Sustainable Battery Lifecycle: Non-Destructive Separation of Batteries and Potential Second Life Applications

Abstract

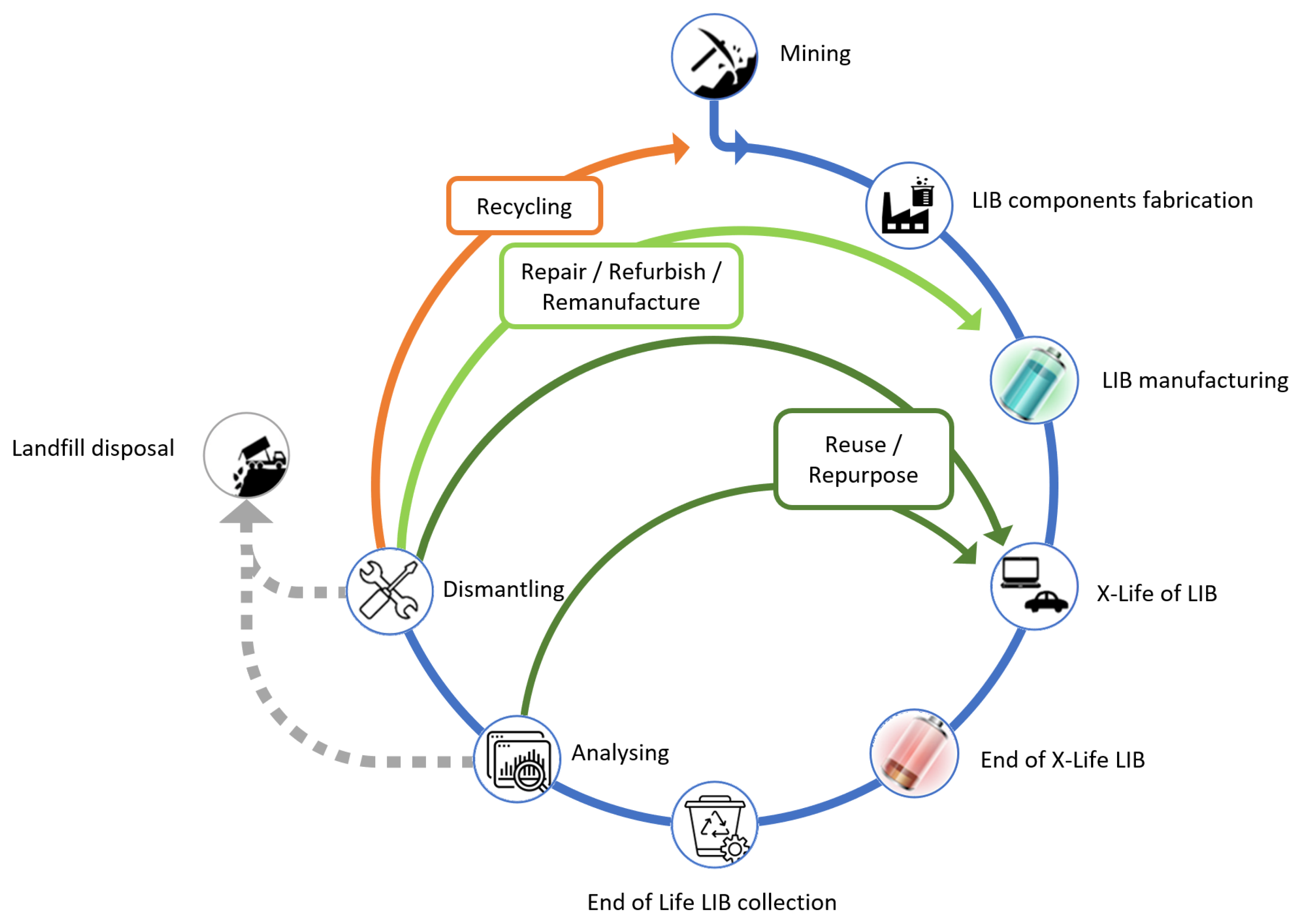

1. Introduction

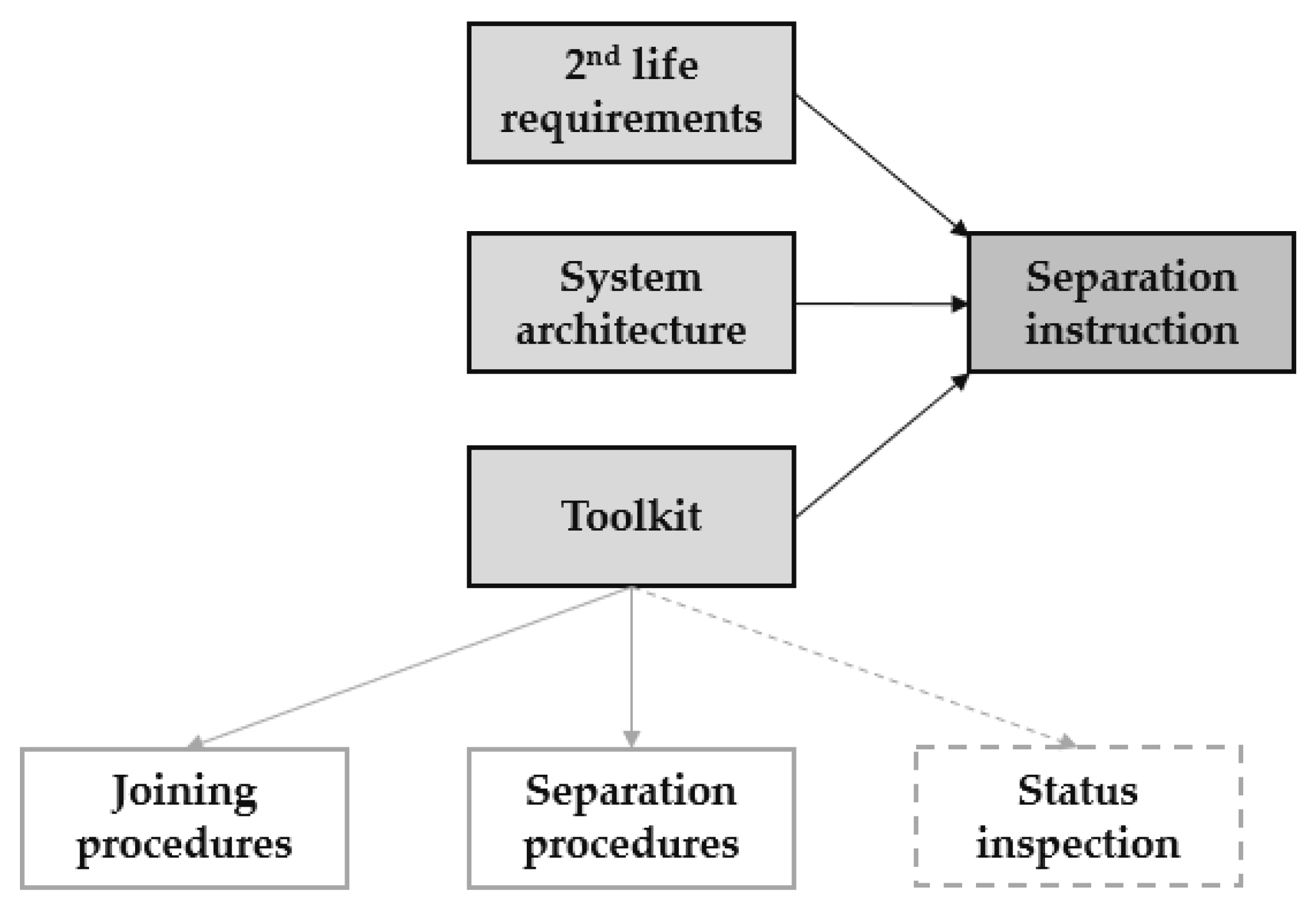

2. Materials and Methods

- Categorization of second life applications.

- Definition of requirements and key performance indicators (KPIs) of second life applications.

- Selection of the three commercially available battery systems to evaluate the applicability of non-destructive separation methods.

- Use case study: joining techniques used in these battery systems.

- Use case study: potential separation methods for non-destructive extraction of ESCs for further use.

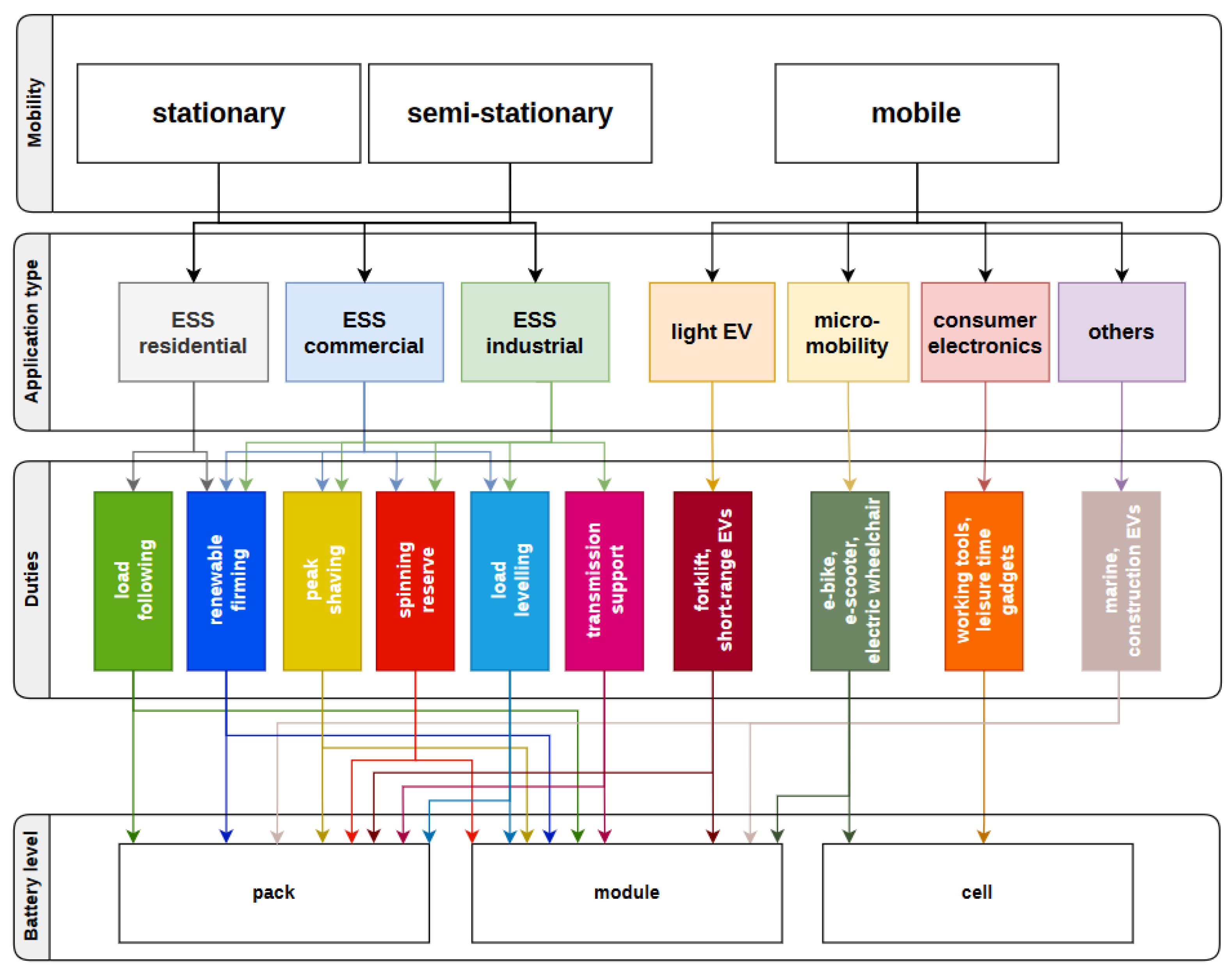

2.1. Categorization of Second Life Applications

2.1.1. Definition of KPIs for Second Life Applications

- Lifetime (calendar lifetime of the entire system);

- Power (required to meet the specification of the surrounding systems);

- Capacity (of the entire system);

- C-Rate (to meet the required energy consumption);

- Volume (of the entire system);

- Mass (of the entire system);

- Serviceability (of the entire system in order to maintain or shut it down, taking into account the associated consequences).

2.1.2. KPIs of Different Second Life Applications

- (Semi-) stationary ESSs offer a wide range of possibilities for product development;

- Geometric and mass-specific requirements are associated with high disassembly effort;

- From a technical perspective, all the use cases considered are feasible, but may be severely constrained by the highly individual load profiles within the application type.

2.2. Selection of Suitable Battery Systems for Investigation

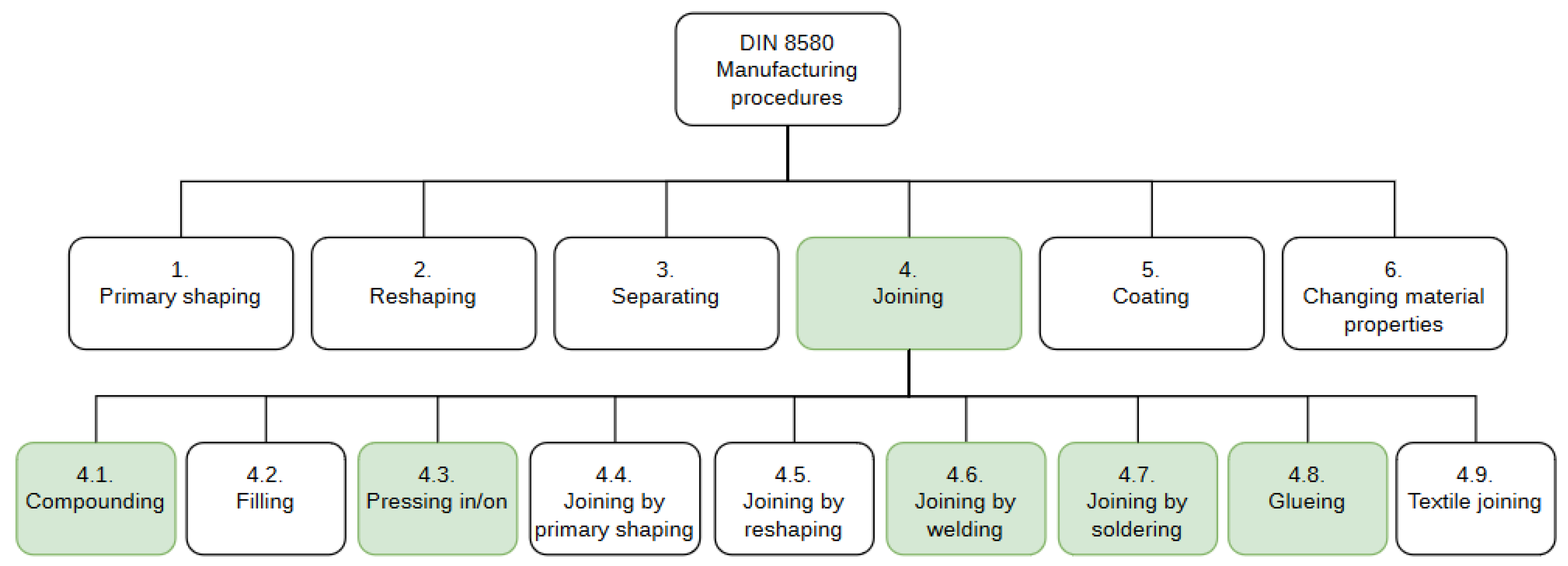

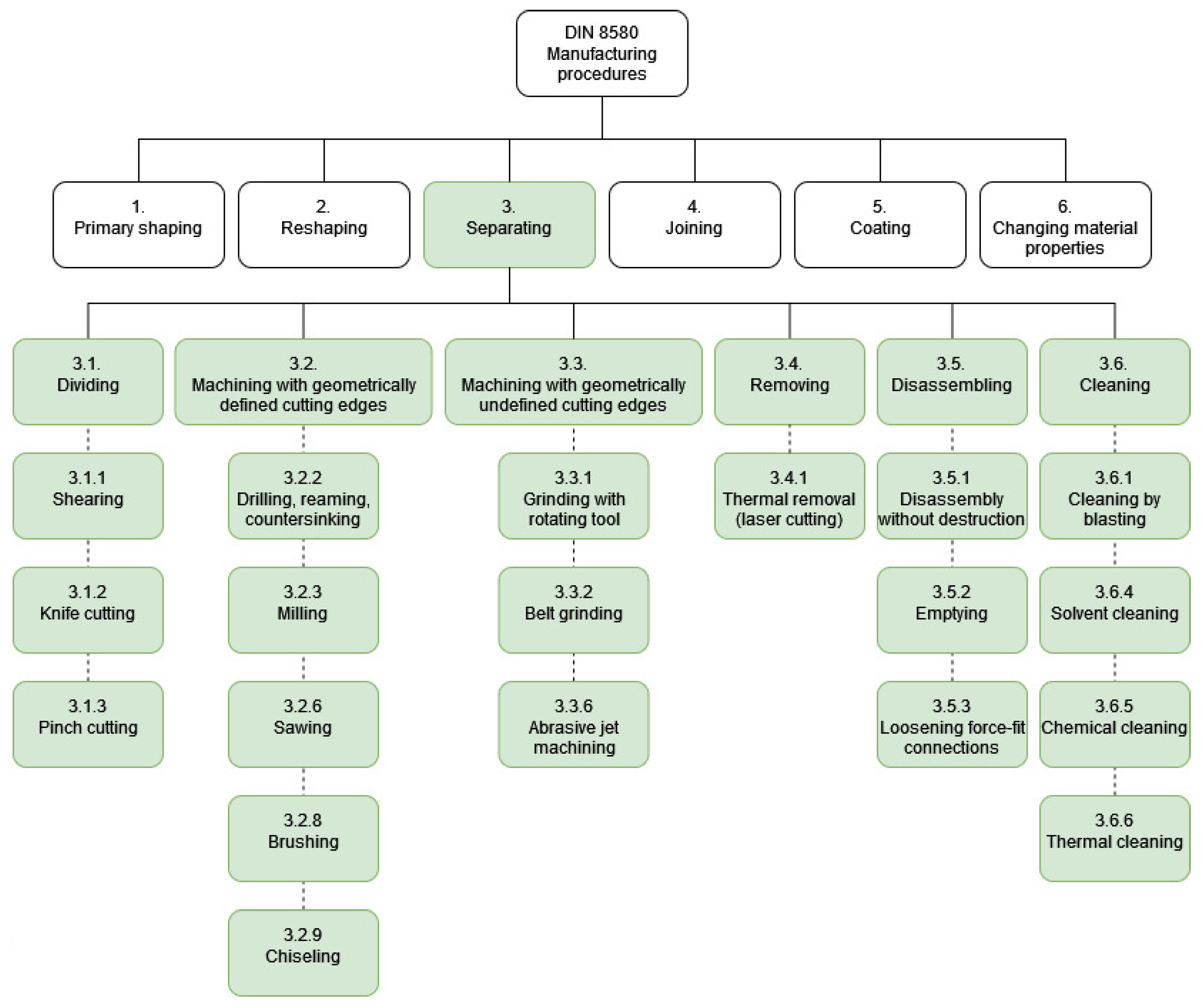

2.3. Joining and Separation Procedures of Investigated Battery Systems

- 4.1.1 Assembling;

- 4.3.1 Screwing;

- 4.3.2 Clamping;

- 4.6 Welding (Arc, Laser, Ultrasonic and Fusion welding);

- 4.7 Soldering and;

- 4.8 Gluing.

- The separation processes are limited to the pack and module levels. Cell disassembly into anode, cathode, and other components is not considered in this study.

- The pack separation process focuses on separating the ESCs so that modules and cells are separated from the peripheral components as quickly as possible.

- The further separation of various components and materials is only taken into account if this is necessary for a hypothetical automated process or can be carried out easily and cost-effectively. This can include the removal of adhesives from the housing, as well as the removal of cooling plates, sensors, and valves.

3. Results

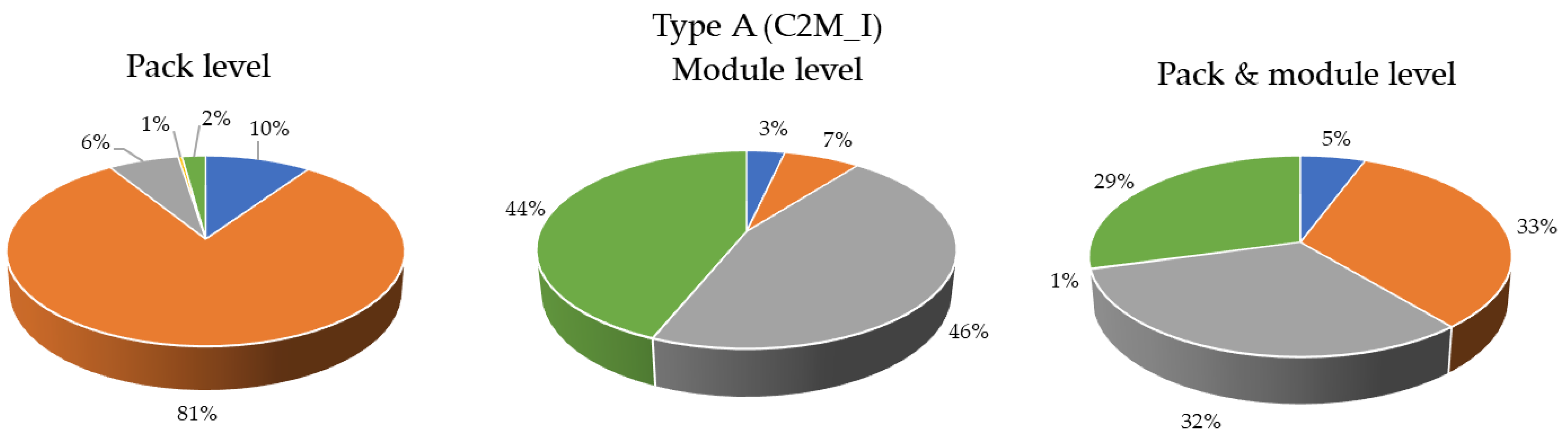

3.1. Joining Procedures of Different Battery Systems

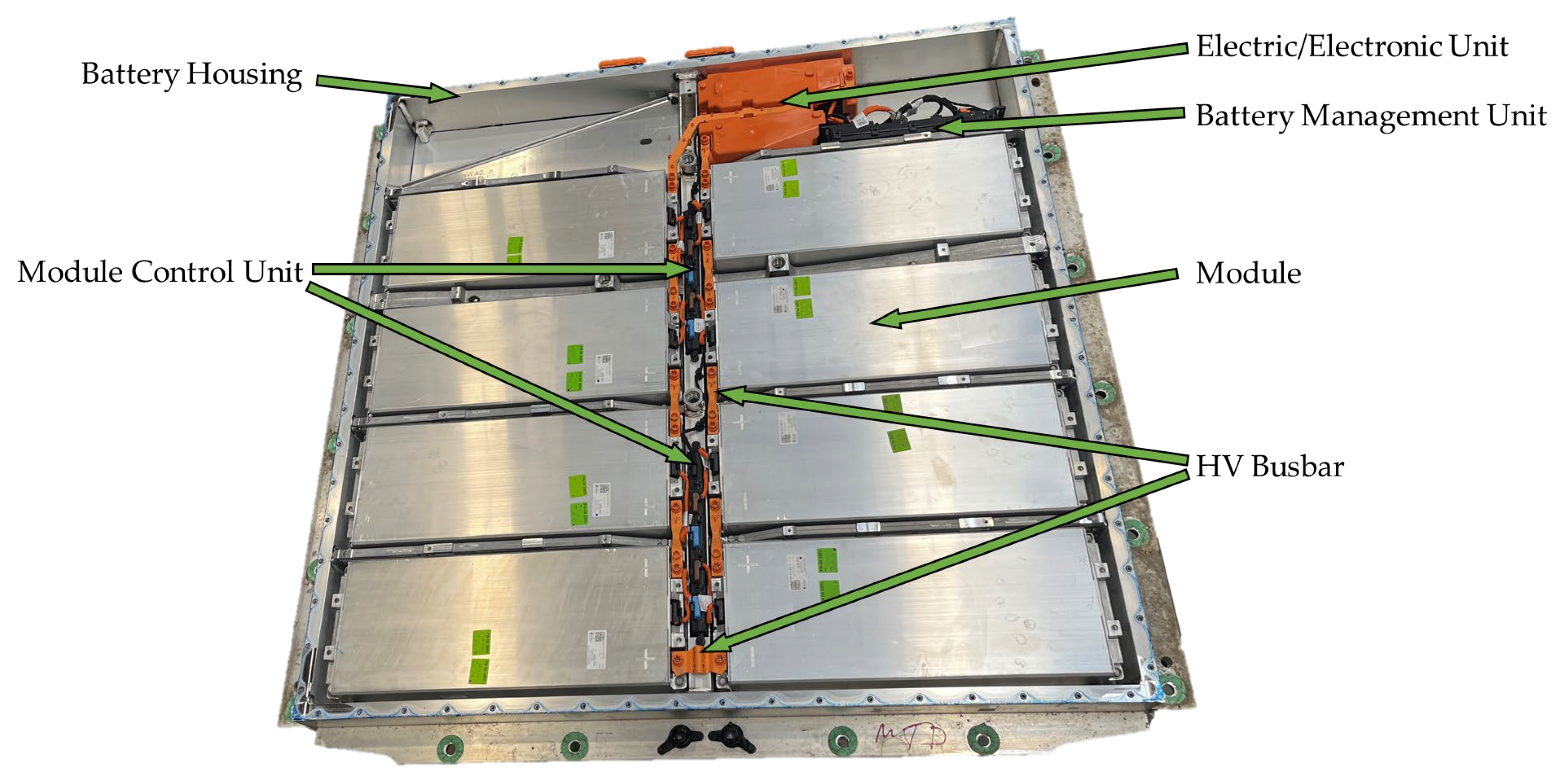

3.1.1. Type A

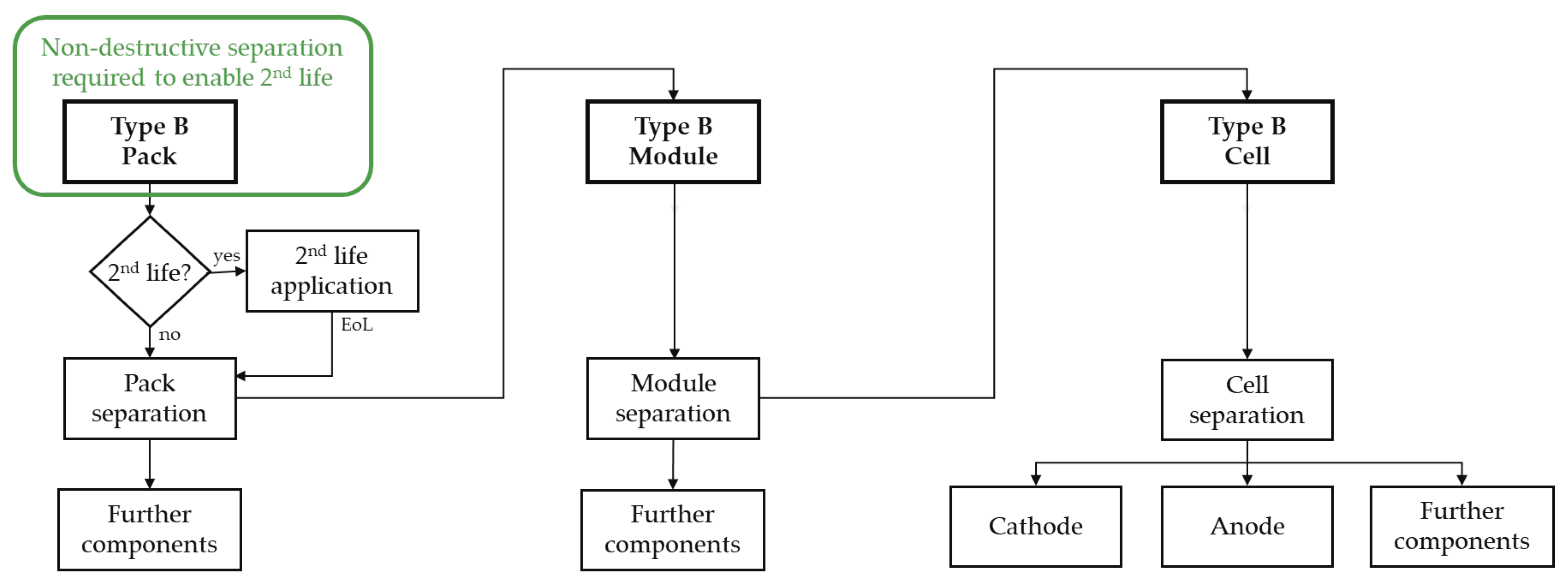

3.1.2. Type B

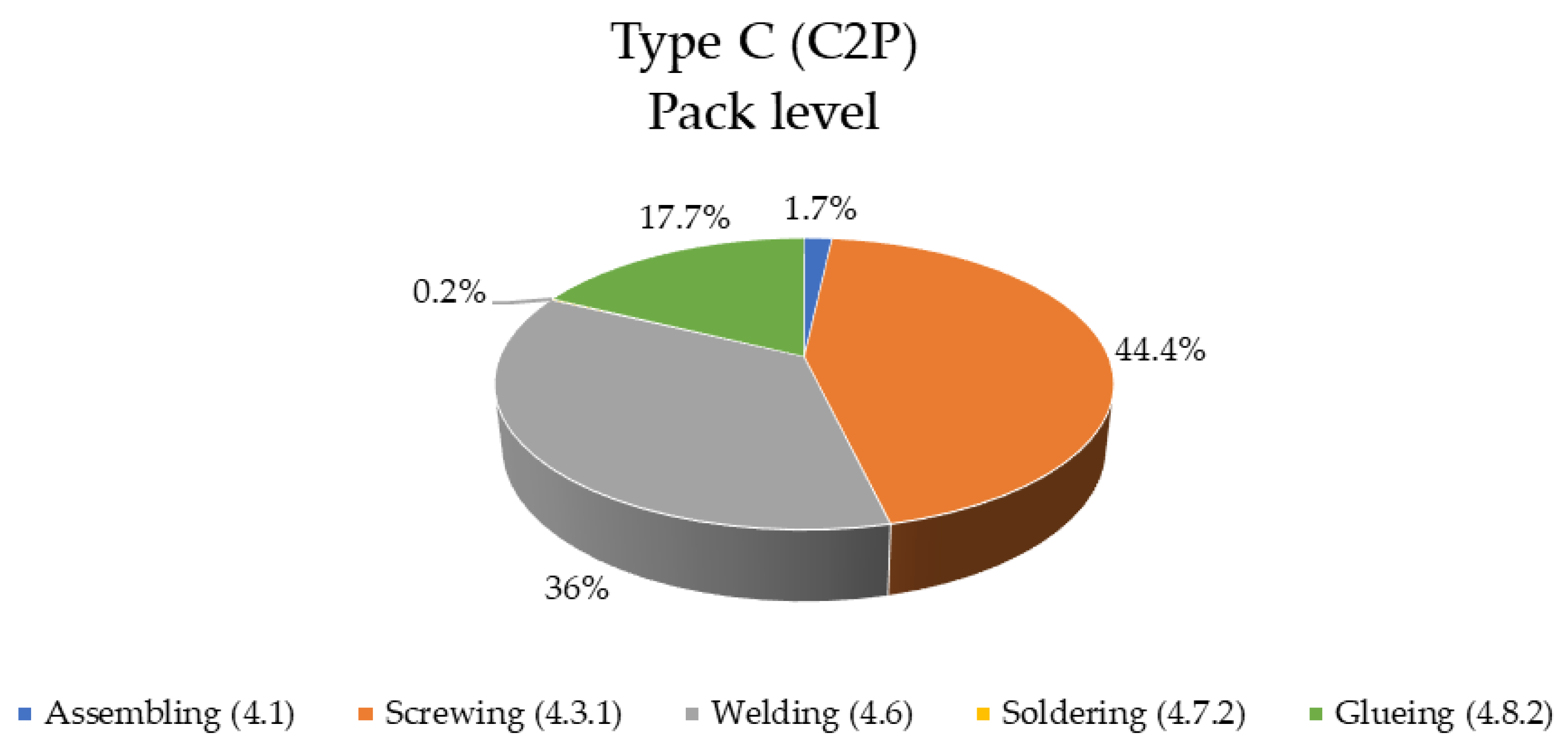

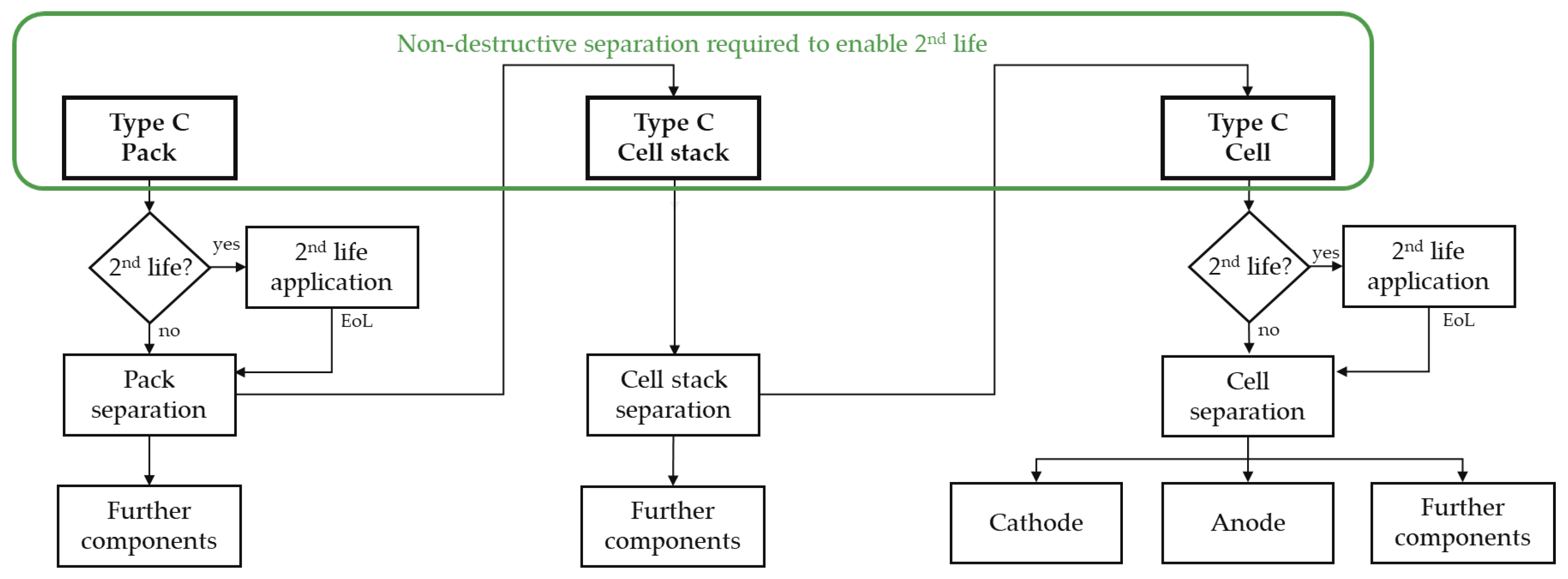

3.1.3. Type C

3.2. Separation Procedures

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, S.; Kaden, N.; Dröder, K. A Systematic Review on Lithium-Ion Battery Disassembly Processes for Efficient Recycling. Batteries 2023, 9, 297. [Google Scholar] [CrossRef]

- Andre, D.; Kim, S.-J.; Lamp, P.; Lux, S.F.; Maglia, F.; Paschos, O.; Stiaszny, B. Future Generations of Cathode Materials: An Automotive Industry Perspective. J. Mater. Chem. A 2015, 3, 6709–6732. [Google Scholar] [CrossRef]

- Haisheng, C.; Zhenhua, Y.; We, L. Energy Storage Industry White Paper 2023. China, 2023. China Energy Storage Alliance. Energy Storage Industry White Paper 2022 (Summary Version). Available online: https://en.cnesa.org/our-work (accessed on 15 July 2024).

- Gao, Y.; Pan, Z.; Sun, J.; Liu, Z.; Wang, J. High-Energy Batteries: Beyond Lithium-Ion and Their Long Road to Commercialisation. Nano-Micro Lett. 2022, 14, 94. [Google Scholar] [CrossRef] [PubMed]

- Dhir, S.; Wheeler, S.; Capone, I.; Pasta, M. Outlook on K-Ion Batteries. Chem 2020, 6, 2442–2460. [Google Scholar] [CrossRef]

- International Energy Agency. Global EV Outlook 2021; International Energy Agency: Paris, France, 2021.

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.J.R.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking It down: A Techno-Economic Assessment of the Impact of Battery Pack Design on Disassembly Costs. Appl. Energy 2023, 331, 120437. [Google Scholar] [CrossRef]

- Olsson, L.; Fallahi, S.; Schnurr, M.; Diener, D.; van Loon, P. Circular Business Models for Extended EV Battery Life. Batteries 2018, 4, 57. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A Cascaded Life Cycle: Reuse of Electric Vehicle Lithium-Ion Battery Packs in Energy Storage Systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Gu, X.; Bai, H.; Cui, X.; Zhu, J.; Zhuang, W.; Li, Z.; Hu, X.; Song, Z. Challenges and Opportunities for Second-Life Batteries: Key Technologies and Economy. Renew. Sustain. Energy Rev. 2024, 192, 114191. [Google Scholar] [CrossRef]

- Michelini di San Martino, E.; Höschele, P.; Ratz, F.; Stadlbauer, M.; Rom, W.; Ellersdorfer, C.; Moser, J. Potential and Most Promising Second-Life Applications for Automotive Lithium-Ion Batteries Considering Technical, Economic and Legal Aspects. Energies 2023, 16, 2830. [Google Scholar] [CrossRef]

- Wu, W.; Lin, B.; Xie, C.; Elliott, R.J.R.; Radcliffe, J. Does Energy Storage Provide a Profitable Second Life for Electric Vehicle Batteries? Energy Econ. 2020, 92, 105010. [Google Scholar] [CrossRef]

- Ioakimidis, C.; Murillo-Marrodán, A.; Bagheri, A.; Thomas, D.; Genikomsakis, K. Life Cycle Assessment of a Lithium Iron Phosphate (LFP) Electric Vehicle Battery in Second Life Application Scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef]

- Zanoletti, A.; Carena, E.; Ferrara, C.; Bontempi, E. A Review of Lithium-Ion Battery Recycling: Technologies, Sustainability, and Open Issues. Batteries 2024, 10, 38. [Google Scholar] [CrossRef]

- Wett, C.; Lampe, J.; Haß, J.; Seeger, T.; Turan, B. On the State of Usability for Lithium–Ion Batteries. Batteries 2024, 10, 57. [Google Scholar] [CrossRef]

- IEC 63330-1:2024 ED1; Repurposing of Secondary Batteries—Part 1: General Requirements. IEC: Geneva, Switzerland, 2024.

- IEC 63338 ED1; General Guidance on Reuse and Repurposing of Secondary Cells and Batteries. IEC: Geneva, Switzerland, 2024.

- UL1974; ANSI/CAN/UL Standard for Evaluation for Repurposing Batteries. UL: Northbrook, IL, USA, 2018.

- Christensen, P.A.; Mrozik, W.; Wise, M.S. Safety of Second Life Batteries in Battery Energy Storage Systems. 2023. Available online: https://assets.publishing.service.gov.uk/media/63d91ff0e90e0773da7fdb92/safety-of-second-life-batteries-in-bess.pdf (accessed on 14 July 2024).

- Zhu, J.; Mathews, I.; Ren, D.; Li, W.; Cogswell, D.; Xing, B.; Sedlatschek, T.; Kantareddy, S.N.R.; Yi, M.; Gao, T.; et al. End-of-Life or Second-Life Options for Retired Electric Vehicle Batteries. Cell Rep. Phys. Sci. 2021, 2, 100537. [Google Scholar] [CrossRef]

- Zwicker, M.F.R.; Moghadam, M.; Zhang, W.; Nielsen, C.V. Automotive Battery Pack Manufacturing—A Review of Battery to Tab Joining. J. Adv. Join. Process. 2020, 1, 100017. [Google Scholar] [CrossRef]

- Yang, X.-G.; Liu, T.; Wang, C.-Y. Thermally Modulated Lithium Iron Phosphate Batteries for Mass-Market Electric Vehicles. Nat. Energy 2021, 6, 176–185. [Google Scholar] [CrossRef]

- Thompson, D.; Hyde, C.; Hartley, J.M.; Abbott, A.P.; Anderson, P.A.; Harper, G.D.J. To Shred or Not to Shred: A Comparative Techno-Economic Assessment of Lithium Ion Battery Hydrometallurgical Recycling Retaining Value and Improving Circularity in LIB Supply Chains. Resour. Conserv. Recycl. 2021, 175, 105741. [Google Scholar] [CrossRef]

- Nehls, G. AZL Opens New Project in Cell-to-Pack Composite Battery Enclosures; CompositesWorld: Cincinnati, OH, USA, 2022. [Google Scholar]

- Kim, S.; Bang, J.; Yoo, J.; Shin, Y.; Bae, J.; Jeong, J.; Kim, K.; Dong, P.; Kwon, K. A Comprehensive Review on the Pretreatment Process in Lithium-Ion Battery Recycling. J. Clean. Prod. 2021, 294, 126329. [Google Scholar] [CrossRef]

- Harper, G.D.J.; Kendrick, E.; Anderson, P.A.; Mrozik, W.; Christensen, P.; Lambert, S.; Greenwood, D.; Das, P.K.; Ahmeid, M.; Milojevic, Z.; et al. Roadmap for a Sustainable Circular Economy in Lithium-Ion and Future Battery Technologies. J. Phys. Energy 2023, 5, 021501. [Google Scholar] [CrossRef]

- Baazouzi, S.; Rist, F.P.; Weeber, M.; Birke, K.P. Optimization of Disassembly Strategies for Electric Vehicle Batteries. Batteries 2021, 7, 74. [Google Scholar] [CrossRef]

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.R.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial Viability of Electric Vehicle Lithium-Ion Battery Recycling. iScience 2021, 24, 102787. [Google Scholar] [CrossRef]

- Kay, I.; Farhad, S.; Mahajan, A.; Esmaeeli, R.; Hashemi, S.R. Robotic Disassembly of Electric Vehicles’ Battery Modules for Recycling. Energies 2022, 15, 4856. [Google Scholar] [CrossRef]

- Choux, M.; Marti Bigorra, E.; Tyapin, I. Task Planner for Robotic Disassembly of Electric Vehicle Battery Pack. Metals 2021, 11, 387. [Google Scholar] [CrossRef]

- Li, L.; Maftouni, M.; Kong, Z.J.; Li, Z. An Automated Recycling Process of End-of-Life Lithium-Ion Batteries Enhanced by Online Sensing and Machine Learning Techniques. In Proceedings of the REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I); Lazou, A., Daehn, K., Fleuriault, C., Gökelma, M., Olivetti, E., Meskers, C., Eds.; Springer International Publishing: Cham, Germany, 2022; pp. 475–486. [Google Scholar]

- Zhou, L.; Garg, A.; Zheng, J.; Gao, L.; Oh, K.-Y. Battery Pack Recycling Challenges for the Year 2030: Recommended Solutions Based on Intelligent Robotics for Safe and Efficient Disassembly, Residual Energy Detection and Secondary Utilization. Energy Storage 2020, 3, e190. [Google Scholar] [CrossRef]

- Soto, A.; Berrueta, A.; Zorrilla, P.; Iribarren, A.; Castillo, D.H.; Rodríguez, W.E.; Rodríguez, A.J.; Vargas, D.T.; Matias, I.R.; Sanchis, P.; et al. Integration of Second-Life Battery Packs for Self-Consumption Applications: Analysis of a Real Experience. In Proceedings of the 2021 IEEE International Conference on Environment and Electrical Engineering and 2021 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Bari, Italy, 7–10 September 2021; pp. 1–6. [Google Scholar]

- DIN 8580:2022-12; Manufacturing Processes—Terms and Definitions, Division. DIN: Berlin, Germany, 2022.

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers & Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73239–73243. [Google Scholar] [CrossRef]

- Iliadis, P.; Ntomalis, S.; Atsonios, K.; Nesiadis, A.; Nikolopoulos, N.; Grammelis, P. Energy Management and Techno-Economic Assessment of a Predictive Battery Storage System Applying a Load Levelling Operational Strategy in Island Systems. Int. J. Energy Res. 2021, 45, 2709–2727. [Google Scholar] [CrossRef]

- Capacity Firming: The Variable, Intermittent Power Output from a Renewable Power Generation Plant, Such as Wind or Solar, Can Be Maintained at a Committed Level for a Period of Time. Available online: https://www.megawatts.com.sg/renewable-energy/energy-storage/capacity-firming/ (accessed on 23 April 2024).

- Spinning Reserve: To Provide Effective Spinning Reserve, the Energy Storage System Is Maintained at a Level of Charge Ready to Respond to a Generation or Transmission Outage. Available online: https://storydesign.ecmweb.com/Global/FileLib/ABB/Endeavor_20221026_ABB_Supporting_Global_Megatrends_with_Energy_Storage_v2.pdf (accessed on 23 April 2024).

- Marnell, K.; Obi, M.; Bass, R. Transmission-Scale Battery Energy Storage Systems: A Systematic Literature Review. Energies 2019, 12, 4603. [Google Scholar] [CrossRef]

- European Commission. Energy Storage—Underpinning a Decarbonised and Secure EU Energy System; European Commission: Brussels, Belgium, 2023.

- European Commission, Directorate-General for Research and Innovation. Strategic Research and Innovation Agenda (SRIA) of the European Open Science Cloud (EOSC); Publications Office of the European Union: Luxembourg, 2024.

- World Economic Forum. A Vision for a Sustainable Battery Value Chain in 2030: Unlocking the Full Potential to Power Sustainable Development and Climate Change Mitigation; World Economic Forum: Geneva, Switzerland, 2019. [Google Scholar]

- Fritz, W.; Ladermann, A.; Willemsen, S. Batteriespeicher in Netzen; Federal Ministry for Economic Affairs and Climate Action: Aachen, Germany, 2022.

- Hill, N.; Clarke, D.; Blair, L.; Menadue, H. Circular Economy Perspectives for the Management of Batteries Used in Electric Vehicles; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- KPIs Benchmarking II. Available online: https://batterieseurope.eu/results/kpis-benchmarking-2/kpis-benchmarking-2-october-2023/ (accessed on 23 April 2024).

- Komarnicki, P.; Lombardi, P.; Styczynski, Z.A. Elektrische Energiespeichersysteme: Flexibilitätsoptionen für Smart Grid, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- International Renewable Energy Agency. Innovation Landscape Brief: Utility-Scale Batteries, International Renewable Energy Agency; International Renewable Energy Agency: Masdar City, Abu Dhabi, 2019. [Google Scholar]

- Commercial and Industrial ESS. Available online: https://en.cntepower.com/commercial-and-industrial-ess (accessed on 23 April 2024).

- ST2752UX-US: Liquid Cooling Energy Storage System. Available online: https://info-support.sungrowpower.com/application/pdf/2022/06/21/DS_20220225_ST2752UX-US_Datasheet_V15_EN.pdf (accessed on 23 April 2024).

- Neef, C.; Link, S.; Wicke, T.; Hettesheimer, T. Development Perspectives for Lithium-Ion Battery Cell Formats; Fraunhofer Institute for Systems and Innovation Research ISI: Karlsruhe, Germany, 2022. [Google Scholar]

- Moll, C.; Durand, A.; Rohde, C. Preparatory Study on Ecodesign and Energy Labelling of Batteries under FWC ENER/C3/2025-619-Lot 1; European Commission: Luxembourg, 2019.

- Sidi-Ali-Cherif, K.; Aznar, G.F.; Comba, J.C. Roadmap on Stationary Applications for Batteries: Second Life Batteries for Stationary Applications; European Commission: Brussels, Belgium, 2022.

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of Utilising Second Life EV Batteries: Applications, Lifespan, Economics, Environmental Impact, Assessment, and Challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Commercial ESS Cabinet Energy Storage System 215Kwh Lithium Iron Phosphate LiFePO4. Available online: https://www.lifepo4lithiumbatteries.com/quality-40428162-commercial-ess-cabinet-energy-storage-system-215kwh-lithium-iron-phosphate-lifepo4 (accessed on 23 April 2024).

- Tesla Powerwall. Available online: https://www.tesla.com/en_gb/powerwall (accessed on 23 April 2024).

- ESS Home Series. Available online: https://www.lg.com/de/business/ess-homeseries/ (accessed on 23 April 2024).

- ESS Batteries by Samsung SDI. Available online: https://www.samsungsdi.com/upload/ess_brochure/201902_Samsung%20SDI%20ESS_EN.pdf (accessed on 23 April 2024).

- Becker, J.; Beverungen, D.; Winter, M.; Menne, S. Umwidmung und Weiterverwendung von Traktionsbatterien, 1st ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019. [Google Scholar]

- RX 60 3,5-5,0 t. Available online: https://www.still.at/fahrzeuge/gabelstapler-und-lagertechnik/elektro-stapler/rx-60-35-50-t.html (accessed on 23 April 2024).

- RX 60 6,0-8,0 t. Available online: https://www.still.at/fahrzeuge/gabelstapler-und-lagertechnik/elektro-stapler/rx-60-60-80-t.html (accessed on 23 April 2024).

- RXE 10-16C. Available online: https://www.still.at/fahrzeuge/gabelstapler-und-lagertechnik/elektro-stapler/rxe-10-16c.html (accessed on 23 April 2024).

- Produktpalette Elektrorollstuhl. Available online: https://www.burbach-goetz.de/rollstuhl/elektro (accessed on 23 April 2024).

- SCEWO BRO Elektrorollstuhl. Available online: https://www.burbach-goetz.de/mobilitaet-und-agilitaet/scewo-bro-elektrorollstuhl-inkl-treppensteiger-raupenmodus-inkl-lift-hoehenverstellung-probefahrt-kostenlos-anfordern/a-1235703 (accessed on 23 April 2024).

- FreedomChair. Available online: https://e-goes.co.uk/freedom-chair-range (accessed on 23 April 2024).

- The Best E-Mountainbike of 2023–The Biggest Group Test yet: 30 e-Mountainbikes Head-to-Head. Available online: https://ebike-mtb.com/en/best-emtb-group-test-review (accessed on 23 April 2024).

- Electric Bike Batteries Explained. Available online: https://www.ebikekit.com/blogs/news/electric-bike-batteries-explained (accessed on 23 April 2024).

- Ninebot KickScooter E2 Powered by Segway. Available online: https://at-de.segway.com/products/ninebot-kickscooter-e2-powered-by-segway (accessed on 23 April 2024).

- Akkus & Ladegeräte. Available online: https://www.bosch-professional.com/at/de/akkus-ladegeraete-212566-ocs-c/?unterteilung-der-produktkategorien--akkupack%20Development%20Perspective%20for%20LIB%20cell%20formats_pp.%2015 (accessed on 23 April 2024).

- ProCORE18V+ 8.0Ah Professional. Available online: https://www.bosch-professional.com/at/de/products/procore18v-8-0ah-1600A02X00 (accessed on 23 April 2024).

- Nuron-Akku B 22-255. Available online: https://www.hilti.at/c/CLS_CORDLESS_TOOLS_7123/CLS_CORDLESS_BATT_CHARGE_7123/CLS_CORDLESS_BATTERIES_7123/r13250381?combo_content=069f5cb19c089edc1c5cbd923d46d2db&salespackquantity=1&itemCode=2251363 (accessed on 23 April 2024).

- Application of Lithium-Ion Batteries in Marine and Boats. Available online: https://nanografi.com/blog/-applications-of-lithiumion-batteries-in-marine-and-boats/ (accessed on 23 April 2024).

- Corvus Energy Storage Solutions. Available online: https://corvusenergy.com/products/energy-storage-solutions/ (accessed on 23 April 2024).

- Power 48-5000. Available online: https://www.torqeedo.com/de/produkte/batterien/power-48-5000/2104-00.html (accessed on 23 April 2024).

- EV Database Volkswagen ID.3 1st. Available online: https://ev-database.org/de/pkw/1300/Volkswagen-ID3-1st (accessed on 4 June 2024).

- Huppertz, H. Kfz-Tech.de-2019 VW ID.3. Available online: https://kfz-tech.de/Hersteller/VW/VWID32019.htm (accessed on 4 June 2024).

- EV Database Tesla Model 3 Long Range Performance. Available online: https://ev-database.org/car/1139/Tesla-Model-3-Long-Range-Performance (accessed on 4 June 2024).

- EVShop.EU 75kWh Tesla Model 3 Battery Pack Long Range. Available online: https://evshop.eu/en/batteries/292-tesla-model-3-full-battery-pack-75kwh-long-range.html (accessed on 4 June 2024).

- EV Database NIO ET7 75 kWh. Available online: https://ev-database.org/car/1751/NIO-ET7-75-kWh (accessed on 4 June 2024).

- NIO ET7 User Manual. Available online: https://www.nio.com/cdn-static/www/user-instructions/ET7/index.html#TUM128125-EN (accessed on 4 June 2024).

- Wetzig, A.; Herwig, P.; Hauptmann, J.; Baumann, R.; Rauscher, P.; Schlosser, M.; Pinder, T.; Leyens, C. Fast Laser Cutting of Thin Metal. Procedia Manuf. 2019, 29, 369–374. [Google Scholar] [CrossRef]

- Pushing the Solid-State Laser Speed Limit. Fabricator 2015, 45, 56–58. Available online: https://www.thefabricator.com/thefabricator/article/lasercutting/pushing-the-solid-state-laser-speed-limit (accessed on 6 July 2024).

| KPI | ESS Industrial | ESS Commercial | ESS Residential | Light EV | Micro Mobility | Consumer Electronics | Marine |

|---|---|---|---|---|---|---|---|

| Lifetime/years | 20 | 20 | 15 | 8–10 | 2 | 3 | 10–15 |

| Capacity/kWh | 700–120,000 | 5–4000 | 2.5–20 | 12–90 | 0.18–1.5 | 0.02–0.5 | 35–5000 |

| Power/kW | 500–10,000 | 100–300 | 5–7 | 1.5–8 | 0.2–1 | 0.05–2 | 8–500 |

| Volume/m3 | 5–50 | 2–5 | 0.5–2 | 0.4–1.5 | 3·10−3 | 10−4 | 100 |

| Mass/kg | 5–40,000 | 800–5000 | 100–250 | 350–1000 | 1–7 | 0.1–2 | 1000–150,000 |

| Serviceability | very high | high | medium | high | low | very low | very high |

| C-Rate | 0.5–8 | 0.5–8 | 1 | 2–3 | 0.5–2 | 2–5; >10 | 0.7–3 |

| Sources | [46,47,48,49] | [11,50,51,52,53,54] | [43,51,55,56,57,58] | [58,59,60,61] | [58,62,63,64,65,66,67] | [58,68,69,70] | [71,72,73] |

| Lifetime /years | Capacity /kWh | Power /kW | Volume /m3 | Mass /kg | Serviceability | C-Rate | Standardized Value |

|---|---|---|---|---|---|---|---|

| 0–2 | 0–0.5 | 0–5 | 0–0.05 | 0–2 | very low | 0–1 C | 1 |

| 2–3 | 0.5–2 | 5–20 | 0.05–2 | 2–5 | low | 1–2 C | 2 |

| 3–5 | 2–20 | 20–100 | 2–5 | 5–100 | medium | 2–3 C | 3 |

| 5–15 | 20–100 | 100–500 | 5–50 | 100–1000 | high | 3–5 C | 4 |

| >15 | >100 | >500 | >50 | >1000 | very high | >5 C | 5 |

| Type A (C2M_I) | Type B (C2M_II) | Type C (C2P) | |

|---|---|---|---|

| System architecture | Cell–Module–Pack | Cell–Module–Pack | Cell–Pack |

| Cell type | Pouch | Cylindric | Prismatic |

| Capacity (nominal) | ~60 kWh | ~80 kWh | ~75 kWh |

| Power (continuous) | ~70 kW | ~120 kW | ~125 kW |

| Voltage (nominal) | 400 V | 400 V | 400 V |

| Number of cells | 216 | 4416 | 118 |

| Overall weight | 385 kg | 479 kg | 535 kg |

| Origin of OEM | Europe | North America | Asia |

| Source | [74,75] | [76,77] | [78,79] |

| Investigated Types | ESC Level | 2nd Life Application | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stationary | Semi- Stationary | Mobile | |||||||||||

| EES | Electric Vehicle | Micro-Mobility | Consumer Electronic | Others | |||||||||

| EES Industrial | EES Commercial | ESS Residential | Short-Range EV | Forklift | E-Bike | E-Scooter | E-Wheelchair | Working Tools | Leisure Gadgets | Marine | |||

| A | Pack | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | |

| Module | ✔ | ✔ | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | ||

| Cell | ✔ | ✔ | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | ||

| B | Pack | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | |

| Module | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | ||

| Cell | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| C | Pack | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | |

| Cell | ✔ | ✔ | ✔ | ✔ | ✔ | ✖ | ✖ | ✔ | ✖ | ✖ | ✔ | ||

| ✔ | usable | ✖ | not usable | ||||||||||

| Investigated Types | ESC Level | 2nd life Application | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stationary | Semi- Stationary | Mobile | |||||||||||

| EES | Electric Vehicle | Micro-Mobility | Consumer Electronic | Others | |||||||||

| EES Industrial | EES Commercial | ESS Residential | Short-Range EV | Forklift | E-Bike | E-Scooter | E-Wheelchair | Working Tools | Leisure Gadgets | Marine | |||

| A | Pack | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | |

| Module | ✔ | ✔ | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | ||

| Cell | ! | ! | ! | ! | ! | ✖ | ✖ | ✖ | ✖ | ✖ | ! | ||

| B | Pack | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | |

| Module | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | ||

| Cell | ! | ! | ! | ! | ! | ! | ! | ! | ! | ! | ! | ||

| C | Pack | ✔ | ✔ | ✔ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✖ | ✔ | |

| Cell | ✔ | ✔ | ✔ | ✔ | ✔ | ✖ | ✖ | ✔ | ✖ | ✖ | ✔ | ||

| ✔ | usable/non-destructive separation | ✖ | not usable | ! | destructive separation necessary | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schlögl, G.; Grollitsch, S.; Ellersdorfer, C.; Feist, F.; Kirschner, C.; Ecker, J.; Haas, F. Sustainable Battery Lifecycle: Non-Destructive Separation of Batteries and Potential Second Life Applications. Batteries 2024, 10, 280. https://doi.org/10.3390/batteries10080280

Schlögl G, Grollitsch S, Ellersdorfer C, Feist F, Kirschner C, Ecker J, Haas F. Sustainable Battery Lifecycle: Non-Destructive Separation of Batteries and Potential Second Life Applications. Batteries. 2024; 10(8):280. https://doi.org/10.3390/batteries10080280

Chicago/Turabian StyleSchlögl, Gernot, Stefan Grollitsch, Christian Ellersdorfer, Florian Feist, Christoph Kirschner, Josef Ecker, and Franz Haas. 2024. "Sustainable Battery Lifecycle: Non-Destructive Separation of Batteries and Potential Second Life Applications" Batteries 10, no. 8: 280. https://doi.org/10.3390/batteries10080280

APA StyleSchlögl, G., Grollitsch, S., Ellersdorfer, C., Feist, F., Kirschner, C., Ecker, J., & Haas, F. (2024). Sustainable Battery Lifecycle: Non-Destructive Separation of Batteries and Potential Second Life Applications. Batteries, 10(8), 280. https://doi.org/10.3390/batteries10080280