Intelligent State of Health Estimation for Lithium-Ion Battery Pack Based on Big Data Analysis. J. Energy Storage 2020, 32, 101836. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, G.; Zhen, D.; Gu, F.; Ball, A. A Review on Online State of Charge and State of Health Estimation for Lithium-Ion Batteries in Electric Vehicles. Energy Rep. 2021, 7, 5141–5161. [Google Scholar] [CrossRef]

- Hosen, M.S.; Jaguemont, J.; Van Mierlo, J.; Berecibar, M. Battery Lifetime Prediction and Performance Assessment of Different Modeling Approaches. iScience 2021, 24, 102060. [Google Scholar] [CrossRef] [PubMed]

- Hong, J.; Wang, Z.; Chen, W.; Wang, L.; Lin, P.; Qu, C. Online Accurate State of Health Estimation for Battery Systems on Real-World Electric Vehicles with Variable Driving Conditions Considered. J. Clean. Prod. 2021, 294, 125814. [Google Scholar] [CrossRef]

- Hashemi, S.R.; Mahajan, A.M.; Farhad, S. Online Estimation of Battery Model Parameters and State of Health in Electric and Hybrid Aircraft Application. Energy 2021, 229, 120699. [Google Scholar] [CrossRef]

- Feng, X.; Weng, C.; He, X.; Han, X.; Lu, L.; Ren, D.; Ouyang, M. Online State-of-Health Estimation for Li-Ion Battery Using Partial Charging Segment Based on Support Vector Machine. IEEE Trans. Veh. Technol. 2019, 68, 8583–8592. [Google Scholar] [CrossRef]

- Tang, X.; Liu, K.; Li, K.; Widanage, W.D.; Kendrick, E.; Gao, F. Recovering Large-Scale Battery Aging Dataset with Machine Learning. Patterns 2021, 2, 100302. [Google Scholar] [CrossRef]

- Wang, S.; Jin, S.; Deng, D.; Fernandez, C. A Critical Review of Online Battery Remaining Useful Lifetime Prediction Methods. Front. Mech. Eng. 2021, 7, 719718. [Google Scholar] [CrossRef]

- Li, K.; Zhou, P.; Lu, Y.; Han, X.; Li, X.; Zheng, Y. Battery Life Estimation Based on Cloud Data for Electric Vehicles. J. Power Sources 2020, 468, 228192. [Google Scholar] [CrossRef]

- Bosch Developing Cloud-Based Swarm Intelligence Services to Augment EV Battery Management Systems. Available online: https://www.greencarcongress.com/2019/07/20190710-bosch.html (accessed on 4 August 2022).

- Hemmati, R.; Mehrjerdi, H. Investment Deferral by Optimal Utilizing Vehicle to Grid in Solar Powered Active Distribution Networks. J. Energy Storage 2020, 30, 101512. [Google Scholar] [CrossRef]

- Lacap, J.; Park, J.W.; Beslow, L. Development and Demonstration of Microgrid System Utilizing Second-Life Electric Vehicle Batteries. J. Energy Storage 2021, 41, 102837. [Google Scholar] [CrossRef]

- Sanz-Gorrachategui, I.; Pastor-Flores, P.; Pajovic, M.; Wang, Y.; Orlik, P.V.; Bernal-Ruiz, C.; Bono-Nuez, A.; Artal-Sevil, J.S. Remaining Useful Life Estimation for LFP Cells in Second-Life Applications. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Cui, Y.; Yang, J.; Du, C.; Zuo, P.; Gao, Y.; Cheng, X.; Ma, Y.; Yin, G. Prediction Model and Principle of End-of-Life Threshold for Lithium Ion Batteries Based on Open Circuit Voltage Drifts. Electrochim. Acta 2017, 255, 83–91. [Google Scholar] [CrossRef]

- Arrinda, M.; Oyarbide, M.; Macicior, H.; Muxika, E.; Popp, H.; Jahn, M.; Ganev, B.; Cendoya, I. Application Dependent End-of-Life Threshold Definition Methodology for Batteries in Electric Vehicles. Batteries 2021, 7, 12. [Google Scholar] [CrossRef]

- Lin, C.; Tang, A.; Wang, W. A Review of SOH Estimation Methods in Lithium-Ion Batteries for Electric Vehicle Applications. Energy Procedia 2015, 75, 1920–1925. [Google Scholar] [CrossRef]

- USABC Electric Vehicle Battery Test Procedures Manual; Revision 2; Idaho National Engineering Laboratory: Idaho Falls, ID, USA, 1996.

- Groenewald, J.; Grandjean, T.; Marco, J. Accelerated Energy Capacity Measurement of Lithium-Ion Cells to Support Future Circular Economy Strategies for Electric Vehicles. Renew. Sustain. Energy Rev. 2017, 69, 98–111. [Google Scholar] [CrossRef]

- Podias, A.; Pfrang, A.; Di Persio, F.; Kriston, Á.; Bobba, S.; Mathieux, F.; Messagie, M.; Boon-Brett, L. Sustainability Assessment of Second Use Applications of Automotive Batteries: Ageing of Li-Ion Battery Cells in Automotive and Grid-Scale Applications. World Electr. Veh. J. 2018, 9, 24. [Google Scholar] [CrossRef]

- Kim, E.; Wu, B.; Shin, K.; Lee, J.; He, L. Adaptive Battery Diagnosis/Prognosis for Efficient Operation. In Proceedings of the Tenth ACM International Conference on Future Energy Systems; Association for Computing Machinery: New York, NY, USA, 2019; pp. 150–159. [Google Scholar]

- Grandjean, T.R.B.; Groenewald, J.; McGordon, A.; Widanage, W.D.; Marco, J. Accelerated Internal Resistance Measurements of Lithium-Ion Cells to Support Future End-of-Life Strategies for Electric Vehicles. Batteries 2018, 4, 49. [Google Scholar] [CrossRef]

- Ecker, M.; Gerschler, J.B.; Vogel, J.; Käbitz, S.; Hust, F.; Dechent, P.; Sauer, D.U. Development of a Lifetime Prediction Model for Lithium-Ion Batteries Based on Extended Accelerated Aging Test Data. J. Power Sources 2012, 215, 248–257. [Google Scholar] [CrossRef]

- Wralsen, B.; Faessler, B. Multiple Scenario Analysis of Battery Energy Storage System Investment: Measuring Economic and Circular Viability. Batteries 2022, 8, 7. [Google Scholar] [CrossRef]

- Asian Development Bank. Handbook on Battery Energy Storage System; Asian Development Bank: Manila, Philippines, 2018. [Google Scholar]

- ENTSOE’s (European Network of Transmission System Operators for Electricity). Available online: https://www.entsoe.eu/ (accessed on 15 November 2021).

- Saez-de-Ibarra, A.; Martinez-Laserna, E.; Stroe, D.-I.; Swierczynski, M.; Rodriguez, P. Sizing Study of Second Life Li-Ion Batteries for Enhancing Renewable Energy Grid Integration. IEEE Trans. Ind. Appl. 2016, 52, 4999–5008. [Google Scholar] [CrossRef] [Green Version]

- Kamath, D.; Arsenault, R.; Kim, H.C.; Anctil, A. Economic and Environmental Feasibility of Second-Life Lithium-Ion Batteries as Fast-Charging Energy Storage. Environ. Sci. Technol. 2020, 54, 6878–6887. [Google Scholar] [CrossRef] [PubMed]

- Xiaomi Mi Electric Scooter 3—Andar Mucho Más Seguro|Xiaomi España|Mi.com. Available online: https://www.mi.com/es/product/mi-electric-scooter-3/ (accessed on 30 June 2022).

- BU-205: Types of Lithium-Ion. Available online: https://batteryuniversity.com/article/bu-205-types-of-lithium-ion (accessed on 22 November 2021).

- TPS-E|Tesvolt GmbH. Available online: https://www.tesvolt.com/en/products/tps-e.html (accessed on 10 November 2021).

- Battery Solutions-Atess Power Technology. Available online: https://www.atesspower.com/Product/Energy/Battery/105.html (accessed on 10 November 2021).

- Off Grid Battery Storage System—PowerCombo-C40|Cubenergy. Available online: https://www.cubenergy.com/battery-energy-storage-system/PowerCombo-C40.html (accessed on 10 November 2021).

- Trilla, L.; Gómez-Núñez, A.; Benveniste, G.; Espinar, C. Second Use Guideline—Full Report; MARBEL EU Project Report; 2021. Available online: https://marbel-project.eu/download/d2-4-second-use-guideline-full-report/ (accessed on 29 June 2022).

- Casals, L.C.; Garcia, B.A. Assessing Electric Vehicles Battery Second Life Remanufacture and Management. JGE 2016, 6, 77–98. [Google Scholar] [CrossRef]

- Casals, L.C.; Garcia, B.A. Communications Concerns for Reused Electric Vehicle Batteries in Smart Grids. IEEE Commun. Mag. 2016, 54, 120–125. [Google Scholar] [CrossRef]

- Gogoana, R.; Pinson, M.B.; Bazant, M.Z.; Sarma, S.E. Internal Resistance Matching for Parallel-Connected Lithium-Ion Cells and Impacts on Battery Pack Cycle Life. J. Power Sources 2014, 252, 8–13. [Google Scholar] [CrossRef]

- Lee, J.W.; Haram, M.H.S.M.; Ramasamy, G.; Thiagarajah, S.P.; Ngu, E.E.; Lee, Y.H. Technical Feasibility and Economics of Repurposed Electric Vehicles Batteries for Power Peak Shaving. J. Energy Storage 2021, 40, 102752. [Google Scholar] [CrossRef]

- Lowe, M.; Tokuoka, S.; Trigg, T.; Gereffi, G. Lithium-Ion Batteries for Electric Vehicles: The U.S. Value Chain; Center Center on Globalization, Governance & Competitiveness: Durham, NC, USA, 2010. [Google Scholar] [CrossRef]

- Desai, A.; Mital, A. Evaluation of Disassemblability to Enable Design for Disassembly in Mass Production. Int. J. Ind. Ergon. 2003, 32, 265–281. [Google Scholar] [CrossRef]

- Kroll, E.; Carver, B.S. Disassembly Analysis through Time Estimation and Other Metrics. Robot. Comput.-Integr. Manuf. 1999, 15, 191–200. [Google Scholar] [CrossRef]

- Sodhi, R.; Sonnenberg, M.; Das, S. Evaluating the Unfastening Effort in Design for Disassembly and Serviceability. J. Eng. Des. 2004, 15, 69–90. [Google Scholar] [CrossRef]

- Boks, C.B.; Kroll, E.; Brouwers, W.C.J.; Stevels, A.L.N. Disassembly Modeling: Two Applications to a Philips 21″ Television Set. In Proceedings of the 1996 IEEE International Symposium on Electronics and the Environment, ISEE-1996, Dallas, TX, USA, 6–8 May 1996; pp. 224–229. [Google Scholar]

- Vanegas, P.; Peeters, J.R.; Cattrysse, D.; Tecchio, P.; Ardente, F.; Mathieux, F.; Dewulf, W.; Duflou, J.R. Ease of Disassembly of Products to Support Circular Economy Strategies. Resour. Conserv. Recycl. 2018, 135, 323–334. [Google Scholar] [CrossRef]

- Neubauer, J.; Smith, K.; Wood, E.; Pesaran, A. Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries; NREL: Golden, CO, USA, 2015; p. 1171780. [Google Scholar]

- Mongird, K.; Viswanathan, V.; Alam, J.; Vartanian, C.; Sprenkle, V.; Baxter, R. 2020 Grid Energy Storage Technology Cost and Performance Assessment. Energy 2020, 2020, 117. [Google Scholar]

- Fu, R.; Remo, T.W.; Margolis, R.M. 2018 U.S. Utility-Scale Photovoltaics-Plus-Energy Storage System Costs Benchmark; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2018. [Google Scholar]

- Marchi, B.; Pasetti, M.; Zanoni, S. Life Cycle Cost Analysis for BESS Optimal Sizing. Energy Procedia 2017, 113, 127–134. [Google Scholar] [CrossRef]

- Shafiee, S.; Zamani-Dehkordi, P.; Zareipour, H.; Knight, A.M. Economic Assessment of a Price-Maker Energy Storage Facility in the Alberta Electricity Market. Energy 2016, 111, 537–547. [Google Scholar] [CrossRef]

- Kazemi, M.; Zareipour, H.; Amjady, N.; Rosehart, W.D.; Ehsan, M. Operation Scheduling of Battery Storage Systems in Joint Energy and Ancillary Services Markets. IEEE Trans. Sustain. Energy 2017, 8, 1726–1735. [Google Scholar] [CrossRef]

- Akhavan-Hejazi, H.; Mohsenian-Rad, H. Optimal Operation of Independent Storage Systems in Energy and Reserve Markets with High Wind Penetration. IEEE Trans. Smart Grid 2014, 5, 1088–1097. [Google Scholar] [CrossRef]

- Li, Y.; Vilathgamuwa, M.; Choi, S.S.; Farrell, T.W.; Tran, N.T.; Teague, J. Development of a Degradation-Conscious Physics-Based Lithium-Ion Battery Model for Use in Power System Planning Studies. Appl. Energy 2019, 248, 512–525. [Google Scholar] [CrossRef]

- Kazemi, M.; Zareipour, H. Long-Term Scheduling of Battery Storage Systems in Energy and Regulation Markets Considering Battery’s Lifespan. IEEE Trans. Smart Grid 2018, 9, 6840–6849. [Google Scholar] [CrossRef]

- He, G.; Chen, Q.; Kang, C.; Pinson, P.; Xia, Q. Optimal Bidding Strategy of Battery Storage in Power Markets Considering Performance-Based Regulation and Battery Cycle Life. IEEE Trans. Smart Grid 2016, 7, 2359–2367. [Google Scholar] [CrossRef]

- Maheshwari, A.; Paterakis, N.G.; Santarelli, M.; Gibescu, M. Optimizing the Operation of Energy Storage Using a Non-Linear Lithium-Ion Battery Degradation Model. Appl. Energy 2020, 261, 114360. [Google Scholar] [CrossRef]

- Xu, B.; Zhao, J.; Zheng, T.; Litvinov, E.; Kirschen, D.S. Factoring the Cycle Aging Cost of Batteries Participating in Electricity Markets. IEEE Trans. Power Syst. 2018, 33, 2248–2259. [Google Scholar] [CrossRef]

- Tan, X.; Wu, Y.; Tsang, D.H.K. A Stochastic Shortest Path Framework for Quantifying the Value and Lifetime of Battery Energy Storage Under Dynamic Pricing. IEEE Trans. Smart Grid 2017, 8, 769–778. [Google Scholar] [CrossRef]

- Namor, E.; Torregrossa, D.; Sossan, F.; Cherkaoui, R.; Paolone, M. Assessment of Battery Ageing and Implementation of an Ageing Aware Control Strategy for a Load Leveling Application of a Lithium Titanate Battery Energy Storage System. In Proceedings of the 2016 IEEE 17th Workshop on Control and Modeling for Power Electronics (COMPEL), Trondheim, Norway, 27–30 June 2016; IEEE: Trondheim, Norway, 2016; pp. 1–6. [Google Scholar]

- Balducci, P.J.; Alam, M.J.E.; Hardy, T.D.; Wu, D. Assigning Value to Energy Storage Systems at Multiple Points in an Electrical Grid. Energy Environ. Sci. 2018, 11, 1926–1944. [Google Scholar] [CrossRef]

- Ambrose, H.; Gershenson, D.; Gershenson, A.; Kammen, D. Driving Rural Energy Access: A Second-Life Application for Electric-Vehicle Batteries. Environ. Res. Lett. 2014, 9, 094004. [Google Scholar] [CrossRef]

- Horesh, N.; Quinn, C.; Wang, H.; Zane, R.; Ferry, M.; Tong, S.; Quinn, J.C. Driving to the Future of Energy Storage: Techno-Economic Analysis of a Novel Method to Recondition Second Life Electric Vehicle Batteries. Appl. Energy 2021, 295, 117007. [Google Scholar] [CrossRef]

- Eichman, J.; Denholm, P.; Jorgenson, J. Operational Benefits of Meeting California’s Energy Storage Targets. Renew. Energy 2015, 94, 1233681. [Google Scholar]

- Martinez-Laserna, E.; Sarasketa-Zabala, E.; Villarreal Sarria, I.; Stroe, D.-I.; Swierczynski, M.; Warnecke, A.; Timmermans, J.-M.; Goutam, S.; Omar, N.; Rodriguez, P. Technical Viability of Battery Second Life: A Study From the Ageing Perspective. IEEE Trans. Ind. Appl. 2018, 54, 2703–2713. [Google Scholar] [CrossRef]

- Braco, E.; San Martín, I.; Berrueta, A.; Sanchis, P.; Ursúa, A. Experimental Assessment of Cycling Ageing of Lithium-Ion Second-Life Batteries from Electric Vehicles. J. Energy Storage 2020, 32, 101695. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).