Vibration Analysis of Pulse-Width-Modulated Nozzles in Vineyard Blast Sprayers

Abstract

1. Introduction

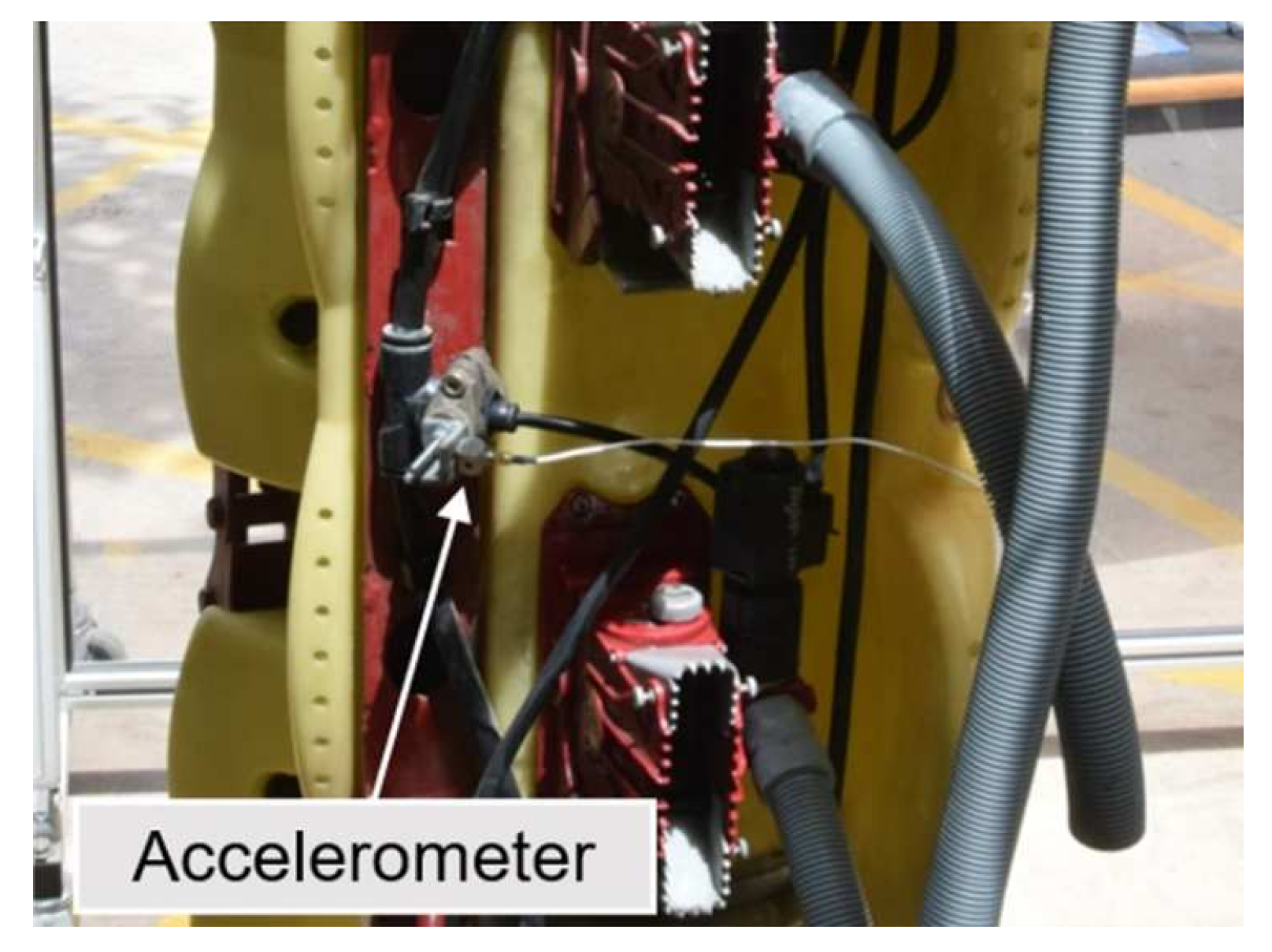

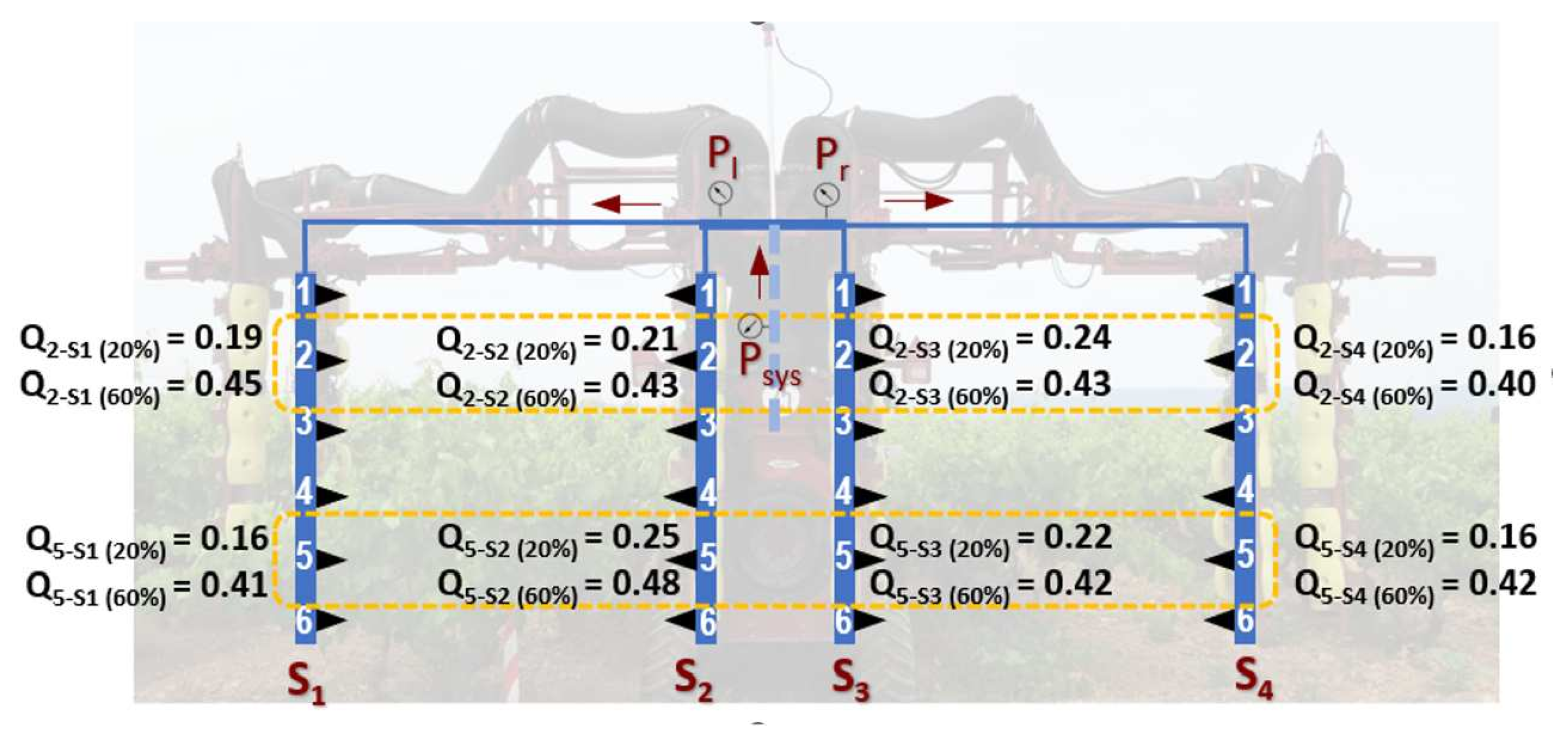

2. Materials and Methods

3. Results

3.1. Homogeneity among Nozzles and Sectors

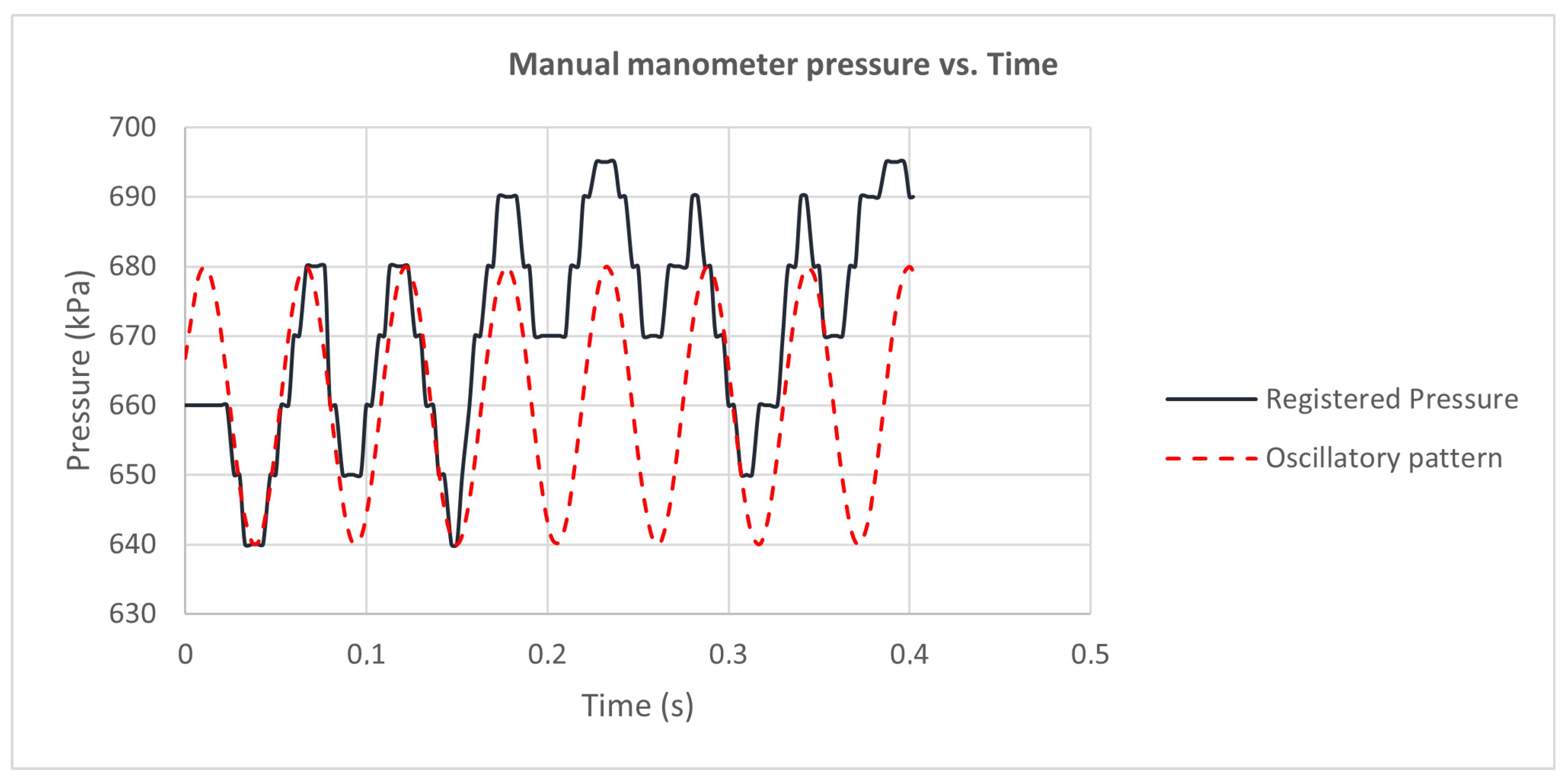

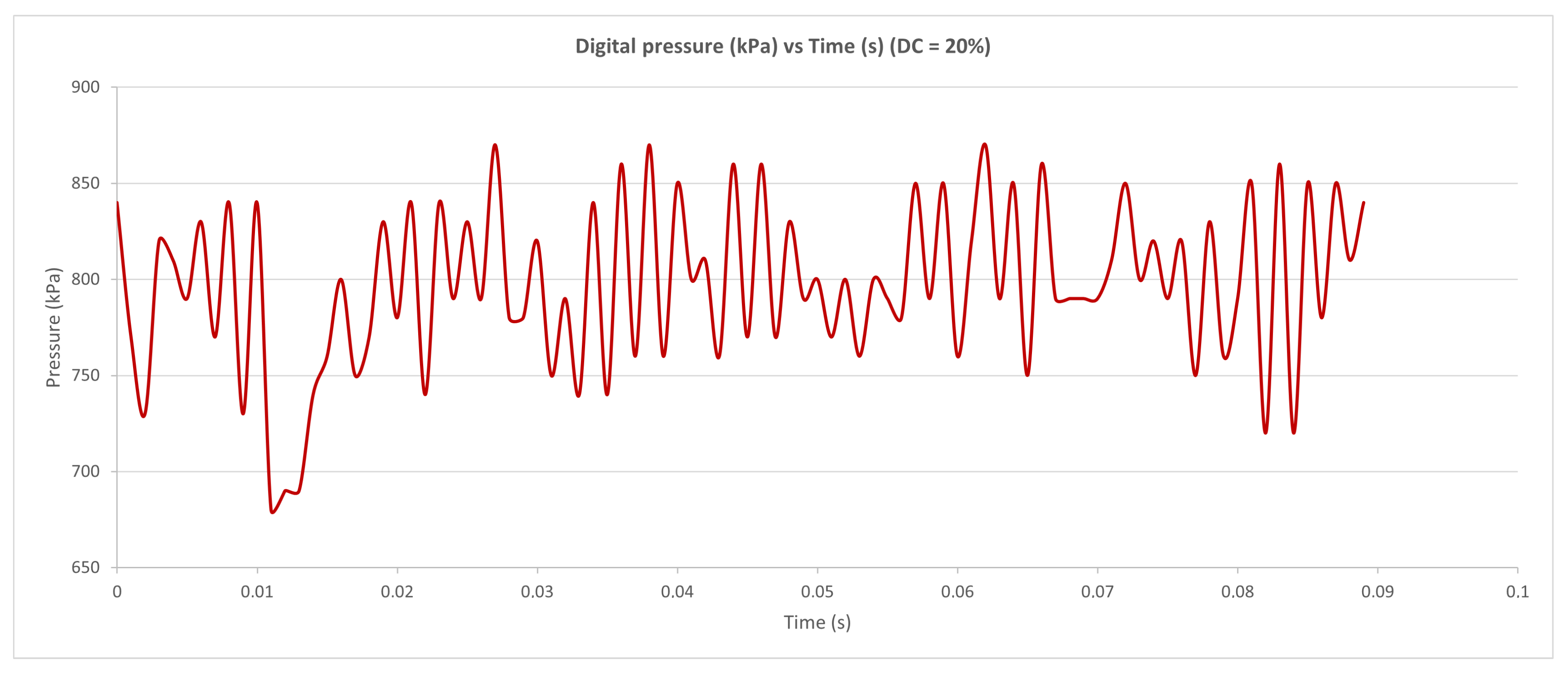

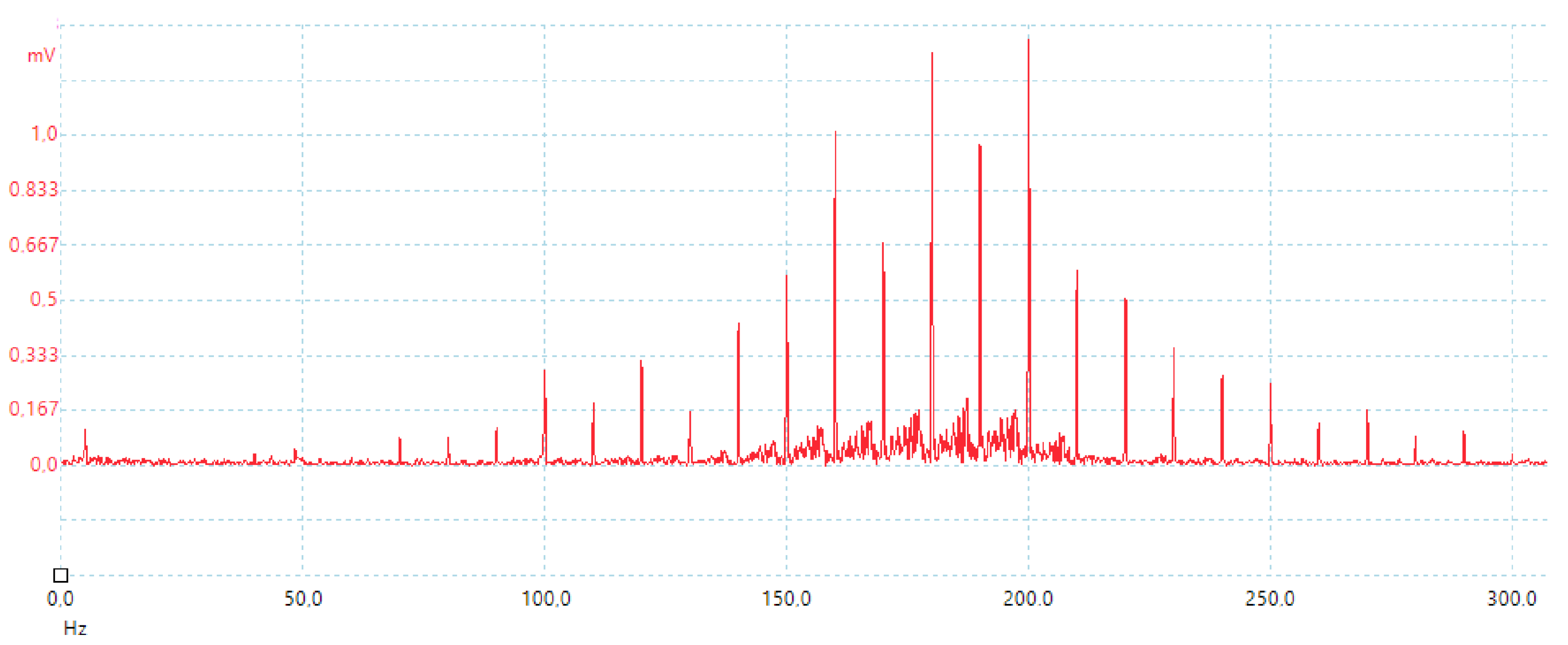

3.2. Pressure Oscillations

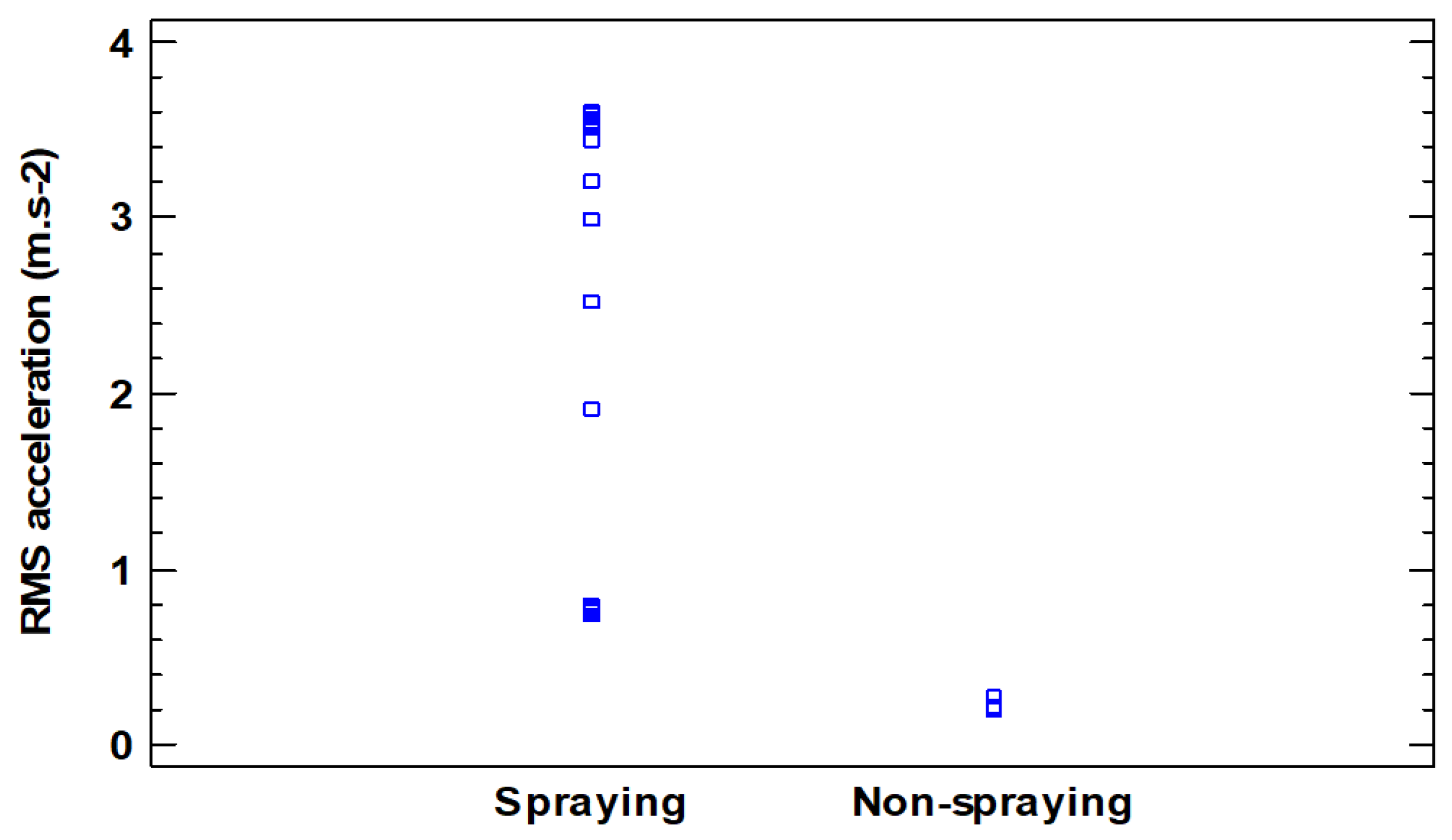

3.3. Vibration Analysis

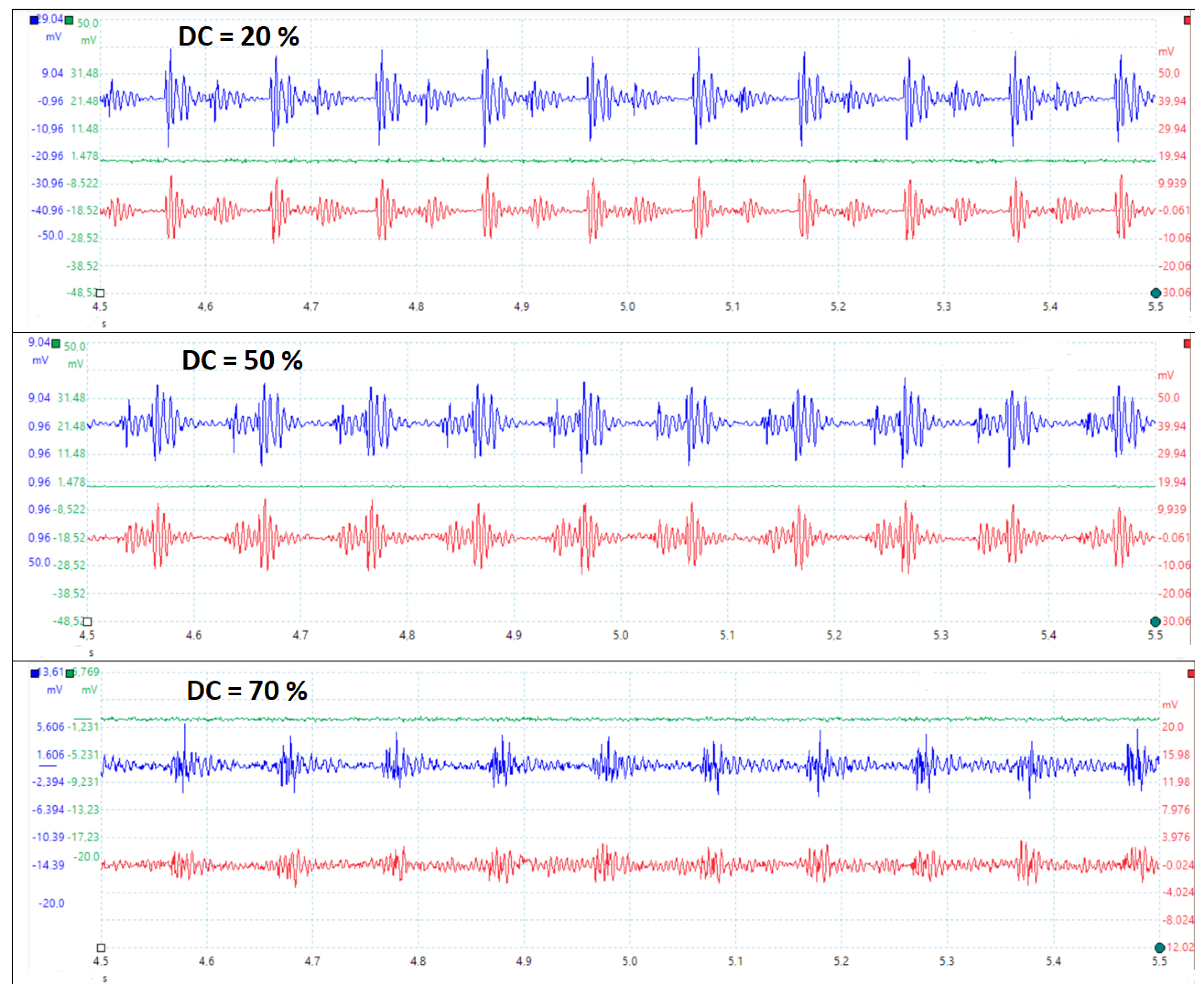

3.4. Waveform Study

- DC is the duty cycle calculated based on the accelerometer signal;

- time is the time when the valve is closing (ms);

- time is the time when the valve is opening (ms);

- time is the total cycle time, repeated every 100 ms (ms).

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Keulemans, W.; Bylemans, D.; de Coninck, B. Farming without Plant Protection Products: Can We Grow without Using Herbicides, Fungicides and Insecticides? European Parliament: Strasbourg, France, 2019; ISBN 978-92-846-3993-9. [Google Scholar]

- Verycruysse, F.; Steurbaut, W. POCER, the pesticide occupational and environmental riskindicator. Crop Prot. 2002, 21, 307–315. [Google Scholar] [CrossRef]

- Ranta, O.; Marian, O.; Muntean, M.V.; Molnar, A.; Ghețe, A.B.; Crișan, V.; Stănilă, S.; Rittner, T. Quality Analysis of Some Spray Parameters When Performing Treatments in Vineyards in Order to Reduce Environment Pollution. Sustainability 2021, 13, 7780. [Google Scholar] [CrossRef]

- Salyani, M.; Cromwell, R.P. Spray drift from ground and aerial applications. Trans. ASABE 1992, 35, 1113–1120. [Google Scholar] [CrossRef]

- Felsot, A.S.; Unsworth, J.B.; Linders, J.B.H.J.; Roberts, G.; Rautman, D.; Harris, C.; Carazo, E. Agrochemical spray drift; assessment and mitigation—A review. J. Environ. Sci. Health Part B 2011, 46, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Schönenberger, U.T.; Simon, J.; Stamm, C. Are spray drift losses to agricultural roads more important for surface water contamination than direct drift to surface waters? Sci. Total Environ. 2019, 809, 151102. [Google Scholar] [CrossRef]

- Rathnayake, A.P.; Khot, L.R.; Hoheisel, G.A.; Thistle, H.W.; Teske, M.E.; Willett, M.J. Downwind spray drift assessment for airblast sprayer applications in a modern apple orchard system. Trans. ASABE 2021, 64, 601–613. [Google Scholar] [CrossRef]

- Tardáguila, J.; Stoll, M.; Gutiérrez, S.; Proffitt, T.; Diago, M.P. Smart applications and digital technologies in viticulture: A review. Smart Agric. Technol. 2021, 1, 100005. [Google Scholar] [CrossRef]

- Reichenberger, S.; Bach, B.; Skitschak, A.; Frede, H.G. Mitigation strategies to reduce pesticide inputs into ground- and surface water and their effectiveness: A review. Sci. Total Environ. 2007, 384, 601–613. [Google Scholar] [CrossRef]

- Arvidsson, T.; Bergström, L.; Kreuger, J. Spray drift as influenced by meteorological and technical factors. Pest Manag. Sci. 2011, 67, 586–598. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Gallart, M. Use of a terrestrial LIDAR sensor for drift detection in vineyard spraying. Sensors 2013, 13, 516–534. [Google Scholar] [CrossRef]

- Gregorio, E.; Rosell-Polo, J.R.; Sanz, R.; Rocadenbosch, F.; Solanelles, F.; Garcerá, C.; Chueca, P.; Arnó, J.; del Moral, I.; Masip, J. LIDAR as an alternative to passive collectors to measure pesticide spray drift. Atmos. Environ. 2014, 82, 83–93. [Google Scholar] [CrossRef]

- Grella, M.; Miranda-Fuentes, A.; Marucco, P.; Balsari, P.; Gioelli, F. Development of drift-reducing spouts for vineyard pneumatic sprayers: Measurement of droplet size spectra generated and their classification. Appl. Sci. 2020, 10, 7826. [Google Scholar] [CrossRef]

- Song, L.; Huang, J.; Liang, X.; Yang, S.X.; Hu, W.; Tang, D. An Intelligent Multi-Sensor Variable Spray System with Chaotic Optimization and Adaptive Fuzzy Control. Sensors 2020, 20, 2954. [Google Scholar] [CrossRef] [PubMed]

- Mahmud, M.S.; Zahid, A.; He, L.; Zhu, H.; Choi, D.; Krawczy, G.; Heinemann, P. Opportunities and possibilities of developing an advanced precision spraying system for tree fruits. Sensors 2021, 21, 3262. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, H.; Chen, Y.; Shen, Y.; Ozkan, H.E. An Electronic Flow Control System for a Variable-rate Tree Sprayer. In Proceedings the 2021 ASABE Annual International Virtual Meeting, Dallas, TX, USA, 29 July–1 August 2021; Paper Number 2100038, ASABE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2021; Volume 121337321. [Google Scholar] [CrossRef]

- Silva, E.J.; Zhu, H.; Arantes Rodrigues da Cunha, J.P. Spray outputs from a variable-rate sprayer manipulated with PWM solenoid valves. Appl. Eng. Agric. 2018, 34, 527–534. [Google Scholar] [CrossRef]

- Fabula, J.V.; Sharda, A.; Flippo, D.; Ciampiti, I.; Kang, Q. Boom pressure and droplet size uniformity of a pulse width modulation (PWM) spray technology. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, Omaha, NB, USA, 12–15 July 2020; Paper Number 2001041, ASABE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2020; Volume 2001041. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Zhang, Z.; Wei, Z.; Chen, L.; Ozkan, E. Evaluation of PWM technologies for pesticide spray applications in a two-year old apple orchard. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, Omaha, NB, USA, 12–15 July 2020; Paper Number 2000079, ASABE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2020; Volume 2000079. [Google Scholar] [CrossRef]

- Salcedo, R.; Zhu, H.; Jeon, H.; Wei, Z.; Ozkan, E.; Gil, E. Characterization of volumetric droplet size distributions from PWM-controlled hollow-cone nozzles designed for variable-rate air-assisted sprayers. In Proceedings of the 2021 ASABE Annual International Virtual Meeting, Virtual, 12–18 July 2021; Paper Number 2100038, ASABE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2021; Volume 2100038. [Google Scholar] [CrossRef]

- Pokharel, P.; Sama, M.P. The effect of nozzle body volume on pressure dynamics in a PWM sprayer system. Trans. ASABE 2022, 65, 1355–1363. [Google Scholar] [CrossRef]

- Fabula, J.; Sharda, A.; Kang, Q.; Flippo, D. Nozzle flow rate, pressure drop, and response time of pulse width modulation (PWM) nozzle control systems. Trans. ASABE 2021, 64, 1519–1532. [Google Scholar] [CrossRef]

- Ortí, E.; Cuenca, A.; Pérez, M.; Torregrosa, A.; Ortiz, C.; Rovira-Más, F. Preliminary Evaluation of a Blast Sprayer Controlled by Pulse-Width-Modulated Nozzles. Sensors 2022, 22, 4924. [Google Scholar] [CrossRef]

- Feijoo, F.; Gomez-Gil, F.J.; Gomez-Gil, J. Application of Composite Spectrum in Agricultural Machines. Sensors 2020, 20, 5519. [Google Scholar] [CrossRef]

- Wang, J.; Xu, C.; Xu, Y.; Wang, J.; Zhou, W.; Wang, Q.; Tang, H. Resonance Analysis and Vibration Reduction Optimization of Agricultural Machinery Frame—Taking Vegetable Precision Seeder as an Example. Processes 2021, 9, 1979. [Google Scholar] [CrossRef]

- Samuel, S.; Singh, H.; Singh, J.; Prakash, C.; Dhabi, Y.K. Whole body vibration exposure among the tractor operator during soil tillage operation: An evaluation using ISO 2631-5 Standard. Shock Vib. 2022, 2022, 6412120. [Google Scholar] [CrossRef]

- Herbst, A.; Osteroth, H.J.; Stendel, H. A novel method for testing automatic systems for controlling the spray boom height. Biosyst. Eng. 2018, 174, 115–125. [Google Scholar] [CrossRef]

- Qiu, W.; Yao, X.; Zhu, Y.; Sun, H.; Zhou, L.; Xiao, M. Analysis of Factors Influencing Vibration Suppression of Spray Boom-Air Suspension for Medium and Small-Scale High-Clearance Sprayersy. Sensors 2021, 21, 6753. [Google Scholar] [CrossRef] [PubMed]

- Kappau, R.; de Meira, A.D.; Walber, M. Development of an automatic airflow control system for precision sprayers based on tree canopy density. Eng. Agric. 2021, 41, 1225–1240. [Google Scholar] [CrossRef]

- Kennes, P.; Anthonis, J.; Ramon, H. Modelling and Optimization of the Dynamic Behaviour of Sprayer Booms. IFAC Proc. Vol. 1998, 31, 321–325. [Google Scholar] [CrossRef]

- Herbst, A.; Wolf, P. Spray deposit distribution from agricultural boom sprayers in dynamic conditions. In Proceedings of the 2001 ASABE Annual International Meeting, Sacramento, CA, USA, 29 July–1 August 2001; Paper Number 210003, ASABE Annual Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2001; Volume 210003. [Google Scholar] [CrossRef]

- Tahmasebi, M.; Mailah, M.; Gohari, M.; Abd Rahman, R. Vibration suppression of sprayer boom structure using active torque control and iterative learning. Part I: Modelling and control via simulation. J. Vibr. Control 2018, 24, 4689–4699. [Google Scholar] [CrossRef]

- Tahmasebi, M.; Mailah, M.; Gohari, M.; Abd Rahman, R. Vibration suppression of sprayer boom structure using active torque control and iterative learning. Part II: Experimental implementation. J. Vibr. Control 2018, 24, 4740–4750. [Google Scholar] [CrossRef]

| Source | Sum of Squares | df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Between groups | 1025.65 | 2 | 512.83 | 1386.04 | 0.0000 |

| Intra groups | 2.22 | 6 | 0.37 | ||

| Total | 1027.87 | 8 |

| Theoretical DC (%) | Registered DC (%) | Maximum DC (%) | Minimum DC (%) |

|---|---|---|---|

| 20 | 43.63 | 43.29 | 43.97 |

| 50 | 70.60 | 70.26 | 70.94 |

| 70 | 89.62 | 89.28 | 89.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz, C.; Torregrosa, A.; Saiz-Rubio, V.; Rovira-Más, F. Vibration Analysis of Pulse-Width-Modulated Nozzles in Vineyard Blast Sprayers. Horticulturae 2023, 9, 703. https://doi.org/10.3390/horticulturae9060703

Ortiz C, Torregrosa A, Saiz-Rubio V, Rovira-Más F. Vibration Analysis of Pulse-Width-Modulated Nozzles in Vineyard Blast Sprayers. Horticulturae. 2023; 9(6):703. https://doi.org/10.3390/horticulturae9060703

Chicago/Turabian StyleOrtiz, Coral, Antonio Torregrosa, Verónica Saiz-Rubio, and Francisco Rovira-Más. 2023. "Vibration Analysis of Pulse-Width-Modulated Nozzles in Vineyard Blast Sprayers" Horticulturae 9, no. 6: 703. https://doi.org/10.3390/horticulturae9060703

APA StyleOrtiz, C., Torregrosa, A., Saiz-Rubio, V., & Rovira-Más, F. (2023). Vibration Analysis of Pulse-Width-Modulated Nozzles in Vineyard Blast Sprayers. Horticulturae, 9(6), 703. https://doi.org/10.3390/horticulturae9060703