Abstract

As electric vehicle (EV) adoption continues to surge globally, the question of what to do with retired EV batteries looms large. While these batteries may no longer meet the rigorous demands of automotive use, they often retain a significant portion of their capacity and functionality. This has led to growing interest in exploring second-life applications for retired EV batteries, ranging from stationary energy storage to grid stabilization and beyond. However, numerous challenges must be addressed to unlock the full potential of this emerging sector. This paper delves into the key challenges and prospects associated with the second life of retired EV batteries. It examines technical hurdles, such as battery degradation, safety concerns, and the development of efficient repurposing methods, along with regulatory and economic barriers, including standards for battery reuse, recycling infrastructure, and market dynamics. Additionally, it highlights the potential environmental benefits, including reduced carbon emissions and resource conservation. In conclusion, the second life of retired EV batteries presents both challenges and opportunities. Addressing technical, regulatory, and economic barriers will be essential for realizing the full potential of this growing sector. However, with continued innovation and collaboration across industries, the future looks bright for leveraging retired EV batteries to create a more sustainable energy ecosystem.

1. Introduction

Global warming and climate change represent some of the most formidable challenges humanity has ever encountered. Over the past 50 years, the Earth’s global average temperature has risen by approximately 1 degree Celsius, already manifesting in longer, hotter heatwaves, more frequent droughts, heavier rainfall, and more intense hurricanes. If we fail to curb our emissions, the consequences will only worsen; glaciers will continue to disappear, and early snowmelt and prolonged droughts will lead to more severe water shortages and heightened wildfire risks. Rising sea levels will exacerbate coastal flooding, while cities will increasingly grapple with scorching heatwaves, heavy downpours, and frequent floods, threatening both ecosystems and human livelihoods. The urgency to address this crisis has never been greater, as the window to mitigate its worst effects continues to narrow.

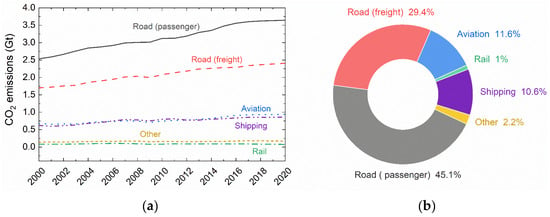

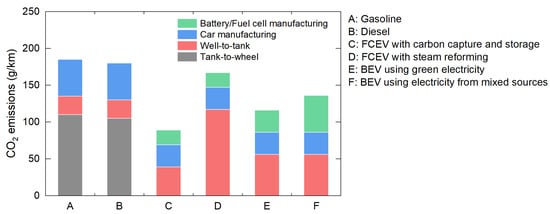

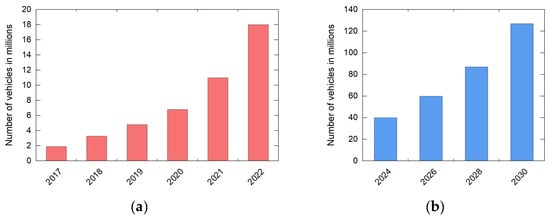

The collective urgency to address climate change, reduce carbon emissions, and enhance sustainability has recently accelerated the global transition toward clean energy and the electrification of transportation. According to the International Energy Agency (IEA), the transport sector was responsible for about 24.5% of global CO2 emissions in 2018, 75% of which came from road vehicles (such as cars, trucks, and buses) [1,2]. Emissions from aviation and shipping are also continually rising, as highlighted in Figure 1 [2]. To mitigate greenhouse gas emissions from the transportation sector, electric vehicles have emerged as a key solution in the green transition, offering significant potential to reduce both emissions and dependence on fossil fuels. As shown in Figure 2, which compares the lifecycle CO2 emissions of internal combustion engine (ICE) vehicles with green alternatives like fuel cell and battery electric vehicles, it is evident that EVs have a much higher decarbonization potential for the transport sector. For example, the per-kilometer lifecycle emissions of a battery electric vehicle (BEV) powered by green electricity amount to just 116 g/km of CO2, which is substantially lower than the emissions from an ICE vehicle over the same distance [3]. Due to the electric vehicle (EV) sector’s higher potential for decarbonizing the transport industry, we have witnessed exponential growth in the adoption of EVs in recent years, and the global EV fleet is projected to reach 127 million vehicles by 2030, as shown in Figure 3 [4]. This growth is encouraging for both our roads and the environment, and it will also help reduce oil dependence. However, challenges lie ahead. The increasing demand for lithium-ion batteries, coupled with the finite supply of critical raw materials, raises concerns about sustainability [5]. Additionally, a new issue has emerged: what happens to these batteries when they reach the end of their useful life in vehicles?

Figure 1.

(a) Global CO2 emissions from the transport sector and (b) sector-wise breakdown for 2018 [2].

Figure 2.

Lifecycle CO2 emissions for gasoline and diesel engine vehicles along with green alternatives like fuel cell electric vehicles (FCEV) and battery electric vehicles (BEV). Adapted from [2].

Figure 3.

(a) Global number of Li-ion battery electric vehicles (EVs) in use and (b) projected growth of the global EV fleet.

The first life cycle of batteries—referring to their original use in EVs as traction batteries—typically last 8 to 10 years, covering approximately 160,000 km or around 1000 charge–discharge cycles [6]. By the end of this period, batteries generally experience a 20–25% loss in capacity [7]. This reduction in capacity makes them unsuitable for reliable use in automotive applications. As these batteries still retain a substantial amount of their original capacity even after being retired from vehicles, they present a significant opportunity for other uses, where a lower energy-to-weight or volume ratio is not a significant issue.

The emerging concept of repurposing retired EV batteries for secondary applications, such as stationary energy storage, presents a promising opportunity to enhance sustainability across the energy and transportation sectors. Retired EV batteries with 70–80% of their original capacity can be effectively reused in less demanding applications, including residential energy storage, grid stabilization, and renewable energy integration [8,9]. This approach not only extends the useful life of lithium-ion batteries, thereby maximizing the return on the resources and energy invested in their production, but also helps to minimize environmental waste associated with premature disposal. Moreover, second-life battery systems can offer cost-effective energy storage solutions that support the transition to a low-carbon energy infrastructure by addressing intermittency issues with solar and wind power [10]. As the global EV market continues to grow, developing efficient strategies for battery repurposing will be crucial to fostering a more circular and sustainable energy ecosystem.

Repurposing retired EV batteries not only maximizes their remaining value but also plays a vital role in enhancing grid stability and supporting the integration of renewable energy sources, which are inherently intermittent. As stationary energy storage systems, these second-life batteries can store surplus energy generated during periods of high production and release it when demand rises or renewable output declines, helping to maintain a stable balance between energy supply and demand across the grid. Numerous studies have explored how repurposed EV batteries can support the integration of wind energy into the power grid, helping to minimize grid disruptions and increase the penetration of renewable energy [11,12,13,14,15,16]. Research by White et al. [13] has demonstrated that integrating second-life batteries can significantly enhance power reliability and support clean energy production by mitigating the variability inherent in renewable sources. Similarly, a study by Gajduk et al. [12] showed that plug-in EVs, when employed in vehicle-to-grid (V2G) systems, can improve grid transient stability by providing backup power during major disturbances, such as generator failures or sudden load shifts.

These findings underscore the potential of repurposed EV batteries and V2G technologies to strengthen grid resilience and enable the seamless integration of intermittent renewable sources. In response to this potential, many countries around the world are deploying grid-scale energy storage systems utilizing repurposed EV batteries. Notably, China has recently launched pilot projects across nine cities to use EVs as mobile energy storage units, intending to stabilize the power grid during peak demand [17]. This initiative highlights a practical and scalable application of V2G technology in advancing grid stability and accelerating the global shift toward renewable energy.

Given the immense potential of second-life applications for retired EV batteries, this paper re-examines the concept to provide a comprehensive perspective on how to fully unlock the value of these batteries in their second life. It explores both the opportunities and challenges associated with their reuse, with a particular focus on key technical hurdles such as battery degradation, capacity fade, and the critical need for robust safety protocols to ensure reliable performance in secondary applications. Additionally, the paper highlights recent advancements in repurposing technologies, including innovations in battery testing, refurbishment processes, and system integration strategies that enhance the viability and efficiency of second-life solutions. Beyond the technical aspects, the paper addresses regulatory and economic challenges. These include the lack of standardized guidelines for battery reuse, the pressing need for scalable recycling infrastructure, and the complex role of market dynamics in either fostering or impeding second-life initiatives. By adopting a multidisciplinary approach, this paper provides a comprehensive overview of the potential of second-life EV batteries, underscoring their ability to contribute meaningfully to a circular economy and support the global transition toward a low-carbon, sustainable energy future.

2. The Concept of the Second Life of EV Batteries

Currently, EV battery packs are typically retired when their capacity falls to about 80% of their nominal level. While this capacity fade poses a significant challenge for vehicle applications, additional economic value can still be extracted from these batteries in applications that require less power and performance. The applications most suitable are those that require less frequent battery cycling—ranging from small-scale residential storage to large-scale grid support [18,19]. Repurposing EV batteries for second-life applications offers substantial environmental and economic benefits. For example, second-life batteries can operate effectively in stationary storage systems for an additional 7–10 years, extending their overall functional life to up to 20 years. Neubauer and Pesaran [8] estimate that implementing second-use strategies could reduce the upfront cost of EVs by up to 1000 USD per vehicle, while simultaneously offering energy storage solutions at costs as low as 100–150 USD per kWh, which is significantly cheaper than new batteries at the time of the study. Additionally, lifecycle assessments indicate that reusing batteries can reduce greenhouse gas emissions associated with lithium-ion battery production by as much as 30% when compared with a single-use lifecycle followed by recycling or disposal [10]. As the number of retired EV batteries increases, integrating them into the energy system through reuse not only reduces environmental impact but also supports the transition to a more flexible, low-carbon power grid.

Leveraging retired batteries for energy storage can enhance grid resilience by providing backup power during peak demand periods and emergencies. Second-life batteries can also be deployed in microgrids, particularly in remote or underserved regions, to ensure a reliable power supply and improve energy access. Instead of being prematurely discarded, these batteries can store energy from intermittent renewable sources, such as solar and wind, thereby stabilizing the grid and reducing the need for new battery production. They can also help balance supply and demand by storing excess renewable energy and releasing it when needed, thus enhancing the reliability of green energy sources. A summary of the capacity ranges required for various potential applications, along with an assessment of the suitability of repurposed batteries, is provided in Table 1. Further details regarding these data are available in [20]. While many applications—especially those that require lower capacity and less frequent battery cycling—appear to be well-suited for repurposed or “second-life” batteries, a few are considered unsuitable due to economic feasibility constraints or the need for excessively high C rates (the rate at which a battery is charged or discharged), which second-life batteries may struggle to meet effectively. For example, industrial-scale energy operations demand substantial amounts of energy storage and release, making them less compatible with repurposed batteries. These batteries often suffer from reduced capacity and ongoing degradation, further limiting their suitability for large-scale applications. Moreover, safety becomes a significant concern when second-life batteries are subjected to the high power demands typical of industrial-scale operations, particularly when operating at elevated C rates, frequently exceeding 2C [20]. At such high rates, the risk of overheating, structural failure, and other safety hazards increases, rendering repurposed batteries unsuitable for these high-power, critical environments.

Table 1.

Viability of each application across different sectors, along with their corresponding capacity ranges. The asterisk (*) indicates that repurposed batteries are unsuitable for the given application. Adapted from [20].

By repurposing EV batteries that would otherwise become waste, the demand for critical raw materials (such as lithium, cobalt, and nickel) that are both finite and associated with environmental impacts during extraction can be significantly reduced. A study published in Environmental Science & Technology indicates that, under idealized conditions, retired batteries could supply up to 60% of global cobalt, 53% of lithium, 57% of manganese, and 53% of nickel by 2040 [21]. If the market shifts towards cathodes dominated by low-cobalt chemistry, there is potential for up to 85% global circularity of cobalt in 2040. However, achieving this potential requires the development of regional recycling and manufacturing infrastructure to recover secondary materials effectively.

Other research indicates that, by 2035, recycled materials from end-of-life EV batteries could supply approximately 22% of Europe’s lithium and nickel needs and 65% of its cobalt requirements for battery production [22]. This reduction in demand for newly mined materials not only alleviates environmental pressures but also diminishes dependency on imports, enhancing supply chain security. Additionally, repurposing batteries supports a circular economy, where materials are continuously reused, thereby reducing the environmental footprint associated with battery production and disposal. However, despite these considerable benefits, the path to realizing second-life applications for EV batteries is fraught with several technical, economic, and regulatory challenges, as discussed below.

3. Challenges in Repurposing EV Batteries

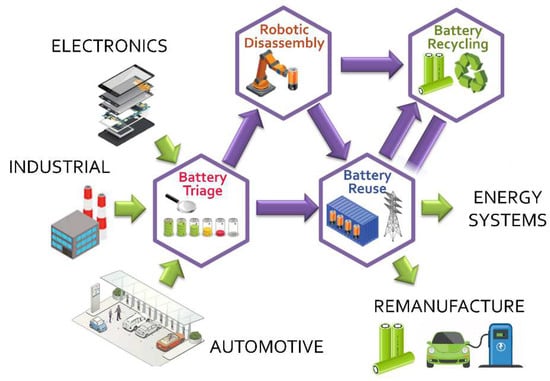

The concept of giving a second life to EV batteries is promising, and the pathway of reusing, recycling, and remanufacturing retired batteries is relatively straightforward (as shown in Figure 4). However, several challenges need to be addressed before it can be widely adopted. Reusing EV batteries for second-life applications is far more complex than simply transferring a battery pack from a vehicle to a stationary system. The process begins with manually removing and disassembling the battery pack into individual cells. Each cell must be tested to determine its state of health (SoH), with those lacking sufficient remaining capacity being directed for recycling. Among the cells deemed reusable, careful sorting is essential to group those with similar capacity levels, as mismatched cells can degrade the performance of the second-life system. Additionally, advanced sensor technologies are required to accurately assess used cells and inform the decision to reuse or recycle. To improve efficiency and safety, AI-powered robotic systems can be employed to automate the disassembly process and streamline secondary battery processing. AI-controlled robotic systems for battery sorting are becoming increasingly relevant in the context of repurposing batteries, as these systems leverage artificial intelligence, machine learning, and robotics to automate the complex and often hazardous process of sorting different types of batteries [23,24]. However, the challenge will be to train robots safely. Moreover, destructive and non-destructive diagnostics of battery packs/cells will be required for the early detection of potential hazards and risks, and the development of safety protocols for manual separation or robotic disassembly.

Figure 4.

A pathway for the reuse, recycling, and remanufacturing of retired batteries. Adapted from [25].

From a technical perspective, the biggest hurdle is the variability in the health and performance of retired batteries, as highlighted in our recent studies [26,27]. Unlike new batteries, which are standardized and reliable, retired EV batteries degrade at different rates based on their prior usage, making it challenging to predict their performance in new applications. Determining the remaining capacity, ensuring safety, and mitigating risks such as thermal runaway are crucial for the viability of second-life batteries [26,27,28]. As part of the Faraday Institute’s ReLib projects [25], our research team has explored methodologies for assessing the remaining capacity of retired EV batteries, ensuring their safety and mitigating the risks associated with thermal runaway. Further information on these methodologies and findings is available in [26,27,28]. Additionally, the processes required to collect, transport, test, and refurbish retired batteries can be complex and costly, raising questions about the economic feasibility of second-life applications. As battery technology evolves, newer models with longer lifespans and improved efficiency could also diminish the competitiveness of second-life batteries, making it essential to explore cost-effective solutions.

4. Technical Challenges

4.1. Battery Degradation

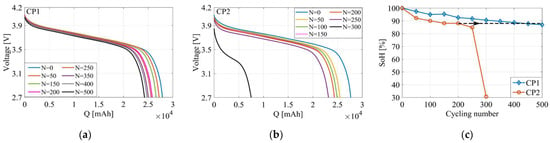

Battery degradation is a critical factor influencing the lifespan and performance of both new and second-life batteries. As batteries are used, their performance degrades due to various factors, including charge–discharge cycles, temperature fluctuations, state of charge (SoC), and material fatigue [27,29,30]. The degradation process typically manifests as a reduction in capacity, energy efficiency, and power output, all of which significantly impact the application of these batteries, especially in second-life applications. As highlighted in Figure 5, a retired EV battery can last over 500 cycles under regular cycling conditions, whereas the same battery may fail after 300 cycles when subjected to rapid cycling. This demonstrates the significant impact that cycling speed and depth have on the lifespan of a battery. Regular cycling, which typically involves slower charge and discharge rates, is less stressful on the battery, allowing it to maintain its capacity over a longer period. In contrast, rapid cycling, with faster charge and discharge rates, accelerates degradation by increasing thermal and mechanical stress on the battery cells, leading to a much shorter lifespan. High temperatures can speed up chemical reactions within the battery, leading to faster wear and reduced capacity. Similarly, frequent deep discharges and rapid charging can put additional stress on the battery cells, further accelerating their decline.

Figure 5.

Discharge profiles for retired EV batteries. (a) Voltage vs. capacity at constant current using a regular cycling procedure (CP1), (b) voltage vs. capacity at constant current using a rapid cycling procedure (CP2), and (c) capacity-based SoH for both batteries. The black dotted line in part (c) indicates the same SoH for both cycling conditions. Reprinted from [27].

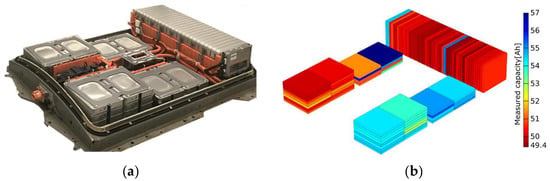

Additionally, variations in the orientation of Li-ion batteries within EV battery packs can result in non-uniform aging, potentially making second-life applications impractical [31]. Some cells may degrade faster than others depending on their position within the pack, creating imbalances that can negatively impact efficiency and longevity in their second life, as highlighted in Figure 6. Figure 6 shows the image of a retired 5-year-old Nissan Leaf battery pack and the measured capacity of each module for this pack. The capacity map in Figure 6b highlights the variation in performance across different modules, with some showing significant degradation. The modules at the beginning of life (BoL) had a capacity of 66.2 Ah at 100% SoC, while the modules at the end of life (EoL) exhibited capacities ranging from 49.4 to 57 Ah, corresponding to 75% to 86% SoH, where SoH is defined as the ratio of the nominal maximum capacity to the maximum capacity at BoL. Figure 6 further reveals that batteries oriented vertically aged more quickly than those positioned flat. However, within the flat-oriented batteries, there was a noticeable discrepancy in aging, with one side showing more significant degradation than the other. This non-uniform aging is likely due to uneven cooling within the battery pack, where one side may have been exposed to higher temperatures or less efficient heat dissipation. If these batteries transition to secondary applications, their reduced capacity and performance can limit their viability, especially in applications requiring consistent power delivery. For instance, a battery that has already lost a portion of its capacity in an EV may no longer meet the performance standards needed for grid storage or backup power systems, where reliability is crucial. To ensure the viability of retired EV batteries in second-life applications, additional precautions may be necessary. This includes careful screening and sorting based on remaining capacity and health before deployment, as well as implementing improved thermal management strategies designed specifically for second-life use. Enhanced cooling systems or passive thermal regulation can help maintain optimal operating conditions, particularly in stationary applications where batteries may be exposed to fluctuating environmental temperatures. These measures are essential to extend the usable life of second-life batteries and maximize their performance and safety.

Figure 6.

(a) Image of a retired Nissan Leaf battery pack and (b) measured capacity of each individual module of this pack. Image credit: Zoran Milojevic, Sustainable Energy Systems Lab, Newcastle University, UK.

The variability in battery degradation makes it challenging to predict the remaining capacity and performance of retired batteries in second-life applications. As each battery may degrade differently depending on factors such as usage history, temperature exposure, and charge cycles, accurately assessing their condition is complex. Advanced diagnostics and testing are necessary to evaluate the state of health of each battery, but this process can be both time-consuming and costly. Without comprehensive evaluation, it is difficult to determine which batteries are suitable for repurposing, and the risk of deploying underperforming or unsafe batteries in second-life applications remains a concern. Our recent research has highlighted several non-destructive techniques—such as infrared thermography, ultrasonic mapping, X-ray tomography, and synchrotron X-ray diffraction—as promising tools for accurately assessing the degradation of retired EV batteries [32]. These methods enable rapid decision-making regarding the most suitable course of action for retired EV batteries, whether it be recycling, repurposing, or reusing in a secondary application [32].

4.2. Safety and Environmental Concerns

Reusing retired EV batteries presents three key risks: electrocution, exposure to hazardous cell contents, and the potential for fire [33]. While the risks of electrocution and exposure to hazardous materials can generally be mitigated with appropriate precautions, managing battery fires remains an exceptionally challenging issue. As batteries age, they become more susceptible to thermal runaway, a condition that can result in fires or explosions. Our recent research investigated the behavior of battery fires under the simulated mechanical abuse of retired EV battery modules, providing valuable insights into their safety risks [28]. The study observed that, when subjected to stress, the batteries rapidly released a dense white vapor, followed by ignition within seconds, as shown in Figure 7. This swift and violent reaction poses a serious safety threat, as the fire can spread uncontrollably, creating hazardous conditions for both personnel and nearby infrastructure.

Figure 7.

Images from the simulated mechanical abuse of a retired EV battery module highlight the rapid release of white vapor, followed by ignition within seconds [28].

Ensuring the safety of second-life batteries requires robust battery management systems (BMSs) capable of continuously monitoring and managing the battery’s condition. The development of efficient and scalable safety protocols is essential to mitigate these risks and ensure safe operation. Retired EV batteries are classified as hazardous waste due to the potential dangers they pose to human health and the environment, primarily due to the presence of heavy metals [34,35]. As a result, landfilling retired EV batteries—whether legally or illegally—is strongly discouraged because of the significant environmental and safety risks involved [36]. Improper disposal can lead to hazardous chemical leaks, soil and water contamination, and the risk of fires or explosions caused by the highly reactive nature of the materials within the batteries [37]. Safe disposal and recycling practices are therefore critical to preventing these negative outcomes and promoting sustainability in battery lifecycle management.

As the adoption of EVs continues to grow, ensuring the safe end-of-life management of these batteries becomes an increasingly critical concern. One of the primary challenges in this area is developing effective fire prevention and mitigation strategies to manage the risks associated with EV batteries. Fires involving these batteries can be particularly difficult to control due to the high energy density and flammability of the materials inside, which make them prone to intense, sustained fires [38]. This underscores the urgent need for specialized fire detection technologies and advanced firefighting techniques specifically tailored to address the unique challenges of EV battery fires.

Innovations in battery design, such as enhanced thermal management systems and safer electrolyte formulations, could help reduce the risk of fires at the source by improving the overall safety of the batteries. In addition to these design improvements, integrating real-time monitoring and early warning systems into battery storage facilities will be crucial for detecting potential issues before they escalate into catastrophic events. These systems could enable the proactive management of battery health and safety throughout the entire lifecycle, ensuring that risks are identified and addressed promptly to prevent accidents.

Beyond fire safety, it is equally crucial to address the broader environmental impact of battery disposal. This involves enhancing recycling processes, developing more efficient infrastructure for battery collection, and enforcing stricter regulations to prevent illegal dumping. Advancing sustainable disposal and recycling methods will not only help mitigate the long-term ecological footprint of EV batteries but also support a circular economy for battery materials. By ensuring the reuse of valuable resources such as lithium, cobalt, and nickel, rather than discarding them, we can reduce environmental harm and conserve critical raw materials [39].

Manufacturers have a key role to play in minimizing the environmental impact of EV batteries. Through the adoption of sustainable practices and innovations, they can significantly reduce the ecological footprint of their products. One area where manufacturers can make a meaningful difference is in the design and production of EV batteries. By utilizing more sustainable materials, reducing the use of hazardous substances, and optimizing the manufacturing process, they can lower the carbon footprint and environmental impact of these batteries. Additionally, manufacturers can support the circular economy by designing their products with recyclability in mind, ensuring that batteries are easier to disassemble and recycle at the end of their life.

4.3. Integration and Reconfiguration

Retired EV batteries were originally designed for automotive applications, so repurposing them for stationary energy storage requires substantial reconfiguration. These batteries are complex in structure, consisting of multiple small cells grouped into modules, with several modules combined to form the complete battery pack (Figure 6a). An automotive battery pack typically contains hundreds or even thousands of individual cells, all of which must be carefully accessed and disassembled from the overall assembly [40]. Consequently, the repurposing process involves disassembling the batteries, testing each cell, and reassembling them into new packs specifically designed for stationary applications. This process can be labor-intensive and time-consuming, requiring a thorough evaluation of each battery’s condition to ensure safe and effective performance in its second life. To streamline this process, the use of standardized procedures and specialized tools is essential. These tools can help automate or simplify tasks such as sorting, testing, and reassembling battery packs, thus reducing labor costs and improving operational efficiency. Standardization also ensures consistent adherence to safety protocols and guarantees that the repurposed batteries meet the stringent performance standards required for stationary energy storage systems, such as those used for grid balancing or backup power.

During reconfiguration, the battery modules may need to be rearranged or reassembled into new packs that meet the voltage and power specifications for their intended use. For instance, a battery pack designed for home energy storage may require different voltage levels compared with an EV battery pack. Multiple cells might need to be connected in series or parallel to achieve the desired voltage and capacity. Additionally, modifications to the original casing and packaging may be necessary to improve cooling, facilitate easier integration, or enhance safety in a stationary setting. This could involve redesigning the housing or adopting modular designs that allow for greater scalability. The BMS, which is crucial for ensuring safe, efficient, and reliable battery operation, may also need to be updated or replaced with a version that is better suited for stationary storage applications. This may involve adjusting the charging and discharging protocols to extend the battery’s lifespan and reduce the rate of degradation.

The integration and reconfiguration of retired EV batteries for reuse is a multi-step process that includes assessment, sorting, diagnostics, reconfiguration, and safe integration into new applications. These steps not only extend the useful life of the batteries but also support resource conservation, cost-effectiveness, and environmental sustainability, contributing to a circular economy model for battery materials.

4.4. Economic Challenges

Repurposing retired EV batteries for secondary applications offers notable economic and environmental advantages. Studies indicate that utilizing second-life batteries can reduce the levelized cost of electricity by 12–57% and lower carbon emissions by 7–31% compared with using new lithium-ion batteries [6,41]. Second-life batteries can be acquired at approximately 50 USD per kilowatt hour (kWh), significantly lower than the 200–300 USD per kWh for new batteries [6]. The extent of these savings depends on factors such as the specific application and geographic location, with the most significant reductions typically seen in utility-scale implementations. However, the declining cost of new batteries presents a challenge for their second-life applications. As the price of new batteries continues to fall, the cost gap between new and used batteries narrows, as remanufacturing costs are expected to decline more slowly than those for new battery production. To make second-life batteries a viable alternative, the cost differential must remain sufficiently large to justify their performance limitations compared with new batteries. Reusing retired EV batteries presents several other economic challenges, including high labor and operational costs, capital investment in infrastructure and tools, limited market demand, recycling and disposal costs, and supply chain complexities. As discussed in previous sections, the process of disassembling, testing, and reconfiguring retired EV batteries for stationary applications is complex and requires specialized knowledge, equipment, and a significant investment of time. Consequently, labor and infrastructure costs can be high, making the process economically challenging—especially when compared with the relatively low cost of producing new batteries for stationary applications.

The lack of standardization in the design and configuration of EV batteries adds complexity to the reuse process. Different EV manufacturers use different battery architectures, chemistries, and designs, making it difficult to easily repurpose these batteries for other applications. The need to adapt each battery to new systems or reconfigure them for specific use cases requires a tailored approach. This customization increases the upfront cost of repurposing.

In addition, the variability in battery performance adds to the cost, as each battery must be carefully sorted and tested. Some cells may need to be replaced or extensively refurbished, further increasing expenses. The infrastructure required to process these retired batteries is also costly, and the high initial capital outlay may deter businesses from investing in battery reuse facilities—particularly when the financial return on investment (ROI) is uncertain. At the end of their second life, repurposed EV batteries must also be responsibly recycled or decommissioned, which can incur additional costs.

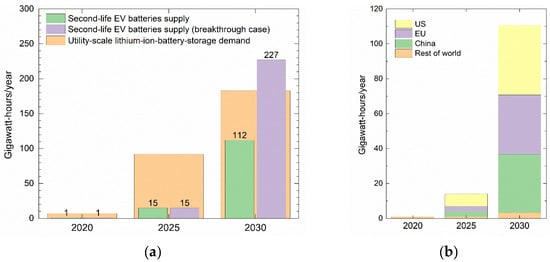

The demand for retired EV batteries in energy storage solutions is growing rapidly, with the supply of second-life lithium-ion batteries expected to exceed 200 gigawatt hours per year (GWh/y) by 2030 [18]. As shown in Figure 8, the utility-scale lithium-ion battery storage demand was just 7 GWh/y in 2020, but it is projected to rise to as much as 183 GWh/y by 2023. However, the supply of second-life EV batteries is currently lagging behind this demand, and only in a breakthrough scenario could it potentially surpass the required supply. Countries like China, the US, and those in the EU are expected to lead the way in this development (Figure 8b). Thus, the market for second-life batteries is still developing. In many regions, the price of new batteries—driven by technological advancements and economies of scale—remains competitive with that of repurposed batteries. Moreover, concerns over performance uncertainty, consumer trust, and the availability of reliable supply chains are major barriers for potential users. As a result, there may not be enough demand to support large-scale battery repurposing operations, limiting the potential for economies of scale.

Figure 8.

(a) Utility-scale lithium-ion battery demand and second-life EV battery supply, and (b) second-life EV battery supply by geography in GWh/year. Data are sourced from [18].

The supply chain for repurposing EV batteries is not yet as well established as that for new battery manufacturing. Sourcing retired EV batteries in sufficient quantities, ensuring their quality, and transporting them safely to processing facilities are all logistical challenges that add costs to the reuse process. Additionally, integrating repurposed batteries into larger energy storage systems requires a robust network of suppliers, which can take time to develop.

While the reuse of EV batteries holds substantial economic promise, overcoming the above-mentioned challenges requires careful consideration of the financial implications. Significant investments in infrastructure and market development are necessary to make battery repurposing economically viable in the long term.

4.5. Regulatory Challenges

Similar to the economic challenges of reusing EV batteries, several regulatory hurdles need to be addressed to unlock the full potential of second-life EV batteries. One of the most pressing challenges is the lack of standardized regulations governing their repurposing. Different regions have varying rules for the safe handling, testing, and reuse of retired EV batteries, making it difficult for businesses to navigate and comply with the regulatory landscape. In the US, the Environmental Protection Agency (EPA) and the Department of Energy (DOE) provide guidelines for recycling and waste management, but there is no comprehensive federal regulation for second-life batteries [42]. States like California, however, have advanced policies on battery recycling and second-life use [43]. In China, the battery recycling regulation mandates the establishment of systems for recycling and repurposing used EV batteries to ensure safe disposal, recycling, and reuse of EV batteries for second-life applications [44]. Conversely, in developing economies, the regulatory landscape and market readiness for second-life batteries are still in their infancy, with significant challenges related to infrastructure and policy development. There are a few global standards, such as the International Electrotechnical Commission standard for safety requirements of secondary lithium-ion cells (IEC 62619) and UL 1973 (for batteries used in stationary energy storage) [45,46], but they are not universally adopted or comprehensive enough to address all aspects of second-life battery use. These inconsistencies in standards can create confusion, delay the adoption of battery reuse programs, and increase compliance costs.

Given the potential risks, particularly concerning battery fires, repurposed batteries must meet rigorous safety standards. However, existing regulations may not fully address the specific risks posed by second-life batteries. Over time, aging and degradation can affect safety and reliability. As a result, regulatory bodies may require extensive testing and certification to ensure that repurposed batteries meet the same safety benchmarks as new batteries. This process can be costly, time-consuming, and complicated by the lack of clear guidance on how to assess second-life batteries. These gaps in regulation further complicate the efforts of businesses attempting to enter the market.

Additionally, the reuse of retired EV batteries raises important questions about liability and risk management. In the event of a failure—such as fire, leakage, or performance degradation—the responsibility for damages is unclear. Without a well-defined legal framework, businesses involved in battery repurposing may face uncertain liability risks. Determining accountability, whether it lies with the original manufacturer, the repurposing company, or a third-party tester, can be complex and vary by jurisdiction. This uncertainty, especially in emerging markets, makes it difficult for businesses to predict returns on investment and plan for long-term projects. As a result, companies may be hesitant to invest in battery reuse due to concerns about potential legal and financial consequences.

Consumer trust is another key issue. Many consumers may have reservations about the safety and reliability of repurposed EV batteries. Regulatory bodies must establish clear protocols for warranties, performance guarantees, and consumer protection measures to ensure that repurposed batteries meet safety and performance standards. Such measures will help to build consumer confidence and support the growth of the second-life battery market.

To address these regulatory challenges, a comprehensive, standardized regulatory framework is essential. Governments and regulatory bodies must collaborate with industry stakeholders to develop clear guidelines for battery testing, safety, liability, consumer protection, and recycling. These efforts will foster a stable and transparent regulatory environment, promote the safe integration of second-life batteries into new applications, and support sustainability goals. By establishing uniform standards, we can ensure that repurposed EV batteries contribute to a circular economy, minimize environmental impact, and provide consumers with safe, reliable, and cost-effective energy solutions.

5. Future Prospects

Even with the technical, economic, and regulatory challenges outlined above, the prospects for second-life applications of retired EV batteries are highly promising, offering substantial environmental, economic, and technological benefits. As the number of EVs reaching the end of their first life continues to rise, the potential for repurposing these batteries for secondary applications expands, with opportunities stretching well beyond grid storage.

The global transition toward renewable energy sources like solar and wind power is driving an increased need for effective management of their variability. Second-life EV batteries offer a cost-effective, scalable solution for storing renewable energy. This makes second-life batteries an attractive option in certain contexts, offering both economic and environmental benefits while also extending the life of existing resources. For instance, using second-life batteries for energy storage applications can lower the levelized cost of electricity by 12–57% compared with deploying new lithium-ion batteries [41]. As demand for reliable energy storage systems intensifies, retired EV batteries will become a vital resource for stabilizing power grids and enhancing energy security. In the future, these batteries could be integrated into vehicle-to-grid systems, allowing energy stored in EV batteries to be fed back into the grid during peak demand periods. This not only supports grid reliability but could also offer financial incentives to vehicle owners. Additionally, second-life batteries could serve a crucial role in off-grid applications, providing energy to remote or underserved areas where electricity access is limited. They could power homes, schools, and businesses in rural areas, bridging the energy access gap and improving the quality of life for off-grid communities.

Economically, the success of second-life battery applications will depend on achieving cost reductions and identifying profitable markets for repurposed batteries, particularly in areas like grid storage where demand is growing. However, the market for second-life batteries remains in its early stages, constrained by regulatory uncertainties. The lack of standardized guidelines for battery repurposing, combined with varying national regulations on waste management, safety, and liability, creates significant barriers to scaling up second-life initiatives. Without clear policies, companies may hesitate to invest in the development of these projects. As governments increasingly recognize the potential of second-life battery applications, they are expected to implement policies and regulations that promote the reuse and recycling of EV batteries. Such measures, including incentives for battery repurposing, investments in recycling infrastructure, and mandates to reduce carbon emissions, will likely accelerate the growth of the second-life battery market. Once regulations become more standardized and favorable, businesses will gain confidence in investing in battery repurposing, further fueling market expansion.

Beyond technological and economic advantages, second-life EV batteries offer a sustainable solution to the environmental challenges posed by battery production and disposal. Repurposing retired EV batteries reduces the need for new batteries, thereby lowering the environmental impact associated with raw material mining, manufacturing, and disposal. This aligns with broader goals of reducing carbon footprints and fostering a circular economy for battery materials, where valuable resources like lithium, cobalt, and nickel are reused rather than discarded. For instance, incorporating second-life batteries into energy storage systems can reduce greenhouse gas emissions by 7–77% compared with using new batteries, with the most significant reductions occurring in large-scale applications [41]. Additionally, repurposing batteries for second-life use can result in an 8–17% decrease in carbon footprint compared with direct recycling after their first life [19]. This underscores the environmental benefits of extending the life of batteries, offering a more sustainable alternative to traditional recycling methods.

6. Conclusions

The second life of retired electric vehicle (EV) batteries offers immense potential but comes with its share of challenges. Repurposing these EV batteries for energy storage, grid stabilization, and off-grid applications can significantly reduce environmental impacts, bolster renewable energy adoption, and drive the transition to a circular economy. As technological advancements, regulatory support, and market demand evolve, the value proposition of second-life batteries is poised to grow, contributing to a cleaner, more resilient energy landscape. However, realizing this potential is not without hurdles. Key limitations include the heterogeneity of battery chemistries and states of health, the lack of standardized testing and certification protocols, and the high costs and technical complexities involved in the repurposing process. Further barriers include regulatory inconsistencies across regions, logistical challenges in battery collection and transportation, and uncertainty surrounding the long-term economic viability of second-life applications. To overcome these challenges, future research and innovation should focus on several critical areas:

- –

- Developing standardized diagnostic methods to efficiently and accurately assess the remaining useful life and safety of retired batteries;

- –

- Designing intelligent battery management systems (BMSs) specifically tailored for second-life applications, and that are capable of dynamically managing performance, safety, and degradation across diverse battery modules;

- –

- Conducting comprehensive life-cycle and cost-benefit analyses to evaluate the economic and environmental viability of different second-life use cases;

- –

- Creating scalable, modular repurposing platforms that facilitate the integration of second-life batteries into a range of applications and simplify refurbishment processes;

- –

- Proposing robust policy frameworks and incentive models that encourage second-life battery utilization while addressing safety, liability, and transportation regulations;

- –

- Exploring sustainable end-of-life strategies, including eco-friendly and cost-effective recycling or disposal methods for batteries after their second-life use.

Addressing these areas will require coordinated action among manufacturers, policymakers, and researchers to establish clear standards, streamline repurposing and recycling processes, and build sustainable business models. Despite the challenges, ongoing technological innovation and growing momentum toward circular economy practices offer a promising outlook. By fostering continued research, collaboration, and strategic investment, we can unlock the full potential of retired EV batteries and transform them into valuable assets in the sustainable energy ecosystem.

Funding

This research was funded by the Faraday Institution as part of its ReLiB Project, grant numbers FIRG005 and FIRG027.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

Support from the Faraday Institution as part of its ReLiB Project (grant numbers FIRG005 and FIRG027) is gratefully acknowledged.

Conflicts of Interest

The author declares no conflict of interest.

References

- Transport Sector CO2 Emissions. Available online: https://www.iea.org/data-and-statistics/charts/transport-sector-co2-emissions-by-mode-in-the-sustainable-development-scenario-2000-2030 (accessed on 14 November 2024).

- Das, P.K.; Jiao, K.; Wang, Y.; Frano, B.; Li, X. Fuel Cells for Transportation: Fundamental Principles and Applications; Woodhead Publishing: Cambridge, MA, USA, 2023. [Google Scholar]

- Aarnes, J.; Eijgelaar, M.; Hektor, E.A. Hydrogen as an Energy Carrier—An Evaluation of Emerging Hydrogen Value Chains; DNV GL Research Review: Oslo, Norway, 2018. [Google Scholar]

- Trends in Electric Vehicle Batteries. Available online: https://www.iea.org/reports/global-ev-outlook-2024/trends-in-electric-vehicle-batteries (accessed on 12 November 2024).

- Sun, X.; Hao, H.; Hartmann, P.; Liu, Z.; Zhao, F. Supply risks of lithium-ion battery materials: An entire supply chain estimation. Mater. Today Energy 2019, 14, 100347. [Google Scholar] [CrossRef]

- Zahoor, A.; Kun, R.; Mao, G.; Farkas, F.; Sápi, A.; Kónya, Z. Urgent needs for second life using and recycling design of wasted electric vehicles (EVs) lithium-ion battery: A scientometric analysis. Environ. Sci. Pollut. Res. 2024, 31, 43152–43173. [Google Scholar] [CrossRef] [PubMed]

- Temporelli, A.; Carvalho, M.L.; Girardi, P. Life cycle assessment of electric vehicle batteries: An overview of recent literature. Energies 2020, 13, 2864. [Google Scholar] [CrossRef]

- Neubauer, J.; Pesaran, A. The ability of battery second use strategies to impact plug-in electric vehicle prices and serve utility energy storage applications. J. Power Sources 2011, 196, 10351–10358. [Google Scholar] [CrossRef]

- Casals, L.C.; Amante García, B.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Richa, K.; Babbitt, C.W.; Nenadic, N.G.; Gaustad, G. Environmental trade-offs across cascading lithium-ion battery life cycles. Int. J. Life Cycle Assess. 2017, 22, 66–81. [Google Scholar] [CrossRef]

- Reused Car Batteries Rev up Electric Grid. Available online: https://www.ornl.gov/news/reused-car-batteries-rev-electric-grid (accessed on 14 April 2025).

- Gajduk, A.; Todorovski, M.; Kurths, J.; Kocarev, L. Improving power grid transient stability by plug-in electric vehicles. New J. Phys. 2014, 16, 115011. [Google Scholar] [CrossRef]

- White, C.; Thompson, B.; Swan, L.G. Repurposed electric vehicle battery performance in second-life electricity grid frequency regulation service. J. Energy Storage 2020, 28, 101278. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, H.; Zhao, P.; Chen, Z.; Yan, J. Repurposing EV batteries for storing solar energy. Engineering 2023, 29, 45–49. [Google Scholar] [CrossRef]

- López, A.I.; Ramírez-Díaz, A.; Castilla-Rodríguez, I.; Gurriarán, J.; Mendez-Perez, J.A. Wind farm energy surplus storage solution with second-life vehicle batteries in isolated grids. Energy Policy 2023, 173, 113373. [Google Scholar] [CrossRef]

- Manousakis, N.M.; Karagiannopoulos, P.S.; Tsekouras, G.J.; Kanellos, F.D. Integration of renewable energy and electric vehicles in power systems: A review. Processes 2023, 11, 1544. [Google Scholar] [CrossRef]

- China to Launch Grid-Connected Car Projects to Balance Power Supply. Available online: https://www.reuters.com/business/autos-transportation/china-launch-grid-connected-car-projects-balance-power-supply-2025-04-02/ (accessed on 14 April 2025).

- Engel, H.; Hertzke, P.; Siccardo, G. Second-Life EV Batteries: The Newest Value Pool in Energy Storage; McKinsey & Company: New York, NY, USA, 2019; Volume 30. [Google Scholar]

- Tao, Y.; Rahn, C.D.; Archer, L.A.; You, F. Second life and recycling: Energy and environmental sustainability perspectives for high-performance lithium-ion batteries. Sci. Adv. 2021, 7, eabi7633. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.N.; Lander, L.; Ahuja, J.; Bulman, J.; Lum, J.K.H.; Pople, J.O.D.; Hales, A.; Patel, Y.; Edge, J.S. Lithium-ion battery second life: Pathways, challenges and outlook. Front. Chem. 2024, 12, 1358417. [Google Scholar]

- Dunn, J.; Slattery, M.; Kendall, A.; Ambrose, H.; Shen, S. Circularity of lithium-ion battery materials in electric vehicles. Environ. Sci. Technol. 2021, 55, 5189–5198. [Google Scholar] [CrossRef]

- Recycling of Critical Minerals. Available online: https://www.iea.org/reports/recycling-of-critical-minerals/executive-summary (accessed on 14 April 2025).

- Hathaway, J.; Shaarawy, A.; Akdeniz, C.; Aflakian, A.; Stolkin, R.; Rastegarpanah, A. Towards reuse and recycling of lithium-ion batteries: Tele-robotics for disassembly of electric vehicle batteries. Front. Robot. AI 2023, 10, 1179296. [Google Scholar] [CrossRef]

- Antony Jose, S.; Cook, C.A.D.; Palacios, J.; Seo, H.; Torres Ramirez, C.E.; Wu, J.; Menezes, P.L. Recent advancements in artificial intelligence in battery recycling. Batteries 2024, 10, 440. [Google Scholar] [CrossRef]

- The Faraday Institution—Relib. Available online: https://www.faraday.ac.uk/research/lithium-ion/recycle-reuse/ (accessed on 12 November 2024).

- Muhammad, M.; Ahmeid, M.; Attidekou, P.S.; Milojevic, Z.; Lambert, S.; Das, P. Assessment of spent EV batteries for second-life application. In Proceedings of the 2019 IEEE 4th International Future Energy Electronics Conference (IFEEC), Singapore, 25–28 November 2019; pp. 1–5. [Google Scholar]

- Attidekou, P.S.; Milojevic, Z.; Muhammad, M.; Ahmeid, M.; Lambert, S.; Das, P.K. Methodologies for large-size pouch lithium-ion batteries end-of-life gateway detection in the second-life application. J. Electrochem. Soc. 2020, 167, 160534. [Google Scholar] [CrossRef]

- Christensen, P.A.; Wise, M.S.; Attidekou, P.S.; Dickmann, N.A.; Lambert, S.M.; Das, P.K. Thermal and mechanical abuse of electric vehicle pouch cell modules. Appl. Therm. Eng. 2021, 189, 116623. [Google Scholar] [CrossRef]

- Rahman, T.; Alharbi, T. Exploring lithium-ion battery degradation: A concise review of critical factors, impacts, data-driven degradation estimation techniques, and sustainable directions for energy storage systems. Batteries 2024, 10, 220. [Google Scholar] [CrossRef]

- Kirkaldy, N.; Samieian, M.A.; Offer, G.J.; Marinescu, M.; Patel, Y. Lithium-ion battery degradation: Comprehensive cycle ageing data and analysis for commercial 21,700 cells. J. Power Sources 2024, 603, 234185. [Google Scholar] [CrossRef]

- Milojevic, Z.; Attidekou, P.S.; Muhammad, M.; Ahmeid, M.; Lambert, S.; Das, P.K. Influence of orientation on ageing of large-size pouch lithium-ion batteries during electric vehicle life. J. Power Sources 2021, 506, 230242. [Google Scholar] [CrossRef]

- Fordham, A.; Milojevic, Z.; Giles, E.; Du, W.; Owen, R.E.; Michalik, S.; Chater, P.A.; Das, P.K.; Attidekou, P.S.; Lambert, S.M. Correlative non-destructive techniques to investigate aging and orientation effects in automotive li-ion pouch cells. Joule 2023, 7, 2622–2652. [Google Scholar] [CrossRef]

- Christensen, P.A.; Anderson, P.A.; Harper, G.D.J.; Lambert, S.M.; Mrozik, W.; Rajaeifar, M.A.; Wise, M.S.; Heidrich, O. Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew. Sustain. Energy Rev. 2021, 148, 111240. [Google Scholar] [CrossRef]

- Stec, A.A.; Dickens, K.; Barnes, J.L.J.; Bedford, C. Environmental contamination following the Grenfell Tower fire. Chemosphere 2019, 226, 576–586. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, X.; Wang, D.; Huang, K.; Wang, L.; Bao, L.; Wu, F. Environmental characteristics comparison of li-ion batteries and ni–mh batteries under the uncertainty of cycle performance. J. Hazard. Mater. 2012, 229–230, 455–460. [Google Scholar] [CrossRef]

- Mrozik, W.; Rajaeifar, M.A.; Heidrich, O.; Christensen, P. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ. Sci. 2021, 14, 6099–6121. [Google Scholar] [CrossRef]

- Kwade, A.; Diekmann, J. Recycling of Lithium-Ion Batteries; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Global EV Outlook 2023. Available online: https://www.iea.org/reports/global-ev-outlook-2023 (accessed on 14 November 2024).

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603. [Google Scholar] [CrossRef]

- Kamath, D.; Shukla, S.; Arsenault, R.; Kim, H.C.; Anctil, A. Evaluating the cost and carbon footprint of second-life electric vehicle batteries in residential and utility-level applications. Waste Manag. 2020, 113, 497–507. [Google Scholar] [CrossRef]

- Bird, R.; Baum, Z.J.; Yu, X.; Ma, J. The regulatory environment for lithium-ion battery recycling. ACS Energy Lett. 2022, 7, 736–740. [Google Scholar] [CrossRef]

- California Public Utilities Commission—Energy Storage. Available online: https://www.cpuc.ca.gov/industries-and-topics/electrical-energy/energy-storage (accessed on 14 April 2025).

- Li, J.; Wang, Z.; Li, H.; Jiao, J. Which policy can effectively promote the formal recycling of power batteries in China? Energy 2024, 299, 131445. [Google Scholar] [CrossRef]

- IEC 62619; Secondary Cells and Batteries Containing Alkaline or Other Non-Acid Electrolytes—Safety Requirements for Secondary Lithium Cells and Batteries, for Use in Industrial Applications. International Electrotechnical Commission: Geneva, Switzerland, 2022. Available online: https://webstore.iec.ch/en/publication/64073 (accessed on 15 November 2024).

- UL 1973; Standard for Batteries for Use in Stationary, Vehicle Auxiliary Power and Light Electric Rail (LER) Applications. TÜV SÜD: Peabody, MA, USA, 1973. Available online: https://www.tuvsud.com/en-us/services/testing/energy-storage/ul-1973 (accessed on 15 November 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).