Overview of Optical Digital Measuring Challenges and Technologies in Laser Welded Components in EV Battery Module Design and Manufacturing

Abstract

1. Introduction

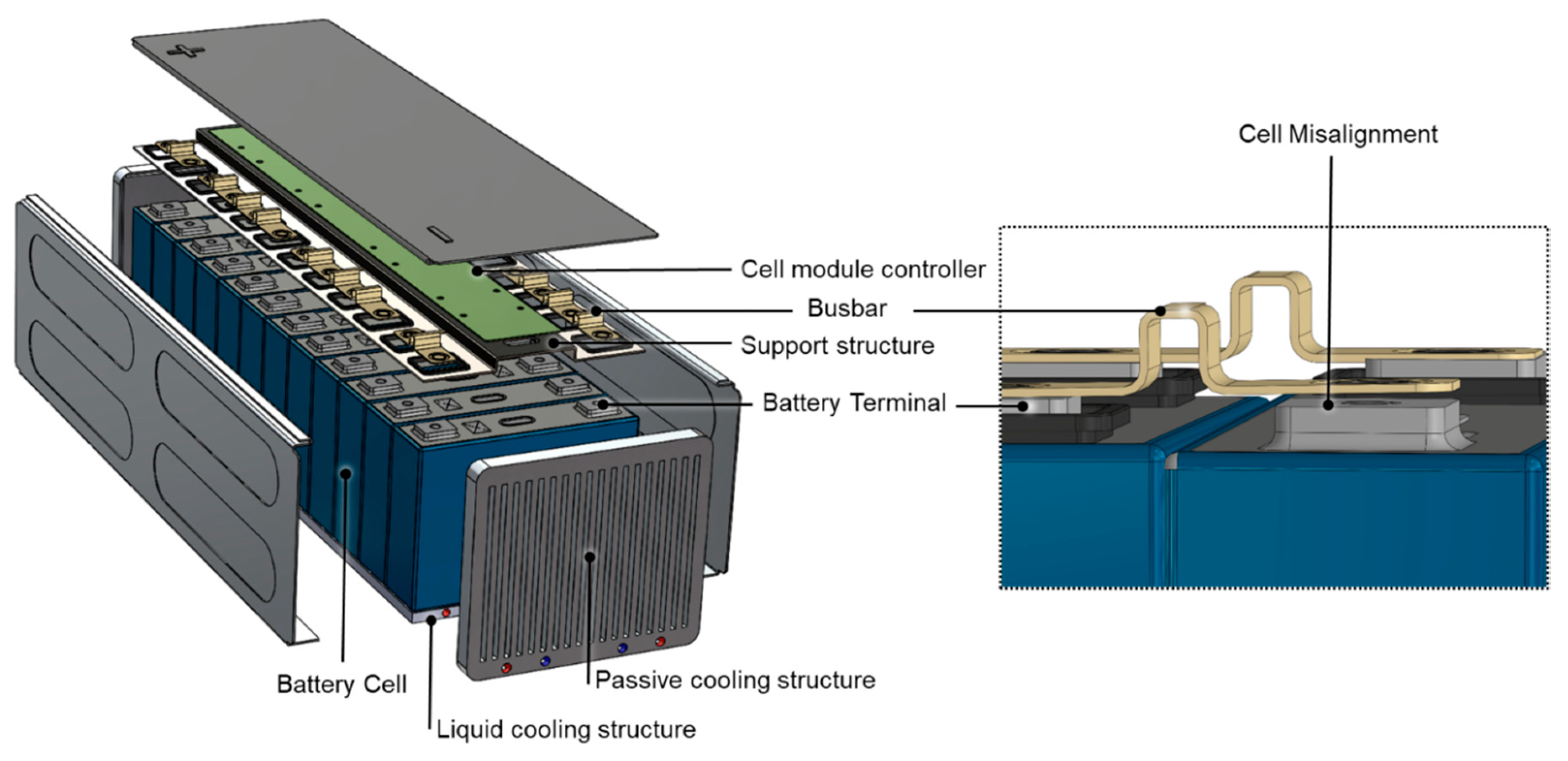

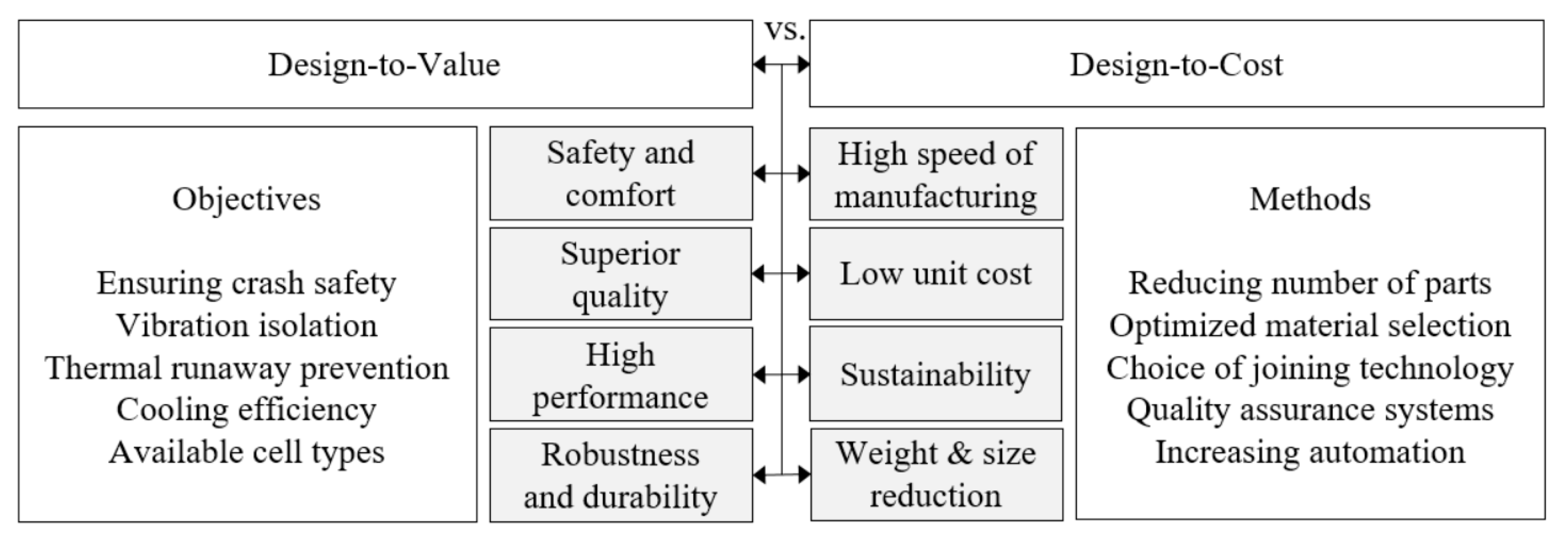

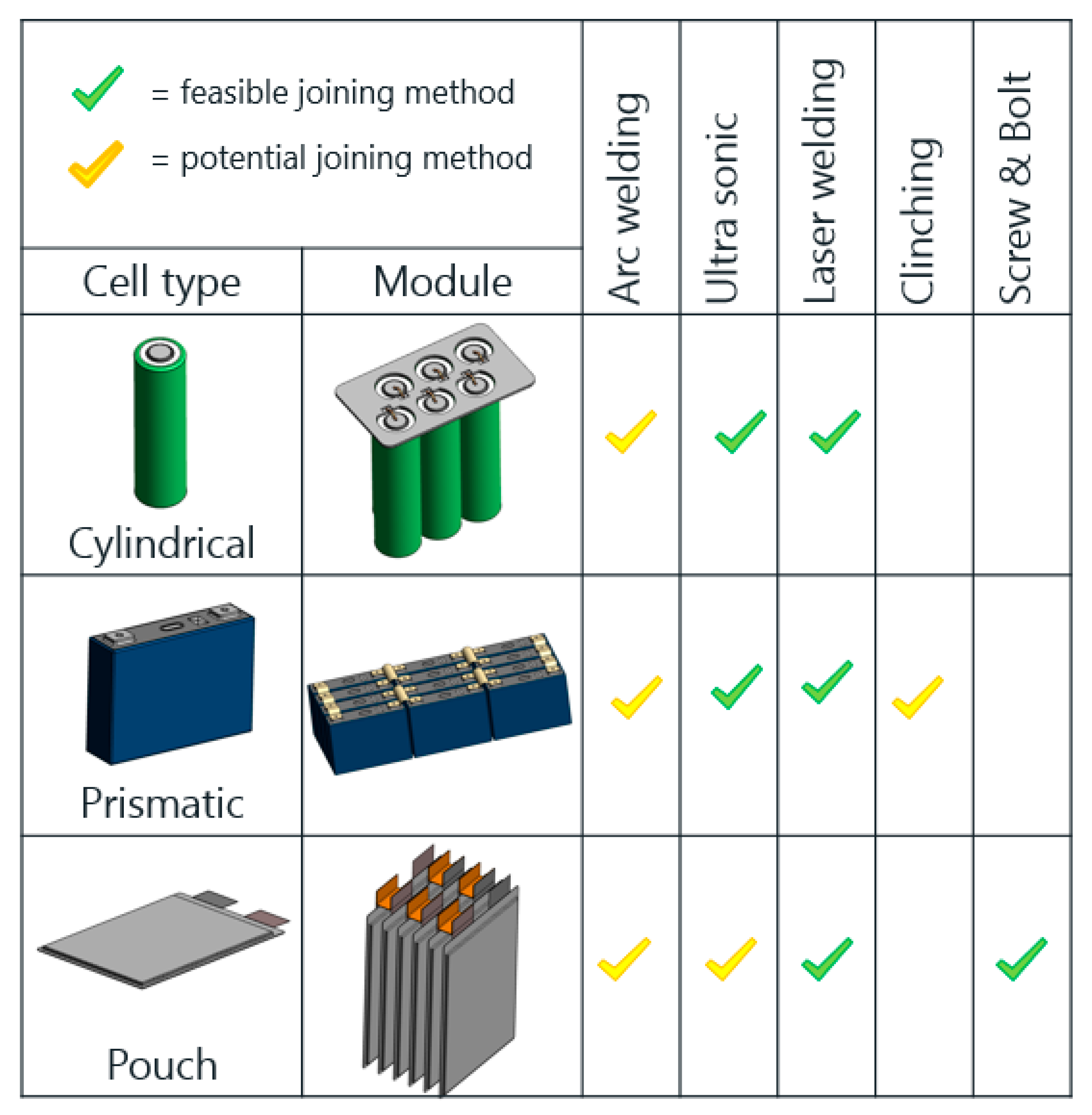

2. EV Battery Design Principles

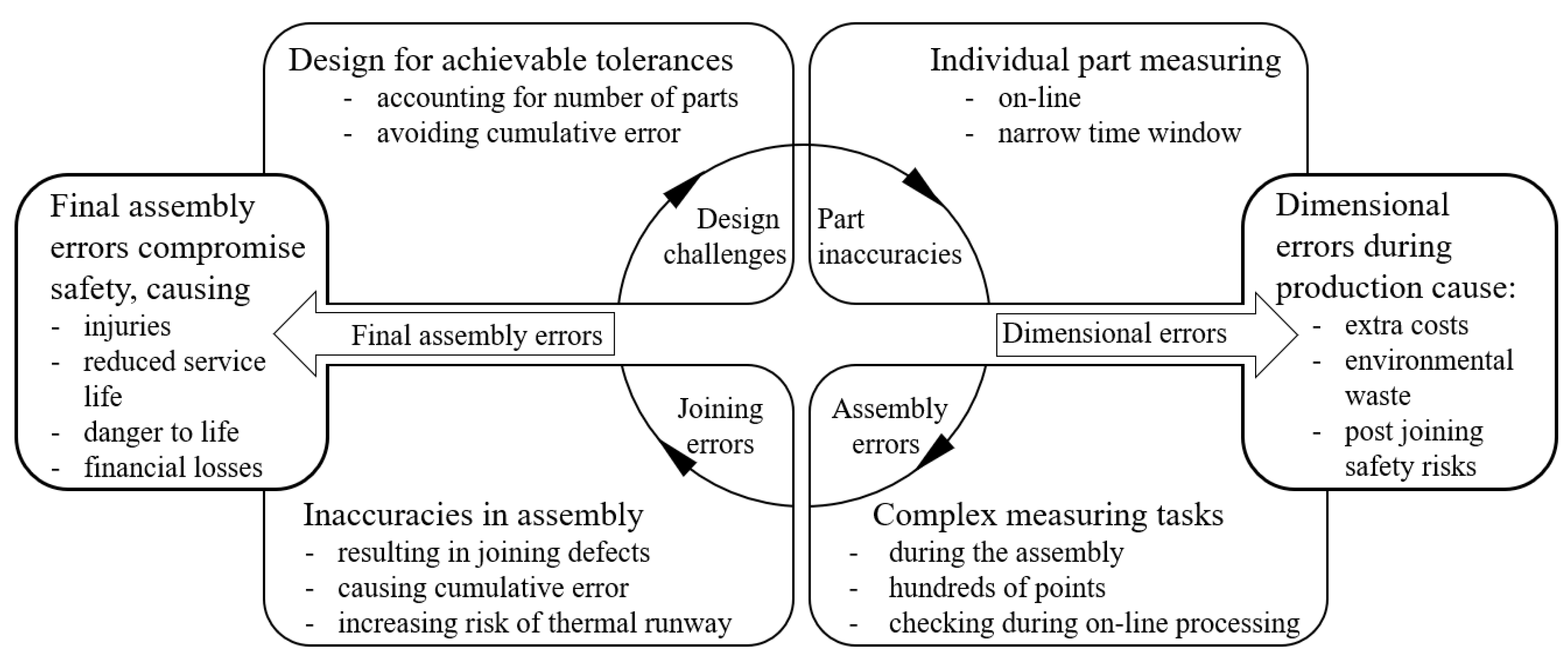

3. Overview of Challenges in Digital Measuring

- -

- Challenges of battery parts production:

- The parts, e.g., busbars, must be produced with high accuracy in accordance with tolerances set in sheet metal standard EN 485-4

- The material used for the parts can affect measuring accuracy, e.g., a smooth and shiny surface may compromise optical measurements

- -

- Challenges of assembly:

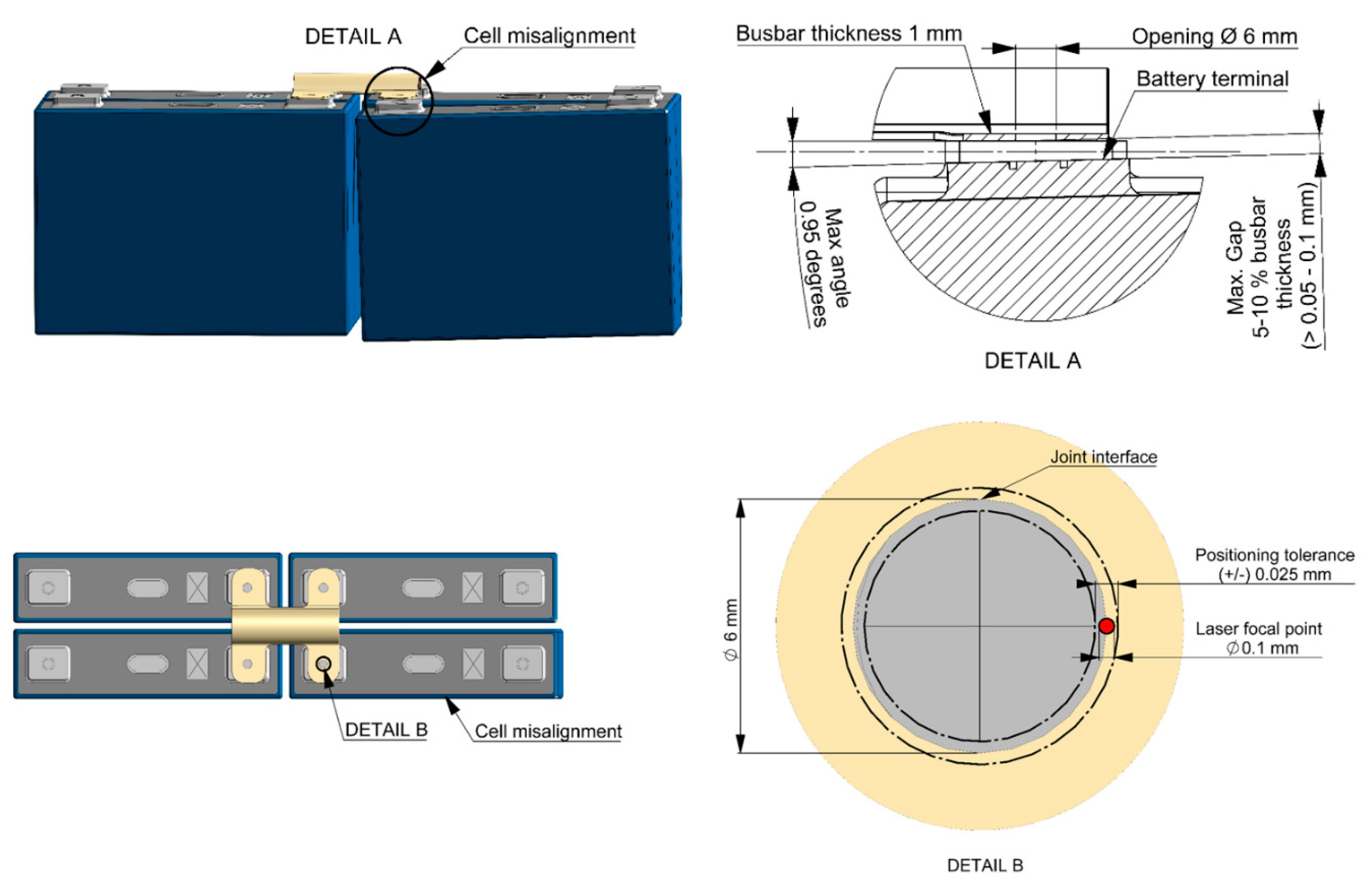

- The dimensional and positioning accuracy of the parts affects assembly. Typically, EV battery modules contain multiple dozens of cells. Therefore, the possible occurrence of cumulative error during assembly should be accounted for during the automatic assembly process

- After assembling the components, the locations of the joints should be validated prior to the joining operation to avoid errors in joining. Assembly tools can generate errors in the assembly process due to tool wear or positioning errors. Therefore, quality measurement after assembly is required

- -

- Challenges of joining:

- Precision of relative part location and orientation is essential for effective joining as positioning errors will result in unacceptable joints

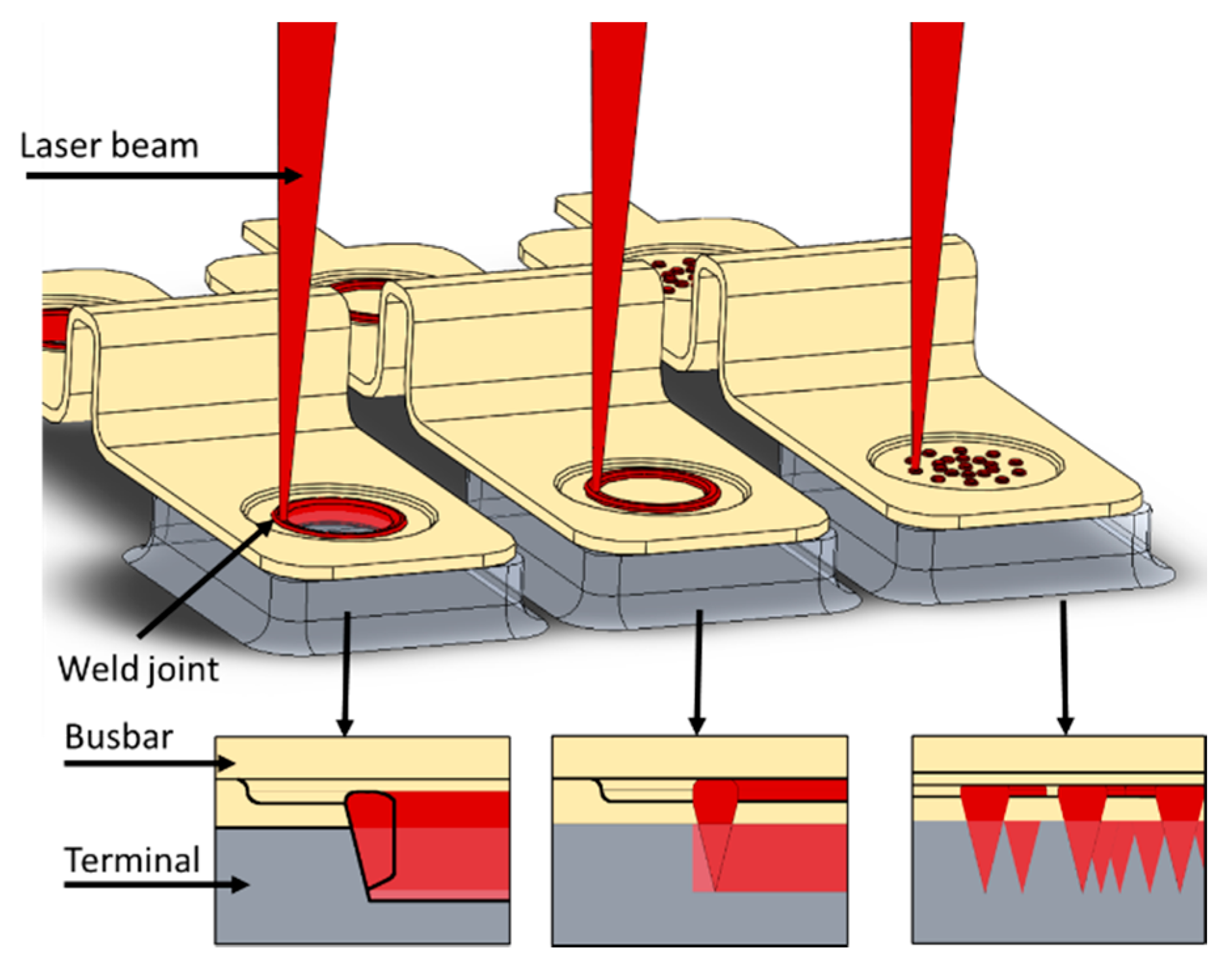

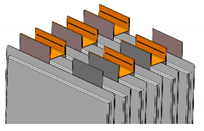

4. Laser Welding of Battery Assembly Terminal Connections

4.1. Lasers Used in Battery Welding

4.2. Welding Challenges of Different Busbar Designs and Joint Types

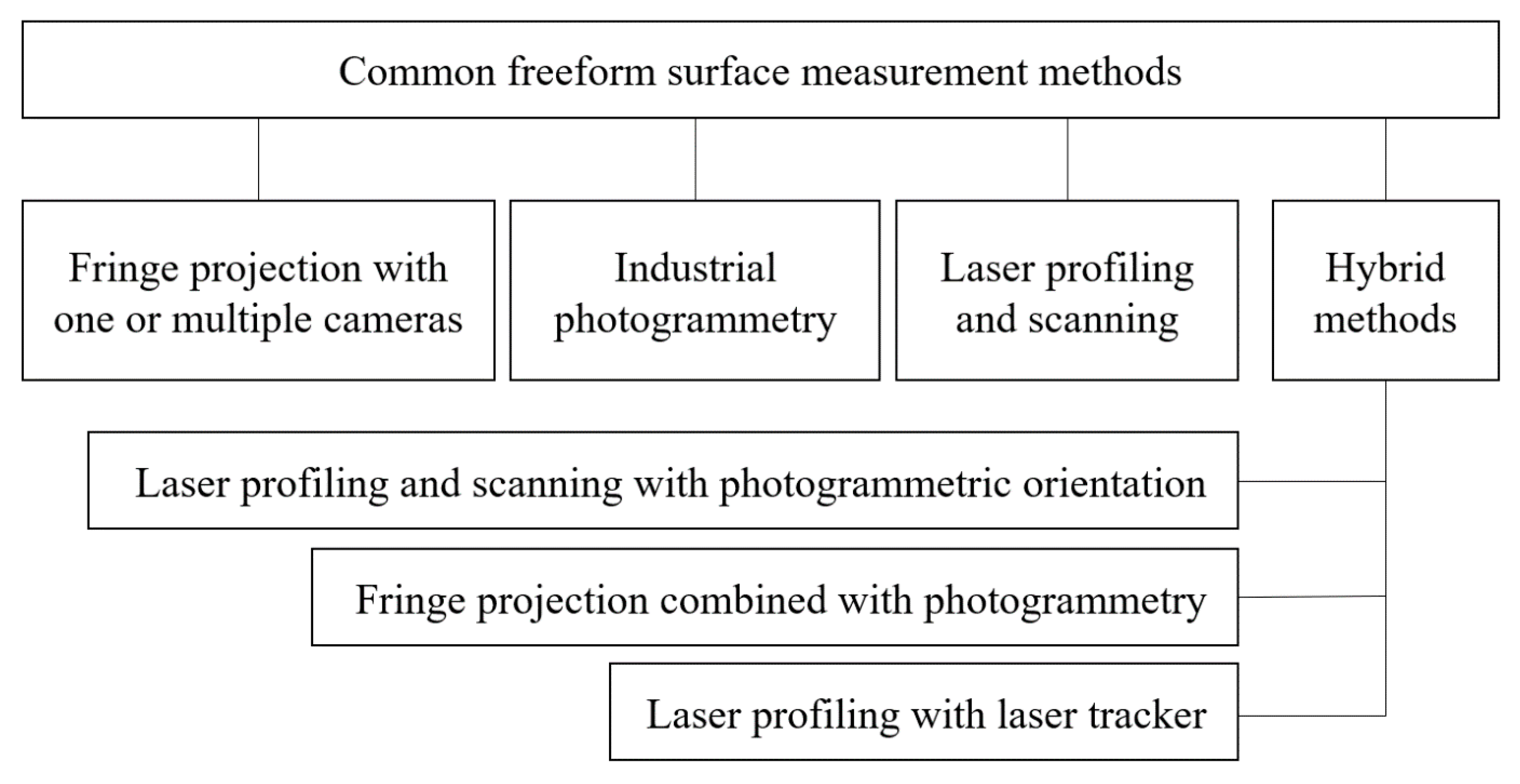

5. Optical Digital Measuring Technologies in Automated EV Battery Manufacturing

5.1. Fringe Projection with Single or Multiple Cameras

5.2. Industrial Photogrammetry

5.3. Laser Profiling and Scanning

5.4. Hybrid Solutions

- Optical sensor navigation by external photogrammetric system

- Mechanical sensor navigation by robot or articulated arm (the position information is received from the robot or from the articulated arm)

- Photogrammetric orientation by means of control points

- Point cloud matching by iterative closest point (ICP) or equivalent method.

5.5. Commercially Available Measurement Systems for Battery Welding

6. Discussion

7. Conclusions

- Quality of assembly in EV battery production is the cumulative impact of part tolerances, assembly features and welded joint quality.

- Typically, the busbar is pressed against the terminal to achieve a zero gap, as terminal height positioning accuracy has small tolerances. The amount of permitted deformation for acceptable welding quality is related to the geometry and material of the busbar.

- The distance between the busbars and battery cell terminals should be minimized before laser welding. In battery module assembly, optical scanning measurement is a fast, non-contact method suitable for establishing the correct location of dozens of terminals prior to welding. Pouch-type cells are an exception because flexibility of the electrodes enables tight fitting.

- Laser systems applied for welding the elements in battery terminal produce high energy density, producing beam diameters from 30 µm to 200 µm on material surface.

- Digital optical measuring significantly shortens the time needed for acquiring the measurement values. High reliability and trackability of collected data help to ensure safety in future exploitation of the battery system.

- The multi-purpose functionality of optical measuring devices makes them suitable for verifying the accuracy before and after welding operations, lessening the need for human visual inspection.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nava, M. The Road Ahead for Electric Vehicles. 2017. Available online: https://www.bbvaresearch.com/wp-content/uploads/2017/02/170213_US_ElectricVehicles.pdf (accessed on 14 September 2020).

- Raff, R.; Golub, V.; Pelin, D.; Topic, D. Overview of Charging Modes and Connectors for the Electric Vehicles. In Proceedings of the 7th International Youth Conference on Energy (IYCE), Bled, Slovenia, 3–6 July 2020; pp. 1–6. [Google Scholar]

- Biresselioglu, M.E.; Demirbag Kaplan, M.; Yilmaz, B.K. Electric mobility in Europe: A comprehensive review of motivators and barriers in decision making processes. Transp. Res. Part A Policy Pract. 2018, 109, 1–13. [Google Scholar] [CrossRef]

- Hildermeier, J.; Kolokathis, C.; Rosenow, J.; Hogan, M.; Wiese, C.; Jahn, A. Smart EV Charging: A Global Review of Promising Practices. World Electr. Veh. J. 2019, 10, 80. [Google Scholar] [CrossRef]

- Gauthami, R.; Nair, V.V.; Sathish, A.; Vishnu Soureesh, K.; Ilango, K.; Sreelekshmi, R.S.; Ilangovan, S.A.; Sujatha, S. Design and Implementation of Efficient Energy Management System in Electric Vehicles. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 626, pp. 543–559. [Google Scholar]

- Iclodean, C.; Varga, B.; Burnete, N.; Cimerdean, D.; Jurchiş, B. Comparison of Different Battery Types for Electric Vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 12058. [Google Scholar] [CrossRef]

- Pistoia, G.; Liaw, B. Behaviour of Lithium-Ion Batteries in Electric Vehicles, 1st ed.; Springer: Cham, Switzerland, 2018; ISBN 9783319699493. [Google Scholar]

- Zeng, X.; Li, M.; Abd El-Hady, D.; Alshitari, W.; Al-Bogami, A.S.; Lu, J.; Amine, K. Commercialization of Lithium Battery Technologies for Electric Vehicles. Adv. Energy Mater. 2019, 9, 1900161. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Li, J.; Zhou, S.; Han, Y. (Eds.) Advances in Battery Manufacturing, Service, and Management Systems; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; ISBN 9781119060741. [Google Scholar]

- Mikkelstrup, A.; Thomsen, M.; Stampe, K.; Endelt, B.; Boll, J.; Kristiansen, E.; Kristiansen, M. Quality Inspection System for Robotic Laser Welding of Double-Curved Geometries. Procedia Manuf. 2019, 36, 50–57. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Zwicker, M.F.R.; Moghadam, M.; Zhang, W.; Nielsen, C.V. Automotive battery pack manufacturing – a review of battery to tab joining. J. Adv. Join. Process. 2020. [Google Scholar] [CrossRef]

- Das, A.; Li, D.; Williams, D.; Greenwood, D. Joining Technologies for Automotive Battery Systems Manufacturing. World Electr. Veh. J. 2018, 9, 22. [Google Scholar] [CrossRef]

- Shannon, G. Improve Tab to Terminal Connections in Battery Pack Manufacturing. Available online: https://www.batterypoweronline.com/articles/improve-tab-to-terminal-connections-in-battery-pack-manufacturing/ (accessed on 14 September 2020).

- Stavridis, J.; Papacharalampopoulos, A.; Stavropoulos, P. Quality assessment in laser welding: A critical review. Int. J. Adv. Manuf. Technol. 2018, 94, 1825–1847. [Google Scholar] [CrossRef]

- Allwood, J.M.; Childs, T.H.C.; Clare, A.T.; De Silva, A.K.M.; Dhokia, V.; Hutchings, I.M.; Leach, R.K.; Leal-Ayala, D.R.; Lowth, S.; Majewski, C.E.; et al. Manufacturing at double the speed. J. Mater. Process. Technol. 2015, 229, 729–757. [Google Scholar] [CrossRef]

- Schnell, J.; Reinhart, G. Quality Management for Battery Production: A Quality Gate Concept. Procedia CIRP 2016, 57, 568–573. [Google Scholar] [CrossRef]

- Kölmel, A.; Sauer, A.; Lanza, G. Quality-oriented Production Planning of Battery Assembly Systems for Electric Mobility. Procedia CIRP 2014, 23, 149–154. [Google Scholar] [CrossRef]

- Glorieux, E.; Franciosa, P.; Ceglarek, D. Coverage path planning with targetted viewpoint sampling for robotic free-from surface inspection. Robot. Comput. Integr. Manuf. 2020, 61, 101843. [Google Scholar] [CrossRef]

- Savio, E.; De Chiffre, L.; Carmignato, S.; Meinertz, J. Economic benefits of metrology in manufacturing. CIRP Ann. Manuf. Technol. 2016, 65, 495–498. [Google Scholar] [CrossRef]

- Pettinger, K.H.; Kampker, A.; Hohenthanner, C.R.; Deutskens, C.; Heimes, H.; vom Hemdt, A. Lithium-ion cell and battery production processes. In Lithium-Ion Batteries: Basics and Applications; Springer: Berlin, Germany, 2018; pp. 211–226. ISBN 9783662530719. [Google Scholar]

- Kraetzsch, M.; Standfuss, J.; Klotzbach, A.; Kaspar, J.; Brenner, B.; Beyer, E. Laser Beam Welding with High-Frequency Beam Oscillation: Welding of Dissimilar Materials with Brilliant Fiber Lasers. Phys. Procedia 2011, 12, 142–149. [Google Scholar] [CrossRef]

- Schröder, R.; Aydemir, M.; Seliger, G. Comparatively Assessing different Shapes of Lithium-ion Battery Cells. Procedia Manuf. 2017, 8, 104–111. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2018, 10, 246–267. [Google Scholar] [CrossRef]

- Zhang, S. Recent progresses on real-time 3D shape measurement using digital fringe projection techniques. Opt. Lasers Eng. 2010, 48, 149–158. [Google Scholar] [CrossRef]

- Niu, H.; Chen, C.; Ji, D.; Li, L.; Li, Z.; Liu, Y.; Huang, X. Thermal-Runaway Propagation over a Linear Cylindrical Battery Module. Fire Technol. 2020. [Google Scholar] [CrossRef]

- Baumann, M.; Wildfeuer, L.; Rohr, S.; Lienkamp, M. Parameter variations within Li-Ion battery packs—Theoretical investigations and experimental quantification. J. Energy Storage 2018, 18, 295–307. [Google Scholar] [CrossRef]

- Kenney, B.; Darcovich, K.; MacNeil, D.D.; Davidson, I.J. Modelling the impact of variations in electrode manufacturing on lithium-ion battery modules. J. Power Sources 2012, 213, 391–401. [Google Scholar] [CrossRef]

- Plötz, P.; Schneider, U.; Globisch, J.; Dütschke, E. Who will buy electric vehicles? Identifying early adopters in Germany. Transp. Res. Part A Policy Pract. 2014, 67, 96–109. [Google Scholar] [CrossRef]

- Hollatz, S.; Kremer, S.; Ünlübayir, C.; Sauer, D.U.; Olowinsky, A.; Gillner, A. Electrical Modelling and Investigation of Laser Beam Welded Joints for Lithium-Ion Batteries. Batteries 2020, 6, 24. [Google Scholar] [CrossRef]

- Wilke, S.; Schweitzer, B.; Khateeb, S.; Al-Hallaj, S. Preventing thermal runaway propagation in lithium ion battery packs using a phase change composite material: An experimental study. J. Power Sources 2017, 340, 51–59. [Google Scholar] [CrossRef]

- Kirchhoff, M. Laser Applications in Battery Production—From Cutting Foils to Welding the Case. 2013, pp. 1–3. Available online: https://ieeexplore.ieee.org/abstract/document/6689743/ (accessed on 14 September 2020).

- Lee, S.S.; Kim, T.H.; Hu, S.J.; Cai, W.W.; Abell, J.A. Joining technologies for automotive lithium-ion battery manufacturing—A review. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, MSEC 2010, Erie, PA, USA, 12–15 October 2010; Volume 1, pp. 541–549. [Google Scholar]

- Schmitz, P. Comparative Study on Pulsed Laser Welding Strategies for Contacting Lithium-Ion Batteries. Adv. Mater. Res. 2016, 1140, 312–319. [Google Scholar] [CrossRef]

- Brand, M.J.; Schmidt, P.A.; Zaeh, M.F.; Jossen, A. Welding techniques for battery cells and resulting electrical contact resistances. J. Energy Storage 2015, 1, 7–14. [Google Scholar] [CrossRef]

- Dimatteo, V.; Ascari, A.; Fortunato, A. Continuous laser welding with spatial beam oscillation of dissimilar thin sheet materials (Al-Cu and Cu-Al): Process optimization and characterization. J. Manuf. Process. 2019, 44, 158–165. [Google Scholar] [CrossRef]

- Schmidt, P.A.; Schweier, M.; Zaeh, M.F. Joining of lithium-ion batteries using laser beam welding: Electrical losses of welded aluminum and copper joints. In Proceedings of the ICALEO 2012—31st International Congress on Applications of Lasers and Electro-Optics, Anaheim, CA, USA, 23–27 September 2012; Volume 2012, pp. 915–923. [Google Scholar]

- Fetzer, F.; Jarwitz, M.; Stritt, P.; Weber, R.; Graf, T. Fine-tuned Remote Laser Welding of Aluminum to Copper with Local Beam Oscillation. Phys. Procedia 2016, 83, 455–462. [Google Scholar] [CrossRef]

- Solchenbach, T.; Plapper, P.; Cai, W. Electrical performance of laser braze-welded aluminum–copper interconnects. J. Manuf. Process. 2014, 16, 183–189. [Google Scholar] [CrossRef]

- Zediker, M.S.; Fritz, R.D.; Finuf, M.J.; Pelaprat, M.J. Laser Welding Components for Electric Vehicles with a High-Power Blue Laser System. In Proceedings of the ICALEO 2019, Orlando, FL, USA, 7–10 October 2019; LIA: Orlando, FL, USA, 2019; p. 104. [Google Scholar]

- Helm, J.; Schulz, A.; Olowinsky, A.; Dohrn, A.; Poprawe, R. Laser welding of laser-structured copper connectors for battery applications and power electronics. Weld. World 2020, 64, 611–622. [Google Scholar] [CrossRef]

- Giordano, G. Laser welding advances fuel new applications. Manuf. Eng. 2018, 160, LF5–LF11. [Google Scholar]

- Kaiser, E.; Dold, E.M.; Killi, A.; Zaske, S.; Pricking, S. Application benefits of welding copper with a 1 kW, 515 nm continuous wave laser. Batter. Congr. 2019, 2019, 1–6. [Google Scholar]

- Havrilla, D.; Ryba, T.; Holzer, M. High-Power Disk Lasers: Advances and Applications. Available online: https://lia.scitation.org/doi/abs/10.2351/1.5062465 (accessed on 14 September 2020).

- Müller, A.; Goecke, S.F.; Rethmeier, M. Laser beam oscillation welding for automotive applications. Weld. World 2018, 62, 1039–1047. [Google Scholar] [CrossRef]

- Rodrigues, M.; Kormann, M.; Schuhler, C.; Tomek, P. An Intelligent Real Time 3D Vision System for Robotic Welding Tasks. In Proceedings of the 2013 9th International Symposium on Mechatronics and its Applications (ISMA), Amman, Jordan, 9–11 April 2013; pp. 1–6. [Google Scholar]

- Wang, Z.; Nguyen, D.A.; Barnes, J. Recent advances in 3D shape measurement and imaging using fringe projection technique. In Proceedings of the Society for Experimental Mechanics—SEM Annual Conference and Exposition on Experimental and Applied Mechanics 2009, Albuquerque, NM, USA, 1–4 June 2009; Volume 4, pp. 2644–2653. [Google Scholar]

- GOM. GOM Acceptance Test, Certificate No. 110826_CP20-170-60086. Acceptance/Reverification Base on VDI/VDE 2634, Part 3. 2011. Available online: https://www.zebicon.com/fileadmin/user_upload/2_Maaleudstyr/9_Certifikater/ATOS_Core_200_SN160300/2019-04-02_Acceptance_test_ATOS_Core_MV200_SN160300.pdf (accessed on 14 September 2020).

- Li, F.; Stoddart, D.; Zwierzak, I. A Performance Test for a Fringe Projection Scanner in Various Ambient Light Conditions. Procedia CIRP 2017, 62, 400–404. [Google Scholar] [CrossRef]

- Robson, S.; MacDonald, L.; Kyle, S.; Boehm, J.; Shortis, M. Optimised multi-camera systems for dimensional control in factory environments. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1707–1718. [Google Scholar] [CrossRef]

- Tuominen, V. The measurement-aided welding cell—Giving sight to the blind. Int. J. Adv. Manuf. Technol. 2016, 86, 371–386. [Google Scholar] [CrossRef]

- Cuypers, W.; Van Gestel, N.; Voet, A.; Kruth, J.-P.; Mingneau, J.; Bleys, P. Optical measurement techniques for mobile and large-scale dimensional metrology. Opt. Lasers Eng. 2009, 47, 292–300. [Google Scholar] [CrossRef]

- Luhmann, T.; Robson, S.; Kyle, S.; Boehm, J. Close-Range Photogrammetry and 3D Imaging, 2nd ed.; De Gruyter: Berlin, Germany, 2013. [Google Scholar]

- Stavroulakis, P.I.; Leach, R.K. Review of post-process optical form metrology for industrial-grade metal additive manufactured parts. Rev. Sci. Instrum. 2016, 87, 041101. Available online: https://aip.scitation.org/doi/abs/10.1063/1.4944983 (accessed on 14 September 2020). [CrossRef]

- Creaform Creaform. Available online: https://www.creaform3d.com/ (accessed on 14 September 2020).

- Luhmann, T. Close range photogrammetry for industrial applications. ISPRS J. Photogramm. Remote Sens. 2010, 65, 558–569. [Google Scholar] [CrossRef]

- GOM. Available online: www.gom.com (accessed on 10 November 2019).

- Rao, M.R.; Radhakrishna, D.; Usha, S. Development of a Robot-mounted 3D Scanner and Multi-view Registration Techniques for Industrial Applications. Procedia Comput. Sci. 2018, 133, 256–267. [Google Scholar] [CrossRef]

- Hexagon Leica Absolute Tracker AT960. Available online: https://www.hexagonmi.com/products/laser-tracker-systems/leica-absolute-tracker-at960 (accessed on 20 October 2019).

| Joining Method | Schematic Representation |

|---|---|

| Laser wire bonding |  |

| |

| Fillet welding of busbar |  |

| |

| Laser spot welded busbar |  |

| |

| Laser lap joint welded busbar |  |

| |

| Laser lap joint welded pouch cells |  |

|

| Beam Source | Power (W) | Material | Focused Beam Diameter (µm) | Wavelength (nm) | Reference |

|---|---|---|---|---|---|

| Disk laser MM/CW | 4000 | Steel/Steel | 170 | 1030 | [35] |

| Fiber laser SM/CW | 3000 | Brass/Brass | 50 | 1070 | [36] |

| Fiber laser SM/CW | 1000 | Al/Cu/Al | 60 | 1070 | [37] |

| Fiber laser SM/CW | 3000 | Al/Cu | 50 | 1070 | [38] |

| Fiber laser SM/CW | 2000 | Al/Cu | 35 | 1070 | [23] |

| Diode laser MM/CW | 4000 | Al/Cu | 280 | 1080 1 | [39] |

| Fiber Laser SM/CW | 400 | Al/Cu | 31 | 1070 | [40] |

| System | Principle | Measuring Volume or Area | Volumetric Accuracy | Scanning Area |

|---|---|---|---|---|

| Zeiss T-Scan 20 | Laser scanning with external photogrammetric orientation | 20 m3 | 0.04 mm + 0.04 (L/1000) mm | 125 mm line |

| Creaform Metrascan 750 Elite | Laser scanning with external photogrammetric orientation | 16.6 m3 | 0.078 mm | 275 × 250 mm |

| Creaform HandyScan BLACK | Laser scanning | Recommended part size 0.05–4 m; | 0.02 mm + 0.06 mm/m | 310 × 350 mm |

| Leica AT960MR and T-Scan | Laser scanning with laser tracker | 20 m | 0.06 mm/0.026 mm + 0.004 mm/m | 100 mm line at standoff distance |

| Hexagon absolute arm | Laser scanning with mechanical arm | Max reach 3480 mm | 0.066 mm (LDIA value is the maximum permissible error for the articulation location, according to ISO 10360-8 Annex D) | 115 mm line |

| GOM Atos III Triple Scan | Fringe projection | 38 × 29 × 15–2000 × 1500 × 1500 mm3 | 0.011 mm (sphere spacing error, measuring volume 560 × 420 × 420 mm) | Not specified |

| Creaform Maxshot Next Elite | Photogrammetry | 2–10 m | 0.015 mm/m (Based on VDI/VDE 2634 part 1) | Not specified |

| Mapvision Quality Gate 2200 Series | Photogrammetry, Multi-camera | 330 × 860 × 320 mm | Repeatability: +/−0.02 mm | Not specified |

| Mapvision Quality Gate 6200 Series | Photogrammetry, Multi-camera | Any standard car or body in white: 5 × 2.3 × 1.5 m | Repeatability: +/−0.02 mm | Not specified |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saariluoma, H.; Piiroinen, A.; Unt, A.; Hakanen, J.; Rautava, T.; Salminen, A. Overview of Optical Digital Measuring Challenges and Technologies in Laser Welded Components in EV Battery Module Design and Manufacturing. Batteries 2020, 6, 47. https://doi.org/10.3390/batteries6030047

Saariluoma H, Piiroinen A, Unt A, Hakanen J, Rautava T, Salminen A. Overview of Optical Digital Measuring Challenges and Technologies in Laser Welded Components in EV Battery Module Design and Manufacturing. Batteries. 2020; 6(3):47. https://doi.org/10.3390/batteries6030047

Chicago/Turabian StyleSaariluoma, Heikki, Aki Piiroinen, Anna Unt, Jukka Hakanen, Tuomo Rautava, and Antti Salminen. 2020. "Overview of Optical Digital Measuring Challenges and Technologies in Laser Welded Components in EV Battery Module Design and Manufacturing" Batteries 6, no. 3: 47. https://doi.org/10.3390/batteries6030047

APA StyleSaariluoma, H., Piiroinen, A., Unt, A., Hakanen, J., Rautava, T., & Salminen, A. (2020). Overview of Optical Digital Measuring Challenges and Technologies in Laser Welded Components in EV Battery Module Design and Manufacturing. Batteries, 6(3), 47. https://doi.org/10.3390/batteries6030047