FMR Damping in Thin Films with Exchange Bias

Abstract

1. Introduction

- (1)

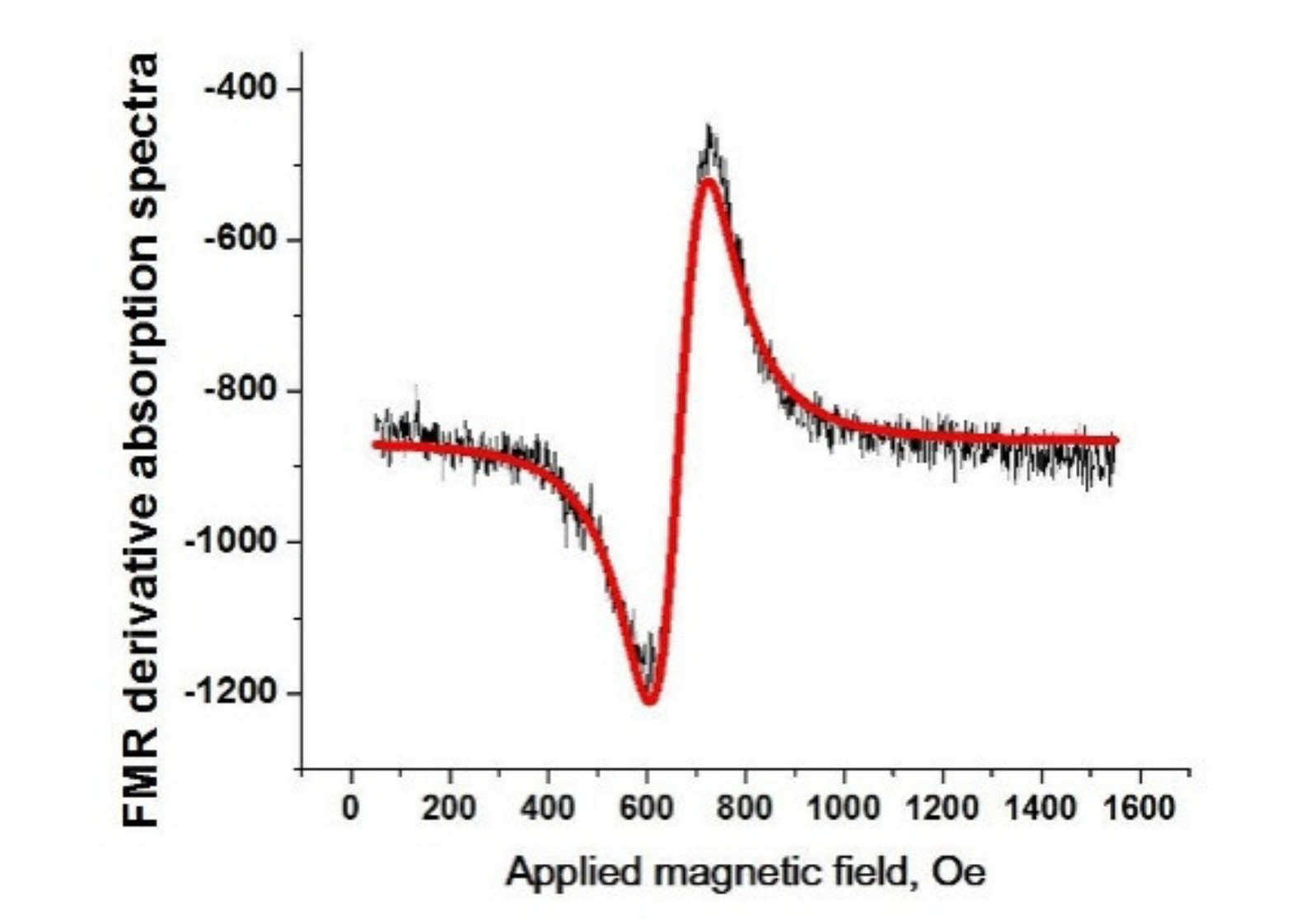

- LW can be considered as a sum of a term proportional to the frequency of exiting microwave radiation ΔHin(ω) and a term ∆Hex(0) independent of the frequency. Following [5,6,7], it can be written as∆HFMR(ω) = ∆Hin(ω) + ∆Hex(0) = 2αinωr/γ + ∆Hex (0)The first term is insensitive to the method of the sample preparation and reflects the intrinsic interaction of exiting microwave radiation with an electronic band structure, leading to so-called intrinsic or Gilbert damping. The damping parameter can be estimated as a derivative of LW ΔHFMR via [8]αin = (√3/2) γ (dΔHFMR/dω)The second term in (5), the so-called extrinsic contribution, reflects an additional LW broadening due to defects and inhomogeneities in crystal structures. It can be obtained as an intercept of the plot of LW vs. ω at zero frequency.

- (2)

- W is low for a perfect bulk single crystalline ferromagnetic but drastically increases when a surface is rough, as shown in classical experiments of LeCraw [9], where single crystalline YAG spherical samples were polished with a variety of grit size polishing paper, introducing different morphological defects on the samples’ surfaces.

- (3)

- The FMR LW in thin films can be much larger than in bulk ferromagnetics, increasing proportionally to inverse square of the thickness, ∆HFMR ~ 1/tFp, with p = 2 in polycrystalline NiO/NiFe in exchange bias films [10] and 1.75 ± 0.2 in epitaxial Fe films [11]. Being able to separate intrinsic and extrinsic contributions, as described above, it is possible to obtain extrinsic damping parameter αex, which does depend on sample thickness and preparation. Thus, in NiFe film, αex was determined to be equal to 0.03 for the thickness tF = 4.3 nm, and decreased to 0.008 at 50 nm [10].

- (4)

- LW for epitaxial films is narrower than in polycrystalline. The damping parameter in epitaxial Fe film was estimated to be αin = 3 × 10−3[11], while, for polycrystalline films, it is normally larger than 5 × 10−3.

2. Results and Discussion

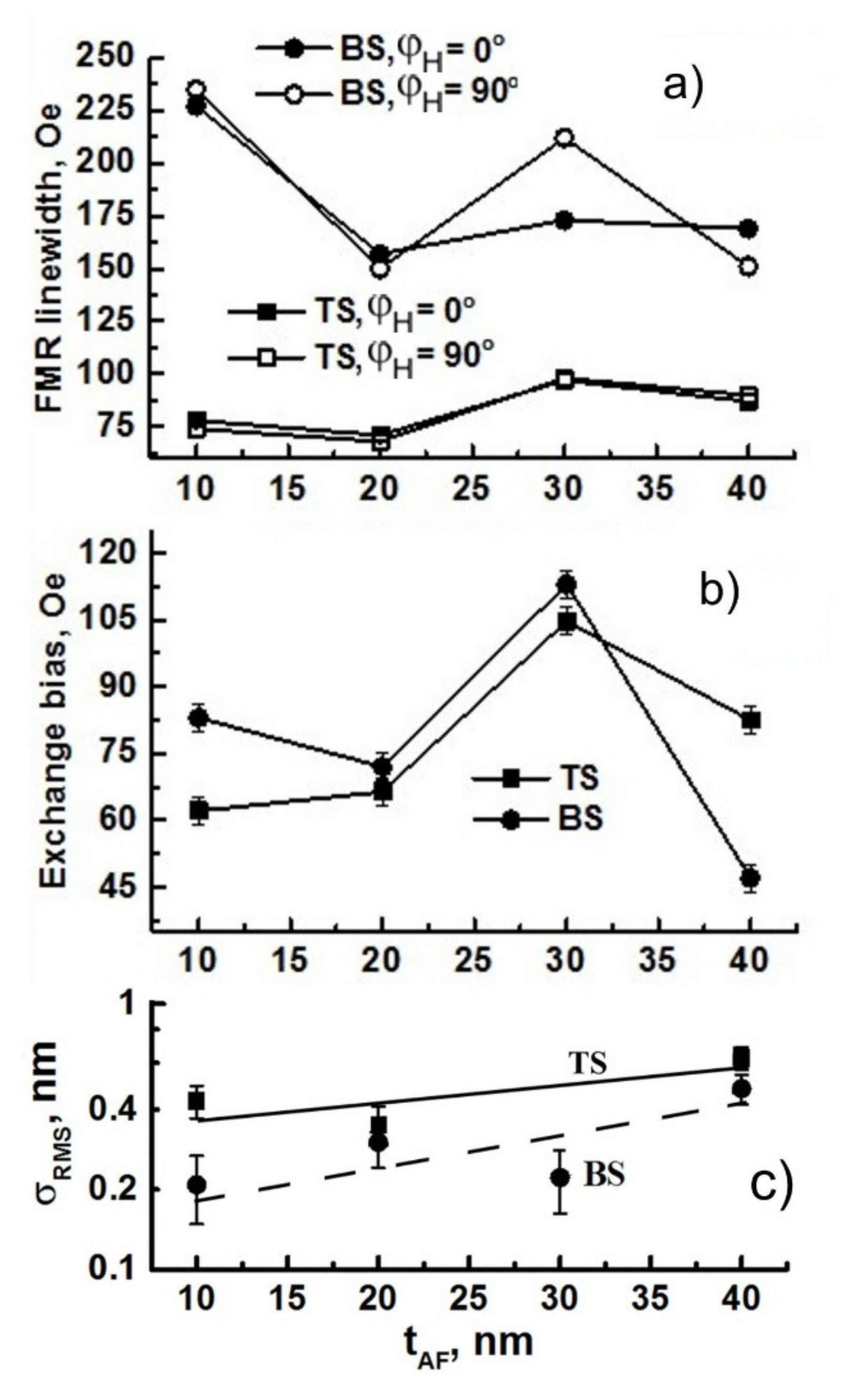

2.1. Analysis of Exchange Bias Effect on FMR LW

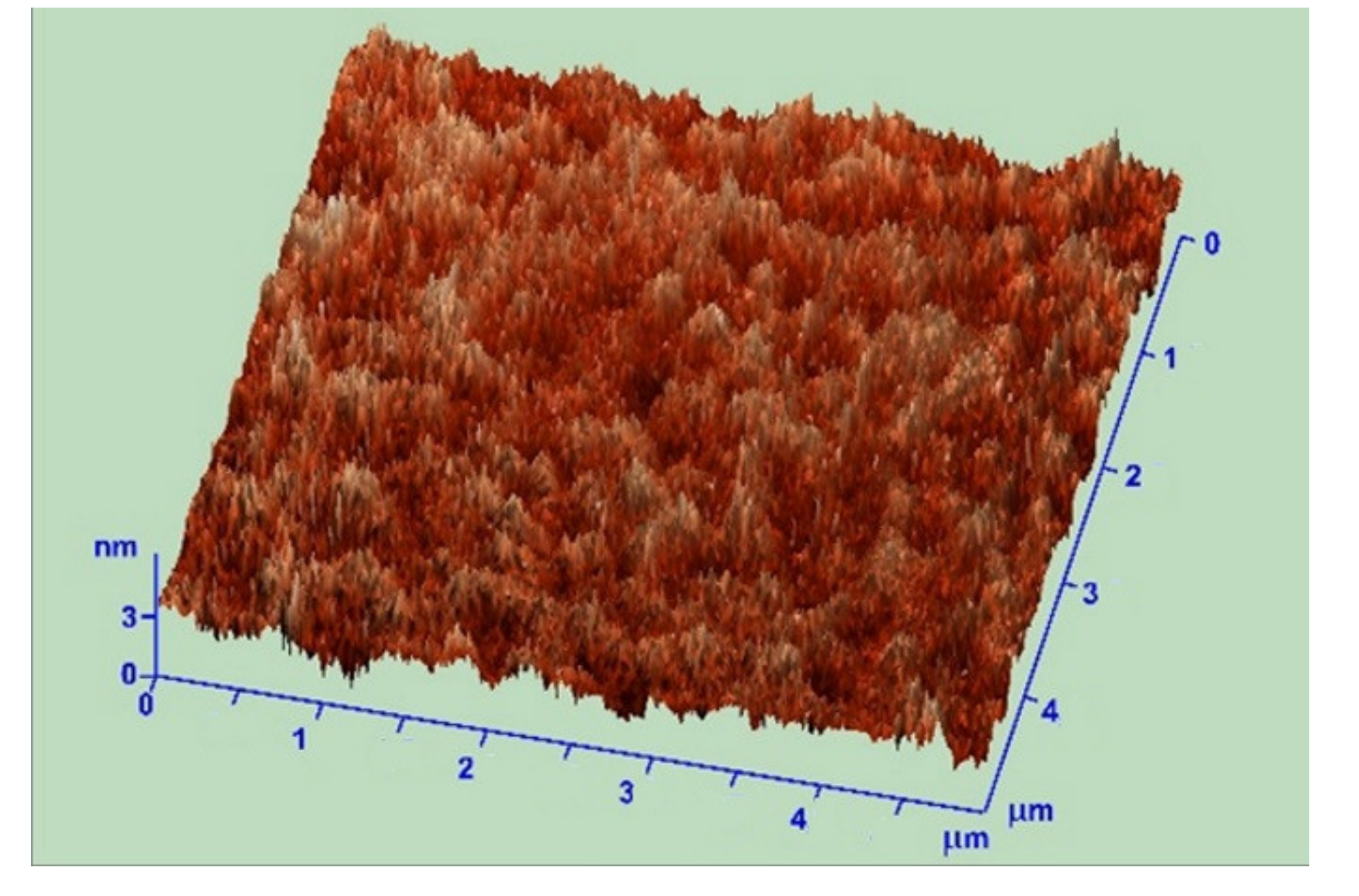

2.2. Roughness Effect on LW

2.3. Influence of Microstructure on FMR Damping

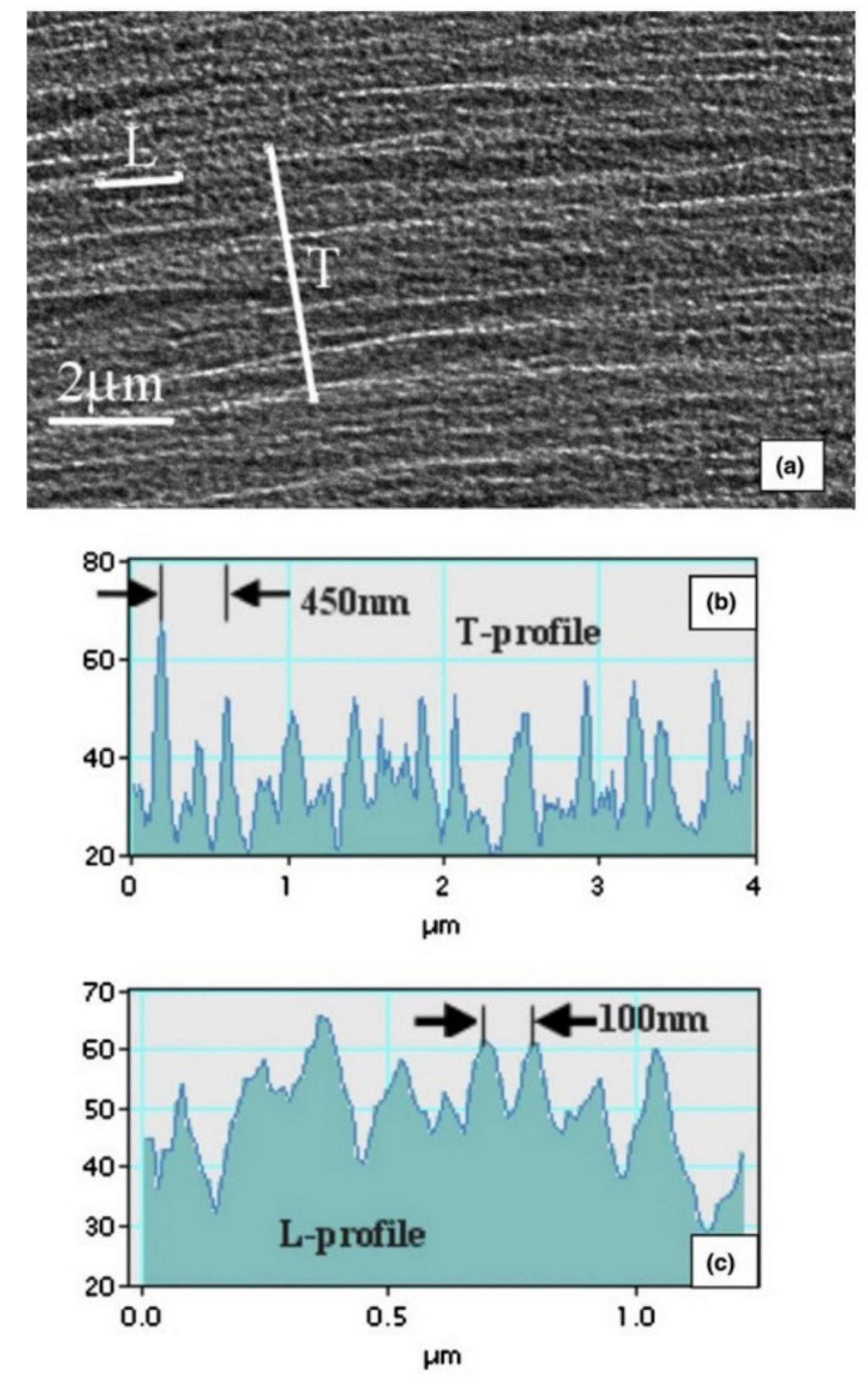

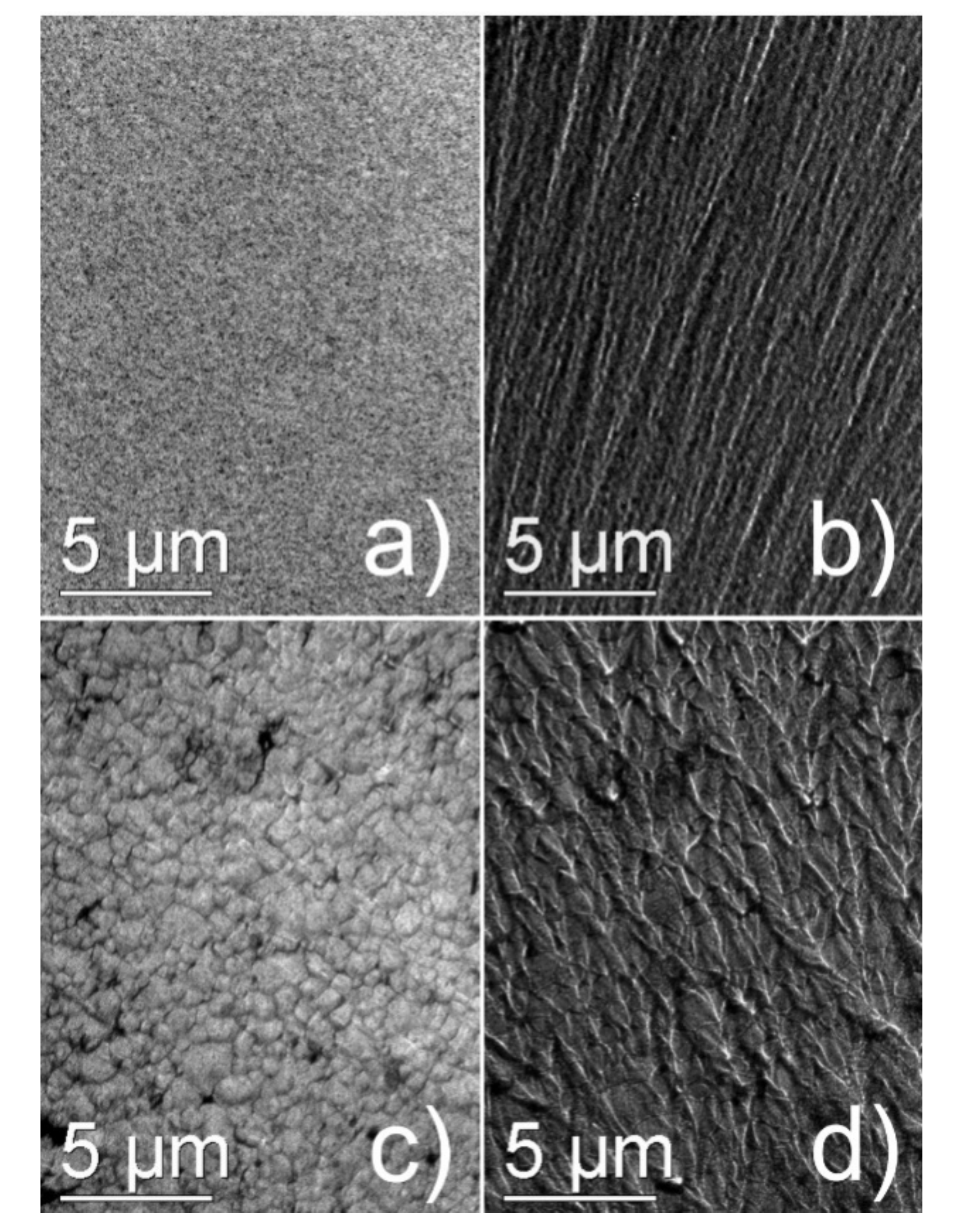

2.3.1. Microstructure and Micromagnetic Ripple

2.3.2. Stray Field Effect on FMR Line Position and Width

3. Conclusions

4. Materials and Methods

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Landau, L.; Lifshitz, E. On the theory of the dispersion of magnetic permeability in ferromagnetic bodies. Phys. Z. Sowjetunion 1935, 8, 153–166. [Google Scholar] [CrossRef]

- Gilbert, T.L. A Lagrangian formulation of the gyromagnetic equation of the magnetic field. Phys. Rev. 1995, 100, 1243. [Google Scholar]

- Dzhun, I.O.; Babaytsev, G.V.; Chechenin, N.G.; Gritsenko, C.A.; Rodionova, V.V. FMR investigations of exchange biased NiFe/IrMn/NiFe trilayers with high and low Ni relative content. JMMM 2019, 470, 151–155. [Google Scholar] [CrossRef]

- Smit, H.J.; Beljers, H.G. Ferromagnetic resonance absorbtion in BaFe12O19, a highly anisotropic crystall. Phillips. Res. Rep. 1955, 10, 113–130. [Google Scholar]

- Heinrich, B.; Cochran, J.F.; Hasegawa, R. FMR linebroadening in metals due to two-magnon scattering. J. Appl. Phys. 1985, 57, 3690–3692. [Google Scholar] [CrossRef]

- Celinski, Z.; Heinrich, B. Ferromagnetic resonance line width of Fe ultrathin films grown on a bcc-Cu substrate. J. Appl. Phys. 1991, 70, 5935–5937. [Google Scholar] [CrossRef]

- Kalarickal, S.S.; Krivosik, P.; Wu, M.; Patton, C.E.; Schneider, M.L.; Kabos, P.; Silva, T.J.; Nibarger, J.P. Ferromagnetic resonance linewidth in metallic thin films: Comparison of measurement methods. J. Appl. Phys. 2006, 99, 1–7. [Google Scholar] [CrossRef]

- Okumura, H.; Twisselmann, D.J.; McMichael, R.D.; Huang, M.J.; Hsu, Y.N.; Laughlin, D.E.; McHenry, M.E. Magnetic and structural characterization and ferromagnetic resonance study of thin film HITPERM soft magnetic materials for data storage, applications. J. Appl. Phys. 2003, 93, 6529–6530. [Google Scholar] [CrossRef]

- LeCraw, R.C.; Spencer, E.G.; Porter, C.S. Ferromagnetic resonance line widths in yttrium iron garnet. Phys. Rev. 1958, 110, 1311–1313. [Google Scholar] [CrossRef]

- Kuanr, B.K.; Camley, R.E.; Celinski, Z. Exchange bias of NiO/NiFe: Linewidth broadening and anomalous spin-wave damping. J. Appl. Phys. 2003, 93, 7723–7725. [Google Scholar] [CrossRef]

- Kuanr, B.K.; Camley, R.E.; Celinski, Z. Relaxation in epitaxial Fe films measured by ferromagnetic resonance. J. Appl. Phys. 2004, 95, 6610–6612. [Google Scholar] [CrossRef]

- Arias, R.; Mills, D.L. Extrinsic contributions to the ferromagnetic resonance response of ultrathin films. Phys. Rev. B 1999, 60, 7395–7409. [Google Scholar] [CrossRef]

- Dzhun, I.O.; Babaytsev, G.V.; Kozin, M.G.; Romashkina, I.L.; Shanova, E.I.; Chechenin, N.G. The effect of extrinsic factors on the line width of ferromagnetic resonance in structures with exchange bias. Fiz. Tverd. Tela 2021, 63, 693–698. (In Russian) [Google Scholar] [CrossRef]

- Speriosu, V.; Parkin, S.; Wilts, C. Standing spinwaves in FeMn/NiFe/FeMn exchange-bias structures. IEEE Trans. Magn. 1987, 23, 2999–3001. [Google Scholar] [CrossRef]

- Stoecklein, W.; Parkin, S.S.P.; Scott, J.C. Ferromagnetic resonance studies of exchange-biased Permalloy films. Phys. Rev. B 1988, 38, 6847–6853. [Google Scholar] [CrossRef]

- McMichael, R.D.; Stiles, M.D.; Chen, P.J.; Egelhoff, W.F. Ferromagnetic resonance line width in thin films coupled to NiO. J. Appl. Phys. 1998, 83, 7037–7039. [Google Scholar] [CrossRef]

- Sparks, M.; Loudon, R.; Kittel, C. Ferromagnetic Relaxation. I. Theory of the Relaxation of the Uniform Precession and the Degenerate Spectrum in Insulators at Low Temperatures. Phys. Rev. 1961, 122, 791–803. [Google Scholar] [CrossRef]

- Gurevich, A.G.; Melkov, G.A. Magnetization Oscillation and Waves; CRC Press, Inc: New York, NY, USA, 1996. [Google Scholar]

- Mills, D.L.; Rezende, S.M. Spin Dynamics in Confined Magnetic Structures II (Topics Appl. Phys., 87); Springer: Berlin/Heidelberg, Germany, 2003; pp. 27–59. [Google Scholar]

- Rezende, S.M.; Azevedo, A.; Lucena, M.A.; de Aguiar, F.M. Anomalous spin-wave damping in exchange-biased films. Phys. Rev. B 2001, 63, 214418. [Google Scholar] [CrossRef]

- Chechenin, N.G. Ultrasoft magnetic films: Micromagnetism and high-frequency properties. Microelectron. Eng. 2005, 81/2–4, 303–309. [Google Scholar] [CrossRef]

- Hoffmann, H. Magnetic properties of thin ferromagnetic films in relation to their structure. Thin Solid Film. 1979, 58, 223–233. [Google Scholar] [CrossRef]

- Herzer, G. Soft magnetic nanocrystalline materials. Scr. Metall. Mater. 1995, 33, 1741–1756. [Google Scholar] [CrossRef]

- Fuller, H.W.; Hale, M.E. Determination of Magnetization Distribution in Thin Films Using Electron Microscopy. J. Appl. Phys. 1960, 31, 238–348. [Google Scholar] [CrossRef]

- Wohlleben, D. Diffraction Effects in Lorentz Microscopy. J. Appl. Phys. 1967, 38, 3341–3352. [Google Scholar] [CrossRef]

- Chechenin, N.G.; Chezan, A.R.; Craus, C.B.; Vystavel, T.; Boerma, D.O.; De Hosson, J.; Niesen, L. Microstructure of nanocrystalline FeZr(N)-films and their soft magnetic properties. J. Magn. Magn. Mater 2002, 42–245 Pt 1, 180–182. [Google Scholar] [CrossRef][Green Version]

- Chechenin, N.G. Micromagnetism and high-frequency properties of soft magnetic films. J. Magn. Magn. Mater. 2006, 300, 198–201. [Google Scholar] [CrossRef]

- Chechenin, N.G.; Craus, C.B.; Chezan, A.; Vystavel, T.; Boerma, D.O.; De Hosson, J.; Niesen, L. Relation between observed micromagnetic ripple and FMR width in ultrasoft magnetic films. IEEE Trans. Magn. 2002, 38, 3027–3029. [Google Scholar] [CrossRef]

- Hoffmann, H. Quantitative calculation of the magnetic ripple of uniaxial thin permalloy films. J. Appl. Phys. 1964, 35, 1790–1798. [Google Scholar] [CrossRef]

- Hoffmann, H. Influence of local inhomogeneities on the magnetic properties of thin ferromagnetic films and nanostructures. Thin Solid Film. 1980, 373, 107–112. [Google Scholar] [CrossRef]

- Harte, K.J. Theory of magnetization ripple in ferromagnetic films. J. Appl. Phys. 1968, 39, 1503–1524. [Google Scholar] [CrossRef]

- Rother, H. Berechnung des Magnetisierungs-“Ripple” in ferromagnetischen dünnen Schichten. Z. Phys. 1964, 179, 229–232. [Google Scholar] [CrossRef]

- Hoffmann, H. Theory of Magnetization Ripple. IEEE Trans. Magn. 1968, 4, 32–38. [Google Scholar] [CrossRef]

- Yuan, L.; Jiang, J.; Di, Y.; Bie, S.; He, H. Micromagnetic simulation of the magnetic dispersion angle and effective damping factor for the single-phase soft magnetic films. J. Magn. Magn. Magn. 2008, 320, 1393–1397. [Google Scholar] [CrossRef]

- Izotov, A.V.; Belyaev, B.A.; Solovev, P.N.; Boev, N.M. Grain-size dependence of magnetic microstructure and high-frequency susceptibility of nanocrystalline thin films: A micromagnetic simulation study. J. Magn. Magn. Magn. 2021, 529, 167856. [Google Scholar] [CrossRef]

- Belyaev, B.A.; Boev, N.M.; Izotov, A.V.; Solovev, P.N. Study of peculiarities of the microwave absorption spectrum of nanocrystalline thin magnetic films. Russ. Phys. J. 2019, 61, 1798–1805. [Google Scholar] [CrossRef]

- Hoffmann, H. Stray fields in thin magnetic films. IEEE Trans. Magn. 1966, 2, 566–570. [Google Scholar] [CrossRef]

- Chechenin, N.G. Effect of Internal Stray Fields on the High-Frequency Properties of Magnetic thin Films. Phys. Solid State 2004, 46, 479–483. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chechenin, N.G.; Dzhun, I.O.; Babaytsev, G.V.; Kozin, M.G.; Makunin, A.V.; Romashkina, I.L. FMR Damping in Thin Films with Exchange Bias. Magnetochemistry 2021, 7, 70. https://doi.org/10.3390/magnetochemistry7050070

Chechenin NG, Dzhun IO, Babaytsev GV, Kozin MG, Makunin AV, Romashkina IL. FMR Damping in Thin Films with Exchange Bias. Magnetochemistry. 2021; 7(5):70. https://doi.org/10.3390/magnetochemistry7050070

Chicago/Turabian StyleChechenin, Nikolay G., Irina O. Dzhun, Georgy V. Babaytsev, Mikhail G. Kozin, Alexey V. Makunin, and Irina L. Romashkina. 2021. "FMR Damping in Thin Films with Exchange Bias" Magnetochemistry 7, no. 5: 70. https://doi.org/10.3390/magnetochemistry7050070

APA StyleChechenin, N. G., Dzhun, I. O., Babaytsev, G. V., Kozin, M. G., Makunin, A. V., & Romashkina, I. L. (2021). FMR Damping in Thin Films with Exchange Bias. Magnetochemistry, 7(5), 70. https://doi.org/10.3390/magnetochemistry7050070