1. Introduction

Vehicle electrification is beneficial to society because it offers greater fuel mileage for hybrid vehicles, lower net greenhouse gas emissions, and lower fuel and operating costs. The long-term movement away from “mild” hybrids, where the electric motor gives a performance-assist to full hybrids, and electric vehicles (EVs), has led to developments in battery technologies, most of which use lithium-ion (Li-ion) chemistries. Due to their higher energy density, Li-ion batteries are the industry standard for EVs [

1,

2]. Although the use of electric vehicle (EV) vehicles with Li-ion batteries reduces greenhouse gases caused by the use of fossil fuels, there are some disadvantages to their use. The key concerns with using Li-ion batteries are an increase in cost, weight, size, and the greater material and financial investment that must be made at the beginning of the battery’s useful life [

3].

When Li-ion batteries from EVs reach their end-of-life (EOL), they can be recycled to recapture some of the materials. However, recycling batteries is not an economical proposition, as the materials being used to create EV batteries are decreasing in recyclable value, with the shift to LiFePO

4, and because EV batteries typically retain 80% of their originally manufactured energy storage capacity when they are removed from functioning vehicles [

4,

5]. The 80% capacity estimation is a rule-of-thumb approximation that is used to roughly determine the condition of a Li-ion EV battery when it is removed from a vehicle. This particular rule-of-thumb is commonly used in research to help determine a benchmark for second-use battery performance [

6,

7,

8,

9]. As the voltage being drawn in the battery’s drive-use phase is constant, a similar decline in energy is observed due to the proportional relationship between capacity and energy. However, in practice, the repurposing of an EV battery would require the use of battery testing infrastructure that would be used to confirm the battery state-of-health (SOH) and energy storage capacity of the battery. This step would be essential as the SOH and remaining energy storage capacity of the battery would depend on the battery’s first use and capacity. A potential evaluation system is discussed in

Section 3.

As EV batteries typically leave vehicles with most of their energy and capacity intact, it is essential that new applications are developed to better utilize EV batteries during their use phase are developed. To extend the useful life of the EV battery, the pack can be re-purposed for a secondary use which delays the battery recycling. In a battery re-purposing scheme, the Li-ion battery is used in a stationary application to provide energy storage for renewable energy integration, to charge other EVs or to provide backup power. In

Table 1 below, a list of current EV batteries is given with their in-use and repurposed energy (kWh) for plug-in hybrid electric vehicles, (PHEV), electric vehicles (EV) and hybrid electric vehicles (HEV).

As the slow increase in Canadian sales of hybrid-electric vehicles (HEV), plug-in hybrid-electric vehicles (PHEV) and EVs continues, in conjunction with the increased penetration of renewable energy sources, there is a new scenario of electrical supply and demand instability [

15]. The use of energy storage devices, such as re-purposed battery packs, can be used to help manage the electric loads on the grid. This load-shifting is a significant necessity of future smart-grid developments, which have been shown to have economic benefits for consumers [

16].

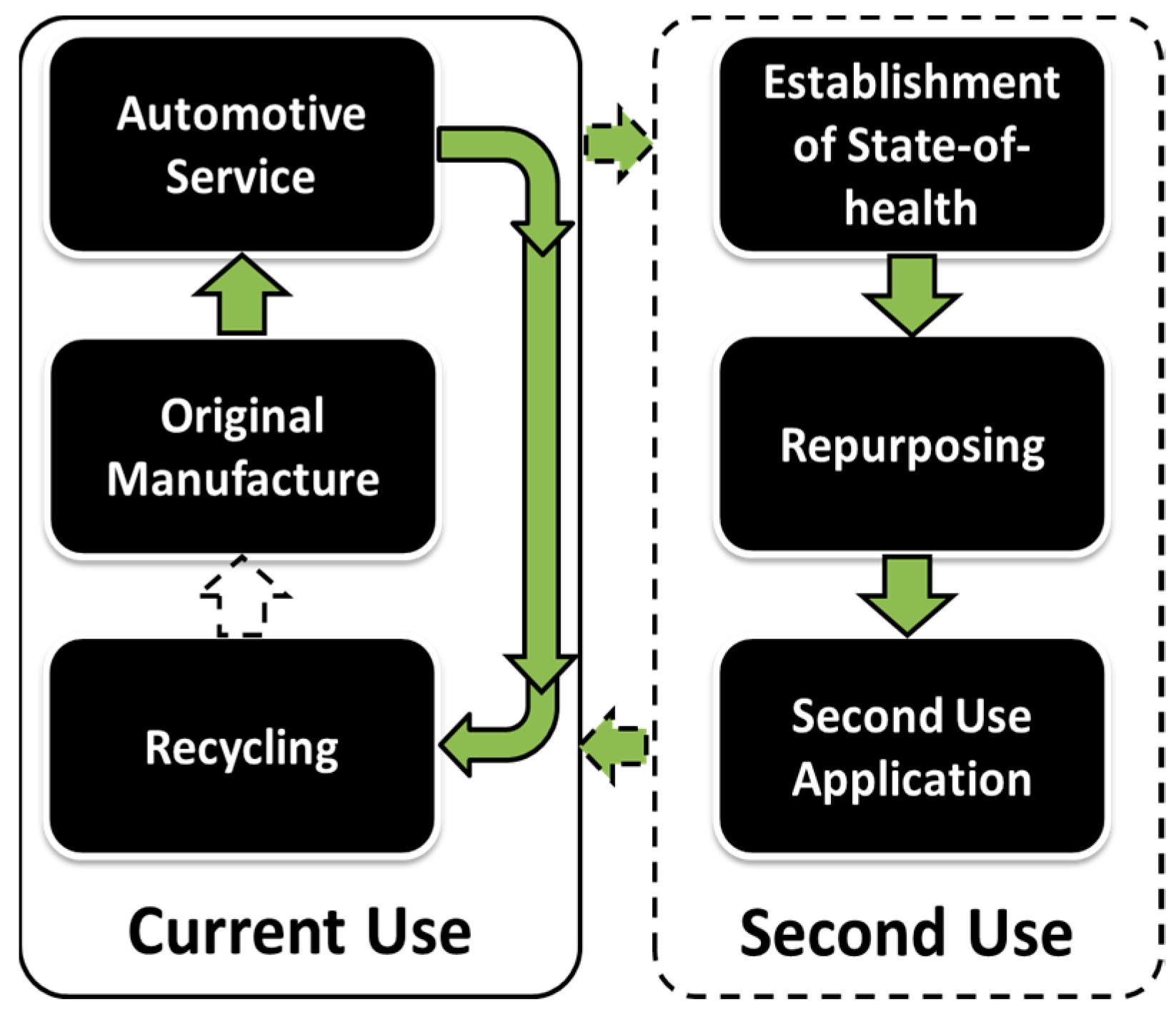

The lifecycle of Li-ion batteries has been explored with a focus on comparing current practices for EV batteries at their EOL, to looking at the potential for second-use applications, as described in

Figure 1 [

8]. By re-purposing EV batteries for stationary energy storage application, there is a significant potential greenhouse gas emissions reduction of 56%, or 24 tonnes of CO

2e, over the total 18-year lifetime of the battery [

8]. The sources of greenhouse gas reduction primarily comes from the use of PHEVs over conventional gasoline vehicles and by offsetting the use of coal and natural gas power with the potential use of renewable power supported by a second-use EV battery.

Re-purposing EV battery packs for secondary applications can significantly increase their overall lifespan. When applied to a second use, there is a much more stable setting for the EV battery. During the automotive service life, the Li-ion batteries must meet rapidly fluctuating demands for acceleration and deceleration that are dependent on the vehicle’s driver. In the second use, however, the fluctuation in energy demand and charge is smaller, which helps the battery to maintain its energy storage capacity longer. Additionally, when the batteries are used in stationary applications, the batteries can be stored in a way that optimizes climate control as there are less size and weight restrictions.

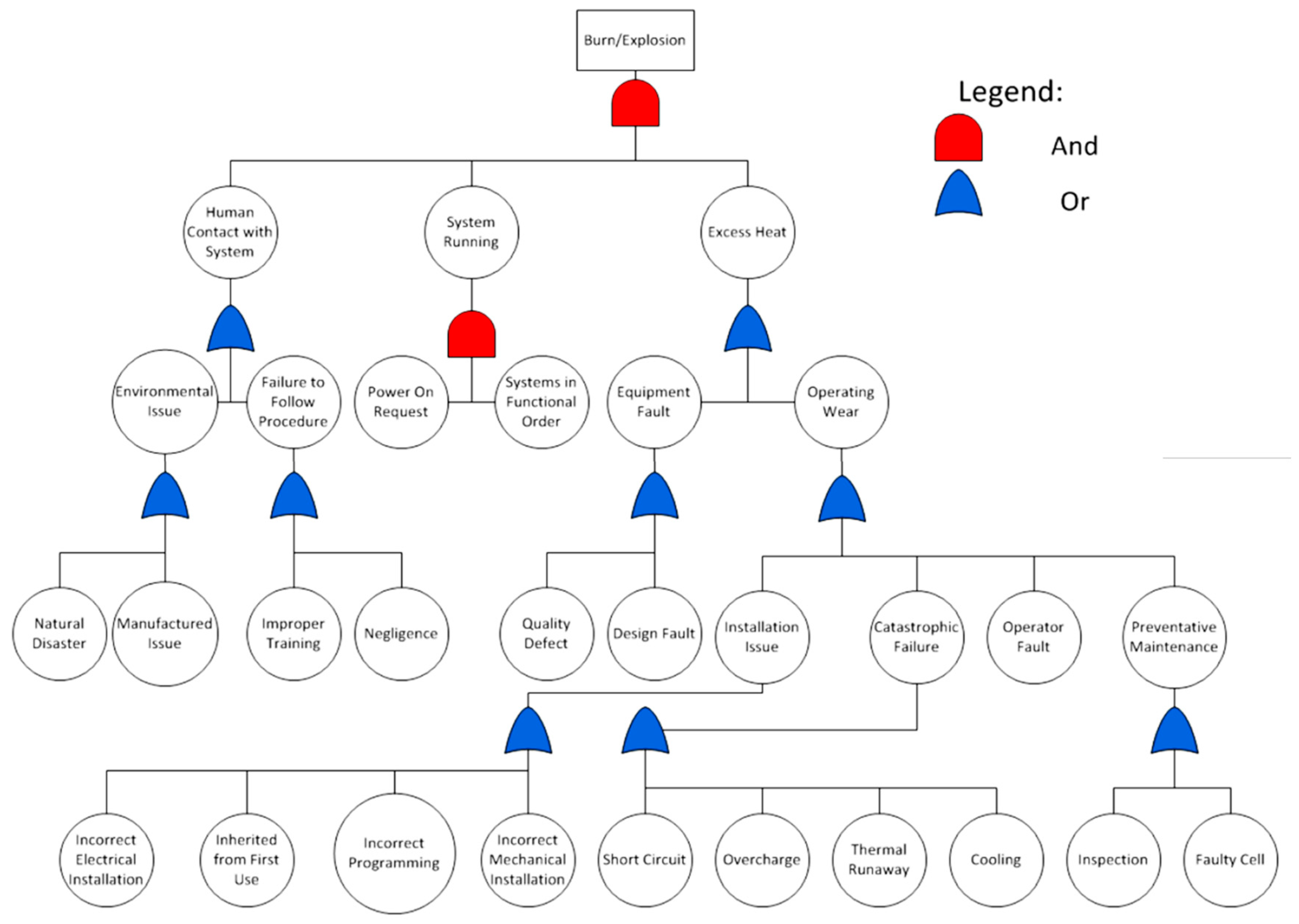

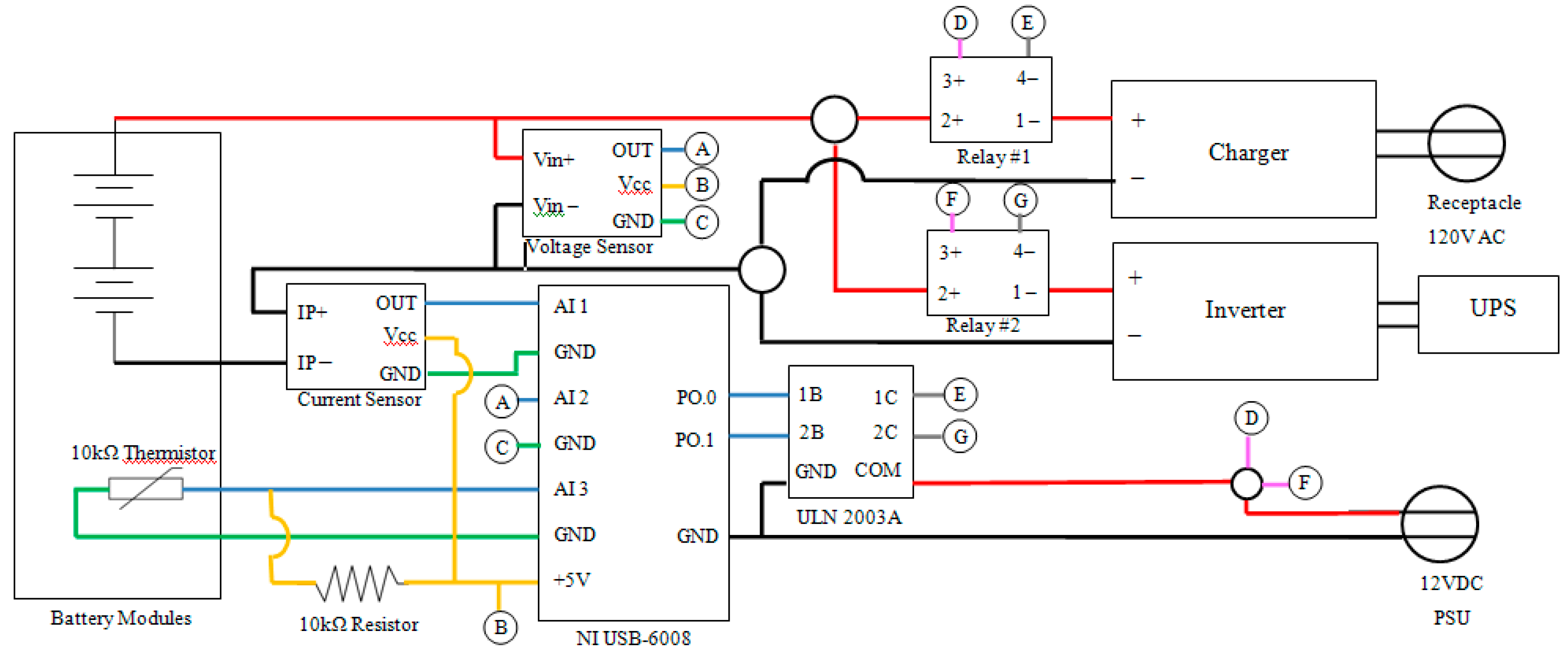

Despite the many benefits of re-purposing Li-ion batteries, there are factors that impede the widespread adoption of this concept. One impediment is that a design methodology and certifications to ensure product safety are not currently available for repurposed EV batteries. Herein, the authors describe a design methodology for building a stationary energy storage system using re-purposed battery packs for use in Canada. A thorough analysis of the current standards is performed to determine the necessary criteria for the design, including the completion of a failure modes and effects analysis (FMEA) and fault tree analysis (FTA) to identify potential safety risks for construction, operation, and installation. Finally, a proof-of-concept of the design is built to ensure the functionality of the system.

1.1. Canadian Electricity Supply Mix

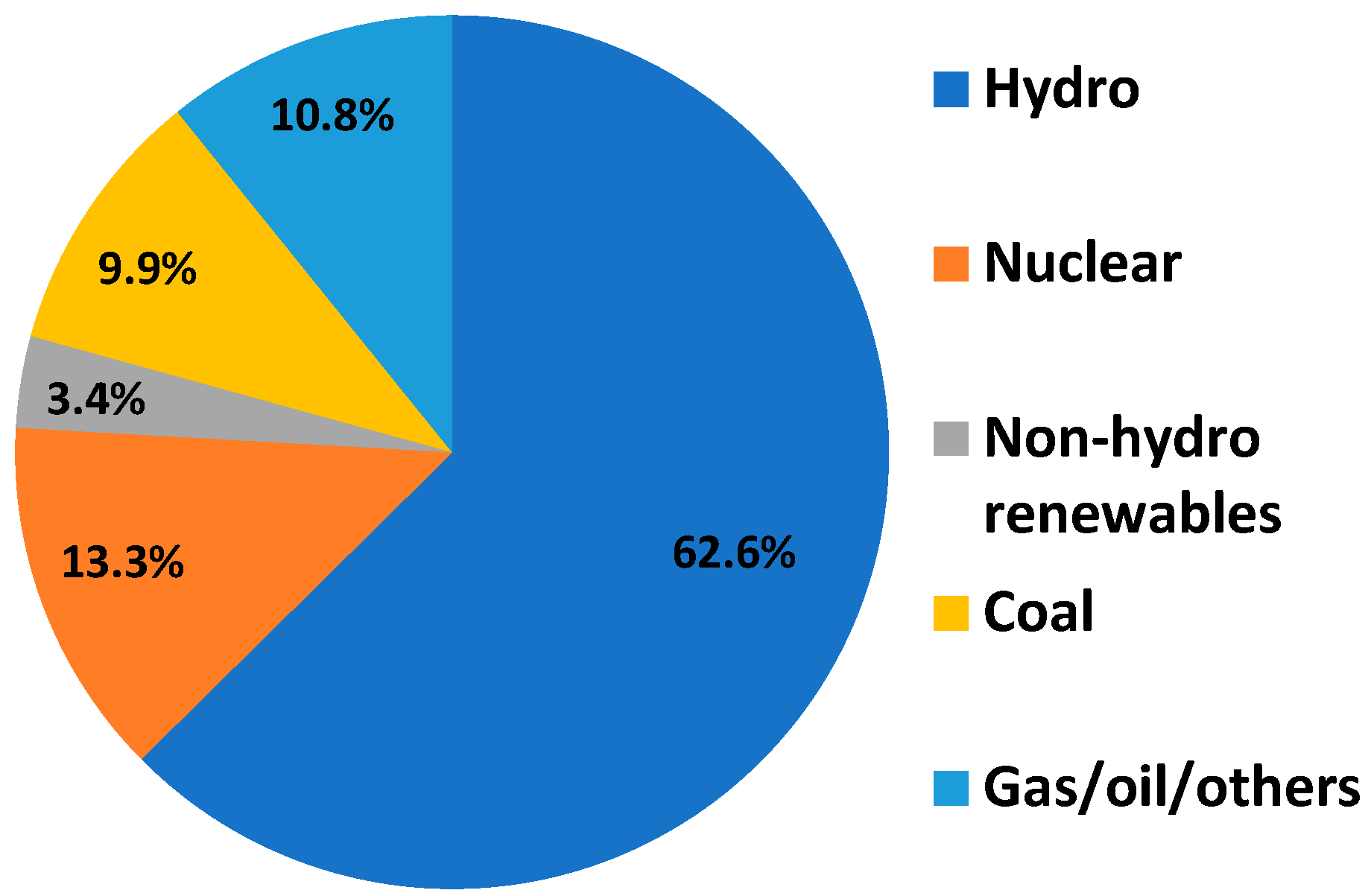

As the focus of this research is to develop a design for the application of re-purposed EV batteries to residential energy storage in Canada, it is important to understand Canada’s energy supply. In order to supply electricity to the millions of households, business, and industries in Canada, a wide variety of energy sources are utilized.

Figure 2 details the Canada’s electricity generations mix.

The largest suppliers for electricity generation are provided by hydroelectricity and nuclear [

18]. Although, the hydroelectricity supply can be somewhat increased and decreased depending on electricity demands, nuclear only provides a base load of power and cannot simply be “ramped up” or “down” depending on electricity demand transients. To account for these fluctuations, non-renewable energy sources are utilized during points of increased demand, but these sources typically produce greenhouse gases adding to the world climate change problem. Non-hydro renewable energy sources would be an excellent method of providing energy during transient demand conditions, but one of their greatest disadvantages is that supply and demand mismatches can occur. A mismatch in this context refers to the time that electricity is generated does not match the demand point and, thus, is not capable of being effectively utilized in Canada’s energy grid.

This demand and supply mismatch issue, though, can be remedied if the energy could be stored in a separate source after it has been produced. Technologies that can be utilized to store energy from renewable technologies include: flywheels, compressed gas, hydrogen gas production, and electrochemical techniques [

19]. As the energy required for a single household is relatively small in comparison to the turbines and large-scale solar arrays that these technologies have been designed for, many of these energy storage techniques would not be economical and would require a significant architectural footprint. Battery technologies, such as lithium-ion, though, have a significant energy density, so they will be able to cover the energy requirements and only take up a small footprint within a household.

Industry leaders have seen the benefits of dedicated home battery packs for smoothing grid demands and have released their own products in the market. In April 2015, for example, Tesla announced the Powerwall, a 6.4 kWh battery pack that can be installed in a residence for daily cycle applications [

20]. Combining the Powerwall with zero-emission power sources, such as solar, allows consumers to charge their battery pack using “clean” power to their homes and utilize it at the time it is demanded. After Tesla’s release of the Powerwall, Nissan released a design for vehicle-to-grid technology called xStorage [

21]. Unlike other energy storage systems, xStorage differentiates itself by utilizing re-purposed batteries from Nissan’s electric fleet. As a result of the roll out of xStorage, Nissan has made a design change to their battery packs making them more modular so that they are easier to remove by technicians and be transferred over to second-life applications [

21].

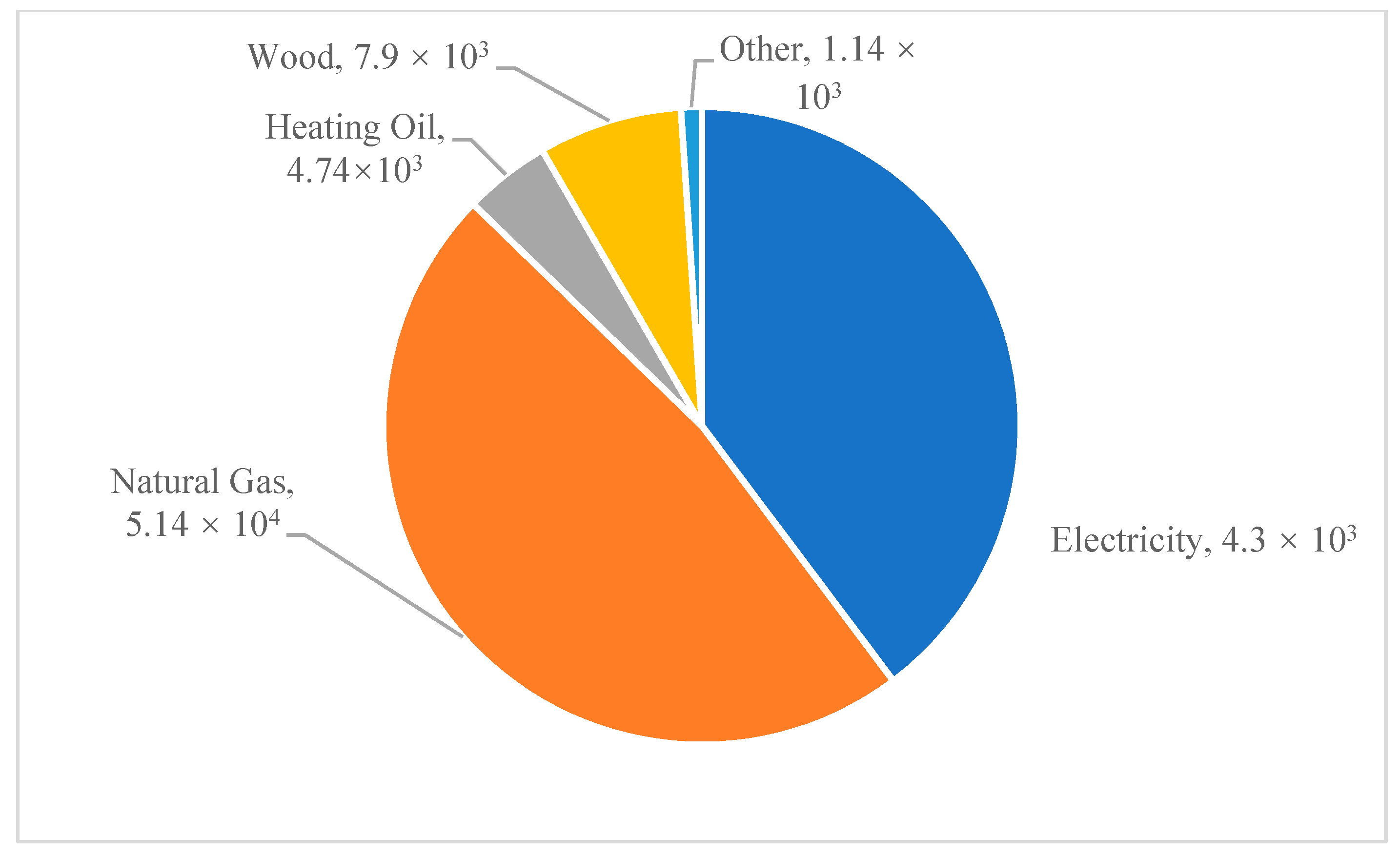

1.2. Identifying Canadian Household Demand

Two markets, which are most suitable for the use of repurposed batteries as energy storage are homes and small commercial installations. Both applications have previously been found to be appropriate application types for battery energy storage and can be powered using a relatively small number of battery packs [

8,

22]. To determine the size required for a battery pack energy storage system in a Canadian residence, the average daily consumption of energy by a Canadian household was determined. Every year, an average Canadian household uses approximately 4.3 × 10

4 kJ of electricity, which is approximately 117.73 kJ daily.

Figure 3 displays the average household annual energy usage in Canada for various fuel types [

23]. This electricity can be supplied, or offset at least, throughout the day by renewable or low carbon surplus nuclear energy stored within a re-purposed battery pack. Studies of the usage of an electric vehicle battery for residential applications have illustrated that these systems can help to reduce energy costs and greenhouse gas emissions [

24,

25]. The application of these systems depends on how the system controller is programmed.

1.3. Current Applicable Design Codes

To use repurposed EV batteries in residences, it is essential to understand the safety measures and applicable codes for their installation and use. As home energy storage is a relatively recent development, there are not many codes that refer specifically to this technology. Underwriters Laboratories have developed a code which details the specifications necessary for the design of stationary energy storage devices; however, the standard is meant to provide guidance for large Li-ion battery packs that store energy from massive photovoltaic systems or turbines [

26]. Since there is no specific code for stationary energy storage devices used in homes, specifications for the battery pack are drawn from similar existing codes for lead-acid battery energy stationary storage applications and for the design of Li-ion batteries. Codes from the Pacific Northwest National Laboratory outline the application of energy storage systems in the United States [

27]. In

Table 2, below, are codes which are applicable to the re-purposed EV battery packs.

Table 2 focuses on codes which are specific to the battery pack used in the stationary assembly, while

Table 3 focuses on codes which outline design considerations for the re-purposed pack assembly.

The main take-aways from the codes given in

Table 3, above, are that the battery should be stored in a secure manner, on a level surface, behind protection to protect personnel from leaks and fires, and at 25 °C. The temperature requirement for the repurposed EV battery pack is noted in the installation manual for Tesla’s Powerwall. Limiting the operating temperature of the battery limits where the battery can be placed, especially in cold locales, such as Canada or hotter ones, like the southern United States. If the final energy storage device is installed in a garage or outdoor area, thermal controllers are needed, in addition to insulation, heating units, or air-conditioning. Although thermal regulation adds to the total cost of the system, it will mitigate thermal runaway and contribute to the longer life of the battery. In a typical home, the battery should be operating at less than 50 V. As part of securing the battery, it is also important that the area be protected from vibrations to prevent disconnects and damage to the interior components of the battery pack casing [

27]. Equipment shall be provided to control the charging process of the battery [

28]. The battery pack itself must be secured and enclosed in a protective case only accessible to the appropriate personnel such as the installer or electrician.

Before being used in a given application, batteries must pass tests that determine the strength of the battery management system (BMS) and the potential for thermal runaway, overcharging, and/or overheating [

29]. A standard by the International Electrotechnical Commission (IEC 62619 Ed. 1.0) is focused on the safe use of re-purposed Li-ion batteries in industry [

27]. Because these secondary use batteries are being applied in a system that they were not designed for, a new controller must be used and the BMS must be re-tested to protect against faults. Several new codes are being developed for the use of Li-ion batteries in stationary energy storage installations [

30]. These newly developed codes will provide requirements for the installation and use of energy storage systems. As such, the wording needs to be understood by those who will be reading it and cannot have erroneous information. Not all codes and standards are developed the same way, but there is a similar process that many codes developers use. It starts with the initial phase of creating a proposal. If accepted the internal council will prepare a draft, which is then sent out to committee to discuss and rework it to create an initial working draft. The draft standard is then sent out for public review, changes are made, and then it is finally published. Over time, the code or standard will go through editing iterations to maintain its relevance to new ideas and continual user reviews [

31,

32]. Currently, the Canadian Standards Association has developed safety guidelines for the use of Li-ion batteries in portable applications; however, this code does not apply to the type of stationary applications being examined here [

33]. The Canadian Electrical Code, Canadian Standards Association C22.1, is the key standard used in Canada used for electrical equipment. [

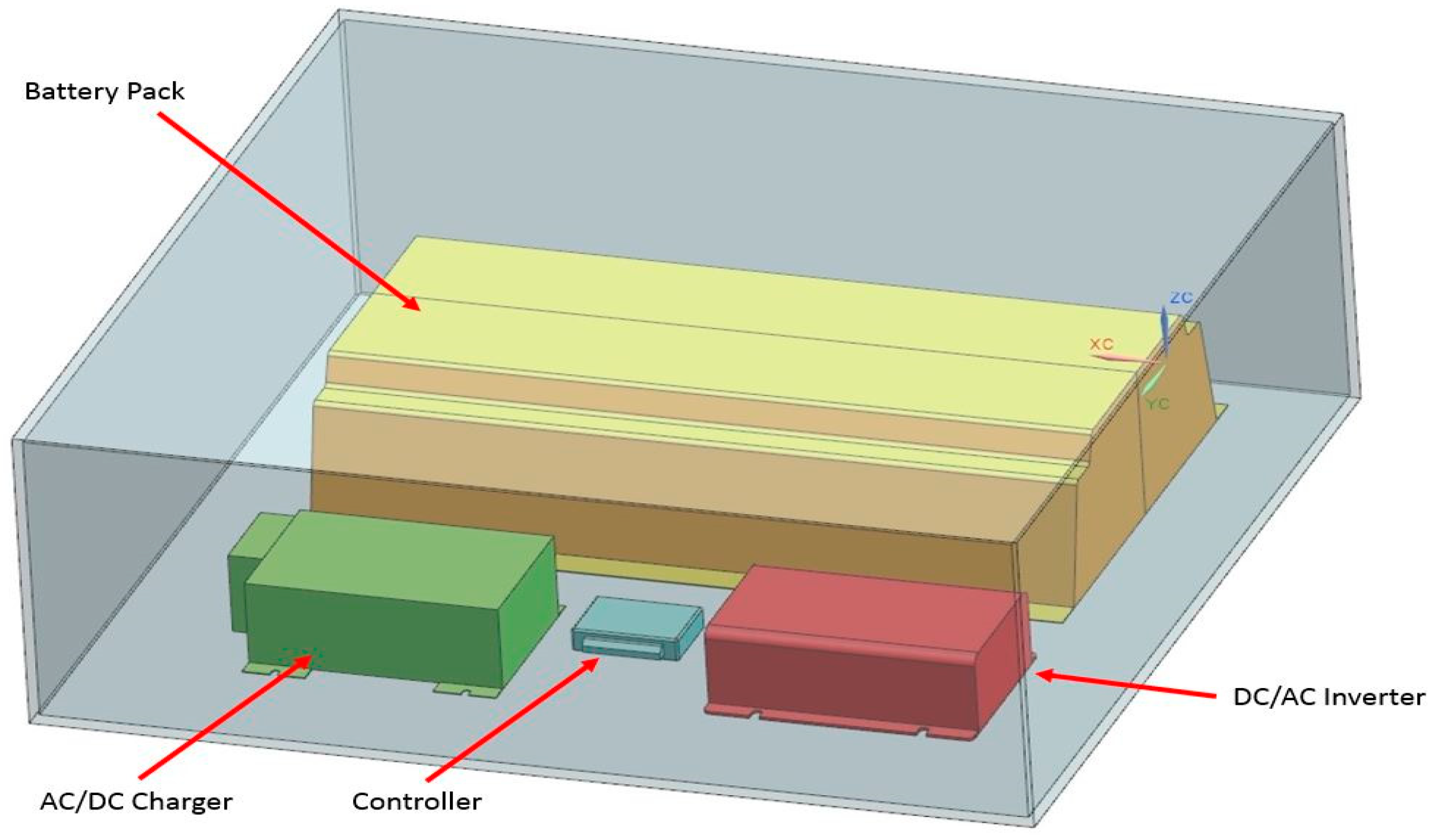

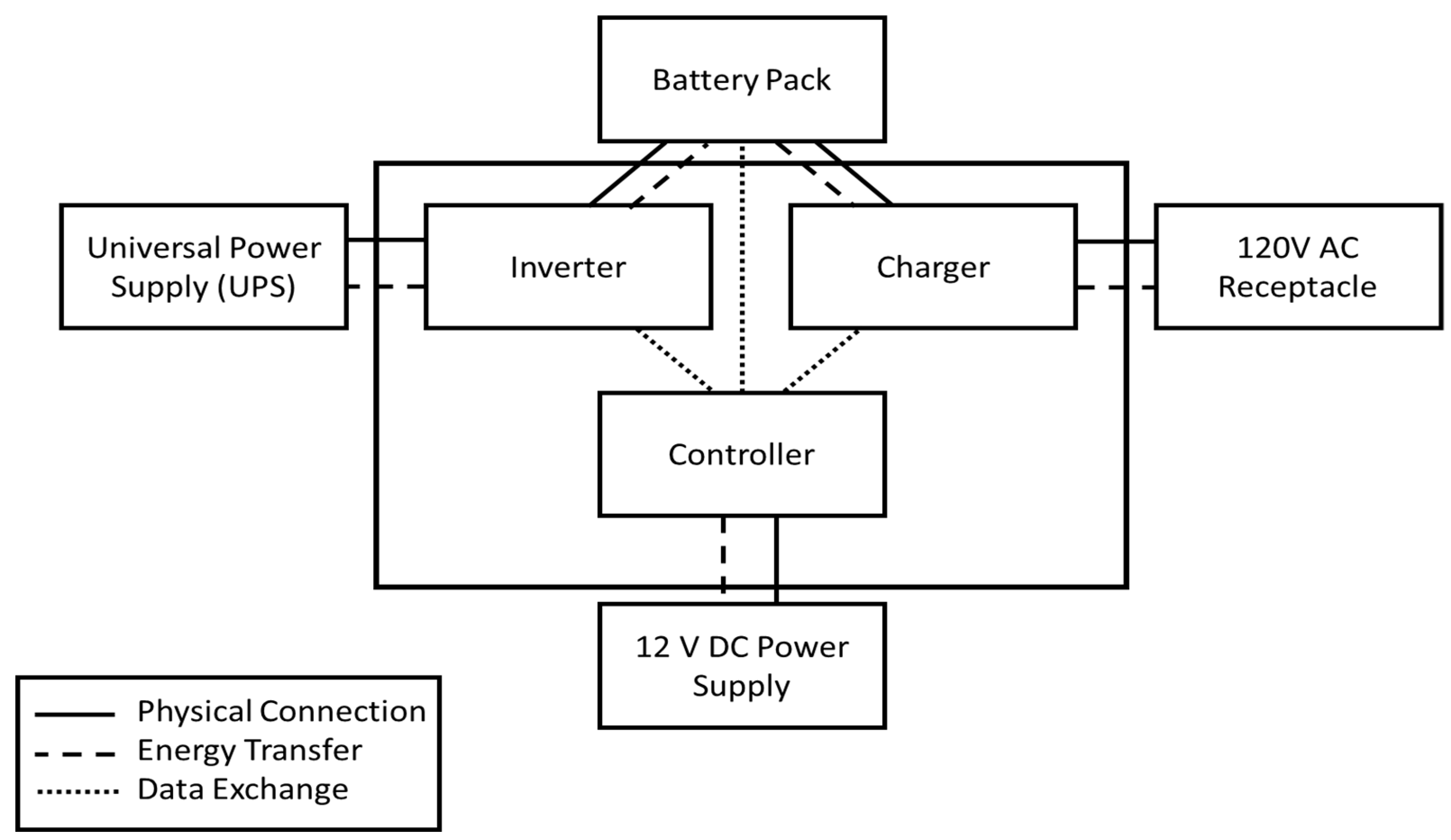

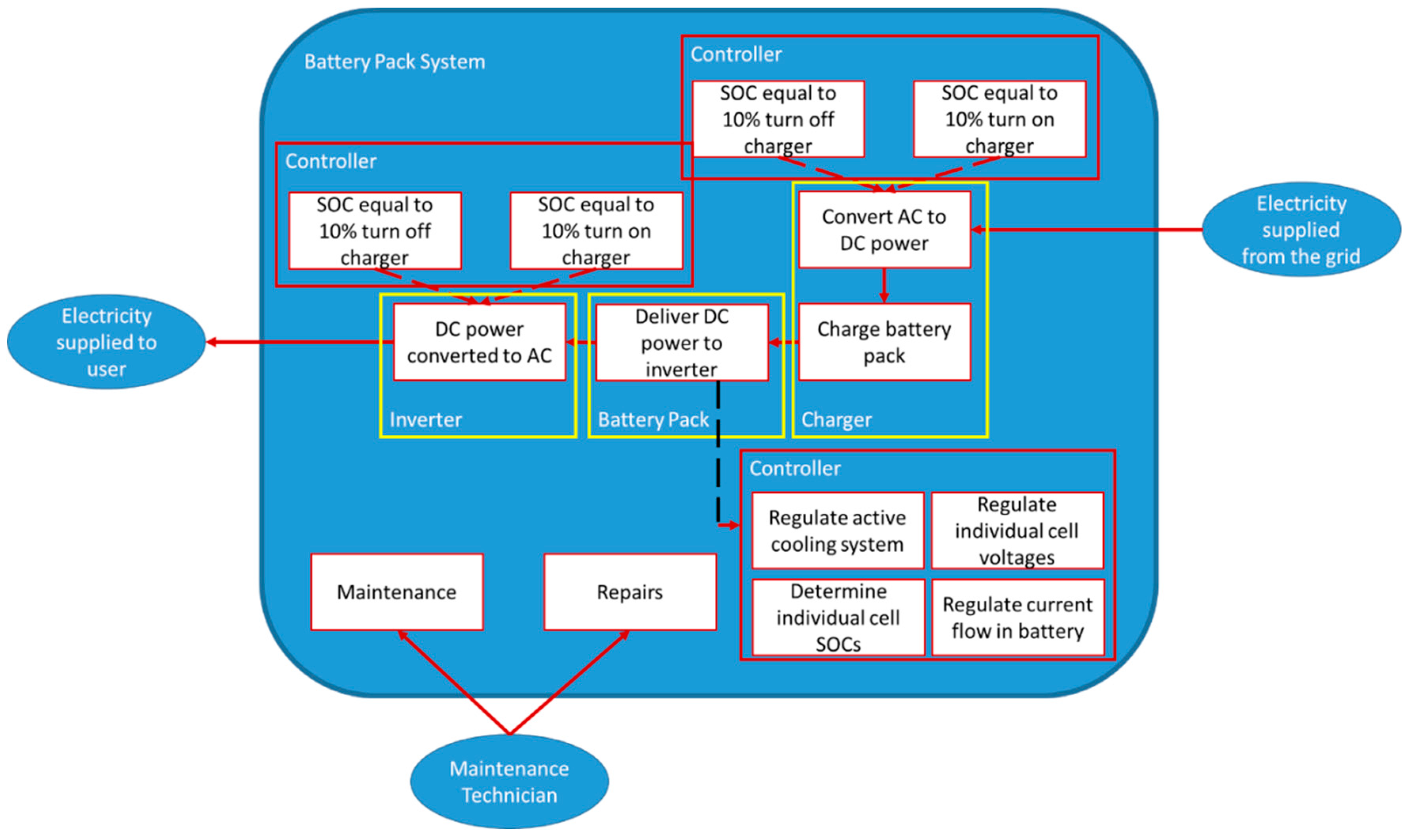

28]. Re-purposed EV battery packs can feed electricity into the grid or can store energy and therefore must meet the CSA standards for energy storage. Given this, the potential housing and energy storage system layout shown in

Figure 4 must be in compliance with the Canadian Electrical Code. A list of some of the current design codes for installation of a re-purposed EV battery pack for energy storage are given in

Table 3 below. In order for energy storage and the proliferation of electric vehicles to expand, it will be necessary to increase the number of applicable standards.

3. Assessing Batteries for Second Use

Currently, there is no system or standard to classify re-purposed batteries. A comprehensive analysis of the remaining states-of-health (SOH) of batteries would enable the proper selection of batteries that are capable of being re-purposed and determine the best course of action for second-life of the cell. To assess the usability of electric vehicle batteries for a second use, the authors propose a five-level system based on the SOH of the battery. The condition of an end-of-life electric vehicle battery depends on the vehicle it was in, how aggressively the vehicle was driven, and where the vehicle was driven. Based on these varying constraints battery parks will degrade differently, creating a variety of different states of health.

Although there are some concerns about how to best evaluate the health of a battery, the current method compares the capacity, and other elements, to ideal conditions as a percentage [

42]. In the automotive industry, it is generally accepted that if the capacity drops below 80% of its initial value, the SOH is also considered less than 80% and the user should change the batteries in their vehicle [

4,

8]. An important element of the health of a battery, the capacity, decreases over time resulting in age-related battery degradation [

36]. The age-related battery degradation occurs in conjunction with the degradation that results from operating the battery. Together aging and cycling of the battery contribute to a general reduction in battery SOH. Additional impacts such as temperature or collisions can also impact the overall health of the battery [

42]. Although the SOH of a battery is a complex metric which is dependent on numerous factors, for this simple system the batteries will be sorted based on the capacity of energy storage remaining, as shown in

Table 8. This can be determined using diagnostic technologies available to electric vehicle dealers and manufacturers.

Batteries that fall into the first two levels can potentially be used in a vehicle again because they have over 80% capacity remaining, which is necessary for use in a vehicle. Batteries that are at the third level have less than 80% of their capacity remaining, but still have enough storage to be used in a re-purposed application. In such a scenario, a second battery would be installed in the donor vehicle to extend its life and the original battery would be used for a residential energy storage system. Batteries that are of the fourth and fifth levels are significantly degraded or have suffered catastrophic damage. In these states, the batteries cannot provide energy for a vehicle or stationary application and should be recycled.

Despite the usefulness of re-purposed Li-ion for energy storage applications, there are many technical and regulatory barriers to their use. Several types of cell degradation occur within the electric vehicle battery pack, which can reduce the energy and capacity of the battery or lead to failure. As a result, the safety risk to the consumer increases and limits the potential for cells to be re-purposed.

The following are barriers to the widespread adoption of the re-purposing of lithium-ion batteries for stationary applications. Insurance costs are a significant barrier to the use of repurposed electric vehicle batteries. As repurposed batteries carry with them an increased risk of failure, insurance premiums are higher for their use [

43]. Because the use of repurposed electric vehicle batteries is a novel technology, there is a lack of statistical risk data for insurance companies to calculate premiums. As insurance companies are risk-averse, they may set high premiums for homeowners using this technology. Additionally, the lack of available data may disrupt the insurance market, if such technology becomes more common [

27].

An additional barrier to the development of extensive repurposed battery use is the question of who owns the battery at its end-of-life. As defects to the repurposed battery may cause some damage to people or property through fires or leaks, the question of who would be liable in such a situation is important [

44]. Battery and electric vehicle manufacturers develop the battery and related software and hardware to insure that the battery performs as intended in the vehicle. However, these corporations do not design their systems with the intent of third parties who would use the battery packs for second uses. If the second-life uses of the battery result in damages, then the automotive manufacturers may be liable as current regulations and standards are unclear. Because of this lack of clarity around their liability, original equipment manufacturers (OEMs) are hesitant to allow their EV batteries to be re-purposed for grid storage applications, resulting in them being recycled or sent to a wrecking yard [

44].

Testing the battery for its SOH and determining whether it qualifies as a first through third level battery, as described in

Table 5, is a significant barrier. Currently, electric vehicle batteries are sent to automotive recyclers at the end of a vehicle’s life, along with the rest of the vehicle. However, automotive recyclers are generally not as familiar with the hazards of storing and managing end-of-life electric vehicle batteries and are unable to determine the state of health of the battery packs [

36,

45]. To effectively manage electric vehicle batteries at the end of their use in vehicles, battery manufacturers may need to participate in the test for the loss of capacity and check for failed cells [

45].

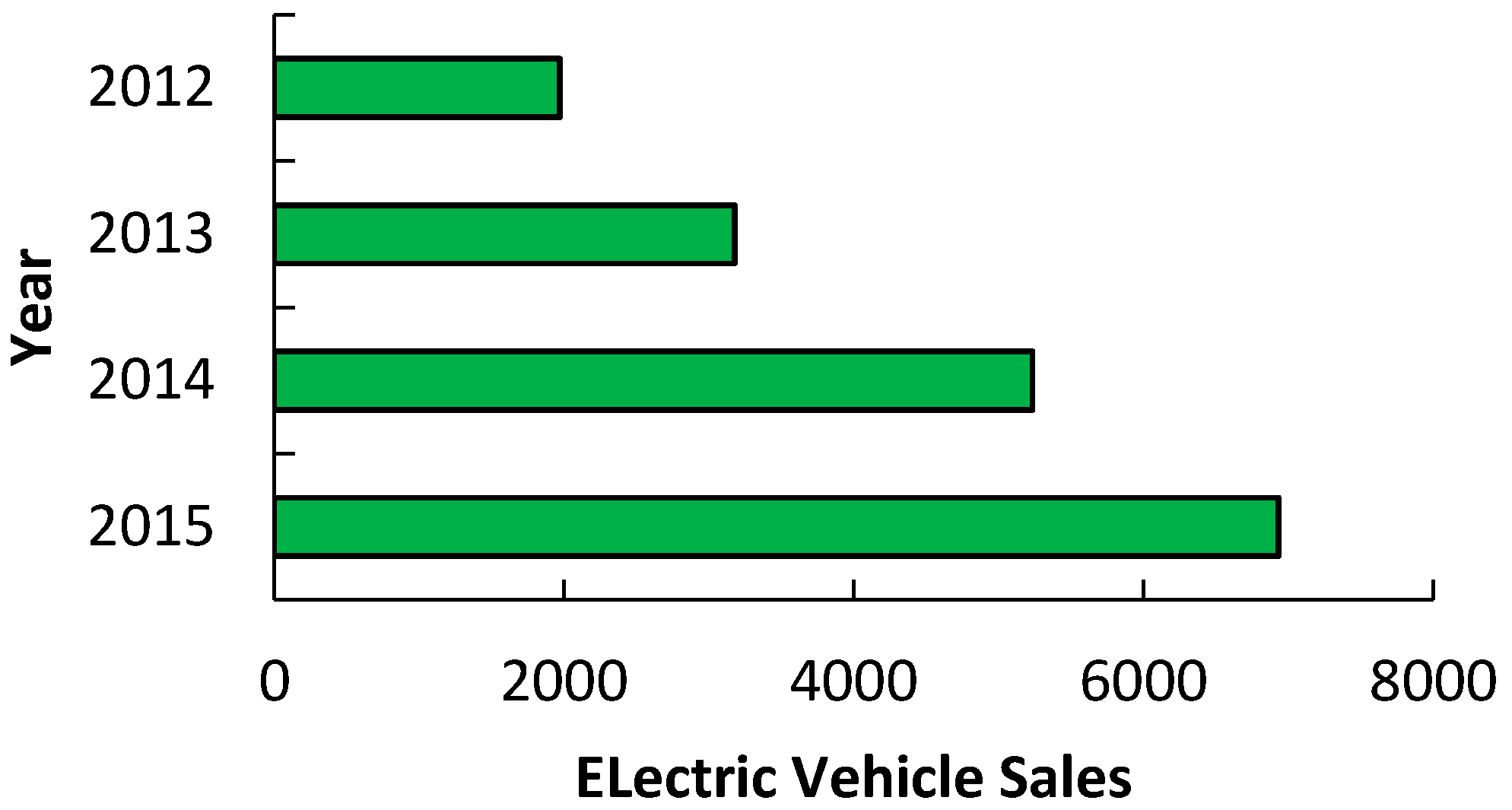

Currently, only vehicle manufacturers and dealers can check the diagnostic codes displayed by the packs to check their state-of-health. Although total plug-in electric vehicle sales reached 144,000 in the United States in 2016, there are significantly less of these vehicles in Canada [

46]. The current Canadian fleet of electric vehicles is just over 18,000 vehicles, of which 54% are battery electric vehicles and the remainder are plug-in hybrids [

47]. Although Canada has progressive environmental regulations, less than 1000 electric vehicles were sold in Canada in 2010 [

48]. The increasing sales of electric vehicles within Canada is illustrated in

Figure 9. In spite of the uptick in sales, the small number of electric vehicles currently on Canadian roads greatly reduces the supply of batteries that can be repurposed. It can be estimated that batteries in electric vehicles should last approximately 10 to 15 years, depending on the vehicle and the driver’s behavior, although previously batteries have had expected lives as short as 8 years [

36,

49]. Thus, of the 7000 electric vehicles sold in Canada in 2015, most of the batteries will not begin to be available from these vehicles until 2025 [

47].

When these batteries are available for re-purposing, it is not known how many of them will have a SOH that will be adequate for re-purposing [

7]. Thus, from the small supply of EVs in Canada, the number of viable batteries for re-purposing may be even smaller. On top of this issue of the small pool of available batteries, there is significant variability in the design and energy of electric vehicles batteries, as shown in

Table 9.

Because of the variation in the design, energy, capacity, and chemistry of these common electric vehicle batteries, the repurposing process will require reassembling the batteries into different configurations with controllers that are unique to the application and battery. These variations make it more difficult to develop a uniform manufacturing process or controller logic [

50]. To make this more difficult, the disassembly of the electric vehicle batteries can be dangerous and damaging to the equipment. Thus, using the packs in their manufactured form is preferred, which leads to further variation [

7,

8,

36].

4. Conclusions

The work presented in this paper provides a design methodology for utilizing depleted lithium-ion batteries for stationary energy storage applications. This design process utilized existing failure analysis techniques to identify potential faults and how to remedy them in the design. In addition, existing standards on lithium-ion batteries and stationary energy storage devices were referenced to determine other potential design requirements. The developed design was built, proving feasibility of the system. In future studies, the authors propose an in-depth performance analysis and safety testing of multiple bench setups.

With additional safety measures in place, the battery pack built by the design team can present a viable option for utilizing depleted lithium-ion batteries, beyond simply sending them to be recycled. Additional work, though, needs to be completed to ensure that the entire system is safe for use by consumers. As the re-purposed EV batteries have been depleted there is a higher risk of a failure occurring. Thus, the employment of multiple layers of safeguards, such as those developed in the Failure Modes and Effects Analysis Action Plan, is crucial, and effective training and standard testing practices need to be developed to ensure personnel have the required knowledge and expertise to quantify the batteries’ SOH and classify which secondary use application that they should be used for.

Although this technology can offer many great benefits to the smoothing of grid supply fluctuations, and the bench testing done in the laboratory has shown the system to be viable, there are a variety of barriers that will prevent its widespread adoption if they are not rectified quickly. Supply chains that can distribute used batteries to a re-manufacturer need to be developed; legislation and standards needs to be drafted in order to properly regulate this market; and proper, standardized validation procedures for evaluating SOH need to be developed; as well as providing design methodologies to ensure the variability in battery designs does not affect the development of the systems.