Experimental Data Comparison of an Electric Minibus Equipped with Different Energy Storage Systems

Abstract

1. Introduction

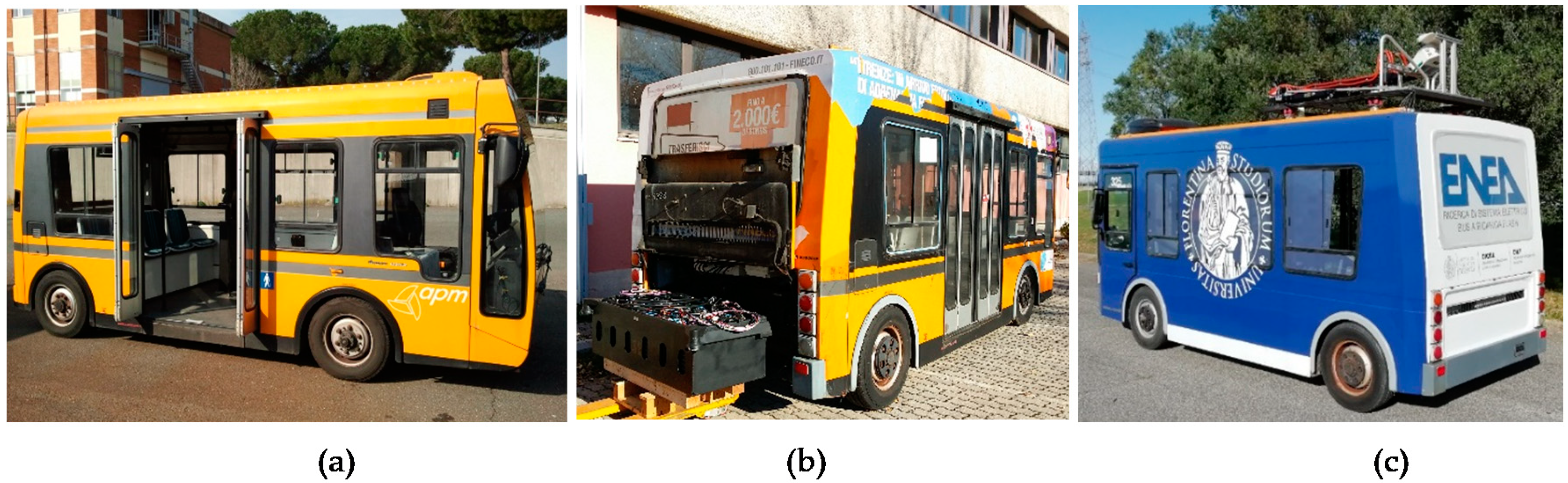

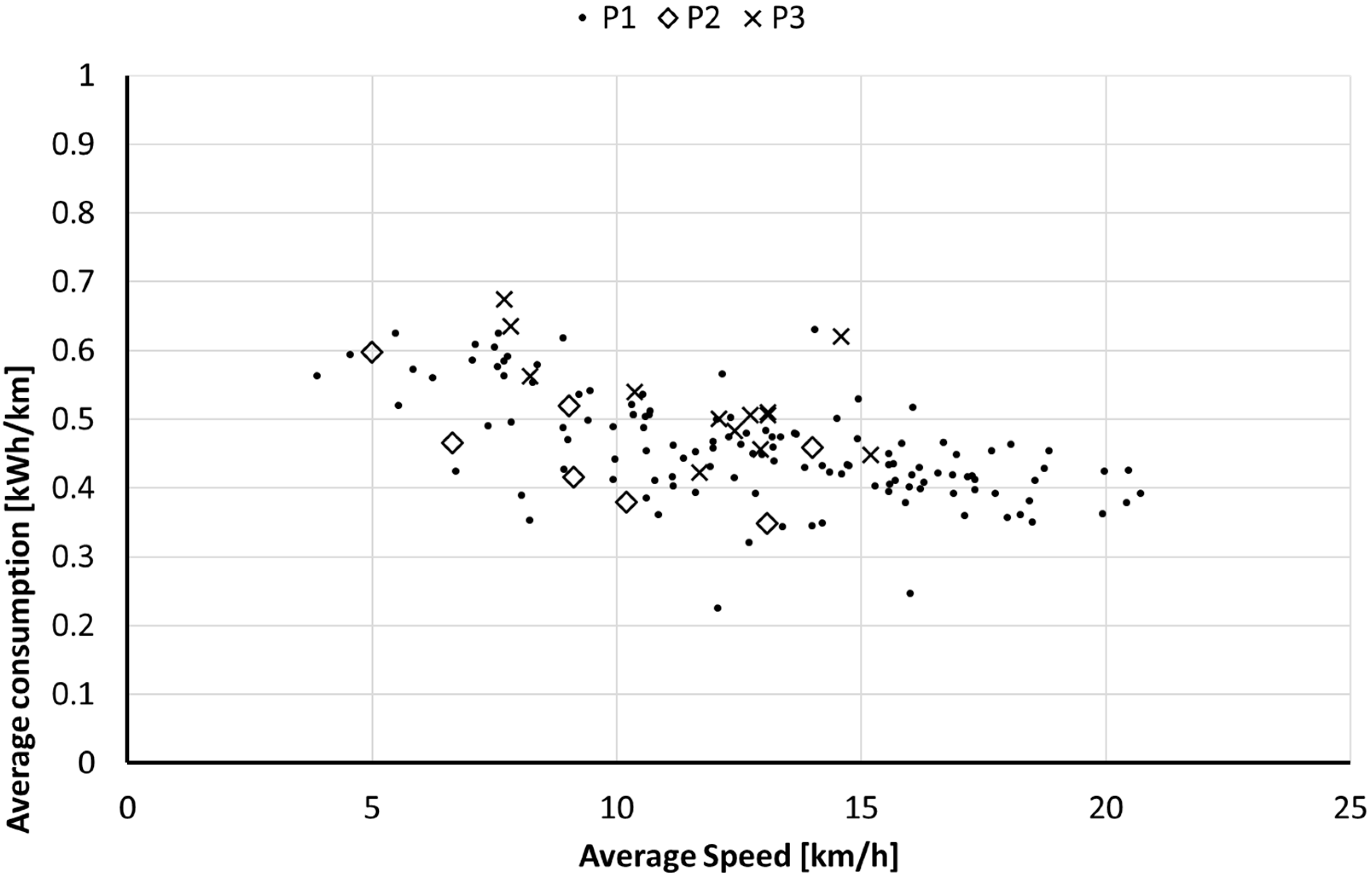

- Project 1 (P1): Bus equipped with lead–acid batteries, as provided by the original equipment manufacturer (OEM). The project tested an innovative on-demand transport service [11].

- Project 2 (P2): lithium-ion iron phosphate batteries designed for 3C (three times the nominal capacity C) fast charging.

- Project 3 (P3): Hybrid storage with supercapacitors (SC) and absorbent glass mat (AGM) lead batteries, with a flash charging system.

2. Details of the Compared Projects

- P1 had not enough range for a day, considering a typical transport line of 100 km; this required two battery packs and two chargers for each bus. A full charge of battery required eight hours and it covered only about four hours of service, so at midday, driver went to depot, where battery was swapped with a second one (just fully charged).

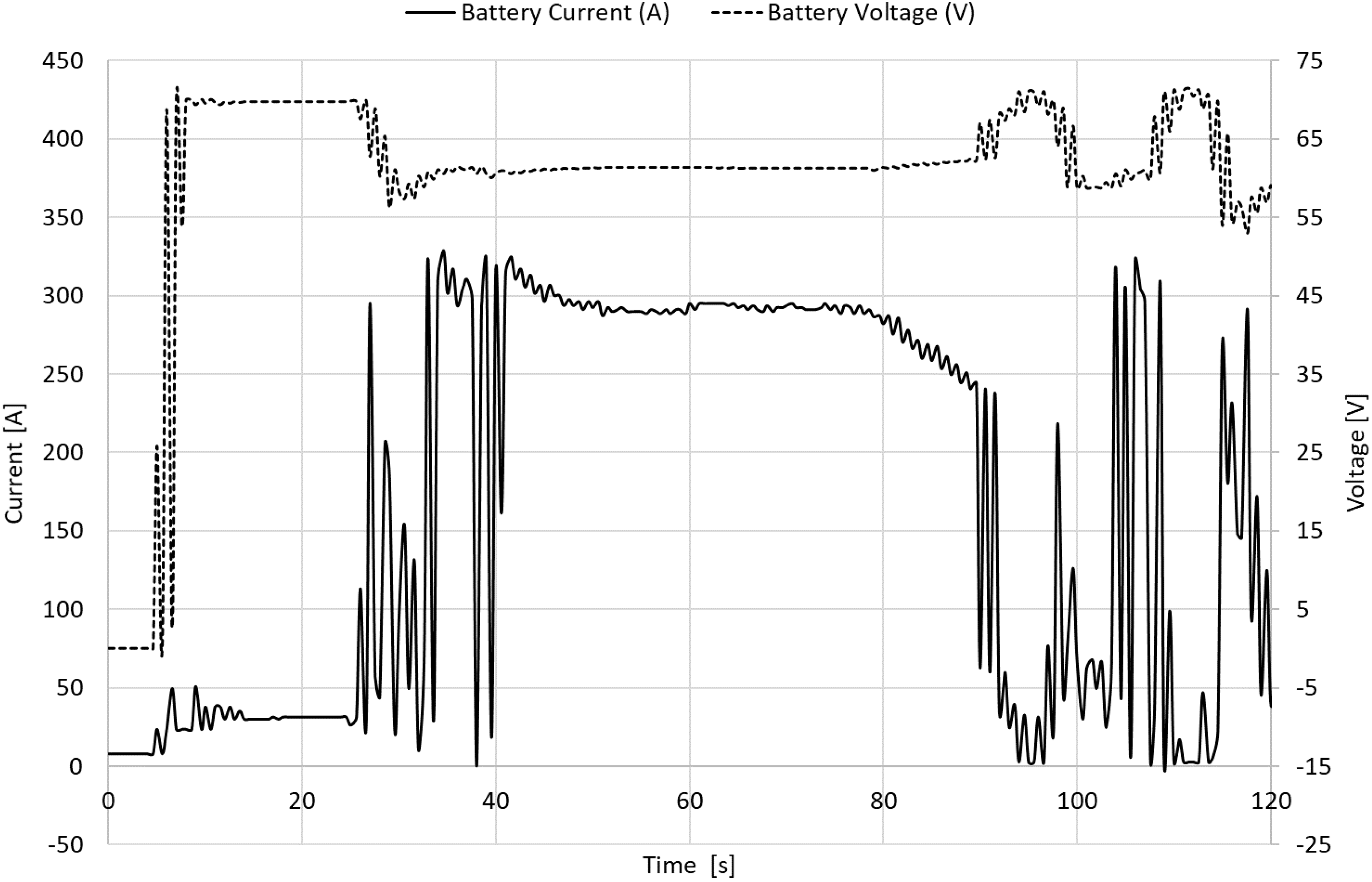

- P2 had a fast charging feature that allowed for twenty-minute ride followed by seven-minute stop (or forty-minute ride and fourteen-minute stop). The long stop was necessary to charge battery.

- P3 had a flash charging feature that allowed to charge SC in thirty seconds, so it could be charged during transport service stops (while passengers are on board), but it had to happen every 700 m [13].

- P4 has a SC with the flash charging feature, as for P3 and, a LiFePO4 battery (as for P2 but with lesser energy stored).

2.1. Project 1 (P1): Lead–acid Batteries

2.2. Project 2 (P2): Lithium-Ion Batteries

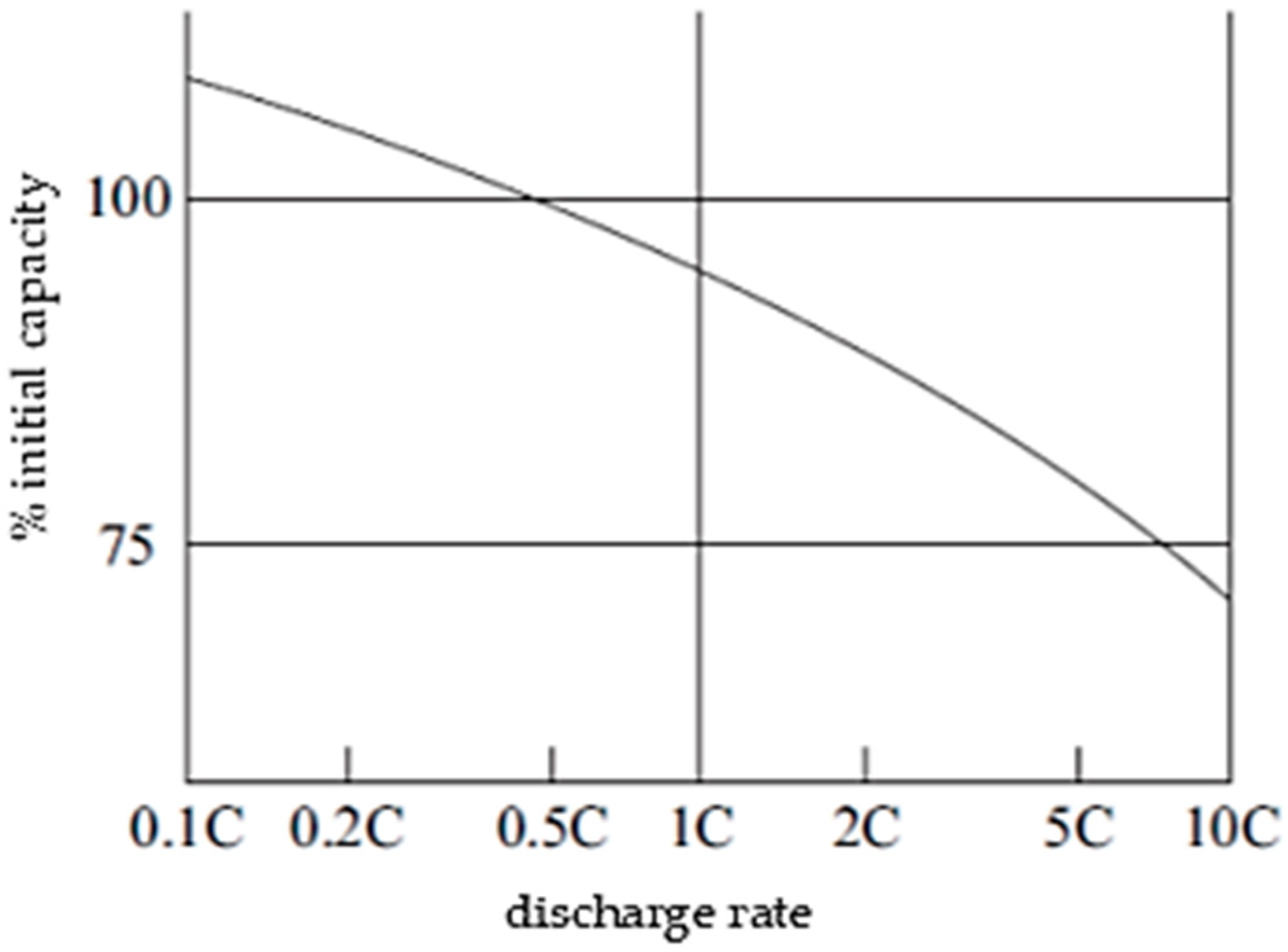

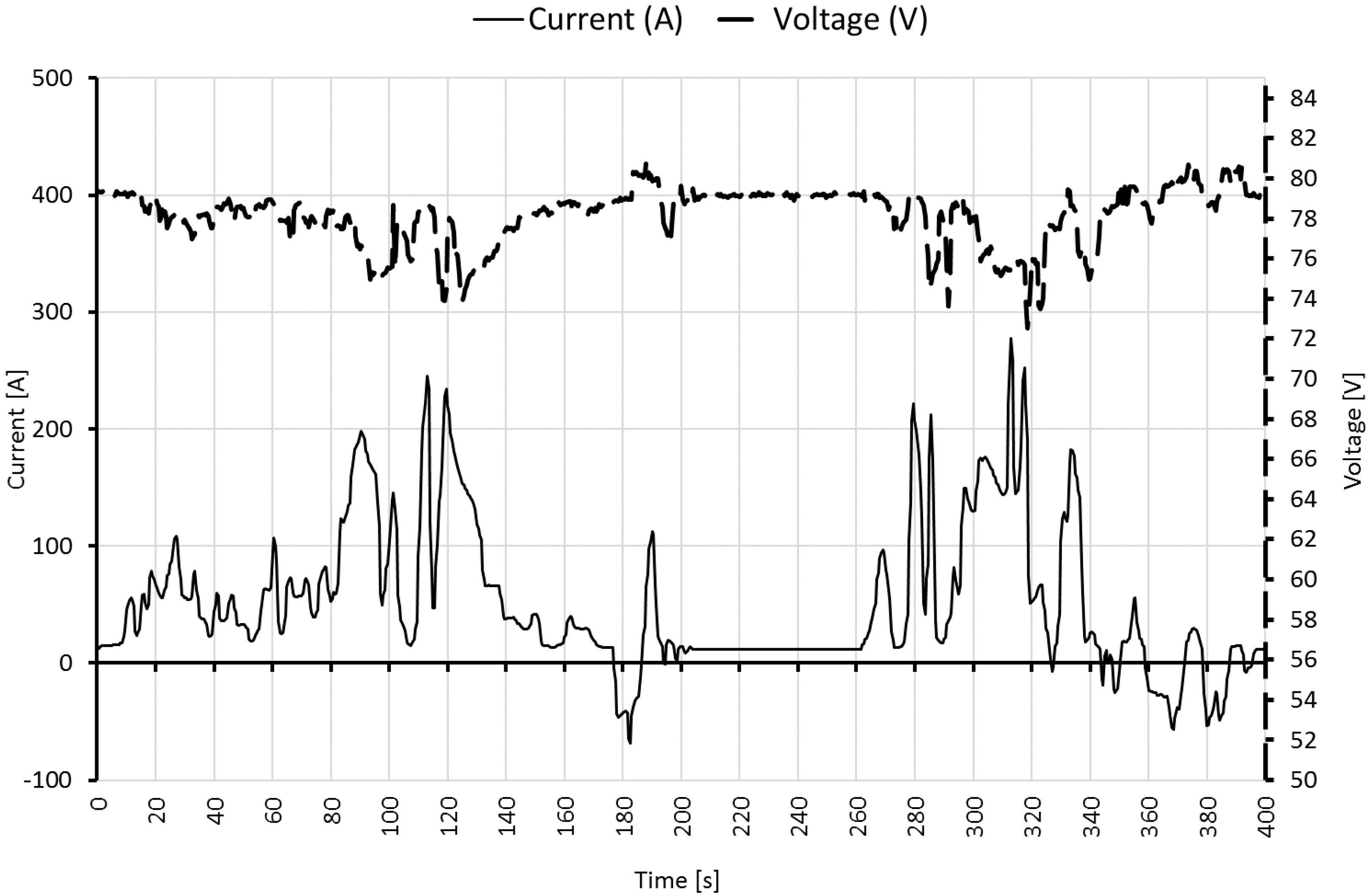

- Maximum discharge current of whole battery pack: the lead–acid one had a greater current (330 A against 280 A). Thanks to parallel and series connections the maximum current of whole ESS was divided among batteries, so each lead–acid ESS achieved up to 50 A of maximum current, while lithium-ion achieved up to 70 A.

- Voltage range: The lead–acid battery had about 20 V (from 53 V to 73 V), whereas the lithium-ion battery had 8 V (from 73 V to 81 V)

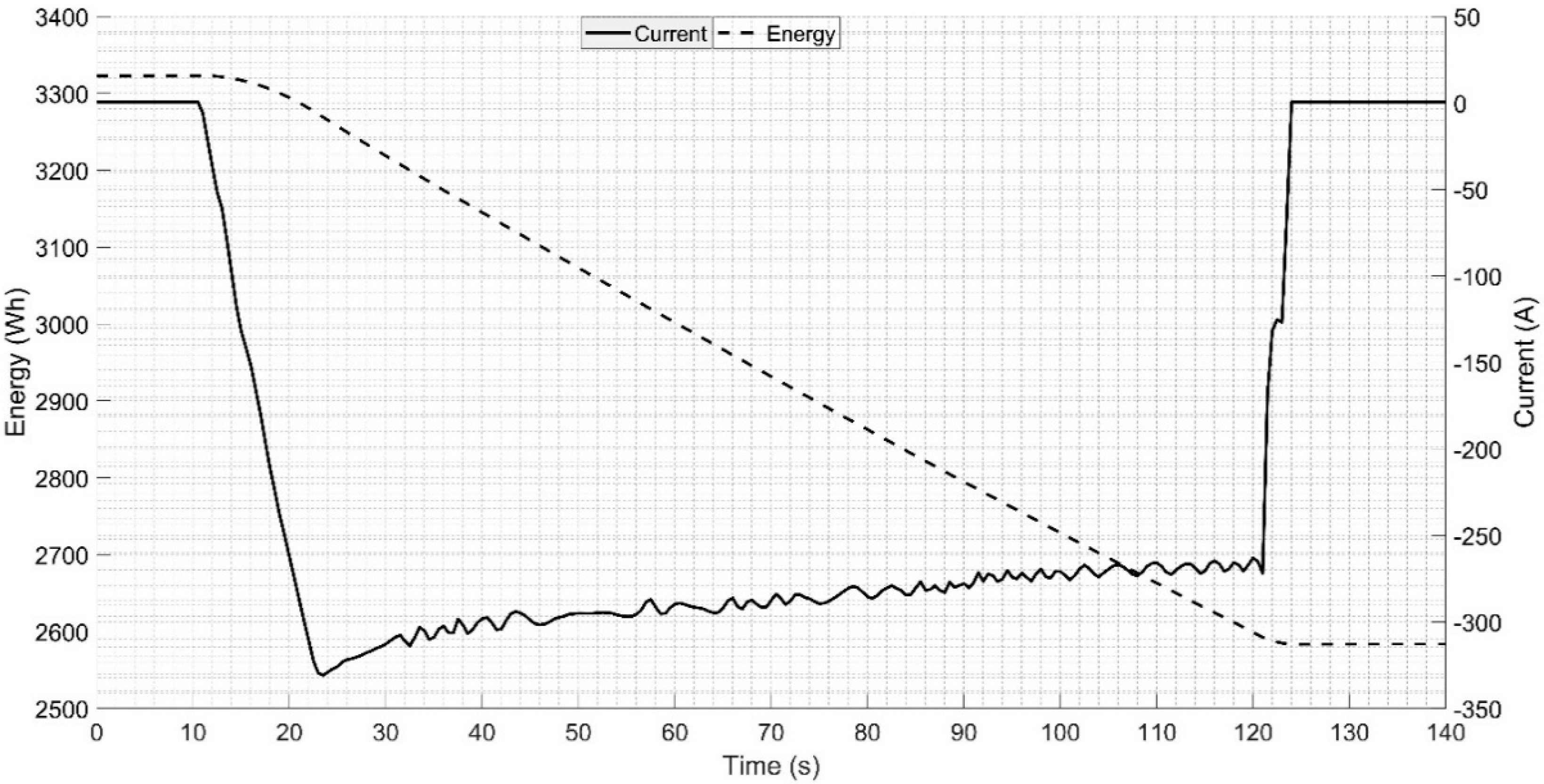

2.3. Project 3 (P3): Hybrid Storage SC and AGM Batteries

3. Results Comparison

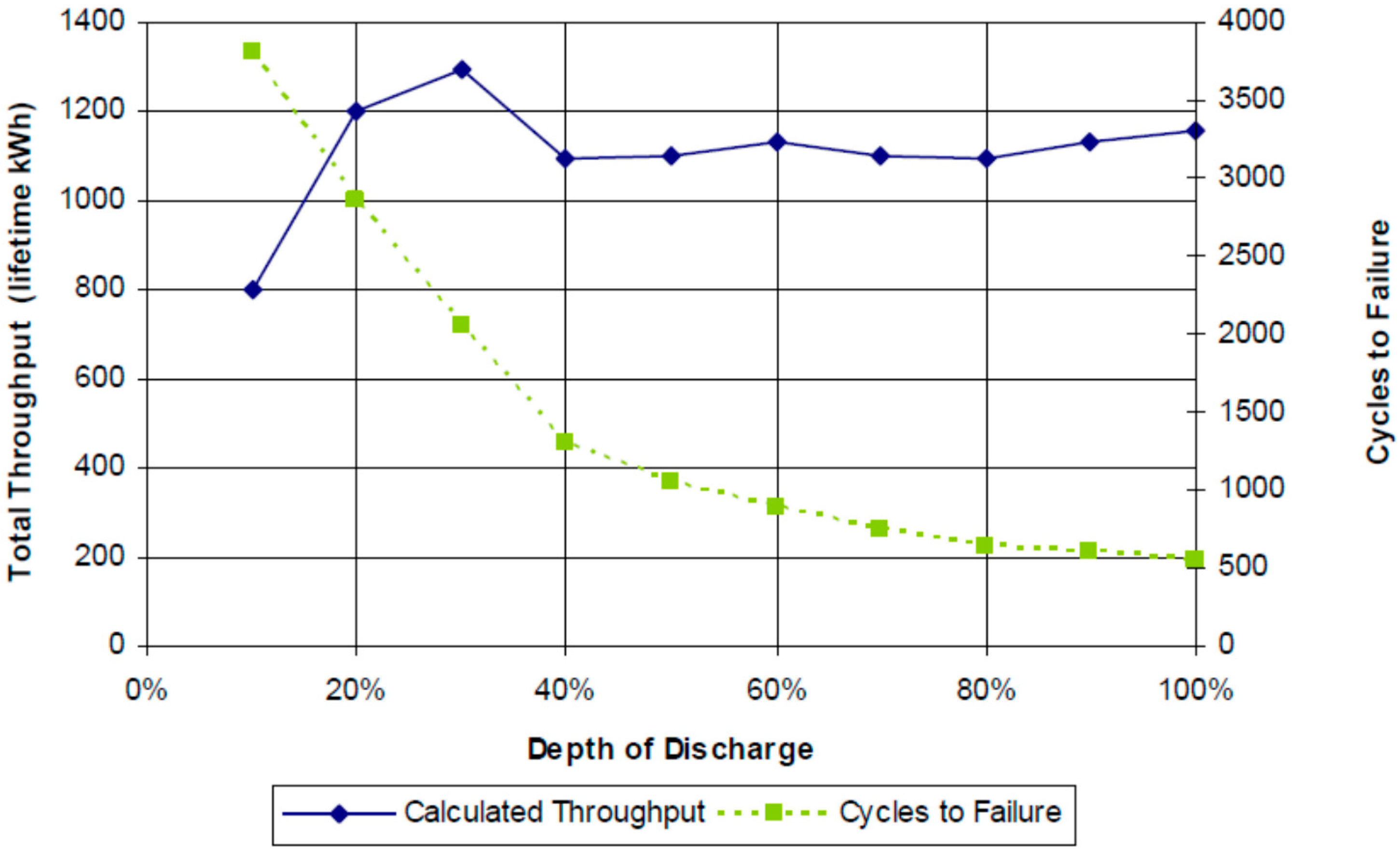

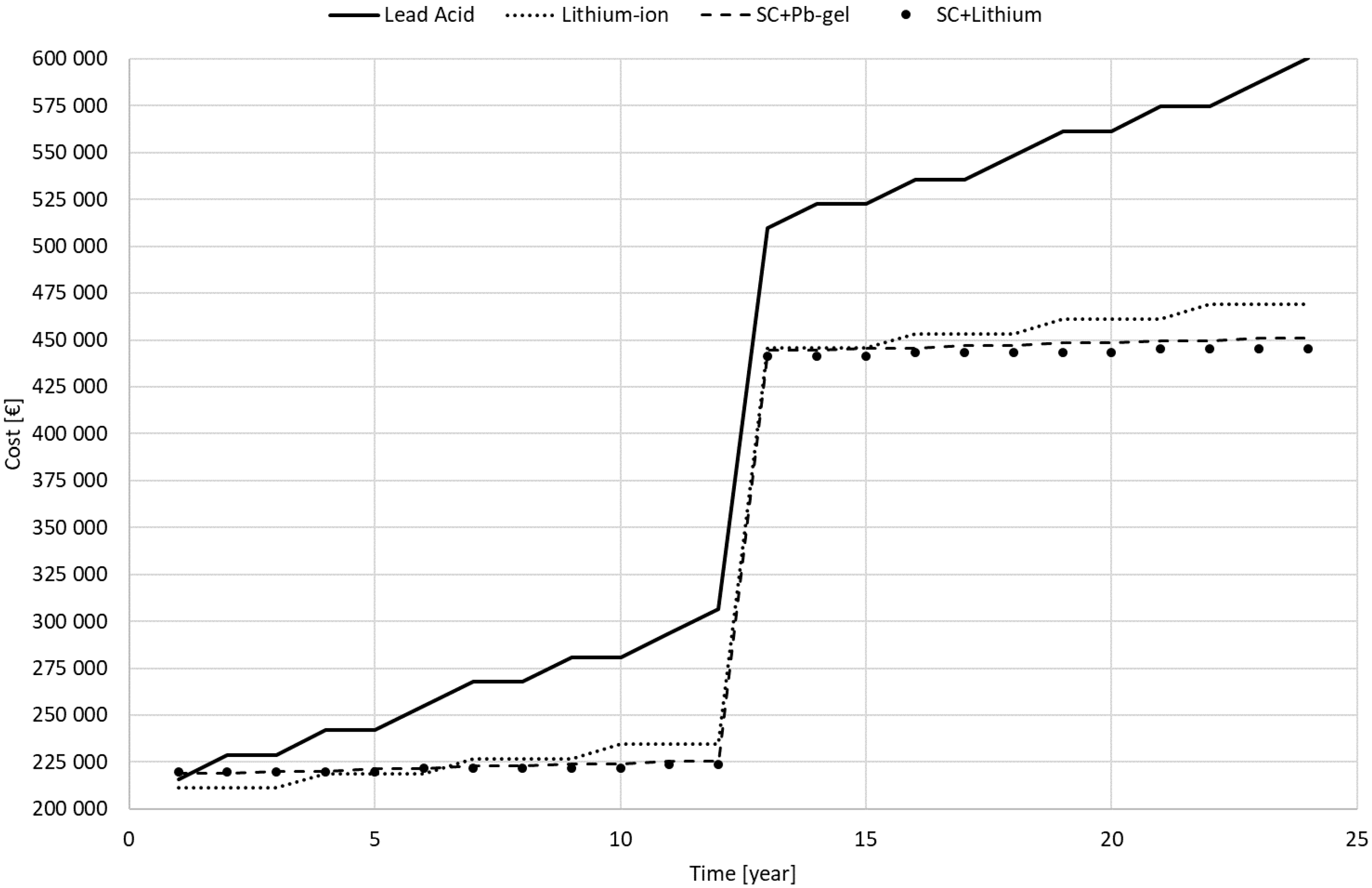

- Lifecycle of P1 and P2 comes from project results.

- Lifecycle of P3 is an estimation based on theory [22] and a maximum DoD of 20%.

- Lifecycle of P4 is evaluated with a mixed approach from theory and results obtained in P2. The LiFePO4 battery lasts 3000 cycles at 80% of DoD, P4 uses only the 40% of DoD so according to [23] its battery lasts three times that of the P2.

- Energy is the total energy stored in the ESS. P1 and P2 need the battery to provide power for traction motor and energy for the daily service, whereas P3 and P4 require less battery capacity. In fact, the presence of SC and fast charge feature (P3 and P4) ensure the energy needs, so, battery is dimensioned with at least 20 kW of power (to supply motor request in case of SC failure).

- Unitary costs refer to available products on the market.

- Range with a single charge is the maximum range without intermediate charging.

- Number of daily full charge represents the number of charges needed daily for the required transport service; each charge refills the battery up to daily initial SoC.

- Life is the expected time in years before replacement due to battery usage, it is the lifecycle parameter divided by annual cycles (number of daily full charge per daily of transport service, 300 days per year). But it must not exceed the battery calendar life (as in the P4, the LiFePO4 has 5 years).

- Lifecycle is provided by manufacturer under nominal working conditions.

- Energy stored is total energy of supercapacitor from maximum voltage to half voltage, as prescribed by manufacturer in order to preserve their life.

- Range with a single charge is the maximum range, it considers the effective energy (up to half nominal voltage).

- Cost due to one bus: some chargers can be used for many buses. The cost is the same paid for prototypes, but it can be reduced with a large-scale production. In other words, the P3 was equipped with flash charge and it used a charger only for forty seconds, then charger required five minutes more to restore its energy before charging another bus. A single charger costs up to twenty thousand Euros.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aneke, M.; Wang, M. Energy storage technologies and real life applications—A state of the art review. Appl. Energy 2016, 179, 350–377. [Google Scholar] [CrossRef]

- Peng, H. Charging Infrastructures for Electric Buses; Politecnico di Milano: Milan, Italy, 2019. [Google Scholar]

- Korkmaz, E. Technically and Economically Viable Future Electricity and Fuel Storage Technologies. Available online: https://aaltodoc.aalto.fi/handle/123456789/40806 (accessed on 20 January 2020).

- European Commission. A Policy Framework for Climate and Energy in the Period from 2020 to 2030. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2014%3A15%3AFIN (accessed on 20 January 2020).

- European Commission. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050. Available online: http://www.europarl.europa.eu/meetdocs/2009_2014/documents/com/com_com(2011)0112_/com_com(2011)0112_en.pdf (accessed on 20 January 2020).

- Green Car Congress. Number of Electric Buses in Europe has Increased from Around 200 to 2200 in 5 years. BusWorld. Available online: https://www.greencarcongress.com/2019/10/20191020-busworld.html (accessed on 20 January 2020).

- European Automobile Manufacturers’ Association (ACEA). ACEA Report: Vehicles in Use. 2019. Available online: https://www.acea.be/uploads/publications/ACEA_Report_Vehicles_in_use-Europe_2019.pdf#page=7 (accessed on 20 January 2020).

- Quéromès, A.; Vogelaar, M.; Huisman, R. Electric Bus Fleets in Europe. Available online: https://www.accuracy.com/wp-content/uploads/2020/01/Perspectives-Print-Electric-bus-v1_anglais.pdf (accessed on 23 January 2020).

- Alessandrini, A.; Cignini, F.; Ortenzi, F.; Pede, G.; Stam, D. Advantages of retrofitting old electric buses and minibuses. Energy Procedia 2017, 126, 995–1002. [Google Scholar] [CrossRef]

- Italian Minister for Economic Development (MISE). DECRETO 1 Dicembre 2015, n. 219. 2016. Available online: https://www.gazzettaufficiale.it/eli/id/2016/01/11/15G00232/sg (accessed on 23 January 2020).

- Parragh, S.N.; Doerner, K.F.; Hartl, R.F. Demand Responsive Transportation. In Wiley Encyclopedia of Operations Research and Management Science; Wiley Online Library: Hoboken, NJ, USA, 15 February 2011; Online ISBN 9780470400531. [Google Scholar]

- Ricci, S. Tecnica ed Economia dei Trasporti; Hoepli: Milano MI, Italy, 1 March 2011. [Google Scholar]

- Ortenzi, F.; Pasquali, M.; Prosini, P.P.; Lidozzi, A.; di Benedetto, M. Design and Validation of Ultra-Fast Charging Infrastructures Based on Supercapacitors for Urban Public Transportation Applications. Energies 2019, 12, 2348. [Google Scholar] [CrossRef]

- Pede, G.; Vellucci, F. Fast-Charge Life Cycle Test on a Lithium-Ion Battery Module. World Electr. Veh. J. 2018, 9, 13. [Google Scholar]

- Cantarella, G.E. Sistemi di Trasporto: Tecnica ed Economia; UTET: Torino, Italy, 2007. [Google Scholar]

- Cartenì, A. Processi decisionali and Pianificazione dei Trasporti; Lulu Press, Inc.: Morrisville, NC, USA, 16 September 2016. [Google Scholar]

- Sheth, A.; Sarkar, D. Life cycle cost analysis for electric vs diesel bus transit in an indian scenario. Int. J. Technol. 2019, 10, 105–115. [Google Scholar] [CrossRef]

- Potkány, M.; Hlatká, M.; Debnár, M.; Hanz, J. Comparison of the Lifecycle Cost Structure of Electric. Naše More 2018, 65, 270–275. [Google Scholar] [CrossRef]

- Wikner, E. Lithium ion Battery Aging: Battery Lifetime Testing and Physics-based Modeling for Electric Vehicle Applications. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2017. [Google Scholar]

- Miranto, A. BU-1003a: Battery Aging in an Electric Vehicle (EV). Battery University. Available online: https://batteryuniversity.com/learn/article/bu_1003a_battery_aging_in_an_electric_vehicle_ev (accessed on 13 February 2020).

- Ortenzi, F.; Pede, G.; Prosini, P.P.; Andrenacci, N. Ageing effects on batteries of high discharge current rate. In EVS30 Symposium; Landesmesse Stuttgart GmbH: Stuttgart, Germany, 2017. [Google Scholar]

- Bindner, H.; Lundsager, P.; Cronin, T.; Manwell, J.F.; Abdulwahid, U.; Baring-Gould, I. Lifetime Modelling of Lead Acid Batteries; Forskningscenter Risoe: Roskilde, Denmark, 2005. [Google Scholar]

- Xu, B.; Oudalov, A.; Andersson, G.; Ulbig, A. Modeling of Lithium-Ion Battery Degradation for Cell Life Assessment. IEEE Trans. Smart Grid 2016, 9, 1131–1140. [Google Scholar] [CrossRef]

- Jongerden, M.; Haverkort, B. Battery Modeling; (CTIT Technical Report Series; No. TR-CTIT-08-01); Design and Analysis of Communication Systems (DACS): London, UK, 2008. [Google Scholar]

- Yang, X.-G.; Zhang, G.; Ge, S.; Wang, C.-Y. Fast charging of lithium-ion batteries at all temperatures. Proc. Natl. Acad. Sci. USA 2018, 115, 7266–7271. [Google Scholar] [CrossRef] [PubMed]

- Baronti, F.; di Rienzo, R.; Moras, R.; Roncella, R.; Saletti, R.; Pede, G.; Vellucci, F. Implementation of the fast charging concept for electric local public transport: The case-study of a minibus. In Proceedings of the IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015. [Google Scholar]

- di Rienzo, R.; Baronti, F.; Vellucci, F.; Cignini, F.; Ortenzi, F.; Pede, G.; Roncella, R.; Saletti, R. Experimental analysis of an electric minibus with small battery and fast charge policy. In Proceedings of the 2016 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Toulouse, France, 2–4 November 2016. [Google Scholar]

- Cignini, F.; Genovese, A.; Ortenzi, F.; Alessandrini, A.; Barbieri, R.; Berzi, L.; Locorotondo, E.; Pierini, M.; Pugi, L. Design of a Hybrid Storage for Road Public Transportation Systems. In IFToMM ITALY; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Ortenzi, F.; Pasquali, M.; Pede, G.; Lidozzi, A.; Benedetto, M. Ultra-fast charging infrastructure for vehicle on-board ultracapacitors in urban public transportation applications. In EVS31, EVTeC and APE; Society of Automotive Engineers of Japan, Inc.: Kobe, Japan, 2018. [Google Scholar]

- Cignini, F.; Genovese, A.; Ortenzi, F.; Alessandrini, A.; Barbieri, R.; Berzi, L.; Locorotondo, E.; Pierini, M.; Pugi, L.; Baldanzini, N.; et al. Structural and energy storage retrofit of an electric bus for high-power flash recharge. Procedia Struct. Integr. 2019, 24, 408–422. [Google Scholar]

- Alessandrini, A.; Cignini, F.; Barbieri, R.; Berzi, L.; Pugi, L.; Pierini, M. Progettazione and Test di un Sistema Ibrido SC-accumulo per la Ricarica Rapida di un bus Alle Fermate; ENEA: Rome, Italy, 2018. [Google Scholar]

- Alessandrini, A.; Cignini, F.; Barbieri, R.; Berzi, L.; Pugi, L.; Genovese, A.; Pierini, M.; Locorotondo, E. A Flash Charge System for Urban Transport. In Proceedings of the International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019. [Google Scholar]

- Ortenzi, F.; Pede, G.; Orchi, S. Technical and economical evalutation of hybrid flash-charging stations for electric public transport. In Proceedings of the 2017 IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017. [Google Scholar]

- Mongird, K.; Fotedar, V.; Viswanathan, V.; Koritarov, V.; Balducci, P.; Hadjerioua, B.; Alam, J. Energy Storage Technology and Cost Characterization Report; HydroWIRES; Pacific Northwest National Lab.(PNNL): Richland, WA, USA, 2019. [Google Scholar]

- Conte, M.; Ortenzi, F.; Genovese, A.; Vellucci, F. Hybrid battery-supercapacitor storage for an electric forklift: A life-cycle cost assessment. J. Appl. Electrochem. 2014, 44, 1–10. [Google Scholar] [CrossRef]

- Skeleton Technologies GmbH. A new approach for ultracapacitor-battery hybrid energy storage solutions. In International Workshop on Supercapacitors and Energy Storage; Skeleton Technologies GmbH: Bologna, Italy, 2019. [Google Scholar]

| Parameters | Unit | 1 | 2 | 3 | 4 | 5 | Average | Total |

|---|---|---|---|---|---|---|---|---|

| Duration | s | 241.0 | 491.0 | 122.0 | 438.5 | 576.0 | 388.7 | 68,411 |

| Distance | km | 1.08 | 1.68 | 0.68 | 2.49 | 2.97 | 1.0 | 176 |

| Total consumption | Wh | 432.3 | 846.0 | 286.8 | 942.9 | 1,218 | 491.3 | 86,463 |

| Commercial speed | km/h | 16.2 | 12.3 | 19.9 | 20.4 | 18.5 | 11.6 | n.a. |

| Average consumption | Wh/km | 398.5 | 503.3 | 424.0 | 378.9 | 410.6 | 489.4 | n.a. |

| Parameters | Unit | 1 | 2 | 3 | 4 | 5 | Average * | Total * |

|---|---|---|---|---|---|---|---|---|

| Duration | s | 440 | 440 | 405 | 640 | 529 | 491 | 2454 |

| Distance | m | 1104 | 1599 | 1147 | 1180 | 1340 | 1274 | 6370 |

| Total consumption | Wh | 574 | 510 | 435 | 550 | 557 | 535 | 2673 |

| Commercial speed | km/h | 9.0 | 13.1 | 10.2 | 6.6 | 9.1 | 9.3 | n.a. |

| Average consumption | Wh/km | 511 | 313 | 364 | 441 | 396 | 422 | n.a. |

| Parameter | Unit | 1 | 2 | 3 | 4 | 5 | Average | Total |

|---|---|---|---|---|---|---|---|---|

| Duration | sec | 272.7 | 263.1 | 307.5 | 252.5 | 250.0 | 279.2 | 3629.3 |

| Distance traveled | km | 1.15 | 0.96 | 1.00 | 0.58 | 0.86 | 0.9 | 11.5 |

| Total energy consumption | Wh | 515.5 | 487.6 | 421.9 | 325.1 | 416.4 | 457.7 | 5950.5 |

| Energy consumption due to auxiliary services | Wh | 83.4 | 79.5 | 92.9 | 77.7 | 76.4 | 84.8 | 1102.9 |

| Traction motor energy consumption | Wh | 432.1 | 408.1 | 329.0 | 247.4 | 340.1 | 372.9 | 4847.6 |

| Average energy consumption | Wh/km | 447.7 | 509.8 | 422.1 | 562.7 | 483.5 | 528.0 | n.a. |

| Commercial speed | km/h | 15.2 | 13.1 | 11.7 | 8.2 | 12.4 | 11.7 | n.a. |

| Energy provided by battery | Wh | 266.5 | 241.2 | 175.6 | 131.3 | 152.5 | 208.4 | 2709.1 |

| Energy provided by supercapacitors | Wh | 249.0 | 246.3 | 246.2 | 193.8 | 263.9 | 249.3 | 3241.4 |

| Supercap rate usage | % | 58% | 60% | 75% | 78% | 78% | 68% | n.a. |

| Battery Ah | Ah | 3.5 | 3.2 | 2.3 | 1.7 | 2.0 | 2.7 | 35.6 |

| Nominal Parameter | Unit | Value |

|---|---|---|

| Purchase cost (bus without battery) | € | 200,000 |

| Lifespan | year | 12 |

| Average consumption (OEM data) | kWh/km | 0.5 |

| Daily mileage required (min) | km | 100 |

| Curb weight (without battery) | kg | 2370 |

| Motor power (DC-brushed) | kW | 21 (25 peak) |

| Motor torque | Nm | 235 (at 950 RPM) |

| Component | Description | Unit | Project 1 | Project 2 | Project 3 | Project 4 |

|---|---|---|---|---|---|---|

| Lead–acid | LiFePO4 | SC + PbAGM | SC + Lithium | |||

| ESS weight | Battery, electronics and other mechanical additions total weight | kg | 1500 | 800 | 1100 | 700 |

| Component | Parameter | Unit | P1 | P2 | P3 | P4 |

|---|---|---|---|---|---|---|

| lead–acid | LiFePO4 | SC + PbAGM | SC + Li | |||

| Battery | Lifecycle | # | 800 | 3000 | 3000 | 9000 |

| Energy | kWh | 43.2 | 17.3 | 8.6 | 4.3 | |

| Unitary cost | €/kWh | 150 | 450 | 150 | 450 | |

| Range with a single charge | km | 67.2 | 30.7 | 11.6 | 5.8 | |

| Total cost | € | 12,960 | 7776 | 1296 | 1944 | |

| Number of daily full charge | # | 1 | 3 | 5 | 5 | |

| Life | Year | 2.7 | 3.3 | 2.0 | 5.0 | |

| Supercap | Lifecycle | # | Na | Na | 1,000,000 | 1,000,000 |

| Energy | kWh | Na | Na | 0.4 | 0.4 | |

| Unitary costs | €/kWh | Na | Na | 37,000 | 37,000 | |

| Range with a single charge | km | Na | Na | 0.7 | 0.7 | |

| Number of daily full charge | # | Na | Na | 141 | 141 | |

| Life | Year | Na | Na | 23.6 | 23.6 | |

| Total cost | € | Na | Na | 15,170 | 15,170 | |

| Charger | Cost due to one bus | € | 3000 | 3333 | 2500 | 2500 |

| Charger life | Year | 12 | 12 | 12 | 12 |

| Parameter | Unit | Project 1 lead–acid | Project 2 LiFePO4 | Project 3 SC + PbAGM | Project 4 SC + Lithium |

|---|---|---|---|---|---|

| Actualized Costs | € | 487,156 | 392,504 | 381,810 | 377,731 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cignini, F.; Genovese, A.; Ortenzi, F.; Alessandrini, A.; Berzi, L.; Pugi, L.; Barbieri, R. Experimental Data Comparison of an Electric Minibus Equipped with Different Energy Storage Systems. Batteries 2020, 6, 26. https://doi.org/10.3390/batteries6020026

Cignini F, Genovese A, Ortenzi F, Alessandrini A, Berzi L, Pugi L, Barbieri R. Experimental Data Comparison of an Electric Minibus Equipped with Different Energy Storage Systems. Batteries. 2020; 6(2):26. https://doi.org/10.3390/batteries6020026

Chicago/Turabian StyleCignini, Fabio, Antonino Genovese, Fernando Ortenzi, Adriano Alessandrini, Lorenzo Berzi, Luca Pugi, and Riccardo Barbieri. 2020. "Experimental Data Comparison of an Electric Minibus Equipped with Different Energy Storage Systems" Batteries 6, no. 2: 26. https://doi.org/10.3390/batteries6020026

APA StyleCignini, F., Genovese, A., Ortenzi, F., Alessandrini, A., Berzi, L., Pugi, L., & Barbieri, R. (2020). Experimental Data Comparison of an Electric Minibus Equipped with Different Energy Storage Systems. Batteries, 6(2), 26. https://doi.org/10.3390/batteries6020026