Considerations when Modelling EV Battery Circularity Systems

Abstract

1. Introduction

2. Frame of Reference

2.1. Life Cycle Impact of Electric Vehicles and Batteries

2.2. The Battery Role in the Electric Vehicle

2.3. The 3R System for Vehicle Industry

3. Materials and Methods

- Description the overall electrical vehicle system and general impact factors, R&D—First, four semi-structured interviews were performed together with a workshop (with 30 participants from industry and academia) on future Swedish driveline development, in order to describe the overall electric vehicle system and general impact factors on the system.

- Current state and technical development of Li battery recycling—Additionally, empirical data were gathered in a workshop on recycling of lithium-ion batteries (arranged by Chalmers Competence Centre for Recycling, Gothenburg, 18 January 2018) with participants from both industry and academia. This second workshop focused on the current state and technical development of Li-battery recycling. The above events were then supplemented by seven semi-structured interviews with vehicle and battery producers (sales) and two interviews with recycling system developers.

- Future trends and R&D—In cooperation with the research project TransMission, a development meeting on the ongoing transition of the driveline industry took place (arranged by TransMission, Gothenburg, 6 September 2018), and a third workshop (arranged by TransMission Industry Insights, Eskilstuna) on foresight [32,33] regarding the driveline industry was held 19 September 2018. To catch the most recent research and development, the authors also made observations at three conferences (i) Circular Materials Conference, Gothenburg, 7–8 March 2018; (ii) Conference on Circular Economy of Batteries: Production and Recycling, Gothenburg, 24–26 September 2018; (iii) Going Green—CARE INNOVATION 2018, Vienna, 26–29 November 2018) and research network meetings on electrification (Chalmers) and in the EU funded regional project CAR.

4. Results

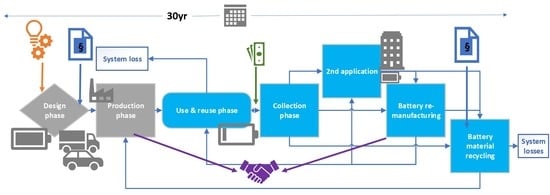

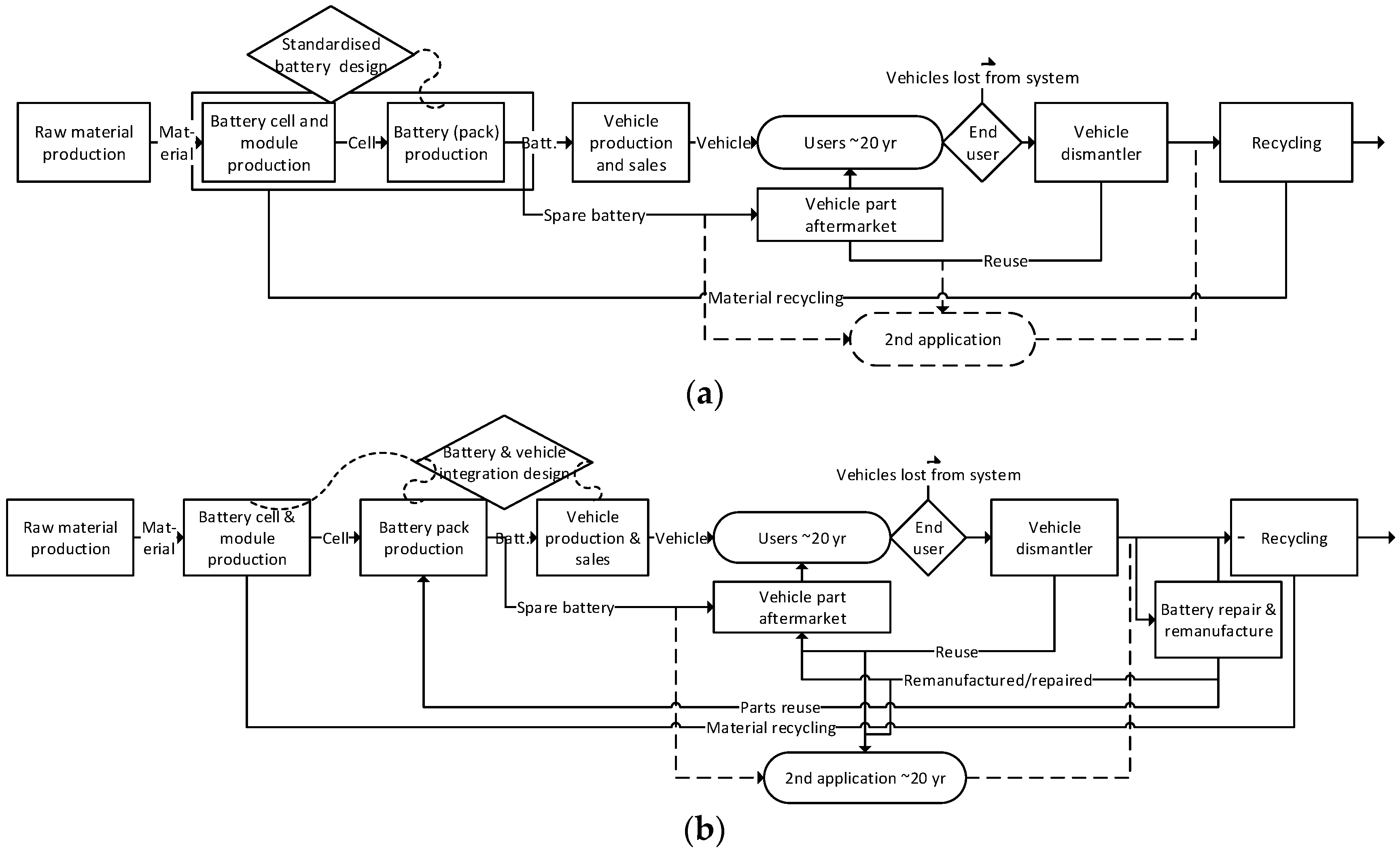

4.1. Current and Expected 3R Systems

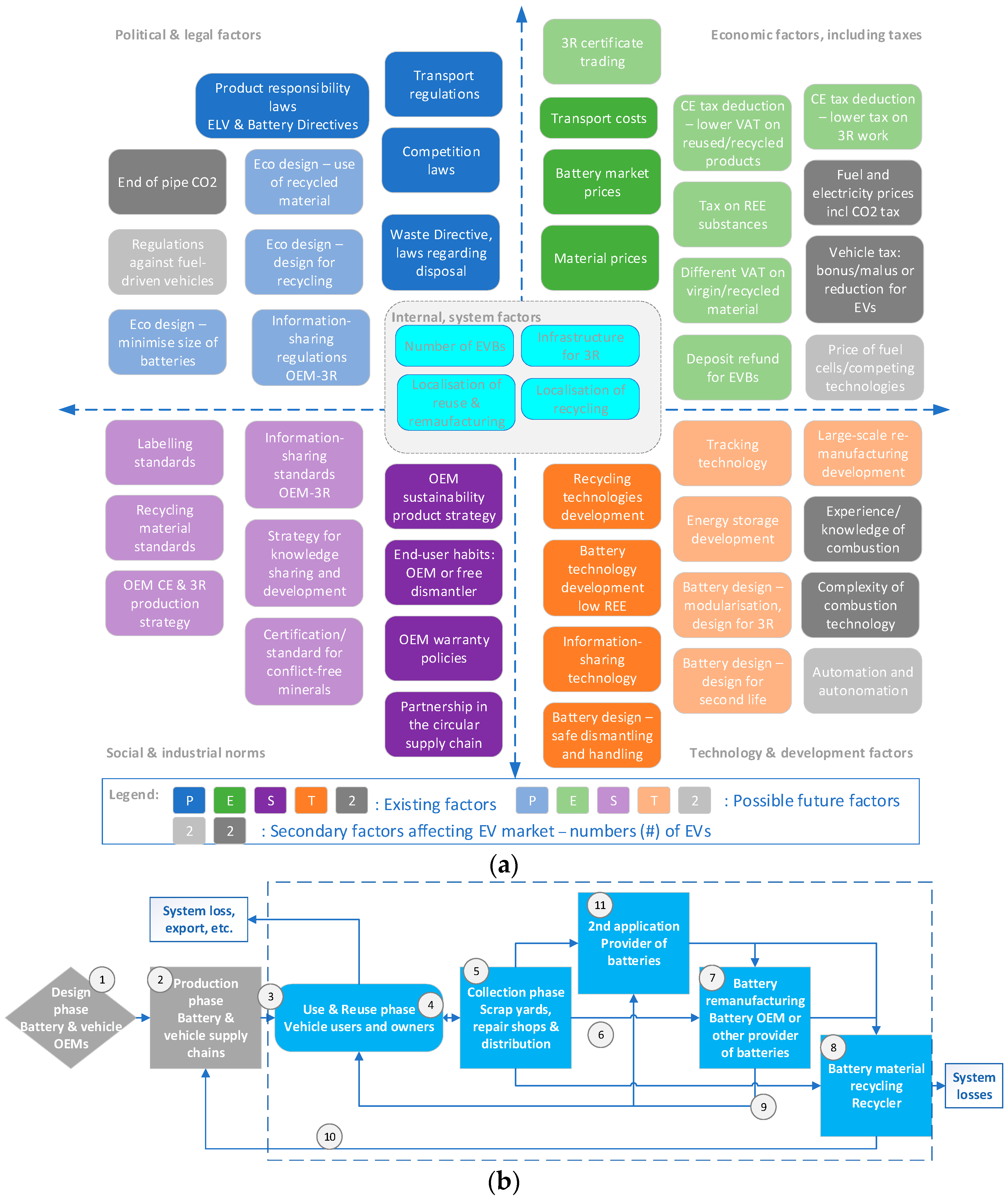

4.2. Influencing Factors Identified in the PEST Analysis

4.2.1. Political and Legal Factors (P)

4.2.2. Economic Factors Including Taxes (E)

4.2.3. Social and Industrial Norms (S)

4.2.4. Technology and Development Factors (T)

4.2.5. Coupling between Perspectives and Internal 3R Factors

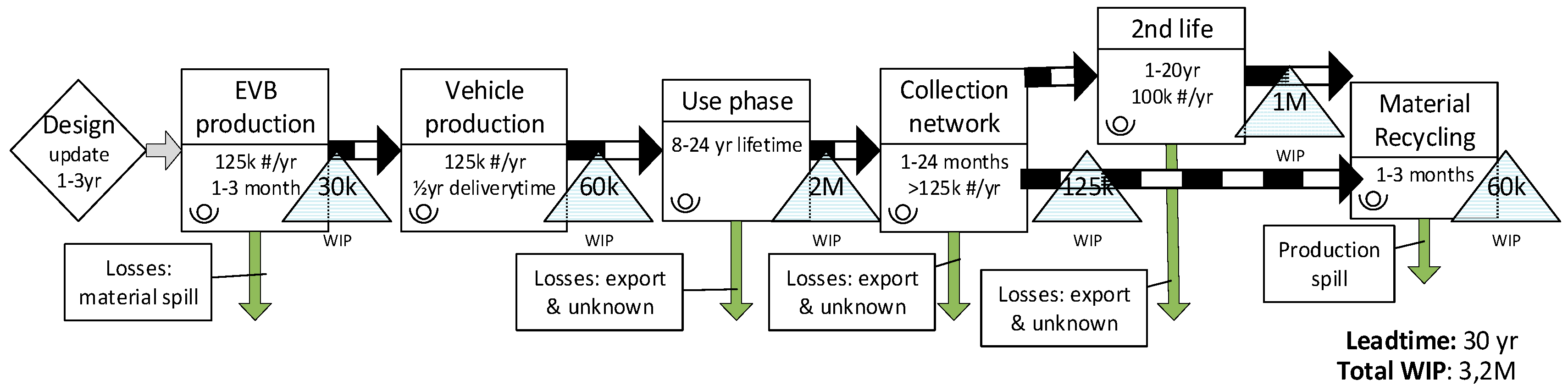

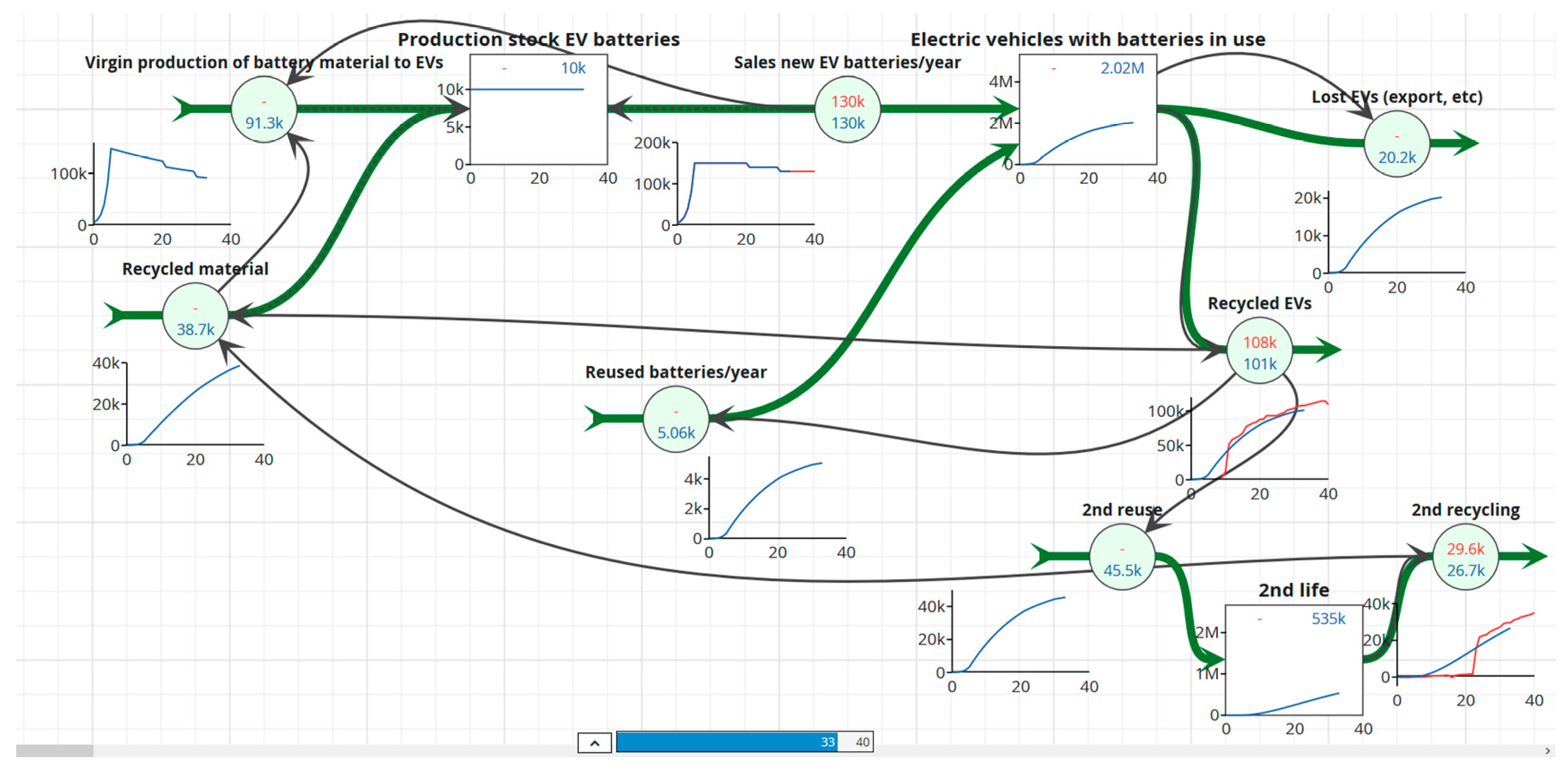

4.3. Exemplifying the Time Effects in the Case of Sweden

4.4. Discussion and Modelling Implications

- What timeframe is the modelled system and input data valid for?

- Are all significant changing factors modelled as variables?

- Are all other factors stated and modelled as constant?

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

- Design phase

- Production phase

- Sales to user—Use and reuse phase

- End of use of battery—User and reuse phase

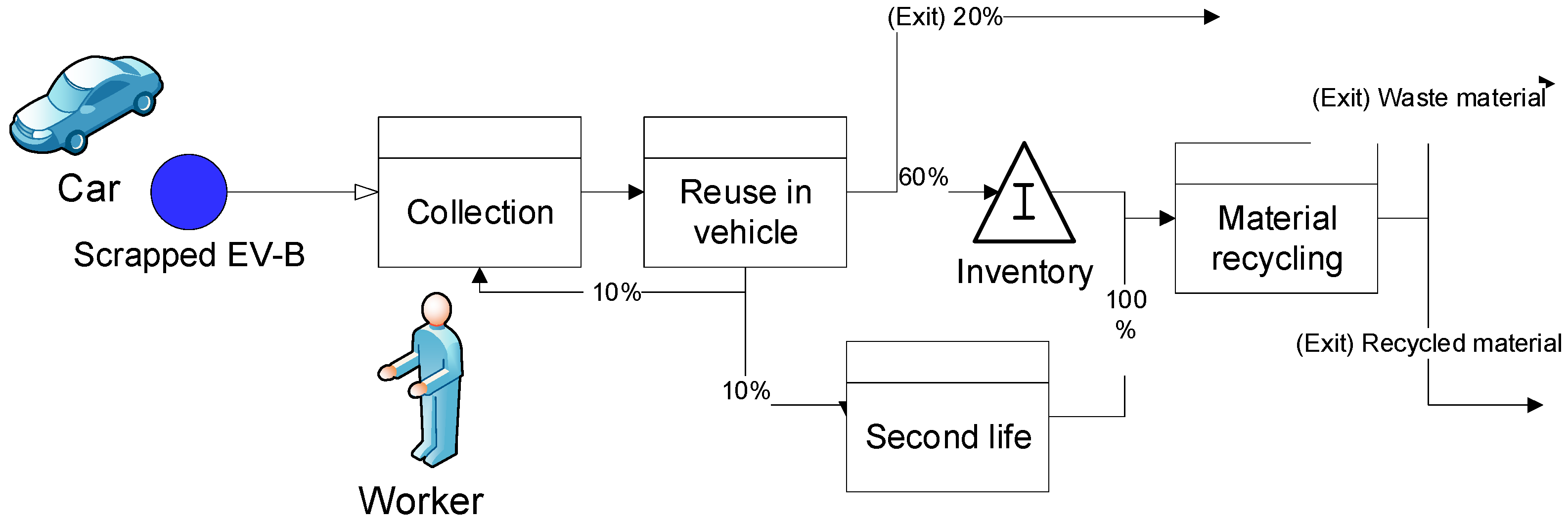

- Collection phase

- 3R-system infrastructure and connections

- Battery remanufacturing

- Battery material recycling

- Provision of remanufactured batteries and or reused parts

- Provision of recycled battery material

- Second application, non-vehicle reuse of batteries and remanufactured batteries.

| Factor | Description | Point of in-Fluence | point of Effect | Comment | Empirics |

|---|---|---|---|---|---|

| P: Political and legal factors | PoI | PoE | Comment | Empirics | |

| Product responsibility | ELV dir. recycling targets 95% | 1 | 8 | In place—weak follow up | OEM interviews, WS, car-sales interviews |

| Product responsibility | Battery dir. recycling targets 50% | 1 | 8 | In place for collected batteries | Some battery OEM |

| Competition/aftermarket law | Not allowed to “abuse a dominant position” | 3 | 4 | In place—weakening | Literature |

| Waste dir. disposal laws | Illegal to dispose in landfill | 8 | 8 | Seen as self evident by interviewees | Experts, some interview |

| Transportation regulation | Batteries as haz. goods transportation | 6 | 6 | Dangerous goods/hazardous mtrl | Recycler |

| Ecodesign—use recycled materials | Demand x% recycled mtrl | 1 | 2,1 | Influences market price for Re | Suggested in WS |

| Ecodesign—efficiency | Minimise battery size | 1 | 2 | So far demands on en-efficiency | Not mentioned/adressed |

| Ecodesign—DfRecycling | Demand on recycling instructions etc | 1 | 8 | “Could give great effect” | Mentioned in WS&int. |

| Information sharing | Demand status and dissasembly instr. | 1 | 5 | Important according to recyclers | WS & recycler int. & CEB |

| (EU) export regulations | export control | 1 | 4 | Since ELV dir. is not valid outside EU | Car OEM interview |

| End of pipe—CO2 | Ecodesign CO2 /fuel consumption | 1 | 2 | Secondary factor | OEM interviews |

| Rule out fuelled vehicles | Regulations stopping fuelled vehicles | 3 | 3 | Buss lane, parking, etc. | News |

| E: Economic including taxes | PoI | PoE | Comment | Empirics | |

| Material prices | Market prices of each of (rare) material | 2 | 10 | depend on demand, | OEM interviews |

| Battery market price | Price of batteries | 3 | 3 | decreasing? | Some OEM interviréws |

| Transport cost | Cost to transport Haz material | 6 | 6 | High, decreasing | Recycler |

| Deposit-refund systems | Refund fee at purchase-return at recycling | 3 | 5 | Defined per kWh? Time aspect? | WS/interviews |

| CE tax deduction—work | Tax reduction on repair/reuse operations | 7, 8 | 9, 10 | Exist for e.g. bike repairs. | Not mentioned |

| CE tax deduction—product | Lower VAT on Re-X products | 3 | 9, 10 | Increase sales of reused batteries | mentioned in WS |

| CE tax deduction—recycl.material | Tax on virgin or tax cut for recycled mtrl | 2 | 10 | Mining tax vs recycling tax | Recycler |

| 3R certificate trading | E.g. recycling certificate trading | 10 | 3 | Tried in UK, not clear success | Mentioned in WS |

| Scarce material taxes | Taxes/tolls on certain products/materials | 2 | 10 | E.g. Cobolt tax | Literature |

| Vehicle tax | Bonus malus on vehicle taxation | 3 | 3 | Increase EV market share | OEM interviews |

| Fuel price—CO2 cost | CO2 fee | 3 | 3 | Increase EV market share | OEM interviews |

| Fuel prices—fuel | Price and taxes of fossile fuel | 3 | 3 | Increase EV market share | OEM interviews |

| Fuel prices—electricity | Price and taxes of electricity | 3 | 3 | Decrease EV market share | Secondary |

| Price for competing tecnhnol. | E.g. price of fuel cells | 3 | 3 | Decrease EV market share | Some OEM interviréws |

| S: Social and industrial norms | PoI | PoE | Comment | Empirics | |

| OEM warranty policies | OEM warranty policies and regulations | 3 | 4 | Warranty and takeback agreement | Vehicle OEM |

| Business strategy-product | Corporate product strategies (economic) | 1 | 3, 5 | Green product strategy- | Battery OEM |

| Labelling—standards | Labelling standards (combined Tracking?) | 3 | 5, 6 | Important according to recyclers | Recycler int, WS & CEB |

| Industrial information sharing | Standard information syst. (from BMS) | 2, 5 | 4, 5 | Not widely used. | Recycler |

| End user habits/behaviour | Users used to going to OEM certified dealer/scrapper | 4 | 5 | OEM-controlled 3R | Vehicle OEM |

| End user habits/behaviour | Users used to using “free part dealers” | 4 | 5 | Free market 3R | Not mentioned |

| Business strategy for CE & 3R | Customers + OEM aim at 3R production | 2 | 9, 10 | 3R awareness | Mentioned in WS |

| Business strategy—partnership | Partnership in (circular) supply chain (e.g. material flow partnership) | 3 | 5, 7 | Negotiate information sharing | Literature |

| Business strategy—sharing innov. | Different strategies for knowledge sharing | 1 | 5, 7, 8 | E.g. open innovation in SC | Literature |

| Recycling material standards | Industrial standards for recycled mtrl | 8 | 10 | May increase rec. market (value) | Suggested in WS |

| Conflict-free materials | Standard or certification of conflict-free/ethical demands | 9 | 10 | Raise price and or incr. recycling | Not mentioned |

| Cluster | T: Technological factors/trends | PoI | PoE | Comment | Empirics |

| Recycling technologies | Recycling technology development | 8 | 8 | Chemical & mechanical separation | Recycler Battery OEM |

| Battery development | New chemistry (low Co low Li etc.) | 1 | 2 | Low REE - organic dev. | |

| Information sharing system | Status check of batteries—state of health of battery | 1 | 4 | Manual today, developed/standardised digital | Recycler, battery OEM |

| Battery design safe dismantling and handling | Hazardousness of (handling) used batteries automation of dissasembly | 1 | 4…8 | Ongoing dev. | Recycler |

| Battery design—modularisation | Design for module/cell replacement | 1 | 5 | Important for reconfiguration | Recycler, + conf.litt |

| Battery design—Df-2nd-life | Design for second purpose (second life) | 1 | 11 | Reconfigurable | Battery OEM, V-OEM |

| Tracking technology | Track where the battery/vehicle is. | 3 | 5 | What if export outside EU | Vehicle OEM |

| Energy store dev. | Energy storage developments | 11 | 9 | Park battery vs. valuable use | Battery OEM |

| Reman development | Introduction of large scale remfg./repair | 7 | 7 | Not developed due to low volumes | Recycler |

| Powertrain technology | Experience in industry | 1 | 3 | Used to fueldrive | Some OEM interviews |

| Complexity of fuel drive | Complexity of fossil-free driveline system | 2 | 3 | Electric car is less complex | OEM interviews |

| Smart systems | Automation and digitalisation | 1 | 3 | EVs and AI dev. | OEM interviews |

| Internal factors | System factors (inner) | PoI | PoE | ||

| Number of Evs | Vehicle stock | 4 | 4 | Low today | Everyone mention this |

| Infrastructure 3Rsystem | Relations and infrastructure btw. actors | 6 | 6 | OEM 3R relations | OEM |

| Reuse/reman system | Localisation of disassembly and remfg. | 5,7 | 5, 7 | Distributed for other carparts | Recycler |

| Recycling localisation | Localisation of or flexible recycling | 8 | 8 | Co-location wt. mine/melt/mfg. | CEB |

References

- Zhang, X.; Li, L.; Fan, E.; Xue, Q.; Bian, Y.; Wu, F.; Chen, R. Toward sustainable and systematic recycling of spent rechargeable batteries. Chem. Soc. Rev. 2018, 47, 7239–7302. [Google Scholar] [CrossRef]

- Ortego, A.; Valero, A.; Valero, A.; Iglesias, M. Downcycling in automobile recycling process: A thermodynamic assessment. Resour. Conserv. Recycl. 2018, 136, 24–32. [Google Scholar] [CrossRef]

- Hao, H.; Qiao, Q.; Liu, Z.; Zhao, F. Impact of recycling on energy consumption and greenhouse gas emissions from electric vehicle production: The China 2025 case. Resour. Conserv. Recycl. 2017, 122, 114–125. [Google Scholar] [CrossRef]

- Ortego, A.; Valero, A.; Valero, A.; Restrepo, E. Vehicles and Critical Raw Materials: A Sustainability Assessment Using Thermodynamic Rarity. J. Ind. Ecol. 2018, 22, 1005–1015. [Google Scholar] [CrossRef]

- Yu, A.; Wei, Y.; Chen, W.; Peng, N.; Peng, L. Life cycle environmental impacts and carbon emissions: A case study of electric and gasoline vehicles in China. Transp. Res. Part D Transp. Environ. 2018, 65, 409–420. [Google Scholar] [CrossRef]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life cycle assessment of lithium-ion batteries for plug-in hybrid electric vehicles–Critical issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Romare, M.; Dahllöf, L. The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries; IVL: Stockholm, Sweden, 2017. [Google Scholar]

- Olsson, L.; Fallahi, S.; Schnurr, M.; Diener, D.; van Loon, P. Circular Business Models for Extended EV Battery Life. Batteries 2018, 4, 57. [Google Scholar] [CrossRef]

- Kumar, S.; Yamaoka, T. System dynamics study of the Japanese automotive industry closed loop supply chain. J. Manuf. Technol. Manag. 2007, 18, 115–138. [Google Scholar] [CrossRef]

- Natkunarajah, N.; Scharf, M.; Scharf, P.J.P.C. Scenarios for the return of lithium-ion batteries out of electric cars for recycling. Procedia CIRP 2015, 29, 740–745. [Google Scholar] [CrossRef]

- Kumar, V.; Sutherland, J.W. Sustainability of the automotive recycling infrastructure: Review of current research and identification of future challenges. Int. J. Sustain. Manuf. 2008, 1, 145–167. [Google Scholar] [CrossRef]

- Gross, S. End-of-Life Vehicles Management in Europe-Driving the Change; Lund University: Lund, Sweden, 2008. [Google Scholar]

- Wegener, K.; Andrew, S.; Raatz, A.; Dröder, K.; Herrmann, C. Disassembly of electric vehicle batteries using the example of the Audi Q5 hybrid system. Procedia CIRP 2014, 23, 155–160. [Google Scholar] [CrossRef]

- Aguirre, K.; Eisenhardt, L.; Lim, C.; Nelson, B.; Norring, A.; Slowik, P.; Tu, N. Lifecycle Analysis Comparison of a Battery Electric Vehicle and a Conventional Gasoline Vehicle; California Air Resources Board: Sacramento, CA, USA, 2012; Volume 6, pp. 107–111. [Google Scholar]

- Berg, H.; Zackrisson, M. Perspectives on environmental and cost assessment of lithium metal negative electrodes in electric vehicle traction batteries. J. Power Sources 2019, 415, 83–90. [Google Scholar] [CrossRef]

- Hall, D.; Lutsey, N. Effects of Battery Manufacturing on Electric Vehicle Life-Cycle Greenhouse Gas Emissions. Available online: http://www.theicct.org/publications/EV-battery-manufacturing-emissions (accessed on 15 February 2019).

- Zackrisson, M. Life Cycle Assessment of Long Life Lithium Electrode for Electric Vehicle Batteries: Cells for Leaf, Tesla and Volvo Bus; Swerea IVF: Mölndal, Sweden, 2017; p. 50. [Google Scholar]

- Yoney, D. 7 Electric Cars With The Biggest Batteries. Available online: https://insideevs.com/seven-electric-cars-biggest-batteries/ (accessed on 15 February 2019).

- EVDB. Tesla Model S 75D. Available online: https://ev-database.org/car/1070/Tesla-Model-S-75D#charging (accessed on 14 March 2019).

- Zackrisson, M. De Vanligaste Litiumjonbatterierna Kemier och Produktionsvolymer 2016 Och Framåt; Swerea IVF: Mölndal, Sweden, 2017. [Google Scholar]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Pavel, C.C.; Thiel, C.; Degreif, S.; Blagoeva, D.; Buchert, M.; Schüler, D.; Tzimas, E. Role of substitution in mitigating the supply pressure of rare earths in electric road transport applications. Sustain. Mater. Technol. 2017, 12, 62–72. [Google Scholar] [CrossRef]

- Sakti, A.; Michalek, J.J.; Fuchs, E.R.; Whitacre, J.F. A techno-economic analysis and optimization of Li-ion batteries for light-duty passenger vehicle electrification. J. Power Sources 2015, 273, 966–980. [Google Scholar] [CrossRef]

- Rothgang, S.; Baumhöfer, T.; van Hoek, H.; Lange, T.; De Doncker, R.W.; Sauer, D.U. Modular battery design for reliable, flexible and multi-technology energy storage systems. Appl. Energy 2015, 137, 931–937. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A. Integration issues of lithium-ion battery into electric vehicles battery pack. J. Clean. Prod. 2016, 113, 1032–1045. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A.J.R.; Reviews, S.E. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Lindsten, P.-O. Det här är Sveriges 500 största företag 2015 (“These are Swedens 500 largest enterprices” in Swedish). Available online: https://www.va.se/nyheter/2015/12/16/det-har-ar-sveriges-500-storsta-foretag-2015/ (accessed on 28 December 2018).

- SCB. Näringslivets (SNI Sektion A-S exkl K och O) Förädlingsvärde per Region (län) Fördelat på Bransch (SNI Sektioner) 2013, Procent; Statistiska Centralbyrån: Stockholm, Sweden, 2015. [Google Scholar]

- FKG. Fordonsindustrin. Available online: http://www.fkg.se/fordonsindustrin/ (accessed on 30 January 2019).

- Vogel, L.; Vogel, J. Automobile Sector and Competition Law: An Overview of EU and National Case Law. In Competition Law Digest: A Synthesisis of EU and National Leading Cases; Jenny, F., Charbit, N., Eds.; Institute of Competition Law: Paris, France, 2010. [Google Scholar]

- EU. Regulation (EC) No 443/2009 of the European Parliament and of the Council of 23 April 2009 setting emission performance standards for new passenger cars as part of the Community’s integrated approach to reduce CO2 emissions from light-duty vehicles. Off. J. Eur. Union 2009, 140, 5–6. [Google Scholar]

- Ruff, F. The advanced role of corporate foresight in innovation and strategic management—Reflections on practical experiences from the automotive industry. Technol. Forecast. Soc. Chang. 2015, 101, 37–48. [Google Scholar] [CrossRef]

- Rohrbeck, R.; Battistella, C.; Huizingh, E. Corporate foresight: An emerging field with a rich tradition. Technol. Forecast. Soc. Chang. 2015, 101, 1–9. [Google Scholar] [CrossRef]

- Shahbazi, S.; Sjödin, C.; Bjelkemyr, M.; Wiktorsson, M. A foresight study on future trends influencing material consumption and waste generation in production. In Proceedings of the 24th International Conference on Flexible Automation and Intelligent Manufacturing FAIM2014, San Antonio, TX, USA, 20–23 May 2014. [Google Scholar]

- Yılmaz, S.; Ustaoğlu, M. Electric Vehicles Production in Turkish Automotive Industry and Sectoral PEST Analisys. Procedia-Soc. Behav. Sci. 2013, 75, 10–17. [Google Scholar] [CrossRef]

- Mehlhart, G.; Hermann, A.; Baron, Y.; Kosińska, I. Assessment of the Implementation of Directive 2000/53/EU on End-of-Life Vehicles (the ELV Directive) with Emphasis on the End of Life Vehicles of Unknown Whereabouts; EU Publications: Luxembourg, Luxembourg, 2018. [Google Scholar]

- Huisman, J.; Habib, H.; Brechu, M.G.; Downes, S.; Herreras, L.; Løvik, A.N.; Wäger, P.; Cassard, D.; Tertre, F.; Mählitz, P. ProSUM: Prospecting Secondary raw materials in the Urban mine and Mining wastes. In Proceedings of the Electronics Goes Green 2016+(EGG), Berlin, Germany, 6–9 September 2016; pp. 1–8. [Google Scholar]

- Andersson, M. Towards Recycling of Scarce Metals from Complex Products. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2018. [Google Scholar]

- Aaltonen, M.; Peng, C.; Wilson, B.P.; Lundström, M. Leaching of Metals from Spent Lithium-Ion Batteries. Recycling 2017, 2, 20. [Google Scholar] [CrossRef]

- Wittstock, R.; Pehlken, A.; Wark, M. Challenges in automotive fuel cells recycling. Recycling 2016, 1, 343. [Google Scholar] [CrossRef]

- Sakai, S.; Yoshida, H.; Hiratsuka, J.; Vandecasteele, C.; Kohlmeyer, R.; Rotter, V.S.; Passarini, F.; Santini, A.; Peeler, M.; Li, J. An international comparative study of end-of-life vehicle (ELV) recycling systems. J. Mater. Cycles Waste Manag. 2014, 16, 1–20. [Google Scholar] [CrossRef]

- Elwert, T.; Goldmann, D.; Römer, F.; Buchert, M.; Merz, C.; Schueler, D.; Sutter, J. Current developments and challenges in the recycling of key components of (hybrid) electric vehicles. Recycling 2016, 1, 25. [Google Scholar] [CrossRef]

- EU. Commission Regulation (EU) No 461/2010 of 27 May 2010 on the application of Article 101(3) of the Treaty on the Functioning of the European Union to categories of vertical agreements and concerted practices in the motor vehicle sector. In Document 32010R0461; Commission, E., Ed.; EUR-Lex: Brussels, Belgium, 2010; Volume 461. [Google Scholar]

- Jensen, C.; Felix, J.; Söderman, M.L.; Alongi, S.; Skenhall, T.R.; Rapport, B. Utvärdering av Förändrad Demontering och Återvinning av Uttjänta Fordon i Sverige; IVL Swedish Environmental Research Institute: Gothenburg, Sweden, 2012; Volume 2086. [Google Scholar]

- Dalhammar, C.; Machacek, E.; Bundgaard, A.; Zacho, K.O.; Remmen, A. Addressing Resource Efficiency through the Ecodesign Directive: A Review of Opportunities and Barriers; Nordic Council of Ministers: København, Denmark, 2014. [Google Scholar]

- Mohan, T.K.; Amit, R. Dismantlers’ dilemma in end-of-life vehicle recycling markets: A system dynamics model. Ann. Oper. Res. 2018, 1–29. [Google Scholar] [CrossRef]

- Bulach, W.; Schüler, D.; Sellin, G.; Elwert, T.; Schmid, D.; Goldmann, D.; Buchert, M.; Kammer, U. Electric vehicle recycling 2020: Key component power electronics. Waste Manag. Res. 2018, 36, 311–320. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, D.; Wang, T.; Hu, S. Policies on end-of-life passenger cars in China: Dynamic modeling and cost-benefit analysis. J. Clean. Prod. 2015, 108, 1140–1148. [Google Scholar] [CrossRef]

- Kierkegaard, S.J.C.L.; Review, S. Charging up the batteries: Squeezing more capacity and power into the new EU Battery Directive. Comput. Law Secur. Rev. 2007, 23, 357–364. [Google Scholar] [CrossRef]

- Wegener, K.; Chen, W.H.; Dietrich, F.; Dröder, K.; Kara, S. Robot assisted disassembly for the recycling of electric vehicle batteries. Procedia CIRP 2015, 29, 716–721. [Google Scholar] [CrossRef]

- Li, J.; Barwood, M.; Rahimifard, S. Robotic disassembly for increased recovery of strategically important materials from electrical vehicles. Robot. Comput. Integr. Manuf. 2018, 50, 203–212. [Google Scholar] [CrossRef]

- Sperling, D. Three Revolutions: Steering Automated, Shared, and Electric Vehicles to a Better Future; Island Press: Washington, DC, USA, 2018. [Google Scholar]

- NVV. Med de Nya Svenska Klimatmålen i Sikte (With Aim at the New Swedish Climate Goals, in Swedish); Naturvårdsverket (Swedish EPA): Stockholm, Sweden, 2017. [Google Scholar]

- Küpper, D.; Kuhlmann, K.; Wolf, S.; Pieper, C.; Xu, G.; Ahmad, J. The Future of Battery Production for Electric Vehicles; Boston Consulting Group: Boston, MA, USA, 2018. [Google Scholar]

- Metro. Kolla livslängden på din bil. Available online: https://www.metro.se/artikel/kolla-livsl%C3%A4ngden-p%C3%A5-din-bil-xr (accessed on 30 January 2019).

- SCB. Personbilar i Trafik 1923–2017, Tidsserie; SCB/Trafikanalys, Ed.; Statistikmyndigheten SCB (Statistiska Centralbyrån): Stockholm, Sweden, 2018. [Google Scholar]

- Schönemann, M.; Bockholt, H.; Thiede, S.; Kwade, A.; Herrmann, C. Multiscale simulation approach for production systems. Int. J. Adv. Manuf. Technol. 2019, 1–18. [Google Scholar] [CrossRef]

| Area | Type of Data | Empirics |

|---|---|---|

| A. Overall description of electrical vehicle system and general impact factors | Interviews | 4 semi-structured interviews |

| Workshops & observations | Workshop 1. “TransMission” (30 participants from industry and academy working with development and research of driveline and production development in mid-Sweden) | |

| B. Current state and technical development of Li battery recycling | Workshops & observations | Workshop 2. “Li-ion scarcity and recycling” (ca 20 external participants from battery and recycling industry and academy) |

| Interviews | 7 semi-structured interviews (vehicle and battery producers/salespersonell), 2 open interviews (recycling system developers) | |

| C. Future trends and R&D | Workshops & observations | Workshop 3. Fore sight—TRM (13 participants from driveline industry/production system developers)TransMission development meeting (8 experts in driveline industry development) |

| Conference discussion & observationss | 3 conferences: Circular material Conference 2018,Circular Economy of Batteries: Production and Recycling 2018, Going Green—Care Innovation 2018 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurdve, M.; Zackrisson, M.; Johansson, M.I.; Ebin, B.; Harlin, U. Considerations when Modelling EV Battery Circularity Systems. Batteries 2019, 5, 40. https://doi.org/10.3390/batteries5020040

Kurdve M, Zackrisson M, Johansson MI, Ebin B, Harlin U. Considerations when Modelling EV Battery Circularity Systems. Batteries. 2019; 5(2):40. https://doi.org/10.3390/batteries5020040

Chicago/Turabian StyleKurdve, Martin, Mats Zackrisson, Mats I. Johansson, Burcak Ebin, and Ulrika Harlin. 2019. "Considerations when Modelling EV Battery Circularity Systems" Batteries 5, no. 2: 40. https://doi.org/10.3390/batteries5020040

APA StyleKurdve, M., Zackrisson, M., Johansson, M. I., Ebin, B., & Harlin, U. (2019). Considerations when Modelling EV Battery Circularity Systems. Batteries, 5(2), 40. https://doi.org/10.3390/batteries5020040