Advances in the Battery Thermal Management Systems of Electric Vehicles for Thermal Runaway Prevention and Suppression

Abstract

1. Introduction

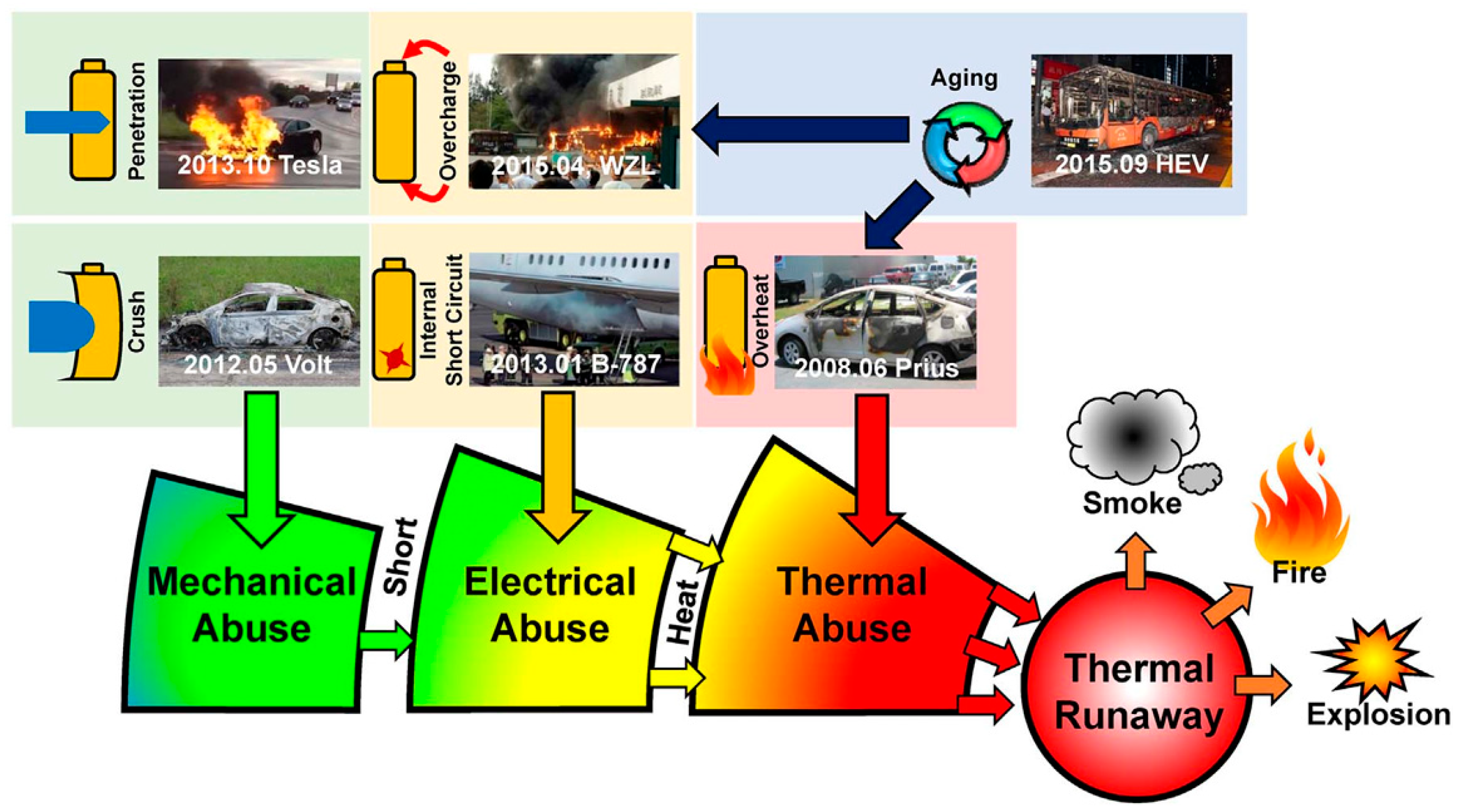

2. TR Characterization

2.1. TR Mechanism

2.2. TRP

2.3. Heat Generation During TR

2.4. Comparison Between Traditional and Advanced Cooling Strategies

3. Advanced Cooling Strategies for TR Prevention and Suppression in LIBs

3.1. Liquid Cooling

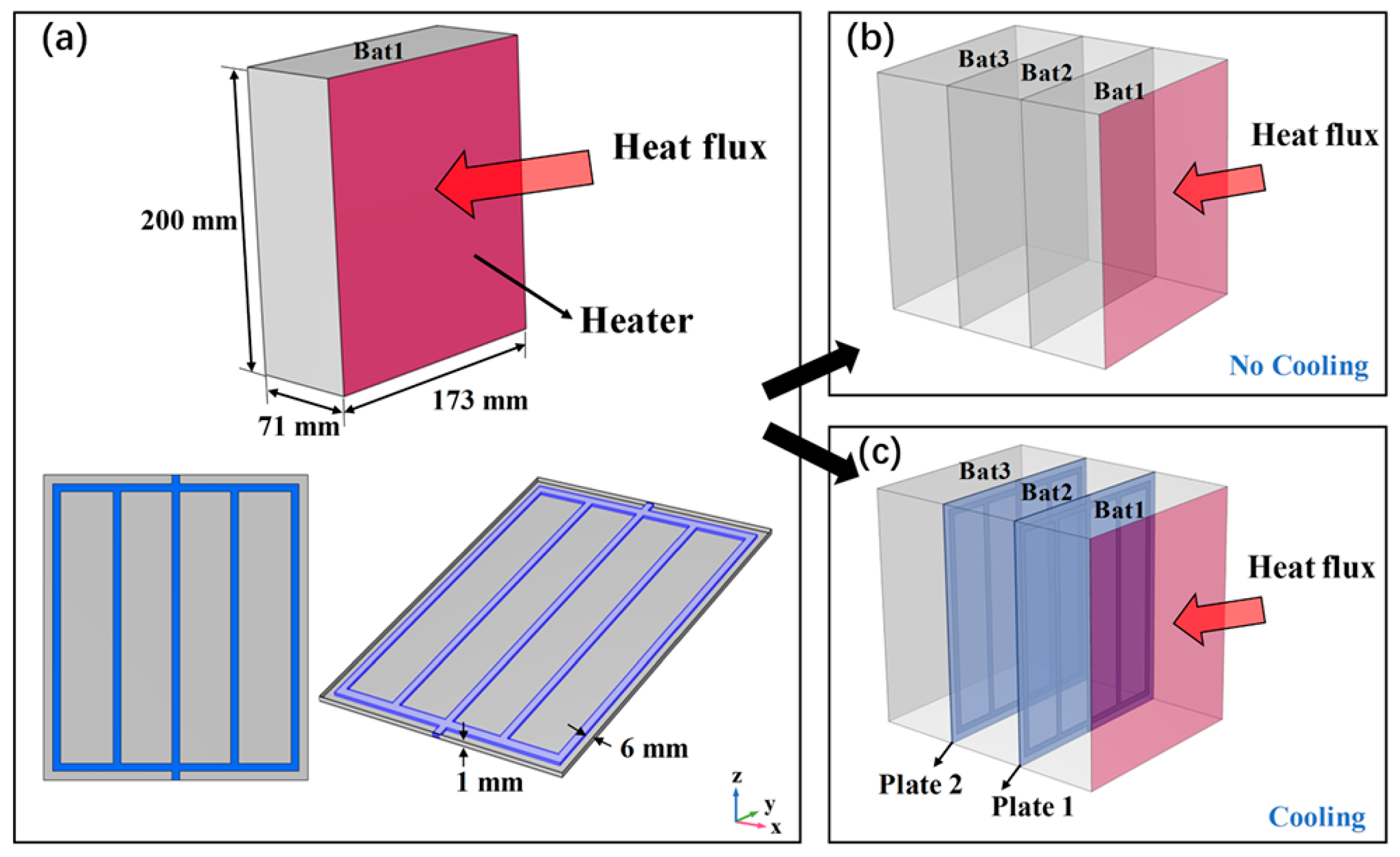

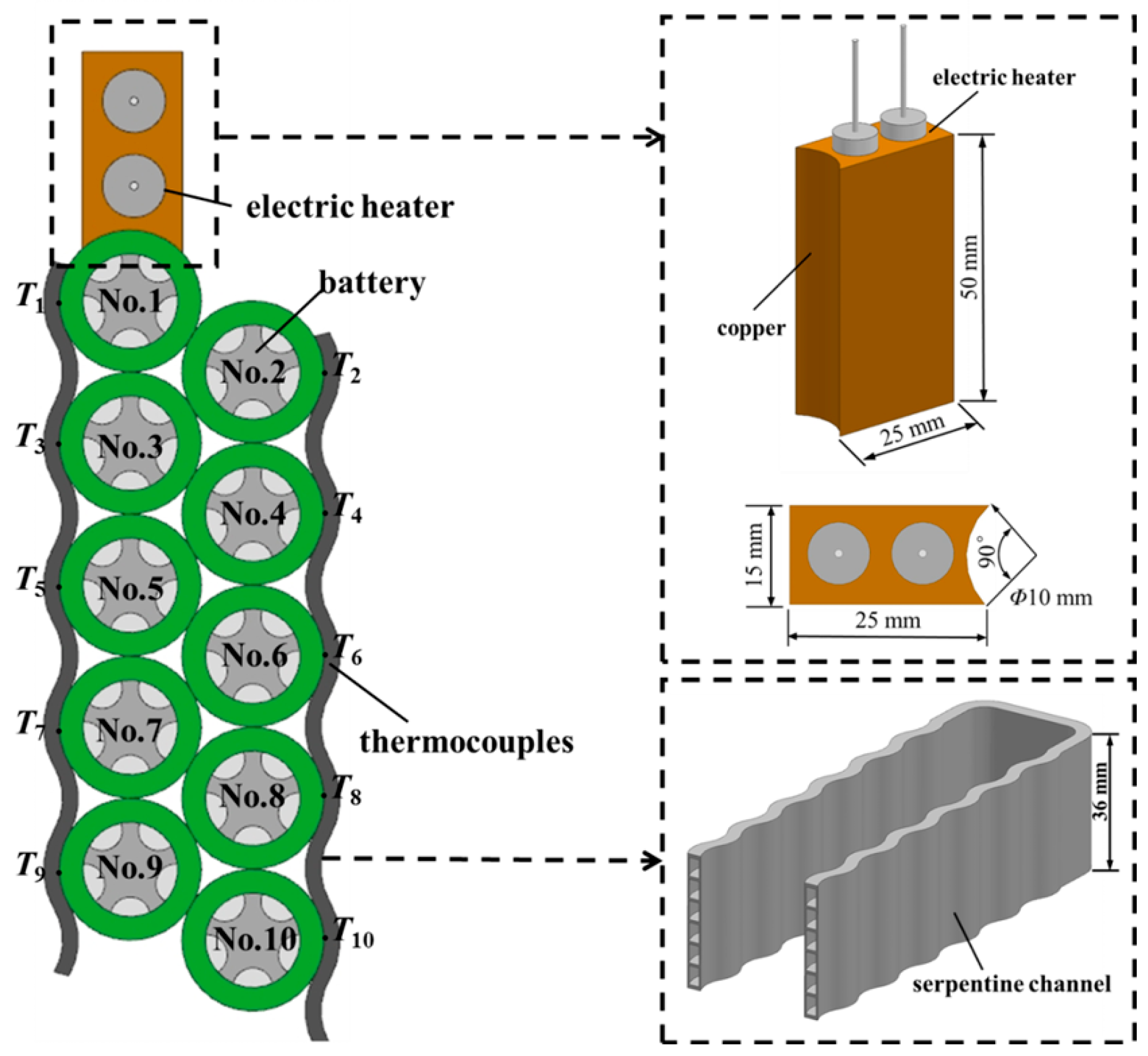

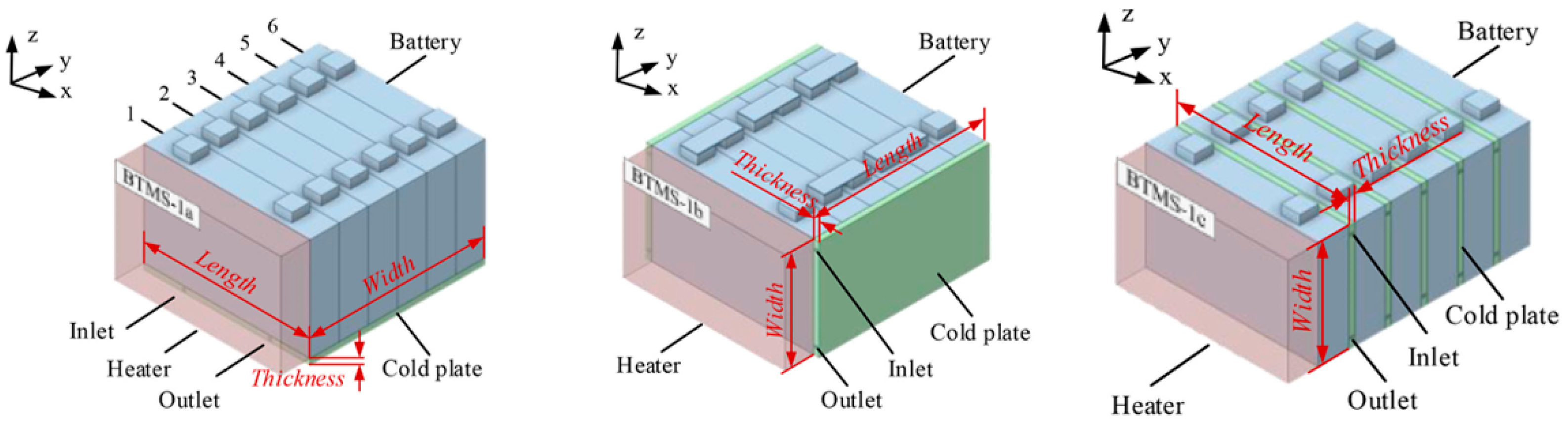

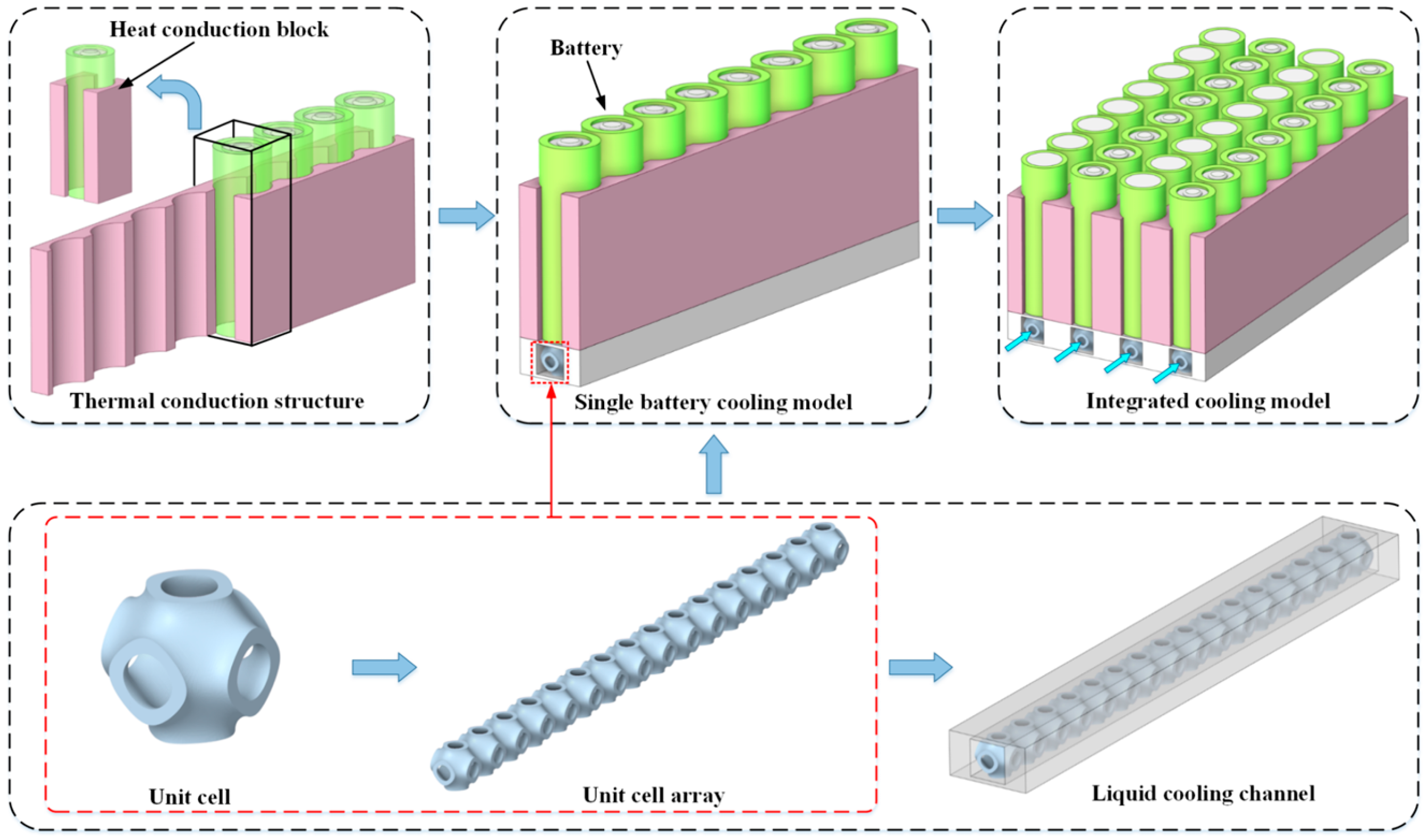

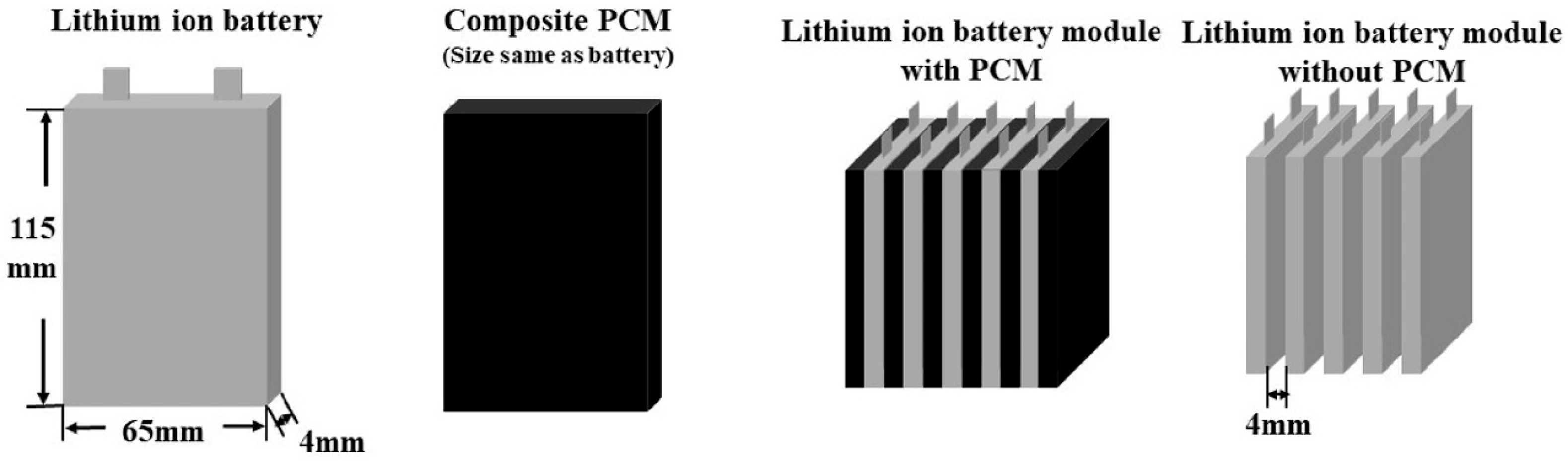

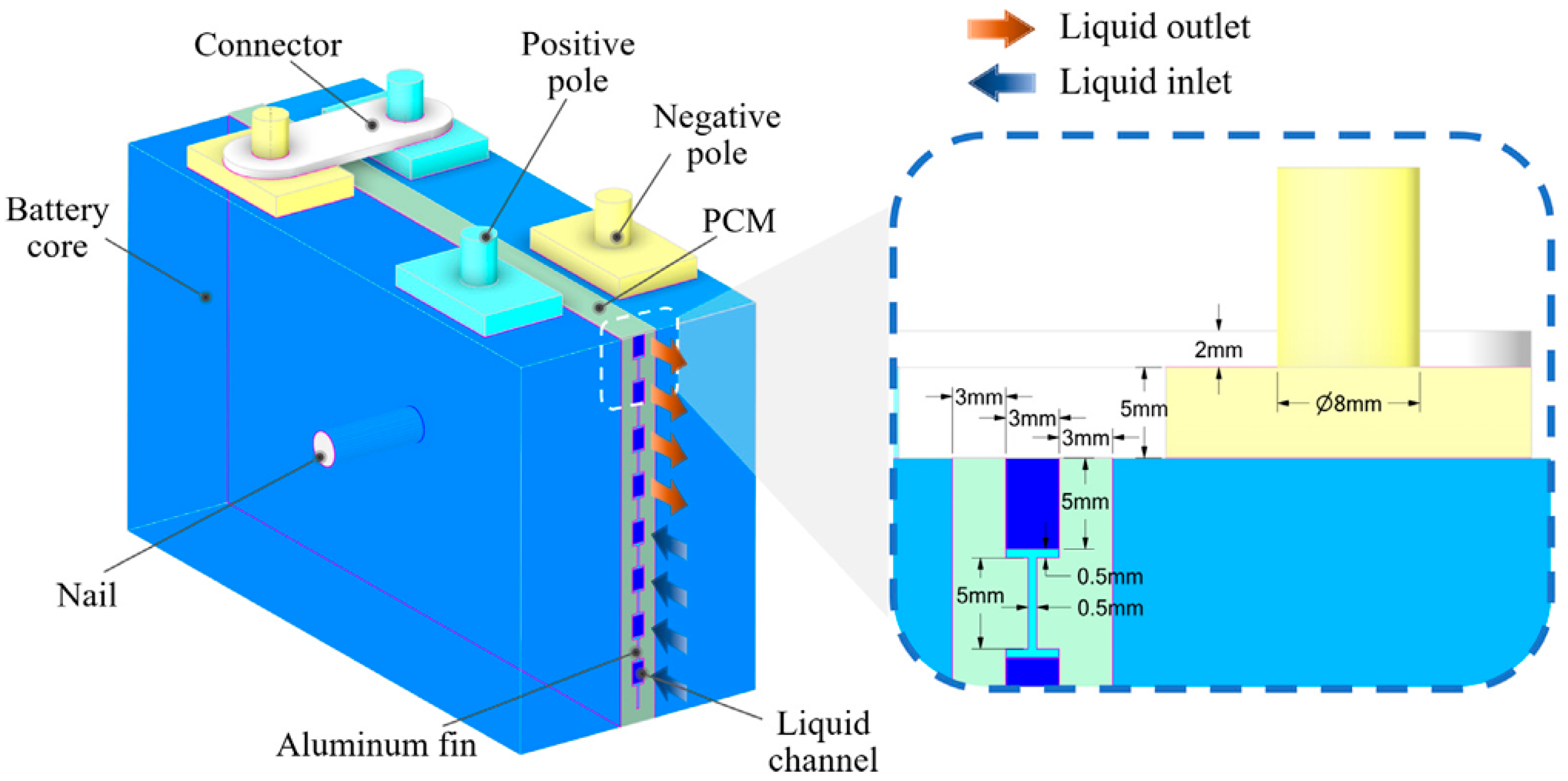

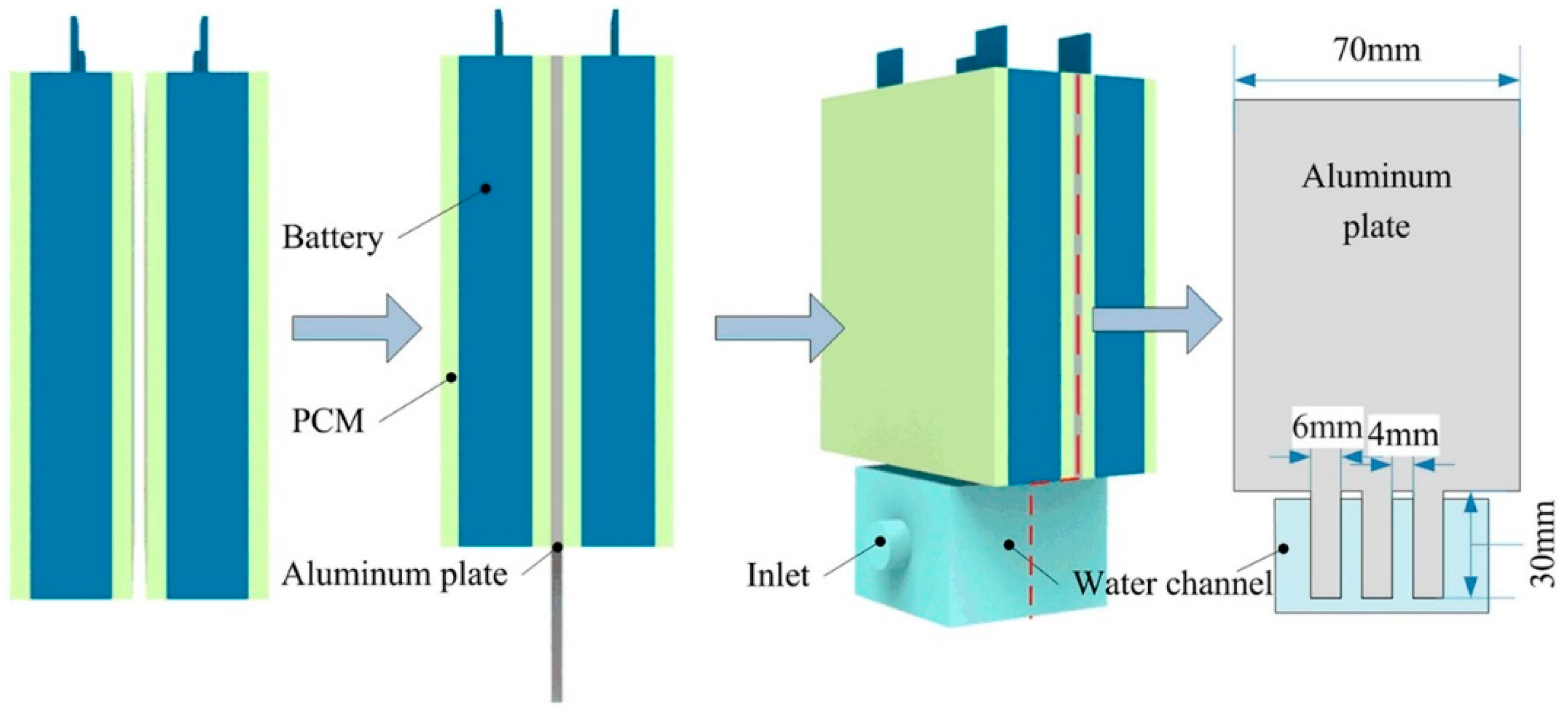

3.1.1. Indirect Liquid Cooling

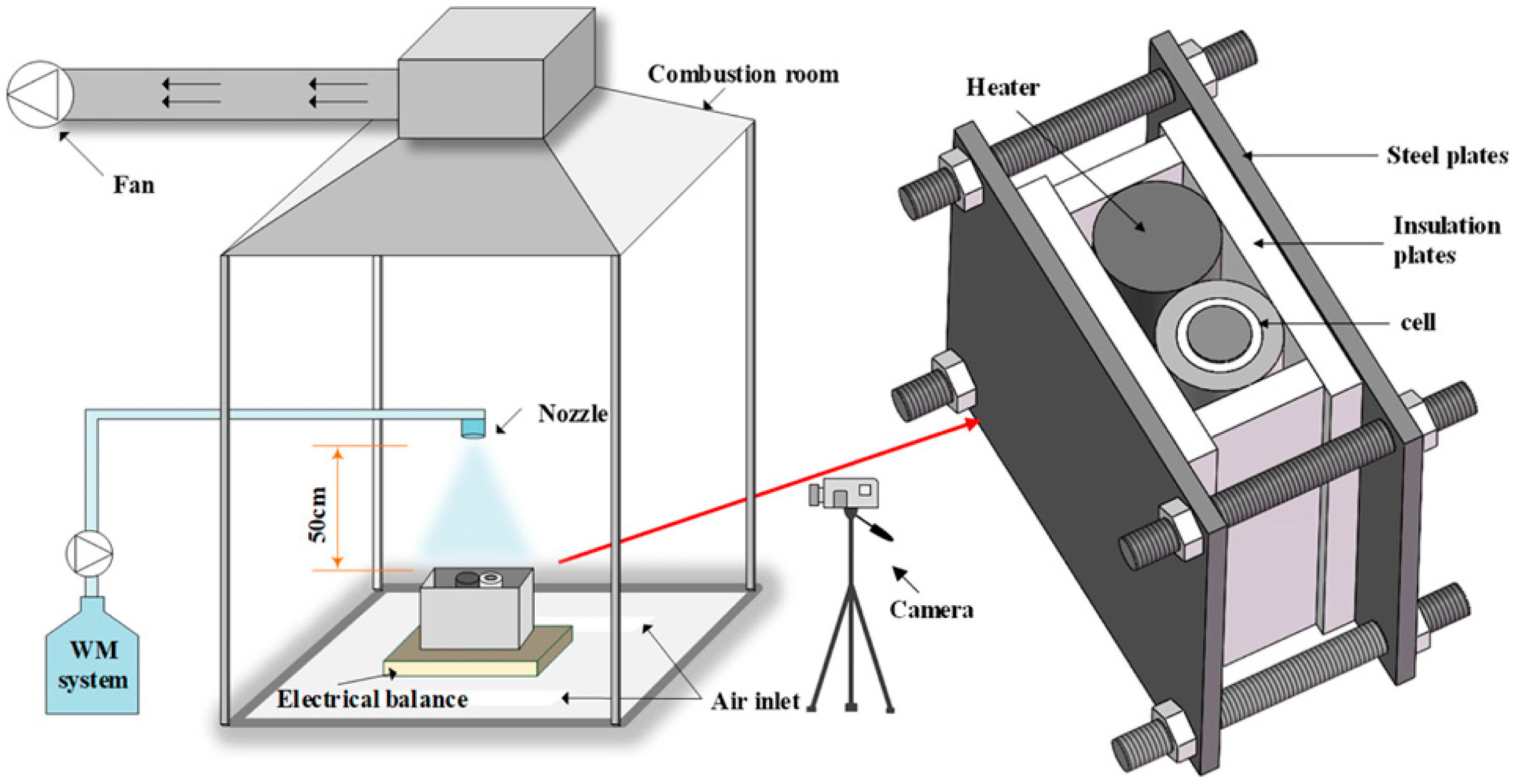

3.1.2. Water Mist

3.1.3. Immersion Cooling

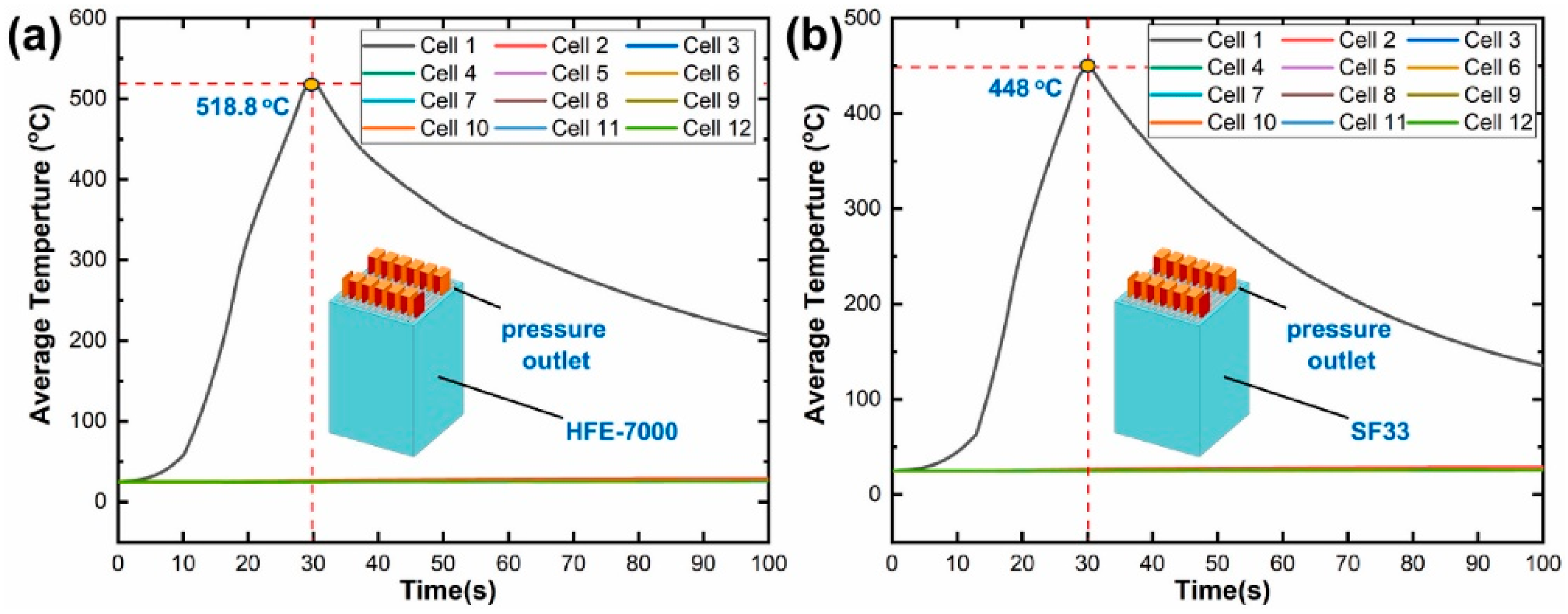

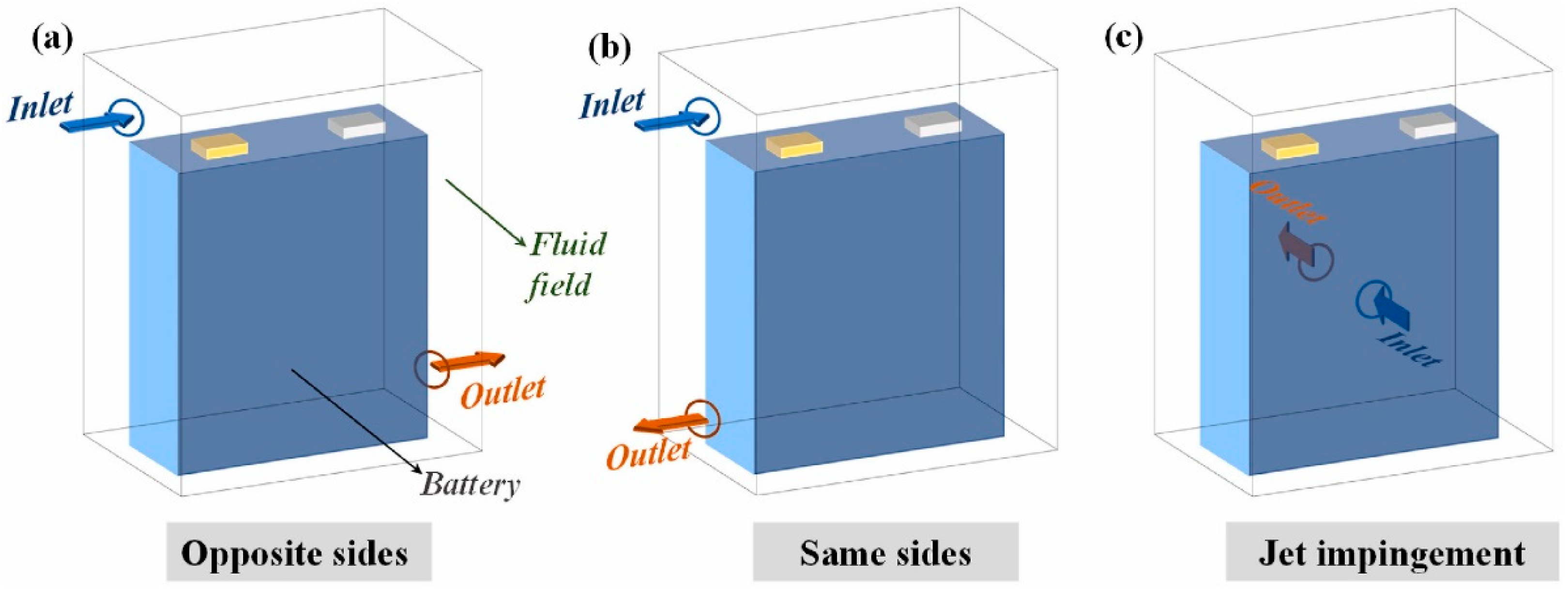

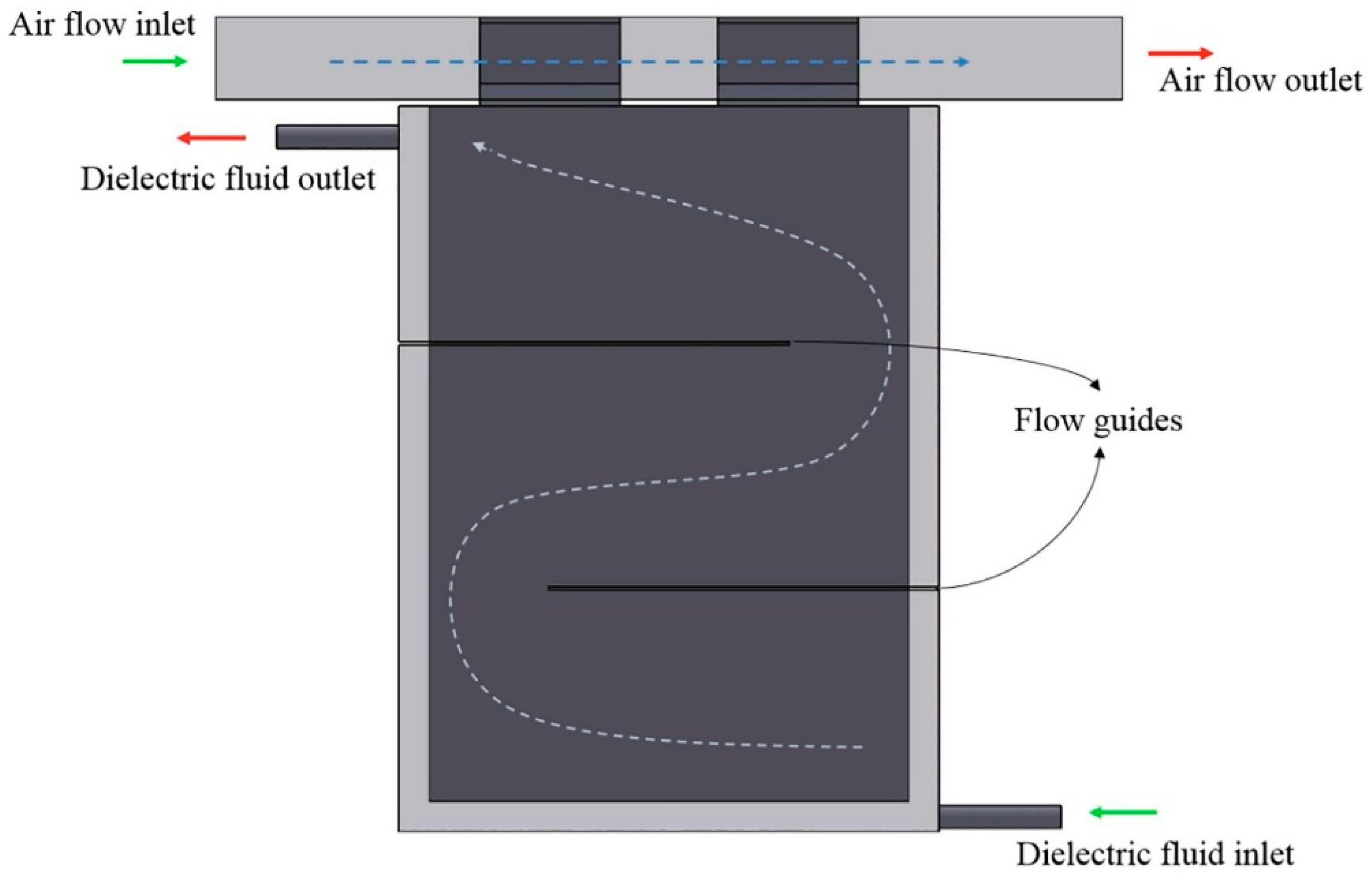

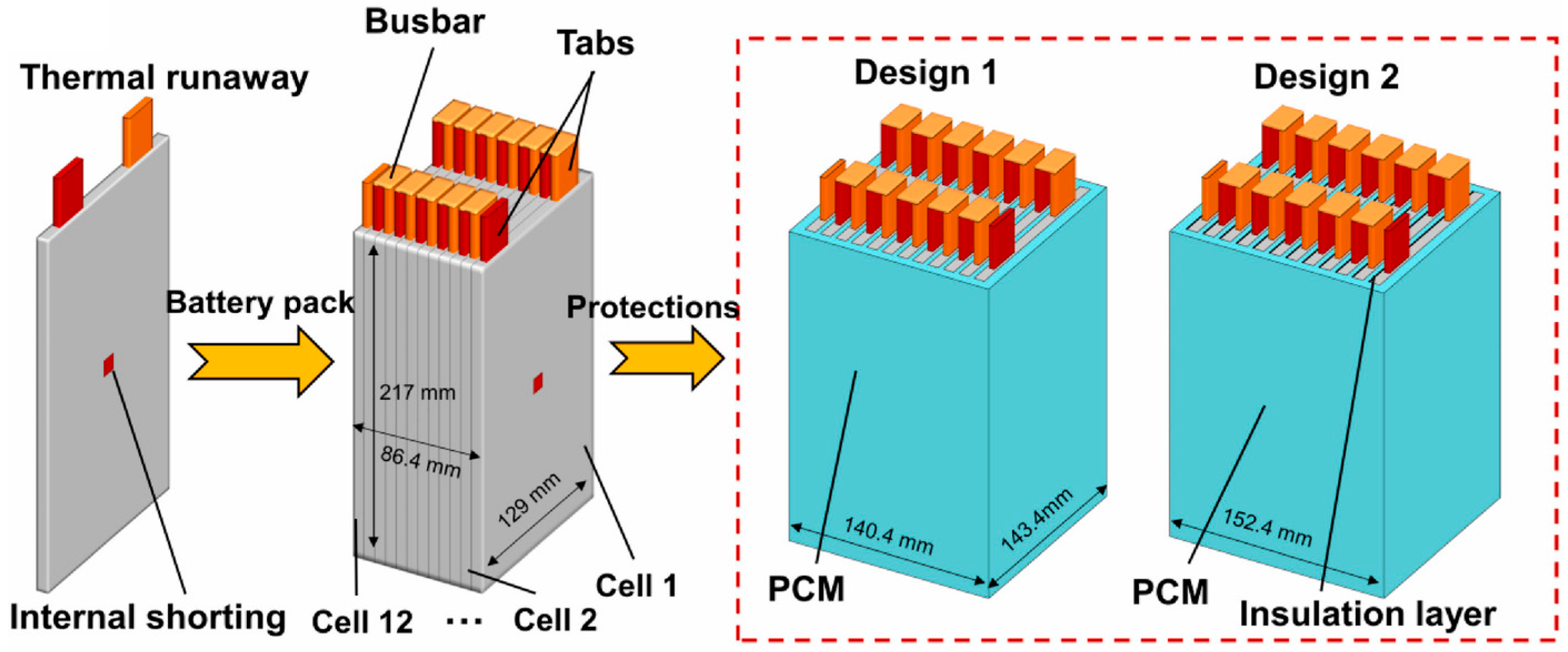

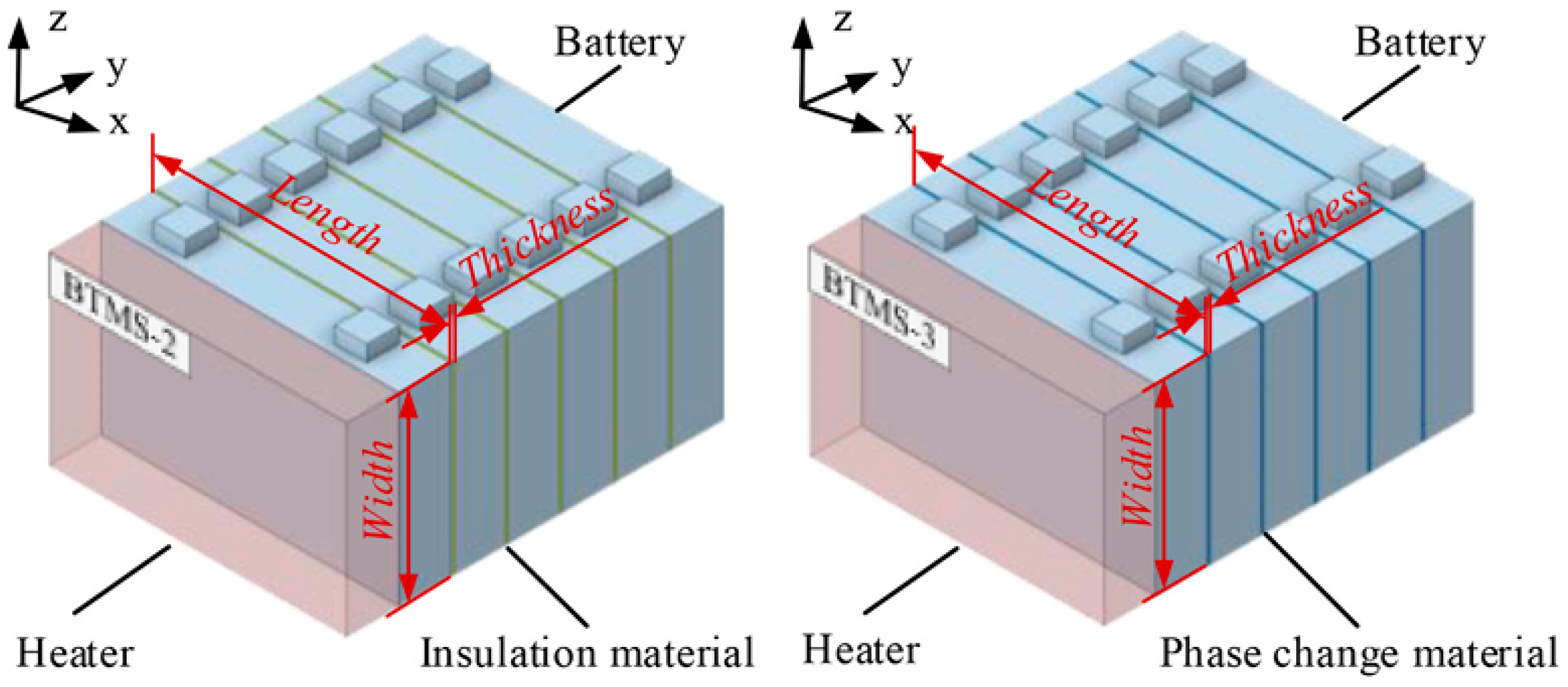

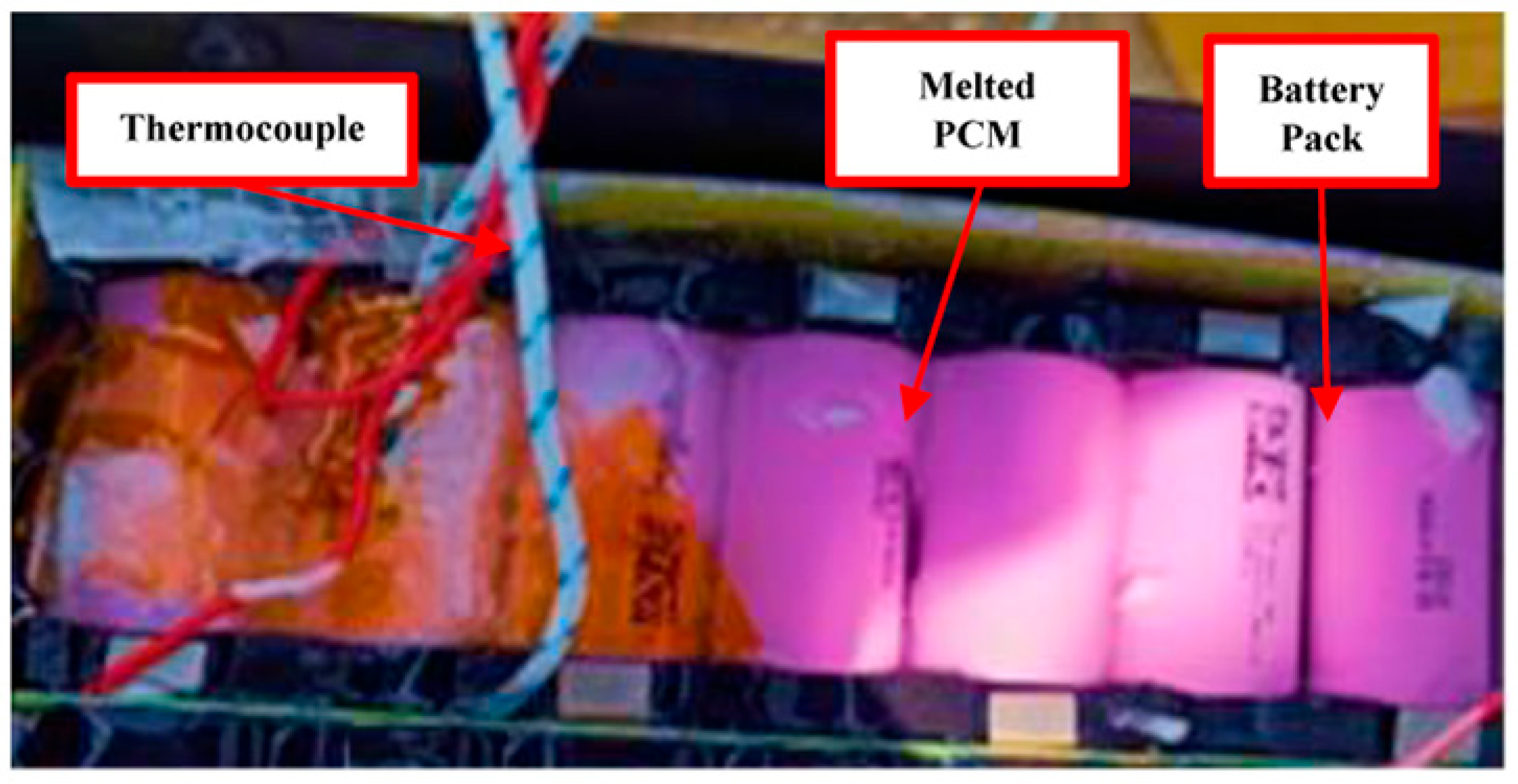

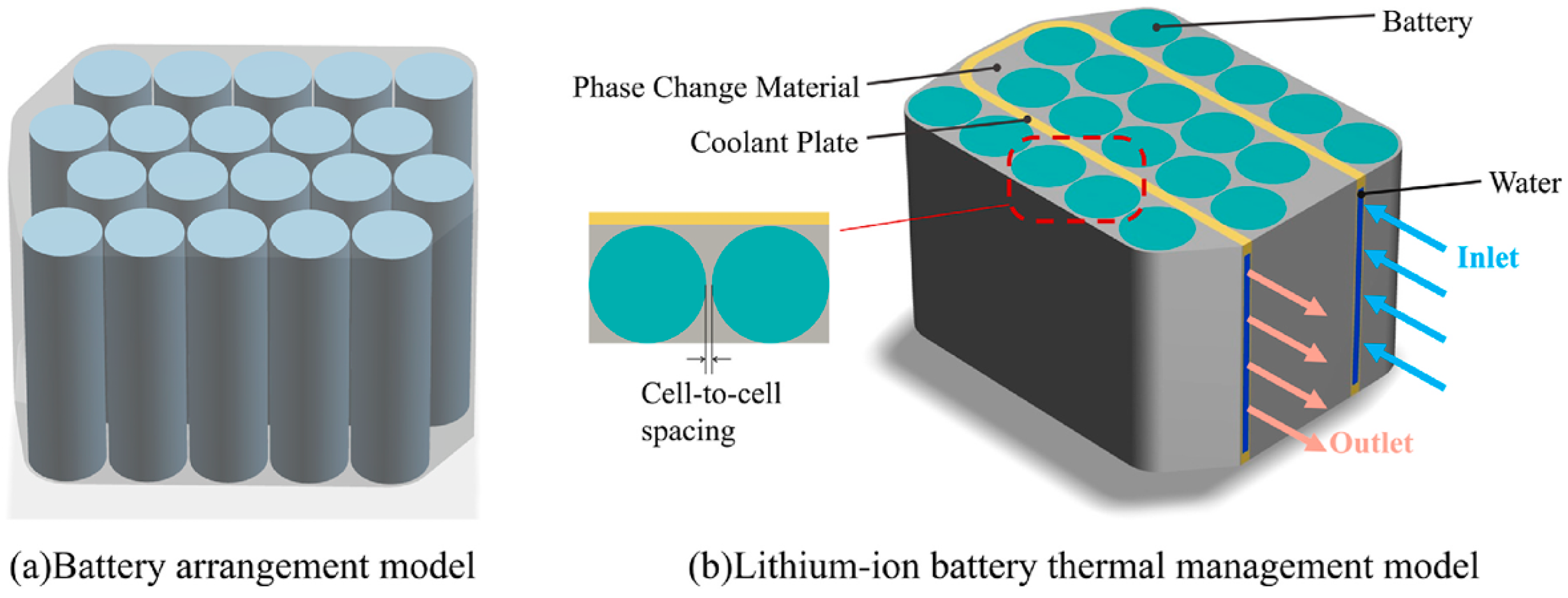

3.2. PCM Cooling

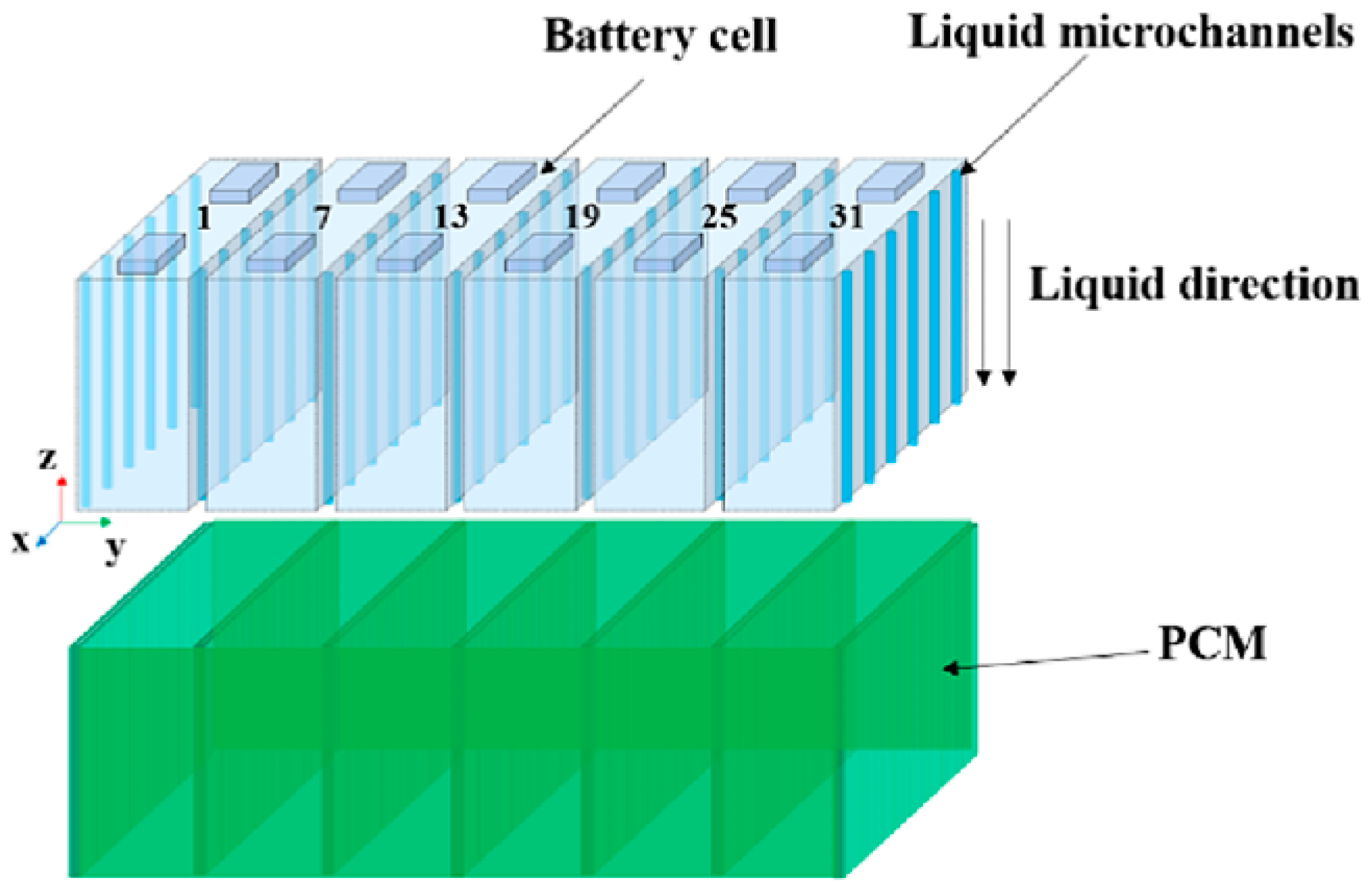

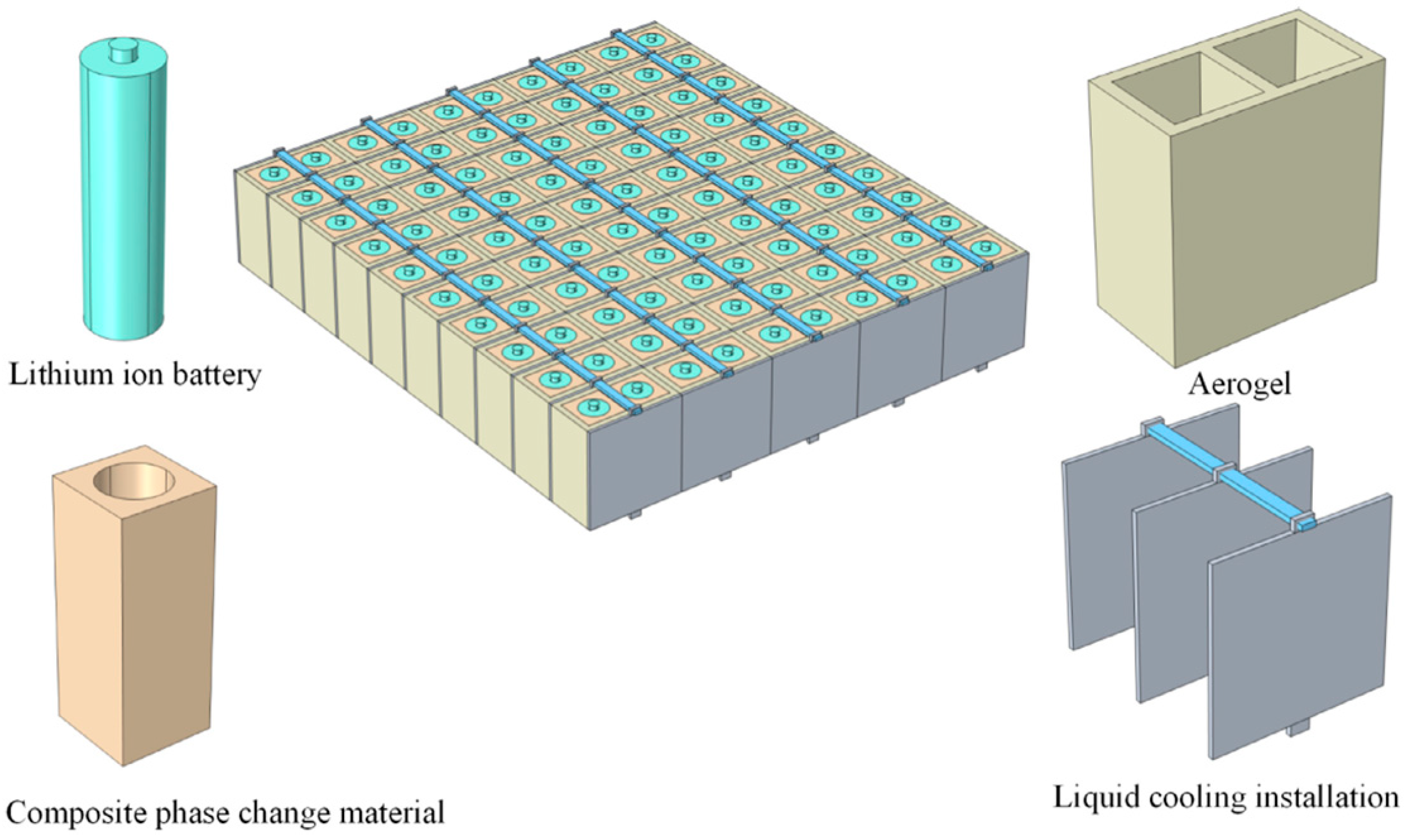

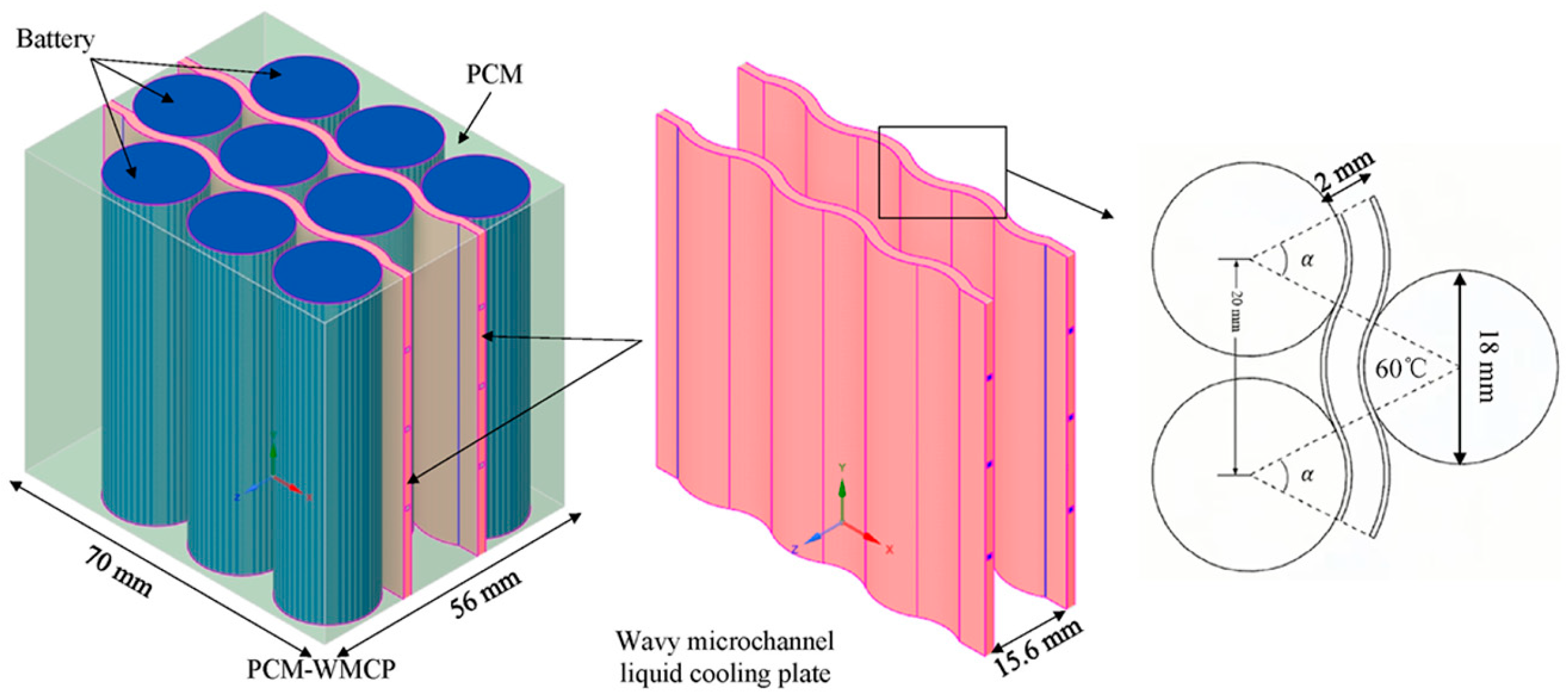

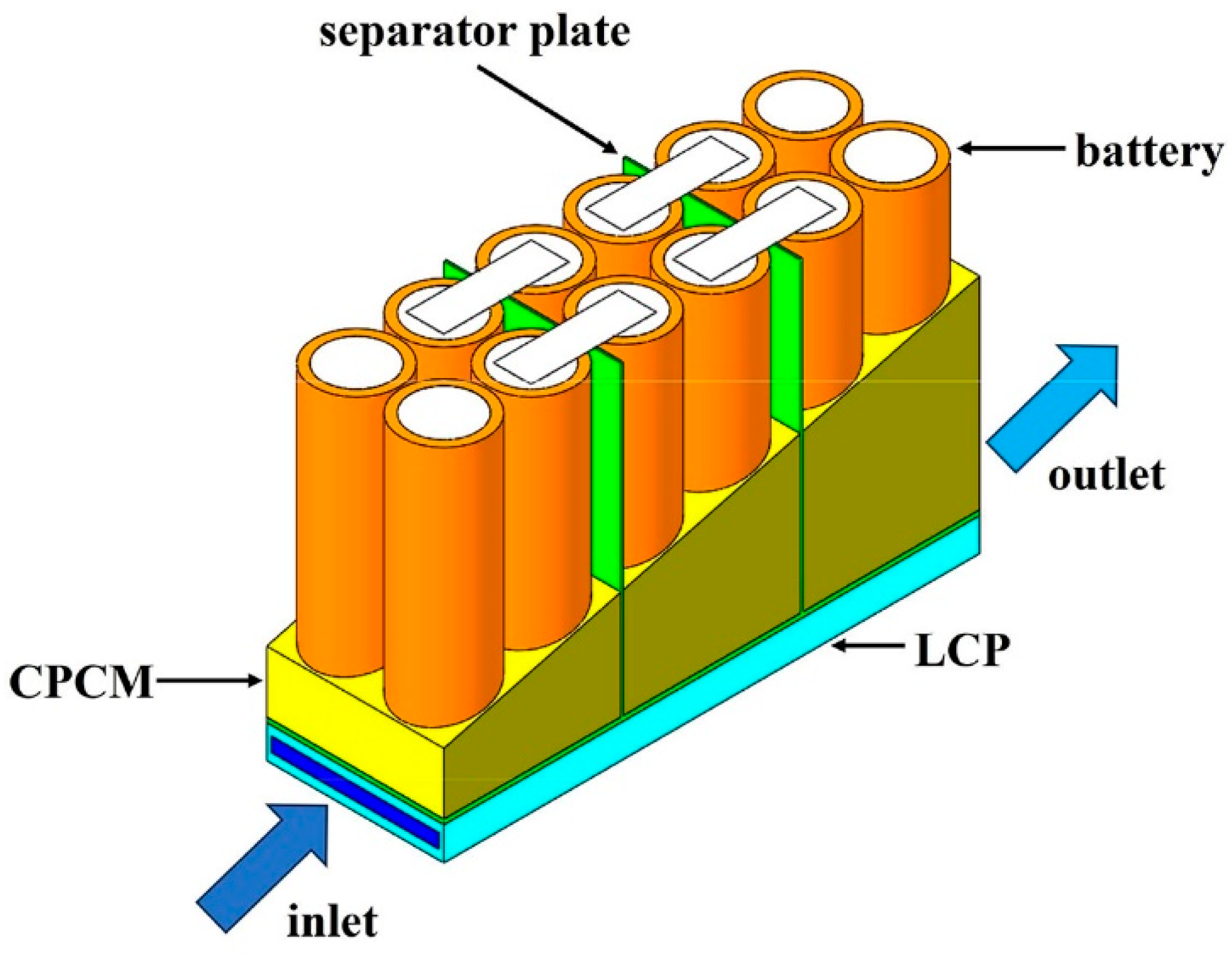

3.3. Hybrid Cooling

4. Summary and Recommendations

- (a)

- Indirect liquid cooling is a widely adopted thermal management technique that offers superior heat dissipation compared to traditional air-cooled methods, primarily due to the higher thermal conductivity and specific heat capacity of liquid coolants such as water or water–glycol mixtures. This approach enables more effective temperature regulation and improved thermal uniformity across the battery module. However, the presence of multiple thermal interfaces between the battery cells and cold plates introduces significant thermal resistance, limiting the cooling effectiveness during critical (TR) events. Additionally, indirect liquid cooling systems often involve complex structural designs, increasing the risks related to coolant leakage, corrosion, and higher parasitic energy consumption. These factors contribute to increased system weight, maintenance demands, and overall cost, posing challenges for scaling to next-generation high-power LIB applications. Therefore, while indirect liquid cooling remains effective under standard operating conditions, its application for TR prevention and suppression in future high-capacity systems requires further optimization in terms of system design, coolant management, and safety validation.

- (b)

- Water mist cooling has emerged as a promising strategy to mitigate TR and its propagation in LIBs due to its high latent heat of vaporization and rapid heat absorption through droplet evaporation. By cooling both the ambient environment and the battery surface, water mist can significantly reduce the temperature rise during TR events. Furthermore, water mist systems offer environmental advantages, being non-toxic, readily available and cost-effective. However, their effectiveness can be compromised in dense battery modules where flame-induced buoyancy and gas ejection limit mist penetration to inner cells. Additionally, large water volumes are often required to sustain sufficient cooling performance, which increases system complexity and weight. Despite these limitations, water mist cooling demonstrates strong potential for TR suppression, and further improvements in delivery methods, droplet sizing, hybrid agent use, and real-time thermal control are needed to enable its broader application in advanced battery thermal management systems.

- (c)

- Immersion cooling, also known as direct liquid cooling, offers a highly effective approach for preventing and suppressing TR and TRP in high-energy LIB systems. By directly submerging battery cells in dielectric fluids, immersion cooling eliminates thermal interface resistance and achieves rapid, uniform heat dissipation. Single-phase immersion cooling provides flexible system design options, while two-phase immersion cooling leverages latent heat for enhanced cooling performance. However, challenges such as the high cost, environmental sensitivity, and chemical stability requirements of dielectric fluids, along with concerns over leakage, material compatibility, and system complexity restricted widespread adoption. Additionally, ensuring robust structural sealing is critical, particularly in two-phase systems where boiling-induced pressure variations occur. Despite these issues, innovative designs such as tab-assisted cooling, optimized coolant flows, and improved immersion architectures show strong potential to make immersion cooling a reliable and scalable solution for enhancing LIB safety against TR and TRP events.

- (d)

- PCM cooling presents a promising passive thermal management strategy for LIBs, particularly in compact and safety-critical applications. PCMs absorb substantial amounts of heat through latent heat during phase transitions, effectively delaying or suppressing rapid temperature rises without external energy input. Paraffin- and hydrated salt-based PCMs have demonstrated significant benefits in retarding TRP by maintaining temperature uniformity within battery packs. Enhancements through composite formulations, such as adding expanded graphite or metallic fillers, further improve thermal conductivity and structural stability. However, the inherently low thermal conductivity of pure PCMs limits their standalone performance, especially under severe abuse conditions. Moreover, PCM systems lack active heat dissipation mechanisms, making them more suitable for low to moderate power densities or as supplementary layers in hybrid cooling architectures. Future developments in high-conductivity composite PCMs and integration with active cooling systems are critical to overcoming current limitations and unlocking the full potential of PCM cooling for advanced battery thermal management.

- (e)

- Hybrid cooling systems that integrate passive and active thermal management techniques have emerged as highly effective solutions for mitigating TR and TRP risks in LIB modules. By combining the latent heat absorption of PCMs with the continuous heat dissipation of liquid cooling, hybrid systems achieve superior control over both peak temperatures and temperature uniformity. Studies have demonstrated that hybrid configurations can significantly delay TRP events and prevent adjacent cells from reaching critical failure conditions. However, the complexity of integrating active and passive components increases design difficulty, system volume, and cost. Inefficient thermal coupling between PCM layers and liquid cooling structures can limit overall system performance, particularly during rapid TR events. Additionally, PCM saturation over prolonged abuse conditions may reduce cooling effectiveness. Therefore, future research must focus on optimizing composite materials, refining liquid channel geometries, and developing modular, lightweight, hybrid architectures to fully realize the potential of hybrid cooling in next-generation BTMS designs.

- (f)

- In addition, thermal insulation layers have shown substantial potential as a passive mitigation strategy for TRP in LIB systems. By introducing low thermal conductivity materials such as aerogels or glass fiber composites between adjacent cells, insulation layers act as thermal barriers, effectively delaying or even preventing the spread of heat generated during a TR event. Moreover, when combined with active cooling systems such as cold plates or immersion cooling setups, insulation layers allow for the cooling system to have more time to remove heat before it reaches critical levels. Despite their advantages, insulation layers can accumulate heat over prolonged operation and reduce energy density due to added volume, necessitating careful thermal design and material selection. Nonetheless, their simplicity, reliability, and proven efficacy make them a valuable component in next-generation BTMS aimed at enhancing safety and suppressing TRP in high-energy-density LIB packs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Febriyanto, R.; Ariyadi, H.M.; Pranoto, I.; Rahman, M.A. Experimental study of serpentine channels immersion cooling for lithium-ion battery thermal management using single-phase dielectric fluid. J. Energy Storage 2024, 97, 112799. [Google Scholar] [CrossRef]

- Berwal, P.; Mehrotra, A.; Lee, Y.; Padhi, U.P.; Yoh, J. Combustion theory based cooling strategies for preventing thermal runaway in modern batteries. Combust. Flame 2025, 274, 113995. [Google Scholar] [CrossRef]

- Hwang, S.-G.; Lee, M.-Y.; Ko, B.-S. Numerical Analysis on Cooling Performances for Connectors Using Immersion Cooling in Ultra-Fast Chargers for Electric Vehicles. Symmetry 2025, 17, 624. [Google Scholar] [CrossRef]

- Chandrasekaran, M.; Jithin, K.V.; Soundarya, T.; Rajesh, P.K. Comprehensive experimental study of battery thermal management using single-phase liquid immersion cooling. J. Energy Storage 2025, 111, 115445. [Google Scholar]

- Kim, S.-H.; Park, S.-Y. Computational Analysis for Efficient Battery Cooling for Eletric Vehicles using Various Cooling Methods. J. Korea Acad. Ind. Coop. Soc. 2025, 26, 9–20. [Google Scholar]

- Song, Y.; Wang, Z.; Jia, D.; Yuan, D.; Chang, Y.; Zheng, X.; Zhang, S. Effect of immersion cooling design optimization on thermal management for lithium battery module. Appl. Therm. Eng. 2025, 272, 126401. [Google Scholar] [CrossRef]

- Wahab, A.; Najmi, A.; Senobar, H.; Amjady, N.; Kemper, H.; Khayyam, H. Immersion cooling innovations and critical hurdles in Li-ion battery cooling for future electric vehicles. Renew. Sustain. Energy Rev. 2025, 211, 115268. [Google Scholar] [CrossRef]

- Baek, S.-H.; Ma, B.-C. Optimization of thermal management for immersion cooled lithium-ion batteries based on experimental design methods. J. Korea Acad. Ind. Coop. Soc. 2025, 26, 21–28. [Google Scholar]

- Tai, L.D.; Garud, K.S.; Lee, M. Experimental Study on Thermal Management of 5S7P Battery Module with Immersion Cooling Under High Charging/Discharging C-Rates. Batteries 2025, 11, 59. [Google Scholar] [CrossRef]

- Tai, L.D.; Garud, K.S.; Hwang, S.; Lee, M. A Review on Advanced Battery Thermal Management Systems for Fast Charging in Electric Vehicles. Batteries 2024, 10, 372. [Google Scholar] [CrossRef]

- Garud, K.S.; Tai, L.D.; Hwang, S.; Nguyen, N.; Lee, M. A Review of Advanced Cooling Strategies for Battery Thermal Management Systems in Electric Vehicles. Symmetry 2023, 15, 1322. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, M.K.; Pathak, M. Thermal management of high-energy lithium titanate oxide batteries using an effective channeled dielectric fluid immersion cooling system. Energy Convers. Manag. 2024, 313, 118644. [Google Scholar] [CrossRef]

- Han, J.; Garud, K.S.; Hwang, S.; Lee, M. Experimental Study on Dielectric Fluid Immersion Cooling for Thermal Management of Lithium-Ion Battery. Symmetry 2022, 14, 2126. [Google Scholar] [CrossRef]

- Han, J.; Garud, K.S.; Kang, E.; Lee, M. Numerical Study on Heat Transfer Characteristics of Dielectric Fluid Immersion Cooling with Fin Structures for Lithium-Ion Batteries. Symmetry 2022, 15, 92. [Google Scholar] [CrossRef]

- Huang, H.; Li, W.; Xiong, S.; Luo, Z.; Ahmed, M. Single-phase static immersion-cooled battery thermal management system with finned heat pipes. Appl. Therm. Eng. 2024, 254, 123931. [Google Scholar] [CrossRef]

- Garud, K.S.; Han, J.; Hwang, S.; Lee, M. Artificial Neural Network Modeling to Predict Thermal and Electrical Performances of Batteries with Direct Oil Cooling. Batteries 2023, 9, 559. [Google Scholar] [CrossRef]

- Moon, J.-H. Air-Cooled Battery Cooling Simulation Techniques Using Simulink and Simscape. J. Korea Acad. Ind. Coop. Soc. 2025, 26, 35–40. [Google Scholar] [CrossRef]

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Mater. 2017, 10, 246–267. [Google Scholar] [CrossRef]

- Shahid, S.; Agelin-Chaab, M. A review of thermal runaway prevention and mitigation strategies for lithium-ion batteries. Energy Convers. Manag. X 2022, 16, 100310. [Google Scholar] [CrossRef]

- Chavan, S.; Venkateswarlu, B.; Prabakaran, R.; Salman, M.; Joo, S.W.; Choi, G.S.; Kim, S.C. Thermal runaway and mitigation strategies for electric vehicle lithium-ion batteries using battery cooling approach: A review of the current status and challenges. J. Energy Storage 2023, 72, 108569. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, R.; Shen, Z.; Yu, Q.; Xiong, R.; Shen, W. Towards a safer lithium-ion batteries: A critical review on cause, characteristics, warning and disposal strategy for thermal runaway. Adv. Appl. Energy 2023, 11, 100146. [Google Scholar] [CrossRef]

- Dhuchakallaya, I.; Saechan, P. Numerical study of a pressurized gas cooling system to suppress thermal runaway propagation in high-energy-density lithium-ion battery packs. J. Energy Storage 2024, 101, 113916. [Google Scholar] [CrossRef]

- Hong, Y.; Wu, H.; Wong, S.K.; Jin, C.; Xu, C.; Wang, H.; Peng, Y.; Zheng, Y.; Feng, X.; Ouyang, M. Dynamic thermophysical modeling and parametric sensitivity analysis of flood cooling suppressing the thermal runaway propagation for electric bicycle battery. J. Energy Storage 2024, 98, 113084. [Google Scholar] [CrossRef]

- Ye, Y.; Mao, Y.; Zhao, L.; Chen, Y.; Chen, M. Experimental investigation of thermal runaway behavior and propagation inhibition of lithium-ion battery by immersion cooling. Appl. Therm. Eng. 2024, 256, 124093. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Z.; Wu, W.; Wei, L.; Wu, W.; Li, Y.; Gao, L.; Li, Y.; Song, Y. Modelling for the mitigation of lithium ion battery thermal runaway propagation by using phase change material or liquid immersion cooling. Case Stud. Therm. Eng. 2023, 52, 103749. [Google Scholar] [CrossRef]

- Tong, B.; Shi, J.; Cao, M.; Xuan, W.; Chen, J.; Jin, K.; Sun, J.; Wang, Q. Comprehensive comparison study on battery thermal management modules with indirect and direct liquid cooling. Appl. Therm. Eng. 2025, 268, 125945. [Google Scholar] [CrossRef]

- Zhao, L.; Song, G.; Yang, X.; Pan, R. Experiments on the effects of liquid immersion cooling on the thermal runaway (TR) behaviors of 280 Ah lithium-ion batteries subjected to different TR-triggering conditions. J. Energy Storage 2025, 121, 116358. [Google Scholar] [CrossRef]

- Kshetrimayum, K.S.; Yoon, Y.; Gye, H.; Lee, C. Preventing heat propagation and thermal runaway in electric vehicle battery modules using integrated PCM and micro-channel plate cooling system. Appl. Therm. Eng. 2019, 159, 113797. [Google Scholar] [CrossRef]

- Luo, P.; Gao, K.; Hu, L.; Chen, B.; Zhang, Y. Adaptive hybrid cooling strategy to mitigate battery thermal runaway considering natural convection in phase change material. Appl. Energy 2024, 361, 122920. [Google Scholar] [CrossRef]

- Choi, D.-H.; Kim, M.-J.; Yu, J.-S.; Hong, D.-S. Experimental Study on the Heat Charging and Discharging Characteristics of a Heat Absorption Device Applied to the Cooling System of Electric Vehicle Chargers. J. Korea Acad. Ind. Coop. Soc. 2024, 25, 536–542. [Google Scholar]

- Choi, D.-H.; Kim, T.-W.; Kim, M.-J.; Yu, J.-S.; Hong, D.-S. Experimental Study on the Thermal Characteristics and Melting Behavior of Phase Change Materials Applied to the Cooling System of Electric Vehicle Chargers. J. Korea Acad. Ind. Coop. Soc. 2024, 25, 349–356. [Google Scholar]

- Jiang, Z.; Li, H.; Qu, Z.; Zhang, J. Recent progress in lithium-ion battery thermal management for a wide range of temperature and abuse conditions. Int. J. Hydrogen Energy 2022, 47, 9428–9459. [Google Scholar] [CrossRef]

- Zhi, M.; Liu, Q.; Xu, Q.; Pan, Z.; Sun, Q.; Su, B.; Zhao, H.; Cui, H.; He, Y. Review of prevention and mitigation technologies for thermal runaway in lithium-ion batteries. Aerosp. Traffic Saf. 2024, 1, 55–72. [Google Scholar] [CrossRef]

- Yang, L.; Liu, F.; Li, F.; Chen, Z.; Wang, J.; Gao, L.; Xiao, F.; Sun, J.; Romagnoli, A. Thermal runaway prevention and mitigation for lithium-ion battery-powered electric aircraft: Challenges and perspectives. Aerosp. Traffic Saf. 2024, 1, 103–118. [Google Scholar] [CrossRef]

- Leising, R.A.; Palazzo, M.J.; Takeuchi, E.S.; Takeuchi, K.J. Abuse Testing of Lithium-Ion Batteries: Characterization of the Overcharge Reaction of LiCoO2/Graphite Cells. J. Electrochem. Soc. 2001, 148, 8. [Google Scholar] [CrossRef]

- Saito, Y.; Takano, K.; Negishi, A. Thermal behaviors of lithium-ion cells during overcharge. J. Power Sources 2001, 97–98, 693–696. [Google Scholar] [CrossRef]

- Wen, J.; Yu, Y.; Chen, C. A review on lithium-ion batteries safety issues: Existing problems and possible solutions. Mater. Express 2012, 2, 197–212. [Google Scholar] [CrossRef]

- Lin, C.; Ren, Y.; Amine, K.; Qin, Y.; Chen, Z. In situ high-energy X-ray diffraction to study overcharge abuse of 18,650-size lithium-ion battery. J. Power Sources 2013, 230, 32–37. [Google Scholar] [CrossRef]

- Zhang, L.; Ma, Y.; Cheng, X.; Du, C.; Guan, T.; Cui, Y.; Sun, S.; Zuo, P.; Gao, Y.; Yin, G. Capacity fading mechanism during long-term cycling of over-discharged LiCoO2/mesocarbon microbeads battery. J. Power Sources 2015, 293, 1006–1015. [Google Scholar] [CrossRef]

- Guo, R.; Lu, L.; Ouyang, M.; Feng, X. Mechanism of the entire overdischarge process and overdischarge-induced internal short circuit in lithium-ion batteries. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef]

- Maleki, H.; Howard, J.N. Effects of overdischarge on performance and thermal stability of a Li-ion cell. J. Power Sources 2006, 160, 1395–1402. [Google Scholar] [CrossRef]

- Beauregard, G.P.; Phoenix, A.Z. Report of Investigation: Hybrids Plus Plug in Hybrid Electric Vehicle; Revision 1; US Department of Energy and National Rural Electric Cooperative Association, Inc.: Phoenix, AZ, USA, 2008. [Google Scholar]

- Feng, X.; Sun, J.; Ouyang, M.; Wang, F.; He, X.; Lu, L.; Peng, H. Characterization of penetration induced thermal runaway propagation process within a large format lithium ion battery module. J. Power Sources 2015, 275, 261–273. [Google Scholar] [CrossRef]

- Chen, M.; Dongxu, O.; Liu, J.; Wang, J. Investigation on thermal and fire propagation behaviors of multiple lithium-ion batteries within the package. Appl. Therm. Eng. 2019, 157, 113750. [Google Scholar] [CrossRef]

- Li, H.; Duan, Q.; Zhao, C.; Huang, Z.; Wang, Q. Experimental investigation on the thermal runaway and its propagation in the large format battery module with Li(Ni1/3Co1/3Mn1/3)O2 as cathode. J. Hazard. Mater. 2019, 375, 241–254. [Google Scholar] [CrossRef]

- Xiao, H.; Jiaqiang, E.; Tian, S.; Huang, Y.; Song, X. Effect of composite cooling strategy including phase change material and liquid cooling on the thermal safety performance of a lithium-ion battery pack under thermal runaway propagation. Energy 2024, 295, 131093. [Google Scholar] [CrossRef]

- Xu, H.; Cheng, L.; Paizulamu, D.; Zheng, H. Safety and Reliability Analysis of Reconfigurable Battery Energy Storage System. Batteries 2024, 11, 12. [Google Scholar] [CrossRef]

- Fang, J.; Yin, X.; Guan, J.; Han, X.; Jia, F.; Chen, B.; Cao, F.; Wang, X. Comparative study on the thermal performance of the battery two-phase direct CO2 cooling system with parallel and half-series configuration for electric vehicles. Renew. Energy 2025, 242, 122461. [Google Scholar] [CrossRef]

- Min, Z.; Li, M.; Liu, H.; Gan, Y.; Wang, Y.; You, J.; Jiang, Y. Battery temperature performance of external cooling method for electric vehicles under different working conditions. Appl. Therm. Eng. 2025, 269, 126010. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Z.; Shen, Y.; Li, J. Simulation analysis of battery thermal management system for electric vehicles based on direct cooling cycle optimization. Appl. Therm. Eng. 2025, 268, 125938. [Google Scholar] [CrossRef]

- Wankhede, S.; Pingale, A.D.; Kale, A. Experimental investigation on thermal management of lithium-ion battery pack for formula student electric vehicle using air-cooling system. Energy Storage Sav. 2025, 4, 38–47. [Google Scholar] [CrossRef]

- Luo, Y.; Qiu, X.; Wang, S.; Jia, Z. Optimizing a direct flow cooling battery thermal management with bod baffles for electric vehicles: An experimental and simulation study. J. Energy Storage 2023, 74, 109410. [Google Scholar] [CrossRef]

- Larrañaga-Ezeiza, M.; Vertiz, G.; Arroiabe, P.; Martinez-Agirre, M.; Berasategi, J. A novel direct liquid cooling strategy for electric vehicles focused on pouch type battery cells. Appl. Therm. Eng. 2022, 216, 118869. [Google Scholar] [CrossRef]

- Hong, S.H.; Jang, D.S.; Park, S.; Yun, S.; Kim, Y. Thermal performance of direct two-phase refrigerant cooling for lithium-ion batteries in electric vehicles. Appl. Therm. Eng. 2020, 173, 115213. [Google Scholar] [CrossRef]

- Suresh, C.; Awasthi, A.; Kumar, B.; Im, S.; Jeon, Y. Advances in battery thermal management for electric vehicles: A comprehensive review of hybrid PCM-metal foam and immersion cooling technologies. Renew. Sustain. Energy Rev. 2025, 208, 115021. [Google Scholar]

- Sadeh, M.; Tousi, M.; Sarchami, A.; Sanaie, R.; Kiani, M.; Ashjaee, M.; Houshfar, E. A novel hybrid liquid-cooled battery thermal management system for electric vehicles in highway fuel-economy condition. J. Energy Storage 2024, 86, 111195. [Google Scholar] [CrossRef]

- Mohammed, A.G.; Wang, Q.; Elfeky, K.E. Rapid cooling effectiveness of Li-ion battery module with multiple phase change materials for plug-in hybrid electric vehicle. Int. J. Therm. Sci. 2023, 185, 108040. [Google Scholar] [CrossRef]

- Yetik, O. Innovative-serpentine cooling method of batteries: Both thermal and statistical method approach. Int. J. Therm. Sci. 2025, 208, 109437. [Google Scholar] [CrossRef]

- Fu, H.; Wang, J.; Li, L.; Gong, J.; Wang, X. Numerical study of mini-channel liquid cooling for suppressing thermal runaway propagation in a lithium-ion battery pack. Appl. Therm. Eng. 2023, 234, 121349. [Google Scholar] [CrossRef]

- Ke, Q.; Li, X.; Guo, J.; Cao, W.; Wang, Y.; Jiang, F. The retarding effect of liquid-cooling thermal management on thermal runaway propagation in lithium-ion batteries. J. Energy Storage 2022, 48, 104063. [Google Scholar] [CrossRef]

- Rui, X.; Feng, X.; Wang, H.; Yang, H.; Zhang, Y.; Wan, M.; Wei, Y.; Ouyang, M. Synergistic effect of insulation and liquid cooling on mitigating the thermal runaway propagation in lithium-ion battery module. Appl. Therm. Eng. 2021, 199, 117521. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Z.; Wu, T.; Lv, J.; Hu, C.; Gao, L.; Li, Y.; Li, Y.; Song, Y. Inhibition of Thermal Runaway Propagation in Lithium-Ion Battery Pack by Minichannel Cold Plates and Insulation Layers. Int. J. Energy Res. 2022, 2023, 6661693. [Google Scholar] [CrossRef]

- Yang, S.; Luo, X.; Li, X.; Nian, V.; Liu, S.; Wang, Y.; Li, H. Comparing different battery thermal management systems for suppressing thermal runaway propagation. J. Energy Storage 2024, 101, 114005. [Google Scholar] [CrossRef]

- Du, X.; Wang, Z.; Gao, Q.; Yang, H.; Bao, R.; Xiong, S. Study on novel battery thermal management using triply periodic minimal surface porous structures liquid cooling channel. Appl. Therm. Eng. 2024, 257, 124384. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Chen, N.; Lai, Z.; Zhu, L.; Chen, S.; Teng, Z.; Zhang, N.; Mao, B. Thermal runaway propagation behavior and cooling effect of water mist within a 18650-type LiFePO4 battery module under different conditions. Process Saf. Environ. Prot. 2024, 185, 1362–1372. [Google Scholar] [CrossRef]

- Liu, T.; Huang, J.; Hu, X.; Hu, J.; Wang, X. Experimental study on the cooling effect of fine water mist on the thermal runaway in a single lithium ion battery. Appl. Therm. Eng. 2024, 240, 122194. [Google Scholar] [CrossRef]

- Liu, T.; Tao, C.; Wang, X. Cooling control effect of water mist on thermal runaway propagation in lithium ion battery modules. Appl. Energy 2020, 267, 115087. [Google Scholar] [CrossRef]

- Yao, Y.; Jiang, Y.; Chen, F.; Wang, Y.; Zhou, H.; Zhao, J. Experimental study of the strategy of C6F12O and water mist intermittent spray to suppress lithium-ion batteries thermal runaway propagation. J. Loss Prev. Process Ind. 2024, 91, 105407. [Google Scholar] [CrossRef]

- Xu, J.; Duan, Q.; Zhang, L.; Liu, Y.; Sun, J.; Wang, Q. The enhanced cooling effect of water mist with additives on inhibiting lithium ion battery thermal runaway. J. Loss Prev. Process Ind. 2022, 77, 104784. [Google Scholar] [CrossRef]

- Sadar, A.; Mohammad, N.; Amir, M.; Haque, A. An experimental study on lithium-ion electric vehicles battery packs behavior under extreme conditions for prevention of thermal runaway. Process Saf. Environ. Prot. 2024, 191, 1024–1034. [Google Scholar] [CrossRef]

- Yang, C.; Liu, Q.; Liu, M.; Shi, Q.; Cao, X.; Pei, J.; Cao, C.; Lei, H.; Ping, X.; Ju, X. Investigation of the immersion cooling system for 280Ah LiFePO4 batteries: Effects of flow layouts and fluid types. Case Stud. Therm. Eng. 2024, 61, 104922. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.; Lee, M. A novel dielectric fluid immersion cooling technology for Li-ion battery thermal management. Energy Convers. Manag. 2021, 229, 113715. [Google Scholar] [CrossRef]

- Zhi, M.; Fan, R.; Zheng, L.; Yue, S.; Pan, Z.; Sun, Q.; Liu, Q. Experimental investigation on hydrated salt phase change material for lithium-ion battery thermal management and thermal runaway mitigation. Energy 2024, 307, 132685. [Google Scholar] [CrossRef]

- Lu, D.; Cui, N.; Zhou, J.; Li, C. Hybrid cooling system with phase change material and liquid microchannels to prevent thermal runaway propagation within lithium-ion battery packs. Appl. Therm. Eng. 2024, 247, 123118. [Google Scholar] [CrossRef]

- Ouyang, T.; Liu, B.; Wang, C.; Ye, J.; Liu, S. Novel hybrid thermal management system for preventing Li-ion battery thermal runaway using nanofluids cooling. Int. J. Heat Mass Transf. 2023, 201, 123652. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Z.; Yin, X.; Ling, G. Avoiding thermal runaway propagation of lithium-ion battery modules by using hybrid phase change material and liquid cooling. Appl. Therm. Eng. 2021, 184, 116380. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; He, T.; Mao, N. A numerical study on a hybrid battery thermal management system based on PCM and wavy microchannel liquid cooling. Renew. Energy 2024, 235, 121273. [Google Scholar] [CrossRef]

- Gu, X.; Lei, W.; Xi, J.; Song, M. Investigation and optimization of battery thermal management system based on composite phase change material and variable wall liquid cooling plate. Int. J. Thermofluids 2024, 24, 100886. [Google Scholar] [CrossRef]

- Zonouzi, S.A.; Yousefi, A.; Hosseini, S.H.; Song, M. Improvement of the thermal management of lithium-ion battery with helical tube liquid cooling and phase change material integration. J. Energy Storage 2024, 102, 114113. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, Z.; Wu, W.; Wei, L.; Lyu, J.; Li, Y.; Liu, X.; Li, Y.; Song, Y. Simulations on hybrid thermal management of mini-channel cold plate and PCM for lithium-ion batteries under discharging and thermal runaway conditions. Case Stud. Therm. Eng. 2024, 60, 104837. [Google Scholar] [CrossRef]

- Ji, W.; Dang, Y.; Yu, Y.; Zhou, X.; Li, L. Combination of Phase Change Composite Material and Liquid-Cooled Plate Prevents Thermal Runaway Propagation of High-Specific-Energy Battery. Appl. Sci. 2024, 15, 1274. [Google Scholar] [CrossRef]

| Review | Focus of Review | Highlights | Missing Topics/Future Perspectives |

|---|---|---|---|

| Jiang et al. (2022) [32] |

|

|

|

| Shahid et al. (2022) [19] |

|

|

|

| Chavan et al. (2023) [20] |

|

|

|

| Zhi et al. (2024) [33] |

|

|

|

| Yang et al. (2024) [34] |

|

|

|

| TR Reactions | Temperature Range for the Initiation of Reaction | Reaction Rate Equation | Heat Generation Equation |

|---|---|---|---|

| SEI decomposition reaction | 60–130 °C | ||

| negative-electrolyte reaction | 100–130 °C | ||

| positive-electrolyte reaction | 150–300 °C | ||

| electrolyte decomposition | Around 200 °C | ||

| ISC | Around 130 °C |

| Parameters | Description | Unit |

|---|---|---|

| Frequency factor of the reaction | ||

| Activation energy of the reaction | J/mol | |

| Initial dimensionless content | - | |

| Conversion degree of the positive electrode material | - | |

| Initial dimensionless SEI layer thickness | - | |

| Heat of reaction | J/kg | |

| Material content | kg/m3 | |

| Battery nominal voltage | V | |

| Battery capacity | Ah | |

| Efficiency factor | - | |

| Parameter to control heat generation by ISC: | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tai, L.D.; Lee, M.-Y. Advances in the Battery Thermal Management Systems of Electric Vehicles for Thermal Runaway Prevention and Suppression. Batteries 2025, 11, 216. https://doi.org/10.3390/batteries11060216

Tai LD, Lee M-Y. Advances in the Battery Thermal Management Systems of Electric Vehicles for Thermal Runaway Prevention and Suppression. Batteries. 2025; 11(6):216. https://doi.org/10.3390/batteries11060216

Chicago/Turabian StyleTai, Le Duc, and Moo-Yeon Lee. 2025. "Advances in the Battery Thermal Management Systems of Electric Vehicles for Thermal Runaway Prevention and Suppression" Batteries 11, no. 6: 216. https://doi.org/10.3390/batteries11060216

APA StyleTai, L. D., & Lee, M.-Y. (2025). Advances in the Battery Thermal Management Systems of Electric Vehicles for Thermal Runaway Prevention and Suppression. Batteries, 11(6), 216. https://doi.org/10.3390/batteries11060216