Abstract

Redox flow batteries are one of the most promising technologies for large-scale energy storage, especially in applications based on renewable energies. In this context, considerable efforts have been made in the last few years to overcome the limitations and optimise the performance of this technology, aiming to make it commercially competitive. From the monitoring point of view, one of the biggest challenges is the estimation of the system internal states, such as the state of charge and the state of health, given the complexity of obtaining such information directly from experimental measures. Therefore, many proposals have been recently developed to get rid of such inconvenient measurements and, instead, utilise an algorithm that makes use of a mathematical model in order to rely only on easily measurable variables such as the system’s voltage and current. This review provides a comprehensive study of the different types of dynamic models available in the literature, together with an analysis of the existing model-based estimation strategies. Finally, a discussion about the remaining challenges and possible future research lines on this field is presented.

1. Introduction

Energy production constitutes the cornerstone of the society’s economic and industrial development. During the last two centuries, fossil fuels have consistently been the main energy source because of their inherent flexibility and, originally, their high abundance [1]. However, this way of producing energy has proved to be non-sustainable, given the fast reduction of fossil fuels reserves and, especially, the grave environmental impacts originated by carbon dioxide and other pollutants emissions resulting from their burning. To confront this scenario, global efforts are being put by governments and international organisations to migrate to a new energy matrix based on renewable energies [2]. For instance, the International Energy Agency (IEA) states that the growth of renewable energy is accelerating faster than ever worldwide, expecting it to be 60% higher by 2026 in comparison to 2020 [3]. Similar predictions are shared by other reports, such as the one presented at [4], that looking further into the future, expects a use of renewable energy close to 85%.

In the traditional fossil-fuel based paradigm, the energy production can be planned and regulated in order to match the demand. In contrast, this is not possible with most renewable sources, such as wind, solar and marine, owing to their intermittent and stochastic nature [5]. Therefore, this energy transition can only be accomplished if the renewables are complemented with efficient energy storage systems (ESS) capable to balance the energy production and demand [6,7]. These could enable renewables to be the base-load of the electricity supply, eliminating grid stability concerns as well as the need of a conventional energy reserve [8,9,10]. ESS can be classified according to the way of converting energy into three main groups:

- Mechanical. These use mechanical physical principles to store the energy. The most common types are the pumped hydroelectric (PH) and compressed air (CA).

- Chemical. These use a fuel to produce energy from a chemical reaction. The traditional fossil fuels are based in this principles, as well as their renewable counterparts such as biogas or biodiesel. Although electric power can be produced from these sources, the inverse process is generally not possible.

- Electrochemical. These use different chemical species that react with an electric field, allowing the storage or delivery of energy. Within this group it is possible to find all different types of batteries such as molten salt, lithium-ion (Li-ion), lead-acid and redox flow batteries (RFB). Hydrogen technologies (HT), based on electrolysers/fuel cells are also included in this category.

In order to compare the different types of ESS named, some characteristics have been analysed, which are summarised in Table 1. This table shows some of the most important indicators for ESS, such as the power and energy density [11], lifetime, efficiency and capital cost per unit (CPU) of energy [12]. Note that, in the case of the lifetime, the time unit utilised is years. However, for batteries, the typical unit used is the number of cycles, considering as a cycle a total charging and discharging process at the operational conditions for which the battery has been designed.

Table 1.

Comparison of the main indicators of ESS. Extracted from [11,12,13].

As can be noticed from the characteristics presented in Table 1, the mechanical ESS have the advantage of generating high power during several hours. However, the low energy density of CA is a strong limitant in many applications, while PH depends on the existence of geographical heights and the availability of large volumes of water. For its part, hydrogen technologies, although very appealing for vehicles, are rather limited for stationary applications because of their comparatively low efficiency. Finally, the use of electrochemical ESS appear as a good choice due to their short and long-term energy discharges, high energy densities and efficiencies which make them suitable for different types of applications. Nevertheless, it should be noted that its lifetime is limited to a certain number of cycles, being the RFB the ones with the largest number of them.

Besides their long lifespan, there are other reasons that explain why RFB have become one of the most promising candidates for large-scale energy storage. The most distinctive feature of this technology is that the energy is contained in two solutions of chemical active species which are stored in two independent reservoirs, while the electric power is produced in a separate device, where the electrochemical reactions take place. Thus, the energy capacity, linked to the volume of electrolyte stored in the tanks, can be completely decoupled from the system power which is associated with the size of the electrochemical stack [14]. This confers RFB a great deal of flexibility with respect to their scalability, modular design and, if required, enables the possibility of a fast recharge by renewing the tanks content [15]. Additionally, it can be remarked their high round-trip efficiency (∼75%), fast response time, simple and safe operation, absence of environmental risks and low maintenance [16].

Considering all these characteristics related to the RFB, there is a wide variety of applications in which they can be very useful, being in particular applications the best alternative among the different ESS presented. Some specific applications in which RFB can perform particularly well are briefly described below:

- Energy management. This include the load levelling and the peak shaving processes, in which the battery is charged during low demand periods and discharged during high demand. Specifically, the objective of load levelling is stabilising the electrical load, avoiding sharp fluctuations in the consumed power. In the case of peak shaving process, the battery is in standby mode most of the time, and the stored energy is used only to remove load peaks consumption [15]. This function is essential in electric grids based on renewable energies.

- Grid stabilisation. In combination with other ESS such as supercapictors, the RFB can be utilised to create hybrid systems able to quickly release and absorb active power within tens of milliseconds. Thus, it can be employed to improve the power quality by participating in the sag compensation, power smoothing, and voltage and frequency regulation processes. This guarantees that the power quality meet the requirements, and thereby provides stability to the grid [17,18].

- Backup power in critical applications. In those applications where it is critical to guarantee an uninterrupted supply of energy (e.g., hospitals), RFB can be used as a backup energy system when the main power source fails. This is possible thanks to their very low self discharge rate when they are in standby mode and the pumps are shut down [14,19].

- Buffering in electric vehicle charging station. The steep growth in electric vehicles proportion, together with the development of fast charging technologies of over 100 kW is coupled with some challenging issues [15]. In particular, the high power demand may cause grid instability and, in addition, the cost of the transformers for the interconnection with the fast charging station can be very high. However, as the peak power is only reached during relatively short time windows, the utilisation of redox flow batteries as a buffering module becomes an appealing possibility [20]. In this hybrid topology, the battery would gradually store energy during low-demand periods and release it in load peaks. As a result, the interconnection cost would be substantially reduced and, furthermore, the RFB could be also used to improve the quality of the grid power during low demand.

- Powering electric vehicles. Although the use of RFB in mobile applications is limited by their low energy density, they are well suited to be used in applications where weight and autonomy are not an issue, such as in urban electric buses [21,22]. Furthermore, in the future, high energy density RFBs could be competitive for powering a broader range of electric vehicles, with the particular advantage that, if necessary, they could be fastly recharged by renewing the tanks contents [23].

- Dual redox flow batteries for hydrogen production. The development of new technologies of RFBs gives the opportunity to create extended topologies that include a hydrogen production module. In these systems, the RFB active species may not only be used in the energy storing process but also as a reactant in a hydrogen production catalytic reactor. This concept has several advantages over conventional electrolysis in terms of safety, durability, modularity, and purity, and may be specially interesting in certain applications such as a combined electric/fuel cell vehicles charging station [24].

There are different types of redox flow batteries, which can be classified depending on the chemical composition of the active species of electrolytes. The pool of possible electrolyte chemistriesis practically unlimited, and several options have already been tried, ranging from the classic chromium-iron RFB, discovered in 1973 [25] to the recently developed of organic base [26], such as sulfonate viologen, going through the vanadium redox flow batteries (VRFB) invented by Professor Skyllas-Kazacos in 1983 [27]. A comparison of some of the different types of RFB in terms of maximum cell voltage, power and energy densities and lifetime in number of cycles is presented in [28], being summarized in Table 2.

Table 2.

Comparison of different RFB systems based on their active species. Extracted from [28,29].

From the different alternatives developed so far, the VRFB are considered to be the closest to reach a commercial success. The main advantage of this particular technology is that, as the active species in both tanks are based on vanadium, degradation problems associated to the electrolyte cross-contamination are prevented which, in turn, results in a very long lifespan of 10,000–20,000 charge/discharge cycles [38]. The same property is exhibited by the iron-iron RFB, but compared to the VRFB, the other performance indicators have lower values. Thus, although organic and zinc-bromine RFBs have better performance in terms of cell voltage and power and energy densities compared to VRFB, their useful life is much shorter, which can be translated into higher long-term costs [16]. Considering these aspects, the VRFB is the most used and studied, being the protagonist of the vast majority of works related to redox flow batteries and cited in this review. For this reason, from this point on, no further distinction will be made between the different types of RFBs, considering always the case of the VRFB for discuss all properties and important aspects. However, it must be remarked that, as the fundamental principles of the majority of RFB technologies are essentially the same, most of the analysis and formulations presented hereafter can be readily extended to other RFB systems.

Redox flow batteries auspicious prospect has motivated many efforts to make them commercially competitive compared with other mature technologies, such as Li-ion and lead-acid batteries. To this end, research is being conducted to reduce the cost of RFBs systems, as well as to improve their efficiency, reliability and service life. In particular, a great deal of the current work is focused on the development of materials with enhanced properties to be used as membranes, electrodes and, especially, new electrolyte chemistries (both active species and additives) to achieve lower costs and higher energy densities [39,40,41]. Furthermore, new flow fields and patterns [42], as well as stack-level structures and configurations [43], are being designed and tested to improve the hydraulic and electrochemical performance of the system.

Another hot research topic is the system modelling and monitoring [44]. In order to manage the RFB operation properly, the knowledge of the battery internal information is of paramount importance. However, some of the most relevant variables, such as the State of Charge (SoC) and State of Health (SoH), cannot be directly measured in a simple way. Traditional approaches based on experimental measures, such as UV-vis spectroscopy analysis and conductivity measurements require the installation of additional sensors to the system which, in turn, increases the cost and complexity of the facilities [45]. Additionally, these direct measures usually require large amounts of experimental data under every possible operating condition and, moreover, need to be periodically re-calibrated in order to avoid error originated by drifts in the sensor or changes in the electrolyte properties. To overcome the limitations of experimental based measures, the alternative is to utilise algorithms capable to infer the internal states of the battery, only from easily measurable variables such as the current and the terminal voltage [46]. As a result, numerous methodologies have been developed in recent years to indirectly estimate the RFB internal states. These methodologies typically involve two steps [47]. The first step is to define a mathematical model capable to describe, with sufficient accuracy, the behaviour of the RFB system. The second step is to implement an estimation algorithm in order to process the measured data and determine the battery parameters and states.

The information obtained through the estimation algorithms is not only necessary to monitor the battery status, but is also needed to develop advanced automatic control setups to optimise the performance and extend the lifetime of RFB systems. However, given the intrinsically non-linear nature of RFB, together with the multiplicity of variables and phenomena involved in their operation, flow batteries’ estimation remains an open challenging field with plenty of problems that still need to be worked out. Therefore, the design of new estimation strategies is essential for the viability of RFB technologies.

In spite of the growing interest and dynamism of VRFB state and parameter estimation, to the authors knowledge no work has yet been published dedicated to organise and analyse the existing literature on the subject. Therefore, this review aims to fill up this gap, providing a valuable tool for those willing to implement any of these algorithms, on the one hand; and for those interested in improving the existing state of the art, on the other. The remaining of this paper is organised as follows: Section 2 provides a general description of a VRFB system; Section 3 presents the models that represent the behaviour of a VRFB available in the literature, specially focusing on those suitable for estimators design; Section 4 systematically analyses the existing model-based methodologies for estimating the battery State of Charge, State of Health and other internal parameters; and, finally, Section 5 presents the conclusions and discusses the current challenges in the field, aiming to orientate future research lines.

2. System Description

This section addresses the main characteristics of a vanadium redox flow battery system, to facilitate the understanding of the next modelling and estimation sections. First of all, the fundamental components and general working principles of VRFB are described. Afterwards, the main side reactions that can damage the system, reduce its efficiency and lifetime and, especially, provoke a condition known as electrolyte imbalance are introduced. Then, it is presented the sizing of a VRFB in terms of power and energy and, finally, the main indicators that permit to characterise and monitor the behaviour of the battery are defined.

2.1. General Working Principles

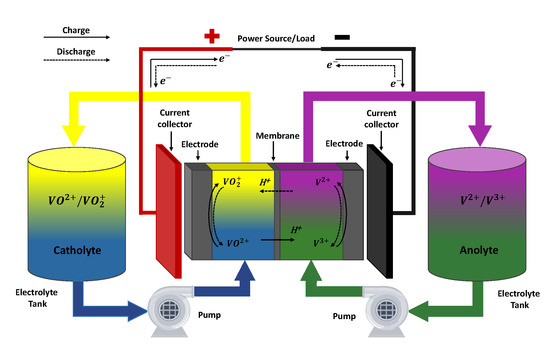

In VRFB, the energy is provided by the electrochemical redox reaction between vanadium ions with four possible oxidation states. These, in turn, are found dissolved in a sulphuric acid solution known as electrolyte. The function of the sulphuric acid is to enhance the solubility of vanadium species, on the one hand, and to provide the protons that allow to conduct the electric current in the cells and to balance the main reactions of the battery, on the other. The system is divided in a “negative side”, where the electrolyte (anolyte) contains and , and a “positive side”, where the electrolyte (catholyte) contains and (the latter in the form of the oxides and , respectively) [23]. Normally, a VRFB system is integrated by, at least, three essential components: a pair of tanks where both electrolytes are stored; an electrochemical stack responsible of producing the electric power; and an hydraulic subsystem in charge of the electrolytes flow between the previous components [39]. An schematic representation of a VRFB system is presented in Figure 1.

Figure 1.

General scheme of a VRFB and its main reactions.

When the battery is operating, the electrolytes are pumped from the tanks to the electrochemical stack where the electron transfer reaction takes place. Specifically, the reaction occurs at the surface of the electrodes, which are typically a porous material made of carbon fibres. Within the stack, both electrolytes are kept separated by a proton exchange membrane that allows the passage of protons in order to close the circuit internally, hence keeping the electrical neutrality of the solutions [48]. As the electrolytes flow through a closed circuit, once they leave the stack they are reintroduced to their respective tanks. In order to achieve greater voltages and power, it is common practice to arrange several cells in series to conform a stack. In such case, each cell is separated from the other by a bipolar plate which is also responsible of providing structural support to the stack and electrical connection between adjacent cells [49]. The electrons released in the eletrochemical reaction are collected in the current collectors located at the end cells of the stack, which are connected to the power load/source. The battery operation is reversible so, when an external voltage is applied, the reaction proceeds in opposite direction regenerating the reactants consumed during the discharge.

The main reactions that take place at the surface of the electrodes are the following (note that the are provided by the sulphuric acid present in the electrolyte):

The amount of energy stored in the system is directly related to the volume of electrolyte in the tanks and the concentration of the vanadium “charged species” ( and ). Evidently, charged species concentrations will increase during charge operation and decrease during discharge. Due to limitations in the vanadium solubility, the total vanadium concentration in each electrolyte rarely exceeds 2 M [50].

2.2. Side Reactions and Electrolyte Imbalance

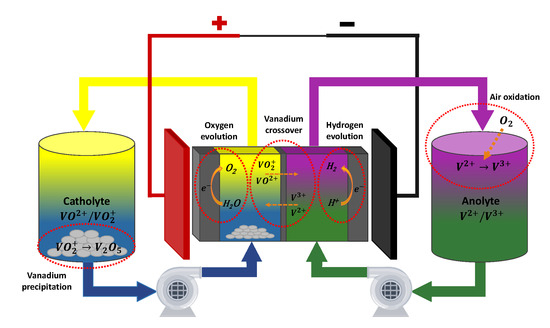

Besides of the fundamental working principles described in the previous subsection, in VRFB there exist other undesired processes that occur at a lower pace, but may have a strong influence in the system’s performance. These processes are typically caused by imperfections in the membrane, that allows a passage of small amounts water and vanadium, or by side reactions, i.e., reactions that take place at the same time as the main reaction, but at a lesser extent, as illustrated in Figure 2. These undesired processes include:

Figure 2.

Scheme of a VRFB with its most important side reactions.

- 1

- Vanadium ions crossover. Despite the membrane is ideally only permeable to protons, in practice it can also be crossed by small amounts of vanadium species [51]. After crossing the membrane, and species become very unstable in the positive half cell, while the inverse occurs to and in the negative one. Therefore, once these ions reach the opposite half cell, they tend to react very fast with other ions present in the electrolyte. These chemical reactions are assumed to be instantaneous, and proceed as follows [52]:If the flux to the positive half cell is exactly compensated by the flux to the negative one, the crossover is said to by symmetric, and its only effect is to accelerate the electrolyte self discharge. However, in practice, crossover will be generally asymmetric, thus leading not only to self discharge, but also to a build up on one of the electrolytes and a dilution on the other. Although the direction of this mechanism depends on several factors such as the operating conditions and the membrane composition, typically, the net vanadium flow is from the negative to the positive half cell [53].

- 2

- Water transfer. In certain cases, the water may also cross the membrane from one half cell to the other due to several driving forces, such as diffusion, osmosis, electro-osmotic drag and hydraulic pressure difference [54,55]. This may lead to a net volume change of the battery’s electrolytes. Less likely, the evaporation of water from the tanks can also contribute to a change in the electrolyte volume.

- 3

- Gas evolution side reactions. These side reactions occur at the surface of the electrodes, when the supposedly inert support electrolyte (particularly, water and protons), starts participating in the electron transfer reactions generating gaseous products, competing with the redox reaction of the vanadium species. The most common gassing reaction is the hydrogen evolution, that takes place during charging at the negative electrode [56,57]. In this case, the electrons are taken by the protons which get reduced to gaseous hydrogen (see Equation (5)). Since a fraction of the current destined to charge the anolyte is captured by the protons, the reduction of at the negative electrode becomes slower than the oxidation of at the positive one. Hence, the concentration in the catholyte becomes lower than the in the anoloyte, causing electrolyte imbalance. Additionally, this process may have other serious consequences, such as the corrosion of the carbon electrodes [58] and the bipolar plates [50,59]. The other gassing side reaction is the oxygen evolution at the positive electrode [60] (see Equation (6)), which has similar effects to the hydrogen evolution although its occurrence is comparatively less frequent.

- 4

- Air oxidation. When the negative electrolyte tank is exposed to the atmosphere, oxygen present in the air tends to dissolve in the liquid and produce the oxidation of to [61].Consequently, in order to prevent this phenomenon, it is essential to keep the negative electrolyte tank isolated from the atmosphere. This protection can be also attained by periodically purging the electrolyte with an inert gas, such as nitrogen [62].

- 5

- Vanadium precipitation. All vanadium ions present in a VRFB may precipitate as a result of employing an excesively concentrated solution or because of thermal inestabilty. Vanadium precipitation does not only reduce the available active species of the system but, more importantly, also may block the electrolyte channels and damage the membrane, seriously affecting the performance of the VRFB [63]. It has been found found that is the most unstable among the four species, and has a strong tendency to form solid when the temperature surpasses 40 °C [53], as expressed in Equation (8). On the contrary, the remaining of the vanadium ions tend to precipitate in the form of sulphates when the operating temperature is below 5 °C [50,64]. Therefore, to prevent vanadium precipitation the system temperature should be kept within the range 5–40 °C.

- 6

- Solid components corrosion. The strongly acidic nature of the electrolyte together with the oxidising nature of the make VRFB medium highly corrosive [49]. This forces the utilisation of carbon based electrodes and bipolar plates rather than metallic ones, as well as a particularly chemically stable membrane. In spite of utilising these resistant materials, VRFB components corrosion has been often reported, especially when the system is subjected to overcharging [53].

One of the most important consequences of the aforementioned processes is the electrolyte imbalance. In principle, vanadium redox flow batteries are expected to be balanced, i.e., that the liquid volume in both tanks is the same and concentrations of and in the negative electrolyte are equal to the concentrations of and in the positive electrolyte, respectively. However, these undesired processes have a cumulative effect that may generate electrolyte imbalance over extended charge-discharge cycling.

Electrolyte imbalance is a serious issue for redox flow batteries because it undermines the system performance, leading to capacity loss and, when unnoticed, even more severe consequences such as electrodes corrosion or membrane damage [46,54]. Consequently, understanding the multiple causes of this phenomenon is important not only to recognise and mitigate the main mechanism that is causing the problem but also to determine the best way to recover the electrolyte. Processes 1 and 2 cause what it’s commonly known as “stoichiometric imbalances”, which can be addressed in a relatively simple way by remixing the electrolytes of both reservoirs, thereby equalising the vanadium concentrations and liquid levels. Conversely, imbalances associated to mechanisms 3 and 4, commonly known as “faradaic imbalances”, can only be corrected by means of more complex chemical or electrochemical methods [51]. The difference between these two kind of imbalances is explained by the fact that the former mechanisms do not alter the original average oxidation state of the electrolytes (often referred to as ), while the latter produce a net shift towards a lower (oxidative imbalance) or higher (reductive imbalance) oxidation states [55]. As for the mechanisms 5 and 6, they typically do not occur during the VRFB normal operation and, when detected, specific measures aiming to solve the underlying cause must be taken.

Given the negative consequences of electrolyte imbalance, it is crucial, in first place, to design a proficient management system to mitigate, as far as possible, the progression of this phenomenon [51]. Secondly, as electrolyte imbalance cannot be completely eliminated even when the VRFB is correctly operated, it is also essential to develop a methodology that permits to rapidly detect and quantify the imbalance and its causes [65]. Finally, a smart strategy to restore the imbalanced electrolyte is required [55,66].

2.3. Sizing

Being the modularity in terms of power and energy the main property of a RFB, it is important to clarify on which parameters and variables they depend.

- Power. It depends exclusively on the current flowing through the cell from the current collectors, and the voltage generated between these plates. Therefore, power only depends on the cell-stack properties.The current is directly related with the area of the electrodes, and the current density that go through them, being computed as:where I is the current, the electrode area and j the current density.It is straightforward to see that in order to increase the current, there are two possibilities. On the one hand, make greater the area of the cell, which will lead to higher costs due to the materials. On the other hand, increasing the current density seems to be the optimal solution as it does not have associated costs of any kind and the cell does not need to modify its size. However, high current densities lead to less efficient behaviour of the battery and reduce the lifetime [67]. Typical values of current densities are ranged between 100 and 400 mA/cm with energy efficiency ranging from 82% to 88% [68]. Other studies have shown that for current densities of 200, 400 and 600 mA/cm the energy efficiencies obtained are 91.98%, 86.45% and 80.83%, respectively [69], where it can be clearly appreciated the negative effects of operating at high current densities.The voltage depends on the nature of the RFB species, as well as other variables such as the temperature and current in the cell. Its calculation is discussed in detail in Section 3.2, where the the expression to compute the voltage of a single cell is derived. Once the voltage of a single cell is known, it is possible to compute the voltage of the stack, namely , as:where is the cell voltage and n is the number of cells that compose the stack. Considering the VRFB as the case of study, the experimental value found in the literature for achieves a maximum 1.7 V for a charging process, going down to a minimum of 0.8 V for a discharging one [70].Therefore, considering (9) and (10) it is possible to determine the power as:

- Energy. It depends exclusively on the amount of electrolyte stored in the system and its concentration. Taking into account that the tanks are much larger in size compared to the cell, the latter contribution can be generally neglected.Beginning from the definition of electric energy as the product between the potential difference and charge, it is possible to obtain the following expression:where is the energy and is the charge inside the tanks, that can be computed as:being the electrolyte tank volume, F the Faraday constant and the vanadium concentration.As the total energy is divided in the two tanks, if they are considered of the same size, its value can be calculated in Joules as:or in the most common unit of energy in Wh as:It is obvious by looking expression (15) that the energy can be selected by choosing the volume of the tanks and the total vanadium concentration. It is important to remark, that as have been previously explained, due to the limitations of vanadium solubility, can not exceed 2 M. For this reason, the tank volume is the parameter that has to be designed according to the desired energy capacity.The energy density can be obtained directly from Equation (15) dividing by two times the volume of each tank. Theoretically, it is possible to calculate the energy density of a RFB if all parameters and variables are known. Thus, considering as a cell voltage the maximum value, = 1.7 V and a total vanadium concentration of 2 M, the energy density obtained is 53.51 Wh/L. However, the battery can not operate at maximum voltage, so most works consider an average value of 1.35 V obtaining an energy density of 36.12 Wh/L [71]. Moreover, it is important to remark that expression (15) is related with the energy stored in the electrolyte, but in order to compute the ones of the complete battery some factors must be considered as for example the energy consumed by the pumps or the external and internal losses in form of side reactions or overpotentials. Considering all these aspects, the real values of energy densities for VRFB are close to 25 Wh/L [72].

2.4. Indicators

Like any other type of battery, RFB have different indicators that allow to describe their behaviour. There is no universal consensus regarding the formulation of most of these indicators, being in many cases simplified to facilitate their computation. The aim of this section is to present the most important ones [46].

- Charge (). It is the electric charge the battery can provide, starting from a not necessarily fully charged initial condition, if it is operated during a time until it gets fully discharged:

- Charge capacity (). It is the electric charge the battery can deliver from fully charged, if it is operated during a time until it gets fully discharged:

- Nominal charge capacity (). It is the original charge capacity of the battery, i,e., a reference value that assumes that it has not experienced any degradation or capacity loss.

- State of Charge (SoC). It is an index that is typically defined as the ratio between the electric charge stored in the battery (Q) at a specific time and the total battery capacity (), as expressed in Equation (18). Note that the maximum electrical charge that the battery can deliver when fully charged, , may vary over extended cycling as a consequence of electrolyte imbalance or other degradation phenomena and, consequently, needs to be differentiated from its nominal value .As previously said, the electrical charge stored in a VRFB system depends on the amount of vanadium charged species present in the electrolyte. Therefore, an equivalent concentration-based definition for the SoC can be derived. Assuming that the battery is balanced, the resulting equation for the SoC in terms of the vanadium species concentrations is:where is the concentration of vanadium species V. When the VRFB suffers from electrolyte imbalance, Equation (19) is no longer valid, and it becomes necessary to define a different SoC for each half-cell electrolyte:

- State of Health (SoH). It is a figure of merit that compares the battery condition at a specific moment with the ideal one corresponding to a new or nominal battery. Depending on what aspect of the battery’s degradation is being considered, different definitions may be given for the SoH. The most popular one is related to its maximum capacity [73]:where is the critical (or minimum acceptable) capacity value.Another possibility is to express the SoH in terms of the increase of the battery’s internal resistance, as follows [74]:where is the nominal internal resistance, corresponding to a new battery, and is the end-of-life internal resistance ( depends on the specific application, but it is usually 60% higher than ) [75].

- Coulombic efficiency (). It is the ratio between the electric charge the battery can provide in discharge and the charge received during charging, in a complete cycle:

- Voltage efficiency (). It is the ratio between the average voltage the battery provides, for a certain current, in discharge and the voltage received during charging, in a complete cycle:where E is the battery voltage that can be computed for the case of a single cell with or with for the case of a stack with several cells.

- Energy efficiency (). It is the ratio between the energy the battery can provide in discharge and the energy received during charging, in a complete cycle. Therefore, it can be computed by means of the integral of the power as:where P is the battery power, which can be computed as the product between the current and voltage. Assuming that the current is constant, it is possible to redefine the computation of in terms of previous coulombic and voltage efficiencies:

3. Vanadium Redox Flow Battery Dynamic Modelling

The starting point to address an estimation problem is to develop a mathematical model capable to accurately represent the behaviour of the essential variables of the system. It must be highlighted that modelling is not only a necessary step to develop these strategies, but also constitute a useful-often indispensable-tool to simulate the dynamic behaviour of the system, that may be used to complement and interpret the more costly and time-consuming laboratory analysis [6,48]. Additionally, these models provide an adequate framework for comprehensive understanding of the underlying theoretical and working principles of complex systems that involve many interrelated phenomena, such as the VRFB [48].

There is not a single nor a best way to model a VRFB. On the contrary, there exist many ways to model the behaviour of the system depending on which components are being considered and the level of detail with which those components need to be analysed. In general, observation and automatic control theory require the models to be dynamic, i.e., that comprise a set of equations that include time derivatives of the system variables to represent its time evolution.

Probably, the most convenient way to classify VRFB models is between Distributed Parameter Models (DPM), if they consider a spatial distribution of the system variables and parameters, and Lumped Parameter Models (LPM), if they concentrate all the information of the system into a set of discrete entities with uniform properties [44]. In addition, the latter are subsequently classified in electrochemical models, if their equations are derived from the physics of the system, and electric equivalent circuit models, if the system is represented with an electric circuit that behaves similarly to the real plant.

As a general reflection, the more complete the model is, the greater the level of details that can be achieved but at the expense of dealing with a more complex and time consuming model. Therefore, although DPM are the most faithful in terms of their representation of the real system and constitute powerful tools for design purposes, they are difficult to be handled, and usually cannot be easily adapted to be used in most control and estimation approaches. Conversely, LPM are much simpler and thus normally well suited to be used in the design of control and estimation strategies if all the essential phenomena are included.

3.1. Distributed Models

Distributed models attempt to represent, in a comprehensive way, the behaviour of the real system by considering the spatial distribution of its variables and parameters. Although they may be unsuitable to be directly employed in the development of estimation and control strategies, they contribute to interpret the physics of the system, and constitute the base for the simplified lumped parameter models.

The wide majority of VRFB distributed parameter models developed up to now are focused on the electrochemical stack. This is reasonable because, as the chemical reaction takes place in this component, its processes are the most determinant in the overall system performance, as well as the most complex to be analysed. In general, VRFB electrochemical models rely on a series of balances of mass, momentum, charge, energy and chemical species that describe the relationship between the different phenomena that occur inside the stack. Therefore, a brief summary of the governing equations that build up a DPM of a VRFB is presented and discussed below.

- Continuity Equation. Expresses the electrolyte mass conservation at every position of the system, under the common assumption that the fluid is uncompressible, i.e., that its density is constant [76].where is the velocity of the electrolyte.

- Dracy’s Law. It is a simplification of the more complex Navier-Stokes equation, that is applicable for porous media such as the electrodes of the VRFB. Specifically, it is utilised to represent the momentum conservation of the electrolyte, relating its velocity at every point in a linear law with the pressure gradient [77].where p is the liquid pressure, is the liquid viscocity, is the electrode porosity, is the mean pore diameter and K is the Kozeny-Carman constant for a porous medium.

- Nernst-Planck Equation [78]. It permits to express charged chemical balances in a fluid medium. In a VRFB, it is utilised to describe the protons and vanadium species balances in the electrolyte. In certain cases, it has also been utilised to express the motion of these ions in the membrane, accordingly adjusting the values of the phisicochemical constants [76].where , , and are the concentration, the effective diffusivity, the ion charge and the stoichiometric number of the species i, respectively; and T is the temperature, is the ionic potential of the electrolyte, F is the Faraday constant, and j is the current density.On the left hand of the Nernst-Planck equation, the first term stands for the accumulation of species i. The second term represents the convective transport due to the electrolyte flow; the third one represents the diffusive transport caused by the gradient of species i concentration; and the fourth one represents the migration caused by the electrical potential gradient. The right side of the equation contains the source term, originated by the consumption or generation of species i as a consequence of the electrochemical reaction.It is usually assumed that the Bruggemann correction is valid to derive the effective diffusion coefficient from the free-space value :Additionally, presents a positive dependency with the temperature, which is given by the Arrhenius Equation [79]:where A and are two physicochemical constants, called the Pre-exponential Factor and the Activation Energy, respectively.

- Electroneutrality. Expresses that the charge of the electrolyte must be strictly equal to 0 at every point of the space, and it is usually employed to obtain the value of the concentration [77].

- Charge conservation. Expresses that, at the porous electrodes, the charge leaving the solid phase is equal to the charge entering the electrolyte .In turn, the total current density in the electrolyte can be obtained by combining the Equations (30) and (33), and summing for all species [77]:where is the effective electrical conductivity of the electrolyte that can be calculated by:

- Thermal balance. Describes the temperature variation and its distribution along the porous electrodes, taking into account the heat generation and its transference [80].where is the especific heat capacity of the electrolyte and and are the volume-averaged thermal conductivity and thermal capacitance, respectively. are the heat generation terms, originated by the electrochemical reaction, side reactions, and voltage and hydraulic losses. In many applications, when the produced heat is not significant, it is common practice to assume that the VRFB operates isothermically. Therefore, if the variation of temperature across the electrochemical stack is neglected, the energy balance can be omitted.

The former set of equations constitute the core of the distributed model formulations. In order to be employed in simulation they need to be coupled with boundary and initial conditions such as those presented in [77,81,82,83,84]. Moreover, additional work has been conducted to enhance DPM to include other relevant phenomenons. For instance, Shah et al. [57] and Al-Fetlawi et al. and [60] developed models that include the hydrogen and oxygen evolution at the electrodes, respectively. These models include the electrochemical kinetics of these side reactions and significantly increase the complexity of the approach, by considering a liquid-gas multiphase system. Likewise, Delgado et al. [78] have expanded the model by considering the differences between the cells that comprise the stack, hence predicting the bypass currents that flow through the electrolyte manifolds commonly known as shunt currents.

Other authors, have focused their work in adapting the conservation Equations (28) to (44) to analyse membrane phenomena such as the Donnan potential originated by the difference of concentrations in the positive and negative electrolytes [85] or the multiple water transport and vanadium crossover mechanisms [76,82,85,86]. The inclusion of explicit dependencies of the system parameter on the temperature and concentration is another aspect that received much attention in the DPMs. In [81] the effects of the temperature and concentration on the ion mobility is analysed, while in [64] a distributed model is utilised to predict the possibility of vanadium precipitation under low temperature operation conditions.

On the other hand, research has also been conducted in the opposite direction: instead of introducing more phenomena to increase the accuracy of the model, they attempted to simplify it to obtain equations that could be handled more easily [87]. With this aim, in [83,84] some assumptions are made to find analytical solutions to the mass and charge balances. Some proposals have also been made aiming to reduce the original DPM to a 1D plug flow model that neglect any variations but those in the flow direction [88,89]. Conversely, other authors have utilised 1D models that only consider gradients in the direction perpendicular to the membrane [90,91,92].

3.2. Cell Voltage

The cell voltage () of an electrochemical cell can be calculated as the sum of an open circuit voltage (OCV) and a series of overpotentials, which represent the deviation with respect to the OCV originated by the passage of electric current [93,94] (see Equation (38)). Evidently, the effect of the overpotentials will be to reduce the when the battery operates in discharge mode, and increase it when charging. This means that the voltage required to charge the battery will be higher than the voltage that provides the battery in discharge, consequently reducing the energy efficiency of the VRFB.

where is the real voltage of the electrochemical cell, is the open circuit voltage, is the overpotential associated to ohmic resistances of membrane, the electrolyte, the porous electrodes and the current collector; and and are the overpotentials associated to the electrochemical reaction that takes place at the positive and negative elctrode, respectively. The sign of the overpotentials is positive in charge and negative in discharge. As previously discussed, in applications that require stacks of n cells in series, assuming that all of them behave exactly the same, the open-circuit voltage of the stack is straightforwardly given by (10).

The OCV is calculated by means of the Nernst Equation:

where is the standard cell voltage, is the concentration and are the activity coefficients of the species involved in the reaction. With respect to the vanadium species concentrations () it is normally used an average value between the inlet cell concentration () and the outlet cell concentration () [95]:

In practice, activity coefficients are very difficult to be evaluated. Then, by assuming they remain approximately constant throughout operation, Equation (39) can be reduced to a simplified version where is replaced by a nominal voltage () that groups all the constant terms in (39), whose value is approximately 1.35 V [96]:

Some authors also consider the protons concentration constant, thereby incorporating their effect in () [95]. Other authors have proposed to take into account the Donnan potential, that appears in the membrane when the concentration of protons in the catholyte and anolyte differ [97]. Then, Equation (41) can be reformulated as:

where and are the the concentration in the catholyte and anolyte sides, respectively.

The voltage drop can be calculated by summing the effects of the different elements that make up the electrochemical cell:

where , , and are the thicknesses and , , , are the electrical conductivity of the membrane, the current collector and the electrolyte/porous electrode of the negative and positive half cells, respectively. Alternatively, these ohmic effects can be combined in a single equivalent resistance, .

The overpotentials and are given by the Butler-Volmer Equation (44) [78]. This equation takes into account the combined effect of the activation and concentration overpotentials. The first one is associated to the mass transport resistance that leads to a reactant depletion and a product accumulation next to the electrode’s surface described by Equation (45), whereas the second one is linked to the energy required to produce the charge transfer reaction on the active sites of the electrode. Note that the Butler-Volmer equation is implicit in .

where are the reaction rate constants and is the charge transfer coefficient of the reaction. The Butler-Volmer equation takes into account the possible concentration difference between the bulk electrolyte () and the surface of the electrode () as a consequence of mass transfer resistance. It is assumed that this difference occurs in a thin layer next to the electrode’s fibres surface and follows a lineal law, governed by the mass transfer coefficient of species i, [35]:

Under certain assumptions, Murthy et al. deducted expressions that decouple activation and concentration contributions of the overpotentials and [98]:

For during charging, the negative sign holds and species i represents , whereas the positive sign holds and species i represents during discharging. Equivalently, for during charging, the negative sign holds and species i represents whereas the positive sign holds and species i represents during discharging. For its part, represents the difference between the bulk and the surface concentration () and is obtained from Equation (45): .

Other authors use more drastic simplifications of the Butler-Volmer equation. For instance, in [99,100], the activation component is combined with the ohmic overpotential by defining an equivalent resistance that takes into account both effects. Then, they use a simplified expression for the concentration overpotential in each half cell:

where is the limiting current density (i.e., a theoretical maximum) for a certain concentration of reactive :

Other authors neglect the effects of mass transport resistance, and consequently the term of the Butler-Volmer Equation (44) becomes equal to 1 for all species [93]. Consequently, and can be computed in the way presented in Equations (46a) and (46b). Moreover, for high values of overpotentials, the Butler-Volmer equation for each electrode reaction can be further simplified to an expression known as Tafel equation [72]:

where and are the reduced and oxidised species of the redox couple, respectively.

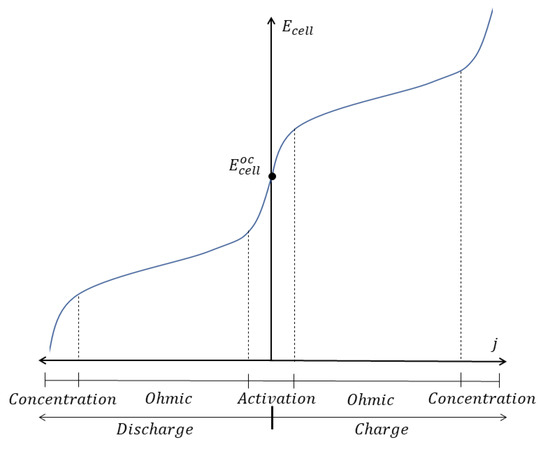

Finally, it’s worth mentioning that the relative contribution of each overpotential to the total voltage drop may vary with the operating conditions. In general, activation overpotentials are dominant for very low current densities, while ohmic losses prevail in a wide range of intermediate current densities. For its part, concentration overpotential become much more relevant when the current is high or the battery is reaching the end of a charge-discharge cycle, as under these conditions the factor (equal to ) tends to be much lower than 1 for the reactants. The described situation is qualitatively illustrated in Figure 3.

Figure 3.

Illustration of the regions of prevalence of each overpotential in a cell voltage vs. current density curve.

3.3. Vanadium Species Balances

In this subsection, the LPM that describe the evolution of the active species concentrations of a VRFB system are presented. These models neglect space variations by considering a discrete set of subsystems with uniform properties. In general, for VRFB these subsystems are the electrolyte tanks and the electrochemical stack.

The first LPM models developed for redox flow batteries were developed by Li et al. [101] and Shah et al. [94]. Although these models accounted significantly well some relevant phenomena of the VRFB, they neglected a critical aspect of these batteries: despite the membrane is supposed to be permeable only to protons, small amounts of vanadium species can also cross the membrane, as discussed in Section 2.2. The first model to take crossover processes into account was presented by Skyllas-Kazacos et al. [52]. Since then, this model has been the most commonly used to describe the time evolution of vanadium species in a VRFB system. The model was completed by Li et al. [102] by introducing a term to describe the oxidation with atmospheric oxygen that may suffer the present in the negative electrolyte reservoir, as introduced in Section 2.2.

The vanadium species balances proposed by Skyllas-Kazacos, with Li’s contribution are the following:

Note that the molar flow of species i through the membrane () does not only appear in the dynamic equation of that species, but also in the dynamic equations of the species present in the opposite half-cell. This is explained by the fact that, as introduced in Section 2.2, and species are very unstable in the positive half cell, while the inverse occurs to and in the negative one. Therefore, after reaching the opposite half cell, the vanadium species react with other vanadium ions according to Equations (1)–(4), further affecting the species mass balance.

The molar flux through the membrane is a rather complex factor, as it is affected in a non linear way by the operating conditions, variables and parameters of the stack. The main mechanisms that produce a crossover of vanadium species are: diffusion, caused by the gradient of species i concentration; migration, caused by the electrical potential gradient that appears when there is a net current in the cell; and convection, caused by a net flow of electrolyte through the membrane, and can be easily visualised in the distributed Equation (30). Under certain assumptions, Darling et al. [103] provide an analytical solution for that takes into account the three mechanisms, obtained by integrating the Nernst-Planck equation in the membrane. A slightly improved version of this expression that explicitly distinguishes the direction of the flux is presented in [99] (see Equations (54)–(56)).

- When convection and migration are in the same direction with diffusion:

- When convection and migration are in the opposite direction with diffusion:

Note that diffusion always proceeds in opposite direction to the concentration gradient, i.e., and go from the negative half cell to positive one, and the other way round for and . Conversely, the direction of migration and convection depend on the sign of the electric current. In discharge mode, the electric current goes from the negative electrode to the positive one which requires to be compensated by a ion flux through the membrane to keep the electroneutrality (see Figure 1). Therefore, as all the vanadium ions have a net positive charge, for and the migration and convection flux go in the same way as diffusion as described in Equation (54), while for and migration and convection are opposed to diffusion and the equation to be applied is (51). In charge mode, the electric current goes from the negative electrode to the positive one and, accordingly, the situation is inverted.

It is also important to remark two additional aspects regarding . Firstly, it must be stressed that the effects of migration/convection are present even when they flow in the same direction to the concentration gradient (e.g., in charge mode there will be migration of from the positive to the negative electrolyte). This may seem impossible, as each vanadium species are only present in one of the half cells (e.g., concentration is 0 in the catholyte). However, as Equations (54) and (55) come from integrating the distributed Nernst-Planck equation in the membrane and within the membrane the four vanadium species may be present, it is possible to interpret that in this case the effect of migration/convection is to diminish diffusion. Secondly, a qualitative difference can be highlighted between the processes of diffusion, on the one hand, and convection/migration, on the other. While the former is only proportional to concentration gradients, the latter also depend on the electric current. When migration/convection mechanisms are not being considered, the expression for gets reduced to a purely diffusive expression (see Equation (57)) but, as a consequence of the previous analysis, this is only strictly true when I is equal to 0.

Another aspect that may be taken into account in the mass balances are the gassing side reactions described in Section 2.2, particularly, the hydrogen evolution. To obtain the reaction rate of the evolution, a Butler-Volmer equation equivalent to that presented in Section 3.2 for the vanadium species can be formulated which, in turn, can be simplified to a Tafel expression [57].

where is the exchange current density, is the transfer coefficient and is the overpotential of the hydrogen evolution reaction. Then, given that the potential difference between the solid and the liquid at the negative electrode is unique and can be computed either by considering the main reduction reaction or the undesired hydrogen evolution, the following equality holds:

where and are the Nernst potentials of the and the reduction reactions, respectively: and ranges from 0 to +0.1 depending on the protons concentration.

By solving Equation (59), the can be obtained and then replaced in Equation (58) to obtain the hydrogen evolution rate . Then, the current can be computed. As this reaction competes with the reduction of , it must be subtracted from the electrochemical reaction terms of Equations (50a) and (51a), and the effective electric current in these equations becomes: .

It is worth mentioning that the electrochemical reduction of is thermodynamically favoured over the main reduction and is only limited by the very low values of . Therefore, it is very important to prevent operating the VRFB in conditions that produce very high , which is more likely to occur at high currents and SoC.

3.4. Thermal Model

Thermal effects in flow batteries are not as significant as in other devices that have similar operating principles, such as fuel cells. Therefore, in many cases it is possible for them to operate at room temperature without resorting to temperature control strategies.

However, temperature has a substantial influence in some of the most important phenomena that take place in the system [104]. Firstly, as already stated, it affects the voltage of the system by means of the Nernst equation. Secondly, it strongly influences the internal resistance of the VRFB, by increasing the electrode and electrolyte conductivity and the constant k of the Butler-Volmer equations, hence reducing the overpotentials and increasing the voltage efficiency . Furthermore, electrolyte viscosity also reduces with temperature, which means that a lower pump power will be required if the VRFB is operating at higher temperature. On the other hand, it was found that a high operating temperature increases the permeability of the vanadium ions in the membrane [79] resulting in a higher crossover, and accelerates the reaction rate of the undesired hydrogen and oxygen evolution side reactions [105].

The thermal stability of the electrolyte is another key aspect that must be taken into account. As discussed in Section 2.2, precipitates if the temperature rises above 40 °C whereas, on the contrary, the remaining ions may precipitate when the battery operates below 5 °C. Given the serious consequences of vanadium precipitation, it is essential to keep the system temperature in the range of 5–40 °C, which may require active control strategies if the VRFB is placed in a site with severe weather conditions. This temperature control may be achieved, for instance, by installing a heat exchanger between the tanks and the stack [63].

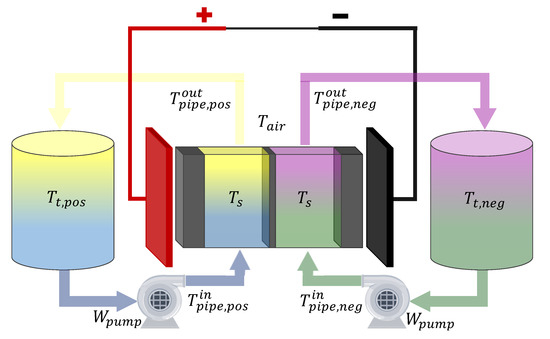

In the remaining of this subsection the thermal balances of the VRFB are described. The equations are based on the work of Tang et al. [106], with the inclusion of the entropic heat proposed by Trovo [107]. The system is divided in seven discrete elements: the electochemical stack, represented by the subscript s; the electrolyte tanks represented by the subscrpit t; the pipes that connects the tanks with the stack inlet, represented by the subscrpit and the superscript , and the pipes that connects stack outlet with the tanks, represented by the subscrpit and the superscript ; the subscript k indicates the positive () or negative () side of the battery and applies to every element, except the stack. In order to clarify this description, the different temperatures of the system are shown in Figure 4.

Figure 4.

Scheme of a VRFB with the temperatures involved in the thermal balances.

The thermal energy balance in the stack is:

where is the specific heat of the electrolyte, is the heat transfer coefficient between the stack and the environment, is the external surface of the stack, is the temperature of the surrounding air, is the entropy change of the main reaction, is the reaction heat of the self discharge reactions, are each of the overpotentials of the stack and the power of the pump.

In this balance, the left side of the equation stands for the accumulation of thermal energy in the stack. The first two terms of the right side represent the thermal energy carried by the negative and positive electrolytes, respectively. The third term stands for the energy transferred to the environment as a consequence of the temperature difference between the stack and the surrounding air. The fourth term is the entropic heat generated by the main electrochemical reactions, while the fifth one is the reaction heat due to the self-discharge reactions. Finally, the sixth term represents the heat generated by the stack overpotentials, and the seventh is the heat produced by the electrolyte friction with the porous electrode. As the stack is the main source of pressure drop in the hydraulic system, the last term is assumed to be equal to , i.e., it is assumed that the energy provided by the pump is mainly used in overcoming the friction of the stack [63]. The entropic (or “reversible”) heat rate is negative during charge (endothermic reaction) and positive during discharge (exothermic reaction) [107]. The rest of the generation terms are always positive, thereby, the stack temperature tends to increase in both operation modes if the heat transfer capacity of the stack and the fluid is not enough.

The thermal energy balances in the remaining elements of the VRFB system are:

In the previous balances the temperature of the stack is assumed to be unique and, consequently, only one balance is needed to represent its behaviour. Some authors lifted that hypothesis [79,107,108] by considering a different balance for each of the n cells that make up the stack. In such case, Equation (60) would become a set of n equations, which would be essentially identical to the original one but with a new term that accounts for the heat transfer between the cells as a consequence of their temperature difference.

In many cases, since the heat transferred and produced in the pipes is relatively small in comparison with that of the stack and the tanks, Equations (60) to (63) may be simplified by neglecting the balances in the pipes, combining their effects with the tanks. Note that, in case that a heat exchanger is used for temperature control, the balances would remain exactly the same, with the only difference that the exchange between the pipes and the air in the previous formulation would be replaced by that produced in the heat exchanger, thereby becoming much more relevant.

3.5. Hydraulic Model

In VRFB, the electrolyte flow rate plays an important role in the overall system performance: to provide a sufficiently high supply of reactants to the stack is crucial to guarantee its proper operation. Generally speaking, a high flow rate increases the cell voltage in discharge and reduces it in charge, hence improving the voltage efficiency of the system, . This positive effect on the electrochemical performance is explained by the fact that a high flow rate increases the reactant concentration inside the stack, thus raising (reducing) the discharge (charge) voltage via the Nernst equation and, more importantly, enhances the mass transport, which permits to substantially reduce the concentration overpotentials [109]. Furthermore, as the end points of the charge/discharge processes are usually determined by voltage limits, the flow rate also affects the effective charge capacity of the battery [110]. In other words, as the concentration overpotentials are reduced when operating at high flow rates, the accessible SoC window is expanded, while an insufficient flow rate would result in an premature voltage cut-off. However, an excessive flow rate results in an increase of the pump power, and augments the pressure drop within the cells which, in turn, may increase the risk of leakage.

The theoretical minimum flow of electrolyte () is such that it provides the stack with a reactant supply that is exactly equal to the consumption produced by the electrochemical reaction (see Equation (64)) [110]. However, in practice, an excess supply is always needed to ensure that enough reactant will reach the electrolyte active sites, as well as to reduce overpotentials and minimise the risk of side reactions such as hydrogen evolution. Then, a “flow factor” that links the real flow rate (q) with can be defined as follows: [109].

The most common approach is to select an appropriate so that the total losses of the system (hydraulic and electrochemical) are minimised [109,111]. There exist other more complex approaches to determine the optimal flow rate but their discussion is out of the scope of this review [112,113]. In any case, to select the optimal q as well as to analyse the behaviour of the VRFB system, it is essential to have an hydraulic model that permits to compute the hydraulic losses in terms of the electrolyte flow rate, as discussed below. Additionally, both the and the optimal q will be highly dependent on the battery SoC, remarking the necessity of having an accurate SoC estimation methodolgy, which will be analysed in deep in Section 4.

The total pressure drop in the system is produced by the viscous friction between the electrolyte and all the elements that make up the hydraulic circuit of the battery [110]:

The can be calculated by using an integrated version of the Dracy’s Law presented in (29) of Section 3.1 [114]:

where and are the length and cross-section area of the electrode’s channels, respectively, and is the permeability coefficient of the electrode, which can be calculated from its porosity , its mean fiber diameter and the Kozeny-Carman constant .

The can be calculated in the follwing way [110]:

where and are the pipe diameter and the pipe length, respectively. f is the friction factor, which depends on the Reynolds number . In laminar flow, f cam be computed as:

Usually the circuit involves more than one pipe section, in which case the contribution of each of them must be added to obtain the total .

To compute the pressure drop caused by congestions in the hydraulic circuit, such as bends in the pipes, tanks inlet and outlet, sensors and other ancillaries, etc., it is employed a parameter that is characteristic of each of these elements:

Then, the pump power required to produce the desired flow q in the VRFB system will be proportional to the total pressure drop, according to the following equation [43]:

where is the efficiency of the pump, which is typically obtained from correlations or tables provided by the manufacturer.

As a result of this analysis, the energy efficiency definition given by Equation (26) can be expanded to consider also the hydraulic losses of the system. Therefore, the total energy efficiency of the VRFB taking into account the pump power, , is defined as follows [115]:

3.6. Equivalent Circuit Models

Equivalent circuit models (ECM) are a particular type of lumped parameter models that utilise electrical components such as resistances, capacitors and voltage or current sources to represent the behaviour of a dynamical system [14]. Although modelling VRFB with ECM has some limitations in their ability to reflect the details of the physicochemical processes that take place in the system, they are very popular for control and estimation applications [99]. This is thanks to their simplicity and fast computation time on the one hand and, on the other, because they demonstrate excellent adaptability and a great deal of accuracy in predicting the electric dynamic response of the system [95].

The first ECM for VRFB were basic models derived from those utilised in lithium-ion batteries [116]. More recently, researchers have introduced more complete ECMs that take into account some of the particular phenomena of the VRFB such as the self discharge because of vanadium crossover [95], the coupling between the electrochemical and thermal dynamics [117] and the relation between the state of charge and the flow rate with the model parameters [118]. ECM can also be used to model the shunt currents that may appear in the electrolyte manifolds [43,78].

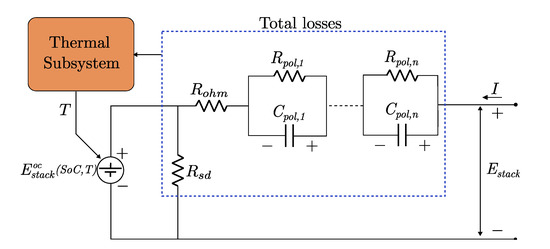

A typical scheme of an ECM for a VRFB is presented in Figure 5 and the meaning of its components is discussed below.

Figure 5.

Equivalent electric circuit model of a VRFB.

- (a)

- Open circuit voltage (). This element represents the open circuit voltage of the stack, given by the Nernst equation [95]. It depends on the SoC of the battery and also on its temperature if the system is considered non-isothermal. Alternatively, the open circuit voltage may be composed by a nominal constant voltage source in series with a non-linear capacitor that reproduces the non linear behaviour defined by the Nernst equation [75].

- (b)

- Series resistance (). It lumps all the ohmic losses due to the resistance of the current collectors, porous electrodes, electrolyte, membrane and bipolar plates.

- (c)

- RC modules (). A series of n resistor-capacitor pairs is included to represent transient dynamics of such as activation and concentration polarisation. If these phenomena are considered separately, there would be two RC modules, while a simplified 1st order RC network can be employed if only one dynamic is taken into account. Up to now, there are no published works that include more than 2 RC modules.

- (d)

- Self-discharge. The self discharge that takes place in the cell because of the vanadium crossover through the membrane and the shunt currents due to potential gradient across the stack cells are typically represented by a parallel resistance () [75,117] or a controlled current source [95]. Alternatively, the shunt current effects can be modelled in a more detailed way by considering each cell individually, interconnected by a network of series and parallel resistances. Although the self discharge resistance (or current source) permits to represent satisfactorily the Coulombic efficiency, it does not account for the capacity loss caused by the electrolyte imbalance originated by side reactions or differential vanadium ion transfer across the membrane.

- (e)

- Thermal subsystem. A module representing the thermal behaviour of the system may be attached to the main circuit. Xiong et al. [117] proposed a third-order Cauer network to mimic the heat transfer process in the stack, the tanks and, eventually, the heat exchangers. Another possibility would be to model the electrochemical behaviour with the ECM, and combine it with the thermal model previously presented in Section 3.4. In Xiong’s work, only the dependence of the OCV with temperature is considered, but further temperature dependencies of the ECM elements may be also included.

To clarify the most relevant concepts discussed in the current section, the following summary analysis can be provided. It can be firstly established that the models utilised in the literature to describe the behaviour of VRFB can be primarily classified between distributed parameter models and lumped parameter models. The former are suitable for simulation and design purposes and, furthermore, provide a comprehensive understanding of the main processes that take place within a VRFB. It was found that these models are usually centred in the electrochemical stack, where the complex electrochemical processes and mass transport phenomena have more relevance. However, DPM entail a highly complex computational problem that cannot normally be solved online, and, furthermore, are difficult to be handled in an analytical manner, resulting almost always in a numerical resolution. In contrast, LPM are generally simpler. They allow to reduce the simulation time, facilitate their online implementation and can be analytically manipulated for the design of estimation strategies, such as those developed in the following section. These, in turn, can be classified in electrochemical models that preserve the physic interpretation of the variables, and equivalent circuit models if a higher degree of simplicity is preferred.

The central aspects to consider regarding dynamic modelling, especially oriented to control and estimation design, are the mass balances of the vanadium species and the stack voltage. The former permit to describe the time evolution of the active species of the battery originated by the main electrochemical reactions and possible side reactions. For its part, the stack voltage is normally expressed as a sum of an ideal open circuit voltage, given by the Nernst equation, and a series of overpotentials originated by different processes such as the ohmic, concentration and activation losses. It was found in the literature that those overpotentials can be expressed from the rather complex Butler-Volmer equations, to simpler versions that allow an explicit expression for the concentration or activation losses. Additionally, models have also been formulated to describe the thermal and hydraulic dynamics of the VRFB, which may be particularly relevant in certain applications, especially in those where a fine optimisation of the system operation is performed.

4. Redox Flow Battery Internal State Estimation

The internal state estimation is one of the most challenging topics at the moment in VRFB research. To have accurate information of the system is essential to monitor and properly plan its operation, as well as to optimise its performance and prevent its degradation. One of the most relevant indicators to be estimated is the State of Charge, which quantifies the available energy of the battery. Not less important is the State of Health, which provides a measure of the battery condition. Therefore, this section reviews the existent methodologies to estimate the aforementioned indicators and other VRFB parameters of interest.

4.1. Estimation Algorithms

This review is particularly focused in model-based estimation methodologies, although some experimental methods are briefly discussed in the next subsection. From the theoretical point of view, the variables to be estimated can be classified as states, if its time evolution is described by the dynamic equations of the model; and parameters, if their possible variation is not described by the model.

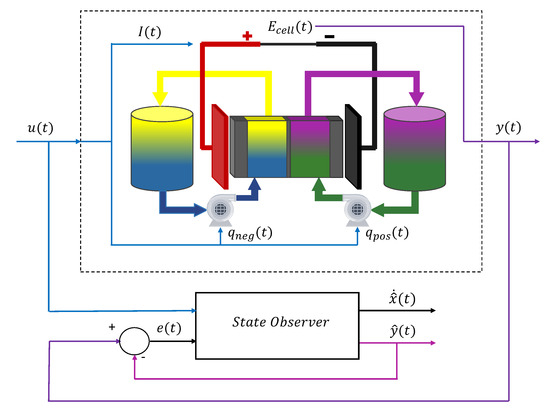

The state estimation task is generally carried out by a so-called state observer, whose function is to estimate the internal state (x) of a system (in this case, the VRFB), from measurements of the inputs (u) and outputs (y) of the real plant. These typically consist of a copy of the model dynamics able to provide an estimation of the internal state () and a correction term which, in the simplest case, is proportional to the difference (e) of a function of the measured output and its estimation () using the model, as illustrated in Figure 6.

Figure 6.

General scheme of a state observer for a VRFB.

State observers [119,120,121] permit to obtain online estimation of the SoC, SoH or other battery internal states by employing only easily measurable variables such as the current or the terminal voltage. Apart from the information provided by the sensors, this approach requires to have a mathematical model that links the measurable inputs and outputs with the system internal states and, on the other hand, an algorithm capable to adequately process the incomplete and imperfect acquired data to reconstruct a reliable estimation of the system state. Although these methods generally require an accurate battery model and increase the computational demands, they are considered to be particularly cost effective as they enable to substantially simplify the monitoring setup and simultaneously increase the robustness and reliability of the measurement process by increasing the rejection to measurement noise. With an adequate model, if the observer is properly designed and the input signal contains enough information, the estimated states converge, at least asymptotically, to the real ones and, hence, variables as the SoC of the system can be determined [122].

Parameter estimation usually utilise a different type of algorithms which, in turn, can be run either online or offline. This is possible thanks to the fact that parameters normally vary much more slowly than states. The offline approach is the simplest one, and consists in performing a set of parameter identification experiments and assuming them approximately constant during the system operation. However, offline methods require time-consuming experiments that may interrupt the system’s operation and, furthermore, are not capable to track the variations they may suffer because of changes in the operating conditions or the ageing status. In contrast, online methods involve a more complex joint estimation of parameters and states, but are better suited for system monitoring with strongly time-varying parameters.

Before delving deeper in the specific estimation objectives, a short summary of the types of algorithms that have been utilised in VRFB estimation is presented hereafter in order to ease the comprehension of the remaining of this section. In addition to the linear and non-linear state observers reported in the literature, some algorithms specifically oriented to parameter estimation as well as data driven algorithms are also presented. The main features of these algorithms are summarised in Table 3.

Table 3.

Comparison of different state observers and parameter estimation algorithms.

- (a)

- Linear state observers