Ni@C/PPy Composites Derived from Ni-MOF Materials for Efficient Microwave Absorption

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Tubular PPy

2.3. Preparation of Ni@C Composite Materials

2.4. Preparation of Ni@C/PPy Composites

2.5. Characterization

3. Results and Discussion

3.1. Structural and Component Analysis

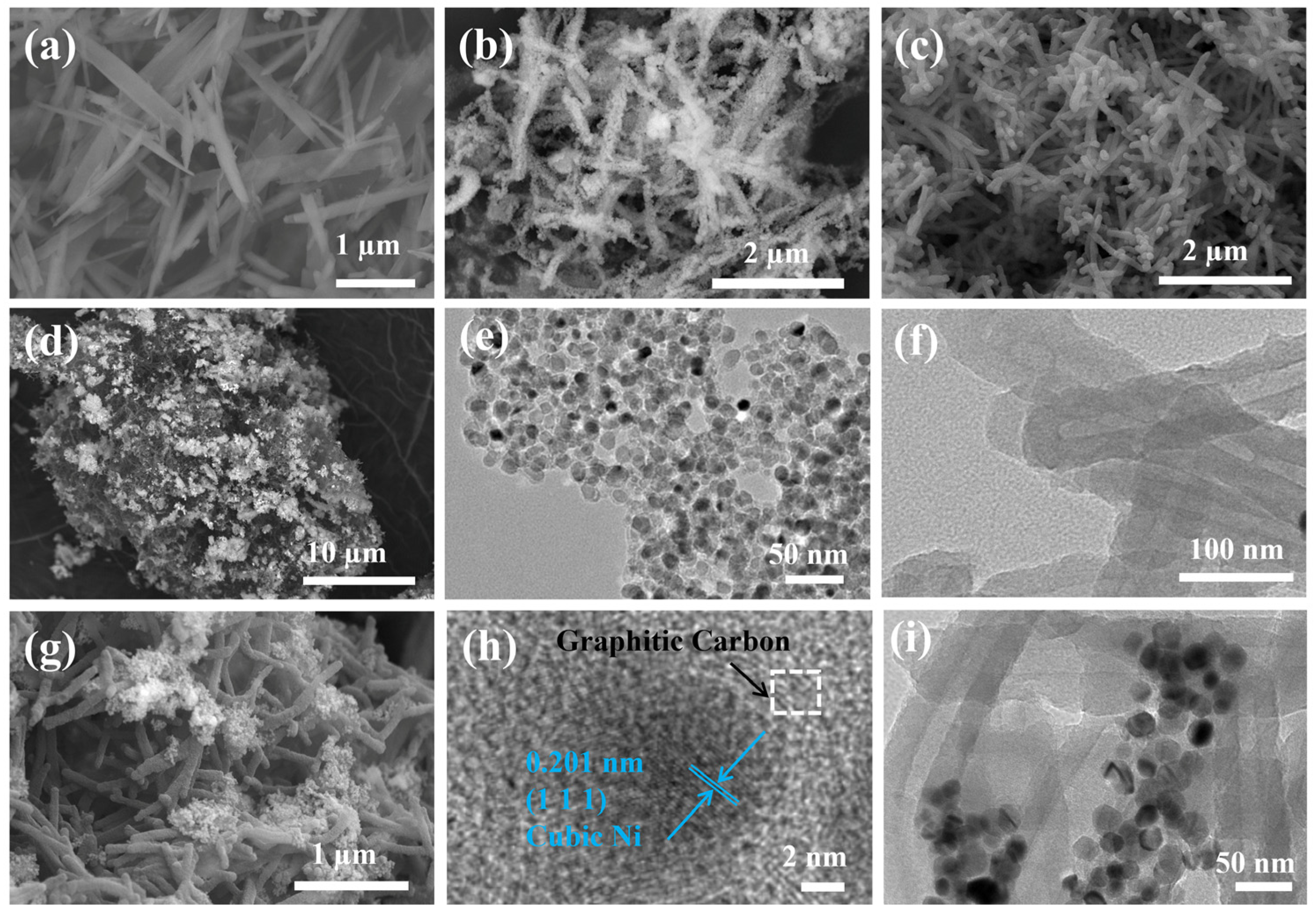

3.2. Morphological Analysis

3.3. Electromagnetic Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, L.; Hamidinejad, M.; Liang, C.; Zhao, B.; Habibpour, S.; Yu, A.; Filleter, T.; Park, C.B. Enhanced electromagnetic wave absorption performance of polymer/SiC-nanowire/MXene (Ti3C2Tx) composites. Carbon 2021, 179, 408–416. [Google Scholar] [CrossRef]

- Zhang, S.; Jia, Z.; Cheng, B.; Zhao, Z.; Lu, F.; Wu, G. Recent progress of perovskite oxides and their hybrids for electromagnetic wave absorption: A mini-review. Adv. Compos. Hybrid Mater. 2022, 5, 2440–2460. [Google Scholar] [CrossRef]

- Xu, J.; Cao, J.; Guo, M.; Yang, S.; Yao, H.; Lei, M.; Hao, Y.; Bi, K. Metamaterial mechanical antenna for very low frequency wireless communication. Adv. Compos. Hybrid Mater. 2021, 4, 761–767. [Google Scholar] [CrossRef]

- Ruan, J.; Chang, Z.; Rong, H.; Alomar, T.S.; Zhu, D.; AlMasoud, N.; Liao, Y.; Zhao, R.; Zhao, X.; Li, Y.; et al. High-conductivity nickel shells encapsulated wood-derived porous carbon for improved electromagnetic interference shielding. Carbon 2023, 213, 118208. [Google Scholar] [CrossRef]

- Guo, J.; Chen, Z.; Xu, X.; Li, X.; Liu, H.; Xi, S.; Abdul, W.; Wu, Q.; Zhang, P.; Bin Xu, B.; et al. Enhanced electromagnetic wave absorption of engineered epoxy nanocomposites with the assistance of polyaniline fillers. Adv. Compos. Hybrid Mater. 2022, 5, 1769–1777. [Google Scholar] [CrossRef]

- Zhang, S.; Cheng, B.; Jia, Z.; Zhao, Z.; Jin, X.; Zhao, Z.; Wu, G. The art of framework construction: Hollow-structured materials toward high-efficiency electromagnetic wave absorption. Adv. Compos. Hybrid Mater. 2022, 5, 1658–1698. [Google Scholar] [CrossRef]

- Chang, Q.; Liang, H.; Shi, B.; Li, X.; Zhang, Y.; Zhang, L.; Wu, H. Ethylenediamine-assisted hydrothermal synthesis of NiCo2O4 absorber with controlled morphology and excellent absorbing performance. J. Colloid Interface Sci. 2021, 588, 336–345. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.; Qiu, H.; Song, P.; Shi, X.; Kong, J.; Gu, J. Ultra-light MXene aerogel/wood-derived porous carbon composites with wall-like “mortar/brick” structures for electromagnetic interference shielding. Sci. Bull. 2020, 65, 616–622. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Cheng, B.; Gao, Z.; Lan, D.; Zhao, Z.; Wei, F.; Zhu, Q.; Lu, X.; Wu, G. Two-dimensional nanomaterials for high-efficiency electromagnetic wave absorption: An overview of recent advances and prospects. J. Alloys Compd. 2022, 893, 162343. [Google Scholar] [CrossRef]

- Gao, Z.; Lan, D.; Zhang, L.; Wu, H. Simultaneous manipulation of interfacial and defects polarization toward Zn/Co phase and ion hybrids for electromagnetic wave absorption. Adv. Funct. Mater. 2021, 31, 2106677. [Google Scholar] [CrossRef]

- Liu, J.; Che, R.; Chen, H.; Zhang, F.; Xia, F.; Wu, Q.; Wang, M. Microwave absorption enhancement of multifunctional composite microspheres with spinel Fe3O4 cores and anatase TiO2 shells. Small 2012, 8, 1214–1221. [Google Scholar] [CrossRef] [PubMed]

- Song, Q.; Ye, F.; Kong, L.; Shen, Q.; Han, L.; Feng, L.; Yu, G.; Pan, Y.; Li, H. Graphene and MXene nanomaterials: Toward high-performance electromagnetic wave absorption in gigahertz band range. Adv. Funct. Mater. 2020, 30, 2000475. [Google Scholar] [CrossRef]

- Lan, D.; Gao, Z.; Zhao, Z.; Kou, K.; Wu, H. Application progress of conductive conjugated polymers in electromagnetic wave absorbing composites. Compos. Commun. 2021, 26, 100767. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, Z.; Feng, A.; Qu, S.; Wang, X.; Liu, X.; Wang, B.; Wu, G. Synthesis of porous carbon embedded with NiCo/CoNiO2 hybrids composites for excellent electromagnetic wave absorption performance. J. Colloid Interface Sci. 2020, 575, 130–139. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Jia, Z.; Zhou, X.; Nie, G.; Lv, H. Interlayer controllable of hierarchical MWCNTs@C@FexOy cross-linked composite with wideband electromagnetic absorption performance. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105687. [Google Scholar] [CrossRef]

- Liu, W.; Shao, Q.; Ji, G.; Liang, X.; Cheng, Y.; Quan, B.; Du, Y. Metal–organic-frameworks derived porous carbon-wrapped Ni composites with optimized impedance matching as excellent lightweight electromagnetic wave absorber. Chem. Eng. J. 2017, 313, 734–744. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, Y.; Li, M.; Yang, L.; Liu, J.; Hou, Y.; Yang, Y. Surface architecture of Ni-based metal organic framework hollow spheres for adjustable microwave absorption. ACS Appl. Nano Mater. 2019, 2, 7888–7897. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, Q.; Chen, X.; Wu, Z.; He, Y.; Lv, Y.; Zhang, L.; Zou, Y. Ni@C composites derived from Ni-based metal organic frameworks with a lightweight, ultrathin, broadband and highly efficient microwave absorbing properties. Appl. Phys. Express 2019, 12, 011001. [Google Scholar] [CrossRef]

- Zhao, X.; Bei, M.; Liu, F.; Bu, F.; Jiang, X.; Yu, L. Solvent-conditioned Ni-MOF-derived flower-like porous carbon composites for electromagnetic wave absorption. Synth. Met. 2023, 293, 117294. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhang, X.; Shi, Y.; Cai, L.; Cheng, J.; Jiang, H.; Zhu, X.; Dong, Y.; Lu, W. Efficient microwave absorption of MOFs derived laminated porous Ni@C nanocomposites with waterproof and infrared shielding versatility. Carbon 2021, 185, 477–490. [Google Scholar] [CrossRef]

- Yan, J.; Huang, Y.; Yan, Y.; Ding, L.; Liu, P. High-performance electromagnetic wave absorbers based on two kinds of nickel-based MOF-derived Ni@C microspheres. ACS Appl. Mater. Interfaces 2019, 11, 40781–40792. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Z.; Wang, X.; Zhang, X.; Shi, Y.; Cai, L.; Zhu, X.; Dong, Y.; Lu, W. Self-assembly of nano/microstructured 2D Ti3CNTx MXene-based composites for electromagnetic pollution elimination and Joule energy conversion application. Carbon 2022, 189, 305–318. [Google Scholar] [CrossRef]

- Xu, X.; Ran, F.; Fan, Z.; Cheng, Z.; Lv, T.; Shao, L.; Liu, Y. Bimetallic metal–organic framework-derived pomegranate-like nanoclusters coupled with CoNi-doped graphene for strong wideband microwave absorption. ACS Appl. Mater. Interfaces 2020, 12, 17870–17880. [Google Scholar] [CrossRef] [PubMed]

- Liao, Z.; Ma, M.; Tong, Z.; Wang, R.; Bi, Y.; Chen, Y.; Chung, K.L.; Ma, Y. Fabrication of ZnFe2O4/C@PPy composites with efficient electromagnetic wave absorption properties. J. Colloid Interface Sci. 2021, 602, 602–611. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.; Lv, L.; Fu, H. Preparation and study of Al2O3@PPy@rGO composites with microwave absorption properties. J. Alloys Compd. 2020, 832, 152957. [Google Scholar] [CrossRef]

- Rumiantsev, A.; Ridler, N. VNA calibration. IEEE Microw. Mag. 2008, 9, 86–99. [Google Scholar] [CrossRef]

- Nicolson, A.M.; Ross, G.F. Measurement of the Intrinsic Properties of Materials by Time-Domain Techniques. IEEE Trans. Instrum. Meas. 1970, 19, 377–382. [Google Scholar] [CrossRef]

- Gai, L.; Zhao, Y.; Song, G.; An, Q.; Xiao, Z.; Zhai, S.; Li, Z. Construction of core-shell PPy@MoS2 with nanotube-like heterostructures for electromagnetic wave absorption: Assembly and enhanced mechanism. Compos. Part A Appl. Sci. Manuf. 2020, 136, 105965. [Google Scholar] [CrossRef]

- Xie, A.; Sun, M.; Zhang, K.; Xia, Y.; Wu, F. Tetrazole amphiphile inducing growth of conducting polymers hierarchical nanostructures and their electromagnetic absorption properties. Nanotechnology 2018, 29, 215604. [Google Scholar] [CrossRef]

- Xie, D.; Zhang, M.; Cheng, F.; Fan, H.; Xie, S.; Liu, P.; Tu, J. Hierarchical MoS2@Polypyrrole core-shell microspheres with enhanced electrochemical performances for lithium storage. Electrochim. Acta 2018, 269, 632–639. [Google Scholar] [CrossRef]

- Chang, C.; Yang, X.; Xiang, S.; Que, H.; Li, M. Layered MoS2/PPy nanotube composites with enhanced performance for supercapacitors. J. Mater. Sci. Mater. Electron. 2016, 28, 1777–1784. [Google Scholar] [CrossRef]

- Gu, H.; Huang, J.; Li, N.; Yang, H.; Wang, Y. Polystyrene-modulated polypyrrole to achieve controllable electromagnetic-wave absorption with enhanced environmental stability. Nanomaterials 2022, 12, 2698. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Yang, Z.; He, N. Hierarchical nanostructured polypyrrole/graphene composites as supercapacitor electrode. RSC Adv. 2015, 5, 15096–15102. [Google Scholar] [CrossRef]

- Bi, Y.; Ma, M.; Liao, Z.; Tong, Z.; Chen, Y.; Wang, R.; Ma, Y.; Wu, G. One-dimensional Ni@Co/C@PPy composites for superior electromagnetic wave absorption. J. Colloid Interface Sci. 2022, 605, 483–492. [Google Scholar] [CrossRef] [PubMed]

- Pan, D.; Yang, G.; Abo-Dief, H.M.; Dong, J.; Su, F.; Liu, C.; Li, Y.; Bin Xu, B.; Murugadoss, V.; Naik, N.; et al. Vertically aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites. Nano-Micro Lett. 2022, 14, 118. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wen, B.; Bai, X.; Liu, C.; Yang, H. NiCo alloy/carbon nanorods decorated with carbon nanotubes for microwave absorption. ACS Appl. Nano Mater. 2019, 2, 7827–7838. [Google Scholar] [CrossRef]

- Huang, Z.; Ma, R.; Zhou, J.; Wang, L.; Xie, Q. Investigation on microstructures, electronic structures, electromagnetic properties and microwave absorption properties of Fe3Si/PPy composites. J. Alloys Compd. 2021, 873, 159779. [Google Scholar] [CrossRef]

- Ren, H.; Li, T.; Wang, H.; Guo, Z.; Chen, T.; Meng, F. Two birds with one stone: Superhelical chiral polypyrrole towards high-performance electromagnetic wave absorption and corrosion protection. Chem. Eng. J. 2022, 427, 131582. [Google Scholar] [CrossRef]

- Pan, F.; Rao, Y.; Batalu, D.; Cai, L.; Dong, Y.; Zhu, X.; Shi, Y.; Shi, Z.; Liu, Y.; Lu, W. Macroscopic electromagnetic cooperative network-enhanced MXene/Ni chains aerogel-based microwave absorber with ultra-low matching thickness. Nano-Micro Lett. 2022, 14, 140. [Google Scholar] [CrossRef]

- Cole, K.S.; Cole, R.H. Dispersion and Absorption in Dielectrics I. Alternating Current Characteristics. J. Chem. Phys. 1941, 9, 341–351. [Google Scholar] [CrossRef]

- Liu, S.; Fang, D.; Xing, F.; Jin, H.; Li, J. Auricularia-shaped MoS2 nanosheet arrays coated hierarchical multilayer MoS2/PPy/rGO composites for efficient microwave absorption. Chem. Eng. J. 2024, 479, 147613. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Zou, Y.; Meng, L.; Cai, L.; Xiong, S.; Chen, G.; Dong, C.; Guan, H. Ni@C/PPy Composites Derived from Ni-MOF Materials for Efficient Microwave Absorption. Magnetochemistry 2024, 10, 24. https://doi.org/10.3390/magnetochemistry10040024

Ma Y, Zou Y, Meng L, Cai L, Xiong S, Chen G, Dong C, Guan H. Ni@C/PPy Composites Derived from Ni-MOF Materials for Efficient Microwave Absorption. Magnetochemistry. 2024; 10(4):24. https://doi.org/10.3390/magnetochemistry10040024

Chicago/Turabian StyleMa, Yu, Yupeng Zou, Lingsai Meng, Lijuan Cai, Shengxiang Xiong, Gang Chen, Chengjun Dong, and Hongtao Guan. 2024. "Ni@C/PPy Composites Derived from Ni-MOF Materials for Efficient Microwave Absorption" Magnetochemistry 10, no. 4: 24. https://doi.org/10.3390/magnetochemistry10040024

APA StyleMa, Y., Zou, Y., Meng, L., Cai, L., Xiong, S., Chen, G., Dong, C., & Guan, H. (2024). Ni@C/PPy Composites Derived from Ni-MOF Materials for Efficient Microwave Absorption. Magnetochemistry, 10(4), 24. https://doi.org/10.3390/magnetochemistry10040024