1. Introduction

Walnut world production keeps increasing, with China as a leader (~50%), followed by the United States (USA, ~25%), Iran, Turkey, Mexico, Ukraine, Chile, Uzbekistan, and France [

1]. The USA is the second-largest producer of English walnuts (

Juglans regia L.) worldwide, generating USD 1.01 billion annually and producing 750,000 tons in 2023 [

1]. However, the USA is the top shelled and in-shell kernel export country in dollar revenue. Ninety-nine percent of English walnuts grown in the USA are grown in California, which has 162,000 hectares under production as of 2023 [

2]. Currently, about one-third of the crop is sold domestically and the rest to export markets (Canada, Germany, India, Italy, Japan, South Korea, Spain, Israel, Turkey, Australia, UAE/Middle East, and the United Kingdom). There is an increase in demand, as two-thirds of exports are sold as shelled ‘ready to use’, but this package style is generating quality challenges.

2. Health Benefits

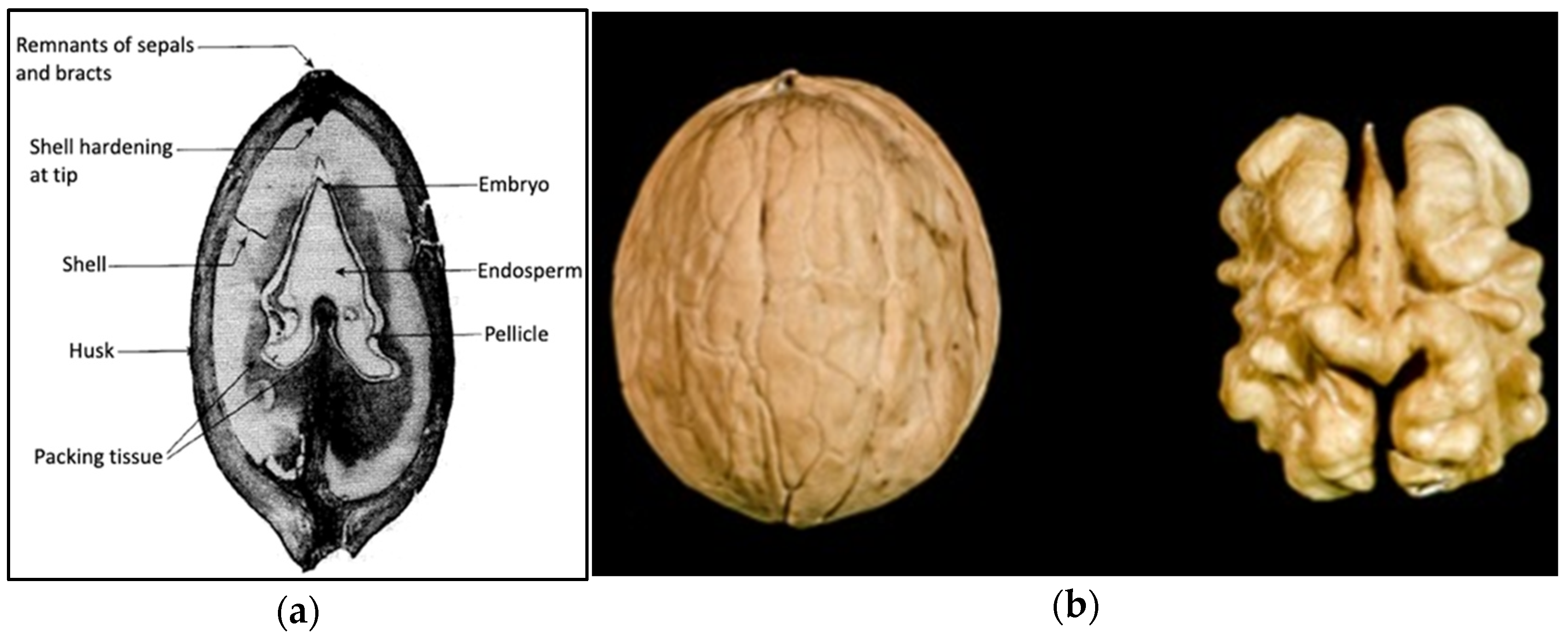

The mature kernel (

Figure 1) contains many nutrients [

3], such as lipids or oil (~50% by dry weight) and proteins (~15.0% by dry weight). Soluble sugars, mainly fructose, glucose, and sucrose, accumulate at the beginning of the nut-growing season, then decline as lipid accumulation begins near harvest maturity [

4]. Contrary to many fruits and vegetables, where the lipid content is usually <1.0%, walnuts contain ~50.0% lipids, with a high proportion of polyunsaturated fatty acids (PUFAs). Many of the physical and chemical properties of lipids are due to the fatty acids present in their structure. Fatty acids are aliphatic monocarboxylic acids, 4 to 26 carbons long, that may be saturated or unsaturated to varying degrees, depending on their cultivar, location, and season [

5]. Saturated fatty acids have no double bonds along their hydrocarbon chain, and monounsaturated fatty acids have a single double bond. PUFAs have more than one double bond, but oleic acid (18:1) and linoleic acid (18:2) are the most prevalent in nature [

5,

6]. Walnuts kernels contain high amounts of PUFAs, such as omega-3 fatty acids, a-linolenic acid, and a ratio of omega-6 to omega-3 fatty acids that is affected by the degree of oil decomposition [

5]. Fatty acids are necessary for human metabolism, particularly to produce hormone-like substances that regulate functions such as blood pressure, blood clotting, blood lipid levels, the immune response, and the inflammatory response [

5,

6]. The human body can produce most fatty acids except for linoleic acid (18:2) and α-linolenic acid (18:3), which are widely distributed in plant oils and foods such as walnuts.

This diversity in lipid composition depending on cultivar, origin, season, and pre- and postharvest handling affect kernel quality and postharvest treatment impacts [

5,

6,

7,

8,

9,

10,

11]. A detailed review leaded by Gama in 2018 [

5] described detailed work across the world evaluating lipid composition from different walnut cultivars, production locations, and seasons.

3. Consumer Problems and Causes

The growing popularity of walnuts can be attributed to their health benefits, flavor, and favorable packaging of easy-to-eat shells. Furthermore, changes in eating habits caused by urbanization and consumer trends are increasing the demand for ready-to-use shelled walnuts as a convenient, healthy, and nutritious snack food. Shelled walnuts are usually sold in bulk as halves, pieces, and finely chopped, among other forms packed in small ‘ready-to-use’ containers and pouches (0.07, 0.45, 0.68, 0.90, and 1.4 kilos). Shelled ‘ready-to-use’ walnuts are available in supermarkets and club stores year-round. Unfortunately, ‘ready to use’ are more susceptible to pellicle darkening and rancidity than their in-shell counterparts. In addition to kernels free of internal damage from insects and mold, as well as low external damage, consumer preference leans heavily toward health benefits, the absence of ‘off flavors’, and light-colored kernels. In-shell walnuts are available in 2.3-, 11.3-, or 13.5-kilo bulk cardboard boxes or in 0.9- and 2.3-kilo plastic bags, mainly during fall and winter.

Quality and Grades Standards

Standards and grades are the first step in the value chain, as walnuts move down the market channel to consumers [

4]. Standards and grading enable orderly marketing by providing a convenient basis for consistent quality evaluations during buying and selling. Grades facilitate the marketing of walnut products across the world. In the USA, there are two voluntary grades, USA No 1 and USA Commercial, defined by the United States Department of Agriculture [

12,

13]. These USA grades are issued under the authority of the Agricultural Marketing Act and are available for use by producers, suppliers, buyers, and consumers. These two grades define proportions of walnut kernels that are dry; clean; and free of shell fragments, foreign material, insect injury, decay, rancidity, and damage caused by shriveling, mold, discoloration, or other means. The difference between the two grades is defined according to the defect allowance percentages. In California, walnut kernel standards and grades are enforced by the California Dried Fruit Association (DFA) and by the quality control personnel and internal standards of each handler/shipper.

The walnut industry currently grades all kernels using a color chart score (

Figure 2) created by the USA Department of Agriculture for use by the Dried Fruit and Tree Nut Association of California (DFA). Kernels are classified into ‘extra light’, ‘light’, ‘light amber’, and ‘amber’ [

12,

13].

For the in-shell product, the highlighted characteristics include the integrity, shape, and hardness of the shell and the brightness and uniformity of its color [

12,

13]. Freedom from foreign material (adhering hull tissue and broken shells) and signs of insect damage or decay are also important. In determining the grade of a lot of walnuts, all nuts in the sample are first graded for size and then examined for external defects. In-shell size follows the following classifications: mammoth, jumbo, large, medium, standard, baby, and minimum diameter. After sizing, the same nuts should be cracked and examined for internal defects. Details on the standards are described at

https://www.ams.usda.gov/grades-standards/walnuts-shell-grades-and-standards (accessed 28 July 2023).

Shelled walnuts should be free of shell debris and foreign material and from insect or fungal damage [

4,

12,

13]. The kernel pellicle should be intact and should show no shriveling or discoloration. Double, split, or broken kernels decrease in value. There should be no indication of a rancid flavor. Kernels are classified by size as ‘halves’, ‘pieces and halves’, ‘pieces’, or ‘small pieces’. The portions of kernels of each size in the lot conform to the requirements of the specified classification as defined in the standards for grading. Details on the standards are described at

https://www.ams.usda.gov/grades-standards/shelled-walnuts-grades-and-standards (accessed 28 July 2023).

These quality parameters are the basic requirements that determine crop acceptance for both local and export trade [

12,

13]. Optimizing the walnut kernel quality is essential to maximize industry returns and maintain and increase markets.

4. Consumer Perception Problems

The walnut kernel consists of two main parts: the light brownish pellicle (seed coat) and an embryo [

4], (

Figure 1). The embryo or seed is rich in nutrient sugars, vitamins, and proteins but especially lipids to support seed development. The pellicle accumulates most of the antioxidant phenolic compounds in the kernel and serves as a physical protection from its environment and a barrier to oxidation.

Rancidity (‘off flavor’) and kernel pellicle browning or darkening (amber color) have become more challenging as the volumes of walnut crops expand. As delivery to distant international markets rises, along with increasing competition from China and Chile for export markets, the marketing of ‘ready-to-use’ shelled kernels becomes more prevalent, and the volume of crop carryover surges [

5,

6,

7,

8,

9,

14,

15]. The growing domestic production combined with additional planting and rising global supply not only increases the global market competition but also emphasizes maintaining high-quality kernels to meet the competitive rising market demand [

16,

17].

4.1. Rancidity

Rancidity is one of the most serious quality problems that threatens commodities, like walnuts, that have a high oil content [

5,

8]. Under adverse environmental conditions, these PUFAs become oxidized over time, leading to off-flavor development and rancidity [

5,

6]. Oxidative deterioration, commonly known as lipid oxidation or rancidity, causes ‘off flavors’, discoloration, unpleasant odors, and reduces the edible oil nutritional value. Lipid oxidation is a problem of economic concern to the worldwide walnut industry, as it decreases walnuts’ positive sensory quality characteristics and shortens their shelf life. The precise cause of rancid ‘off flavors’ is not well understood, but it involves reactions between oxygen and, particularly, reactive oil components, PUFAs. Although improperly handled almonds, pecans, and pistachios can all become rancid [

6], it is most problematic with walnuts due to their especially high proportion of linoleic acid (18:2).

Lipid deterioration is a complex process that includes both hydrolytic and/or oxidative reactions [

5,

6,

8]. Lipid hydrolysis is caused by the reaction of triacylglycerols (fatty acids with an ester linkage to the three alcohol groups in glycerol) with water in the presence of light and heat, releasing free fatty acids (FFAs). Lipid hydrolysis is increased by physical damage to the pellicle during the shelling operation [

6,

9]. FFAs are highly susceptible to subsequent oxidation either via a direct oxygen attack at the unsaturated sites of FFAs and/or enzymatically through lipoxygenases (LOXs). In both pathways, oxygen reacts with FFAs, ending with the formation of hydroperoxides (primary oxidation). Peroxide concentrations measured as for peroxide value (PV) depend on the cultivar, harvest time, delays prior to storage after harvest, ecological conditions, cultural management during the growing season, and handling procedures after harvest [

6]. Hydroperoxides are easily broken down into secondary or tertiary oxidation end products such as aldehydes, ketones, furans, alcohols, malonaldehyde, and alkanes that create the rancid ‘off flavor’ [

9].

Currently, the walnut industry uses PV and FFA acid concentrations as a tool to predict the postharvest rancidity of walnut kernels and marketing of lots. Some minimum FFA and PV concentrations are being suggested as standard indicators of oxidative rancidity. However, acceptable PV concentrations vary widely in the literature, despite their apparent importance as an indicator of nut oil quality. The quantification of FFA and PV are measurements that have been used for decades to evaluate oil oxidative stability. However, these tests provide information regarding the temporal fat oxidative state and rely on the use of toxic solvents and manual titration that may lead to erroneous results. The commercial approach in other commodities has been to segregate by potential postharvest life to avoid selling rancid products to consumers [

14,

15,

16]. As walnuts are stored longer and kernel sensory quality becomes an important issue, and considering that lipid oxidation is a dynamic process, there is a need for new information on validated predictors of oxidation potential.

4.2. Kernel Darkening

Quality losses due to kernel color darkening [

12,

13],

Figure 2 are an impediment to meeting the quality standards for international and domestic markets and decrease the economic value of walnut crops [

8,

14,

15,

16,

17]. The pellicle, with its phenolic compounds, acts as a physical and a chemical shield against oxidation, because the oxygen in the air oxidizes these compounds first [

18,

19,

20]. Kernel damage during shelling can increase the perishability or the oxidation reactions of shelled walnuts [

8,

21,

22]. When the pellicle no longer covers the entire surface, removing its protective shell, oxidation reactions occur more easily in the kernel. The capacity of pellicle antioxidants and tocopherols to protect the kernel is, however, limited. Oxidation of the pellicle phenolics, indicated by pellicle darkening, decreases its antioxidant capacity [

8,

21,

22,

23] and consumer quality.

5. Managing Postharvest Technology to Overcome Kernel Rancidity and Darkening

The maximum kernel postharvest life is attained by the proper handling of environmental conditions during harvest, storage, transportation, distribution, and retail store display [

4,

7,

14,

24]. Cold storage can minimize primary kernel quality deterioration problems such as decay, food safety risks, rancidification, and kernel phenolic oxidation (darkening).

5.1. Field Temperature Management

California walnut orchards are harvested by dropping nuts to the orchard ground with mechanical shakers in late August to November. Then, the nuts are mechanically collected from the ground and stored in-shell in large room facilities, generally under ambient conditions. After shaking walnuts to the orchard floor as the harvest begins, it is important to pick them up from the ground, hull, and dry as rapidly as possible. Walnuts left on the orchard floor can lose kernel quality rapidly, as the kernel pellicle color can darken. Most loss of quality occurs during the first hours after shaking, especially during the hot portion of the day, and this is exacerbated when the hull is still attached. Air temperatures at or above 32.2 °C greatly speed up the kernel darkening of sun-exposed walnuts. Even shaded walnuts lose kernel color rapidly if air temperatures are >37.8 °C. As the harvest continues through the hot portion of the day, the speed at which pickup, hulling, and drying are initiated becomes more important. Walnuts on the tree are cooler, even when exposed to the sun, and thus less likely to reach these critical threshold temperatures than walnuts on the ground. In addition to kernel darkening, walnuts left on damp grounds are more susceptible to mold damage than when still on the tree. The prolonged exposure of walnuts to damp soil may even cause shell staining extensive enough to prevent the walnut from being used for in-shell stock [

25,

26].

Temperatures detrimental to kernel color are reached more quickly and sustained longer when walnuts are harvested with the hulls intact, as is common with early-maturing cultivars like ‘Payne’, ‘Vina’, ‘Solano’, ‘Durham’, ‘Tulare’, and ‘Howard’. Ideally, walnut harvest should be coordinated with the drying capacity to avoid processing delays. The hull causes heat buildup because it insulates the kernel and reduces moisture loss. Therefore, the presence or absence of hulls on the walnuts should determine lot selection for the harvest, hulling, and drying to protect kernels from quality loss. An ethephon preharvest application was developed to enhance hull dehiscence and/or remove hulls prior to reduce this quality problem [

24,

25]. In addition to this, as the ethephon treatment accelerates maturation, it has been observed that the kernel quality of new cultivars such as ‘Solano’, ‘Durham’, ‘Tulare’, and ‘Howard’ benefits greatly because of this ethephon treatment,

The light kernel color and internal damage from insects and mold are adversely affected by harvest delays. Regardless of location or cultivar, it is important to harvest as early as possible to obtain the lightest possible kernels free of navel orange worm (NOW) damage and obtain the most value for the crop.

Ambient temperatures between harvests in October and the following September in some walnut-storing regions of California can get as high as 28 °C during the day, with an outdoor RH that can get as high as 90% during the cold winter months. During cool night air when the RH is between 60 and 65% and the temperature is below 25 °C, air can be forced through the storage facilities to reduce the room and walnut temperatures (venting storage).

5.2. Cold Storage and Transportation Temperature Management

The recommended temperature range for walnut storage is 0 to 10 °C, with 50 to 65% relative humidity to maintain ~2.8 to 7.0% moisture in the kernels, with a water activity of 0.2 to 0.8 [

5,

7]. This postharvest kernel quality is maintained for over a year when kernels are stored at 0 °C (

Figure 3a,b). Where proper environmental storage conditions are applied to well-handled kernels, the lower the temperature, the longer the storage life [

16]. Unfortunately, most storage transportation and handling are carried out without proper temperature control, especially during display at retail stores [

4,

7,

8,

14,

23]. The harvest date has a greater impact on the portion of light-colored kernels during the storage period (24;

Figure 3).

In most cases, in-shell walnuts have a longer potential postharvest life than ‘ready-to-use’ shelled walnuts [

14]. As the kernel quality deteriorates rapidly after thawing [

5,

23], kernels should therefore not be exposed to temperatures near freezing (−10 °C).

For the best kernel postharvest life, kernels during transportation, distribution, and retail store handing kernels should be kept under 10 °C or, ideally, at 0 °C [

15], thus maintaining the cold chain. This cold chain concept is critical when kernels are under long storage or transported to distant markets. During storage and transportation, kernels should not be stored cold or warm with commodities that have strong odors, like garlic, fish, cabbage, or onions, because the high lipid content in walnuts enhances the absorbance of odors [

5,

23].

5.3. Temperature Handling at Destination Retail Stores and at Home

5.3.1. Handling at Retail Store

Walnuts packed in cardboard and/or plastic pouches or bags should be transported from handlers to stores at temperatures equal to or below 10 °C to slow kernel deterioration and optimize the potential postharvest life, thus assuring consumer satisfaction. Walnuts should be kept at low temperatures prior to transferring to dry/warm display tables. This is especially important if nuts are packed in cardboard boxes without a modified atmosphere packaging (MAP) system. It is always preferable to move walnuts quickly. Even for walnuts packed in MAP pouches, sale speed is critical to maximize their postharvest life. Periodic measurements of oxygen concentrations in the pouches are suggested to coordinate and optimize display schedules.

5.3.2. Handling at Home

Immediately after bringing shelled or in-shell walnuts home from the store, walnuts can be stored in their original packaging in the refrigerator or freezer, depending on when they are to be consumed. In the refrigerator, walnuts should be stored away from foods with strong odors (garlic, fish, cabbage, and onions), since walnuts can absorb the flavors of other foods. Walnuts intended for consumption within a week should be placed in the refrigerator. For longer storage, freezing in an airtight container to maintain freshness is recommended. Ideally, walnuts should be shelled, chopped, or ground into meal just prior to use to maintain flavor.

5.4. Special Package Environmental Atmosphere Postharvest Treatments

Shelling occurs throughout the year as needed to fulfill shelled kernel orders from retailers globally. During shelling operations, physical injury to the pellicle that accelerates kernel rancidity and darkening problems is increased [

8]. Thus, shelled kernels should ideally be refrigerated to maintain quality. The storage of shelled or in-shell products can range from weeks up to >12 months, and storage conditions vary throughout the industry. Because of the large volumes of harvested walnuts, it is costly to use refrigerated storage; therefore, there is a need to quantify the potential benefits of refrigeration and/or other technologies on their postharvest life potential.

Reliable information indicates that low oxygen storage also protects against phenolic degradation, lipids, and phenolics oxidation, protecting the kernel pellicle from darkening for a very short period, even when proper temperature management is not available ([

8,

9,

10]). The greatest benefit of low oxygen kernel color darkening protection at warm temperatures was demonstrated for the main California cultivars [

8]. This is very important, as most stores display walnuts at warm temperatures (

Figure 4). The development of darkening kernel colors in ‘Chandler’ and ‘Howard’, expressed as the percentage of light amber and amber kernels, are associated significantly with oxygen exposure under warm conditions (

Figure 5). Using steady oxygen concentrations on ‘Chandler’ (non-sensitive to kernel darkening) and ‘Howard’ (sensitive to kernel darkening) walnuts at a high temperature (35 °C), we found a strong positive correlation between the percentage of amber kernels and oxygen exposure during warm storage (R

2 = 0.75 to 0.99). Oxygen concentrations below 6 kPA protected ‘Chandler’ kernels from darkening for longer than three weeks in a warm temperature (35 °C) display. In both cultivars, there were ~20% amber kernels in walnuts stored in 6% O

2 compared to almost 40% amber kernels stored at room temperature. Kernels stored at 3 or 0 kPA O

2 had 10 kPA or fewer amber kernels [

8];

Figure 5). Thus, for ‘Chandler’ (California’s primary cultivar), ~3–6 kPA oxygen at the end of packaging into consumer containers has been shown to be effective. With the recent significantly increased acreage of other cultivars, such as ‘Howard’, ‘Solano’, ‘Durham’, and ‘Tulare’, the current recommendations point out that 3 kPA oxygen or less is needed to optimize their postharvest life. Factors such as initial kernel quality, processing speed, equipment performance, package material permeability, quality of the package seal, and monitoring are crucial to reach and maintain a low 3 kPA oxygen in consumer packaging. Thus, a low-oxygen, modified atmosphere packaging (MAP) system that reduces oxygen to 6 kPA, 3 kPA, or lower using bags and or pouches will protect kernels from darkening during transportation and retail handling at ambient temperatures (

Figure 5).

The use of low oxygen levels during storage of 1 kPA to 6 kPA has been shown to delay the development of walnut kernel darkening and rancidity in during long-term cold storage. The greatest benefits are attained using a combination of low oxygen and low storage temperature [

7,

8,

9]. A low-oxygen atmosphere can be maintained using a controlled atmosphere (CA) or MAP technologies [

4]. Establishing a CA system requires a special sealed room, equipment to generate gases in the room, and a detector to monitor the gas concentrations during storage [

4]. MAP is more flexible, as it is generated using plastic bags or pouches and initial nitrogen flushing that sets the gas composition inside the large or consumer-sized containers [

6,

7,

8,

10,

11]. For walnut kernels, the packaging equipment induces a vacuum inside the package and then adds nitrogen into the bag until the target oxygen concentration is reached.

6. Challenges

The application of the cold chain concept, reducing physical damage during shelling, and enforcement of low-oxygen MPA should become a main priority. The application of a ‘cold chain’ during all postharvest handling is highly recommended, but it is unpractical for the current USA 750,000 tons. Thus, a useful quality assurance system to rank the lots based on their potential visual and sensory quality is important. Then, lots can be selected based on their potential quality and match market destinations. Studies to better understand walnut lipid oxidation are in progress to complement the current FFA and PV standards to improve kernel sensory quality predictors.

7. Conclusions

Storing and marketing dried and ‘ready-to-use’ shelled kernels in halves and/or pieces that satisfy the current increasing consumers’ demands create new challenges to maintain their visual and sensory quality.

To maintain their visual and sensory kernel quality and maximize their postharvest life, kernels should be stored at low temperatures during all steps in postharvest handling. The ‘cold chain’ concept includes all steps after harvesting, including hulling delays, storage, transportation, distribution, store retail handling, and home storage. This concept is even more critical when kernels are marketed in small packages and stored for long periods or transported to long-distance markets. When well-handled kernels are stored under proper environmental conditions and darkness, the postharvest kernel sensory quality can be maintained for over a year with minimal quality loss.

Shelling operations induce physical injury to the pellicle that accelerates kernel rancidity and darkening problems; thus, this damage should be assessed for each operation cultivar, machinery type, and speed of processing against the amount of damage.

The benefits of low-oxygen packaging (MAP) storage on delaying kernel darkening and rancidity, especially after shelling, have been demonstrated to improve their eating quality, delay rancidity, and kernel darkening. Protection against kernel color quality loss during storage even at warm temperatures can be accomplished at kPA oxygen or less for ‘Chandler’ and kPA or less for ‘Howard’ and ‘Tulare’.

Application of the ‘cold chain’ principle and/or low-oxygen technology is unworkable for 750,000 tons. Thus, a useful quality control system to rank lots based on their potential visual and sensory quality is important. Then, lots can be selected based on their potential quality and match market destinations.

Author Contributions

C.H.C. and I.R.D.-G.: paper Administration, conceptualization, wrote the first draft, and final review and editing; B.D.L. and S.C.W.: format, comments, and review and edit the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the California Walnut Grade and Standard Board and University of California Agriculture and Natural Resources.

Data Availability Statement

Data is available upon request to the senior author.

Acknowledgments

The authors would like to recognize Emily Henry, for their help during the manuscript preparation.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- FAO FAOSTAT Database. Food and Agriculture Organization of the United Nations, Rome. 2020. Available online: https://www.fao.org/faostat/en/#data/QI (accessed on 20 June 2020).

- USADA/NASS. State Agriculture Overview. USA Department of Agriculture, National Agricultural Statistics Service, Washington, DC. 2020. Available online: www.nass.USAda.gov/Quick_Stats/Ag_Overview/ (accessed on 1 April 2020).

- USADA Agricultural Research Service FoodData Central. 2019. Available online: https://www.nass.usda.gov/Quick_Stats/ (accessed on 28 July 2023).

- Kader, A.A.; Thompson, J.E. Postharvest handling systems: Tree nuts. In Postharvest Technology of Horticultural Crops; Kader, A., Ed.; University of California, Division of Agriculture and Natural Resources: Oakland, CA, USA, 2002; pp. 399–406. [Google Scholar]

- Gama, T.; Wallace, H.M.; Trueman, S.J.; Hosseini-Bai, S. Quality and shelf life of tree nuts: A review. Sci. Hort. 2018, 242, 116–126. [Google Scholar] [CrossRef]

- López, A.; Pique, M.; Romero, A.; Aleta, N. Influence of cold-storage conditions on the quality of unshelled walnuts. Intl. J. Refrig. 1995, 18, 544–549. [Google Scholar] [CrossRef]

- Mitcham, E.; Adkison, C.; Lingga, N.; Bikoba, V. Storage Temperature, Relative Humidity, and Time Effects on the Organoleptic Profile of Walnut Kernels. J. Amer. Soc. Hort. Sci. 2022, 147, 291–299. [Google Scholar] [CrossRef]

- Ortiz, C.M.; Vicente, A.R.; Fields, R.P.; Grilo, F.; Labavitch, J.M.; Donis-Gonzalez, I.; Crisosto, C.H. Walnut (Juglans regia L.) kernel postharvest deterioration as affected by pellicle integrity, cultivar and oxygen concentration. Postharvest Biol. Technol. 2019, 156, 110948. [Google Scholar] [CrossRef]

- Christopoulos, M.V.; Tsantili, E. Oil composition in stored walnut cultivars—Quality and nutritional value. Eur. J. Lipid Sci. Technol. 2015, 117, 338–348. [Google Scholar] [CrossRef]

- Bakkalbaşı, E.; Yılmaz, M.; Javidipour, I.; Artık, N. Effects of packaging materials, storage conditions and variety on oxidative stability of shelled walnuts. Lebensm. Wiss. Technol. 2012, 46, 203–209. [Google Scholar] [CrossRef]

- Mexis, S.F.; Badeka, A.V.; Riganakos, K.A.; Karakostas, K.X.; Kontominas, M.G. Effect of packaging and storage conditions on quality of shelled walnuts. Food Control 2009, 20, 743–751. [Google Scholar] [CrossRef]

- United State Department of Agriculture. USA Standards for Grade of Walnuts (Juglans regia) in the shell. 2017. Available online: https://www.ams.usda.gov/grades-standards/walnuts-shell-grades-and-standards (accessed on 28 July 2023).

- United State Department of Agriculture. USADA Standards for Grade of Shelled Walnuts (Juglans regia). 2017. Available online: https://www.ams.usa.gov/grades-standards/shelled-walnuts-grades-and-standards (accessed on 28 July 2023).

- Adkison, C.; Richmond, K.; Lingga, N.; Bikoba, V.; Mitcham, E. Optimizing walnut storage conditions: Effects of relative humidity, temperature, and shelling on quality after storage. HortScience 2021, 56, 1244–1250. [Google Scholar] [CrossRef]

- Félix-Palomares, L.; Donis-González, I.R. Optimization and Validation of Rancimat Operational Parameters to determine Walnut Oil Oxidative Stability. Processes 2021, 9, 651. [Google Scholar] [CrossRef]

- Fichtner, E.; Crisosto, C.H.; Lampinen, B. Maximizing Quality to Improve Value in a Low–Price Year. July. West Coast Nut; JCS Marketing Publication: Visalia, CA, USA, 2019; pp. 52–54. [Google Scholar]

- Donis-González, I.R.; Bergman, S.M.; Sideli, G.M.; Slaughter, D.C.; Crisosto, C.H. Color vision system to assess English walnut (Juglans regia) kernel pellicle color. Postharvest Biol. Technol. 2020, 167, 111199. [Google Scholar] [CrossRef]

- Escobar, M.A.; Shilling, A.; Higgins, P.; Uratsu, S.L.; Dandekar, A.M. Characterization of polyphenol oxidase from walnut. J. Amer. Soc. Hort. Sci. 2008, 133, 139–143. [Google Scholar] [CrossRef]

- Warmund, M.R. Kernel color of three black walnut cultivars after delayed hulling at five successive harvest dates. HortScience 2008, 43, 2256–2258. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, L.; Moore, J.; Wu, T.; Wang, Z. Antioxidant phenolic compounds from walnut kernels (Juglans regia L.). Food Chem. 2009, 113, 160–165. [Google Scholar] [CrossRef]

- Araji, S.; Grammer, T.A.; Gertzen, R.; Anderson, S.D.; Mikulic-Petkovsek, M.; Veberic, R.; Phu, M.L.; Solar, A.; Leslie, C.A.; Dandekar, A.M.; et al. Novel roles for polyphenol oxidase enzyme in secondary metabolism and the regulation of cell death in walnut. Plant Physiol. 2014, 161, 1191–1203. [Google Scholar] [CrossRef] [PubMed]

- Taranto, F.; Pasqualone, A.; Mangini, G.; Tripodi, P.; Miazzi, M.M.; Pavan, S.; Montemurro, C. Polyphenol oxidases in crops: Biochemical, physiological and genetic aspects. Int. J. Mol. Sci. 2017, 18, 377. [Google Scholar] [CrossRef] [PubMed]

- Labavitch, J.M. Walnut. In The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks; ARS Agriculture Handbook Number 66; USADA: Colorado Springs, CO, USA, 2004. Available online: https://www.ars.usda.gov/is/np/CommercialStorage/CommercialStorage.pdf (accessed on 28 July 2023).

- Fields, R.P.; Donis-Gonzalez, I.R.; Lampinen, B.; Crisosto, C.H. Late maturity and excess irrigation trigger amber walnut (Juglans regia L.) kernel color at harvest in ‘Howard’, but not in ‘Chandler’. J. Am. Pomol. Soc. 2020, 74, 135–145. [Google Scholar]

- Sibbett, G.; Hendricks, L.; Carnill, G. Walnut quality and value maximized by harvest management. Calif. Agr. 1974, 28, 15–17. [Google Scholar]

- Beede, R.; The science (and art) of ethephon USAe on walnut. UC CE Kings county Ethephon Newsletter, AugUSAt. 2011. Available online: http://cekings.ucanr.edu/Newsletters_591/Nut_Crops/?newsletteritem=39678 (accessed on 28 July 2023).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).