Sulfurized Polyacrylonitrile for Rechargeable Batteries: A Comprehensive Review

Abstract

1. Introduction

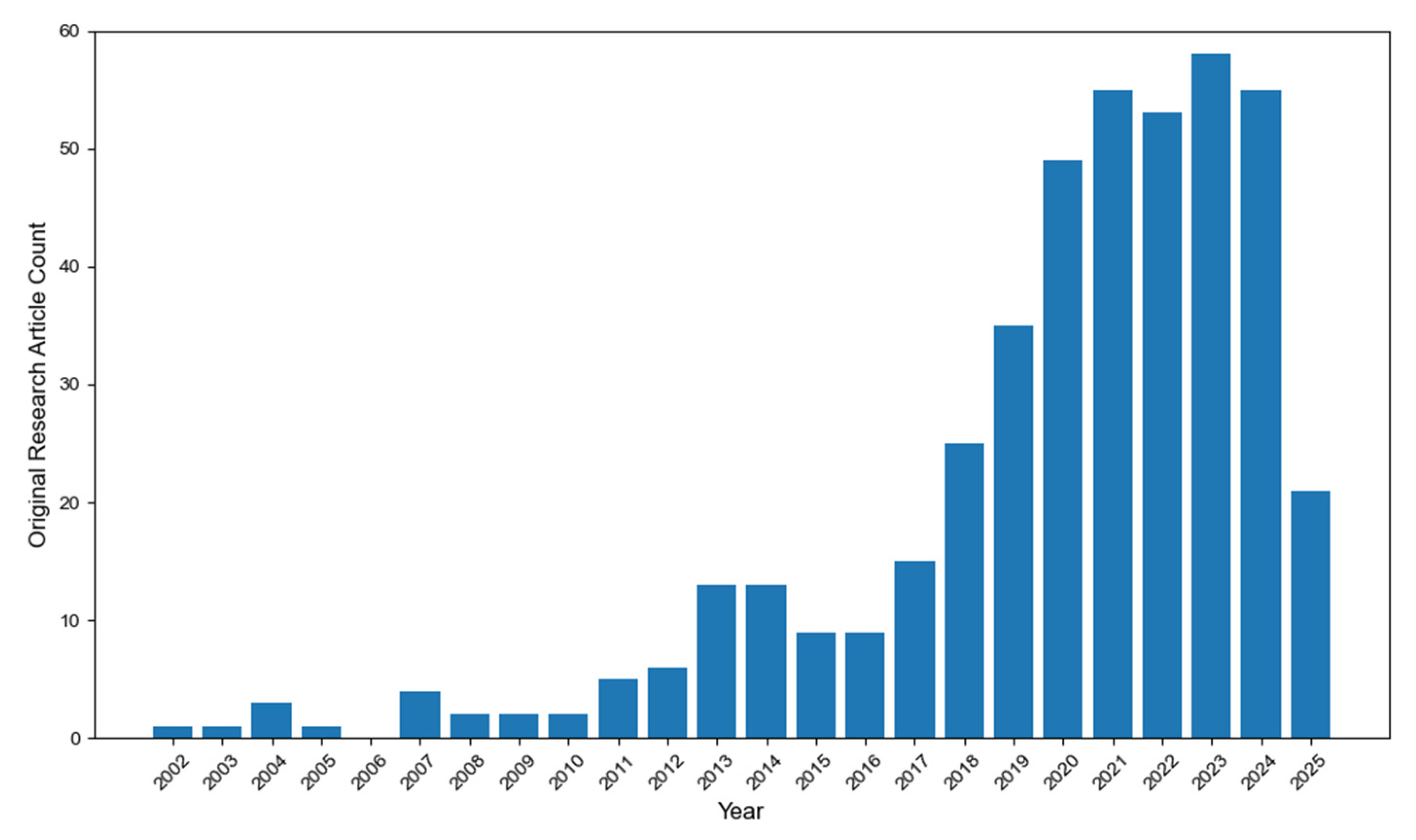

2. Dataset Construction and Research Progress

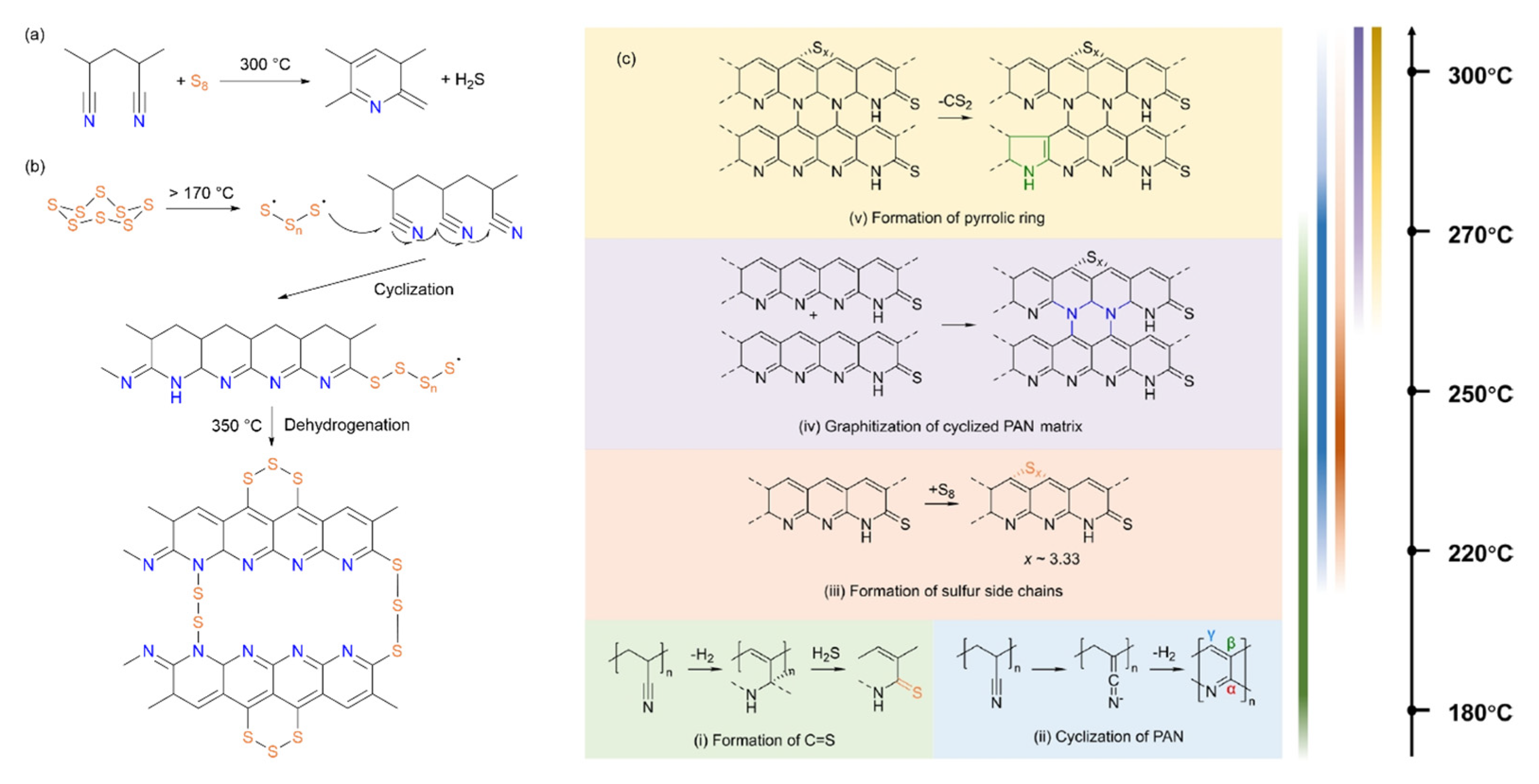

3. Chemical Structure

4. Structural Evolution During Synthesis

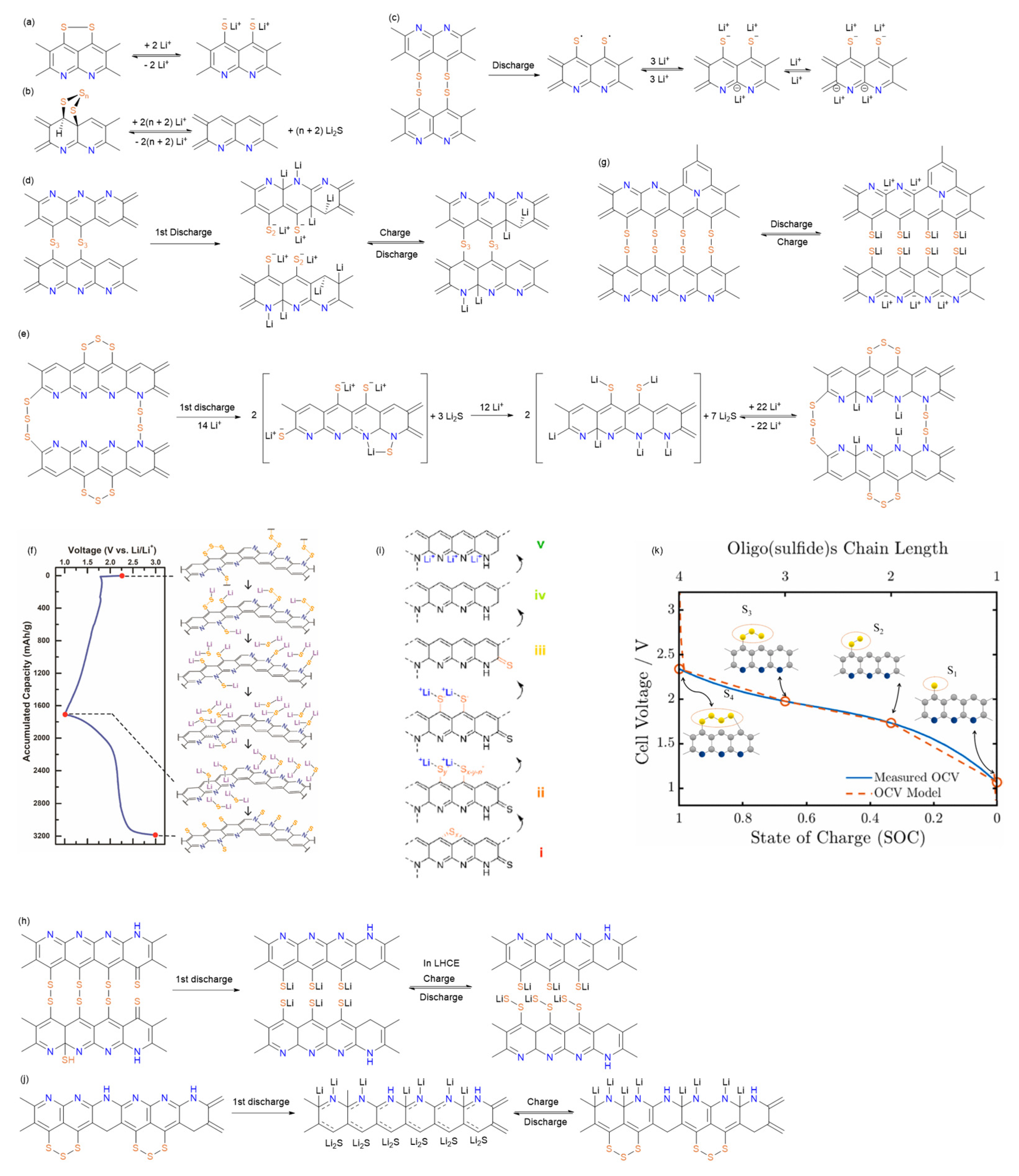

5. Electrochemical Properties

6. Redox Reaction Mechanism

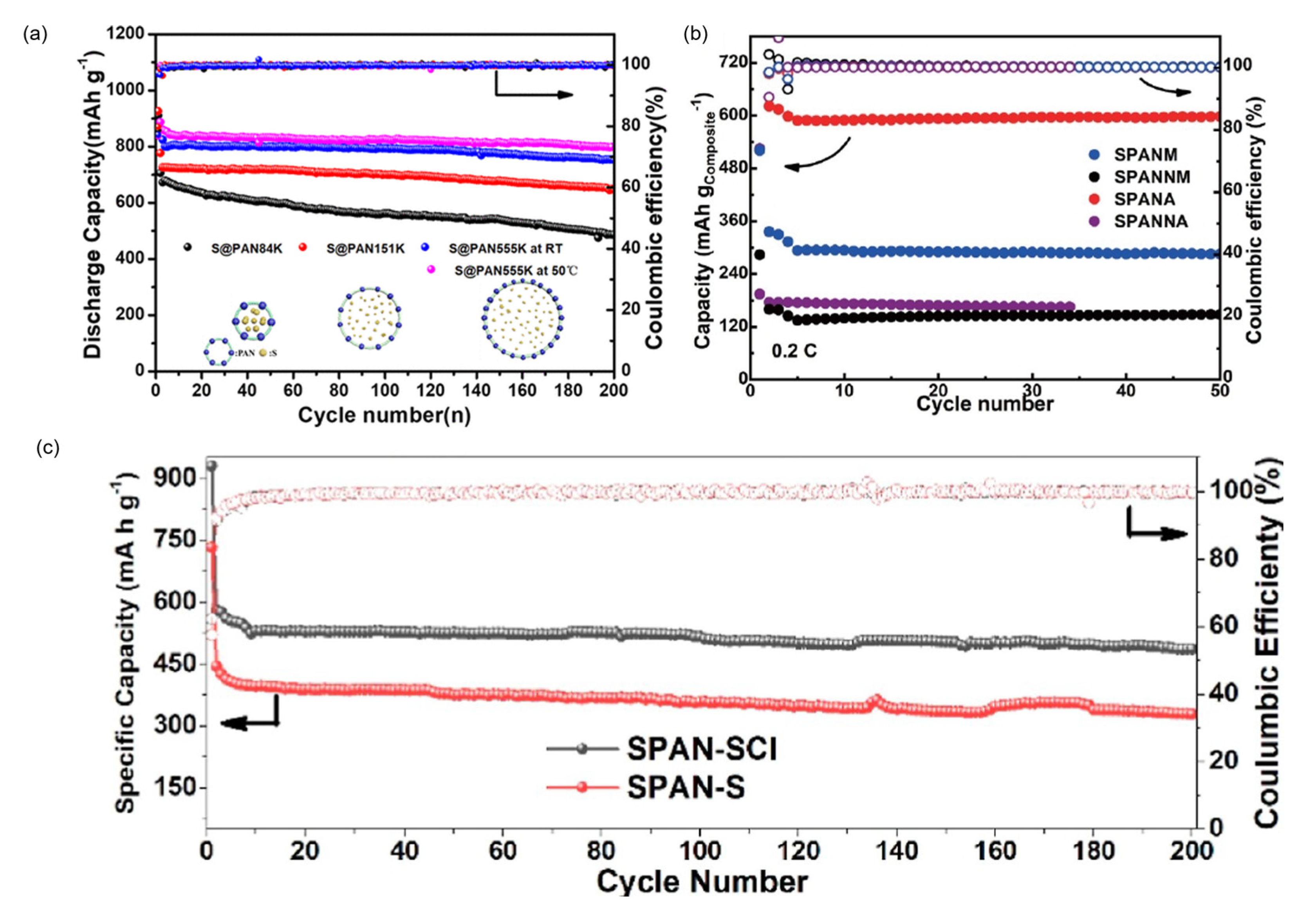

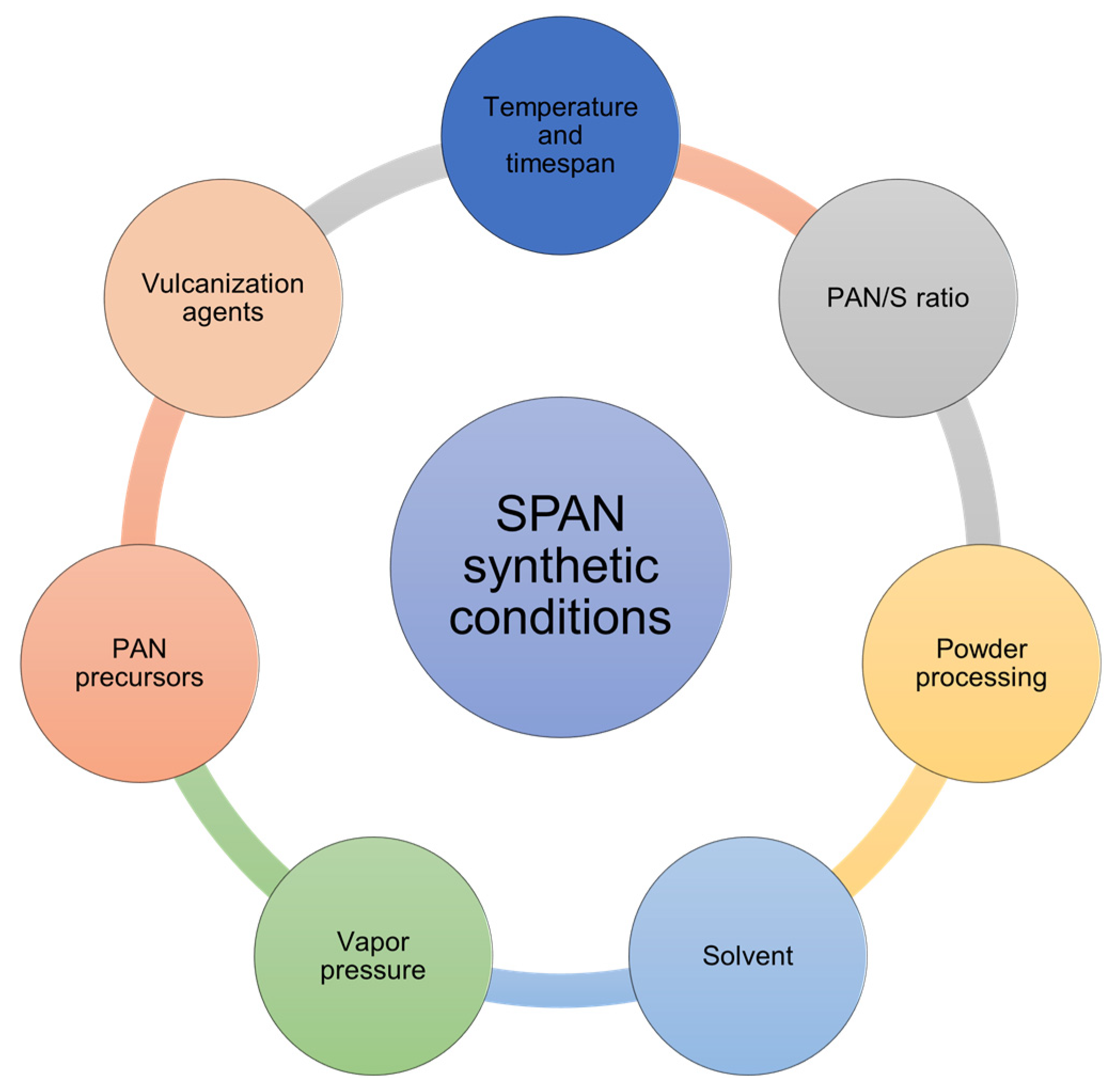

7. SPAN Synthetic Conditions

7.1. Temperature and Timespan

7.2. PAN to Sulfur Ratio

7.3. Powder Processing

7.4. Solvent

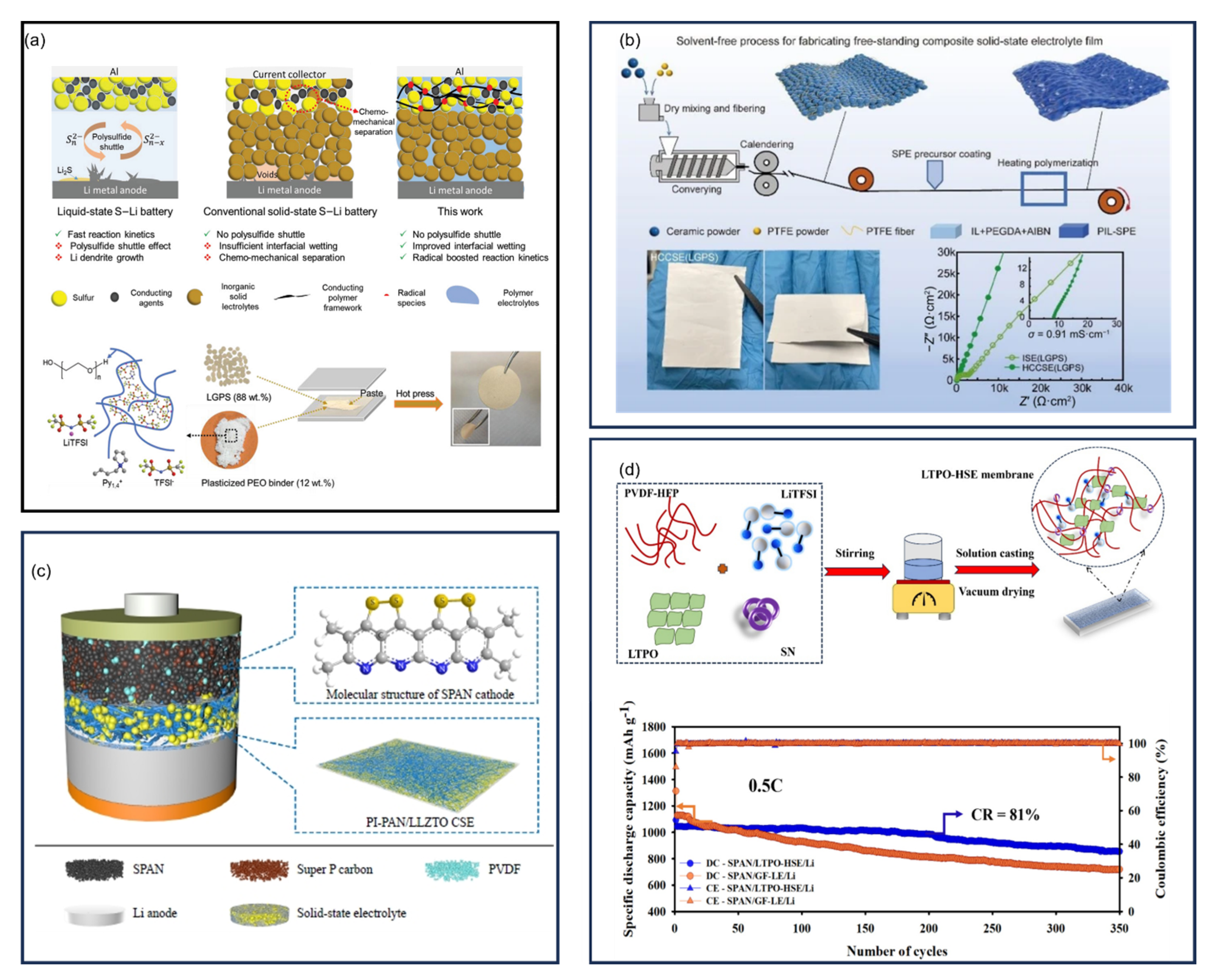

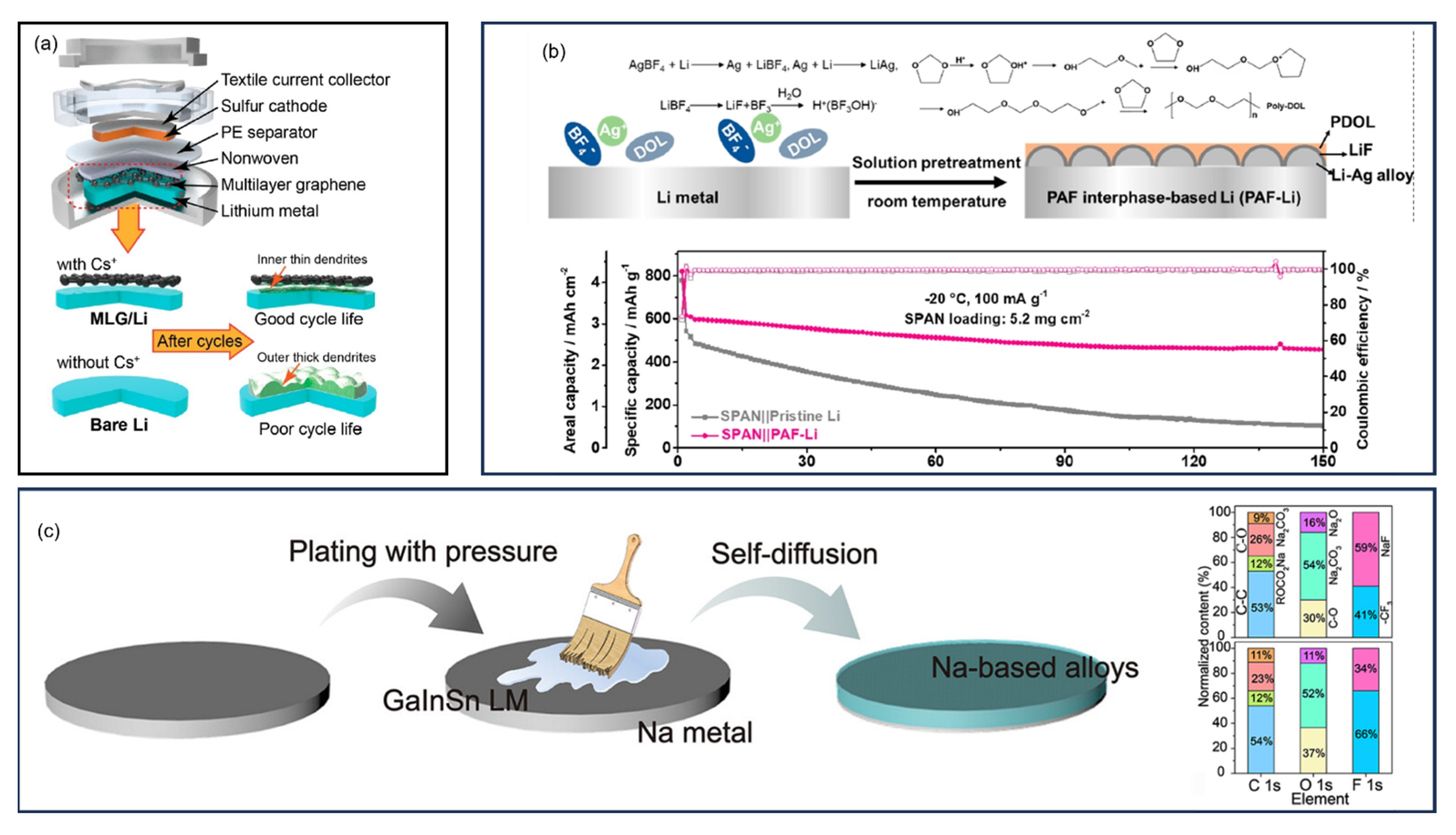

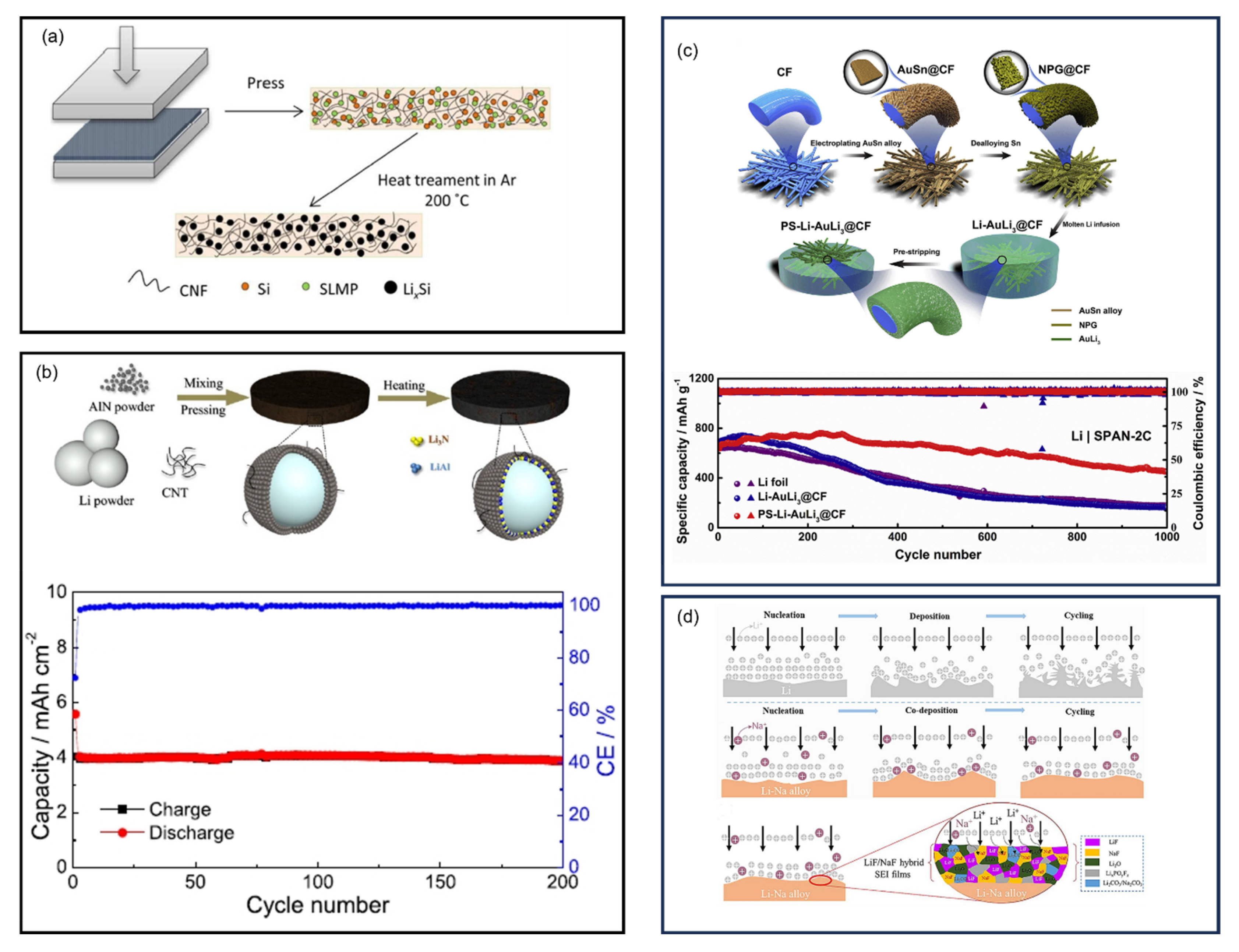

7.5. Vapor Pressure

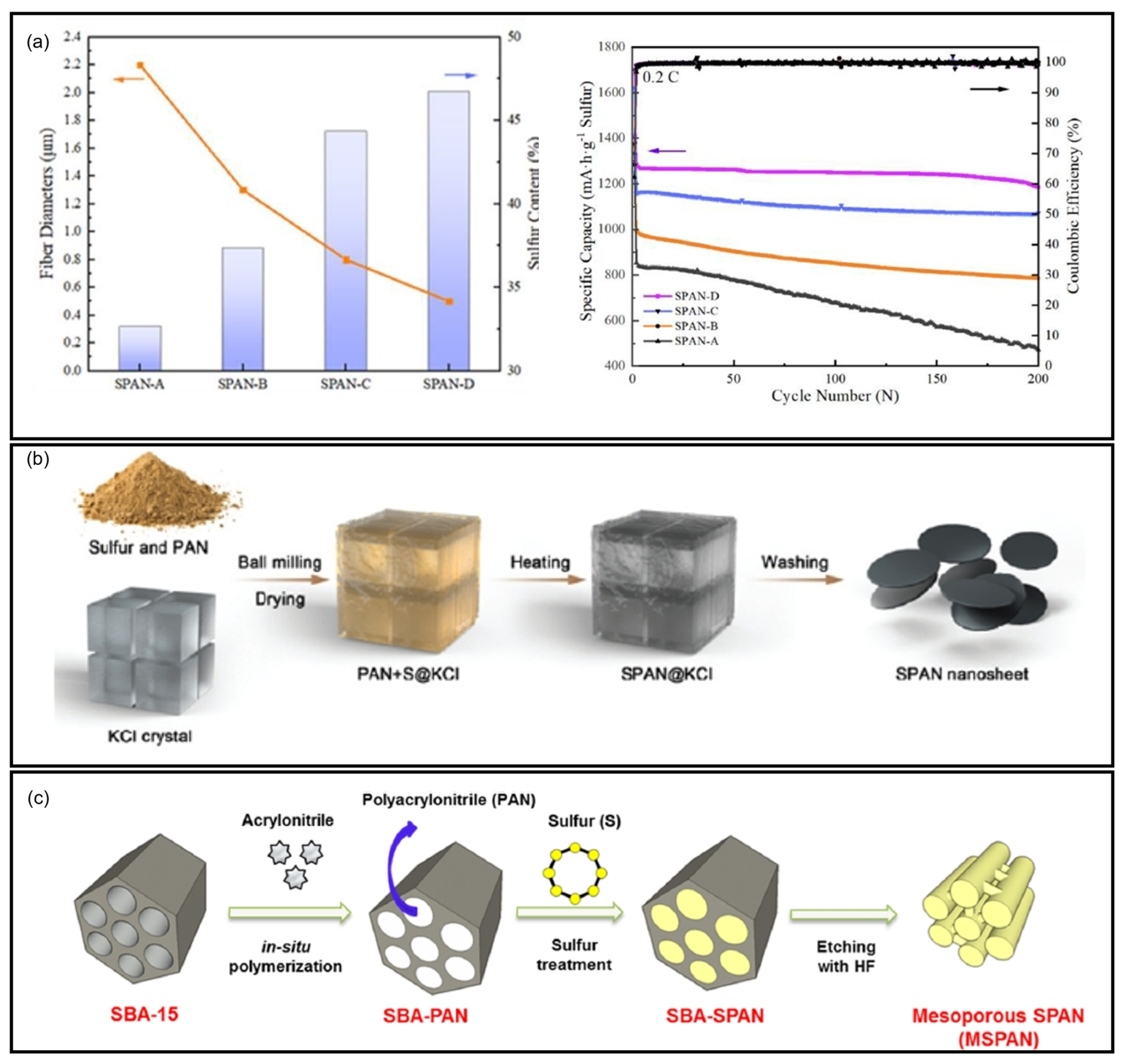

7.6. PAN Precursors

7.7. Vulcanization Agents

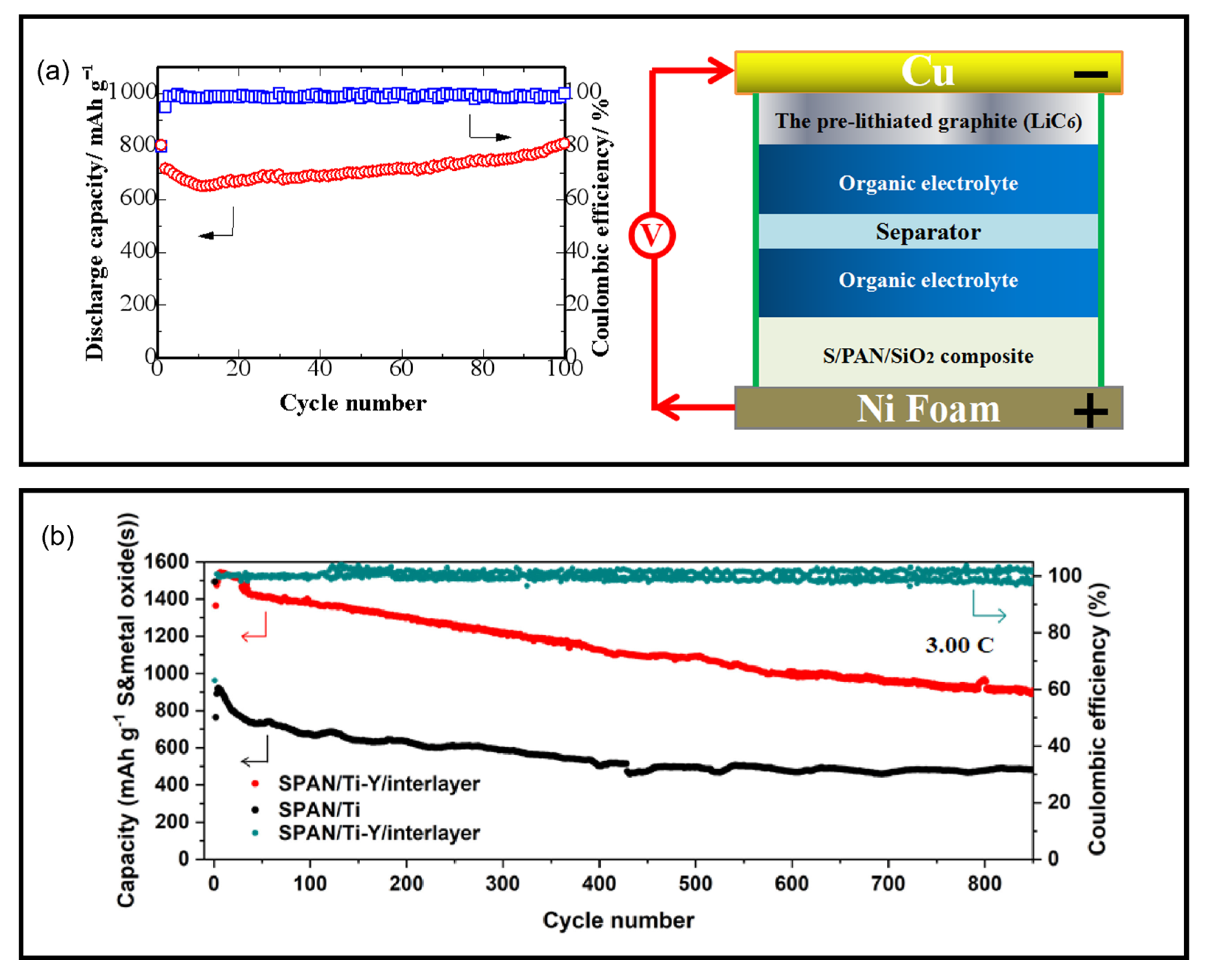

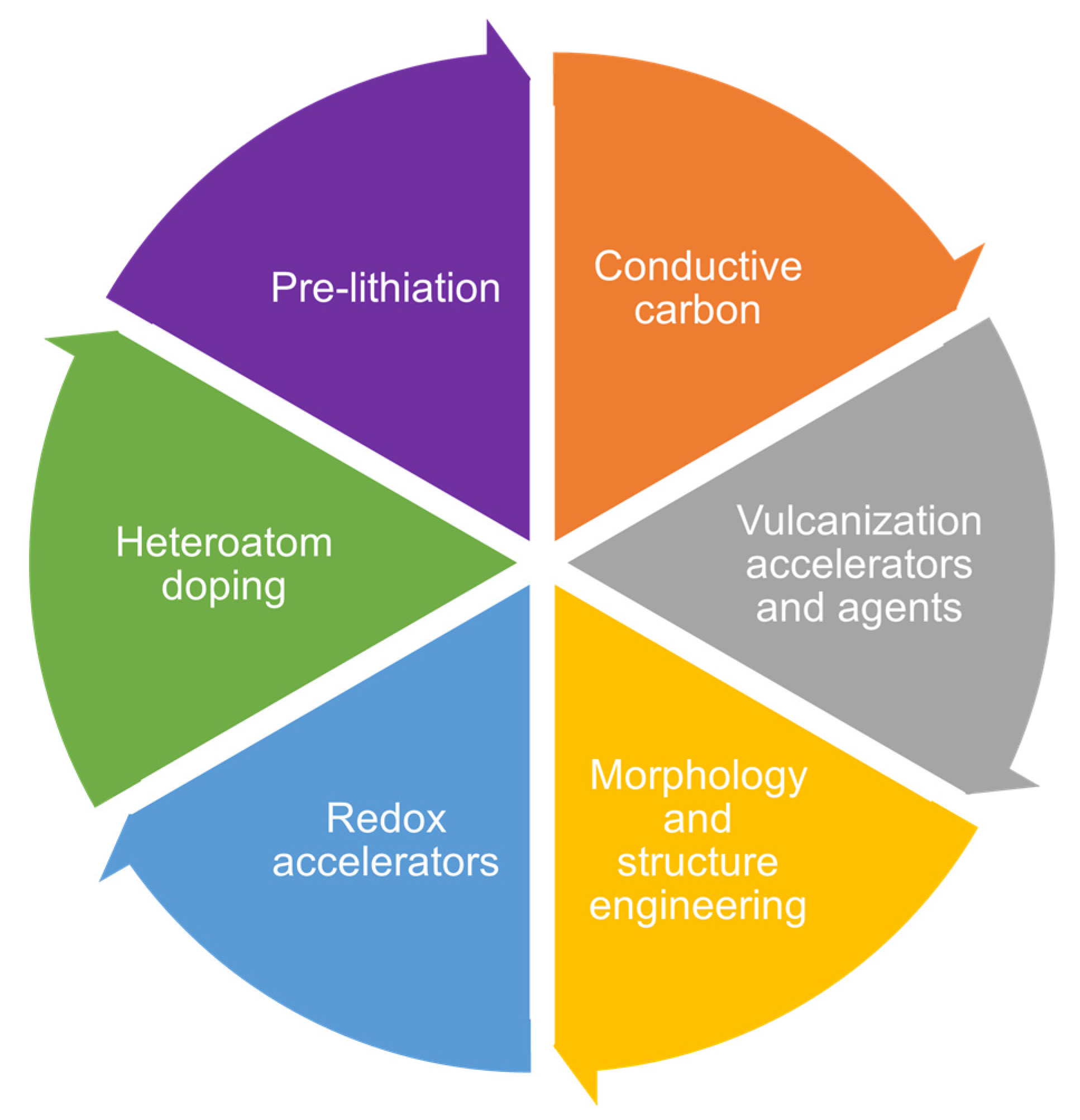

8. Cathode Modification

8.1. Conductive Carbon Additives

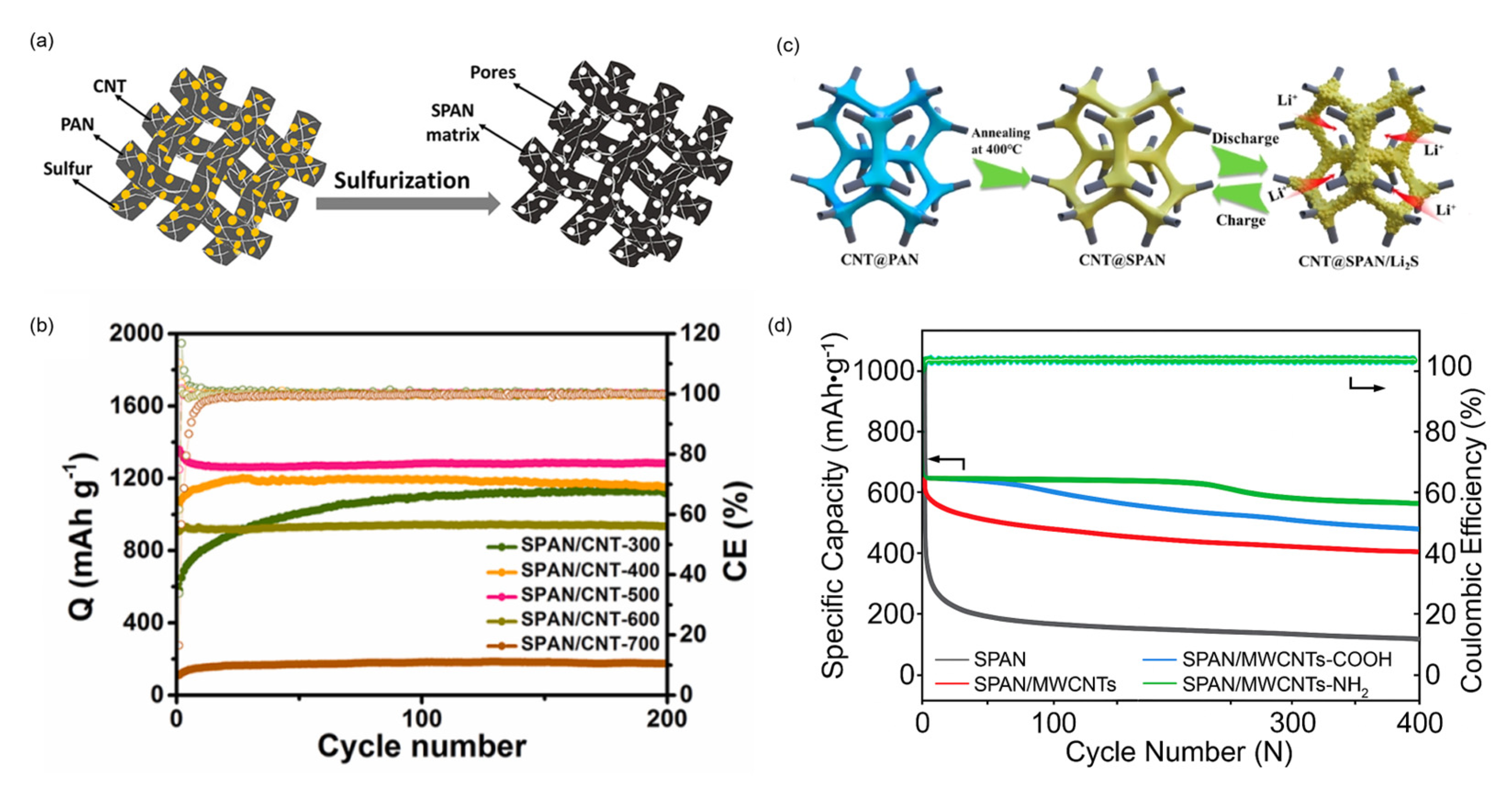

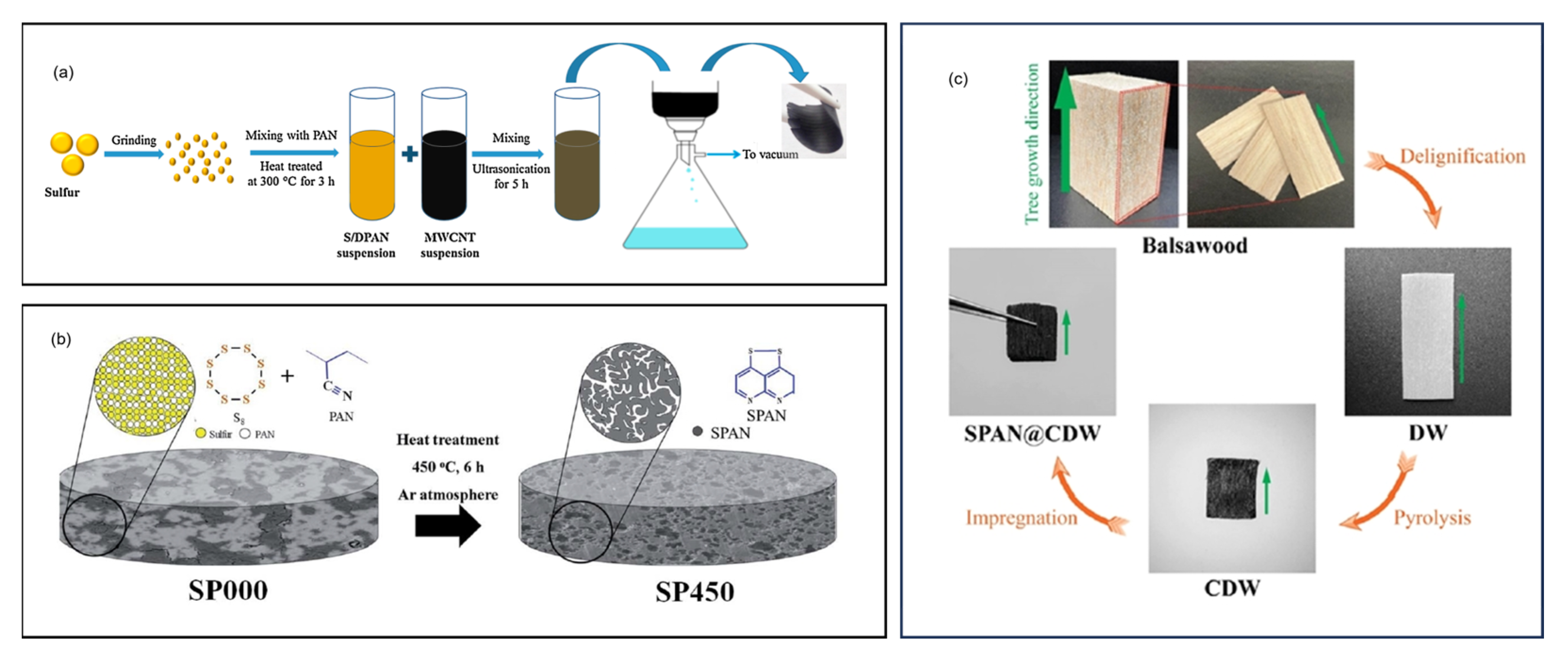

8.1.1. Carbon Nanotubes

8.1.2. Graphene

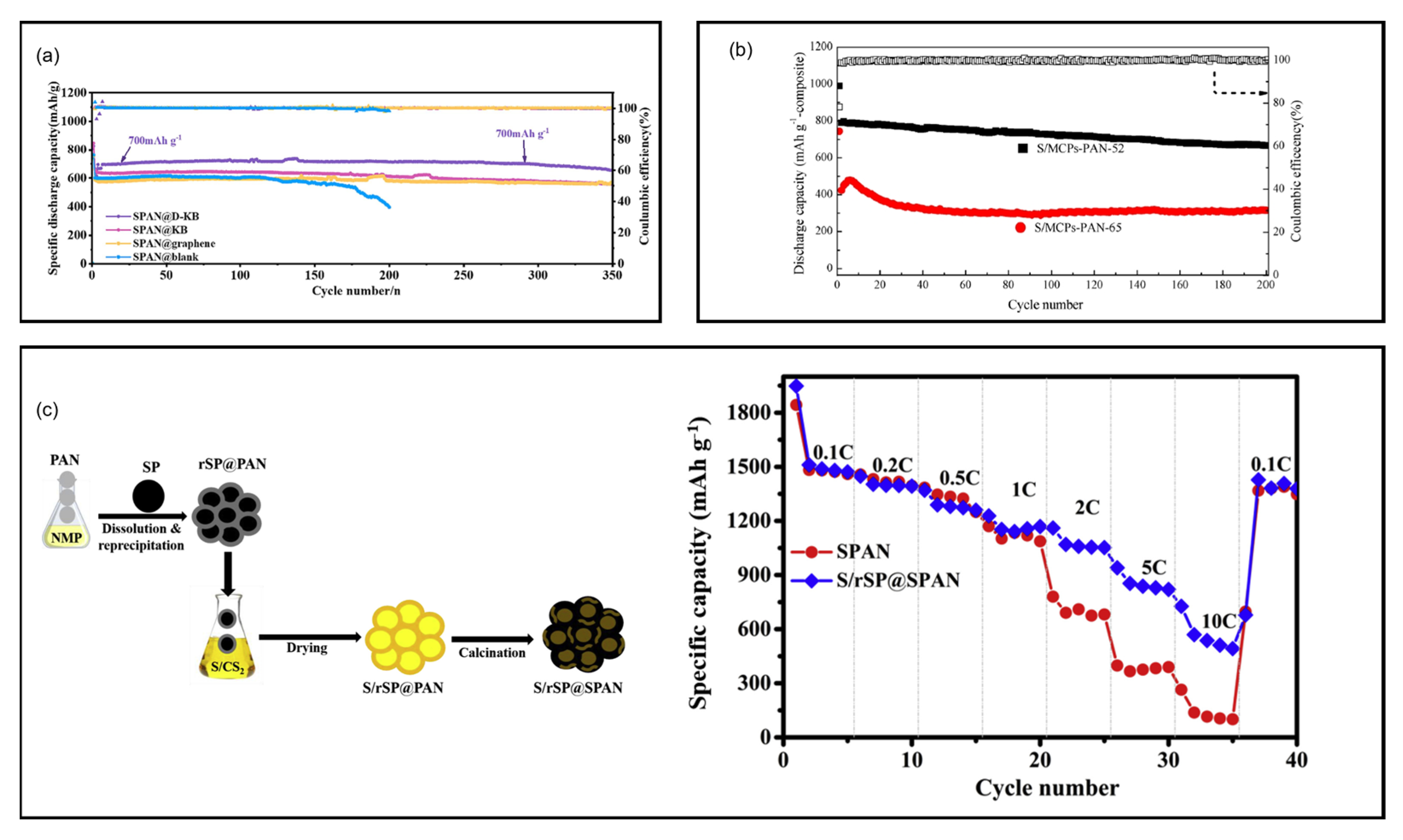

8.1.3. Porous Carbon

8.1.4. Graphite

8.1.5. Carbon Fibers

8.1.6. Dense Carbon

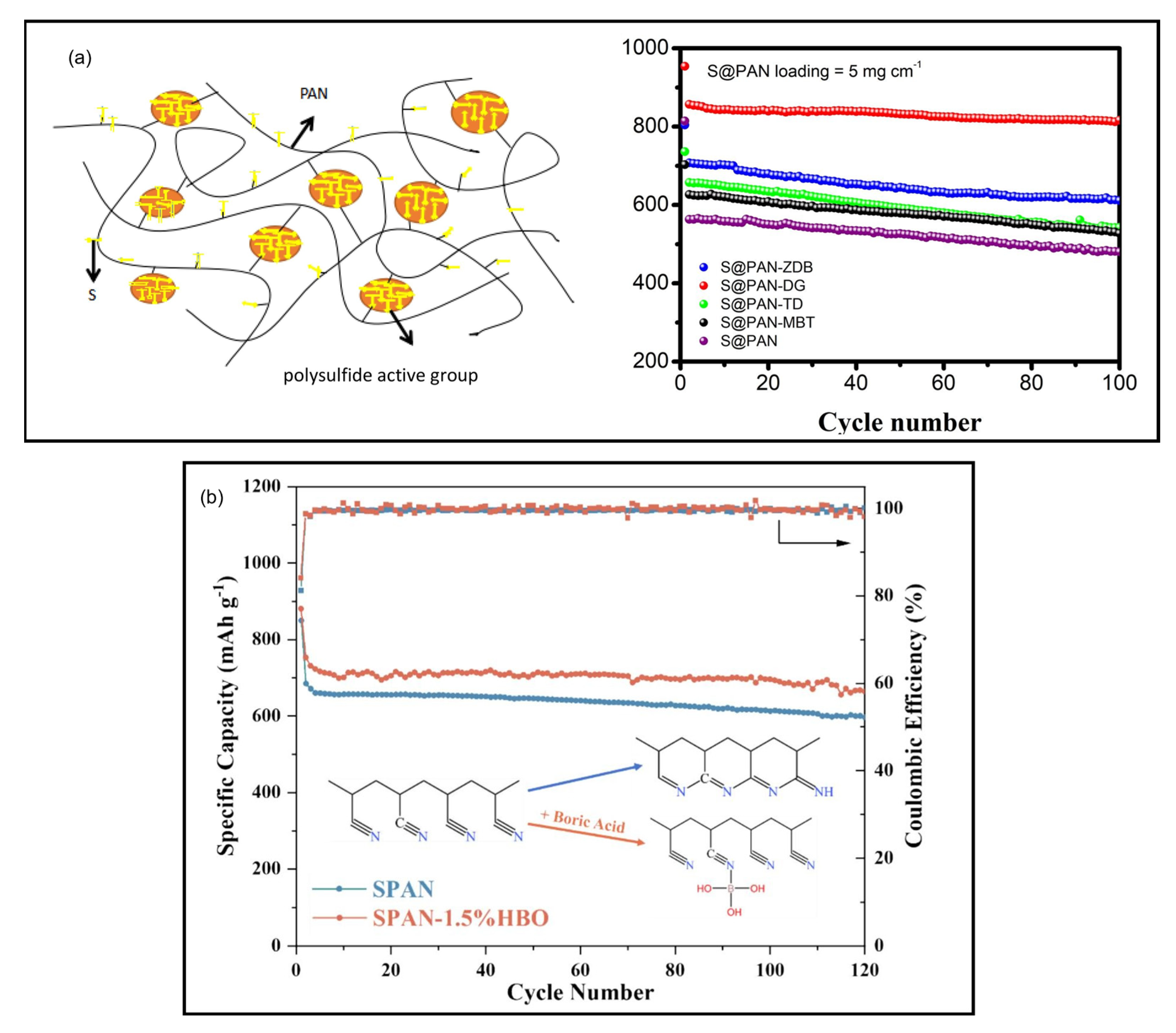

8.2. Vulcanization Accelerators and Vulcanization Agents

8.3. Morphology and Structure Engineering

8.4. Redox Accelerators

8.5. Heteroatoms Doping

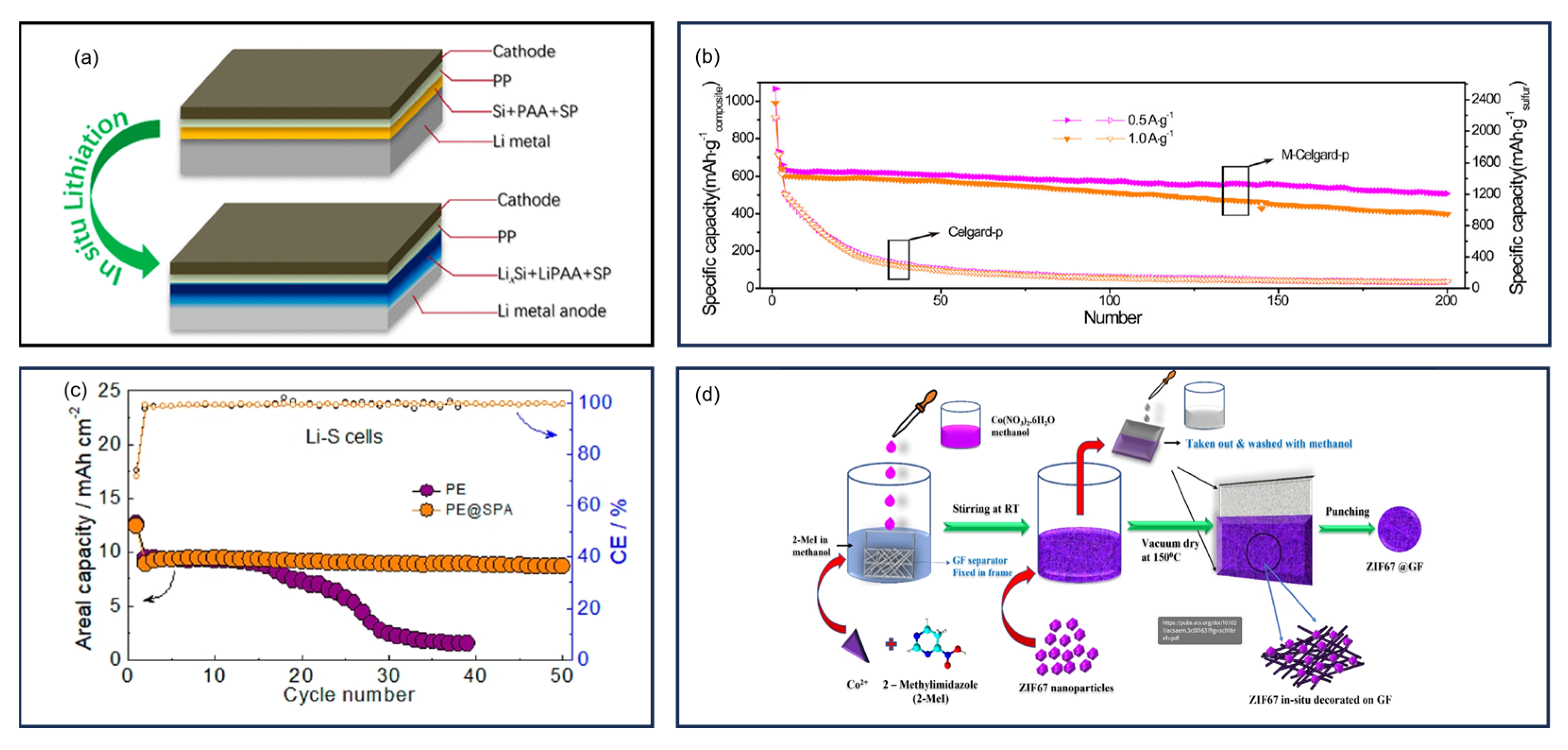

8.6. Pre-Lithiation of SPAN

8.6.1. Half-Cell Electrochemical Method

8.6.2. Short-Circuit Electrochemical Method

8.6.3. Chemical Method

8.6.4. Li-Containing Additives

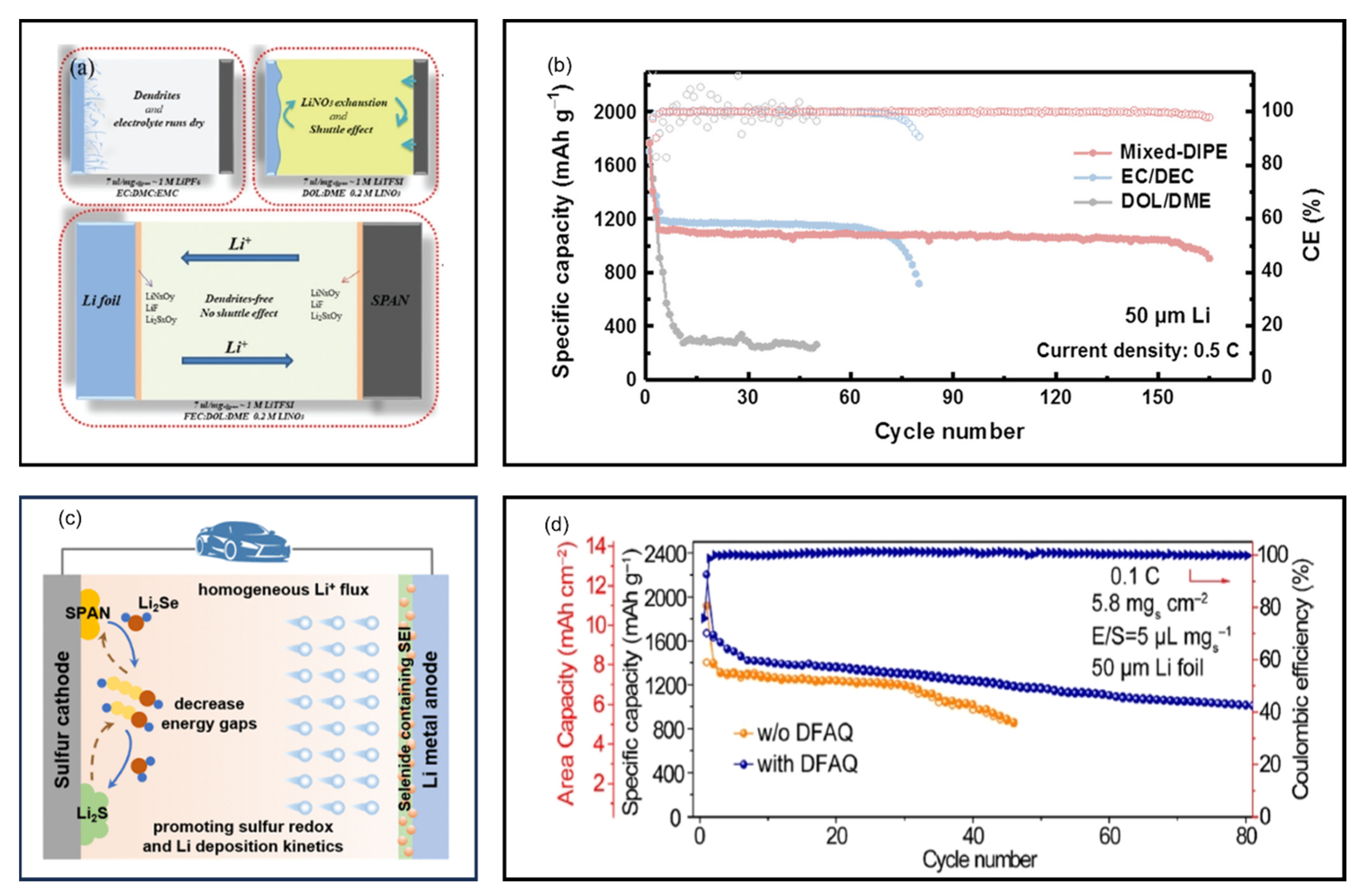

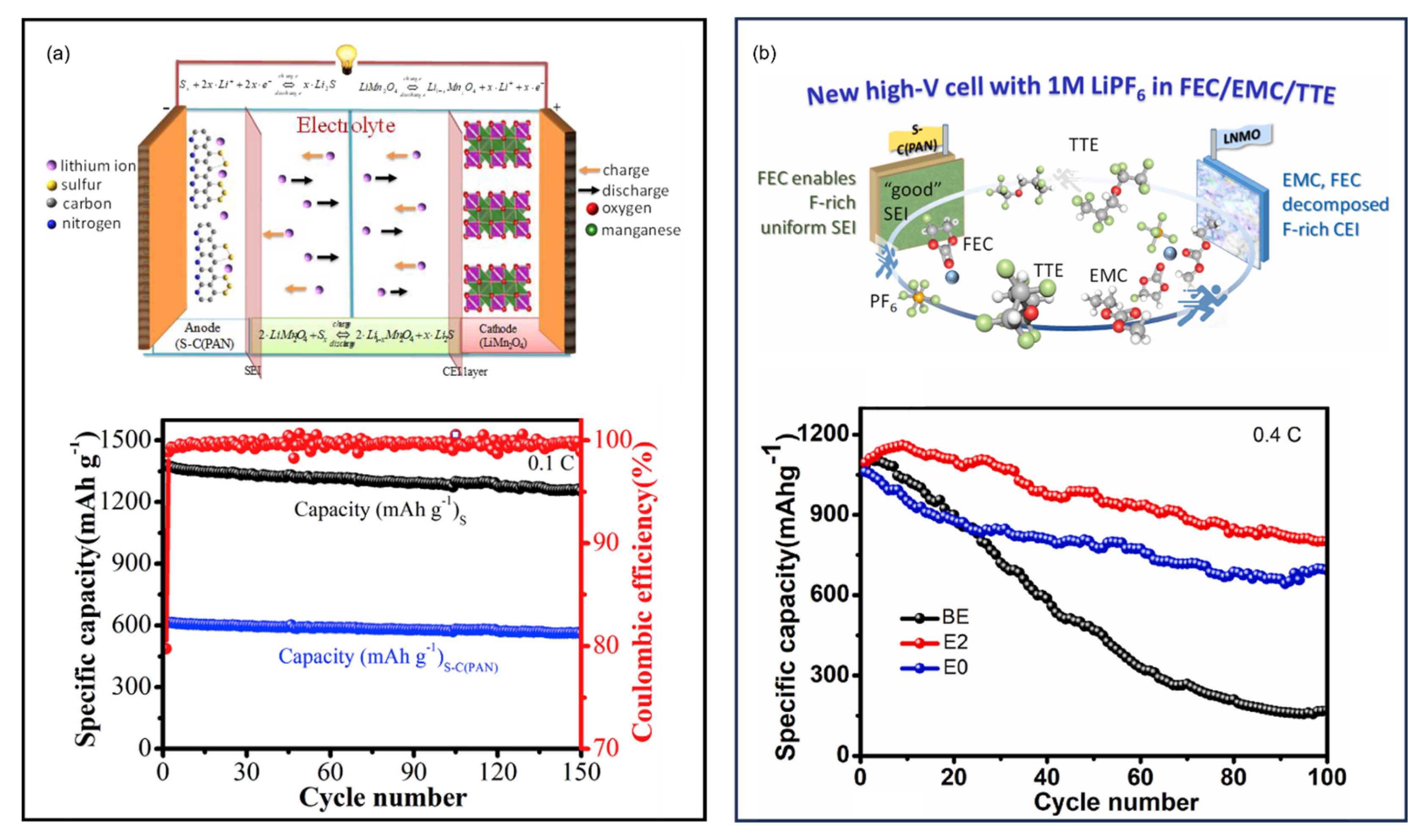

9. Electrolytes

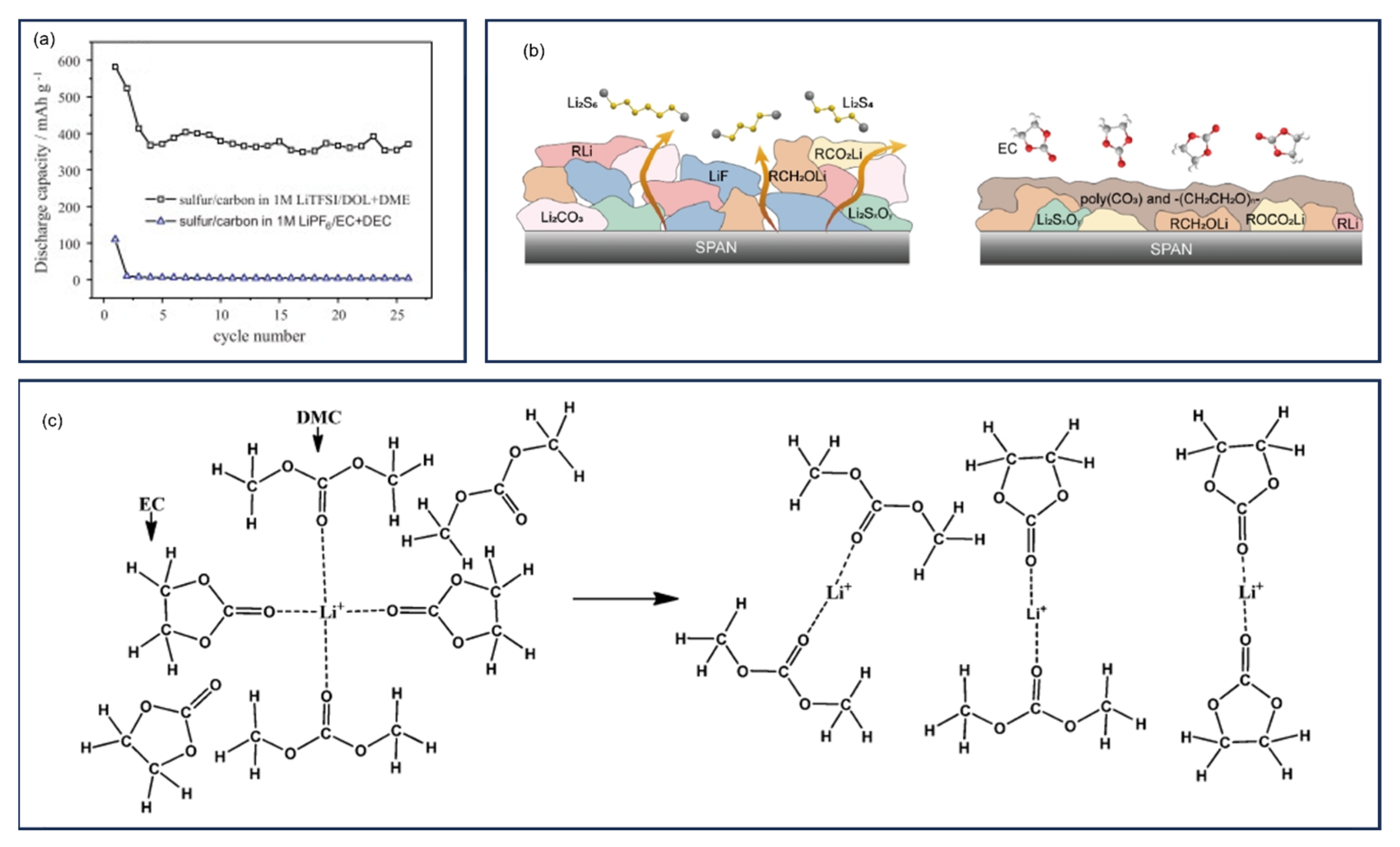

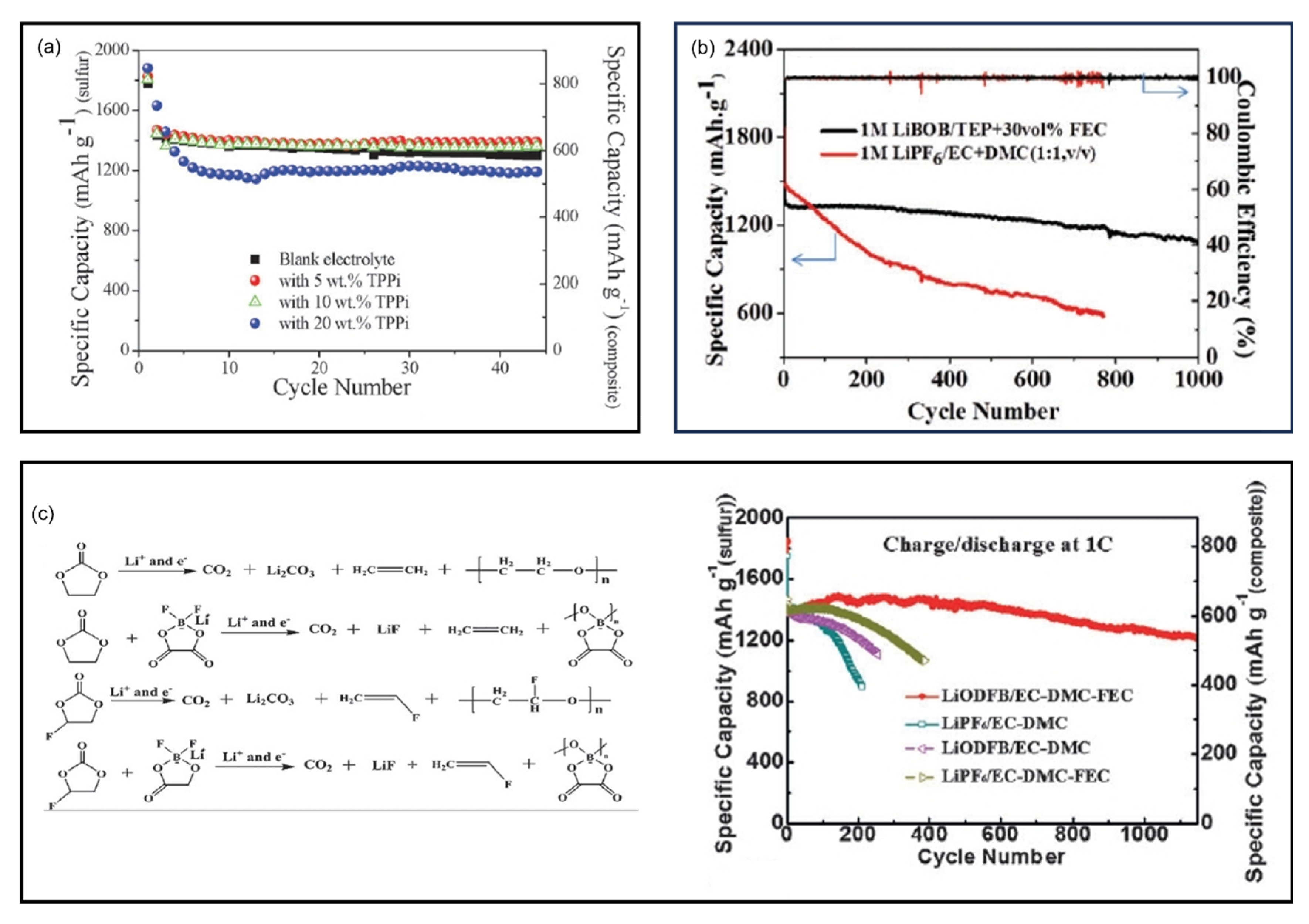

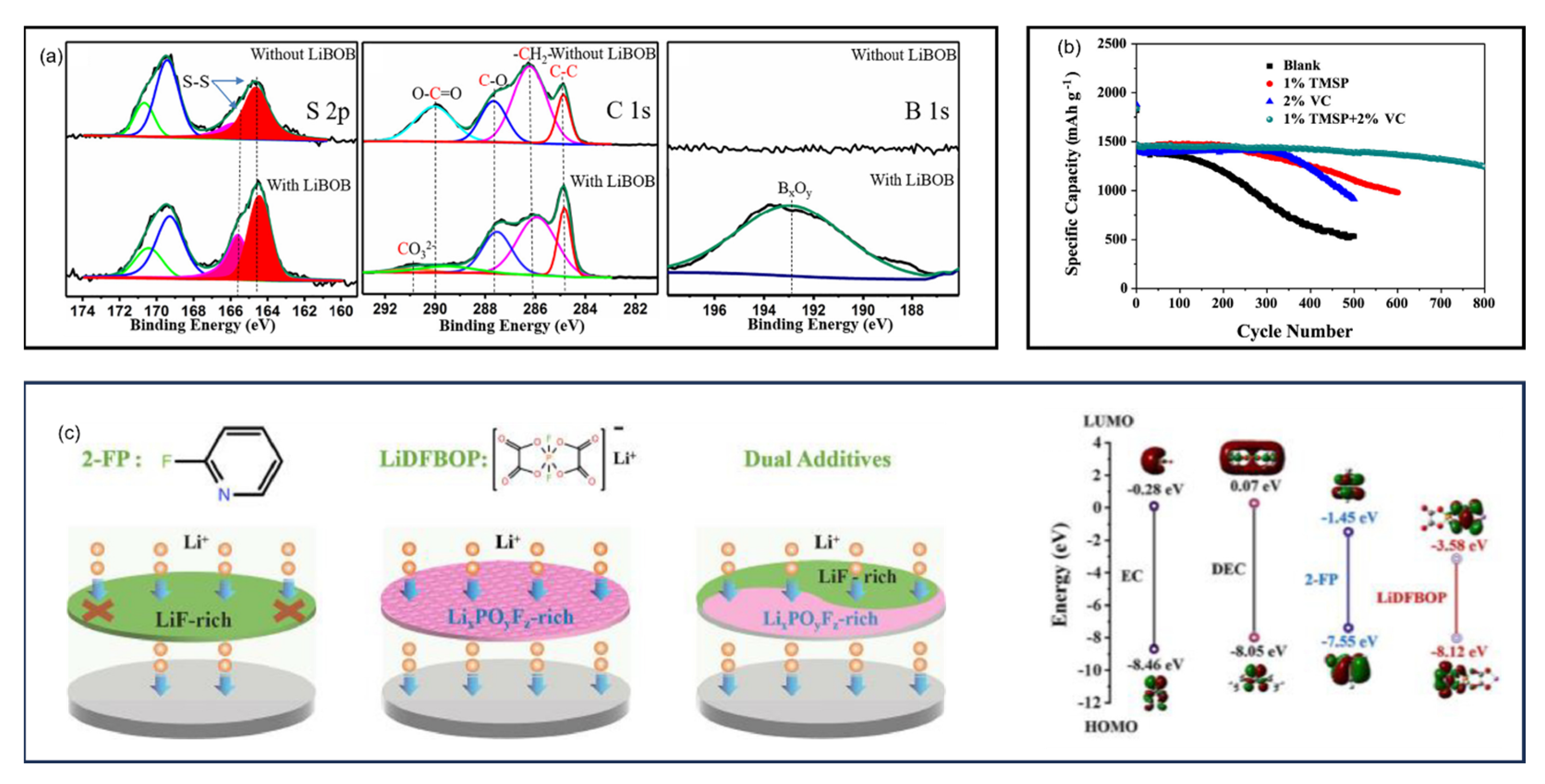

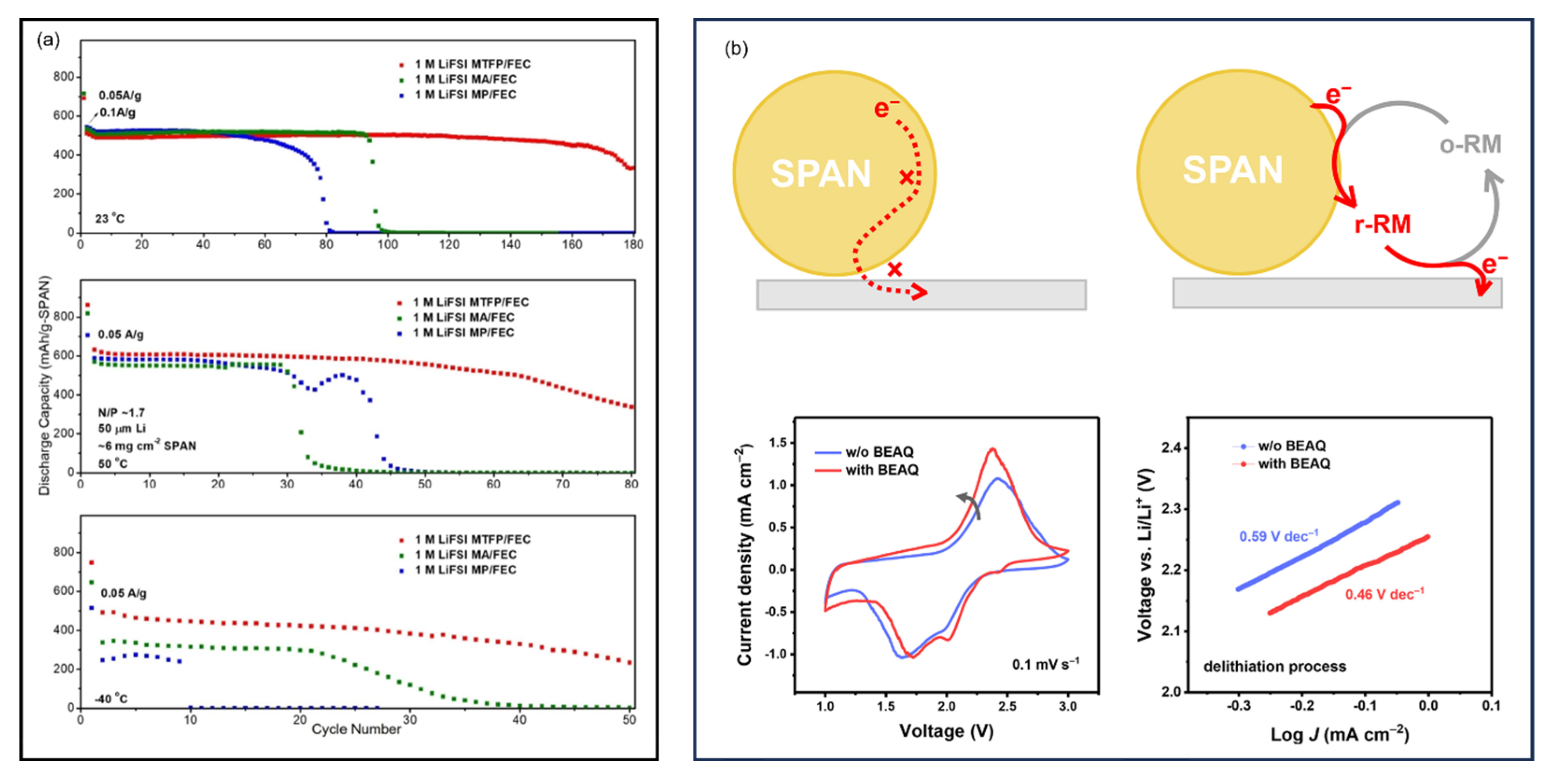

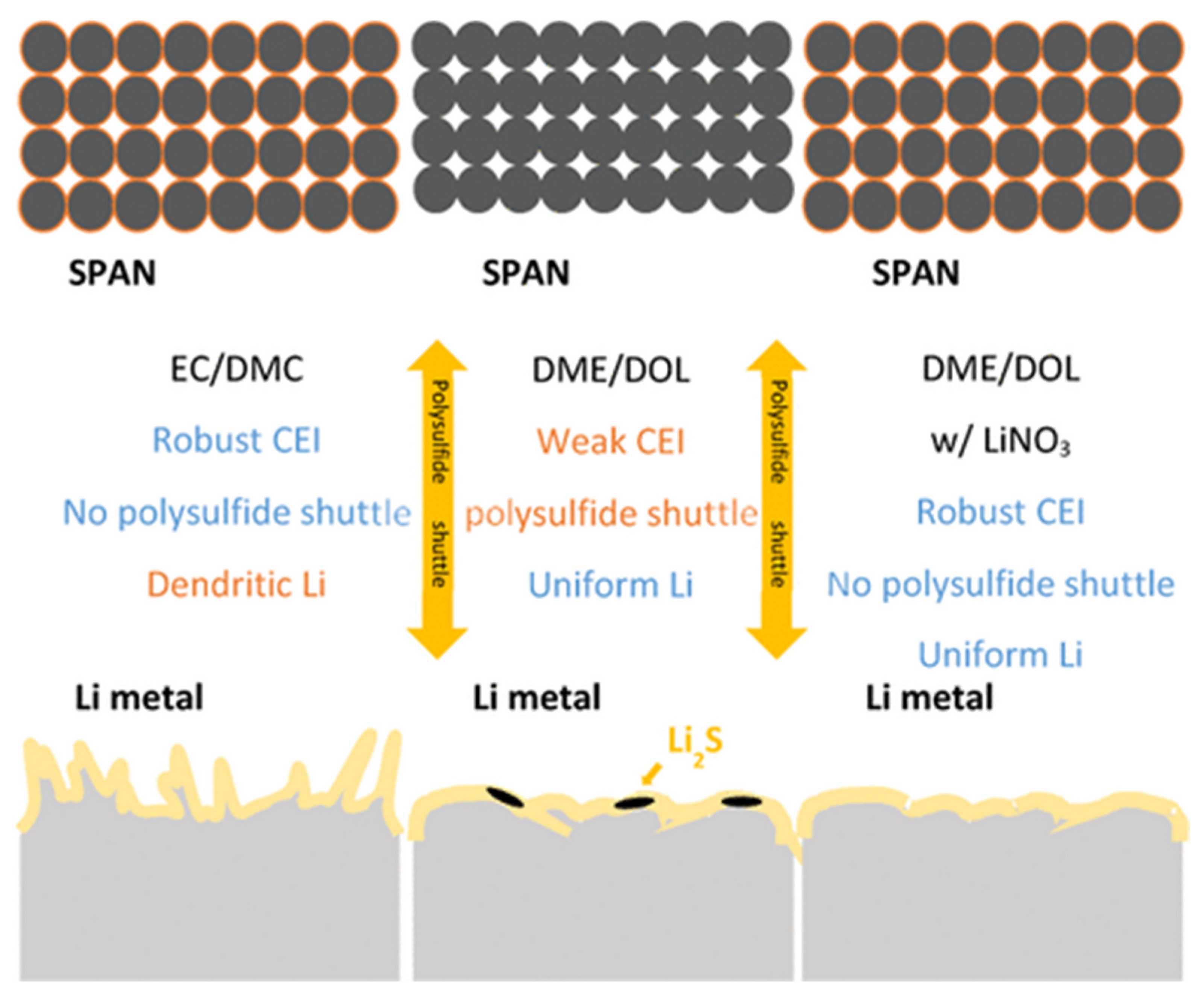

9.1. Carbonate-Based Electrolytes

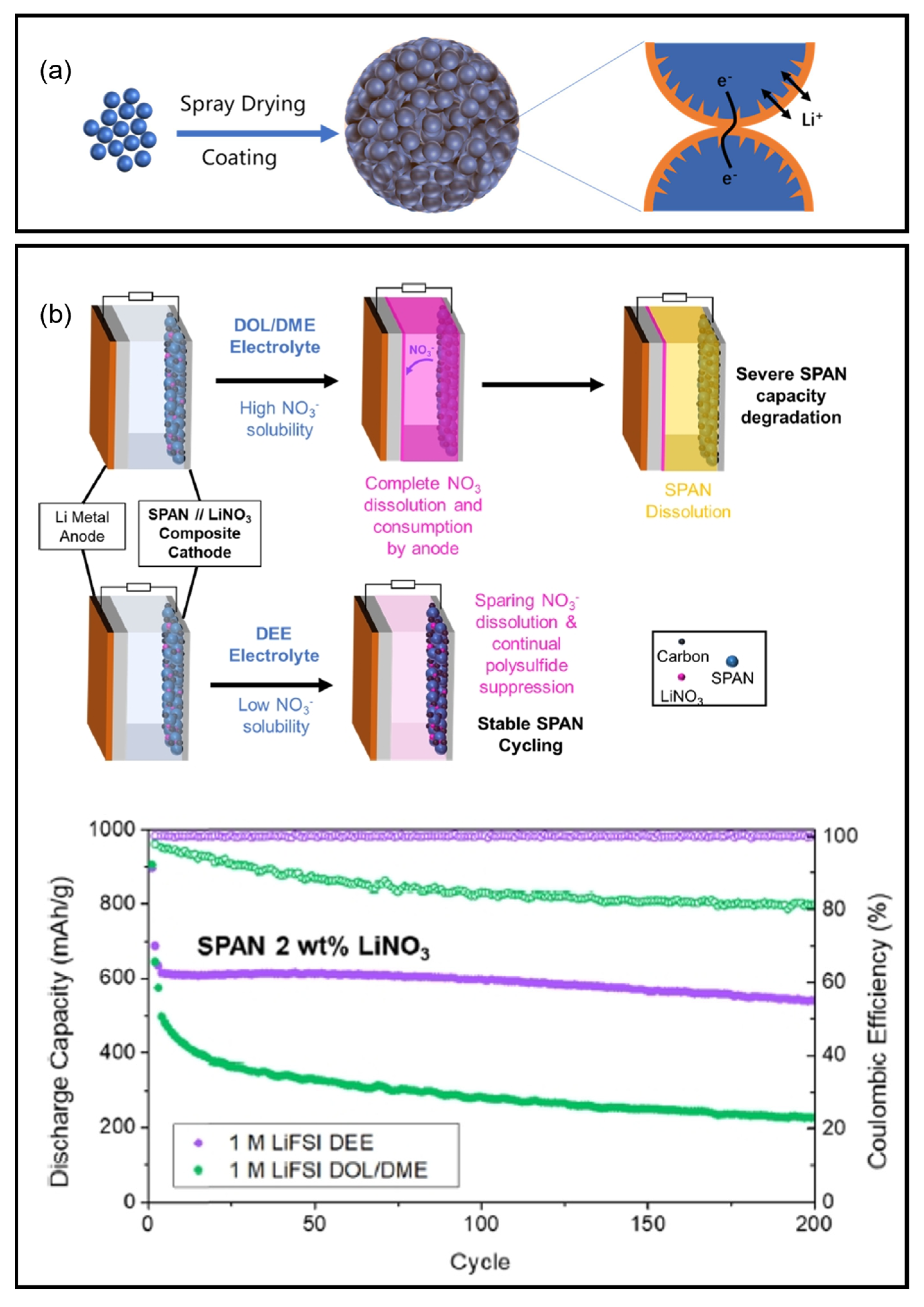

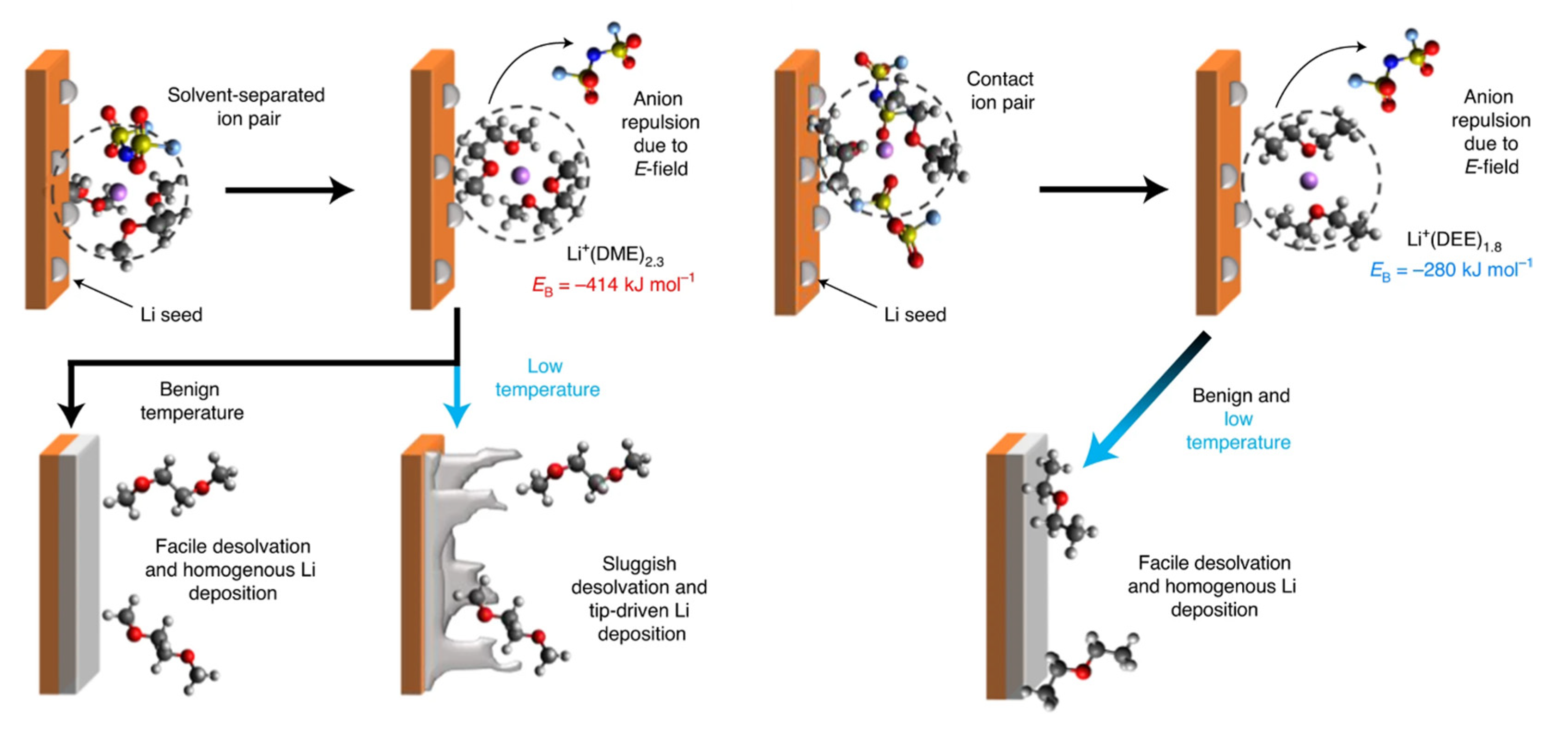

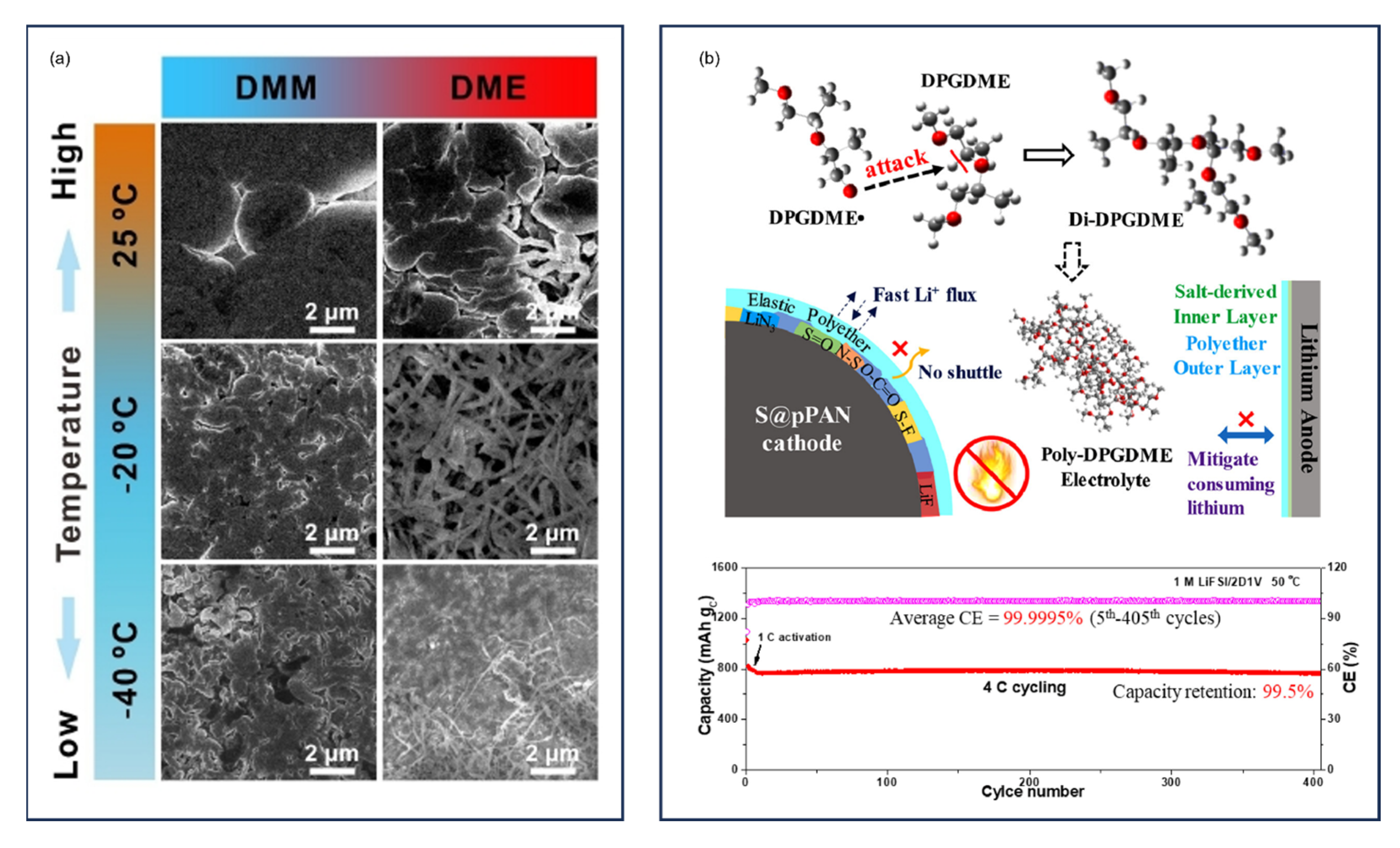

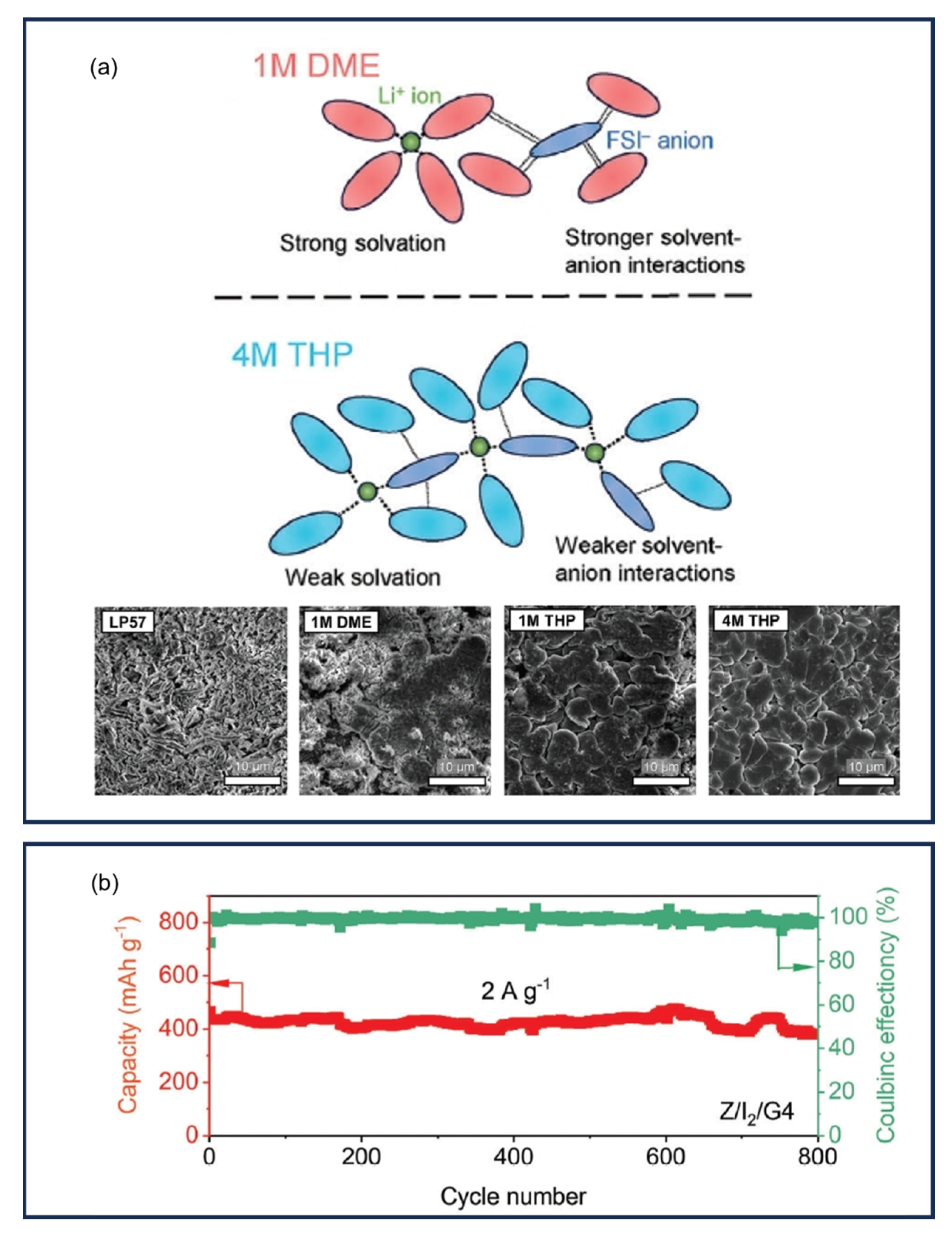

9.2. Dilute Ether-Based Electrolytes

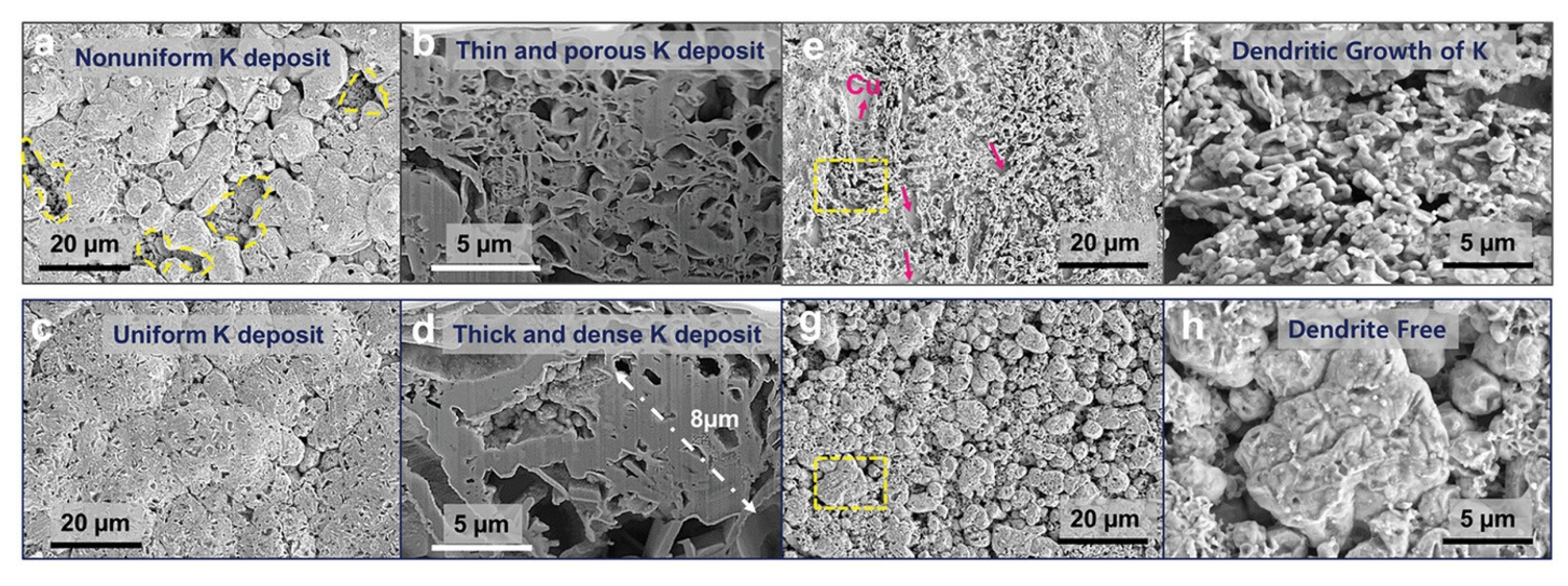

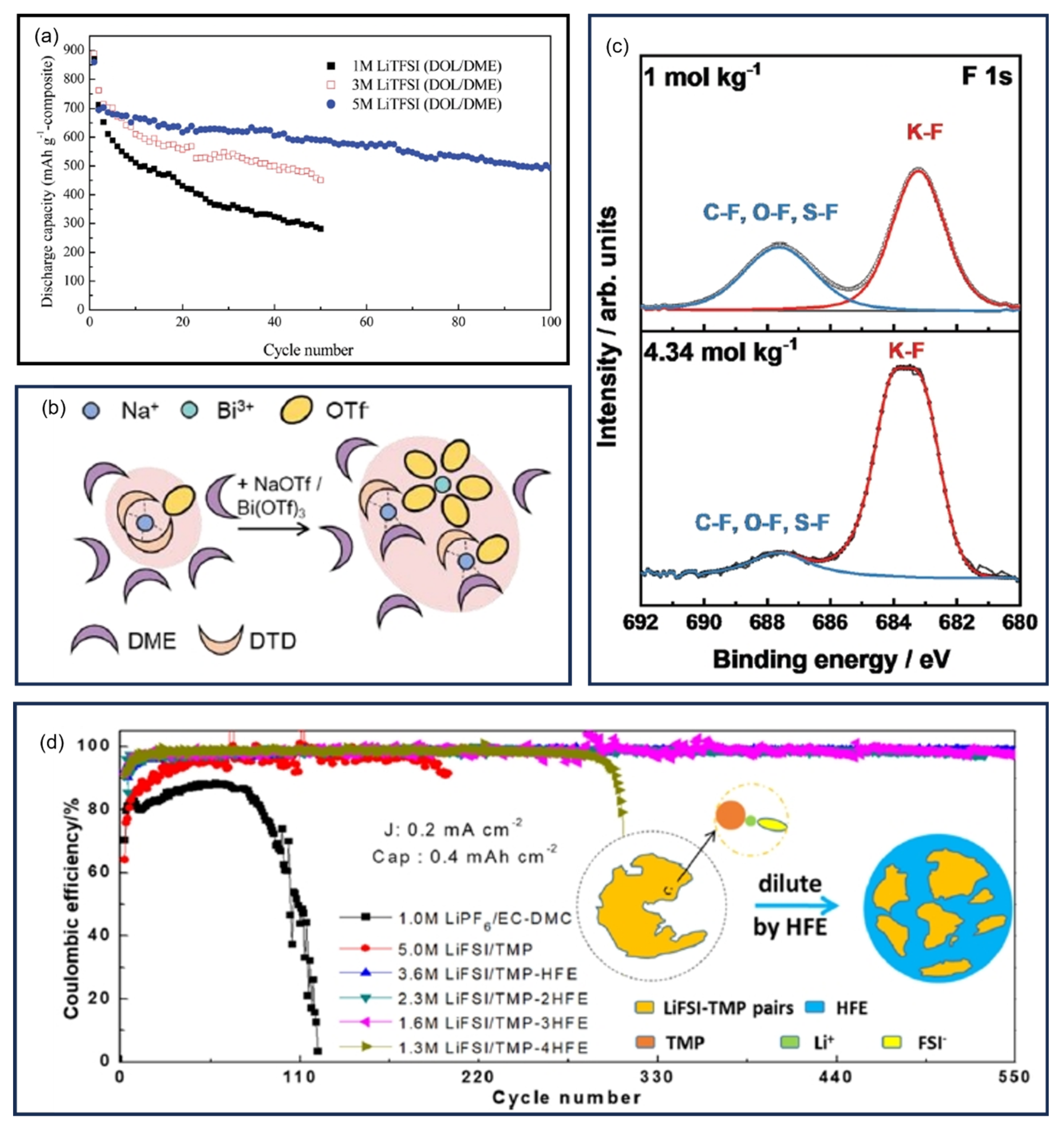

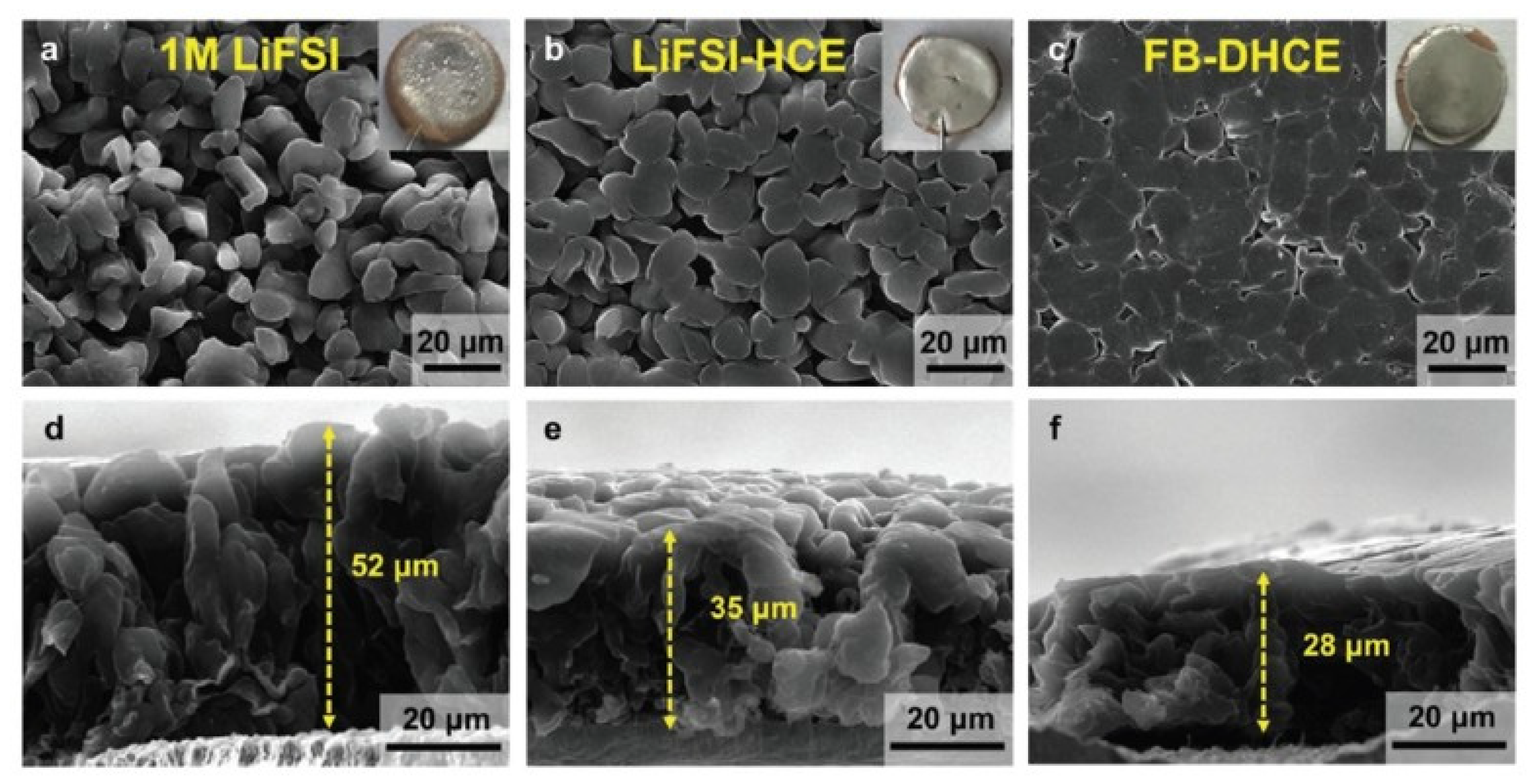

9.3. High-Concentration Electrolytes and Localized High-Concentration Electrolytes

9.4. Other Liquid Electrolytes

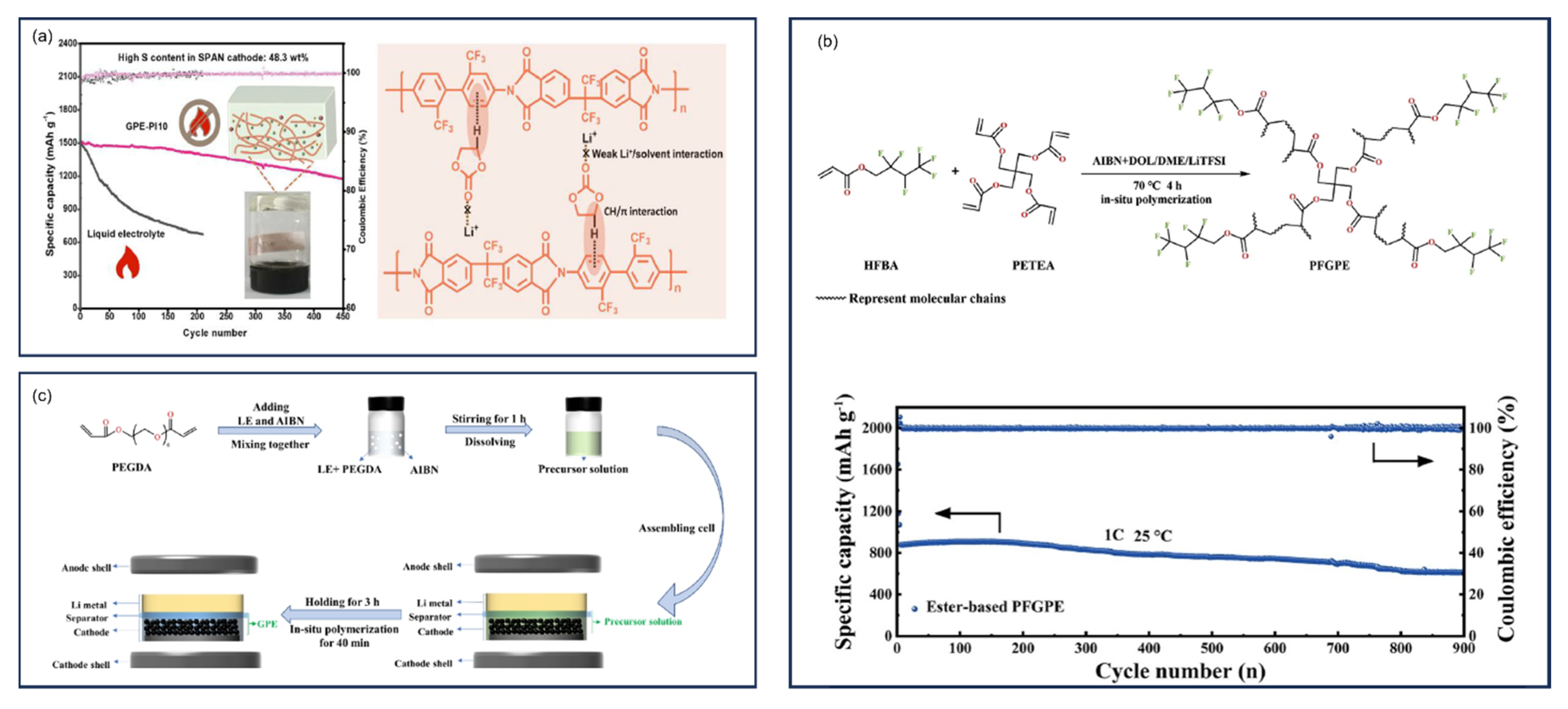

9.5. Gel Polymer Electrolytes

9.6. Solid-State Electrolytes

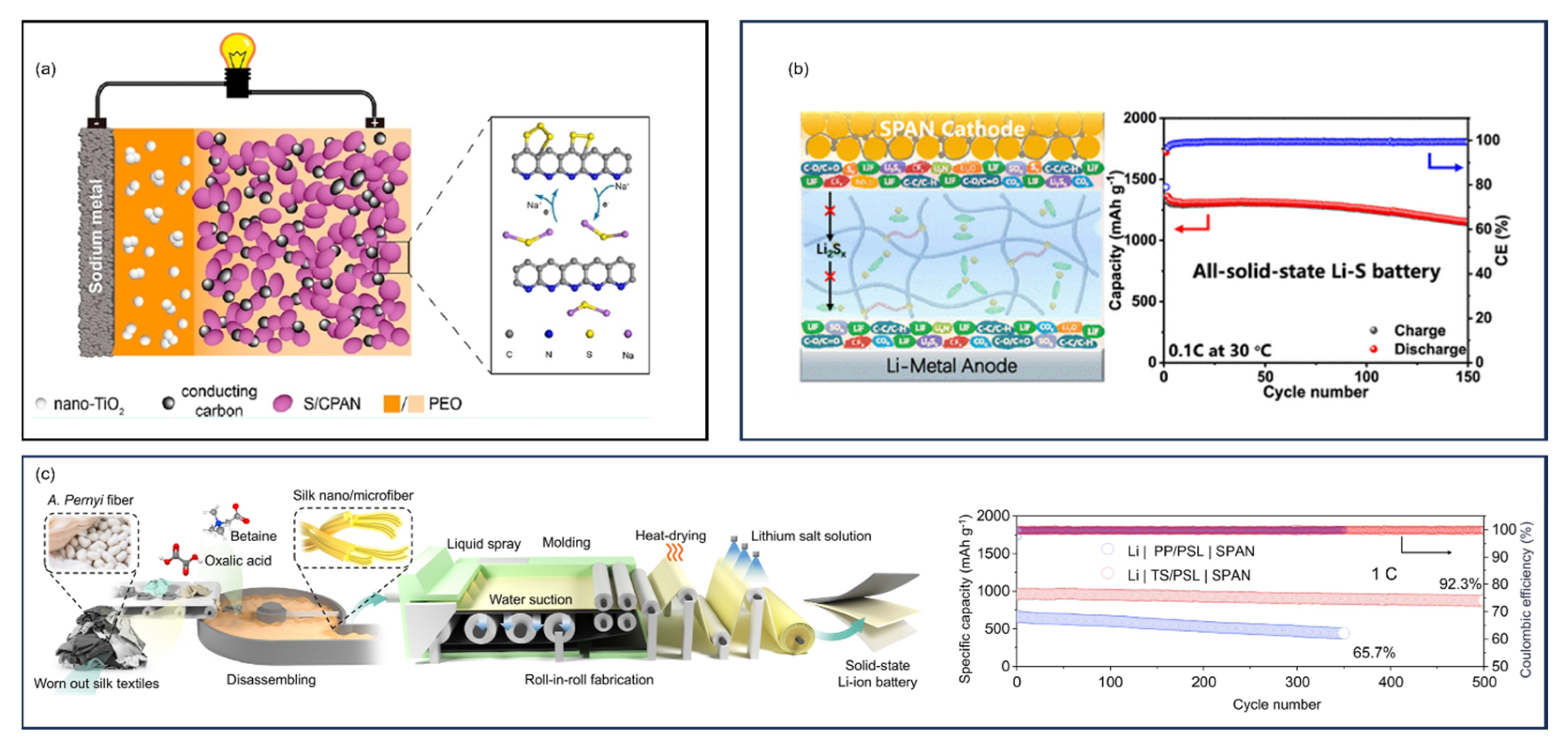

9.6.1. Solid-State Polymer Electrolytes

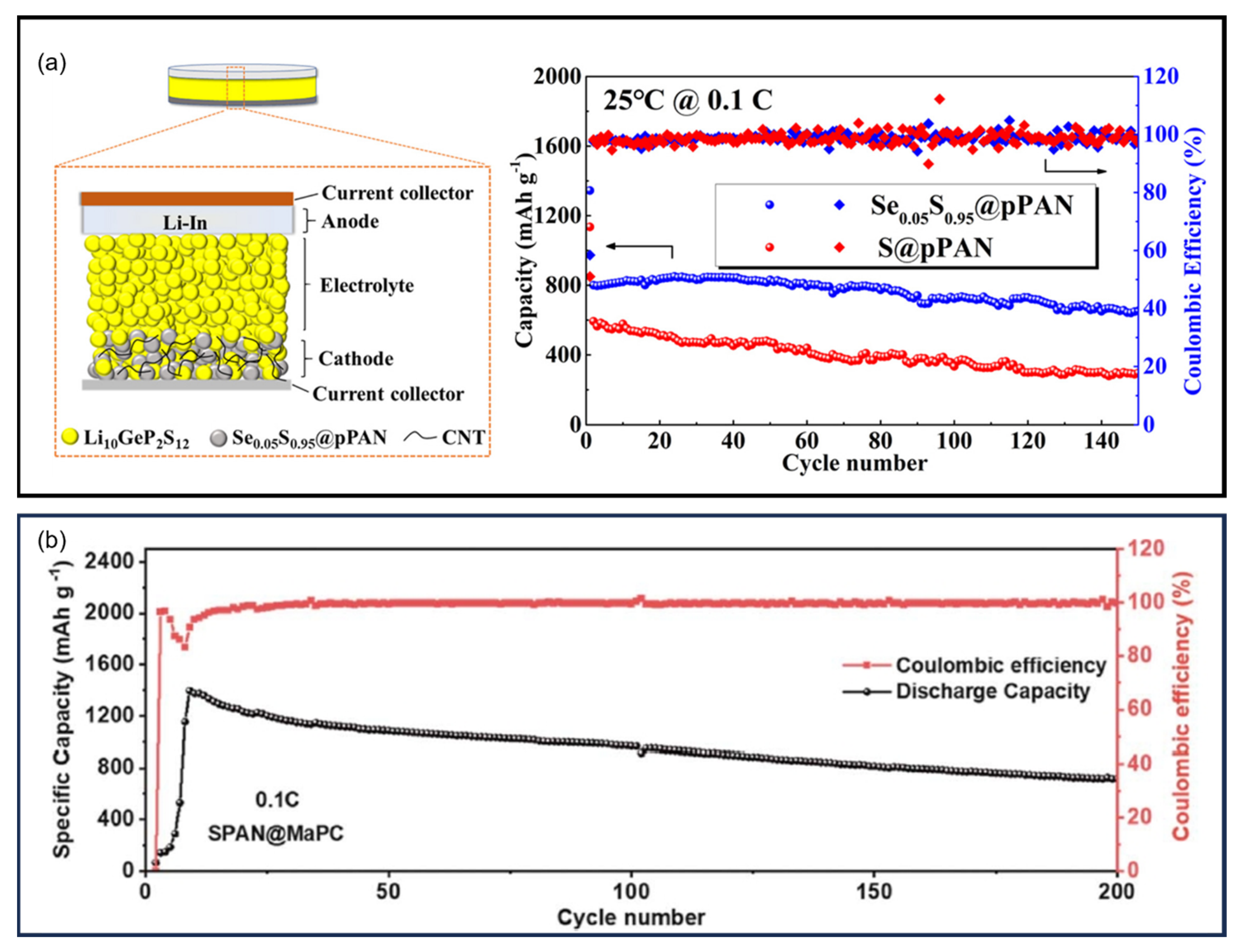

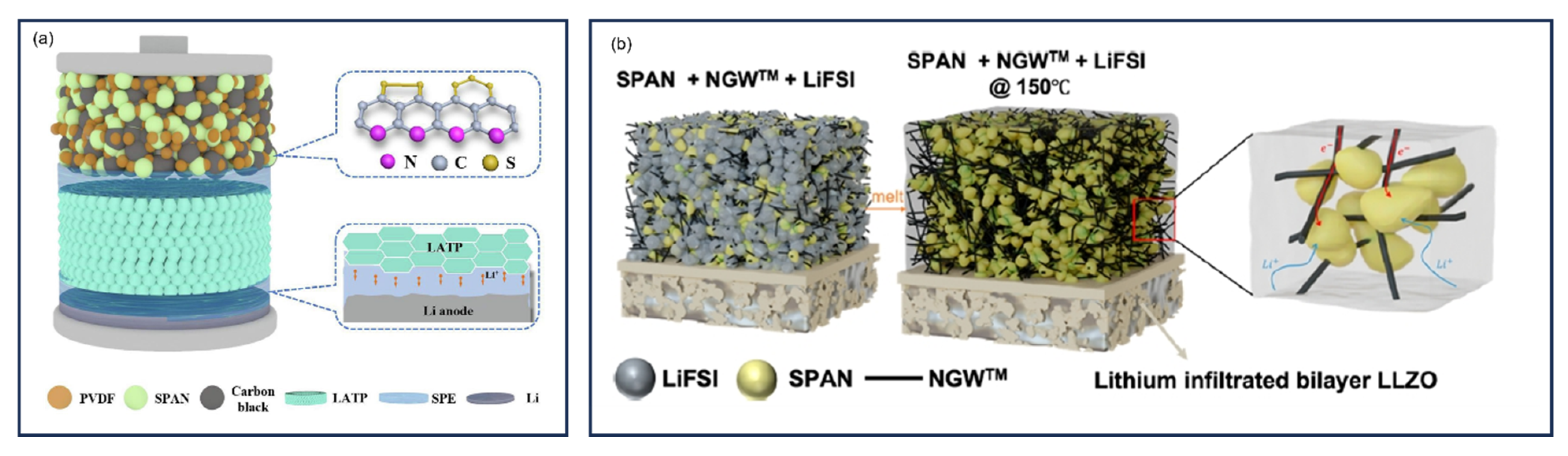

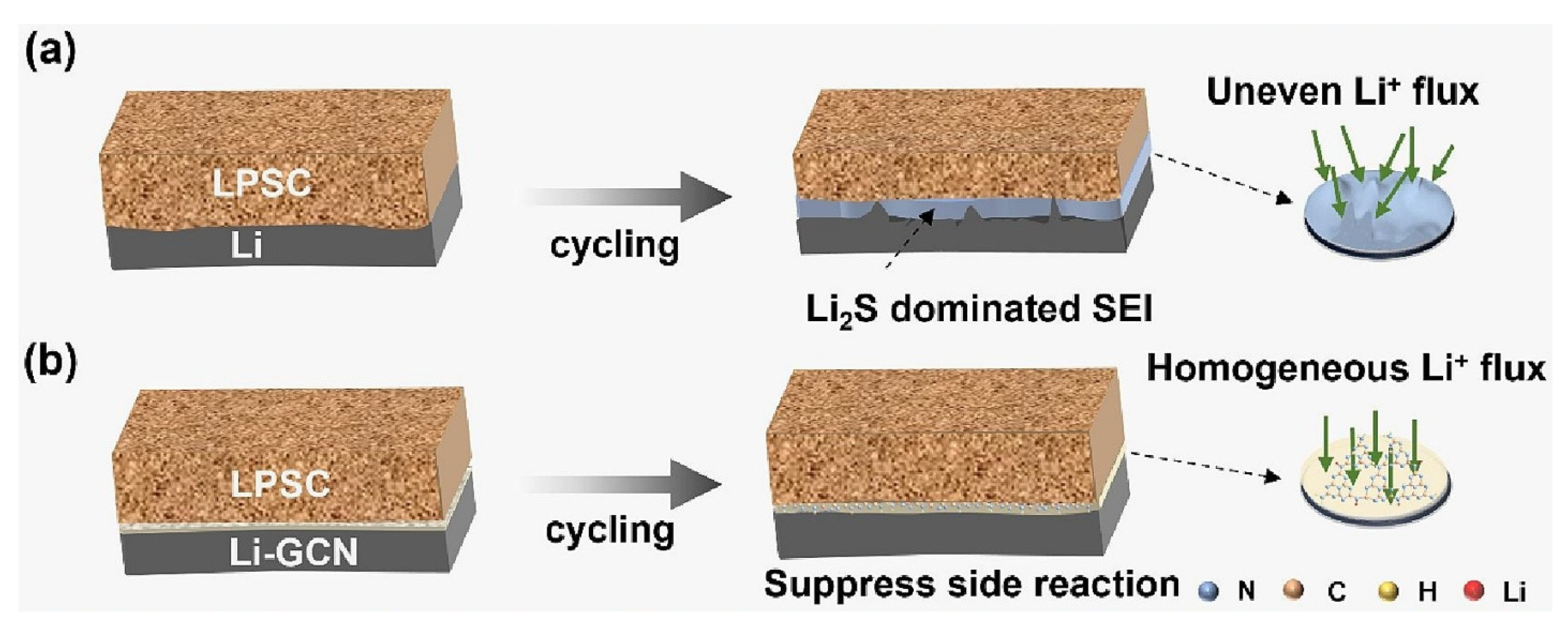

9.6.2. Solid-State Ceramic Electrolytes

9.6.3. Solid-State Composite Electrolytes and Hybrid Electrolytes

10. Binders

11. Current Collectors

12. Separators

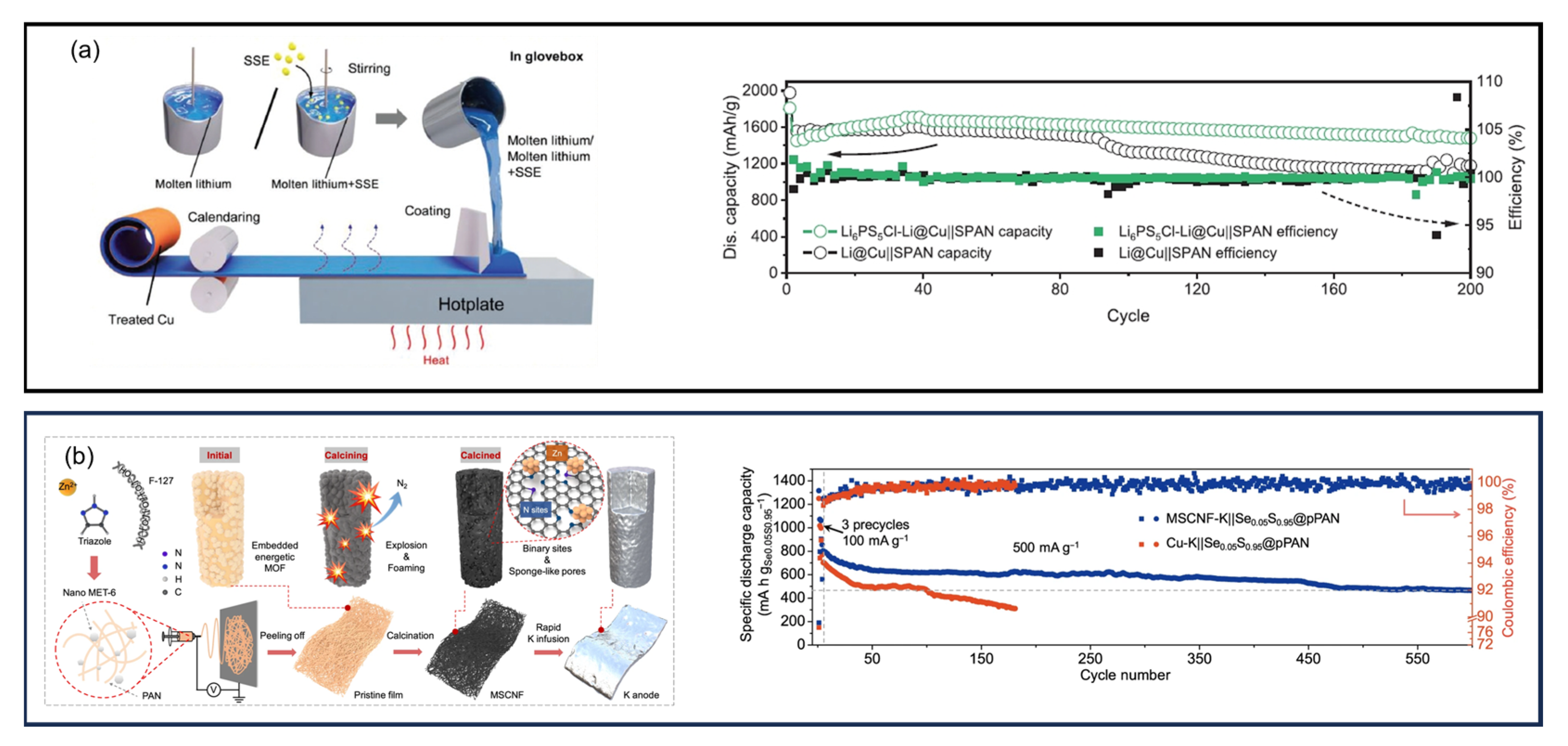

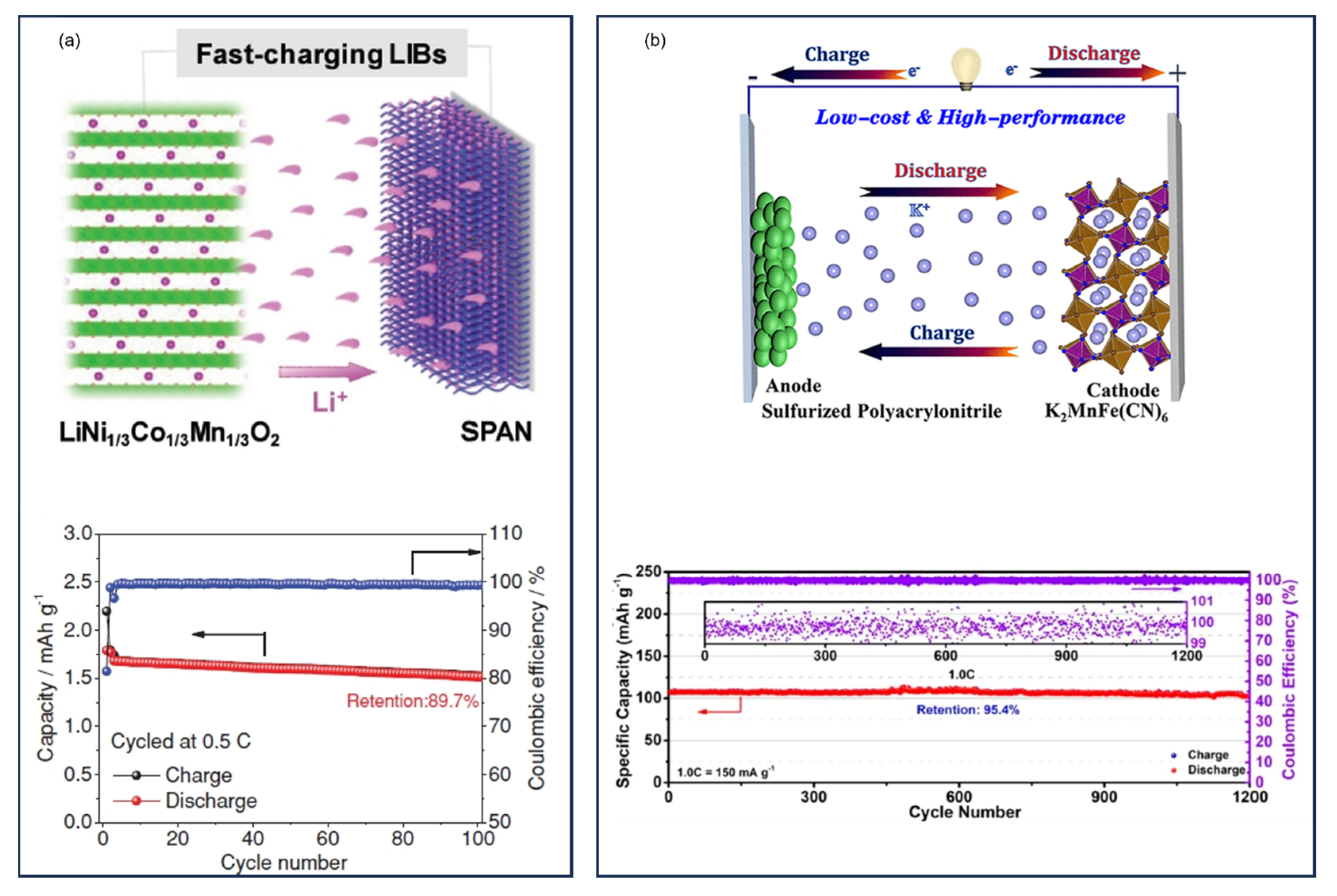

13. Anodes

14. SPAN as a Cathode Additive

15. SPAN as Anode

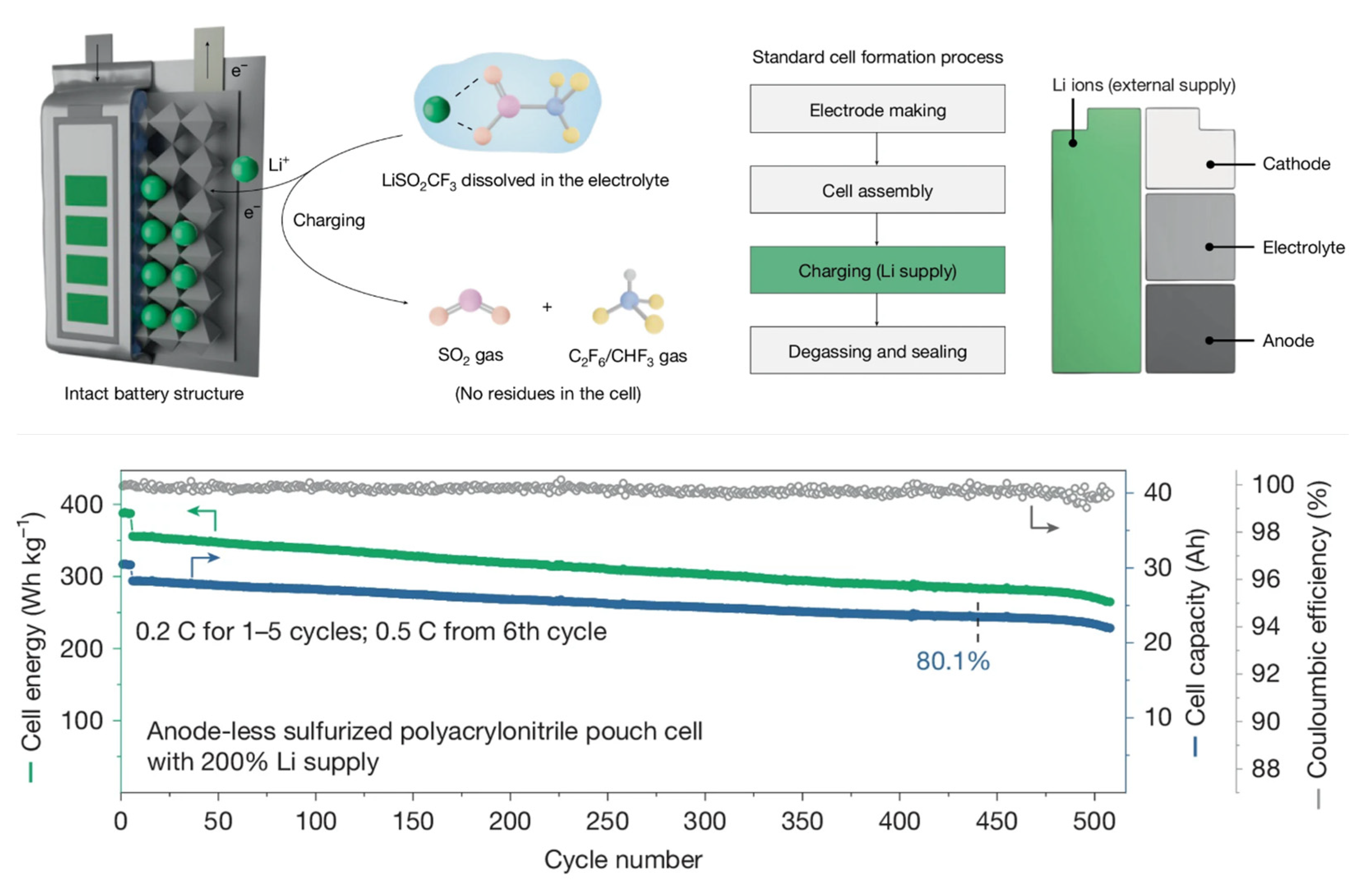

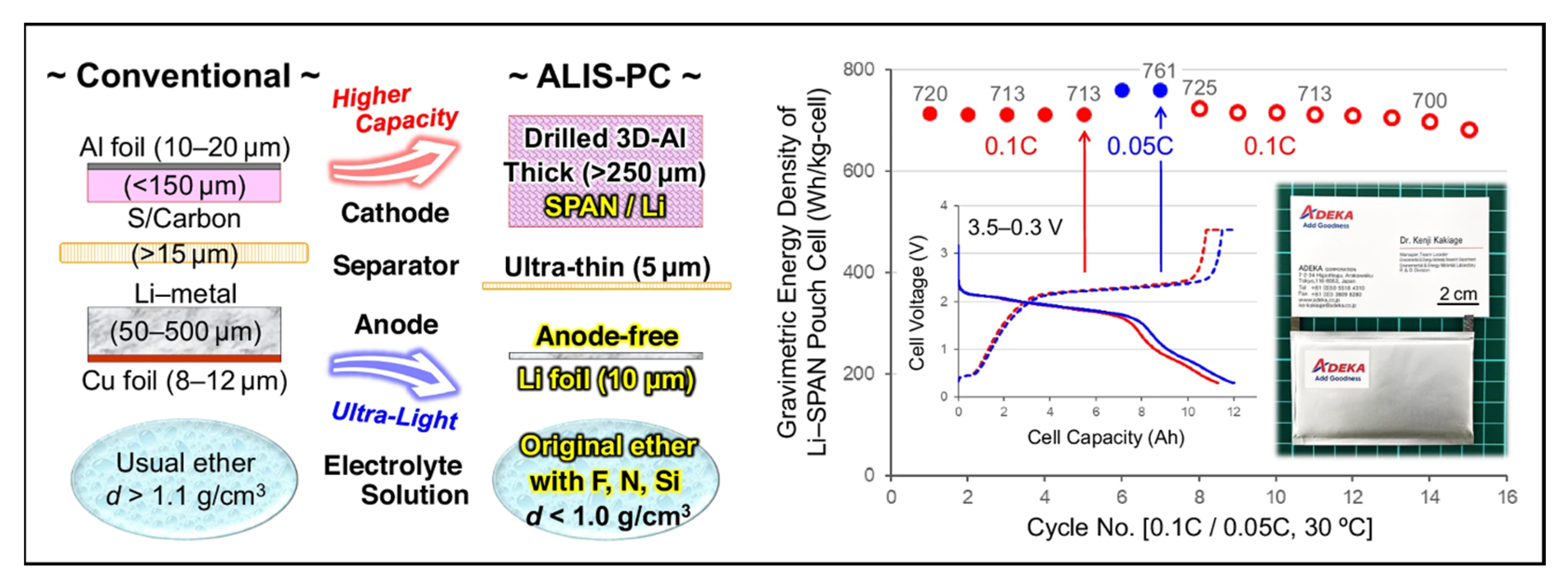

16. High-Energy Li||SPAN Batteries

- A lightweight 3D-Al foam sheet, Al-CELMET, was chosen as the current collector for the SPAN cathode. A high areal loading up to 32.4 mgS cm−2 (68.0 mgSPAN cm−2) on both sides could be achieved, corresponding to an areal capacity up to 46.6 mAh cm−2.

- The 3D-Al foam was laser-drilled with homogeneous hole of φ = 1.0 mm to save the weight by 31%.

- SWCNT and CNF were used as the conducting agent and the binder to achieve higher SPAN weight ratio in the cathode due to their superior electrical conductivity with high surface area and mechanical strength. A cathode fabricated using these materials achieved up to 98.0 wt% SPAN.

- SWCNT was dispersed in water using a soft dispersing method, Nihon Spindle Manufacturing’s JET PASTER technique. The SPAN cathode fabricated via this method exhibited a low ohmic resistance (Rohm).

- A unique shape design of the SPAN composite was employed. SPAN particles and fibers were mixed in a blend ratio of 90/10 to obtain the cathode to improve the electronic and ionic conductivities. As a result, the SPAN cathode exhibited reduced ion diffusion resistance (Rion).

- A porous SPAN fiber prepared via using PAN/PMMA as the electrospinning precursor was applied and exhibited excellent electrolyte absorbency.

- An expanded charge/discharge window was implemented in a potential range of 3.5–0.3 V to fully utilize the sulfur and the backbone redox capacities in SPAN.

- A novel ether-based electrolyte solution (Light-Ele) with properties of lightweight (0.98 g cm−3), high ionic conductivity, and low viscosity was designed. Light-Ele was composed of 0.2 M LiTFSI + 0.2 M LiFSI + 0.1 M LiNO3 + 0.1 M lithium1,1,2,2,3,3-hexafluoropropane-1,3-disulfonimide (LiHFDF) in DME/DOL/(trifluoromethyl)trimethylsilane (TFMTMS) (75/5/20, v/v/v). However, the activity of SPAN with the Light-Ele was lower than those with the conventional carbonate-based electrolytes, leading to a poorer CEI. Therefore, a two-step charge/discharge method using two different electrolytes was applied. First, a carbonate-based electrolyte with FEC and LiBOB additives was used to form a stable CEI. Second, Light-Ele was used to reduce the cell weight after removing the electrolyte from the first step.

- To reduce the cell weight, a thin separator, SETELA PE-type separator film, with a thickness of 5 µm and 35% porosity was used. In addition, a thinner pouch of an aluminum laminated film with a thickness under 80 µm (thin-type DNP Battery Pouch) was applied.

- An anode-free configuration design was implemented to maximize the energy density of the Li||SPAN cells. The SPAN cathode was electrochemically pre-lithiated using the half-cell method in carbonated-based electrolytes with FEC and LiBOB additives (for robust CEI formation). An ultra-thin Li foil ca. 10 µm thickness was used as the negative current collector instead of the conventional Cu foil.

17. Conclusions and Outlook

Supplementary Materials

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AB | acetylene black |

| AN | acrylonitrile |

| ANFs | aramid nanofibers films |

| BEAQ | 1,5-bis(2-(2-(2-methoxyethoxy)ethoxy)ethoxy)anthra-9,10-quinon |

| BME | butyl methyl ether |

| BP | black phosphorus |

| BTFE | bis-(2,2,2-trifluorosulfonyl)imide |

| CDW | carbonized delignified wood |

| CE | Coulombic efficiency |

| CF | carbon foam |

| CFs | carbon fibers |

| CNFs | carbon nanofibers |

| CNTs | carbon nanotubes |

| CPME | cyclopentyl methyl ether |

| CP-MAS | cross-polarization/magic angle spinning |

| CTAC | hexadecyl trimethylammonium chloride |

| CV | cyclic voltammetry |

| C-β-CD | carbonyl-β-cyclodextrin |

| DBB | 2,2-dithiobis(benzothiazole) |

| DBE | dibutyl ether |

| DEC | diethylene carbonate |

| DEE | diethyl ether |

| DEMS | diethoxydimethylsilane |

| DFAQ | 1,4-difluoroanthraquinone |

| DFT | density functional theory |

| DG | diphenylguanidine |

| DGE | desolvated gel electrolyte |

| DIG | diglyme |

| DIPE | diisopropyl ether |

| DMC | dimethyl carbonate |

| DME | dimethoxyethane |

| DMM | dimethoxymethane |

| DMMP | dimethyl methylphosphonate |

| DMMS | dimethyldimethoxysilane |

| DMP | 1,2-dimethyoxypropane |

| DMSO | dimethyl sulfoxide |

| DOD | depth of discharge |

| DOL | 1,3-dioxolane |

| DPC | dipropyl carbonate |

| DPE | dipropyl ether |

| DPGDME | dipropyleneglycol dimethyl ether |

| DSC | differential scanning calorimetric |

| DTD | 1,3,2-dioxathiolane 2,2-dioxide |

| EA | elemental analysis |

| EC | ethylene carbonate |

| EC-AFM | electrochemical atomic force microscopy |

| EGBMC | ethylene glycol bis(methyl carbonate) |

| EIS | electrochemical impedance spectroscopy |

| EMC | ethyl methyl carbonate |

| EPR | electron paramagnetic resonance |

| ET | ethlenethiourea |

| EVs | electric vehicles |

| FB | fluorobenzene |

| FEC | fluoroethylene carbonate |

| FT-IR | Fourier transform infrared |

| GCN | graphitic carbon nitride |

| GE | gel electrolyte |

| GF | glass fiber |

| GFs | graphene foams |

| GG | guar gum |

| GNS | graphene nanosheet |

| GO | graphene oxide |

| GPEs | gel polymer electrolytes |

| Gr | graphite |

| G4 | tetraglyme |

| HBO | boric acid |

| HC-EM | half-cell electrochemical method |

| HCEs | high-concentration electrolytes |

| HFBA | hexafluorobutyl acrylate |

| HFE | hexafluoropropylene |

| IA | itaconic acid |

| IL | ionic liquid |

| IL-GPE | ionic liquid gel polymer electrolyte |

| KB | Ketjen black |

| LA133 | polyacrylic latex |

| LBG | locust beam gum |

| LHCEs | localized high concentration electrolytes |

| LiBOB | lithium bis(oxalate) borate |

| LIBs | lithium-ion batteries |

| LiDFBOP | lithium difluorobis (oxalate) phosphate |

| LiDFOB | lithium difluoro(oxalate)borate |

| LiFSI | lithium bis(fluorosulfonyl)imide |

| LiHFDF | lithium1,1,2,2,3,3-hexafluoropropane-1,3-disulfonimide |

| LiODFB | lithium oxalyldifluoroborate |

| LiPSs | lithium polysulfides |

| LiTFSI | lithium bis(trifluoromethanesulfonyl)imide |

| LMA | lithium metal anode |

| LMO | lithium manganese oxide |

| LSBs | lithium–sulfur batteries |

| MaPC | macro-porous carbon |

| MBA | magnesium bis(diisopropyl)amide |

| MBT | 2-mercaptobenzothiazoles |

| MCPs | microporous carbon polyhedrons |

| MD | molecular dynamics |

| MeIM | 2-methylimidazole |

| MLG | multilayered graphene |

| MOFs | metal–organic frameworks |

| MP | methyl propionate |

| MSBs | metal–sulfur batteries |

| MTFP | methyl 3,3,3-trifluoropionate |

| MWCNTs | multi-walled carbon nanotube |

| NaCMC | sodium carboxymethyl cellulose |

| NaTPB | sodium tetraphenylborate |

| NaTFSI | sodium trifluoromethanesulfonimide |

| NaPPB | sodium bis(perfluoropinacol)borate |

| NCM | lithium nickel manganese cobalt |

| NER | nitrogen evolution reaction |

| NMP | N-methyl-2-pyrrolidone |

| NMR | nuclear magnetic resonance |

| PAA | polyacrylic acid |

| PAAS | sodium polyacrylate |

| PAF | polymer-alloy-fluoride |

| PAN | polyacrylonitrile |

| PC | propylene carbonate |

| PCE | plastic crystal electrolyte |

| PDA | polydopamine |

| pair distribution function | |

| PDSe | phenyl diselenide |

| PE | polyethylene |

| PEG | polyethylene glycol |

| PEGDA | poly(ethylene glycol) diacrylate |

| PEO | polyethylene oxide |

| PEOEC | poly(ethylene oxide-co-ethylene carbonate) |

| PETA | pentaerythritol triacrylate |

| PETEA | pentaerythritol tetraacrylate |

| PI | polyimide |

| PIBs | potassium-ion batteries |

| PMMA | poly(methyl methacrylate) |

| PP | polypropylene separator |

| Ppy | polypyrole |

| PS | polystyrene |

| PuA | pulutan-graft-sodium polyacrylic acid |

| PVA | polyvinyl alcohol |

| PVDF | polyvinylidenefluoride |

| PVP | polyvinyl pyrrolidone |

| RAFT | addition-fragmentation chain transfer |

| Rsf | interfacial impedance |

| Rct | charge transfer resistance |

| rGO | reduced graphene oxide |

| RP | red phosphorus |

| sAXS | soft X-ray absorption spectroscopy |

| SBR | styrene butadiene rubber |

| SCMC | carboxymethyl cellulose |

| SCR | carboxylated styrene butadiene rubber |

| SC-EM | short-circuit electrochemical method |

| Se | selenium |

| SEI | solid-electrolyte interface |

| SEM | scanning electron microscopy |

| SIPS | solvent-induced phase separation |

| SLMP | stable lithium metal powder |

| SPAN | sulfurized polyacrylonitrile |

| SPEs | Solid-state polymer electrolytes |

| SPVac | sulfurized poly(vinylacetylene) |

| SWCNTs | single-walled carbon nanotubes |

| TD | tetrathylthiuruam disulfide |

| Te | tellurium |

| TEGDME | tetraethylene glycol dimethyl ether |

| TEM | transmission electron microscopy |

| TEP | triethyl phosphate |

| TFMTMS | (trifluoromethyl)trimethylsilane |

| TG | thermogravimetry |

| THF | tetrahydrofuran |

| THP | tetrahydropyran |

| TI | triallyl isocyanurate |

| TIPS | thermally induced phase separation |

| TMP | trimethyl phosphate |

| TMSB | tris(trimethylsilyl) borate |

| TMSP | tris(trimethylsilyl) phosphite |

| TMS-N3 | trimethylsilyl azide |

| TPA | terephthalic acid |

| TPOS | tetrapropoxysilane |

| TOF-SIMS | time-of flight secondary ion mass spectrometry |

| TPPi | triphenyl phosphite |

| TTCA | trithiocyanuric acid |

| TTE | 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropylether |

| TTFP | tris(2,2,2-trifluoroethyl) phosphite |

| VAs | vulcanization accelerators |

| VC | vinylene carbonate |

| VGCF | vapor grown carbon fiber |

| XAS | X-ray absorption spectroscopy |

| XPS | X-ray photoelectron spectroscopy |

| XRD | X-ray diffraction |

| ZDB | zinc N-ethyl-N-phenyldithiocarbamate |

| 2-FP | 2-fluoropyridine |

References

- Chung, S.-H.; Manthiram, A. Current Status and Future Prospects of Metal–Sulfur Batteries. Adv. Mater. 2019, 31, 1901125. [Google Scholar] [CrossRef]

- Yu, X.; Manthiram, A. A Progress Report on Metal–Sulfur Batteries. Adv. Funct. Mater. 2020, 30, 2004084. [Google Scholar] [CrossRef]

- Phan, A.L.; Le, P.M.L.; Wang, C. Realizing High-Energy and Long-Life Li/SPAN Batteries. Joule 2024, 8, 1601–1618. [Google Scholar] [CrossRef]

- Wagenfeld, J.-G.; Al-Ali, K.; Almheiri, S.; Slavens, A.F.; Calvet, N. Sustainable Applications Utilizing Sulfur, a by-Product from Oil and Gas Industry: A State-of-the-Art Review. Waste Manag. 2019, 95, 78–89. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, H.; Liu, J.; Chen, J.; Lu, H.; Huang, Y.; Wang, J. Structure and Reactions Mechanism of Sulfurized Polyacrylonitrile as Cathodes for Rechargeable Li-S Batteries. Nano Res. 2023, 16, 8159–8172. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, C.; Li, Z.; Hu, X.; Razzaq, A.A.; Deng, Z. Sulfurized Polyacrylonitrile for High-Performance Lithium Sulfur Batteries: Advances and Prospects. J. Mater. Chem. A 2021, 9, 19282–19297. [Google Scholar] [CrossRef]

- Shaibani, M.; Mirshekarloo, M.S.; Singh, R.; Easton, C.D.; Cooray, M.C.D.; Eshraghi, N.; Abendroth, T.; Dörfler, S.; Althues, H.; Kaskel, S.; et al. Expansion-Tolerant Architectures for Stable Cycling of Ultrahigh-Loading Sulfur Cathodes in Lithium-Sulfur Batteries. Sci. Adv. 2020, 6, eaay2757. [Google Scholar] [CrossRef]

- Li, J.; Gao, L.; Pan, F.; Gong, C.; Sun, L.; Gao, H.; Zhang, J.; Zhao, Y.; Wang, G.; Liu, H. Engineering Strategies for Suppressing the Shuttle Effect in Lithium–Sulfur Batteries. Nano-Micro Lett. 2023, 16, 12. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Xie, J.; Xu, N. A Novel Conductive Polymer–Sulfur Composite Cathode Material for Rechargeable Lithium Batteries. Adv. Mater. 2002, 14, 963–965. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Wan, C.; Du, K.; Xie, J.; Xu, N. Sulfur Composite Cathode Materials for Rechargeable Lithium Batteries. Adv. Funct. Mater. 2003, 13, 487–492. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; He, X.; Ren, J.; Jiang, C.; Wan, C. Electrochemical Characteristics of Sulfur Composite Cathode Materials in Rechargeable Lithium Batteries. J. Power Sources 2004, 138, 271–273. [Google Scholar] [CrossRef]

- Miao, Q.; Solan, N.; Hyun, G.; Holoubek, J.; Liu, P. Electrolyte Engineering for Long-Life Li-SPAN Batteries. ACS Energy Lett. 2023, 8, 4818–4830. [Google Scholar] [CrossRef]

- Wei, M. SPAN Dataset 2025. Available online: https://github.com/weimufeng/SPAN (accessed on 23 July 2025).

- Yu, X.; Xie, J.; Yang, J.; Huang, H.; Wang, K.; Wen, Z. Lithium Storage in Conductive Sulfur-Containing Polymers. J. Electroanal. Chem. 2004, 573, 121–128. [Google Scholar] [CrossRef]

- Fanous, J.; Wegner, M.; Grimminger, J.; Andresen, Ä.; Buchmeiser, M.R. Structure-Related Electrochemistry of Sulfur-Poly(Acrylonitrile) Composite Cathode Materials for Rechargeable Lithium Batteries. Chem. Mater. 2011, 23, 5024–5028. [Google Scholar] [CrossRef]

- Fanous, J.; Wegner, M.; Grimminger, J.; Rolff, M.; Spera, M.B.M.; Tenzer, M.; Buchmeiser, M.R. Correlation of the Electrochemistry of Poly(Acrylonitrile)–Sulfur Composite Cathodes with Their Molecular Structure. J. Mater. Chem. 2012, 22, 23240–23245. [Google Scholar] [CrossRef]

- Doan, T.N.L.; Ghaznavi, M.; Zhao, Y.; Zhang, Y.; Konarov, A.; Sadhu, M.; Tangirala, R.; Chen, P. Binding Mechanism of Sulfur and Dehydrogenated Polyacrylonitrile in Sulfur/Polymer Composite Cathode. J. Power Sources 2013, 241, 61–69. [Google Scholar] [CrossRef]

- Zhang, S.S. Understanding of Sulfurized Polyacrylonitrile for Superior Performance Lithium/Sulfur Battery. Energies 2014, 7, 4588–4600. [Google Scholar] [CrossRef]

- Wei, S.; Ma, L.; Hendrickson, K.E.; Tu, Z.; Archer, L.A. Metal–Sulfur Battery Cathodes Based on PAN–Sulfur Composites. J. Am. Chem. Soc. 2015, 137, 12143–12152. [Google Scholar] [CrossRef]

- Wang, W.; Cao, Z.; Elia, G.A.; Wu, Y.; Wahyudi, W.; Abou-Hamad, E.; Emwas, A.-H.; Cavallo, L.; Li, L.-J.; Ming, J. Recognizing the Mechanism of Sulfurized Polyacrylonitrile Cathode Materials for Li–S Batteries and beyond in Al–S Batteries. ACS Energy Lett. 2018, 3, 2899–2907. [Google Scholar] [CrossRef]

- Jin, Z.-Q.; Liu, Y.-G.; Wang, W.-K.; Wang, A.-B.; Hu, B.-W.; Shen, M.; Gao, T.; Zhao, P.-C.; Yang, Y.-S. A New Insight into the Lithium Storage Mechanism of Sulfurized Polyacrylonitrile with No Soluble Intermediates. Energy Storage Mater. 2018, 14, 272–278. [Google Scholar] [CrossRef]

- Weret, M.A.; Jeffrey Kuo, C.-F.; Zeleke, T.S.; Beyene, T.T.; Tsai, M.-C.; Huang, C.-J.; Berhe, G.B.; Su, W.-N.; Hwang, B.-J. Mechanistic Understanding of the Sulfurized-Poly(Acrylonitrile) Cathode for Lithium-Sulfur Batteries. Energy Storage Mater. 2020, 26, 483–493. [Google Scholar] [CrossRef]

- Huang, C.-J.; Lin, K.-Y.; Hsieh, Y.-C.; Su, W.-N.; Wang, C.-H.; Brunklaus, G.; Winter, M.; Jiang, J.-C.; Hwang, B.J. New Insights into the N–S Bond Formation of a Sulfurized-Polyacrylonitrile Cathode Material for Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2021, 13, 14230–14238. [Google Scholar] [CrossRef]

- Huang, C.-J.; Cheng, J.-H.; Su, W.-N.; Partovi-Azar, P.; Kuo, L.-Y.; Tsai, M.-C.; Lin, M.-H.; Panahian Jand, S.; Chan, T.-S.; Wu, N.-L.; et al. Origin of Shuttle-Free Sulfurized Polyacrylonitrile in Lithium-Sulfur Batteries. J. Power Sources 2021, 492, 229508. [Google Scholar] [CrossRef]

- Zhu, T.; Mueller, J.E.; Hanauer, M.; Sauter, U.; Jacob, T. Structural Motifs for Modeling Sulfur-Poly(Acrylonitrile) Composite Materials in Sulfur-Lithium Batteries. ChemElectroChem 2017, 4, 2494–2499. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, Y.; Li, H.; Zhou, C.; Wang, X.; Du, L. Sulfurized Polyacrylonitrile as Cathodes for Advanced Lithium–Sulfur Batteries: Advances in Modification Strategies. Nanoscale 2024, 16, 5060–5078. [Google Scholar] [CrossRef]

- He, X.-M.; Wang, L.; Pu, W.-H.; Ren, J.-G.; Wu, W.; Jiang, C.-Y.; Wan, C.-R. Thermal Analysis of Sulfurization of Polyacrylonitrile with Elemental Sulfur. J. Therm. Anal. Calorim. 2008, 94, 151–155. [Google Scholar] [CrossRef]

- Xie, J.; Chen, J.; Guo, L.; Li, Y.; Wang, Y.; Zheng, S.; Zhang, N.; Meng, J.; Zhang, K.; Li, Q.; et al. Deciphering the Sulfur-Involved Bonding Interactions in Sulfurized Polyacrylonitrile: The Formation Thermodynamics and the Roles in Electrochemical Characteristics. ACS Nano 2025, 19, 3931–3943. [Google Scholar] [CrossRef]

- He, X.; Pu, W.; Ren, J.; Wang, L.; Wang, J.; Jiang, C.; Wan, C. Charge/Discharge Characteristics of Sulfur Composite Cathode Materials in Rechargeable Lithium Batteries. Electrochim. Acta 2007, 52, 7372–7376. [Google Scholar] [CrossRef]

- He, X.; Pu, W.; Ren, J.; Wang, L.; Wang, J.; Jiang, C.; Wan, C. Charge/Discharge Characteristics of Sulfur Composite Electrode at Different Temperature and Current Density in Rechargeable Lithium Batteries. Ionics 2008, 14, 335–337. [Google Scholar] [CrossRef]

- He, X.; Ren, J.; Wang, L.; Pu, W.; Jiang, C.; Wan, C. Expansion and Shrinkage of the Sulfur Composite Electrode in Rechargeable Lithium Batteries. J. Power Sources 2009, 190, 154–156. [Google Scholar] [CrossRef]

- Wang, L.; He, X.; Ren, J.; Pu, W.; Li, J.; Gao, J. The Electrochemical Characteristics of Sulfur Composite Cathode. Ionics 2010, 16, 689–695. [Google Scholar] [CrossRef]

- Niesen, S.; Trück, J.; Seidl, C.; Renger, K.; Buchmeiser, M.R. Lithium-Sulfur Batteries Based on Sulfurized Poly(Acrylonitrile) Cathodes: Impact of Electrode Density on Cell Performance. J. Electrochem. Soc. 2021, 168, 110513. [Google Scholar] [CrossRef]

- Moschner, R.; Gerle, M.; Danner, T.; Simanjuntak, E.K.; Michalowski, P.; Latz, A.; Nojabaee, M.; Kwade, A.; Friedrich, K.A. Impact of the Sulfurized Polyacrylonitrile Cathode Microstructure on the Electrochemical Performance of Lithium–Sulfur Batteries. Adv. Sci. 2025, 12, 2415436. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, J.; He, X.; Wan, C. Kinetic Investigation of Sulfurized Polyacrylonitrile Cathode Material by Electrochemical Impedance Spectroscopy. Electrochim. Acta 2011, 56, 5252–5256. [Google Scholar] [CrossRef]

- Wang, L.; He, X.; Sun, W.; Li, J.; Gao, J.; Tian, G.; Wang, J.; Fan, S. Organic Polymer Material with a Multi-Electron Process Redox Reaction: Towards Ultra-High Reversible Lithium Storage Capacity. RSC Adv. 2013, 3, 3227–3231. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, H.-J.; Zeng, Z.; Chen, X.; Lei, Y.; Liang, X.; Han, Z.; Hu, W.; Feng, J.; Wen, R.; et al. In Situ Characterization of Over-Lithiation of Organosulfide-Based Lithium Metal Anodes. ACS Appl. Mater. Interfaces 2021, 13, 41555–41562. [Google Scholar] [CrossRef]

- Dominko, R.; Patel, M.U.M.; Bele, M.; Pejovnik, S. Sulphured Polyacrylonitrile Composite Analysed by in Operando UV-Visible Spectroscopy and 4-Electrode Swagelok Cell. Acta Chim. Slov. 2016, 63, 569–577. [Google Scholar] [CrossRef]

- Warneke, S.; Eusterholz, M.; Zenn, R.K.; Hintennach, A.; Dinnebier, R.E.; Buchmeiser, M.R. Differences in Electrochemistry between Fibrous SPAN and Fibrous S/C Cathodes Relevant to Cycle Stability and Capacity. J. Electrochem. Soc. 2017, 165, A6017. [Google Scholar] [CrossRef]

- Kappler, J.; Klostermann, S.V.; Lange, P.L.; Dyballa, M.; Veith, L.; Schleid, T.; Weil, T.; Kästner, J.; Buchmeiser, M.R. Sulfur-Composites Derived from Poly(Acrylonitrile) and Poly(Vinylacetylene)—A Comparative Study on the Role of Pyridinic and Thioamidic Nitrogen. Batter. Supercaps 2023, 6, e202200522. [Google Scholar] [CrossRef]

- Wang, S.; Lu, B.; Cheng, D.; Wu, Z.; Feng, S.; Zhang, M.; Li, W.; Miao, Q.; Patel, M.; Feng, J.; et al. Structural Transformation in a Sulfurized Polymer Cathode to Enable Long-Life Rechargeable Lithium–Sulfur Batteries. J. Am. Chem. Soc. 2023, 145, 9624–9633. [Google Scholar] [CrossRef]

- Tan, S.; Rahman, M.M.; Wu, Z.; Liu, H.; Wang, S.; Ghose, S.; Zhong, H.; Waluyo, I.; Hunt, A.; Liu, P.; et al. Structural and Interphasial Stabilities of Sulfurized Polyacrylonitrile (SPAN) Cathode. ACS Energy Lett. 2023, 8, 2496–2504. [Google Scholar] [CrossRef]

- Pereira, R.; Sarode, K.K.; Rafie, A.; Fafarman, A.; Kalra, V. In-Operando FTIR Study on the Redox Behavior of Sulfurized Polyacrylonitrile as Cathode Material for Li–S Batteries. J. Phys. Chem. C 2023, 127, 19356–19365. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Z.; Lyu, L.; Qin, N.; Li, Y.; Gu, S.; Wang, Z.; Chen, J.; Yuan, H.; Yang, M.; et al. New Insights into the Reaction Mechanism of Sulfurized Polyacrylonitrile Cathode Material for Li–S Batteries. Compos. Commun. 2024, 49, 101971. [Google Scholar] [CrossRef]

- Liu, J.; Lu, H.; Wang, Q.; Kong, X.; Hao, C.; Yang, J.; NuLi, Y.; Duan, H.; Wang, J. Roles of the Polymer Backbone for Sulfurized Polyacrylonitrile Cathodes in Rechargeable Lithium Batteries. J. Am. Chem. Soc. 2025, 147, 426–435. [Google Scholar] [CrossRef]

- Kappler, J.; Tonbul, G.; Schoch, R.; Murugan, S.; Nowakowski, M.; Lange, P.L.; Klostermann, S.V.; Bauer, M.; Schleid, T.; Kästner, J.; et al. Understanding the Redox Mechanism of Sulfurized Poly(Acrylonitrile) as Highly Rate and Cycle Stable Cathode Material for Sodium-Sulfur Batteries. J. Electrochem. Soc. 2023, 170, 010526. [Google Scholar] [CrossRef]

- Zhu, T.; Mueller, J.E.; Hanauer, M.; Sauter, U.; Jacob, T. Theoretical Studies on the Charging and Discharging of Poly(Acrylonitrile)-Based Lithium-Sulfur Batteries. ChemElectroChem 2017, 4, 2975–2980. [Google Scholar] [CrossRef]

- Bertolini, S.; Jacob, T. Atomistic Discharge Studies of Sulfurized-Polyacrylonitrile through Ab Initio Molecular Dynamics. Electrochim. Acta 2022, 403, 139538. [Google Scholar] [CrossRef]

- Beltran, S.P.; Balbuena, P.B. First-Principles Explorations of the Electrochemical Lithiation Dynamics of a Multilayer Graphene Nanosheet-Based Sulfur–Carbon Composite. J. Mater. Chem. A 2018, 6, 18084–18094. [Google Scholar] [CrossRef]

- Perez Beltran, S.; Balbuena, P.B. Sulfurized Polyacrylonitrile for High-Performance Lithium–Sulfur Batteries: In-Depth Computational Approach Revealing Multiple Sulfur’s Reduction Pathways and Hidden Li+ Storage Mechanisms for Extra Discharge Capacity. ACS Appl. Mater. Interfaces 2021, 13, 491–502. [Google Scholar] [CrossRef]

- Perez Beltran, S.; Balbuena, P.B. Sulfurized Polyacrylonitrile (SPAN): Changes in Mechanical Properties during Electrochemical Lithiation. J. Phys. Chem. C 2021, 125, 13185–13194. [Google Scholar] [CrossRef]

- Bertolini, S.; Jacob, T. Density Functional Theory Studies on Sulfur–Polyacrylonitrile as a Cathode Host Material for Lithium–Sulfur Batteries. ACS Omega 2021, 6, 9700–9708. [Google Scholar] [CrossRef]

- Bertolini, S.; Jacob, T. Sulfurized-Polyacrylonitrile in Lithium-Sulfur Batteries: Interactions between Undercoordinated Carbons and Polymer Structure under Low Lithiation. J. Energy Chem. 2022, 66, 587–596. [Google Scholar] [CrossRef]

- Bertolini, S.; Jacob, T. Capturing Polysulfides by Sulfurized-Polyacrylonitrile in Lithium-Sulfur Batteries and the Sulfur-Chain Effects through Density Functional Theory. Electrochem. Sci. Adv. 2022, 2, e2100129. [Google Scholar] [CrossRef]

- Bertolini, S.; Venezuela, P.; Delcorte, A. The Effect of Lithium Battery Overpotential on Sulfurized-Polyacrylonitrile (SPAN): A Theoretical Approach. J. Energy Storage 2024, 78, 110049. [Google Scholar] [CrossRef]

- Simanjuntak, E.K.; Danner, T.; Wang, P.; Buchmeiser, M.R.; Latz, A. A Novel Modeling Approach for Sulfurized Polyacrylonitrile (SPAN) Electrodes in Li Metal Batteries. Electrochim. Acta 2024, 497, 144571. [Google Scholar] [CrossRef]

- Yu, X.; Xie, J.; Li, Y.; Huang, H.; Lai, C.; Wang, K. Stable-Cycle and High-Capacity Conductive Sulfur-Containing Cathode Materials for Rechargeable Lithium Batteries. J. Power Sources 2005, 146, 335–339. [Google Scholar] [CrossRef]

- Wang, L.; He, X.; Li, J.; Gao, J.; Guo, J.; Jiang, C.; Wan, C. Analysis of the Synthesis Process of Sulphur–Poly(Acrylonitrile)-Based Cathode Materials for Lithium Batteries. J. Mater. Chem. 2012, 22, 22077–22081. [Google Scholar] [CrossRef]

- Langrud, S.; Razzaq, A.A.; Santhanagopalan, S.; Brow, R.; Xing, W. Comprehensive Characterization of Multi-Phase Sulfurized Polyacrylonitrile Cathodes for Lithium-Sulfur Batteries. J. Electrochem. Soc. 2022, 169, 070514. [Google Scholar] [CrossRef]

- Pan, J.; Nie, J.; Zeng, B.; Chen, X.; Chen, Z.; Kang, D.; Miao, Y.; Liu, W.; Zhang, W. Optimized Preparation of Polyacrylonitrile/Sulfur Composite as Cathode for Lithium Sulfur Batteries. Int. J. Electrochem. Sci. 2022, 17, 22021. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, Y.; Liu, M.; Ma, J.; Yue, H.; Hu, Z.; Yang, S.-T.; Yin, Y. Synthesis of Highly Cyclized Polyacrylonitrile via Liquid-Phase Cyclization for Advanced Cathode Materials. ACS Sustain. Chem. Eng. 2024, 12, 17806–17816. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Wang, A.; Jin, Z.; Zhao, H.; Yang, Y. Effect of Vapor Pressure on Performance of Sulfurized Polyacrylonitrile Cathodes for Li/S Batteries. RSC Adv. 2016, 6, 106625–106630. [Google Scholar] [CrossRef]

- Páez Jerez, A.L.; Chemes, D.M.; Sham, E.L.; Davies, L.E.; Tesio, A.Y.; Flexer, V. Low-Temperature Synthesis of a Sulfur-Polyacrylonitrile Composite Cathode for Lithium-Sulfur Batteries. ChemistrySelect 2020, 5, 5465–5472. [Google Scholar] [CrossRef]

- Fanous, J.; Wegner, M.; Spera, M.B.M.; Buchmeiser, M.R. High Energy Density Poly(Acrylonitrile)-Sulfur Composite-Based Lithium-Sulfur Batteries. J. Electrochem. Soc. 2013, 160, A1169. [Google Scholar] [CrossRef]

- Cho, G.-B.; Park, H.-B.; Jeong, J.-S.; Chae, M.-R.; Im, Y.-M.; Han-Gyeol, L.; Sang-Hui, P.; Kim, K.-W. Effect of Ball Milling on Electrochemical Properties of Sulfur/Polyacrylonitrile (SPAN) Cathode in Li/S Battery. J. Nanosci. Nanotechnol. 2018, 18, 6431–6436. [Google Scholar] [CrossRef]

- Konarov, A.; Gosselink, D.; Doan, T.N.L.; Zhang, Y.; Zhao, Y.; Chen, P. Simple, Scalable, and Economical Preparation of Sulfur–PAN Composite Cathodes for Li/S Batteries. J. Power Sources 2014, 259, 183–187. [Google Scholar] [CrossRef]

- Du, K.; Zhang, Q. Facile Fabrication of Sulfur Entrapped Carbonized Material as a Cathode for High-Performance Lithium Batteries. RSC Adv. 2016, 6, 87690–87695. [Google Scholar] [CrossRef]

- Sarode, K.; Yim, T.; Pereira, R.; Cardoza, N.; Kalra, V. Solid–Liquid–Solid Mediated Artificial SEI Coated Stable Lithium and High-Sulfur Percentage SPAN for High Performance Li–S Batteries. Energy Adv. 2024, 3, 584–591. [Google Scholar] [CrossRef]

- Zhu, G. A Novel Suspension Polymerization Process to Prepare Sulfur Composite Cathode Materials for Lithium/Sulfur Batteries. World Electr. Veh. J. 2010, 4, 332–334. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Bakenov, Z.; Konarov, A.; Chen, P. Preparation of Novel Network Nanostructured Sulfur Composite Cathode with Enhanced Stable Cycle Performance. J. Power Sources 2014, 270, 326–331. [Google Scholar] [CrossRef]

- Pu, W.; He, X.; Wang, L.; Tian, Z.; Jiang, C.; Wan, C. Sulfur Composite Cathode Materials: Comparative Characterization of Polyacrylonitrile Precursor. Ionics 2007, 13, 273–276. [Google Scholar] [CrossRef]

- Lei, J.; Chen, J.; Zhang, H.; Naveed, A.; Yang, J.; Nuli, Y.; Wang, J. High Molecular Weight Polyacrylonitrile Precursor for S@pPAN Composite Cathode Materials with High Specific Capacity for Rechargeable Lithium Batteries. ACS Appl. Mater. Interfaces 2020, 12, 33702–33709. [Google Scholar] [CrossRef]

- Liu, H.; He, R.; Li, Y.; Jin, Y.; Liu, H.; Zhang, X. Effect of Sulfurized Polyacrylonitrile-g-rGO Composition on the Specific Capacity and Cycling Stability of Lithium Sulfur Batteries. J. Electroanal. Chem. 2023, 939, 117465. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Shi, C.; Shen, Y. Diphenylguanidine Combined with High Molecular Weight Polyacrylonitrile Precursor for High-Conductivity and High-Sulfur-Loading Cathode of Lithium-Sulfur Battery. Mater. Lett. 2023, 336, 133831. [Google Scholar] [CrossRef]

- Yi, Y.; Hai, F.; Chen, W.; Gao, X.; Guo, J.; Xue, W.; Li, M. A Universal Strategy for the Refined Frameworks and Improved Performance of Distinct Commercial Polyacrylonitriles in Sulfur Cathodes. Sci. China Mater. 2024, 67, 2915–2924. [Google Scholar] [CrossRef]

- Geller, B.E. Status and Prospects for Development of Polyacrylonitrile Fibre Production. A Review. Fibre Chem. 2002, 34, 151–161. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Wei, W.; Wang, J.; Zhou, L.; Yang, J.; Schumann, B.; NuLi, Y. CNT Enhanced Sulfur Composite Cathode Material for High Rate Lithium Battery. Electrochem. Commun. 2011, 13, 399–402. [Google Scholar] [CrossRef]

- Shi, Z.; Bi, D.; Wang, L.; Xu, H.; Yue, H.; Yin, Y.; Yang, S. Disulfide Dichloride: A High Efficiency Vulcanizing Agent for Sulfurized Polyacrylonitrile. ACS Appl. Energy Mater. 2022, 5, 8015–8022. [Google Scholar] [CrossRef]

- Liu, X.-M.; Huang, Z.D.; Oh, S.W.; Zhang, B.; Ma, P.-C.; Yuen, M.M.F.; Kim, J.-K. Carbon Nanotube (CNT)-Based Composites as Electrode Material for Rechargeable Li-Ion Batteries: A Review. Compos. Sci. Technol. 2012, 72, 121–144. [Google Scholar] [CrossRef]

- Tong, Z.; Lv, C.; Bai, G.-D.; Yin, Z.-W.; Zhou, Y.; Li, J.-T. A Review on Applications and Challenges of Carbon Nanotubes in Lithium-Ion Battery. Carbon Energy 2025, 7, e643. [Google Scholar] [CrossRef]

- Yin, L.; Wang, J.; Yang, J.; Nuli, Y. A Novel Pyrolyzed Polyacrylonitrile-sulfur@MWCNT Composite Cathode Material for High-Rate Rechargeable Lithium/Sulfur Batteries. J. Mater. Chem. 2011, 21, 6807–6810. [Google Scholar] [CrossRef]

- Electrochemical properties of lithium/sulfur-polyacrylonitrile-carbon nanotube composite cells using ether-based electrolyte at high rate. J. Ceram. Process. Res. 2015, 16, 199–202. [CrossRef]

- Abdul Razzaq, A.; Yao, Y.; Shah, R.; Qi, P.; Miao, L.; Chen, M.; Zhao, X.; Peng, Y.; Deng, Z. High-Performance Lithium Sulfur Batteries Enabled by a Synergy between Sulfur and Carbon Nanotubes. Energy Storage Mater. 2019, 16, 194–202. [Google Scholar] [CrossRef]

- Razzaq, A.A.; Yuan, X.; Chen, Y.; Hu, J.; Mu, Q.; Ma, Y.; Zhao, X.; Miao, L.; Ahn, J.-H.; Peng, Y.; et al. Anchoring MOF-Derived CoS2 on Sulfurized Polyacrylonitrile Nanofibers for High Areal Capacity Lithium–Sulfur Batteries. J. Mater. Chem. A 2020, 8, 1298–1306. [Google Scholar] [CrossRef]

- Abdul Razzaq, A.; Chen, G.; Zhao, X.; Yuan, X.; Hu, J.; Li, Z.; Chen, Y.; Xu, J.; Shah, R.; Zhong, J.; et al. Cobalt Coordination with Pyridines in Sulfurized Polyacrylonitrile Cathodes to Form Conductive Pathways and Catalytic M-N4S Sites for Accelerated Li-S Kinetics. J. Energy Chem. 2021, 61, 170–178. [Google Scholar] [CrossRef]

- Wang, X.; Qian, Y.; Wang, L.; Yang, H.; Li, H.; Zhao, Y.; Liu, T. Sulfurized Polyacrylonitrile Cathodes with High Compatibility in Both Ether and Carbonate Electrolytes for Ultrastable Lithium–Sulfur Batteries. Adv. Funct. Mater. 2019, 29, 1902929. [Google Scholar] [CrossRef]

- Li, H.; Xue, W.; Xu, W.; Wang, L.; Liu, T. Controllable Synthesis of Sulfurized Polyacrylonitrile Nanofibers for High Performance Lithium–Sulfur Batteries. Compos. Commun. 2021, 24, 100675. [Google Scholar] [CrossRef]

- Hu, X.; Jiang, H.; Hou, Q.; Yu, M.; Jiang, X.; He, G.; Li, X. Scalable SPAN Membrane Cathode with High Conductivity and Hierarchically Porous Framework for Enhanced Ion Transfer and Cycling Stability in Li–S Batteries. ACS Mater. Lett. 2023, 5, 2047–2057. [Google Scholar] [CrossRef]

- Shao, J.; Huang, C.; Zhu, Q.; Sun, N.; Zhang, J.; Wang, R.; Chen, Y.; Zhang, Z. Flexible CNT-Interpenetrating Hierarchically Porous Sulfurized Polyacrylonitrile (CIHP-SPAN) Electrodes for High-Rate Lithium-Sulfur (Li-S) Batteries. Nanomaterials 2024, 14, 1155. [Google Scholar] [CrossRef]

- Zuo, W.; Guo, Y.; Zhang, C.; Zhang, L.; Zhang, S. Mussel and Cobweb Inspired High Areal Capacity SPAN Electrode. Small 2024, 20, 2309126. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Li, Y.; Liu, H.; Han, N.; Zhang, X. Loadings of Functionalized Multiwalled Carbon Nanotubes for Enhancing Sulfurized Polyacrylonitrile Performance in Lithium–Sulfur Batteries. ACS Appl. Nano Mater. 2023, 6, 21058–21067. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The Rise of Graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Yin, L.; Wang, J.; Lin, F.; Yang, J.; Nuli, Y. Polyacrylonitrile/Graphene Composite as a Precursor to a Sulfur-Based Cathode Material for High-Rate Rechargeable Li–S Batteries. Energy Environ. Sci. 2012, 5, 6966–6972. [Google Scholar] [CrossRef]

- Yin, L.; Wang, J.; Yu, X.; Monroe, C.W.; NuLi, Y.; Yang, J. Dual-Mode Sulfur-Based Cathode Materials for Rechargeable Li–S Batteries. Chem. Commun. 2012, 48, 7868–7870. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Bakenov, Z.; Babaa, M.-R.; Konarov, A.; Ding, C.; Chen, P. Effect of Graphene on Sulfur/Polyacrylonitrile Nanocomposite Cathode in High Performance Lithium/Sulfur Batteries. J. Electrochem. Soc. 2013, 160, A1194. [Google Scholar] [CrossRef]

- Wang, J.; Yin, L.; Jia, H.; Yu, H.; He, Y.; Yang, J.; Monroe, C.W. Hierarchical Sulfur-Based Cathode Materials with Long Cycle Life for Rechargeable Lithium Batteries. ChemSusChem 2014, 7, 563–569. [Google Scholar] [CrossRef]

- Konarov, A.; Bakenov, Z.; Yashiro, H.; Sun, Y.-K.; Myung, S.-T. Effect of Carbon-Sulphur Bond in a Sulphur/Dehydrogenated Polyacrylonitrile/Reduced Graphene Oxide Composite Cathode for Lithium-Sulphur Batteries. J. Power Sources 2017, 355, 140–146. [Google Scholar] [CrossRef]

- Krishnaveni, K.; Subadevi, R.; Sivakumar, M. Graphene Oxide-Crowned Poly(Acrylonitrile)/Sulfur as a Lithium–Sulfur Battery Cathode: Performance and Characterization. SN Appl. Sci. 2020, 2, 766. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Q.; Zhong, J.; Chen, M.; Deng, H.; Cao, J.; Wang, L.; Peng, L.; Zhu, J.; Lu, B. 3D Holey Graphene/Polyacrylonitrile Sulfur Composite Architecture for High Loading Lithium Sulfur Batteries. Adv. Energy Mater. 2021, 11, 2100448. [Google Scholar] [CrossRef]

- Kim, H.; Hwang, J.-Y.; Bang, S.; Jung, H.-G.; Sun, Y.-K. Geometrical Engineering of a SPAN–Graphene Composite Cathode for Practical Li–S Batteries. J. Mater. Chem. A 2022, 10, 10844–10853. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, Y.; Huang, J.; Jiang, H.; Liang, B.; Wang, B.; He, D.; Chen, H. A Free-Standing Sulfide Polyacrylonitrile/Reduced Graphene Oxide Film Cathode with Nacre-like Architecture for High-Performance Lithium-Sulfur Batteries. J. Power Sources 2025, 629, 235916. [Google Scholar] [CrossRef]

- Li, Y.; Zeng, Q.; Gentle, I.R.; Wang, D.-W. “Soft” Graphene Oxide-Organopolysulfide Nanocomposites for Superior Pseudocapacitive Lithium Storage. Chin. Chem. Lett. 2018, 29, 603–605. [Google Scholar] [CrossRef]

- Kumar, A.; Verma, C.J.; Singh, M.K.; Prakash, R. 5—Porous Carbon from Conducting Polymers for Electrochemical Applications. In Conjugated Polymers for Next-Generation Applications; Kumar, V., Sharma, K., Sehgal, R., Kalia, S., Eds.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2022; Volume 1, pp. 147–180. ISBN 978-0-12-823442-6. [Google Scholar]

- Wen, Z.; Lu, D. Fabrication and Electrochemical Performance of Polyacrylonitrile-S/Carbon Composite as Cathode for Lithium Ion Batteries. J. Electrochem. Soc. 2013, 160, A2311. [Google Scholar] [CrossRef]

- Sohn, H.; Gordin, M.L.; Regula, M.; Kim, D.H.; Jung, Y.S.; Song, J.; Wang, D. Porous Spherical Polyacrylonitrile-Carbon Nanocomposite with High Loading of Sulfur for Lithium–Sulfur Batteries. J. Power Sources 2016, 302, 70–78. [Google Scholar] [CrossRef]

- Xu, A.; Jin, Z.; Wang, B.; Xie, X.; Xiao, X.; Wang, A.; Zhang, J.; Wang, W.; Lu, J.; Zeng, F. Unraveling the Mechanism on Improved Kinetics Performance of Sulfurized Polyacrylonitrile with Defective Conductive Carbon Matrix. Chem. Eng. J. 2024, 484, 149558. [Google Scholar] [CrossRef]

- Chang, Z.; Dou, H.; Ding, B.; Wang, J.; Wang, Y.; Xu, G.; Li, C. Interconnected Core–Shell Pyrolyzed Polyacrylonitrile@sulfur/Carbon Nanocomposites for Rechargeable Lithium–Sulfur Batteries. New J. Chem. 2016, 40, 7680–7686. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Wu, Z.-Z.; Pan, G.-L.; Liu, S.; Gao, X.-P. Microporous Carbon Polyhedrons Encapsulated Polyacrylonitrile Nanofibers as Sulfur Immobilizer for Lithium–Sulfur Battery. ACS Appl. Mater. Interfaces 2017, 9, 12436–12444. [Google Scholar] [CrossRef]

- Kuo, C.J.; Weret, M.A.; Hung, H.; Tsai, M.; Huang, C.; Su, W.; Hwang, B. Sulfurized−poly(Acrylonitrile) Wrapped Carbonsulfur Composite Cathode Material for High Performance Rechargeable Lithiumsulfur Batteries. J. Power Sources 2019, 412, 670–676. [Google Scholar] [CrossRef]

- Zhang, W.; Pan, J.; Liu, P.; Ouyang, Z.; Fang, R.; Zhang, S.; Lian, J. A Li+-Conductive Porous Carbon/Polyacrylonitrile/Sulfur Composite for Li-S Batteries. Int. J. Electrochem. Sci. 2020, 15, 7925–7934. [Google Scholar] [CrossRef]

- Qin, F.; Zhang, K.; Hong, B.; Zhang, L.; Zhang, Z.; Li, J.; Wang, X.; Lai, Y. A New Insight into Capacity Fading of Sulfurized Polyacrylonitrile Composite in Carbonate Electrolyte. J. Electroanal. Chem. 2021, 882, 114964. [Google Scholar] [CrossRef]

- Insinna, T.; Bassey, E.N.; Märker, K.; Collauto, A.; Barra, A.-L.; Grey, C.P. Graphite Anodes for Li-Ion Batteries: An Electron Paramagnetic Resonance Investigation. Chem. Mater. 2023, 35, 5497–5511. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, P.; Chen, Z.; Fang, R.; Kang, D.; Ouyang, Z.; Zhang, S. Polyacrylonitile/Sulphur (PAN-S) Cathode with KS6 Graphite as the Conductive Agent for Li-S Battery. Int. J. Electrochem. Sci. 2021, 16, 210247. [Google Scholar] [CrossRef]

- Liu, Y.; Haridas, A.K.; Lee, Y.; Cho, K.-K.; Ahn, J.-H. Freestanding Porous Sulfurized Polyacrylonitrile Fiber as a Cathode Material for Advanced Lithium Sulfur Batteries. Appl. Surf. Sci. 2019, 472, 135–142. [Google Scholar] [CrossRef]

- Han, Z.; Li, S.; Xiong, R.; Jiang, Z.; Sun, M.; Hu, W.; Peng, L.; He, R.; Zhou, H.; Yu, C.; et al. Low Tortuosity and Reinforced Concrete Type Ultra-Thick Electrode for Practical Lithium–Sulfur Batteries. Adv. Funct. Mater. 2022, 32, 2108669. [Google Scholar] [CrossRef]

- Jo, C.-H.; Yu, J.H.; Kim, H.J.; Hwang, J.-Y.; Kim, J.-Y.; Jung, H.-G.; Myung, S.-T. Sulfurized Carbon Composite with Unprecedentedly High Tap Density for Sodium Storage. Adv. Energy Mater. 2022, 12, 2102836. [Google Scholar] [CrossRef]

- Dogadkin, B.A.; Shershnev, V.A. Vulcanization of Rubber in the Presence of Organic Accelerators. Rubber Chem. Technol. 1962, 35, 1–56. [Google Scholar] [CrossRef]

- Chen, H.; Wang, C.; Hu, C.; Zhang, J.; Gao, S.; Lu, W.; Chen, L. Vulcanization Accelerator Enabled Sulfurized Carbon Materials for High Capacity and High Stability of Lithium–Sulfur Batteries. J. Mater. Chem. A 2014, 3, 1392–1395. [Google Scholar] [CrossRef]

- Wang, Y.; Shuai, Y.; Chen, K. Diphenyl Guanidine as Vulcanization Accelerators in Sulfurized Polyacrylonitrile for High Performance Lithium-Sulfur Battery. Chem. Eng. J. 2020, 388, 124378. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Shuai, Y.; Chen, K. Diphenyl Guanidine Vulcanization Accelerators Enable Sulfurized Polyacrylonitrile Cathode for High Capacity and Ether-Compatible by Fast Kinetic. Energy 2021, 233, 121160. [Google Scholar] [CrossRef]

- Qin, J.; Lu, Y.; Wang, R.; Li, Z.; Shen, T.; Wang, D. Sulfurization Accelerator Coupled Fe1−xS Electrocatalyst Boosting SPAN Cathode Performance. Nano Res. 2023, 16, 9231–9239. [Google Scholar] [CrossRef]

- Wu, Q.; Qin, M.; Wu, Y.; Zhu, H.; Cheng, S.; Xie, J. Triallyl Isocyanurate Enabled SPAN-Based Organosulfur Featuring High Sulfur & Selenium Loading for Advanced Li/Na–S Batteries. J. Mater. Chem. A 2023, 11, 22913–22921. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, H.-C.; Hao, C.-R.; Liu, J.-Q.; Kong, X.-R.; Wang, J.-L. Delaying Cyclization of Polyacrylonitrile by Boric Acid for Sulfurized Poly(Acrylonitrile) Cathode Materials. Chem. Eng. J. 2024, 500, 156857. [Google Scholar] [CrossRef]

- Ouyang, Q.; Wang, H.; Cheng, L.; Sun, Y. Effect of Boric Acid on the Stabilization of Poly(Acrylonitrile-Co-Itaconic Acid). J. Polym. Res. 2007, 14, 497–503. [Google Scholar] [CrossRef]

- Ouyang, Q.; Cheng, L.; Wang, H.; Li, K. FTIR Study of the Retardation Effect of Boric Acid on the Cyclization Reaction of Polyacrylonitrile. e-Polym. 2009, 9, 015. [Google Scholar] [CrossRef][Green Version]

- Xiang, J.; Guo, Z.; Yi, Z.; Zhang, Y.; Yuan, L.; Cheng, Z.; Shen, Y.; Huang, Y. Facile Synthesis of Sulfurized Polyacrylonitrile Composite as Cathode for High-Rate Lithium-Sulfur Batteries. J. Energy Chem. 2020, 49, 161–165. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.; Liu, H.; Zhang, Y.; Zhang, X. Effects of Fiber Diameter on Sulfur Loading and Lithium–Sulfur Battery Performance of Semicarbonized and Sulfurized Polyacrylonitrile Cathode Materials. ACS Appl. Energy Mater. 2023, 6, 8511–8520. [Google Scholar] [CrossRef]

- Hwang, T.H.; Jung, D.S.; Kim, J.-S.; Kim, B.G.; Choi, J.W. One-Dimensional Carbon–Sulfur Composite Fibers for Na–S Rechargeable Batteries Operating at Room Temperature. Nano Lett. 2013, 13, 4532–4538. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, T.; Zhang, N.; Feng, T.; Li, L.; Wu, F.; Chen, R. Powering Lithium–Sulfur Batteries by Ultrathin Sulfurized Polyacrylonitrile Nanosheets. Nanoscale 2021, 13, 16690–16695. [Google Scholar] [CrossRef]

- Frey, M.; Zenn, R.K.; Warneke, S.; Müller, K.; Hintennach, A.; Dinnebier, R.E.; Buchmeiser, M.R. Easily Accessible, Textile Fiber-Based Sulfurized Poly(Acrylonitrile) as Li/S Cathode Material: Correlating Electrochemical Performance with Morphology and Structure. ACS Energy Lett. 2017, 2, 595–604. [Google Scholar] [CrossRef]

- Liu, Y.; Haridas, A.K.; Cho, K.-K.; Lee, Y.; Ahn, J.-H. Highly Ordered Mesoporous Sulfurized Polyacrylonitrile Cathode Material for High-Rate Lithium Sulfur Batteries. J. Phys. Chem. C 2017, 121, 26172–26179. [Google Scholar] [CrossRef]

- Warneke, S.; Zenn, R.K.; Lebherz, T.; Müller, K.; Hintennach, A.; Starke, U.; Dinnebier, R.E.; Buchmeiser, M.R. Hybrid Li/S Battery Based on Dimethyl Trisulfide and Sulfurized Poly(Acrylonitrile). Adv. Sustain. Syst. 2018, 2, 1700144. [Google Scholar] [CrossRef]

- Wang, K.; Ju, S.; Gao, Q.; Xia, G.; Wang, G.; Yan, H.; Dong, L.; Yang, Z.; Yu, X. Porous Sulfurized Poly(Acrylonitrile) Nanofiber as a Long-Life and High-Capacity Cathode for Lithium–Sulfur Batteries. J. Alloys Compd. 2021, 860, 158445. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Lu, Y.; Lou, X.W. (David) A Pyrolyzed Polyacrylonitrile/Selenium Disulfide Composite Cathode with Remarkable Lithium and Sodium Storage Performances. Sci. Adv. 2018, 4, eaat1687. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, W.; Zhu, Z.; Huang, Q.; Liu, X.; Zhang, M.; Pei, W.-B.; Wu, J. Multi-Channel Sulfurized Polyacrylonitrile with Hollow Structure as Cathode for Room Temperature Sodium–Sulfur Batteries. J. Solid State Chem. 2021, 301, 122359. [Google Scholar] [CrossRef]

- Huang, X.; Liu, J.; Huang, Z.; Ke, X.; Liu, L.; Wang, N.; Liu, J.; Guo, Z.; Yang, Y.; Shi, Z. Flexible Free-Standing Sulfurized Polyacrylonitrile Electrode for Stable Li/Na Storage. Electrochim. Acta 2020, 333, 135493. [Google Scholar] [CrossRef]

- Song, Y.; Lai, J.; Li, X.; Huo, J.; Zhao, C.; He, C. Steaming Inspired 3D Porous Architecture for Improving the Capability and Stability of Sulfurized Polyacrylonitrile Cathode. Mater. Lett. 2021, 296, 129933. [Google Scholar] [CrossRef]

- Lebherz, T.; Frey, M.; Hintennach, A.; Buchmeiser, M.R. Influence of Morphology of Monolithic Sulfur–Poly(Acrylonitrile) Composites Used as Cathode Materials in Lithium–Sulfur Batteries on Electrochemical Performance. RSC Adv. 2019, 9, 7181–7188. [Google Scholar] [CrossRef]

- He, R.; Li, Y.; Mu, Z.; Liu, H.; Zhang, Y.; Zhang, X. Flower-Shaped Sulfurized Polyacrylonitrile Nanostructures as Cathode Materials for High-Performance Lithium–Sulfur Batteries. ACS Appl. Nano Mater. 2023, 6, 23163–23172. [Google Scholar] [CrossRef]

- Lei, J.; Chen, J.; Naveed, A.; Zhang, H.; Yang, J.; Nuli, Y.; Wang, J. Sulfurized Polyacrylonitrile Cathode Derived from Intermolecular Cross-Linked Polyacrylonitrile for a Rechargeable Lithium Battery. ACS Appl. Energy Mater. 2021, 4, 5706–5712. [Google Scholar] [CrossRef]

- Lei, J.; Lu, H.; Chen, J.; Yang, J.; Nuli, Y.; Wang, J. Crosslinked Polyacrylonitrile Precursor for S@pPAN Composite Cathode Materials for Rechargeable Lithium Batteries. J. Energy Chem. 2022, 65, 186–193. [Google Scholar] [CrossRef]

- Moschner, R.; Cavers, H.; Michalowski, P.; Kwade, A. Investigation of an Industrially Scalable Production of Sulfur-Polyacrylonitrile Based Cathodes. Batter. Supercaps 2024, 7, e202400154. [Google Scholar] [CrossRef]

- Wang, W.; Xu, W.; Xia, S.; Xue, W.; Wang, J.; Wang, X.; Li, H.; Lin, S.; Zhao, Y.; Wang, L.; et al. A New Insight into the Molecular Rearrangement of Sulfurized Polyacrylonitrile Cathode in Ether Electrolyte. Chem. Eng. J. 2023, 470, 144142. [Google Scholar] [CrossRef]

- Xue, W.; Xu, W.; Wang, W.; Gao, G.; Wang, L. Iodine-Doped Fibrous Sulfurized Polyacrylonitrile with Accelerated Reaction Kinetics. Compos. Commun. 2022, 30, 101078. [Google Scholar] [CrossRef]

- Li, H.; Xue, W.; Wang, L.; Liu, T. Two Competing Reactions of Sulfurized Polyacrylonitrile Produce High-Performance Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2021, 13, 25002–25009. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Feng, J.; Wang, C.; Cai, X.; Qin, R. Feasible Catalytic-Insoluble Strategy Enabled by Sulfurized Polyacrylonitrile with In Situ Built Electrocatalysts for Ultrastable Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2021, 13, 50936–50947. [Google Scholar] [CrossRef]

- Haridas, A.K.; Heo, J.; Li, X.; Ahn, H.-J.; Zhao, X.; Deng, Z.; Agostini, M.; Matic, A.; Ahn, J.-H. A Flexible and Free-Standing FeS/Sulfurized Polyacrylonitrile Hybrid Anode Material for High-Rate Sodium-Ion Storage. Chem. Eng. J. 2020, 385, 123453. [Google Scholar] [CrossRef]

- Weret, M.A.; Kuo, C.-F.J.; Su, W.-N.; Zeleke, T.S.; Huang, C.-J.; Sahalie, N.A.; Zegeye, T.A.; Wondimkun, Z.T.; Fenta, F.W.; Jote, B.A.; et al. Fibrous Organosulfur Cathode Materials with High Bonded Sulfur for High-Performance Lithium-Sulfur Batteries. J. Power Sources 2022, 541, 231693. [Google Scholar] [CrossRef]

- Yi, Y.; Hai, F.; Guo, J.; Gao, X.; Chen, W.; Tian, X.; Tang, W.; Hua, W.; Li, M. Electrochemical Enhancement of Lithium-Ion Diffusion in Polypyrrole-Modified Sulfurized Polyacrylonitrile Nanotubes for Solid-to-Solid Free-Standing Lithium–Sulfur Cathodes. Small 2023, 19, 2303781. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Li, Y.; Han, N.; Liu, H.; Zhang, X. Solid-State Transformations of Active Materials in the Pores of Sulfurized-Polyacrylonitrile Fiber Membranes via Nucleophilic Reactions for High-Loading and Free-Standing Lithium–Sulfur Battery Cathodes. Adv. Fiber Mater. 2024, 6, 772–785. [Google Scholar] [CrossRef]

- Gao, G.; Wang, J.; Zhang, X.; Li, H.; Wang, L.; Liu, T. An Ionic Liquid Enhanced Gel Polymer Electrolyte for High Performance Lithium-Metal Batteries Based on Sulfurized Polyacrylonitrile Cathode. Compos. Commun. 2022, 31, 101100. [Google Scholar] [CrossRef]

- Kim, I.; Kim, C.H.; Choi, S.h.; Ahn, J.-P.; Ahn, J.-H.; Kim, K.-W.; Cairns, E.J.; Ahn, H.-J. A Singular Flexible Cathode for Room Temperature Sodium/Sulfur Battery. J. Power Sources 2016, 307, 31–37. [Google Scholar] [CrossRef]

- Kim, H.; Sadan, M.K.; Kim, C.; Jo, J.; Seong, M.; Cho, K.-K.; Kim, K.-W.; Ahn, J.-H.; Ahn, H.-J. Enhanced Reversible Capacity of Sulfurized Polyacrylonitrile Cathode for Room-Temperature Na/S Batteries by Electrochemical Activation. Chem. Eng. J. 2021, 426, 130787. [Google Scholar] [CrossRef]

- Mentbayeva, A.; Belgibayeva, A.; Umirov, N.; Zhang, Y.; Taniguchi, I.; Kurmanbayeva, I.; Bakenov, Z. High Performance Freestanding Composite Cathode for Lithium-Sulfur Batteries. Electrochim. Acta 2016, 217, 242–248. [Google Scholar] [CrossRef]

- Kim, H.; Kim, C.; Sadan, M.K.; Yeo, H.; Cho, K.-K.; Kim, K.-W.; Ahn, J.-H.; Ahn, H.-J. Binder-Free and High-Loading Sulfurized Polyacrylonitrile Cathode for Lithium/Sulfur Batteries. RSC Adv. 2021, 11, 16122–16130. [Google Scholar] [CrossRef]

- Yang, K.; Kim, S.; Yang, X.; Cho, M.; Lee, Y. Binder-Free and High-Loading Cathode Realized by Hierarchical Structure for Potassium–Sulfur Batteries. Small Methods 2022, 6, 2100899. [Google Scholar] [CrossRef] [PubMed]

- Sabet, S.M.; Sapkota, N.; Chiluwal, S.; Zheng, T.; Clemons, C.M.; Rao, A.M.; Pilla, S. Sulfurized Polyacrylonitrile Impregnated Delignified Wood-Based 3D Carbon Framework for High-Performance Lithium–Sulfur Batteries. ACS Sustain. Chem. Eng. 2023, 11, 2314–2323. [Google Scholar] [CrossRef]

- Peng, H.; Wang, X.; Zhao, Y.; Tan, T.; Mentbayeva, A.; Bakenov, Z.; Zhang, Y. Enhanced Electrochemical Performance of Sulfur/Polyacrylonitrile Composite by Carbon Coating for Lithium/Sulfur Batteries. J. Nanopart. Res. 2017, 19, 348. [Google Scholar] [CrossRef]

- Wang, S.-L.; Hong, J.-L. Polydopamine as an Interfacial Layer to Enhance Mechanical and Adhesive Properties of the Active Materials in a Sulfur Cathode of Sodium-Sulfur Batteries. Chem. Eng. J. Adv. 2022, 11, 100352. [Google Scholar] [CrossRef]

- Zuo, W.; Li, R.; Wu, X.; Guo, Y.; Zhou, S.; Wen, B.; Luo, J.; Zhang, L. SPAN Secondary Particles Enabled High Energy Density Lithium-Sulfur Battery. Chem. Eng. J. 2024, 491, 151977. [Google Scholar] [CrossRef]

- Holoubek, J.; Yan, Q.; Liu, H.; Wu, Z.; Xing, X.; Zhou, H.; Luo, J.; Chen, Z.; Liu, P. Low-Cost Li||SPAN Batteries Enabled by Sustained Additive Release. ACS Appl. Energy Mater. 2021, 4, 6422–6429. [Google Scholar] [CrossRef]

- Qin, R.; Wang, Z.; Li, J.; Deng, L. Sulfureted Polyacrylonitrile Derived Carbon Encapsulated Silicon as High-Performance Anode Material for Lithium-Ion Batteries. J. Alloys Compd. 2022, 929, 167355. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, W.; Wang, A.; Jin, Z.; Zhao, H.; Yang, Y. A Polysulfide Reduction Accelerator—NiS2-Modified Sulfurized Polyacrylonitrile as a High Performance Cathode Material for Lithium–Sulfur Batteries. J. Mater. Chem. A 2017, 5, 22120–22124. [Google Scholar] [CrossRef]

- Haridas, A.K.; Heo, J.; Liu, Y.; Ahn, H.-J.; Zhao, X.; Deng, Z.; Agostini, M.; Matic, A.; Cho, K.-K.; Ahn, J.-H. Boosting High Energy Density Lithium-Ion Storage via the Rational Design of an FeS-Incorporated Sulfurized Polyacrylonitrile Fiber Hybrid Cathode. ACS Appl. Mater. Interfaces 2019, 11, 29924–29933. [Google Scholar] [CrossRef]

- Li, Y.; He, R.; Liu, H.; Zhang, Y.; Liu, H.; Han, N.; Zhang, X. Construction of CoS2 Reduction Accelerator-Modified Sulfurized Polyacrylonitrile Nanofibers as High-Performance Cathode Materials for Practical Lithium–Sulfur Batteries. ACS Appl. Energy Mater. 2023, 6, 8466–8478. [Google Scholar] [CrossRef]

- Xu, Z.-Q.; Zou, R.; Liu, W.-W.; Liu, G.-L.; Cui, Y.-S.; Lei, Y.-X.; Zheng, Y.-W.; Niu, W.-J.; Wu, Y.-Z.; Gu, B.-N.; et al. Design of Atomic Cobalt Selenide-Doped Sulfurized Polyacrylonitrile Cathode with Enhanced Electrochemical Kinetics for High Performance Lithium-SPAN Batteries. Chem. Eng. J. 2023, 471, 144581. [Google Scholar] [CrossRef]

- Wang, L.; Shi, H.; Xie, Y.; Wu, Z.-S. Boosting Solid–Solid Conversion Kinetics of Sulfurized Polyacrylonitrile via MoS2 Doping for High-Rate and Long-Life Li-S Batteries. Carbon Neutralization 2023, 2, 262–270. [Google Scholar] [CrossRef]

- Lei, Z.; Zheng, J.; He, X.; Wang, Y.; Yang, X.; Xiao, F.; Xue, H.; Xiong, P.; Wei, M.; Chen, Q.; et al. Defect-Rich WS2–SPAN Nanofibers for Sodium/Potassium-Ion Batteries: Ultralong Lifespans and Wide-Temperature Workability. Inorg. Chem. Front. 2023, 10, 1187–1196. [Google Scholar] [CrossRef]

- Xiao, F.; Zhang, J.; Zhou, W.; Fang, Y.; He, X.; Lai, W.; Lin, C.; Ge, M.; Fan, H.; Qian, Q.; et al. Defect-Engineered WSxSe2−x Nanocrystals Anchored on Selenized Polyacrylonitrile Fibers toward High-Performance Sodium/Potassium-Ion Batteries with a Wide Working Temperature Range. Inorg. Chem. Front. 2024, 11, 2164–2177. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Lin, C.; Wang, Y.; Lei, Z.; Xiong, P.; Luo, Y.; Chen, Q.; Zeng, L.; Wei, M.; et al. Structure Engineering of BiSbS Nanocrystals Embedded within Sulfurized Polyacrylonitrile Fibers for High Performance of Potassium-Ion Batteries. Chem.—Eur. J. 2022, 28, e202200028. [Google Scholar] [CrossRef]

- Li, R.; Tong, L.; Jiang, Y.; Wang, Y.; Long, J.; Chen, X.; Wu, J.; Li, X.; Chen, Y. SnS2 Nanoparticles Embedded in Sulfurized Polyacrylonitrile Composite Fibers for High-Performance Potassium-Ion Batteries. Interdiscip. Mater. 2024, 3, 150–159. [Google Scholar] [CrossRef]

- Wang, Y.; Guan, Z.; Zhang, Y.; Qu, B.; Sa, B.; Zhou, X.; Wang, J.; Peng, D.-L.; Xie, Q.; Pan, F. Li+/Mg2+ Co-Intercalation SnS2-SPAN Cathode for Super-Stable Magnesium-Based Batteries. J. Magnes. Alloys 2024, in press. [CrossRef]

- Zhang, Y.; Zhao, Y.; Yermukhambetova, A.; Bakenov, Z.; Chen, P. Ternary Sulfur/Polyacrylonitrile/Mg0.6Ni0.4O Composite Cathodes for High Performance Lithium/Sulfur Batteries. J. Mater. Chem. A 2012, 1, 295–301. [Google Scholar] [CrossRef]

- He, Y.; Shan, Z.; Tan, T.; Chen, Z.; Zhang, Y. Ternary Sulfur/Polyacrylonitrile/SiO2 Composite Cathodes for High-Performance Sulfur/Lithium Ion Full Batteries. Polymers 2018, 10, 930. [Google Scholar] [CrossRef] [PubMed]

- Páez Jerez, A.L.; Davies, L.E.; Tesio, A.Y.; Flexer, V. Synergistic Combination of TiO2 and S-PAN for Li-S Batteries with Long-Term Cyclability at High C-Rates. J. Electrochem. Soc. 2021, 168, 120536. [Google Scholar] [CrossRef]

- Fang, L.; Xu, W.; Lyu, X.; Liu, Y.; Reinhart, B.; Nguyen, H.; Li, T. Suppressing the Shuttle Effects with FeCo/SPAN Cathodes and High-Concentration Electrolytes for High-Performance Lithium–Sulfur Batteries. ACS Appl. Energy Mater. 2023, 6, 795–801. [Google Scholar] [CrossRef]

- Blázquez-Moreno, J.M.; Páez Jerez, A.L.; Tesio, A.Y.; Benítez, A.; Caballero, Á. Stable Long-Term Cycling of Room-Temperature Sodium-Sulfur Batteries Based on Non-Complex Sulfurised Polyacrylonitrile Cathodes. Batter. Supercaps 2025, 8, e202400640. [Google Scholar] [CrossRef]

- Páez Jerez, A.L.; Vera, M.L.; Sham, E.L.; Tesio, A.Y.; Flexer, V. Novel Multicomponent Composite with TiO2/Y2O3 as Cathode Material and Interlayer for Li-SPAN Batteries Cycled at High C-Rates. Electrochim. Acta 2023, 463, 142876. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Feng, J.; Wang, C.; Cai, X.; Qin, R. An In-Situ Catalytic-Insoluble Strategy Enabled by Sulfurized Polyacrylonitrile-Based Composite Cathode for Potassium–Sulfur Batteries. Funct. Mater. Lett. 2021, 14, 2143003. [Google Scholar] [CrossRef]

- Ma, S.; Zuo, P.; Zhang, H.; Yu, Z.; Cui, C.; He, M.; Yin, G. Iodine-Doped Sulfurized Polyacrylonitrile with Enhanced Electrochemical Performance for Room-Temperature Sodium/Potassium Sulfur Batteries. Chem. Commun. 2019, 55, 5267–5270. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Z.; Wang, Y.; Yu, Z.; Cui, C.; He, M.; Huo, H.; Yin, G.; Zuo, P. Iodine-Doped Sulfurized Polyacrylonitrile with Enhanced Electrochemical Performance for Lithium Sulfur Batteries in Carbonate Electrolyte. Chem. Eng. J. 2021, 418, 129410. [Google Scholar] [CrossRef]

- Ma, S.; Wang, Y.; Fu, C.; Ma, Y.; Gao, Y.; Yin, G.; Zuo, P. Black Phosphorus-Modified Sulfurized Polyacrylonitrile with High C-Rate and Cycling Performance in Ether-Based Electrolyte for Lithium Sulfur Batteries. Chem. Commun. 2020, 56, 12797–12800. [Google Scholar] [CrossRef]

- Wang, Y.; Zuo, P.; Ma, S.; Xie, B.; Yu, Z.; Yin, G. DFT and Experimental Study of Nano Red Phosphorus Anchoring on Sulfurized Polyacrylonitrile for Lithium-Ion Batteries. Chem. Commun. 2020, 56, 12857–12860. [Google Scholar] [CrossRef] [PubMed]

- Rabiei Baboukani, A.; Khakpour, I.; Adelowo, E.; Drozd, V.; Shang, W.; Wang, C. High-Performance Red Phosphorus-Sulfurized Polyacrylonitrile Composite by Electrostatic Spray Deposition for Lithium-Ion Batteries. Electrochim. Acta 2020, 345, 136227. [Google Scholar] [CrossRef]

- Hu, Y.; Li, B.; Jiao, X.; Zhang, C.; Dai, X.; Song, J. Stable Cycling of Phosphorus Anode for Sodium-Ion Batteries through Chemical Bonding with Sulfurized Polyacrylonitrile. Adv. Funct. Mater. 2018, 28, 1801010. [Google Scholar] [CrossRef]

- Abouimrane, A.; Dambournet, D.; Chapman, K.W.; Chupas, P.J.; Weng, W.; Amine, K. A New Class of Lithium and Sodium Rechargeable Batteries Based on Selenium and Selenium–Sulfur as a Positive Electrode. J. Am. Chem. Soc. 2012, 134, 4505–4508. [Google Scholar] [CrossRef]

- Wang, H.; Li, S.; Chen, Z.; Liu, H.K.; Guo, Z. A Novel Type of One-Dimensional Organic Selenium-Containing Fiber with Superior Performance for Lithium–Selenium and Sodium–Selenium Batteries. RSC Adv. 2014, 4, 61673–61678. [Google Scholar] [CrossRef]

- Guo, J.; Wen, Z.; Wang, Q.; Jin, J.; Ma, G. A Conductive Selenized Polyacrylonitrile Cathode Material for Re-Chargeable Lithium Batteries with Long Cycle Life. J. Mater. Chem. A 2015, 3, 19815–19821. [Google Scholar] [CrossRef]

- Zhu, T.; Pang, Y.; Wang, Y.; Wang, C.; Xia, Y. S0.87Se0.13/CPAN Composites as High Capacity and Stable Cycling Performance Cathode for Lithium Sulfur Battery. Electrochim. Acta 2018, 281, 789–795. [Google Scholar] [CrossRef]

- Liu, Y.; Tai, Z.; Zhang, Q.; Wang, H.; Pang, W.K.; Liu, H.K.; Konstantinov, K.; Guo, Z. A New Energy Storage System: Rechargeable Potassium-Selenium Battery. Nano Energy 2017, 35, 36–43. [Google Scholar] [CrossRef]

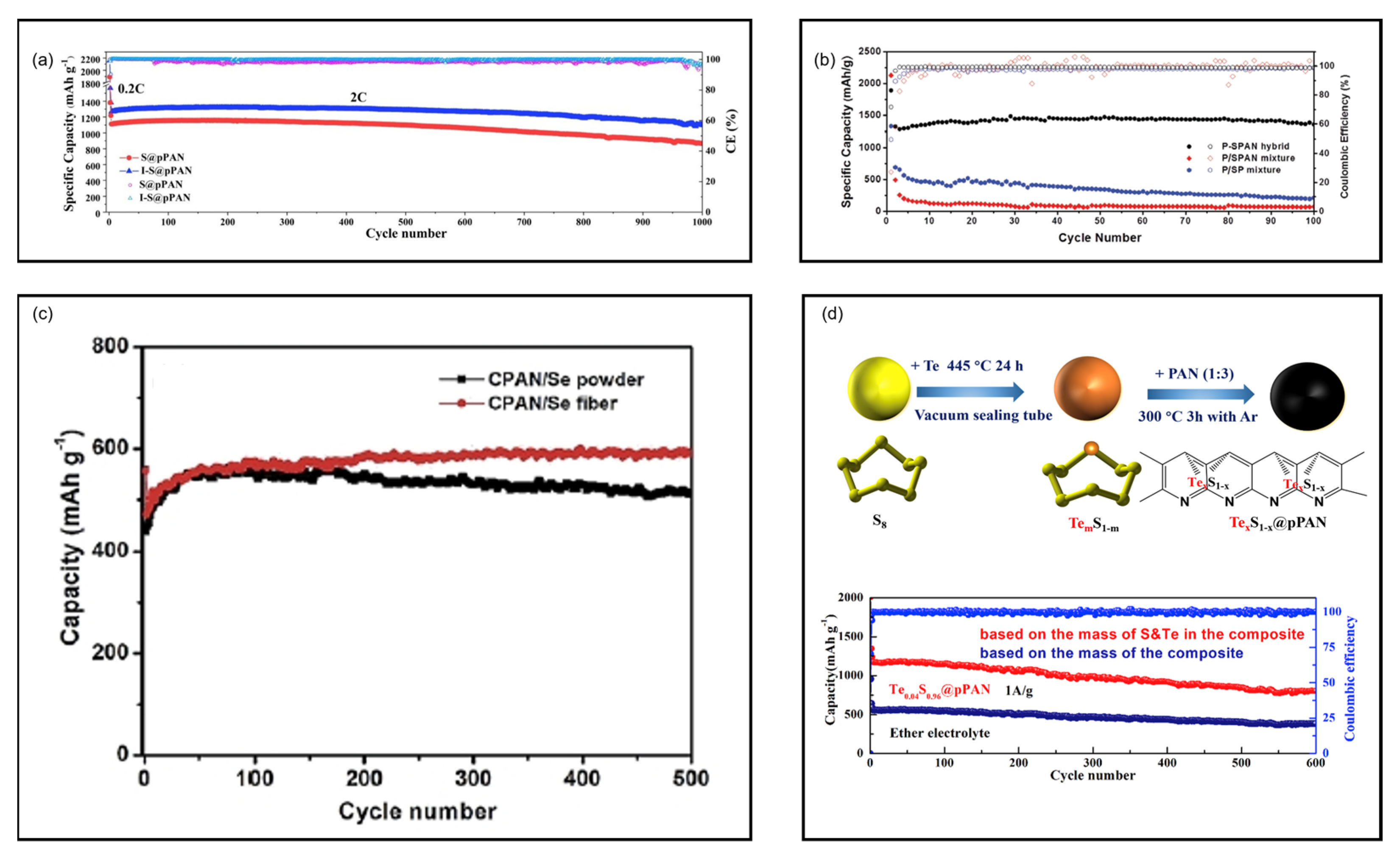

- Chen, X.; Peng, L.; Wang, L.; Yang, J.; Hao, Z.; Xiang, J.; Yuan, K.; Huang, Y.; Shan, B.; Yuan, L.; et al. Ether-Compatible Sulfurized Polyacrylonitrile Cathode with Excellent Performance Enabled by Fast Kinetics via Selenium Doping. Nat. Commun. 2019, 10, 1021. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, K.; Gao, S.; Wang, R.; Han, J.; Yan, J.; Cheng, S.; Jiang, K. Selenium as Extra Binding Site for Sulfur Species in Sulfurized Polyacrylonitrile Cathodes for High Capacity Lithium-Sulfur Batteries. ChemElectroChem 2019, 6, 1365–1370. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, H.; Zhang, N.; Liu, H.; Chen, Z.; Zhang, L.; Guo, S.; Li, D.; Xu, J. One-Step In Situ Preparation of Polymeric Selenium Sulfide Composite as a Cathode Material for Enhanced Sodium/Potassium Storage. ACS Appl. Mater. Interfaces 2019, 11, 29807–29813. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, Y.; Peng, L.; Yang, J.; Jia, H.; Zhang, Z.; Shan, B.; Xie, J. Se as Eutectic Accelerator in Sulfurized Polyacrylonitrile for High Performance All-Solid-State Lithium-Sulfur Battery. Energy Storage Mater. 2019, 21, 287–296. [Google Scholar] [CrossRef]

- Wang, L.; Chen, X.; Li, S.; Yang, J.; Sun, Y.; Peng, L.; Shan, B.; Xie, J. Effect of Eutectic Accelerator in Selenium-Doped Sulfurized Polyacrylonitrile for High Performance Room Temperature Sodium–Sulfur Batteries. J. Mater. Chem. A 2019, 7, 12732–12739. [Google Scholar] [CrossRef]

- Pham, V.H.; Boscoboinik, J.A.; Stacchiola, D.J.; Self, E.C.; Manikandan, P.; Nagarajan, S.; Wang, Y.; Pol, V.G.; Nanda, J.; Paek, E.; et al. Selenium-Sulfur (SeS) Fast Charging Cathode for Sodium and Lithium Metal Batteries. Energy Storage Mater. 2019, 20, 71–79. [Google Scholar] [CrossRef]

- Jia, H.; Liang, X.; An, T.; Peng, L.; Feng, J.; Xie, J. Effect of Halogen Doping in Sodium Solid Electrolytes Based on the Na–Sn–Si–P–S Quinary System. Chem. Mater. 2020, 32, 4065–4071. [Google Scholar] [CrossRef]

- Jia, H.; Peng, L.; Zhang, Z.; An, T.; Xie, J. Na3.8 [Sn0.67Si0.33]0.8Sb0.2S4: A Quinary Sodium Fast Ionic Conductor for All-Solid-State Sodium Battery. J. Energy Chem. 2020, 48, 102–106. [Google Scholar] [CrossRef]

- An, T.; Jia, H.; Peng, L.; Xie, J. Material and Interfacial Modification toward a Stable Room-Temperature Solid-State Na–S Battery. ACS Appl. Mater. Interfaces 2020, 12, 20563–20569. [Google Scholar] [CrossRef]

- Zhang, Z.; Cao, H.; Yang, M.; Yan, X.; Yu, C.; Liu, D.; Zhang, L. High Performance Room Temperature All-Solid-State Na-SexS Battery with Na3SbS4–Coated Cathode via Aqueous Solution. J. Energy Chem. 2020, 48, 250–258. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, C.; Xu, R.; Peng, L.; Ren, H.; Zhang, J.; Zhang, L.; Cheng, S.; Xie, J. Iodine-Rich Lithium Argyrodite with Enhanced Ionic Conductivity for Solid-State Batteries. Scr. Mater. 2022, 210, 114475. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, H.-J.; Zeng, Z.; Han, Z.; Hu, W.; Wen, R.; Xie, J. Reconfiguring Organosulfur Cathode by Over-Lithiation to Enable Ultrathick Lithium Metal Anode toward Practical Lithium–Sulfur Batteries. ACS Nano 2020, 14, 13784–13793. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Zeng, Z.; Liang, X.; Yang, L.; Hu, W.; Zhang, C.; Han, Z.; Feng, J.; Xie, J. Fluorobenzene, A Low-Density, Economical, and Bifunctional Hydrocarbon Cosolvent for Practical Lithium Metal Batteries. Adv. Funct. Mater. 2021, 31, 2005991. [Google Scholar] [CrossRef]

- Jiang, Z.; Zeng, Z.; Hu, W.; Han, Z.; Cheng, S.; Xie, J. Diluted High Concentration Electrolyte with Dual Effects for Practical Lithium-Sulfur Batteries. Energy Storage Mater. 2021, 36, 333–340. [Google Scholar] [CrossRef]

- Zhang, W.; Li, S.; Wang, L.; Wang, X.; Xie, J. Insight into Sulfur-Rich Selenium Sulfide/Pyrolyzed Polyacrylonitrile Cathodes for Li–S Batteries. Sustain. Energy Fuels 2020, 4, 3588–3596. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, D.; Wang, W.; Hu, K.; Huang, Q.; Zhang, Y.; Miao, Y.; Fu, L.; Wu, M.; Wu, Y. Toward Heat-Tolerant Potassium Batteries Based on Pyrolyzed Selenium Disulfide/Polyacrylonitrile Positive Electrode and Gel Polymer Electrolyte. J. Mater. Chem. A 2020, 8, 4544–4551. [Google Scholar] [CrossRef]

- He, B.; Rao, Z.; Cheng, Z.; Liu, D.; He, D.; Chen, J.; Miao, Z.; Yuan, L.; Li, Z.; Huang, Y. Rationally Design a Sulfur Cathode with Solid-Phase Conversion Mechanism for High Cycle-Stable Li–S Batteries. Adv. Energy Mater. 2021, 11, 2003690. [Google Scholar] [CrossRef]

- Teng, W.; Li, Y.; Ma, T.; Ren, X.; Nan, D.; Liu, J.; Wang, X.; Yang, Q.; Deng, J. Uniform Lithium Deposition Induced by ZnFx(OH)y for High-Performance Sulfurized Polyacrylonitrile-Based Lithium-Sulfur Batteries. Polymers 2022, 14, 4494. [Google Scholar] [CrossRef]

- Kong, X.; Kong, Y.; He, L.; Zhang, W.; Song, Y.; Liu, S.; Zhao, Y. A New Ether-Based Medium-Concentrated Electrolyte for Lithium–Sulfur Battery with Lean Li Anode. J. Power Sources 2022, 551, 232211. [Google Scholar] [CrossRef]

- Kong, X.; Kong, Y.; Liao, X.; Liu, S.; Zhao, Y. A Novel Mixed Ether-Based Electrolyte for Lithium–Sulfur Batteries with Li Anode Protection by Dual Salts. Sustain. Energy Fuels 2022, 6, 3658–3668. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, H.; Wu, Q.; Li, S.; Zhong, W.; He, R.; Cheng, S.; Xie, J. High-Performance Prelithiated Si-S Full Cell Enabled by Trifluorobenzene Modified Diluted High-Concentration Electrolyte. Mater. Today Energy 2022, 28, 101069. [Google Scholar] [CrossRef]

- Li, S.; Zhu, H.; Liu, Y.; Han, Z.; Peng, L.; Li, S.; Yu, C.; Cheng, S.; Xie, J. Codoped Porous Carbon Nanofibres as a Potassium Metal Host for Nonaqueous K-Ion Batteries. Nat. Commun. 2022, 13, 4911. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Chen, X.; Lin, C.; Wang, H.-E.; Xiong, P.; Chen, Q.; Qian, Q.; Wei, M.; Zeng, L. Stabilizing Intermediate Phases via the Efficient Confinement Effects of the SnS2-SPAN Fibre Composite for Ultra-Stable Half/Full Sodium/Potassium-Ion Batteries. J. Mater. Chem. A 2022, 10, 11449–11457. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, F.; Chen, X.; Xiong, P.; Lin, C.; Wang, H.-E.; Wei, M.; Qian, Q.; Chen, Q.; Zeng, L. Extraordinarily Stable and Wide-Temperature Range Sodium/Potassium-Ion Batteries Based on 1D SnSe-SePAN Composite Nanofibers. InfoMat 2023, 5, e12467. [Google Scholar] [CrossRef]

- He, R.; Li, Y.; Wei, S.; Liu, H.; Zhang, S.; Han, N.; Liu, H.; Wang, X.; Zhang, X. Construction of High-Performance Sulfurized Poly(Acrylonitrile) Cathodes for Lithium-Sulfur Batteries via Catalytic and Conductive Regulation. J. Alloys Compd. 2022, 919, 165838. [Google Scholar] [CrossRef]

- He, R.; Li, Y.; Yin, Z.; Liu, H.; Jin, Y.; Zhang, Y.; Liu, H.; Zhang, X. Selenium-Doped Sulfurized Poly(Acrylonitrile) Composites as Ultrastable and High-Volumetric-Capacity Cathodes for Lithium–Sulfur Batteries. ACS Appl. Energy Mater. 2023, 6, 3903–3914. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, W.; Li, S.; Zhong, W.; Zhu, H.; Zeng, Z.; Yu, C.; Cheng, S.; Xie, J. Electrospun Sulfurized Polyacrylonitrile Nanofibers for Long-Term Cycling Stability and High-Rate Lithium–Sulfur Batteries. ACS Appl. Energy Mater. 2022, 5, 5212–5218. [Google Scholar] [CrossRef]

- Xu, L.; Ye, J.; Guo, W.; Chen, T.; Chen, X.; Qian, Q.; Zhang, J.; Wei, M.; Peng, X.; Zeng, L. Rational Construction of VSe2 Encapsulated in Selenized Polyacrylonitrile toward a High-Rate Capacity and Wide Temperature Tolerance for Potassium-Ion Batteries. Inorg. Chem. Front. 2023, 10, 5053–5063. [Google Scholar] [CrossRef]

- Yuan, Z.; Zheng, J.; Chen, X.; Xiao, F.; Yang, X.; Luo, L.; Xiong, P.; Lai, W.; Lin, C.; Qin, F.; et al. In Situ Encapsulation of MoSxSe2–x Nanocrystals with the Synergistic Function of Anion Doping and Physical Confinement with Chemical Bonding for High-Performance Sodium/Potassium-Ion Batteries with Wide Temperature Workability. ACS Sustain. Chem. Eng. 2023, 11, 13050–13061. [Google Scholar] [CrossRef]

- Yang, F.; Yun, Z.; Gao, H.; Gao, S.; Tian, Z.; Huang, J. Se as Eutectic Accelerator SPAN Cathode for K−S Batteries with Improved Specific Capacity and Reaction Kinetics. ChemistrySelect 2023, 8, e202302227. [Google Scholar] [CrossRef]

- Liu, H.; Yan, T.; Xu, Q.; Zhang, Y.; Li, Y.; Han, N.; Liu, H.; Zhang, X. Enhancing the Performance of a Lithium-Sulfur Battery with Spatially Confined Mesoporous Nanoreactors in Sulfurized Polyacrylonitrile Cathodes. J. Colloid Interface Sci. 2025, 678, 829–840. [Google Scholar] [CrossRef]

- Ma, T.; Ren, X.; Hu, L.; Teng, W.; Wang, X.; Wu, G.; Liu, J.; Nan, D.; Li, B.; Yu, X. A Diluted Electrolyte for Long-Life Sulfurized Polyacrylonitrile-Based Anode-Free Li-S Batteries. Polymers 2022, 14, 3312. [Google Scholar] [CrossRef] [PubMed]

- Ma, T.; Deng, J.; Lin, Y.; Liang, Q.; Hu, L.; Wang, X.; Liu, J.; Zhao, X.; Li, Y.; Nan, D.; et al. Li-Rich Organosulfur Cathode with Boosted Kinetics for High-Energy Lithium-Sulfur Batteries. Energy Environ. Mater. 2024, 7, e12704. [Google Scholar] [CrossRef]

- Ma, S.; Yu, Z.; Wang, L.; Zuo, P. Selenium-Doped Sulfurized Polyacrylonitrile Hybrid Cathodes with Ultrahigh Sulfur Content for High-Performance Solid-State Lithium Sulfur Batteries. Langmuir 2024, 40, 9255–9264. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, T.; Liu, Y.; Yu, T.; Chen, G.; Tang, W.; Li, L.; Wu, F.; Chen, R. Accelerating Redox Kinetics of Sulfurized Polyacrylonitrile Nanosheets by Trace Doping of Element. Chem. Eng. J. 2024, 487, 150300. [Google Scholar] [CrossRef]

- Li, S.; Han, Z.; Hu, W.; Peng, L.; Yang, J.; Wang, L.; Zhang, Y.; Shan, B.; Xie, J. Manipulating Kinetics of Sulfurized Polyacrylonitrile with Tellurium as Eutectic Accelerator to Prevent Polysulfide Dissolution in Lithium-Sulfur Battery under Dissolution-Deposition Mechanism. Nano Energy 2019, 60, 153–161. [Google Scholar] [CrossRef]

- Li, S.; Zeng, Z.; Yang, J.; Han, Z.; Hu, W.; Wang, L.; Ma, J.; Shan, B.; Xie, J. High Performance Room Temperature Sodium–Sulfur Battery by Eutectic Acceleration in Tellurium-Doped Sulfurized Polyacrylonitrile. ACS Appl. Energy Mater. 2019, 2, 2956–2964. [Google Scholar] [CrossRef]

- Wang, K.; Guan, Y.; Jin, Z.; Wang, W.; Wang, A. Te0.045S0.955PAN Composite with High Average Discharge Voltage for Li–S Battery. J. Energy Chem. 2019, 39, 249–255. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Peng, L.; Li, S.; Wang, X.; Cheng, S.; Xie, J. Elevating Reactivity and Cyclability of All-Solid-State Lithium-Sulfur Batteries by the Combination of Tellurium-Doping and Surface Coating. Nano Energy 2020, 76, 105083. [Google Scholar] [CrossRef]

- Li, Y.; He, R.; Liu, H.; Zhang, X. Construction of High-Rate Performance Sulfurized Poly(Acrylonitrile) Nanofibers Cathodes for Practical Lithium–Sulfur Batteries via Tellurium Catalytic Regulation. Mater. Chem. Phys. 2023, 308, 128288. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, W.; Qin, M.; Zhong, W.; Yan, H.; Zhu, H.; Cheng, S.; Xie, J. Tellurium Doped Sulfurized Polyacrylonitrile Nanoflower for High-Energy-Density, Long-Lifespan Sodium-Sulfur Batteries. Nano Energy 2024, 129, 110049. [Google Scholar] [CrossRef]

- Fang, C.; Li, J.; Zhang, M.; Zhang, Y.; Yang, F.; Lee, J.Z.; Lee, M.-H.; Alvarado, J.; Schroeder, M.A.; Yang, Y.; et al. Quantifying Inactive Lithium in Lithium Metal Batteries. Nature 2019, 572, 511–515. [Google Scholar] [CrossRef]

- Liu, J.; Bao, Z.; Cui, Y.; Dufek, E.J.; Goodenough, J.B.; Khalifah, P.; Li, Q.; Liaw, B.Y.; Liu, P.; Manthiram, A.; et al. Pathways for Practical High-Energy Long-Cycling Lithium Metal Batteries. Nat. Energy 2019, 4, 180–186. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Y.; Zhou, Z. Towards Practical Lithium-Metal Anodes. Chem. Soc. Rev. 2020, 49, 3040–3071. [Google Scholar] [CrossRef] [PubMed]

- Albertus, P.; Babinec, S.; Litzelman, S.; Newman, A. Status and Challenges in Enabling the Lithium Metal Electrode for High-Energy and Low-Cost Rechargeable Batteries. Nat. Energy 2018, 3, 16–21. [Google Scholar] [CrossRef]

- Ding, J.-F.; Xu, R.; Yan, C.; Li, B.-Q.; Yuan, H.; Huang, J.-Q. A Review on the Failure and Regulation of Solid Electrolyte Interphase in Lithium Batteries. J. Energy Chem. 2021, 59, 306–319. [Google Scholar] [CrossRef]

- Jin, L.; Shen, C.; Wu, Q.; Shellikeri, A.; Zheng, J.; Zhang, C.; Zheng, J.P. Pre-Lithiation Strategies for Next-Generation Practical Lithium-Ion Batteries. Adv. Sci. 2021, 8, 2005031. [Google Scholar] [CrossRef]

- He, X.; Ren, J.; Wang, L.; Pu, W.; Wan, C.; Jiang, C. Electrochemical Characteristics of Sulfur Composite Cathode for Reversible Lithium Storage. Ionics 2009, 15, 477–481. [Google Scholar] [CrossRef]

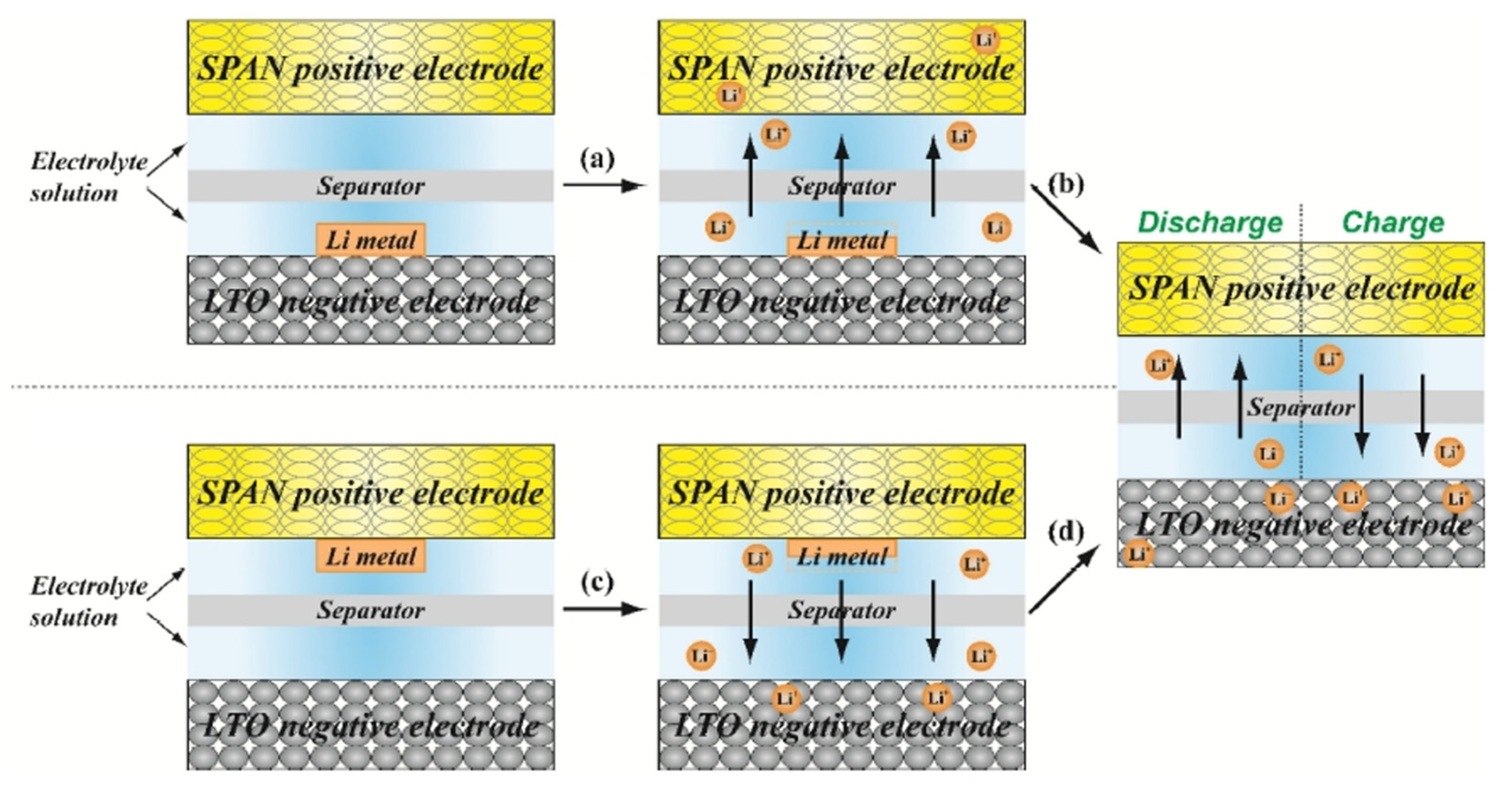

- Machida, K.; Miyauchi, H.; Ushioda, Y.; Takahashi, K.; Seki, S. Investigation for Charge-Discharge Operations of Li4Ti5O12-Sulfur Batteries by Suitable Choice of Materials and Cell Preparation Processes. Electrochemistry 2022, 90, 067006. [Google Scholar] [CrossRef]

- Shen, C.; Ye, D.; Jin, L.; Andrei, P.; Zheng, J.P. Communication—A Simple and Scalable Pre-Lithiation Approach for High Energy and Low Cost Lithium Ion Sulfur Batteries. J. Electrochem. Soc. 2020, 167, 060517. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Zhan, R.; Chen, Z.; Tu, S.; Li, C.; Liu, X.; Seh, Z.W.; Sun, Y. Nanocomposite of Conducting Polymer and Li Metal for Rechargeable High Energy Density Batteries. ACS Appl. Mater. Interfaces 2022, 14, 37709–37715. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Cao, C.; Zhao, W.; Huang, K.; Zhang, Y.; Shen, Y.; Li, Z.; Huang, Y. Lithium–Sulfur Pouch Cells with 99% Capacity Retention for 1000 Cycles. Energy Environ. Sci. 2024, 17, 7047–7057. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, J.; Pu, Y.; Wang, H.; Wang, B.; Qian, J.; Cao, Y.; Zhong, F.; Ai, X.; Yang, H. Effective Chemical Prelithiation Strategy for Building a Silicon/Sulfur Li-Ion Battery. ACS Energy Lett. 2019, 4, 1717–1724. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, S.; Mu, X.; Li, R.; Yin, G.; Zuo, P. A Scalable Cathode Chemical Prelithiation Strategy for Advanced Silicon-Based Lithium Ion Full Batteries. ACS Appl. Mater. Interfaces 2021, 13, 11985–11994. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, T.; Kuai, Y.; Yang, J.; Wang, J.; Nuli, Y.; Guo, Y.; Liang, C. A Superb 3D Composite Lithium Metal Anode Prepared by in-Situ Lithiation of Sulfurized Polyacrylonitrile. Energy Storage Mater. 2020, 33, 452–459. [Google Scholar] [CrossRef]

- Guo, J.; Yang, Z.; Yu, Y.; Abruña, H.D.; Archer, L.A. Lithium–Sulfur Battery Cathode Enabled by Lithium–Nitrile Interaction. J. Am. Chem. Soc. 2013, 135, 763–767. [Google Scholar] [CrossRef]

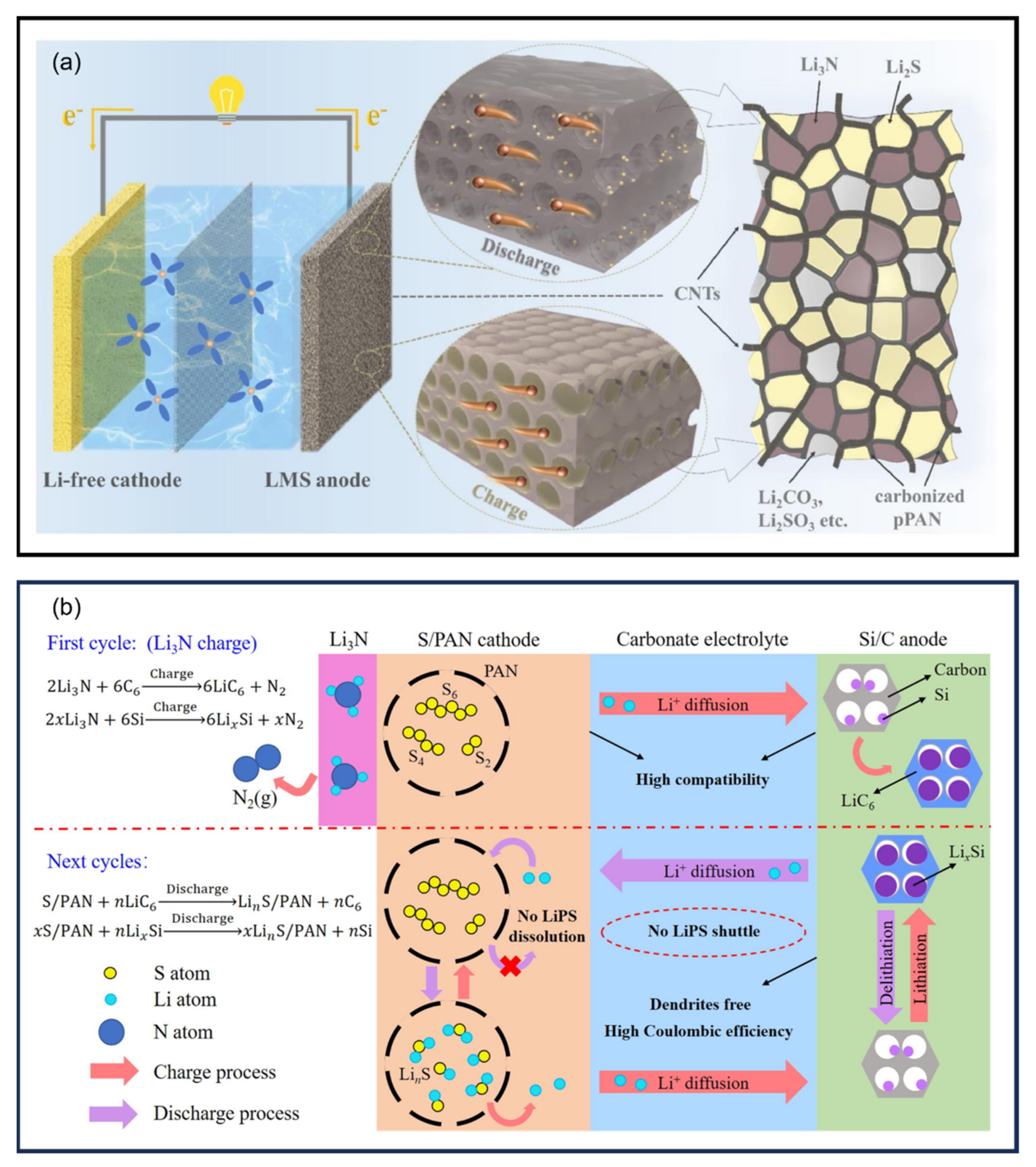

- Wang, P.; Xia, C.; Yang, J.; He, X.; Lv, K.; Ren, S.; Song, H.; Wang, J.; He, P.; Zhou, H. High-Energy Silicon-Sulfurized Poly(Acrylonitrile) Battery Based on a Nitrogen Evolution Reaction. Sci. Bull. 2022, 67, 256–262. [Google Scholar] [CrossRef]

- Chen, W.-J.; Li, B.-Q.; Zhao, C.-X.; Zhao, M.; Yuan, T.-Q.; Sun, R.-C.; Huang, J.-Q.; Zhang, Q. Electrolyte Regulation towards Stable Lithium-Metal Anodes in Lithium–Sulfur Batteries with Sulfurized Polyacrylonitrile Cathodes. Angew. Chem. Int. Ed. 2020, 59, 10732–10745. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Lee, S.; Agostini, M.; Jeong, M.-G.; Jung, H.-G.; Ming, J.; Sun, Y.-K.; Kim, J.; Hwang, J.-Y. Multiscale Understanding of Covalently Fixed Sulfur–Polyacrylonitrile Composite as Advanced Cathode for Metal–Sulfur Batteries. Adv. Sci. 2021, 8, 2101123. [Google Scholar] [CrossRef]

- Ma, T.; Tao, Z. Challenges and Prospects of Electrolyte Design for Lithium-Sulfurized Polyacrylonitrile Batteries. Batter. Supercaps 2024, 7, e202400284. [Google Scholar] [CrossRef]

- Wang, L.; He, X.; Li, J.; Chen, M.; Gao, J.; Jiang, C. Charge/Discharge Characteristics of Sulfurized Polyacrylonitrile Composite with Different Sulfur Content in Carbonate Based Electrolyte for Lithium Batteries. Electrochim. Acta 2012, 72, 114–119. [Google Scholar] [CrossRef]

- Warneke, S.; Hintennach, A.; Buchmeiser, M.R. Communication—Influence of Carbonate-Based Electrolyte Composition on Cell Performance of SPAN-Based Lithium-Sulfur-Batteries. J. Electrochem. Soc. 2018, 165, A2093. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, W.; Mao, S.; Li, S.; Wang, X.; Lu, Y. Tailored Electrolytes Enabling Practical Lithium–Sulfur Full Batteries via Interfacial Protection. ACS Energy Lett. 2021, 6, 2673–2681. [Google Scholar] [CrossRef]

- Wu, B.; Liu, Q.; Mu, D.; Ren, Y.; Li, Y.; Wang, L.; Xu, H.; Wu, F. New Desolvated Gel Electrolyte for Rechargeable Lithium Metal Sulfurized Polyacrylonitrile (S-PAN) Battery. J. Phys. Chem. C 2014, 118, 28369–28376. [Google Scholar] [CrossRef]

- Beltran, S.P.; Balbuena, P.B. A Solid Electrolyte Interphase to Protect the Sulfurized Polyacrylonitrile (SPAN) Composite for Li–S Batteries: Computational Approach Addressing the Electrolyte/SPAN Interfacial Reactivity. J. Mater. Chem. A 2021, 9, 7888–7902. [Google Scholar] [CrossRef]

- Klostermann, S.V.; Kappler, J.; Waigum, A.; Buchmeiser, M.R.; Köhn, A.; Kästner, J. The Reduction Behavior of Sulfurized Polyacrylonitrile (SPAN) in Lithium–Sulfur Batteries Using a Carbonate Electrolyte: A Computational Study. Phys. Chem. Chem. Phys. 2024, 26, 9998–10007. [Google Scholar] [CrossRef]

- Lin, F.; Wang, J.; Jia, H.; Monroe, C.W.; Yang, J.; NuLi, Y. Nonflammable Electrolyte for Rechargeable Lithium Battery with Sulfur Based Composite Cathode Materials. J. Power Sources 2013, 223, 18–22. [Google Scholar] [CrossRef]

- Wang, J.; Lin, F.; Jia, H.; Yang, J.; Monroe, C.W.; NuLi, Y. Towards a Safe Lithium–Sulfur Battery with a Flame-Inhibiting Electrolyte and a Sulfur-Based Composite Cathode. Angew. Chem. Int. Ed. 2014, 53, 10099–10104. [Google Scholar] [CrossRef]

- Jia, H.; Wang, J.; Lin, F.; Monroe, C.W.; Yang, J.; NuLi, Y. TPPi as a Flame Retardant for Rechargeable Lithium Batteries with Sulfur Composite Cathodes. Chem. Commun. 2014, 50, 7011–7013. [Google Scholar] [CrossRef]

- Yang, H.; Li, Q.; Guo, C.; Naveed, A.; Yang, J.; Nuli, Y.; Wang, J. Safer Lithium–Sulfur Battery Based on Nonflammable Electrolyte with Sulfur Composite Cathode. Chem. Commun. 2018, 54, 4132–4135. [Google Scholar] [CrossRef]

- Wu, J.; Liu, J.; Lu, Z.; Lin, K.; Lyu, Y.-Q.; Li, B.; Ciucci, F.; Kim, J.-K. Non-Flammable Electrolyte for Dendrite-Free Sodium-Sulfur Battery. Energy Storage Mater. 2019, 23, 8–16. [Google Scholar] [CrossRef]

- Wu, B.; Chen, F.; Mu, D.; Liao, W.; Wu, F. Cycleability of Sulfurized Polyacrylonitrile Cathode in Carbonate Electrolyte Containing Lithium Metasilicate. J. Power Sources 2015, 278, 27–31. [Google Scholar] [CrossRef]