Abstract

Objective: The rapid growth of electric vehicle (EV) adoption has led to an unprecedented increase in lithium-ion battery (LIB) demand and end-of-life waste, underscoring the urgent need for effective recycling strategies. This review evaluates current progress in EV battery recycling and explores future prospects. Design: Review based on PRISMA 2020. Data sources: Scientific publications indexed in major databases such as Scopus, Web of Science, and ScienceDirect were searched for relevant studies published between 2020 and 15 April 2025. Inclusion criteria: Studies were included if they were published in English between 2020 and 15 April 2025, and focused on the recycling of electric vehicle batteries. Eligible studies specifically addressed (i) recycling methods, technologies, and material recovery processes for EV batteries; (ii) the impact of recycled battery systems on power generation processes and grid stability; and (iii) assessments of materials used in battery manufacturing, including efficiency and recyclability. Review articles and meta-analyses were excluded to ensure the inclusion of only original research data. Data extraction: Data were independently screened and extracted by two researchers and analyzed for recovery rates, environmental impact, and system-level energy contributions. One researcher independently screened all articles and extracted relevant data. A second researcher validated the accuracy of extracted data. The data were then organized and analyzed based on reported quantitative and qualitative indicators related to recycling methods, material recovery rates, environmental impact, and system-level energy benefits. Results: A total of 23 studies were included. Significant progress has been made in hydrometallurgical and direct recycling processes, with recovery rates of critical metals (Li, Co, Ni) improving. Second-life battery applications also show promise for grid stabilization and renewable energy storage. Furthermore, recycled batteries show potential in stabilizing power grids through second-life applications in BESS. Conclusion: EV battery recycling is a vital strategy for addressing raw material scarcity, minimizing environmental harm, and supporting energy resilience. However, challenges persist in policy harmonization, technology scaling, and economic viability. Future progress will depend on integrated efforts across sectors and regions to build a circular battery economy.

1. Introduction

The rapid global adoption of electric vehicles (EVs) is a cornerstone of the transition toward sustainable transportation and net-zero carbon emissions [1]. With EVs projected to account for over 60% of new car sales by 2040 [2], the demand for lithium-ion batteries (LIBs) has surged, leading to an unprecedented accumulation of end-of-life (EoL) battery waste. While EVs significantly reduce greenhouse gas emissions during operation, the environmental footprint of their batteries—spanning resource extraction, manufacturing, and disposal—poses a critical sustainability challenge [3]. Efficient recycling of EV batteries is thus imperative to close the material loop, mitigate resource scarcity, and minimize ecological harm.

LIBs, the dominant energy storage technology in EVs, rely on critical materials such as lithium, cobalt, nickel, and graphite. The extraction of these materials is often associated with severe environmental degradation, geopolitical tensions, and human rights concerns, particularly in cobalt-rich regions like the Democratic Republic of Congo [4]. Furthermore, the linear economy model—where spent batteries are discarded in landfills—results in toxic leakage and wasted valuable resources. Recycling presents a circular economy solution, reducing reliance on virgin mining and cutting lifecycle emissions by up to 50% [5,6].

Despite these benefits, the current recycling rate is less than 5% of LIBs globally. Key barriers include technological limitations, economic viability gaps, regulatory fragmentation, and logistical complexities in battery collection and transportation. Addressing these challenges requires a systematic evaluation of existing recycling methods, emerging innovations, and policy frameworks to scale sustainable practices [4,6].

1.1. Technological Progress in Battery Recycling

Modern recycling technologies for electric vehicle (EV) batteries are primarily categorized into pyrometallurgy, hydrometallurgy, and direct recycling. Pyrometallurgical processes, involving high-temperature smelting, are commercially mature and capable of handling diverse battery chemistries; however, they are energy-intensive and often inefficient in recovering certain elements, particularly lithium [7]. Hydrometallurgical methods, which rely on chemical leaching, offer high recovery rates—exceeding 95% for cobalt and nickel—but generate hazardous liquid waste requiring careful management. Direct recycling, a relatively nascent approach, refurbishes cathode materials without complete breakdown, thereby preserving their electrochemical integrity and reducing energy consumption [8].

Recent developments such as solvent-based separation, bioleaching, and electrochemical techniques have enhanced process efficiency and environmental compatibility [9]. Nonetheless, the heterogeneous nature of battery chemistries—such as lithium nickel manganese cobalt oxide (NMC), lithium iron phosphate (LFP), and lithium cobalt oxide (LCO)—poses significant challenges to standardization and necessitates adaptable and chemistry-specific recycling solutions [10].

The global momentum toward decarbonization, driven by stringent climate policies and growing environmental awareness, has accelerated the transition from internal combustion engine vehicles to EVs. This transition is underpinned by advancements in battery technologies, regulatory mandates, and increasing consumer demand. According to the International Energy Agency (IEA), the global electric car fleet surpassed 26 million units in 2022, with projections indicating continued exponential growth [11,12].

This rapid expansion presents critical sustainability challenges, particularly regarding the management of end-of-life (EoL) lithium-ion batteries (LIBs). As the dominant energy storage technology in EVs, LIBs have a finite operational life and must be responsibly reused, repurposed, or recycled. Improper disposal of EoL batteries, which contain hazardous materials and critical metals, can lead to significant environmental risks. Efficient recycling practices not only mitigate these impacts but also unlock substantial economic opportunities through the recovery of valuable resources [12,13].

A detailed understanding of battery structure and composition is essential for optimizing recycling methods. EV batteries typically comprise four key components: cathodes rich in lithium, cobalt, nickel, and manganese; anodes primarily composed of graphite; electrolytes consisting of lithium salts in organic solvents; and separators that prevent internal short circuits. Variations in battery chemistry directly affect recyclability. For example, while NMC batteries offer high energy density, their cobalt content complicates recovery. In contrast, LFP batteries are safer and more cost-effective but yield fewer high-value materials, reducing the economic incentive for their recycling [14,15].

Recycling serves both environmental and economic objectives. It prevents hazardous waste accumulation, reduces dependence on primary raw material extraction, and mitigates associated environmental and geopolitical risks. Notably, cobalt mining in the Democratic Republic of Congo has raised ethical and environmental concerns. Economically, recycling supports a circular economy by recovering critical metals that can be reintegrated into battery manufacturing, thereby stabilizing supply chains and reducing production costs. With growing EV demand, securing a sustainable supply of battery materials through recycling is becoming increasingly vital [15,16,17].

Each recycling method presents distinct advantages and limitations. Pyrometallurgy, though versatile and industrially established, is energy-intensive and often results in the loss of elements such as lithium and aluminum [18,19]. Hydrometallurgy, typically involving acid leaching, achieves high recovery efficiencies and is less energy-consuming, but it generates substantial liquid waste requiring regulated disposal [20,21]. Direct recycling, which aims to retain the structural and functional integrity of battery components, remains in developmental stages but holds promise for lowering energy input and maintaining material performance [22,23].

Several systemic challenges hinder the widespread implementation of EV battery recycling. One major obstacle is the lack of standardized battery designs, which complicates disassembly and material separation. Many battery packs are integrated with complex electronics and sealed housings, making dismantling labor-intensive and costly. Additionally, the absence of robust collection and logistics infrastructure limits the efficient return of EoL batteries. Public awareness and regulatory clarity regarding battery disposal remain insufficient in many regions.

Economic viability also plays a pivotal role. While the recovery of high-value metals like cobalt and nickel can be profitable, other elements such as lithium and manganese are less economically attractive due to lower market value and more complex recovery processes. Fluctuating raw material prices further affect the financial feasibility of recycling infrastructure investments [14,24,25].

In response, governments and regulatory bodies are introducing frameworks to incentivize and regulate battery recycling. The European Union’s Battery Regulation mandates minimum recycling efficiencies and promotes eco-design principles, including design for disassembly and the implementation of battery passports to facilitate lifecycle tracking. In the United States, although regulatory efforts are less centralized, initiatives such as the Battery Recycling Prize and support from the Department of Energy signal growing momentum. China, a leading player in battery production, has enacted policies obligating manufacturers to take responsibility for battery collection and recycling [26,27].

This review aims to provide a comprehensive analysis of the current landscape of EV battery recycling, with a focus on technological innovation, economic drivers, and regulatory strategies. It examines the full lifecycle of EV batteries, evaluates the performance and limitations of existing recycling technologies, and identifies critical gaps in research and infrastructure. Emphasis is placed on integrating recycling into a circular economy framework, clarifying stakeholder responsibilities across the value chain, and exploring potential innovations such as second-life applications and digital tracking systems. By synthesizing insights from the recent scientific literature, industrial practices, and policy developments, this work seeks to inform the development of sustainable and scalable battery recycling systems that support the broader transition to clean energy and low-carbon mobility.

Electrochemical recovery is an emerging technique that uses electrowinning or electrodeposition to selectively extract valuable metals—such as lithium, cobalt, and nickel—from leachates or spent electrolytes in lithium-ion battery recycling. This method is particularly attractive due to its high selectivity, reduced need for hazardous chemicals, and compatibility with closed-loop hydrometallurgical systems. While still primarily at the lab or pilot scale, it shows strong potential for scaling due to its energy efficiency and ability to operate under milder environmental conditions [28].

Supercritical fluid extraction (SFE) leverages the unique solvating properties of supercritical fluids—often CO2 or water above their critical temperature and pressure—to recover targeted battery components. This method offers a cleaner, more environmentally friendly alternative to traditional leaching by eliminating the use of strong acids or bases. It has demonstrated potential in selectively extracting lithium, organic binders, and electrolytes. However, its commercial viability is currently limited by high equipment costs, process complexity, and the need for further optimization for diverse battery chemistries [29]. Battery types are compared in Table 1 in terms of properties, benefits, and challenges.

Table 1.

Summary of recycling methods and challenges.

1.2. Battery Lifecycle and End-of-Life Scenarios

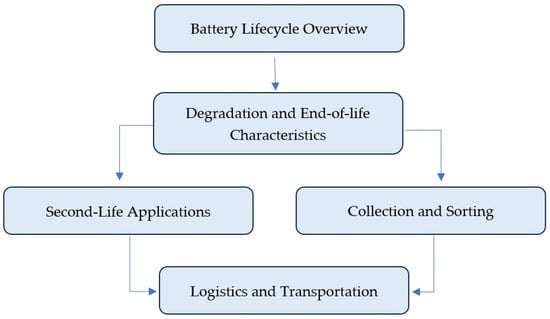

The lifecycle of an electric vehicle (EV) battery extends far beyond its operational service in mobility, encompassing complex stages of production, utilization, degradation, and eventual repurposing or recycling. While LIBs typically retain 70–80% of their initial capacity after 8–10 years of vehicular use [30], their performance degradation necessitates strategic end-of-life (EoL) management to maximize resource efficiency. Potential EoL pathways include second-life applications (e.g., stationary energy storage), direct material recycling, or, in poorly regulated markets, landfilling—each carrying distinct environmental and economic implications. This section analyzes the technical, logistical, and regulatory determinants of these scenarios, emphasizing the critical role of lifecycle planning in achieving a sustainable circular economy for battery materials [30,31,32].

An EV battery typically undergoes several stages during its operational life. These include raw material extraction, manufacturing, first-use in vehicles, second-life applications, and eventual recycling or disposal. Understanding these stages is crucial to identifying intervention points where sustainability measures, such as reuse or material recovery, can be most effectively implemented.

Battery degradation is a natural process resulting from repeated charge–discharge cycles, high temperatures, and other operational stresses. Over time, battery capacity decreases, and its ability to deliver sufficient power declines. When a battery’s state of health (SoH) drops below approximately 70–80%, it is generally considered no longer viable for vehicular use, marking its transition to the EoL phase [32,33].

Before recycling, EoL EV batteries can be repurposed for second-life applications, such as stationary energy storage for renewable energy integration, backup power systems, or grid support services. These applications capitalize on the residual capacity of EV batteries and extend their useful life, delaying environmental impacts and improving overall resource efficiency. However, standardization, safety testing, and performance assurance remain barriers to widespread implementation [31,33].

Effective recycling depends heavily on efficient collection and sorting mechanisms. Currently, many countries lack a streamlined system for collecting EoL EV batteries, which results in missed recovery opportunities and environmental risks. Advanced identification and tracking technologies—such as battery identification codes and digital battery passports—are being explored to facilitate better management and traceability of used batteries [33,34].

Transporting EoL batteries to recycling facilities poses logistical and safety challenges. Lithium-ion batteries are classified as hazardous materials, requiring compliance with stringent regulations for storage, packaging, and transportation. Innovations such as modular packaging systems and real-time monitoring can enhance safety and reduce logistical complexity [31,32,33,34].

The reuse of end-of-life (EoL) EV batteries in stationary energy systems offers a promising interim solution before final recycling (Figure 1), significantly easing pressure on recycling infrastructure. Second-life batteries can be repurposed for renewable energy storage, load leveling, off-grid systems, and backup power—extending their functional lifespan by several years. Studies have shown that repurposed batteries retain 70–80% of their initial capacity, making them suitable for less-demanding energy storage applications. However, reuse is not without challenges [35,36,37]. Key barriers include the lack of standardized testing protocols, variability in battery state-of-health (SoH), and risks associated with safety, thermal stability, and liability. Performance degradation over time, combined with high repurposing costs and uncertain warranties, also limit broader adoption. Despite these issues, successful pilot projects—such as the Nissan x Eaton energy storage systems and the BMW i3 reuse program—demonstrate technical feasibility and growing market interest. In the context of the energy transition, second-life applications can serve as a bridge toward circularity by reducing premature disposal and supporting grid flexibility, particularly in regions with intermittent renewable generation [36,37].

Figure 1.

Battery lifecycle and end-of-life scenarios.

1.3. Technological Advances in Recycling Processes

The recycling of electric vehicle (EV) batteries has undergone significant technological evolution in recent years, driven by the urgent need for sustainable material recovery and the growing volume of end-of-life lithium-ion batteries (LIBs). Conventional methods such as pyrometallurgy and hydrometallurgy, while effective for certain metals, face limitations in energy efficiency, material recovery rates, and environmental impact. In response, cutting-edge advancements—including direct recycling, solvent-assisted separation, and bioleaching—are reshaping the recycling landscape by improving selectivity, reducing energy consumption, and enabling higher purity material regeneration. Furthermore, innovations in automation, artificial intelligence (AI)-driven sorting, and closed-loop hydrometallurgical processes are enhancing scalability and economic viability. This section critically examines these emerging technologies, their comparative advantages, and their potential to overcome the existing barriers in large-scale battery recycling [38].

Several commercial recycling plants utilize pyrometallurgical techniques, particularly for processing mixed battery streams. The process involves shredding batteries followed by smelting in a high-temperature furnace. Metals like cobalt, nickel, and copper are recovered, but lithium and aluminum are typically lost in slag. Emerging improvements aim to lower energy use and recover more materials from the slag phase [39,40].

Hydrometallurgy is gaining traction due to its higher selectivity and recovery rates. Recent research has focused on developing environmentally benign leaching agents, reducing chemical consumption, and integrating closed-loop systems to manage effluents. Startups and industrial players are piloting scalable processes to recover lithium, cobalt, and nickel with minimal environmental footprint [41].

Direct recycling processes aim to retain the structure and chemistry of active materials for immediate reuse. Key steps include battery disassembly, material separation, re-lithiation, and quality testing. Though still in the lab and pilot stages, direct recycling offers a promising path to sustainable and low-energy battery recovery [42].

Automation is increasingly being integrated into battery recycling operations to reduce human exposure to hazardous materials and improve efficiency. Robotic disassembly systems, AI-based sorting mechanisms, and automated diagnostic tools are being developed to handle diverse battery formats and compositions [43].

LCA studies compare the environmental impacts of different recycling technologies. Results generally show that hydrometallurgical and direct recycling methods offer lower GHG emissions and energy use compared to pyrometallurgy. However, regional differences in electricity mix, regulatory context, and plant scale can influence these outcomes significantly [30,33].

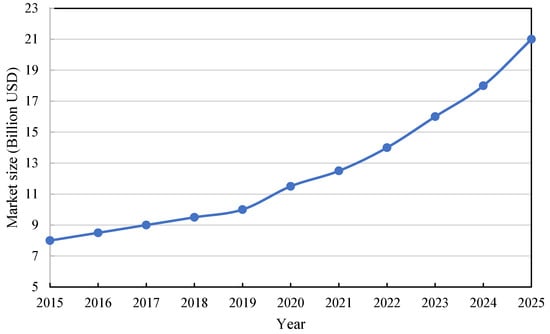

The global battery recycling market (Figure 2) has expanded substantially over the past decade. In 2016, the market was valued at approximately USD 8.74 billion, and by 2025, it is projected to reach USD 21.04 billion, reflecting a compound annual growth rate (CAGR) of 10.4% [44,45].

Figure 2.

Global battery recycling market trend (2015–2025).

Focusing specifically on lithium-ion batteries, which are prevalent in EVs and portable electronics, the recycling market was estimated at USD 3.54 billion in 2023. This segment is expected to grow at a CAGR of 21%, reaching nearly USD 24 billion by 2033 [46].

Over the past decade, numerous studies have examined the recycling of lithium-ion batteries (LIBs), reflecting the growing urgency of sustainable end-of-life (EoL) strategies for electric vehicle (EV) batteries. Harper et al. [47] provided one of the earliest comprehensive overviews, primarily focusing on pyrometallurgical and hydrometallurgical methods, but offered limited insight into regulatory or economic contexts.

Zhou Shen et al. [48] extended the scope by incorporating policy developments and briefly touching on second-life potential, while Michael. J. Lain and Emma Kendrick [49] concentrated on process optimization in metallurgical recovery. Jiang et al. [50] shifted focus toward circular economy integration, presenting a framework that aligns recycling with reuse strategies and policy incentives, but stopped short of detailed techno-economic analysis. More recently, Rachmadhani et al. [51] offered a comprehensive techno-economic evaluation of conventional and hybrid recycling methods, revealing performance trade-offs across different process designs. Ali Amjad et al. [52] contributed a global policy perspective, reviewing national mandates, incentives, and infrastructure gaps but omitting technical or material recovery discussions.

Despite these valuable contributions, a multidimensional synthesis that connects technological advances with regulatory developments, economic viability, and circular economy strategies is still lacking. This review addresses that gap by providing an integrated analysis that spans recycling technologies, policy landscapes, second-life use cases, and logistics, framed through both academic literature and recent industry practices.

Table 2 presents a comparative analysis of key review studies on EV battery recycling published in recent years. It highlights the unique contributions of this review in contrast to earlier works. While previous reviews have focused primarily on individual aspects such as recycling technologies, material flow, or environmental impact, they often lack integration of second-life applications, policy frameworks, and economic feasibility. In contrast, this study offers a multidimensional synthesis that incorporates not only the technical processes—pyrometallurgy, hydrometallurgy, direct recycling, and emerging methods—but also the broader context of circular economy strategies, regulatory developments, and cost-benefit considerations. This holistic approach allows for a more comprehensive understanding of the challenges and opportunities in EV battery recycling, positioning this review as a valuable reference for researchers, industry stakeholders, and policymakers alike.

Table 2.

Comparison of this review with selected existing reviews on EV battery recycling.

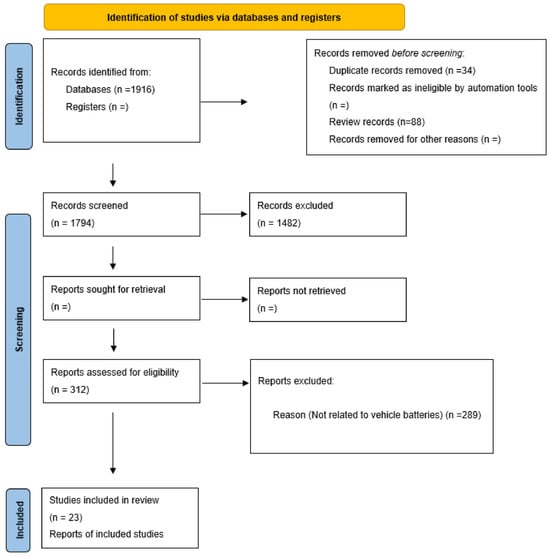

2. Methodology

Based on the Prisma 2020 checklist [53], the present systematic review was conducted by extracting studies from three scientific databases: Web of Science, SCOPUS, and Pub-Med. Published studies from the last 6 years (1 January 2020 to 15 April 2025) were restricted and categorized based on Boolean combinations. These 6 years were dedicated to assessing recent achievements and developments in the field of recycling of vehicle batteries. By adopting the keywords BEV, EV Batteries, Recycling, Lithium-ion Battery, Circular Economy, Sustainable Material Recovery, End-of-Life Management, Policy and Regulatory Frameworks, 16% of the found studies were selected (312 papers). Then, the titles and abstracts of the articles were independently reviewed by two researchers (HS, FDM). In cases of inconsistency, discussions were held until agreement was reached. Then, the titles and abstracts were screened. After this first selection process, the researcher (FDM) independently screened the full-text articles for inclusion. Articles were excluded at this stage if they met any of the following criteria:

- Not focused on EV or lithium-ion battery recycling;

- Not relevant to the scope of circular economy or sustainability;

- Editorials, commentaries, patents, or non-peer-reviewed sources;

- Review or meta-analysis articles (as this study focuses on primary data).

The remaining 312 articles (16%) underwent full-text screening. This step was independently conducted by the primary reviewer (FDM), and discrepancies were resolved through consensus discussions with the second reviewer (HS). An additional 289 articles were excluded due to insufficient data, lack of methodological rigor, or irrelevance upon detailed inspection, leaving 23 articles for final inclusion.

Each study was evaluated on aspects such as clarity of objectives, appropriateness of methodology, transparency of data collection, and validity of results. Only studies scoring above a predetermined threshold (70%) were retained in the final synthesis.

This structured and transparent selection process ensures that the findings are grounded in high-quality evidence and represent the current state of research in EV battery recycling. Detailed Boolean search strings were used in each database (Scopus, Web of Science, PubMed), included the following combinations:

“EV batteries” and (“recycling” or “recovery”) and (“lithium-ion” or “NMC”) and (2020–2025). Exclusion criteria included studies focusing on generic e-waste, review papers, non-English language studies, or those lacking primary data. These changes aim to enhance reproducibility and methodological transparency (Figure 3).

Figure 3.

Flow diagram of the selection process for the studies included in the review.

3. Results

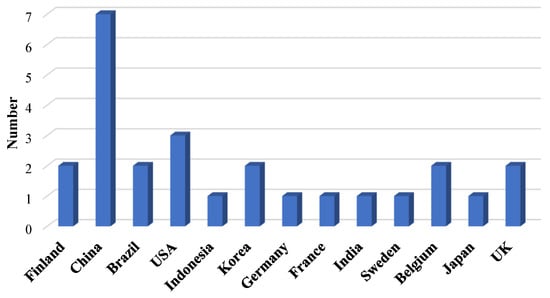

The 23 studies in this review reported on EV battery recycling in 13 countries (Figure 4). Two studies were reported from Finland, seven from China, two from Brazil, three from the United States, one each from Germany and France, one each from India and Sweden, four from East Asia, and two from the United Kingdom (Figure 4). A total of 23 studies were reported from 26 regions, of which eight were from the European Union, three from North America, two from South America, and 12 from Asia (some studies reported from more than one region).

Figure 4.

The number of geographical areas related to the included studies.

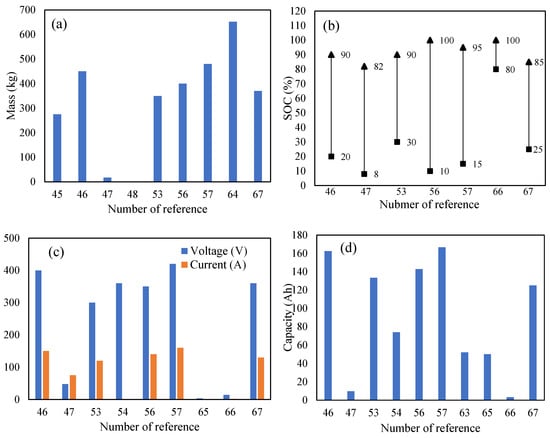

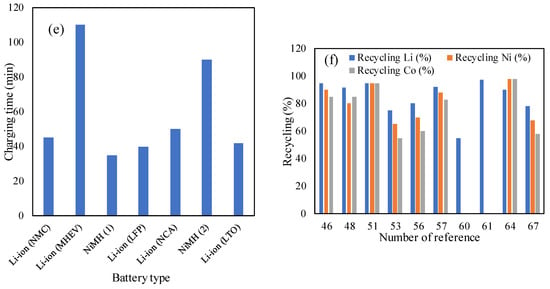

After selecting the studies to be reviewed, the results are summarized in Table 3. This table lists the studies’ titles, objectives, and achievements. The graphs relate to the comparison of battery mass (Figure 5a), state of charge (Figure 5b), voltage and current (Figure 5c), battery capacity (Figure 5d), charging time (Figure 5e), and recycling rate (Figure 5f). Table 4 also lists the parameters of the studies that are reported related to the structure of electric vehicle batteries, such as capacity, energy, voltage, current intensity, weight, and number of cells. These data have also been examined in terms of economics and optimization, and the minimum and maximum state of charge data as well as recycling costs have been provided. The results presented in the articles used in this review are also given in Figure 6.

Table 3.

Overview of the research selected in this review in terms of title, key focus, methodology, and key finding.

Figure 5.

Comparison of important parameters including: (a) battery mass, (b) state of charge, (c) voltage and current, (d) battery capacity, (e) charging time, and (f) recycling rate.

Table 4.

Overview of research on the recycling of EV batteries: optimization objectives and parameters.

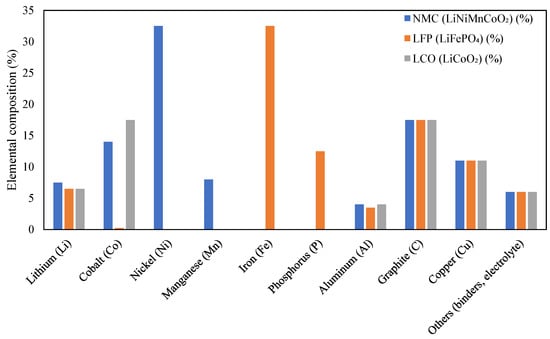

Figure 6.

Representative elemental composition of selected lithium-ion battery chemistries (% by weight of cell materials).

Figure 5 presents a comprehensive comparison of key performance and compositional metrics across various EV battery chemistries, including NMC, LFP, and LCO. Figure 5a–f illustrate differences in critical aspects such as material composition, recycling efficiency, charging time, capacity, and voltage and current of batteries. The reported battery weights ranged from 5 to 680 kg (Figure 5a), depending on the type of system used and the scale of the test. The SOC range was also reported from 8 to 30 for the minimum and 82 to 100 for the maximum (Figure 5b). The normal voltage reported in the referenced papers was between 300 and 400 V, while the current and capacity intensities varied (Figure 5c,d). Figure 5e also reports the charging time of the batteries reported to be between 35 and 110 minutes, which varies depending on the weight and size of the battery. And finally, Figure 5f reports the high recycling rates of the basic metals of batteries, including lithium, nickel, and cobalt.

Some studies have reported the chemical elements present in the structure of batteries. Some of these elements are specified in the battery description and some in the battery recycling. These elements are reported in Table 5, separated by reference number. Also, the reported amount of each element is given separately in Table 6.

Table 5.

Reported elements in battery structure or recycling.

Table 6.

The contribution of each element in the battery structure (kg/kWh).

In more detailed studies, the cost of the elements used in the battery structure has been reported separately in three studies, which can be seen in Table 7.

Table 7.

Disaggregated cost of electric vehicle battery structure elements.

Table 7 provides essential cost and recovery value data that allow for a preliminary assessment of the economic feasibility of recycling different EV battery chemistries. For instance, NMC (Nickel-Manganese-Cobalt) batteries contain high-value materials such as cobalt and nickel, which contribute to a potential revenue of approximately USD 2000–2500 per ton of processed material. In contrast, LFP (Lithium Iron Phosphate) batteries, though more stable and safer, lack cobalt and nickel and yield a significantly lower estimated recovery value—typically in the range of USD 300–600 per ton. When compared against average processing costs, which range from USD 1000 to USD 1400 per ton depending on the method and region, it becomes evident that recycling NMC batteries can be economically viable or even profitable under current market conditions, particularly when combined with policy incentives or subsidies. Conversely, LFP recycling may require regulatory support or material innovation to reach profitability. This comparative analysis highlights the strong influence of battery chemistry on financial returns, underscoring the importance of aligning recycling strategies with material composition and market dynamics.

4. Discussions

The comparative evaluation of different EV/HEV battery chemistries provides essential insights into their technical performance, recyclability, and sustainability, especially in the context of increasing global efforts towards a circular economy. Based on the collected data, Lithium Nickel Manganese Cobalt Oxide (NMC) and Lithium Iron Phosphate (LFP) batteries emerge as prominent contenders, each offering distinct characteristics in terms of energy density, environmental impact, and economic viability during recycling.

4.1. Energy Density and Technical Performance

One of the primary considerations in battery technology is the energy density, which directly influences the vehicle’s driving range and overall efficiency [77]. Among the studied chemistries, NMC batteries show the highest energy density values, making them particularly suitable for long-range electric vehicles. Their high specific energy (ranging between 150–220 Wh/kg) enables automotive manufacturers to design vehicles that require fewer battery modules for a given range, thus optimizing space and weight.

Conversely, LFP batteries offer lower energy density values, generally in the range of 90–160 Wh/kg. Although this is a limitation for high-performance electric vehicles, LFP batteries compensate with superior thermal and chemical stability, longer cycle life, and greater resistance to thermal runaway. These attributes make LFP batteries particularly attractive for applications such as buses, commercial fleets, and lower-range passenger vehicles where safety, longevity, and cost take precedence over high range.

4.2. Recycling Efficiency and Metal Recovery

The recyclability of batteries is increasingly critical given the finite nature of raw materials like cobalt, nickel, and lithium. The study indicates that NMC batteries exhibit higher recovery rates for critical metals, with cobalt and nickel recovery efficiencies often exceeding 90% in optimized recycling processes such as hydrometallurgical treatment [78,79]. However, lithium recovery remains notably lower, typically ranging between 70–85%, due to its dispersion in the electrode materials and the technical challenges associated with its selective extraction.

In contrast, LFP batteries pose a different scenario. The absence of high-value metals such as cobalt and nickel simplifies the chemical processes involved in recycling but simultaneously reduces the economic incentive for recycling operations. While iron and phosphate recovery are technically achievable, the lower market value of these elements compared to cobalt and nickel results in a weaker economic case. Therefore, LFP battery recycling strategies often focus more on the recovery of lithium and the reuse of cathode materials rather than elemental extraction.

4.3. Environmental Impact and Process Conditions

The environmental burden associated with battery recycling is heavily influenced by the process conditions required for material recovery. NMC batteries, with their complex material compositions, often require high-temperature treatments (pyrometallurgy) or chemical-intensive methods (hydrometallurgy) for effective material recovery. These processes, although efficient in terms of metal yield, are energy-intensive and may generate hazardous waste streams if not carefully managed [80,81].

LFP batteries, owing to their simpler material composition and absence of heavy metals, can be recycled through less intensive processes, leading to potentially lower environmental impacts. For instance, direct recycling methods, which aim to recover entire cathode structures rather than elemental metals, are more feasible with LFP batteries and offer significant energy savings. Nonetheless, the widespread adoption of such methods requires advancements in sorting, pre-treatment, and process optimization to ensure high material purity and performance.

In addition to environmental benefits, second-life applications of EV batteries play a critical role in enhancing power system resilience, particularly during large-scale grid disruptions. As highlighted by recent studies, repurposed EV batteries can serve as decentralized energy storage units, providing backup power and supporting grid stability when traditional supply sources are compromised. This resilience-oriented recovery framework complements conventional recycling strategies by extending the useful life of batteries beyond automotive applications and mitigating the impact of supply interruptions. Incorporating second-life batteries into the energy infrastructure not only reduces waste and resource demand but also strengthens the overall reliability and flexibility of power systems, making them better equipped to handle unexpected disturbances [35,82].

4.4. Cost Considerations and Economic Viability

The economic feasibility of lithium-ion battery (LIB) recycling hinges on a multifaceted interplay of material value, processing costs, and market demand. Nickel-manganese-cobalt (NMC) batteries, characterized by elevated cobalt and nickel content, demonstrate higher revenue potential per metric ton of recycled material [83]. However, the multi-stage recycling process—encompassing disassembly, hydrometallurgical or pyrometallurgical treatment, and material purification—substantially increases operational expenditures due to energy, labor, and equipment demands.

In contrast, Lithium Iron Phosphate (LFP) batteries, with inherently lower material value, frequently result in a net economic deficit when subjected to conventional recycling techniques. The market value of recovered iron and phosphate is markedly inferior to that of cobalt and nickel, thus constraining profitability. Consequently, alternative strategies, such as second-life applications for batteries prior to end-of-life processing or governmental subsidies for low-value material recovery, are likely requisite to achieve economic sustainability for LFP recycling.

To rigorously quantify the economic implications of LIB recycling pathways, we report cost and revenue estimates for two prevalent battery chemistries: LFP and NMC. These data were systematically derived from a meta-analysis of peer-reviewed literature and industry reports published between 2020 and 2025, with a primary focus on data from North America and Europe, where recycling operations and market conditions are comparatively well-characterized [83,84,85]. For LFP batteries, recycling costs average USD 1000 per metric ton, with a deviation range of USD 900 to USD 1200 per ton, influenced by variables such as process efficiency, regional energy costs, and labor expenses. The market value of recovered materials—principally lithium, iron, and phosphate—spans from USD 300 to USD 600 per ton, yielding a net economic loss under prevailing conditions. For NMC batteries, processing costs are higher, averaging USD 1300 to USD 1400 per ton (range: USD 1200 to USD 1600 per ton), yet the recovered cobalt, nickel, and lithium generate revenues of USD 1100 to USD 2200 per ton, contingent on material purity, grade, and global commodity prices as of 2024 [84,85]. These estimates were calculated by aggregating reported operational costs (e.g., energy consumption, labor, and capital equipment) and market values of recovered materials, with adjustments applied for inflation and regional economic variability where data permitted. The pronounced disparity between LFP and NMC economics underscores the critical influence of material composition, recovery efficiency, and market dynamics on recycling viability, thereby informing investment and policy priorities (Supplementary Table S1).

Also, for deviation ranges, cost and revenue ranges (e.g., USD 900–USD 1200 per ton for LFP processing; USD 1100–USD 2200 per ton for NMC material value) account for variability arising from process efficiency, regional energy and labor costs, and temporal fluctuations in commodity markets. These data predominantly originate from North America and Europe, regions with established recycling infrastructure and accessible economic datasets, ensuring relevance and reliability. These values were computed via a meta-analysis of operational cost components (energy, labor, and equipment) and material market prices from cited studies, with adjustments for inflation and regional economic factors where specified in source data.

4.5. Safety Considerations: State of Charge (SOC) and Thermal Stability

The State of Charge (SOC) parameter is crucial for both the operational safety of batteries and their handling during end-of-life processing. Batteries that operate within narrower SOC windows tend to exhibit greater stability but at the expense of reduced effective energy usage. The data indicate that LFP batteries maintain excellent thermal and electrochemical stability even at high states of charge, significantly reducing the risk of fire or explosion during transportation, storage, and recycling [86,87].

In comparison, NMC batteries, while offering higher energy densities, are more sensitive to overcharging and high temperatures. This necessitates stringent safety protocols during the collection, transportation, and dismantling stages of recycling operations, including pre-discharge procedures, thermal monitoring, and specialized packaging.

4.6. Strategic Implications for Future Battery Design and Recycling

Given the EU’s Green Deal targets, the “Fit for 55” package, and other global regulatory frameworks, the future of EV battery design must be tightly linked to end-of-life management strategies. Eco-design principles—designing batteries for easier disassembly, standardized component labeling, and modular construction—will be key enablers of more efficient recycling [88,89].

Furthermore, developing “closed-loop” recycling systems, where recovered materials are directly reintroduced into the battery production supply chain, will be essential for reducing dependence on virgin raw materials. This is particularly important for critical materials such as cobalt and lithium, whose geopolitical supply chains are subject to significant volatility.

For NMC batteries, efforts should focus on improving lithium recovery rates and developing more environmentally benign recycling methods. For LFP batteries, innovations in direct recycling technologies and second-life applications (e.g., stationary energy storage) can enhance their economic and environmental profile.

To address the currently low global recycling rate of lithium-ion batteries (LIBs), estimated at below 5%, this review proposes several policy-driven scenarios based on successful international precedents. One approach involves mandating a minimum recycled content requirement in new battery production, which would create sustained demand for recovered materials. Additionally, government-backed subsidies or tax incentives could help offset the high upfront costs of establishing recycling infrastructure, especially in developing economies. A third option is the implementation of deposit–refund schemes, where consumers receive a financial return upon returning used batteries—an approach proven effective in increasing return rates for other waste streams. The European Union’s Battery Regulation sets a precedent by requiring producers to meet specific material recovery targets, while the U.S. Critical Materials Initiative supports domestic recycling capacity through funding and R&D incentives. China, meanwhile, mandates extended producer responsibility (EPR) for battery take-back and recycling. Preliminary modeling suggests that such policy interventions could increase global recycling rates to 25–35% within a decade, depending on enforcement strength and market dynamics. Integrating these strategies would help accelerate the transition to a circular battery economy and reduce dependency on virgin resource extraction [90,91,92,93].

4.7. Policy and Market Dynamics

Public policies and market mechanisms will play a decisive role in shaping the recycling landscape. Extended Producer Responsibility (EPR) regulations, mandatory recycling targets, and recycling content requirements for new batteries are likely to become more stringent. Financial incentives, subsidies for recycling infrastructure, and penalties for non-compliance will further influence manufacturers’ choices regarding battery chemistry and design [93,94].

In particular, mandating minimum recovery rates for lithium and other critical materials can drive technological innovation in recycling processes. Similarly, establishing certification schemes for recycled materials can build trust among battery manufacturers and stimulate demand for secondary raw materials.

Table 8 provides a comparative summary of major battery recycling policies in the European Union [95], United States [96], China [97], and select East Asian [98,99] economies. The European Union stands out for its comprehensive regulatory framework, including mandatory recycling targets and traceability measures such as the battery passport system. The U.S. approach, while lacking binding requirements, focuses on funding and incentives through its Critical Materials Strategy, spurring private-sector interest. China enforces strict extended producer responsibility (EPR) regulations, requiring manufacturers to implement closed-loop recycling systems under government monitoring. In contrast, Japan and the Republic of Korea rely more heavily on voluntary industry initiatives, though pilot programs and public–private partnerships are gaining traction. These differences in policy structure and enforcement directly affect the pace and scale of recycling adoption, and highlight the importance of regulatory alignment in achieving global sustainability targets.

Table 8.

Comparative overview of battery recycling policies in key regions.

4.8. Processing

The elemental composition of various EV battery chemistries ((Figure 6) and detailed in Supplementary Table S2), offers critical insight into both recycling prioritization and economic feasibility. For example, the high cobalt and nickel content in NMC batteries underpins their higher recovery value, while the iron- and phosphate-rich structure of LFP chemistries explains their lower commercial attractiveness for recycling despite favorable safety profiles. These compositional differences directly influence material selection for recycling methods, cost structures (as discussed in Section 4.4), and the design of hybrid recovery strategies. Additionally, the presence of trace elements such as manganese or aluminum informs the selection of leaching agents in hydrometallurgical processes, as discussed in Section 4.2. By incorporating these elemental details into the broader discussion of process selection and value recovery, we aim to provide a more integrated understanding of how chemical makeup shapes the practical and financial dimensions of battery recycling.

Table S3 presents the elemental composition of key materials found in lithium-ion batteries (LIBs), alongside their average market value and estimated economic contribution per kilogram of battery material. This comparative analysis reveals that lithium, nickel, and cobalt represent the highest recovery value, with lithium alone contributing over USD 3 per kg of battery due to its high market price. In contrast, abundant materials such as iron and aluminum offer minimal economic return despite their significant mass share. This differentiation highlights the importance of prioritizing high-value element recovery in recycling system design and policy incentives. Moreover, the table illustrates why chemistries rich in cobalt and nickel (e.g., NMC) are more economically attractive for recyclers compared to those like LFP, which lack such metals.

4.9. Logistical Barriers in Battery Collection and Transport

Efficient logistics for collecting and transporting end-of-life (EoL) batteries are essential to closing the loop in the EV battery value chain, yet they remain a significant bottleneck, especially in developing regions [100]. Lithium-ion batteries are classified as hazardous waste due to their flammability and potential for toxic leakage, making their transport subject to strict regulations [101]. However, compliance with these standards is often difficult in regions lacking trained personnel, certified containers, and inspection protocols [100,101,102]. Moreover, there are widespread disparities in the availability of specialized collection facilities; while high-income countries have designated drop-off points and reverse logistics networks, many lower-income regions lack even basic take-back infrastructure. These challenges are compounded by high transportation costs due to safety packaging, route restrictions, and insurance premiums. In response, emerging innovations—such as modular battery transport containers, real-time tracking technologies, and digital battery passports—are being piloted in the EU and China to improve traceability, streamline handling procedures, and reduce risk. Expanding these models globally could substantially improve battery flow efficiency and enable more equitable recycling participation [101,102].

4.10. Cross-Sectoral Collaboration in EV Battery Recycling

Achieving a truly circular economy for electric vehicle (EV) batteries requires coordinated efforts across the public and private sectors, including automakers, recyclers, policymakers, and research institutions. Collaborative initiatives are proving essential in aligning technological innovation with regulatory compliance and market deployment. For example, the ReCell Center in the United States brings together national laboratories, universities, and industry partners to develop scalable recycling technologies and inform federal policy. In Europe, the European Battery Alliance serves as a strategic platform uniting over 800 stakeholders, including manufacturers, recyclers, and government bodies, to accelerate battery value chain development through joint investments, standards, and workforce training. Additionally, public–private joint ventures such as the Umicore–Audi partnership demonstrate how original equipment manufacturers (OEMs) can work with recyclers to close material loops and integrate recycled metals back into new battery production. These cases underscore the importance of collaboration not only in advancing technical solutions but also in addressing regulatory, financial, and logistical challenges. Embedding such cooperative frameworks globally will be vital for scaling up battery recycling and meeting sustainability targets (Supplementary Table S4).

4.11. Risks and Limitations of Battery Reuse

The reuse of end-of-life (EoL) electric vehicle (EV) batteries, particularly in second-life applications such as battery energy storage systems (BESS) for grid support or renewable energy integration, offers a promising strategy to extend lifecycle value and reduce waste. However, significant risks and limitations must be addressed to ensure safety, reliability, and economic feasibility.

A primary concern is the thermal stability of reused lithium-ion batteries (LIBs), which can pose safety hazards if not properly managed. Studies indicate that aged batteries, particularly those with nickel-manganese-cobalt (NMC) chemistries, exhibit reduced thermal runaway onset temperatures, dropping from approximately 200–250 °C in new cells to 150–200 °C after significant cycling (e.g., 500–1000 cycles at 80% depth of discharge) [103,104]. This heightened risk of thermal runaway—potentially leading to fires or toxic gas emissions—is exacerbated under high-temperature operating conditions (e.g., >40 °C) or during rapid charge–discharge cycles common in grid storage applications. Quantitative risk assessments suggest a failure probability of 0.1–1% per cell under such stress conditions, with the likelihood increasing as state-of-health (SoH) declines below 70% [105].

Degradation rates further complicate reuse. LIBs in second-life applications exhibit accelerated capacity fade, with studies reporting annual capacity losses of 2–5% for LFP batteries and 3–7% for NMC batteries under typical BESS operating conditions (e.g., 25 °C, 50% depth of discharge, 1C charge rate) [106,107]. These rates vary significantly with environmental and operational factors: elevated temperatures (e.g., 35–45 °C) can increase degradation by 1.5–2 times, while irregular cycling patterns, common in renewable energy storage, may further reduce cycle life by 10–20% compared to controlled lab conditions [108]. For instance, a field study of repurposed LFP batteries in solar storage systems reported a capacity retention of 65–80% after 2 years of use at 30 °C, compared to 80–90% for new cells under similar conditions [109].

Additional limitations include performance variability and diagnostic challenges. Reused batteries often display inconsistent state-of-charge (SoC) and SoH due to prior usage history, complicating their integration into standardized systems. The absence of universal testing protocols for second-life batteries further hinders accurate assessment of residual capacity and safety risks. Moreover, economic viability remains a concern, as the costs of testing, refurbishing, and monitoring reused batteries—estimated at USD 50–150 per kWh—may offset savings compared to new units, particularly for low-demand applications [110].

To mitigate these risks, advanced diagnostics (e.g., machine learning-based SoH prediction) and robust thermal management systems are critical. Additionally, standardized testing and certification protocols for second-life batteries, coupled with real-time monitoring during reuse, can enhance safety and reliability. Despite these challenges, second-life applications remain a viable interim strategy, provided risks are rigorously quantified and managed through interdisciplinary research and policy support [103,110].

Supplementary Notes:

Quantitative Risk Assessments: Data on thermal runaway onset temperatures (150–200 °C for aged cells) and failure probabilities (0.1–1% per cell) are derived from experimental studies and failure mode analyses [103,104,105].

5. Conclusions

This systematic review provides a comprehensive analysis of recent developments in the field of electric vehicle battery (EVB) recycling, focusing on technological progress, persisting challenges, and future opportunities. Covering studies published between 2020 and 15 April 2025, this work captures a critical period of growth, innovation, and policy-driven urgency aligned with global sustainability goals, particularly within the context of decarbonization, circular economy adoption, and the Fit for 55 and EU 2030 objectives.

The results reveal that while significant strides have been made in the development of battery energy storage systems (BESS) and material recovery technologies, several gaps and inefficiencies still hinder large-scale, economically viable, and environmentally sustainable recycling efforts. Lithium, cobalt, nickel, and manganese remain the primary focus in most studies due to their high commercial value and critical role in cathode chemistry. Technologies such as hydrometallurgy and pyrometallurgy continue to dominate, but newer methods—including direct recycling and bioleaching—are gaining traction for their potential to reduce energy consumption and environmental harm.

From the data reviewed, a consistent theme emerges around the inefficiency of current material recovery processes when scaled beyond laboratory settings. Energy consumption per kilogram of material recovered often exceeds sustainability thresholds when not optimized through integrated BESS or renewable-powered processing systems. Additionally, many studies emphasize that the carbon footprint of recycling operations must be critically examined to ensure that the process genuinely contributes to decarbonization goals.

One of the clearest challenges identified in this review is the lack of standardization in battery design, which directly complicates the disassembly, sorting, and material recovery stages. Variability in chemistry (e.g., LFP vs. NMC), packaging, and manufacturing methods results in technical difficulties and cost inefficiencies. Furthermore, the absence of harmonized regulatory frameworks across regions creates barriers to cross-border collaboration and investment in recycling infrastructure.

At the same time, significant opportunities are evident. The use of artificial intelligence and machine learning to optimize disassembly, predict battery health, and automate sorting is a rapidly evolving area with strong promise. Moreover, second-life applications for EV batteries—particularly in stationary storage systems—present an underutilized yet practical approach to extending battery lifespan and reducing waste. This dual benefit supports both grid stabilization and energy access, especially in remote or developing areas.

From a policy and economic standpoint, this review highlights the importance of extended producer responsibility (EPR) schemes, subsidies for recycling innovation, and stricter end-of-life regulations to incentivize investment and compliance. The European Union’s Battery Regulation, although still evolving, is a step in the right direction and may serve as a global benchmark for battery lifecycle governance.

In summary, while EV battery recycling technologies are progressing, the field is still in a transitional stage where large-scale, sustainable implementation remains limited. Overcoming the identified challenges—technical, economic, regulatory, and environmental—will require a multi-stakeholder approach involving governments, industry, academia, and consumers. The opportunity to establish a closed-loop battery economy is within reach but will depend on integrated innovation, policy coherence, and strategic investment. This review underscores the urgency and complexity of the task, while also pointing to a future where battery recycling becomes not only feasible but foundational to the sustainable energy transition.

This systematic review elucidates several critical limitations in the recycling of electric vehicle batteries (EVBs). Primarily, material recovery processes exhibit persistent inefficiencies, particularly when scaled beyond laboratory conditions, where energy consumption frequently surpasses sustainability thresholds in the absence of optimized integration with battery energy storage systems (BESS) or renewable energy-powered processing. Additionally, the lack of standardization in battery design—stemming from variations in chemistry (e.g., LFP versus NMC), packaging, and manufacturing techniques—complicates disassembly, sorting, and material recovery, escalating both costs and technical challenges. Furthermore, the absence of harmonized regulatory frameworks across jurisdictions impedes cross-border collaboration and investment in recycling infrastructure. Lastly, despite notable advancements, the economic feasibility and environmental sustainability of large-scale recycling remain constrained, necessitating continued innovation and robust policy support to realize a fully circular battery economy.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/batteries11060230/s1, Supplementary Materials include additional data tables. References [111,112,113,114,115,116,117,118,119,120,121,122,123,124,125] are cited in Supplementary Materials: Table S1: Comparison of Recycling Cost and Revenue by Battery Chemistry, Table S2: Representative elemental composition of selected lithium-ion battery chemistries (% by weight of cell materials), Table S3: Elemental Composition, Market Value, and Economic Recovery Potential of LIB Components, and Table S4: Examples of Cross-Sectoral Collaboration in EV Battery Recycling.

Author Contributions

H.S.: Writing, Investigation, Methodology, Investigation, Formal Analysis, Validation. F.D.M.: Original draft, Validation, Formal analysis, Conceptualization. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Nomenclature

| BEV | Battery Electric Vehicle |

| BMS | Battery Management System |

| BESS | Battery Energy Storage System |

| Co | Cobalt |

| EV | Electric Vehicle |

| EoL | End of Life |

| LIB | Lithium-Ion Battery |

| Li | Lithium |

| LFP | Lithium Iron Phosphate |

| LCO | Lithium Cobalt Oxide |

| LMO | Lithium Manganese Oxide |

| Li-NMC | Lithium Nickel Manganese Cobalt Oxide |

| Li-NCA | Lithium Nickel Cobalt Aluminum Oxide |

| Ni | Nickel |

| NMC | Lithium Nickel Manganese Cobalt Oxides |

| MHEV | Mild hybrid electric vehicle |

| Mn | Manganese |

| Pyrometallurgy | High-temperature process for metal recovery |

| Hydrometallurgy | Aqueous solution-based metal extraction |

| Direct Recycling | Recovery of battery components with minimal reprocessing |

| SOH | State of Health (battery degradation metric) |

| SOC | State of Charge |

| WEEE | Waste Electrical and Electronic Equipment Directive (EU legislation) |

| VOC | Volatile Organic Compounds |

| Circular Economy | Economic system aimed at eliminating waste and continual resource use |

References

- IEA. 2024. Available online: https://www.iea.org/reports/italy-2023/executive-summary (accessed on 30 April 2025).

- Moore, J. BloombergNEF: Strategies for a Cleaner, More Competitive Future. In World Scientific Encyclopedia of Climate Change: Case Studies of Climate Risk, Action, and Opportunity; World Scientific Publishing Co Pte Ltd.: Singapore, 2021; Volume 3, pp. 247–275. [Google Scholar]

- Meegoda, J.N.; Malladi, S.; Zayas, I.C. End-of-life management of electric vehicle lithium-ion batteries in the United States. Clean Technol. 2022, 4, 1162–1174. [Google Scholar] [CrossRef]

- Bell, M. The Cobalt Mines of the Democratic Republic of Congo; Global Encounters: New Visions Department of Geography and Planning, Queen’s University: Kingston, ON, USA, 2024; p. 24. [Google Scholar]

- Wu, W.; Zhang, M.; Jin, D.; Ma, P.; Wu, W.; Zhang, X. Decision-making analysis of electric vehicle battery recycling under different recycling models and deposit-refund scheme. Comput. Ind. Eng. 2024, 191, 110109. [Google Scholar] [CrossRef]

- Tripathy, A.; Bhuyan, A.; Padhy, R.; Corazza, L. Technological, organizational, and environmental factors affecting the adoption of electric vehicle battery recycling. IEEE Trans. Eng. Manag. 2022, 71, 12992–13005. [Google Scholar] [CrossRef]

- Wesselkämper, J.; Von Delft, S. Current status and future research on circular business models for electric vehicle battery recycling. Resour. Conserv. Recycl. 2024, 206, 107596. [Google Scholar] [CrossRef]

- Chan, K.H.; Malik, M.; Azimi, G. Direct recycling of degraded lithium-ion batteries of an electric vehicle using hydrothermal relithiation. Mater. Today Energy 2023, 37, 101374. [Google Scholar] [CrossRef]

- Toro, L.; Moscardini, E.; Baldassari, L.; Forte, F.; Falcone, I.; Coletta, J.; Toro, L. A systematic review of battery recycling technologies: Advances, challenges, and future prospects. Energies 2023, 16, 6571. [Google Scholar] [CrossRef]

- Wang, Y.; Fan, R.; Chen, R.; Xie, X.; Ke, C. Exploring the coevolution dynamics of residents and recyclers in electric vehicle battery recycling decisions on the two-layer heterogeneous complex networks. Appl. Energy 2025, 382, 125235. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, Q.; Liu, B.; Li, Y.; Ni, R.; Wang, Y. What influences residents’ intention to participate in the electric vehicle battery recycling? Evidence from China. Energy 2023, 276, 127563. [Google Scholar] [CrossRef]

- Dong, B.; Ge, J. What affects consumers’ intention to recycle retired EV batteries in China? J. Clean. Prod. 2022, 359, 132065. [Google Scholar] [CrossRef]

- Hao, H.; Xu, W.; Wei, F.; Wu, C.; Xu, Z. Reward–penalty vs. deposit–refund: Government incentive mechanisms for EV battery recycling. Energies 2022, 15, 6885. [Google Scholar] [CrossRef]

- Dikmen, I.C.; Karadag, T. Electrical method for battery chemical composition determination. IEEE Access 2022, 10, 6496–6504. [Google Scholar] [CrossRef]

- Latini, D.; Vaccari, M.; Lagnoni, M.; Orefice, M.; Mathieux, F.; Huisman, J.; Tognotti, L.; Bertei, A. A comprehensive review and classification of unit operations with assessment of outputs quality in lithium-ion battery recycling. J. Power Sources 2022, 546, 231979. [Google Scholar] [CrossRef]

- Wasesa, M.; Hidayat, T.; Andariesta, D.T.; Natha, M.G.; Attazahri, A.K.; Afrianto, M.A.; Mubarok, M.Z.; Zulhan, Z.; Putro, U.S. Economic and environmental assessments of an integrated lithium-ion battery waste recycling supply chain: A hybrid simulation approach. J. Clean. Prod. 2022, 379, 134625. [Google Scholar] [CrossRef]

- Nguyen-Tien, V.; Dai, Q.; Harper, G.D.J.; Anderson, P.A.; Elliott, R.J.R. Optimising the geospatial configuration of a future lithium ion battery recycling industry in the transition to electric vehicles and a circular economy. Appl. Energy 2022, 321, 119230. [Google Scholar] [CrossRef]

- Van Hoof, G.; Robertz, B.; Verrecht, B. Towards sustainable battery recycling: A carbon footprint comparison between pyrometallurgical and hydrometallurgical battery recycling flowsheets. Metals 2023, 13, 1915. [Google Scholar] [CrossRef]

- Liu, A.; Hu, G.; Wu, Y.; Guo, F. Life cycle environmental impacts of pyrometallurgical and hydrometallurgical recovery processes for spent lithium-ion batteries: Present and future perspectives. Clean Technol. Environ. Policy 2024, 26, 381–400. [Google Scholar] [CrossRef]

- Saleem, U.; Joshi, B.; Bandyopadhyay, S. Hydrometallurgical routes to close the loop of electric vehicle (EV) lithium-ion batteries (LIBs) value chain: A review. J. Sustain. Metall. 2023, 9, 950–971. [Google Scholar] [CrossRef]

- Chen, Q.; Hou, Y.; Lai, X.; Shen, K.; Gu, H.; Wang, Y.; Guo, Y.; Lu, L.; Han, X.; Zheng, Y. Evaluating environmental impacts of different hydrometallurgical recycling technologies of the retired nickel-manganese-cobalt batteries from electric vehicles in China. Sep. Purif. Technol. 2023, 311, 123277. [Google Scholar] [CrossRef]

- Chen, Q.; Lai, X.; Hou, Y.; Gu, H.; Lu, L.; Liu, X.; Ren, D.; Guo, Y.; Zheng, Y. Investigating the environmental impacts of different direct material recycling and battery remanufacturing technologies on two types of retired lithium-ion batteries from electric vehicles in China. Sep. Purif. Technol. 2023, 308, 122966. [Google Scholar] [CrossRef]

- Rosenberg, S.; Kurz, L.; Huster, S.; Wehrstein, S.; Kiemel, S.; Schultmann, F.; Reichert, F.; Wörner, R.; Glöser-Chahoud, S. Combining dynamic material flow analysis and life cycle assessment to evaluate environmental benefits of recycling–A case study for direct and hydrometallurgical closed-loop recycling of electric vehicle battery systems. Resour. Conserv. Recycl. 2023, 198, 107145. [Google Scholar] [CrossRef]

- Rizos, V.; Urban, P. Barriers and policy challenges in developing circularity approaches in the EU battery sector: An assessment. Resour. Conserv. Recycl. 2024, 209, 107800. [Google Scholar] [CrossRef]

- Gautam, D.; Bolia, N. Fostering second-life applications for electric vehicle batteries: A thorough exploration of barriers and solutions within the framework of sustainable energy and resource management. J. Clean. Prod. 2024, 456, 142401. [Google Scholar] [CrossRef]

- Lin, Y.; Yu, Z.; Wang, Y.; Goh, M. Performance evaluation of regulatory schemes for retired electric vehicle battery recycling within dual-recycle channels. J. Environ. Manag. 2023, 332, 117354. [Google Scholar] [CrossRef]

- Bird, R.; Baum, Z.J.; Yu, X.; Ma, J. The regulatory environment for lithium-ion battery recycling. ACS Energy Lett. 2022, 7, 736–740. [Google Scholar] [CrossRef]

- Xing, Z.; Srinivasan, M. Electrochemical approach for lithium recovery from spent lithium-ion batteries: Opportunities and challenges. ACS Sustain. Resour. Manag. 2024, 1, 1326–1339. [Google Scholar] [CrossRef]

- Homs, N.; Jamil, T.; Pilar, R.d.l.P. Chapter 1. Catalytic Processes for Activation of CO2. In New and Future Developments in Catalysis; Elsevier Inc.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Kallitsis, E.; Korre, A.; Kelsall, G.H. Life cycle assessment of recycling options for automotive Li-ion battery packs. J. Clean. Prod. 2022, 371, 133636. [Google Scholar] [CrossRef]

- Koroma, M.S.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, S.; Coosemans, T.; Messagie, M. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef]

- Safarian, S. Environmental and energy impacts of battery electric and conventional vehicles: A study in Sweden under recycling scenarios. Fuel Commun. 2023, 14, 100083. [Google Scholar] [CrossRef]

- Castro, F.D.; Mehner, E.; Cutaia, L.; Vaccari, M. Life cycle assessment of an innovative lithium-ion battery recycling route: A feasibility study. J. Clean. Prod. 2022, 368, 133130. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical review of life cycle assessment of lithium-ion batteries for electric vehicles: A lifespan perspective. Etransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Azizighalehsari, S.; Venugopal, P.; Singh, D.P.; Soeiro, T.B.; Rietveld, G. Empowering Electric Vehicles Batteries: A Comprehensive Look at the Application and Challenges of Second-Life Batteries. Batteries 2024, 10, 161. [Google Scholar] [CrossRef]

- Colombo, C.G.; Longo, M.; Zaninelli, D. Batteries: Advantages and Importance in the Energy Transition. In Emerging Battery Technologies to Boost the Clean Energy Transition; Springer: Berlin/Heidelberg, Germany, 2024; p. 69. [Google Scholar]

- Patel, A.N.; Lander, L.; Ahuja, J.; Bulman, J.; Lum, J.K.H.; Pople, J.O.D.; Hales, A.; Patel, Y.; Edge, J.S. Lithium-ion battery second life: Pathways, challenges and outlook. Front. Chem. 2024, 12, 1358417. [Google Scholar]

- Chigbu, B.I. Advancing sustainable development through circular economy and skill development in EV lithium-ion battery recycling: A comprehensive review. Front. Sustain. 2024, 5, 1409498. [Google Scholar] [CrossRef]

- Reinhart, L.; Vrucak, D.; Woeste, R.; Lucas, H.; Rombach, E.; Friedrich, B.; Letmathe, P. Pyrometallurgical recycling of different lithium-ion battery cell systems: Economic and technical analysis. J. Clean. Prod. 2023, 416, 137834. [Google Scholar] [CrossRef]

- Ferrarese, A.; Kumoto, E.A.; Gobo, L.A.; Junior, A.B.B.; Tenório, J.A.S.; Espinosa, D. Flexible Hydrometallurgy Process for Electric Vehicle Battery Recycling; No. 2022-36-0072. SAE Technical Paper; SAE: Warrendale, PA, USA, 2023. [Google Scholar]

- Wang, J.; Ma, J.; Zhuang, Z.; Liang, Z.; Jia, K.; Ji, G.; Zhou, G.; Cheng, H.-M. Toward direct regeneration of spent lithium-ion batteries: A next-generation recycling method. Chem. Rev. 2024, 124, 2839–2887. [Google Scholar] [CrossRef]

- Yang, T.; Luo, D.; Yu, A.; Chen, Z. Enabling future closed-loop recycling of spent lithium-ion batteries: Direct cathode regeneration. Adv. Mater. 2023, 35, 2203218. [Google Scholar] [CrossRef]

- Kay, I.; Farhad, S.; Mahajan, A.; Esmaeeli, R.; Hashemi, S.R. Robotic disassembly of electric vehicles’ battery modules for recycling. Energies 2022, 15, 4856. [Google Scholar] [CrossRef]

- Kalinin, A.; Rudnik, R.; Tsvetov, A.; Bondarenko, K.; Shuranova, A. Emerging Markets Decoded 2024. 2024. Available online: https://ssrn.com/abstract=4862785 (accessed on 9 June 2025).

- Slotte, P.; Pohjalainen, E.; Hanski, J.; Kivikytö-Reponen, P. Effect of life extension strategies on demand and recycling of EV batteries–material flow analysis of Li and Ni in battery value chain for Finnish EV fleet by 2055. Resour. Conserv. Recycl. 2025, 215, 108081. [Google Scholar] [CrossRef]

- Statista. Forecast Lithium-Ion Battery Recycling Market Worldwide from 2023 to 2033. Available online: https://www.statista.com/statistics/1330758/lithium-ion-battery-recycling-market-value-worldwide/ (accessed on 30 April 2025).

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef]

- Shen, Z.; Tiruta-Barna, L.; Karan, S.K.; Hamelin, L. Simultaneous carbon storage in arable land and anthropogenic products (CSAAP): Demonstrating an integrated concept towards well below 2° C. Resour. Conserv. Recycl. 2022, 182, 106293. [Google Scholar] [CrossRef]

- Lain, M.; Kendrick, E. Understanding the limitations of lithium ion batteries at high rates. J. Power Sources 2021, 493, 229690. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, X.; Chen, X.; Ren, Z.J. Energy-efficient microbial electrochemical lignin and alkaline hydroxide recovery from DMR black liquor. Resour. Conserv. Recycl. 2022, 186, 106529. [Google Scholar] [CrossRef]

- Rachmadhani, D.R.; Priyono, B. Techno-economic analysis of the business potential of recycling lithium-ion batteries using hydrometallurgical methods. ASEAN J. Sci. Eng. Mater. 2024, 3, 117–132. [Google Scholar] [CrossRef]

- Ali, A.; Shoaib, A.; Tasbirul, I.M.; Qadir, S.A.; Shahid, M. Sustainable Recycling of End-of-Life Electric Vehicle Batteries: EV Battery Recycling Frameworks in China and the USA. Recycling 2025, 10, 68. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Bachér, J.; Laatikainen-Luntama, J.; Rintala, L.; Horttanainen, M. The distribution of valuable metals in gasification of metal-containing residues from mechanical recycling of end-of-life vehicles and electronic waste. J. Environ. Manag. 2025, 373, 123526. [Google Scholar] [CrossRef]

- Deloitte China, and CAS. Lithium-Ion Battery Recycling: Market & Innovation Trends for a Green Future. 2023. Available online: https://web.cas.org/marketing/pdf/INSGENENGBRO102412-CAS-Insights-Lithium-Ion-Full-Report-Digital.pdf (accessed on 30 April 2025).

- Niemi, T.; Kaarlela, T.; Niittyviita, E.; Lassi, U.; Röning, J. CAN Interface Insights for Electric Vehicle Battery Recycling. Batteries 2024, 10, 158. [Google Scholar] [CrossRef]

- de Castro, R.H.; Espinosa, D.C.R.; Gobo, L.A.; Kumoto, E.A.; Junior, A.B.B.; Tenorio, J.A.S. Design of recycling processes for NCA-type Li-ion batteries from electric vehicles toward the circular economy. Energy Fuels 2024, 38, 5545–5557. [Google Scholar] [CrossRef]

- Yang, H.; Hu, X.; Zhang, G.; Dou, B.; Cui, G.; Yang, Q.; Yan, X. Life cycle assessment of secondary use and physical recycling of lithium-ion batteries retired from electric vehicles in China. Waste Manag. 2024, 178, 168–175. [Google Scholar] [CrossRef]

- Kasy, F.I.; Hisjam, M.; Jauhari, W.A.; Hassan, S.A.H.S. Optimizing the Supply Chain for Recycling Electric Vehicle NMC Batteries. J. Optimasi Sist. Ind. 2024, 23, 207–226. [Google Scholar] [CrossRef]

- Kamath, D.; Moore, S.; Arsenault, R.; Anctil, A. A system dynamics model for end-of-life management of electric vehicle batteries in the US: Comparing the cost, carbon, and material requirements of remanufacturing and recycling. Resour. Conserv. Recycl. 2023, 196, 107061. [Google Scholar] [CrossRef]

- Slattery, M.; Dunn, J.; Kendall, A. Charting the electric vehicle battery reuse and recycling network in North America. Waste Manag. 2024, 174, 76–87. [Google Scholar] [CrossRef] [PubMed]

- Mu, N.; Wang, Y.; Chen, Z.-S.; Xin, P.; Deveci, M.; Pedrycz, W. Multi-objective combinatorial optimization analysis of the recycling of retired new energy electric vehicle power batteries in a sustainable dynamic reverse logistics network. Environ. Sci. Pollut. Res. 2023, 30, 47580–47601. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kim, Y.-T.; Lee, S.-W. Optimization of the electrochemical discharge of spent li-ion batteries from electric vehicles for direct recycling. Energies 2023, 16, 2759. [Google Scholar] [CrossRef]

- Kastanaki, E.; Giannis, A. Dynamic estimation of end-of-life electric vehicle batteries in the EU-27 considering reuse, remanufacturing and recycling options. J. Clean. Prod. 2023, 393, 136349. [Google Scholar] [CrossRef]

- Tankou, A.; Bieker, G.; Hall, D. Scaling Up Reuse and Recycling of Electric Vehicle Batteries: Assessing Challenges and Policy Approaches; ICCT: Washington, DC, USA, 2023; pp. 1–138. [Google Scholar]

- Dunn, J.; Kendall, A.; Slattery, M. Electric vehicle lithium-ion battery recycled content standards for the US–targets, costs, and environmental impacts. Resour. Conserv. Recycl. 2022, 185, 106488. [Google Scholar] [CrossRef]

- Lima, M.C.C.; Pontes, L.P.; Vasconcelos, A.S.M.; Junior, W.d.A.S.; Wu, K. Economic aspects for recycling of used lithium-ion batteries from electric vehicles. Energies 2022, 15, 2203. [Google Scholar] [CrossRef]

- Yang, H.; Song, X.; Zhang, X.; Lu, B.; Yang, D.; Li, B. Uncovering the in-use metal stocks and implied recycling potential in electric vehicle batteries considering cascaded use: A case study of China. Environ. Sci. Pollut. Res. 2021, 28, 45867–45878. [Google Scholar] [CrossRef]

- Qiao, D.; Wang, G.; Gao, T.; Wen, B.; Dai, T. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci. Total Environ. 2021, 764, 142835. [Google Scholar] [CrossRef]

- Fu, Y.; Schuster, J.; Petranikova, M.; Ebin, B. Innovative recycling of organic binders from electric vehicle lithium-ion batteries by supercritical carbon dioxide extraction. Resour. Conserv. Recycl. 2021, 172, 105666. [Google Scholar] [CrossRef]

- Yao, P.; Zhang, X.; Wang, Z.; Long, L.; Han, Y.; Sun, Z.; Wang, J. The role of nickel recycling from nickel-bearing batteries on alleviating demand-supply gap in China’s industry of new energy vehicles. Resour. Conserv. Recycl. 2021, 170, 105612. [Google Scholar] [CrossRef]

- Abdelbaky, M.; Peeters, J.R.; Dewulf, W. On the influence of second use, future battery technologies, and battery lifetime on the maximum recycled content of future electric vehicle batteries in Europe. Waste Manag. 2021, 125, 1–9. [Google Scholar] [CrossRef]

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.R.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial viability of electric vehicle lithium-ion battery recycling. Iscience 2021, 24, 102787. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Su, X.; Wang, D.; Zhang, L.; Liu, Y.; Yang, Y.; Liang, H.; Gong, M.; Zhang, W.; Jiang, J. Economic analysis of lithium-ion batteries recycled from electric vehicles for secondary use in power load peak shaving in China. J. Clean. Prod. 2020, 276, 123327. [Google Scholar] [CrossRef]

- Bat-Orgil, T.; Dugarjav, B.; Shimizu, T. Cell equalizer for recycling batteries from hybrid electric vehicles. J. Power Electron. 2020, 20, 811–822. [Google Scholar] [CrossRef]