Recent Advances of Colossal Magnetoresistance in Versatile La-Ca-Mn-O Material-Based Films

Abstract

1. Introduction

2. Structure, DE Mechanism, and J-T Distortion

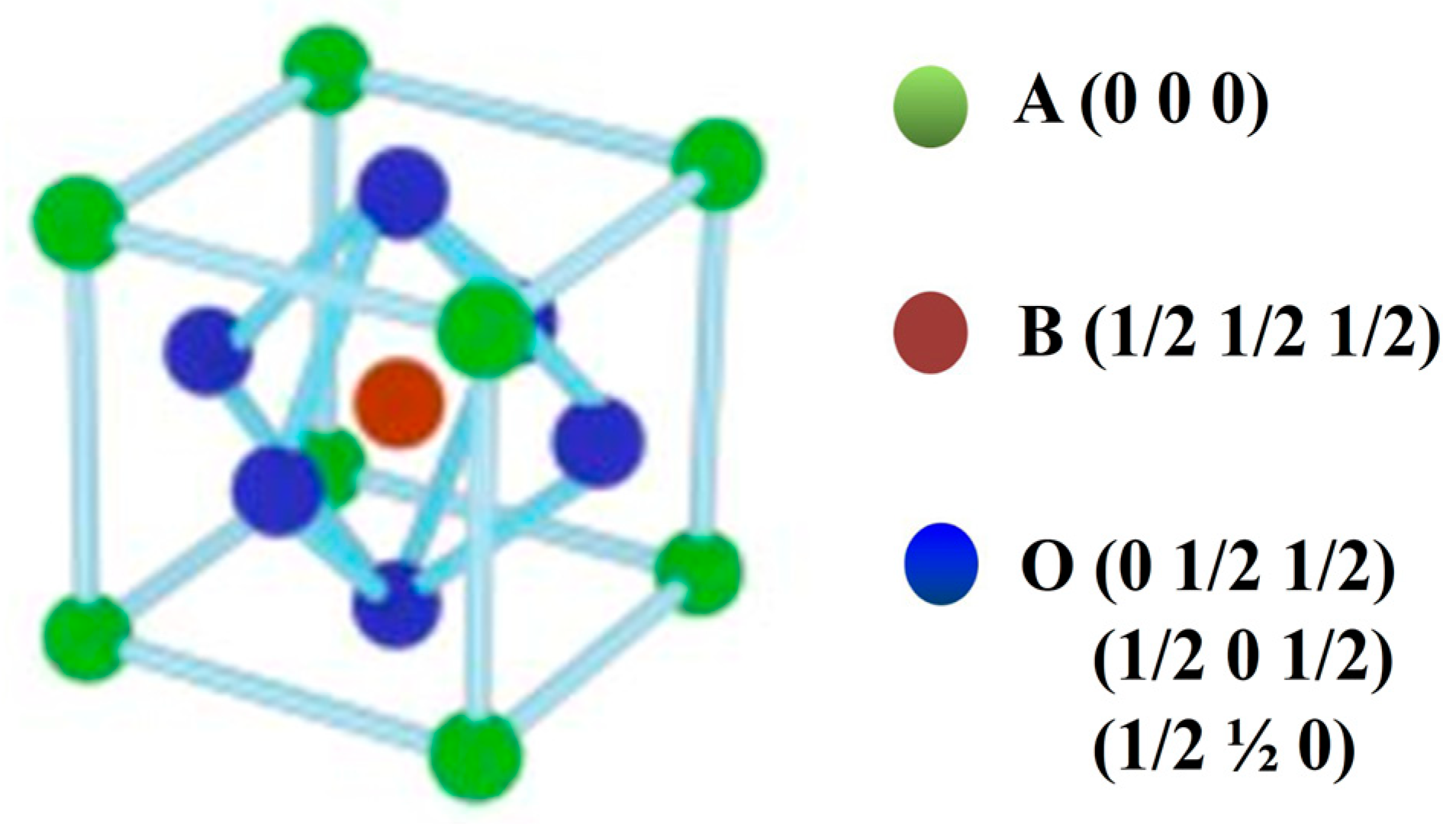

2.1. Crystallographic Structure

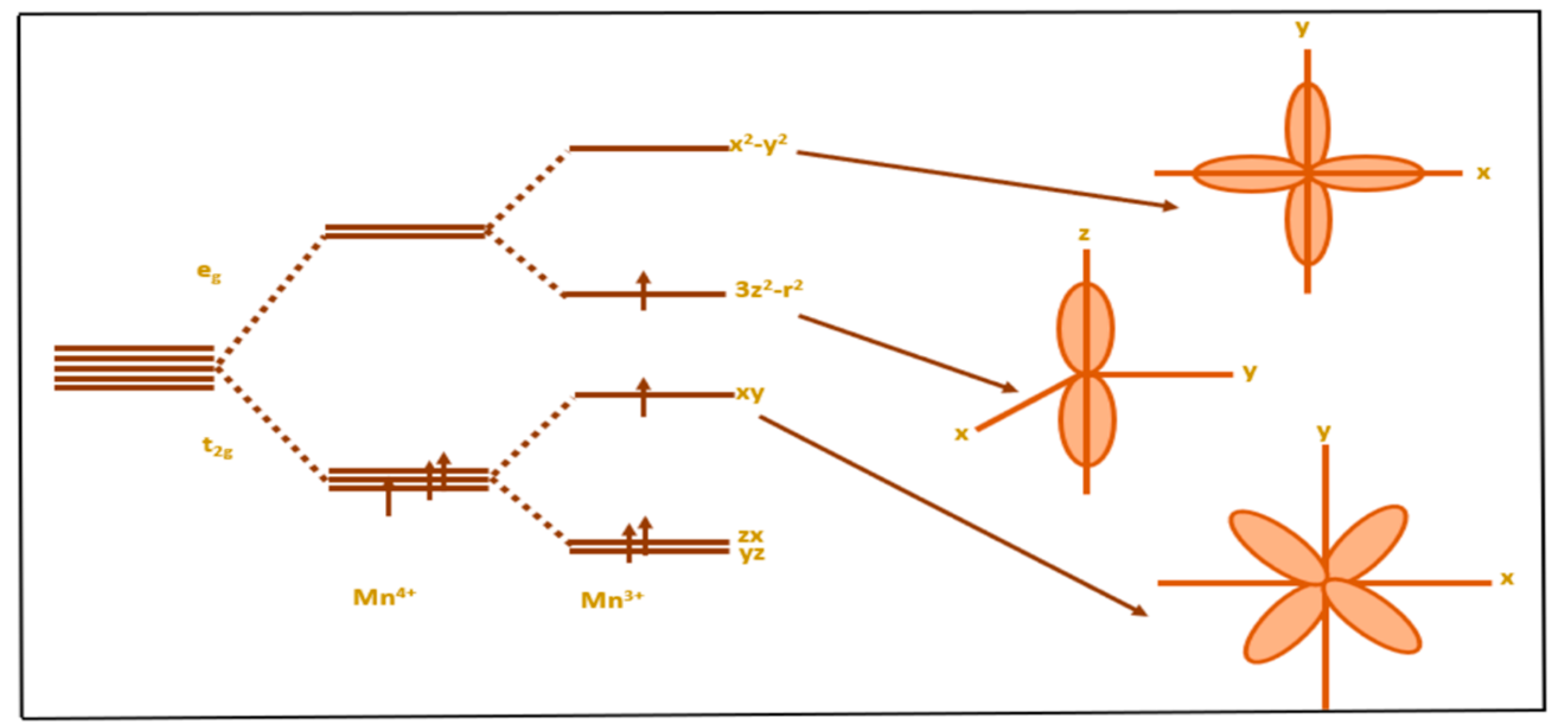

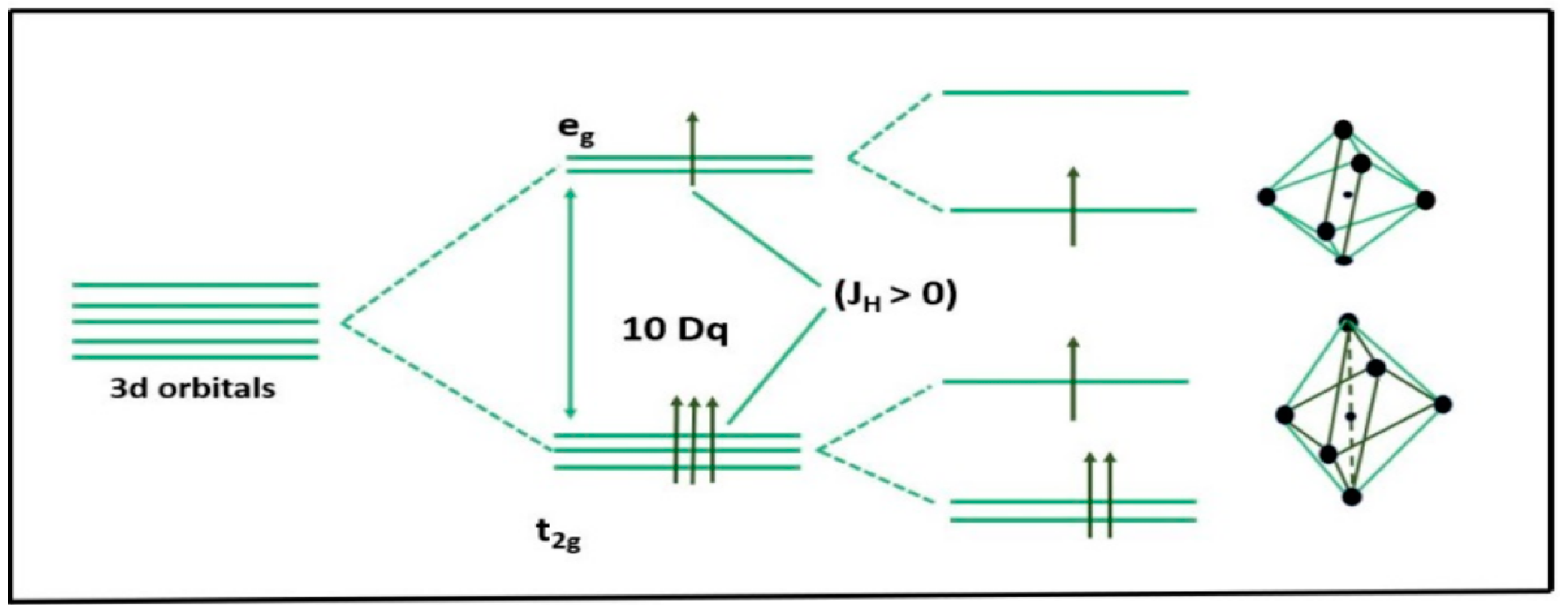

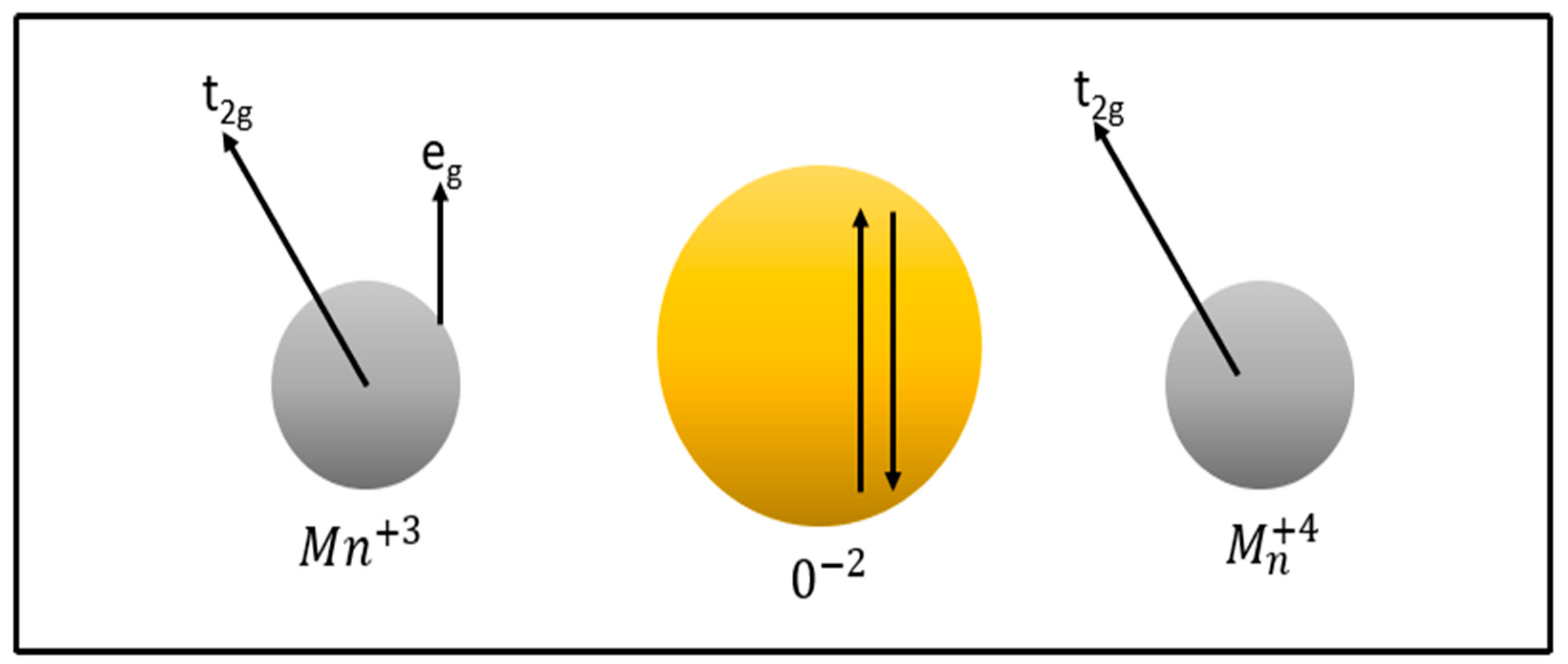

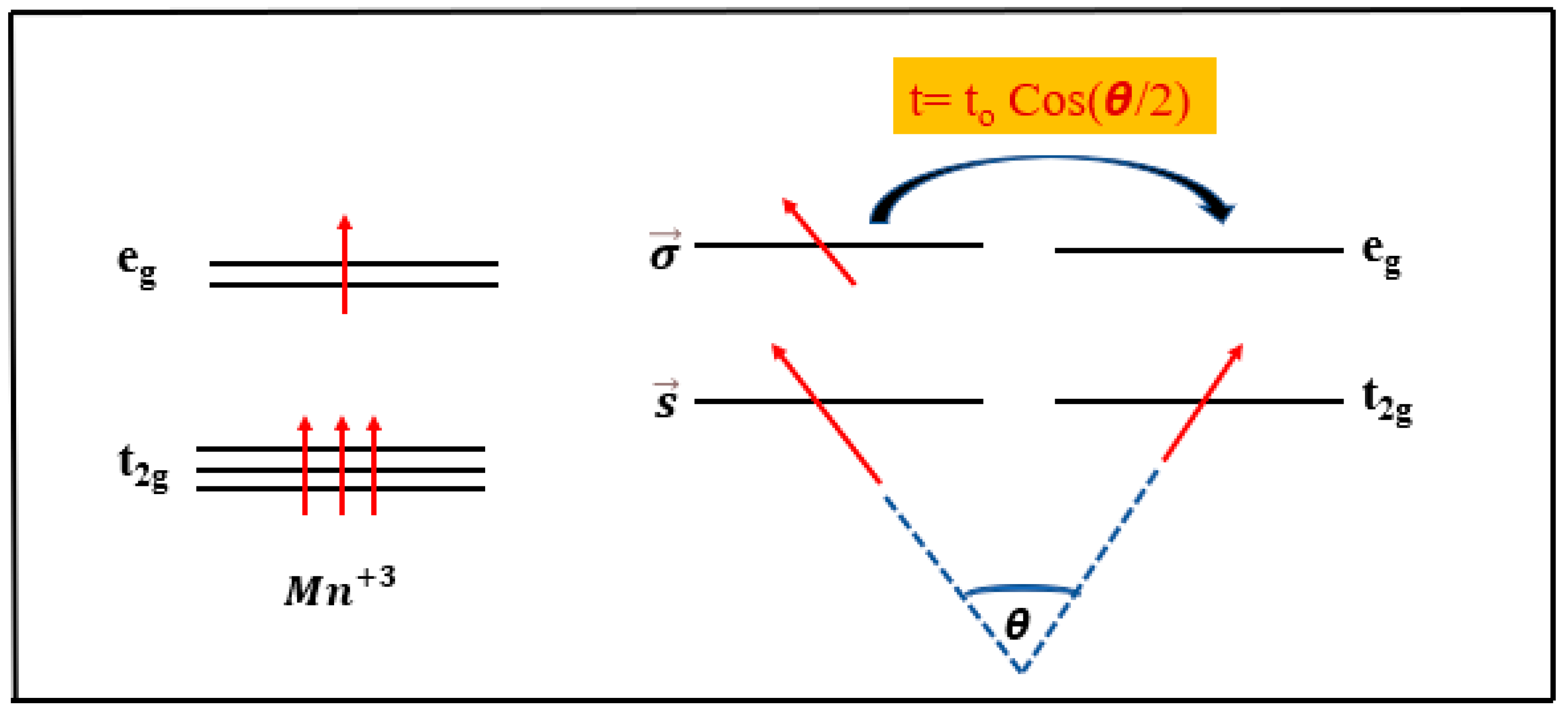

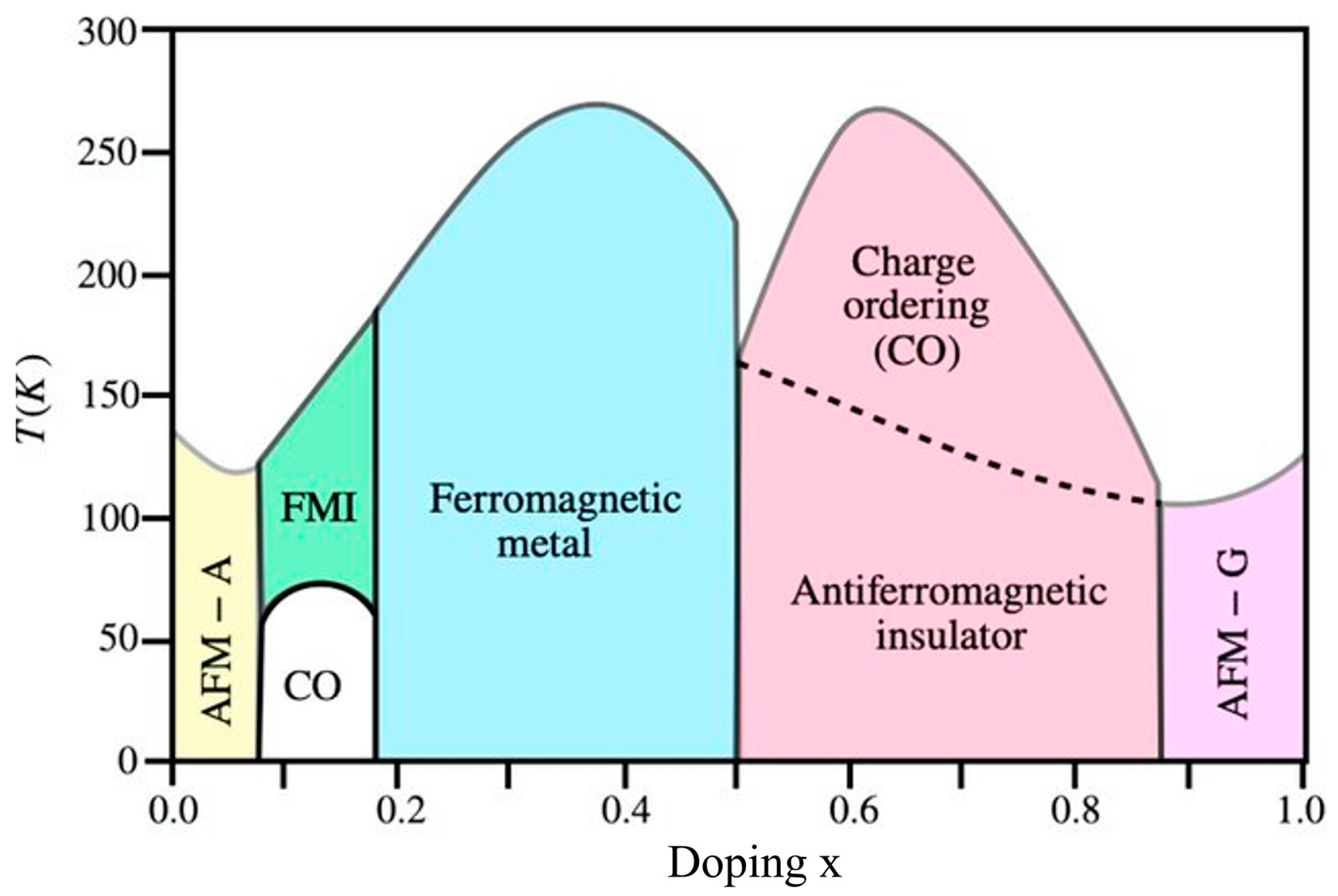

2.2. Crystallographic Structure and 3D-Orbitals of Mn4+ and Mn3+ Ions Determining the Magnetic Properties of LCMO

- Rotations of MnO6 octahedra around the cubic [101] or [010] directions;

- J-T distortion of octahedra;

- Distortions arising due to the presence of electrons in the degenerate eg orbital of the Mn3+ ion;

- Shifts in A-site atoms.

2.3. Electrical Transport/Resistivity

2.3.1. Insulating Region

- (i)

- Thermal activation law:

- (ii)

- The hopping of adiabatic polarons: this is also a causal factor for conduction in the insulator region.

- (iii)

- (a)

- The existence of a pseudo-gap at the Fermi level in the paramagnetic (P) phase.

- (b)

- Local lattice distortion accompanying the movement of charge carriers (J-T polaron).

- (c)

- Localization of charge carriers due to magnetic disorder.

2.3.2. Conduction Regime

2.3.3. Low-Field Magnetoresistance

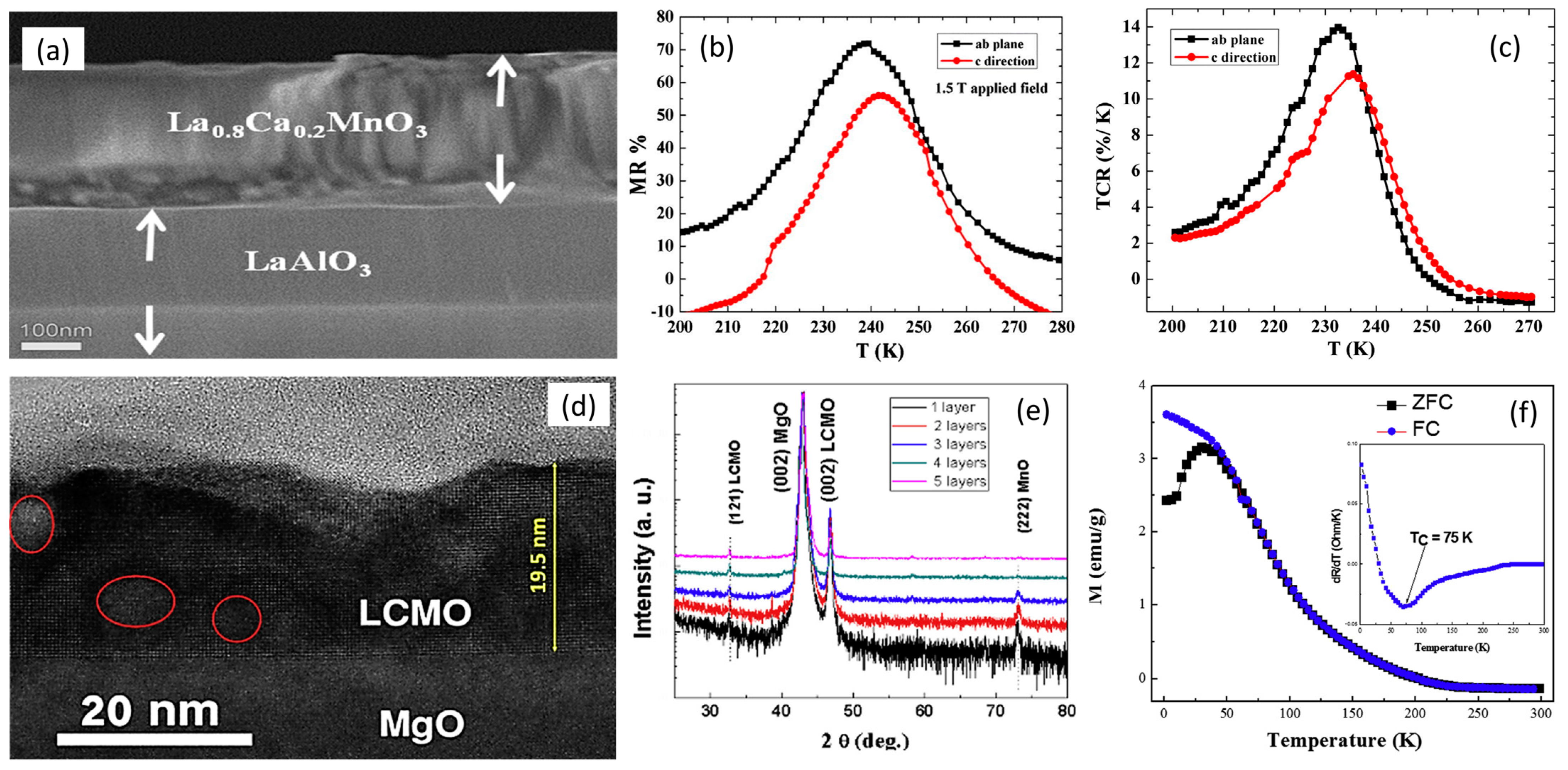

3. La-Ca-Mn-O Thin Films

- Dissimilarities in the film–substrate lattice spacing during epitaxial growth.

- Differences in thermal expansion coefficients between the film and substrate.

- Structural transformations due to additional stress in the film.

4. Early Findings

5. Applications of La-Ca-Mn-O Films

6. Conclusions and Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tokura, Y. Critical Features of Colossal Magnetoresistive Manganites. Rep. Prog. Phys. 2006, 69, 797. [Google Scholar] [CrossRef]

- Searle, C.W.; Wang, S.T. Studies of the Ionic Ferromagnet (LaPb)MnO3 III. Ferromagnetic resonance studies. Can. J. Phys. 1969, 47, 2023. [Google Scholar] [CrossRef]

- Kubo, K.; Ohata, N. A Quantum Theory of Double Exchange. I. J. Phys. Soc. Jpn. 1972, 33, 21–32. [Google Scholar] [CrossRef]

- Zener, C. Interaction Between the d-shells in the Transition Metals. II. Ferromagnetic Compounds of Manganese with Perovskite Structure. Phys. Rev. 1951, 82, 403. [Google Scholar] [CrossRef]

- Anderson, P.W.; Hasegawa, H. Considerations on Double Exchange. Phys. Rev. 1955, 100, 675. [Google Scholar] [CrossRef]

- Gennes, P.G.D. Effects of Double Exchange in Magnetic Crystals. Phys. Rev. 1960, 118, 141. [Google Scholar] [CrossRef]

- Salamon, M.B.; Jaime, M. The Physics of Manganites: Structure and Transport. Rev. Mod. Phys. 2001, 73, 583. [Google Scholar] [CrossRef]

- Dagotto, E.; Hotta, T.; Moreo, A. Colossal Magnetoresistant Materials: The Key Role of Phase Separation. Phys. Rep. 2001, 344, 1. [Google Scholar] [CrossRef]

- Izyumov, Y.A.; Skryabin, Y.N. Double Exchange Model and the Unique Properties of the Manganites. Phys. Usp. 2001, 44, 109. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Viret, M.; Molnar, S.V. Mixed-valence Manganites. Adv. Phys. 1999, 48, 167. [Google Scholar] [CrossRef]

- He, W.; Kong, L.; Zhao, W.; Yu, P. Atomically Thin 2D van der Waals Magnetic Materials: Fabrications, Structure, Magnetic Properties and Applications. Coatings 2022, 12, 122. [Google Scholar] [CrossRef]

- Assirey, E.A.R. Perovskite Synthesis, Properties and Their Related Biochemical and Industrial Application. Saudi Pharm. J. 2019, 27, 817. [Google Scholar] [CrossRef]

- Nagal, V.; Kumar, V.; Ahmad, R.; Khan, M.; Khan, Z.; Singh, K.; Furukawa, H.; Khosla, A.; Hahn, Y.B.; Hafiz, A.K. Emerging Applications of g-C3N4 Films in Perovskite-Based Solar Cells. ECS J. Solid State Sci. Technol. 2021, 10, 065001. [Google Scholar] [CrossRef]

- Wollan, E.O.; Koehler, W.C. Neutron Diffraction Study of the Magnetic Properties of the Series of Perovskite-Type Compounds [(1−x)La,xCa]MnO3. Phys. Rev. 1995, 100, 545. [Google Scholar] [CrossRef]

- Zener, C. Interaction Between the d Shells in the Transition Metals. Phys. Rev. 1951, 81, 440. [Google Scholar] [CrossRef]

- Trotsenko, V.G.; Lahmar, A.; Lyanguzov, N.V.; Marssi, M.E.; Torgashev, V.I. Phase Separation and Local Lattice Distortions Analysis of Charge-Ordered Manganese Films La1−xCaxMnO3− by Raman Spectroscopy. Superlattices Microstruc. 2019, 127, 100. [Google Scholar] [CrossRef]

- Sathpathy, A.; Popovic, Z.S.; Vukajlovic, F.R. Electronic Structure of the Perovskite Oxides: La1−xCaxMnO3. Phys. Rev. Lett. 1996, 76, 960. [Google Scholar] [CrossRef] [PubMed]

- Pickett, W.E.; Singh, D.J. Electronic Structure and Half-Metallic Transport in the La1−xCaxMnO3 System. Phys. Rev. B 1996, 53, 1146. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, M.; Zhang, W.; Ming, N. Spin-Disorder-Scattering-Induced Spectral-Weight Transfer and Pseudogap in Doped Perovskite LaMnO3. Phys. Rev. B 1997, 56, 14547. [Google Scholar] [CrossRef]

- Sing, D.J.; Pickett, W.E. Pseudogaps, Jahn-Teller Distortions, and Magnetic Order in Manganite Perovskites. Phys. Rev. B 1998, 57, 88. [Google Scholar] [CrossRef]

- Khomskii, D.I.; Streltsov, S.V. Magnetic oxides. In Encyclopedia of Condensed Matter Physics, 2nd ed.; Chakraborty, T., Ed.; Academic Press: Cambridge, MA, USA, 2024; pp. 98–111. [Google Scholar]

- Majumder, D.D.; Karan, S. Ceramic Nanocomposites: 2. Magnetic Properties of Ceramic Nanocomposites; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 51–91. [Google Scholar]

- Jonke, G.H.; Santen, J.H.V. Ferromagnetic Compounds of Manganese with Perovskite Structure. Physica 1950, 16, 337. [Google Scholar] [CrossRef]

- Ye, N.C.; Tsuei, C.C. Quasi-Two-Dimensional Phase Fluctuations in Bulk Superconducting YBa2Cu3O7 Single Crystals. Phys. Rev. B 1989, 39, 9708. [Google Scholar]

- Yan, S.S.; Liu, J.P.; Mei, L.M.; Tian, Y.F.; Song, H.Q.; Chen, Y.X.; Liu, G.L. Spin-Dependent Variable Range Hopping and Magnetoresistance in Ti1− xCoxO2 and Zn1−xCoxO Magnetic Semiconductor Films. J. Phys. Condens. Matter. 2006, 18, 10469. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Acevedo, M.C.; Liang, D.; Chew, K.S.; DeGrave, J.P.; Kaiser, N.S.; Jin, S. Synthesis, Characterization, and Variable Range Hopping Transport of Pyrite (FeS2) Nanorods, Nanobelts, and Nanoplates. ACS Nano 2013, 7, 1731. [Google Scholar] [CrossRef] [PubMed]

- Arya, V.P.; Prasad, V.; Kumar, P.A. Effect of Magnetic Field on Mott’s Variable-Range Hopping Parameters in Multiwall Carbon Nanotube Mat. J. Phys. Condens. Matter. 2012, 24, 245602. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Pourret, A.; Guyot-Sionnest, P. Mott and Efros-Shklovskii Variable Range Hopping in CdSe Quantum Dots Films. ACS Nano 2010, 4, 5211. [Google Scholar] [CrossRef]

- Medina, E.; Kardar, M.; Rangel, R. Magnetoconductance Anisotropy and Interference Effects in Variable-Range Hopping. Phys. Rev. B 1996, 53, 7663. [Google Scholar] [CrossRef]

- Rosenbaum, R. Crossover from Mott to Efros-Shklovskii Variable-Range-Hopping Conductivity in InxOy Films. Phys. Rev. B Condens. Matter. 1991, 44, 3599. [Google Scholar] [CrossRef]

- Jiang, J.; Guan, X.; Gu, X.; Han, J.; Wu, K.; Zhao, L.; Yan, Y.; Zhu, X.; Liu, X. Optimization of the Electrical Transport Properties of La0.7Ca0.3MnO3 Films by Sintering Temperature Adjustment. Ceram. Int. 2023, 49, 38174. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, X.; Wang, Y.; Jiang, J.; Wang, H.; Chen, Z.; Pan, Z.; Sun, J.; Ma, J.; Jiang, X.; et al. Improved Electrical Transport Properties of La0.8Ba0.2MnO3 Films via Suppressed Electron Scattering Behavior. Colloids Surf. A Physicochem. Eng. Asp. 2025, 704, 135566. [Google Scholar] [CrossRef]

- Wu, K.; Guan, X.; Li, H.; Gu, X.; Yu, Z.; Jin, S.; Yu, X.; Yan, Y.; Zhao, L.; Liu, H.; et al. Enhanced Electrical Transport Properties of Polycrystalline La0.67SrxCa0.23−xK0.1MnO3 Ceramics Through A-site Multielement Co-doping. Ceram. Int. 2023, 49, 1344. [Google Scholar] [CrossRef]

- Jithin, P.; Bitla, Y.; Patidar, M.M.; Ganesan, V.; Sankaran, K.J.; Kurian, J. Enhanced Magnetoresistance and Evolution of Griffiths-Like Phase in La1−xCaxMnO3 (x = 0.4, 0.5) Nanoparticles. J. Nanopart. Res. 2023, 25, 207. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, J.; Gu, X.; Han, J.; Liang, X.; Wang, Y.; Chen, Z.; Wang, H.; Liu, X. Large Temperature Coefficient of Resistivity (TCR) of La0.67Ca0.33MnO3 Polycrystalline Ceramics Improved by Optimizing Sintering Temperatures. Ceram. Int. 2024, 50, 10160. [Google Scholar] [CrossRef]

- Zhang, K.; Dai, J.; Zhu, X.; Zhu, X.; Zuo, X.; Zhang, P.; Hu, L.; Lu, W.; Song, W.; Sheng, Z.; et al. Vertical La0.7Ca0.3MnO3 Nanorods Tailored by High Magnetic Field Assisted Pulsed Laser Deposition. Sci. Rep. 2016, 6, 19483. [Google Scholar] [CrossRef] [PubMed]

- Fan, M.; Wang, H.; Misra, S.; Zhang, B.; Qi, Z.; Sun, X.; Huang, J.; Wang, H. Microstructure, Magnetic, and Magnetoresistance Properties of La0.7Sr0.3MnO3:CuO Nanocomposite Thin Films. ACS Appl. Mater. Interfaces 2018, 10, 5779. [Google Scholar] [CrossRef] [PubMed]

- Omar, S.; Kulkarni, S.B. Effect of Simultaneous Substitution of Sr and Ca in LaMnO3 Thin-Film Electrode Prepared via In Situ Sol-Gel Process. J. Mater. Sci. Mater. Electron. 2024, 35, 1542. [Google Scholar] [CrossRef]

- Yu, X.; Jin, S.; Guan, X.; Yan, Y.; Wu, K.; Zhao, L.; Liu, X. Large Temperature Coefficient of Resistivity (TCR) of La1−xCaxMnO3 Films Prepared by Spin-Coating Method. J. Alloys Compd. 2022, 890, 161788. [Google Scholar] [CrossRef]

- Chen, X.; Tao, B.; Zhao, R.; Yang, K.; Li, Z.; Xie, T.; Zhong, Y.; Zhang, T.; Xia, Y. Efficient Preparation of the Inclined La1−xCaxMnO3 Films with Excellent Light-Induced Transverse Thermoelectric Performance Based on MOCVD Process. Vacuum 2023, 208, 111695. [Google Scholar] [CrossRef]

- Dadhich, H.; Rajyaguru, B.; Gadani, K.; Goswami, H.; Rathod, V.R.; Shrimali, V.G.; Mukherjee, S.; Asokan, K.; Shah, N.A.; Solanki, P.S. Thermionic Emission Assisted Charge Conduction Mechanisms Across LaMnO3/La0.7Ca0.3MnO3 Interface of Manganite Thin Film Structure. Curr. Appl. Phy. 2023, 50, 1–12. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, J.; Liang, X.; Wang, Y.; Han, J.; Chen, Z.; Wang, H.; Pan, Z.; Sun, J.; Ma, J.; et al. Exploration of Electrical Conduction Mechanisms via Modulating Sintering Period of La0.67Ca0.33MnO3 Films in Various Phase Regions. Ceram. Int. 2024, 50, 55920. [Google Scholar] [CrossRef]

- Mohan, B.; Manral, P.; Rani, R.; Malik, V.K. Large Photoresistance and Photoinduced Magnetoresistance in La0.67Ca0.33MnO3 Thin Film on Silicon Substrate. J. Phys. D Appl. Phys. 2025, 58, 055302. [Google Scholar] [CrossRef]

- Rajyaguru, B.; Gohil, H.; Dadhich, H.; Gadani, K.; Shrimali, V.G.; Choudhary, R.J.; Phase, D.M.; Shah, N.A.; Solanki, P.S. Interface Based Field Effect Configuration and Charge Conduction Mechanisms for Manganite Thin Film Heterostructures. New J. Chem. 2023, 47, 13508. [Google Scholar] [CrossRef]

- Guo, J.; He, B.; Han, Y.; Liu, H.; Han, J.; Ma, X.; Wang, J.; Gao, W.; Lü, W. Resurrected and Tunable Conductivity and Ferromagnetism in the Secondary Growth La0.7Ca0.3MnO3 on Transferred SrTiO3 Membranes. Nano Lett. 2024, 24, 1114. [Google Scholar] [CrossRef]

- Purnakanti, A.; Lakshmi, Y.K.; Kumar, S.; Venkatesh, R.; Reddy, M.S. Grain Boundary Modification in La0.67Ca0.33MnO3 Manganites with Additives: Impact on Magneto-Transport Properties. Appl. Phys. A 2023, 129, 706. [Google Scholar] [CrossRef]

- Hua, W.; Lu, L.; Shen, L.; Jin, J.; Wang, H.; Liu, M.; Ma, C.; Jia, C.L. Modulating the Transport Property of Flexible La0.67Ca0.33MnO3 Thin Film by Mechanical Bending. Appl. Phys. Lett. 2021, 118, 052404. [Google Scholar] [CrossRef]

- Salas-Colera, E.; Muñoz-Noval, A.; Sebastiani-Tofano, E.; Castro, G.R.; Rubio-Zuazo, J. Tuning the Metal-Insulator Transition Temperature by the Controlled Generation of Oxygen Vacancies on La0.7Ca0.3MnO3−x Epitaxial Thin Films. J. Alloys Compd. 2024, 989, 174321. [Google Scholar] [CrossRef]

- Hoang, V.H.; Kim, H.J. Nonohmic Behaviors and Charge-Ordering Phenomena of La0.7Ca0.3MnO3 Sandwiched by CaMnO3 Layers. ACS Appl. Electron. Mater. 2024, 6, 6949. [Google Scholar]

- Yan, L.; Balasubramaniam, K.R.; Wang, S.; Du, H.; Salvador, P.A. Effects of Crystallographic Orientation on the Oxygen Exchange Rate of La0.7Sr0.3MnO3 Thin Films. Solid State Ion. 2011, 194, 9. [Google Scholar] [CrossRef]

- Li, S.; Wang, C.; Shen, Q.; Zhang, L. Substrate-Induced Strain Effect on Magnetic and Electrical Transport Properties of La0·67Ca0·33MnO3 Thin Films with Varying Orientation. Vacuum 2019, 164, 312. [Google Scholar] [CrossRef]

- Rao, R.A.; Lavric, D.; Nath, T.K.; Eom, C.B.; Wu, L.; Tsui, F. Three-Dimensional Strain States and Crystallographic Domain Structures of Epitaxial Colossal Magnetoresistive La0.8Ca0.2MnO3 Thin Films. Appl. Phys. Lett. 1998, 73, 3294. [Google Scholar] [CrossRef]

- Chen, X.J.; Soltan, S.; Zhang, H.; Habermeier, H.U. Strain Effect on Electronic Transport and Ferromagnetic Transition Temperature in La0.9Sr0.1MnO3 Thin Films. Phys. Rev. B 2002, 65, 174402. [Google Scholar] [CrossRef]

- Yeh, N.C.; Vasquez, R.P.; Beam, D.A.; Fu, C.C.; Huynhm, J.; Beach, G. Effects of Lattice Distortion and Jahn-Teller Coupling on the Magnetoresistance of and Epitaxial Films. J. Phys. Condens. Matter. 1997, 9, 3713. [Google Scholar] [CrossRef]

- Yeh, N.C.; Fu, C.C.; Wei, J.Y.T.; Vasquez, R.P.; Huynh, J.; Maurer, S.M.; Beach, G.; Beam, D.A. Effects of Lattice Distortion on the Physical Properties and Surface Morphology of Magnetoresistive Perovskite Epitaxial Films. J. Appl. Phys. 1997, 81, 5499. [Google Scholar] [CrossRef]

- Zarifi, M.; Kameli, P.; Ehsani, M.H.; Ahmadvand, H.; Salamati, H. Effects of Strain on the Magnetic and Transport Properties of the Epitaxial La0.5Ca0.5MnO3 Thin Films. J. Magn. Magn. Mater. 2016, 420, 33. [Google Scholar] [CrossRef]

- Koo, T.Y.; Park, S.H.; Lee, K.B.; Yeong, Y.H. Anisotropic Strains and Magnetoresistance of La0.7Ca0.3MnO3. Appl. Phys. Lett. 1977, 71, 977. [Google Scholar] [CrossRef]

- Haghiri-Gosnet, A.M.; Renard, J.P. CMR Manganites: Physics, Thin Films and Devices. J. Phys. D Appl. Phys. 2003, 36, R127. [Google Scholar] [CrossRef]

- Jaime, M.; Lin, P.; Chun, S.H.; Salamon, M.B.; Dorsey, D.; Rubinstein, M. Coexistence of Localized and Itinerant Carriers near TC in Calcium-Doped Manganites. Phys. Rev. B 1999, 60, 1028. [Google Scholar] [CrossRef]

- Verhage, M.; Minne, E.V.D.; Kiens, E.M.; Korol, L.; Spiteri, R.J.; Koster, G.; Green, R.J.; Baeumer, C.; Flipse, C.F.J. Electronic and Structural Disorder of the Epitaxial La0.67Sr0.33MnO3 Surface. ACS Appl. Mater. Interfaces 2024, 16, 21273. [Google Scholar] [CrossRef]

- Cao, D.; Zhang, Y.; Dong, W.; Yang, J.; Bai, W.; Chen, Y.; Tang, X. Structure, Magnetic and Transport Properties of La0.7Ca0.3−xSrxMnO3 Thin Films by Sol–Gel Method. Ceram. Int. 2015, 41, 381. [Google Scholar] [CrossRef]

- Mikailzade, F.; Onal, F.; Maksutoglu, M.; Zarbali, M.; Goktas, A. Structure and Magnetization of Polycrystalline La0.66Ca0.33MnO3 and La0.66Ba0.33MnO3 Films Prepared Using Sol-Gel Technique. J. Supercond. Nov. Magn. 2018, 31, 4141. [Google Scholar] [CrossRef]

- Wu, X.S.; Cai, H.L.; Xu, J.; Tan, W.S.; Hu, A.; Jiang, S.S.; Hase, T.P.A.; Tanner, B.K.; Xiong, G. Substrate and Thickness Effects on Structure and Transport Properties of La2/3Ca1/3MnO3 Films. J. Appl. Phys. 2004, 95, 7109. [Google Scholar] [CrossRef]

- Lau, L.N.; Hon, X.T.; Wong, Y.J.; Lim, K.P.; Kamis, N.H.; Awang Kechik, M.M.; Chen, S.K.; Ibrahim, N.B.; Shabdin, M.K.; Miryala, M.; et al. Wide temperature range magnetoresistance enhancement of La0.67Ca0.33MnO3: NiO nanocomposites. Appl. Phys. A 2023, 129, 297. [Google Scholar] [CrossRef]

- Boora, N.; Sharma, P.; Alam, A.; Rahman, S.; Ahmad, R.; Awana, V.P.S.; Hafiz, A.K. Impact of NiO Nano-particles on Colossal Magneto-Resistance of La0.70Ca0.30MnO3 composite. Mater. Lett. X 2022, 14, 100147. [Google Scholar] [CrossRef]

- Srivastava, P.; Singh, A.K.; Tyagi, U.P.; Singh, J.; Srivastava, A. Enhanced Magnetotransport Properties of Ag-doped La0.7Ca0.3−xAgxMnO3 Polycrystalline Ceramics. J. Electron. Mater. 2023, 52, 6425. [Google Scholar] [CrossRef]

- Wang, S.; Hou, R.; Tian, L.; Zhang, H.; Li, Y. Qingming Chen, Enhanced TCR and MR by Grain Boundary Modification and Phase Competition in La0.67Ca0.33MnO3: Aux (x = 0, 0.05, 0.1, 0.15) Composite Ceramics. Ceram. Int. 2024, 50, 2443. [Google Scholar] [CrossRef]

- Dhungana, S.; Casey, J.; Neupane, D.; Pathak, A.K.; Karna, S.; Mishra, S.R. Effect of Metal-Oxide Phase on the Magnetic and Magnetocaloric Properties of La0.7Ca0.3MnO3-MO (MO=CuO, CoO, and NiO) Composite. Magnetochemistry 2022, 8, 163. [Google Scholar] [CrossRef]

- Jin, F.; Wu, D.; Lu, Y.; Pan, Z.; Gu, M.; Wang, H. La0.7Ca0.3MnO3−δ:Ag Nanocomposite Thin Films with Large Temperature Coefficient of Resistance (TCR). J. Mater. 2022, 8, 799. [Google Scholar]

- Venkateshwarlu, D.; Dadhich, H.; Rajyaguru, B.; Hans, S.; Ranjan, M.; Venkatesh, R.; Ganesan, V.; Solanki, P.S.; Shah, N.A. Semiconducting Nature and Magnetoresistance Behaviour of ZnO/La0.3Ca0.7MnO3/SrTiO3 heterostructures. Mater. Sci. Semicond. Process. 2021, 136, 106154. [Google Scholar] [CrossRef]

- Adigamova, M.V.; Malyshev, I.V.; Lukiyanchuk, I.V.; Tkachenko, I.A.; Vyaliy, I.E.; Egorkin, V.S. Magnetism of Al2O3 Matrix Containing La0.5Ca0.5MnO3 Particles. J. Alloys Compd. 2024, 1004, 175875. [Google Scholar] [CrossRef]

- Kandoliya, M.; Rajyaguru, B.; Gadani, K.; Vaghela, N.; Dadhich, H.; Venkateshwarlu, D.; Joshi, A.D.; Shah, N.A.; Solanki, P.S. Electric Field Effects on Charge Conduction for LaMnO3 Controlled La0.7Ca0.3MnO3 Manganite. Surf. Interfaces 2022, 30, 101949. [Google Scholar] [CrossRef]

- Lau, L.N.; Lim, K.P.; Ngai, L.M.; Ishak, A.N.; Awang Kechik, M.M.; Chen, S.K.; Ibrahim, N.B.; Shaari, A.H. Influence of Al2O3 on the Low-Field Magnetoresistance of Sol-Gel Grown La0.67Ca0.33MnO3:Al2O3 Nanocomposites. Appl. Phys. A 2020, 126, 730. [Google Scholar] [CrossRef]

- Lau, L.N.; Lim, K.P.; Chok, S.Y.; Ishak, A.N.; Hon, X.T.; Wong, Y.J.; Awang Kechik, M.M.; Chen, S.K.; Ibrahim, N.B.; Miryala, M.; et al. Effect of NiO Nanoparticle Addition on the Structural, Microstructural, Magnetic, Electrical, and Magneto-Transport Properties of La0.67Ca0.33MnO3 Nanocomposites. Coatings 2021, 11, 835. [Google Scholar] [CrossRef]

- Lau, L.N.; Pah, L.K.; Kechik, M.M.A.; Chen, S.K.; Ibrahim, N.B.; Halim, S.A.; Lai, S.Y. Structural, Magnetic and Magnetotransport Properties of Sol-Gel Synthesized La0.67Ca0.33MnO3:TiO2 Nanocomposite. Solid State Phenom. 2020, 307, 9. [Google Scholar] [CrossRef]

- Boora, N.; Rani, P.; Nagal, V.; Rahman, S.; Awana, V.P.S.; Hafiz, A.K. Synthesis and Characterization of LCMO Composite and Fabrication of Its Thin Films by RF Magnetron Sputtering for Room-Temperature Applications. AIP Conf. Proc. 2020, 2276, 020047. [Google Scholar]

- Boora, N.; Ahmad, R.; Rani, P.; Maheshwari, P.K.; Khosla, A.; Bansal, S.; Awana, V.P.S.; Hafiz, A.K. Room Temperature Synthesis of Colossal Magneto-Resistance of La2/3Ca1/3MnO3:Ag0.10 Composite. ECS J. Solid State Sci. Technol. 2021, 10, 027006. [Google Scholar] [CrossRef]

- Tselev, A.; Vasudevan, R.K.; Kalinin, S.V.; Baddorf, A.P. Effect of Silver Doping on the Surface of La5/8Ca3/8MnO3 Epitaxial Films. Appl. Phys. Lett. 2014, 105, 106102. [Google Scholar] [CrossRef]

- Awana, V.P.S.; Tripathi, R.; Balamurugan, S.; Kishan, H.; Takayama-Muromachi, E. Magneto-Transport of High TCR (Temperature Coefficient of Resistance) La2/3Ca1/3MnO3:Ag Polycrystalline Composites. Solid State Commun. 2006, 140, 410. [Google Scholar] [CrossRef][Green Version]

- Awana, V.P.S.; Tripathi, R.; Kumar, N.; Kishan, H.; Bhalla, G.L.; Zeng, R.; Chandra, L.S.S.; Ganesan, V.; Habermeier, H.U. Magnetotransport of La0.70Ca0.3−xSrxMnO3(Ag): A Potential Room Temperature Bolometer and Magnetic Sensor. J. Appl. Phys. 2010, 107, 2331. [Google Scholar] [CrossRef]

- Tripathi, R.; Awana, V.P.S.; Balamurugan, S.; Kotnala, R.K.; Kishore, R.; Kishan, H.; Takayama-Muromachi, E. Inter Comparison of the Magneto Transport of La2/3Ca1/3MnO3:Ag/In Polycrystalline Composites. IEEE Transcations Magn. 2007, 43, 3055. [Google Scholar] [CrossRef]

- Jha, R.; Singh, S.K.; Kumar, A.; Awana, V.P.S. Room Temperature Magnetic Entropy Change and Magnetoresistance in La0.70(Ca0.30−xSrx)MnO3:Ag 10%(x = 0.0 − 0.10). J. Magn. Magn. Mater. 2012, 2853, 2849. [Google Scholar] [CrossRef]

- Ramadhan, M.R.; Kurniawan, B.; Manaf, A.; Pratama, R.; Nanto, D.; Saptari, S.A.; Imaduddin, A. Sintering Temperature Effect on Electric Transport Properties and Magnetoresistance of La0.67Ca0.33MnO3. AIP Conf. Proc. 2016, 1729, 020025. [Google Scholar]

- Zhang, N.; Ding, W.; Zhong, W.; Xing, D.; Du, Y. Tunnel-Type Giant Magnetoresistance in the Granular Perovskite La0.85Sr0.15MnO3. Phys. Rev. B 1997, 56, 8138. [Google Scholar] [CrossRef]

- Siwach, P.K.; Awana, V.P.S.; Kishan, H.; Prasad, R.; Singh, H.K.; Balamurugan, S.; Takama-Muromachi, E.; Srivastava, O.N. Room Temperature Magneto-Resistance and Temperature Coefficient of Resistance in La0.7Ca0.3−xAgxMnO3 Thin Films. J. Appl. Phys. 2007, 101, 073912. [Google Scholar] [CrossRef]

- Kuru, Y.; Habermeier, H.U.; Tripathi, R.; Awana, V.P.S.; Kishan, H. Room Temperature Magnetoresistance of La0.7Ca0.2Ba0.1MnO3/Ag Thin Films. Phys. Status Solidi Appl. 2010, 207, 1485. [Google Scholar]

- Zhang, K.; Dai, J.; Zhu, X.; Zhu, S.; Yin, L.; Tang, X.; Sun, Y. Vertically Aligned Nanostructure Control and Tunable Low-Field Magnetoresistance in La0.5Ca0.5MnO3 Single-Phase Thin Films Manipulated by a High Magnetic Field. Appl. Phys. Lett. 2020, 116, 053103. [Google Scholar] [CrossRef]

- Debnath, J.C.; Strydom, A.M. Large Low Field Magneto-Resistance and Temperature Coefficient of Resistance in La0.8Ca0.2MnO3 Epitaxial Thin Film. J. Alloys Compd. 2015, 621, 7. [Google Scholar] [CrossRef]

- Daoudi, K.; El-Helali, S.; Othmen, Z.; Suleiman, B.M.; Tsuchiya, T. Microstructure and Electrical Transport Mechanisms of the Ca-doped LaMnO3 Films Grown on MgO Substrate. J. Materio. 2020, 6, 17. [Google Scholar] [CrossRef]

- Yotsuya, T.; Kusaka, T.; Kakehi, Y.; Ogawa, S. Optical Response of LaCaMnO Thin Film Prepared by Pulsed Laser Deposition. Mater. Chem. Phys. 1998, 54, 169. [Google Scholar] [CrossRef]

- Zhou, M.; Li, Y.; Jeon, I.; Yi, Q.; Zhu, X.; Tang, X.; Wang, H.; Fei, L.; Sun, Y.; Deng, S.; et al. Enhancement of Low-field Magnetoresistance in Self-Assembled Epitaxial La0.67Ca0.33MnO3:NiO and La0.67Ca0.33MnO3:Co3O4 Composite Films via Polymer-Assisted Deposition. Sci. Rep. 2016, 6, 26390. [Google Scholar] [CrossRef] [PubMed]

- Hao, J.H.; Mao, X.; Chen, C.H.; Lu, D.X. Room Temperature Bolometric Applications Using Manganese Oxide Thin Films. Int. J. Infrared Millim. Waves 1999, 20, 2113. [Google Scholar] [CrossRef]

- Kumari, K.; Kumar, A.; Thakur, A.D.; Ray, S.J. Effect of Temperature and Magnetic Field in Resistive Switching Behavior of La0.7Ca0.3MnO3.rGO Nano-composite. AIP Conf. Proc. 2020, 2220, 080007. [Google Scholar]

- Rajeswari, M.; Chen, C.H.; Goyal, A.; Kwon, C.; Robson, M.C.; Ramesh, R.; Venkatesan, T. Low-Frequency Optical Response in Epitaxial Thin Films of La0.67Ca0.33MnO3 Exhibiting Colossal Magnetoresistance. Appl. Phys. Lett. 1996, 68, 3555. [Google Scholar] [CrossRef]

- Goyal, A.; Rajeswari, M.; Shreekala, R.; Lofland, S.E.; Bhagat, S.M.; Boettcher, T.; Kwon, C.; Ramesh, R.; Venkatesan, T. Material Characteristics of Perovskite Manganese Oxide Thin Films for Bolometric Applications. Appl. Phys. Lett. 1997, 71, 2535. [Google Scholar] [CrossRef]

- Gregg, J.F.; Petej, I.; Jouguelet, E.; Dennis, C. Spin Electronics-A Review. J. Phys. D Appl. Phys. 2002, 35, R121. [Google Scholar] [CrossRef]

- Park, J.H.; Vescovo, E.; Kwon, H.J.; Ramesh, R.; Venkatesan, T. Direct Evidence for a Half-Metallic Ferromagnet. Nature 1998, 392, 794. [Google Scholar] [CrossRef]

- Lan, D.; Chen, B.; Qu, L.; Zhang, K.; Xu, L.; Jin, F.; Guo, Z.; Chen, F.; Gao, G.; Wu, W. Tuning Antiferromagnetic Interlayer Exchange Coupling in La0.67Ca0.33MnO3-Based Synthetic Antiferromagnets. APL Mater. 2019, 7, 031119. [Google Scholar] [CrossRef]

- Wibowo, N.A.; Juharni, J.; Sabarman, H.; Suharyadi, E. A Spin-Valve GMR Based Sensor with Magnetite@silver Core-Shell Nanoparticles as a Tag for Bovine Serum Albumin Detection. ECS J. Solid State Sci. Technol. 2021, 10, 107002. [Google Scholar] [CrossRef]

- Rajeswari, G.; Prabavathi, N.; Prakasam, A.; Kumar, R.; Geetha, S.; Tamizhdurai, P.; ALOthman, Z.A.; Aljuwayid, A.M.; Rajaji, U. Effect of La Doping on NiCr2O4 Properties and Catalytic Applications toward Decolorization of 4-Nitrophenol. ECS J. Solid State Sci. Technol. 2022, 11, 026001. [Google Scholar] [CrossRef]

- Balevicius, S.; Žurauskienė, N.; Stankevič, V.; Keršulis, S.; Plaušinaitienė, V.; Abrutis, A.; Zherlitsyn, S.; Herrmannsdorfer, T.; Wosnitza, J.; Wolff-Fabris, F. Nanostructured Thin Manganite Films in Megagauss Magnetic Field. Appl. Phys. Lett. 2012, 101, 092407. [Google Scholar] [CrossRef]

- Stankevic, T.; Medišauskas, L.; Stankevič, V.; Balevičius, S.; Žurauskienė, N.; Liebfried, O.; Schneider, M. Pulsed Magnetic Field Measurement System Based on Colossal Magnetoresistance-B-Scalar Sensors for Railgun Investigation. Rev. Sci. Instrum. 2014, 85, 044704. [Google Scholar] [CrossRef]

- Schneider, M.; Schneider, R.; Stankevic, V.; Balevicius, S.; Zurauskiene, N. Highly Local Measurements of Strong Transient Magnetic Fields During Railgun Experiments Using CMR-Based Sensors. IEEE Trans. Magn. 2006, 43, 370. [Google Scholar] [CrossRef]

- Schneider, M.; Liebfried, O.; Stankevic, V.; Balevicius, S.; Zurauskiene, N. Magnetic Diffusion in Railguns: Measurements Using CMR-Based Sensors. IEEE Trans. Magn. 2009, 45, 430. [Google Scholar] [CrossRef]

- Haran, T.L.; Hoffman, R.B.; Lane, S.E. Diagnostic Capabilities for Electromagnetic Railguns. IEEE Trans. Plasma Sci. 2013, 41, 1526. [Google Scholar] [CrossRef]

- Liebfried, O.; Loffler, M.; Schneider, M.; Balevicius, S.; Stankevic, V.; Zurauskiene, N.; Abrutis, A.; Plausinaitiene, V. B-Scalar Measurements by CMR-Based Sensors of Highly Inhomogeneous Transient Magnetic Fields. IEEE Trans. Magn. 2009, 45, 5301. [Google Scholar] [CrossRef]

- Balevicius, S.; Žurauskienė, N.; Stankevič, V.; Herrmannsdörfer, T.; Zherlitsyn, S.; Skourski, Y.; Wolff-Fabris, F.; Wosnitza, J. CMR-B-Scalar Sensor Application for High Magnetic Field Measurement in Nondestructive Pulsed Magnets. IEEE Trans. Magn. 2013, 49, 5480. [Google Scholar] [CrossRef]

- Degrave, J.; Felici, F.; Buchli, J.; Neunert, M.; Tracey, B.; Carpanese, F.; Ewalds, T.; Hafner, R.; Abdolmaleki, A.; Casas, D.D.L.; et al. Magnetic Control of Tokamak Plasmas Through Deep Reinforcement Learning. Nature 2022, 602, 414. [Google Scholar] [CrossRef] [PubMed]

- Testa, D.; Toussaint, M.; Chavan, R.; Guterl, J.; Lister, J.B.; Moret, J.M.; Perez, A.; Sanchez, F.; Schaller, B.; Tonetti, G.; et al. The Magnetic Diagnostic Set for ITER. IEEE Trans. Plasma Sci. 2010, 38, 284. [Google Scholar] [CrossRef]

- Zhang, K.; Dai, J.; Zhu, X.; Tian, Y.; Chen, L.; Sun, Y. Vertical Strain Tuning and Perpendicular Magnetic Anisotropy in La0.5Ca0.5MnO3 Vertically Aligned Nanostructured Thin Films by the Application of High Magnetic Fields. J. Alloys Compd. 2021, 888, 161511. [Google Scholar] [CrossRef]

- Lv, F.; Qin, Y.; Gao, Y.; Huang, F.; Tang, H.; Liu, J.; Long, L.; Yang, Y. Nonvolatile Resistive Switching in Lead-Free La2CoMnO6-Based Memory Device. Mater. Today Commun. 2023, 36, 106454. [Google Scholar] [CrossRef]

- Marton, L.C.; Andres, A.D.; Martínez-Lope, M.J.; Casais, M.T.; Alonso, J.A. Raman Phonons as a Probe of Disorder, Fluctuations, and Local Structure in Doped and Undoped Orthorhombic and Rhombohedral Manganites. Phys. Rev. B 2002, 66, 174303. [Google Scholar] [CrossRef]

- Parkin, S.S. Spintronic Materials and Devices: Past, present and future! IEDM Technical Digest. IEEE Int. Electron Devices Meet. 2004, 2004, 903. [Google Scholar]

- Mostufa, S.; Liang, S.; Chugh, V.K.; Wang, J.P.; Wuet, K. Spintronic Devices for Biomedical Applications. NPJ Spintronics 2024, 2, 26. [Google Scholar] [CrossRef]

- Liu, Y.K.; Yin, Y.W.; Li, X.G. Colossal Magnetoresistance in Manganites and Related Prototype Devices. Chin. Phys. B 2013, 22, 087502. [Google Scholar] [CrossRef]

- Yu, V.Z.; Malyarov, V.G. Heat-Sensitive Materials for Uncooled Microbolometer Arrays. J. Opt. Technol. 2001, 68, 939. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boora, N.; Ahmad, R.; Rahman, S.; Dung, N.Q.; Ahmad, A.; Alshammari, M.B.; Lee, B.-I. Recent Advances of Colossal Magnetoresistance in Versatile La-Ca-Mn-O Material-Based Films. Magnetochemistry 2025, 11, 5. https://doi.org/10.3390/magnetochemistry11010005

Boora N, Ahmad R, Rahman S, Dung NQ, Ahmad A, Alshammari MB, Lee B-I. Recent Advances of Colossal Magnetoresistance in Versatile La-Ca-Mn-O Material-Based Films. Magnetochemistry. 2025; 11(1):5. https://doi.org/10.3390/magnetochemistry11010005

Chicago/Turabian StyleBoora, Navjyoti, Rafiq Ahmad, Shafaque Rahman, Nguyen Quoc Dung, Akil Ahmad, Mohammed B. Alshammari, and Byeong-Il Lee. 2025. "Recent Advances of Colossal Magnetoresistance in Versatile La-Ca-Mn-O Material-Based Films" Magnetochemistry 11, no. 1: 5. https://doi.org/10.3390/magnetochemistry11010005

APA StyleBoora, N., Ahmad, R., Rahman, S., Dung, N. Q., Ahmad, A., Alshammari, M. B., & Lee, B.-I. (2025). Recent Advances of Colossal Magnetoresistance in Versatile La-Ca-Mn-O Material-Based Films. Magnetochemistry, 11(1), 5. https://doi.org/10.3390/magnetochemistry11010005