Precise Sensing of Leaf Temperatures for Smart Farm Applications

Abstract

1. Introduction

2. Materials and Methods

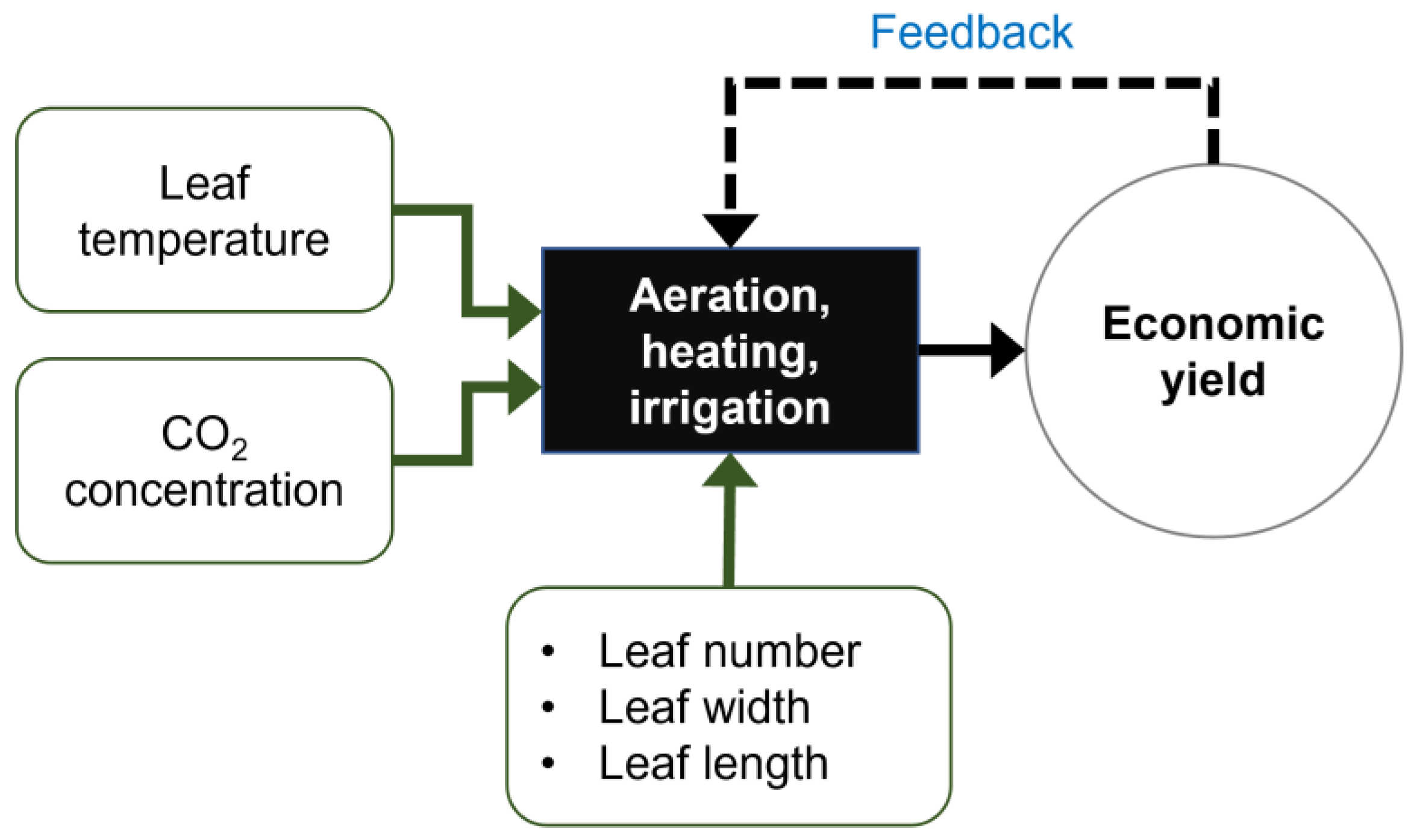

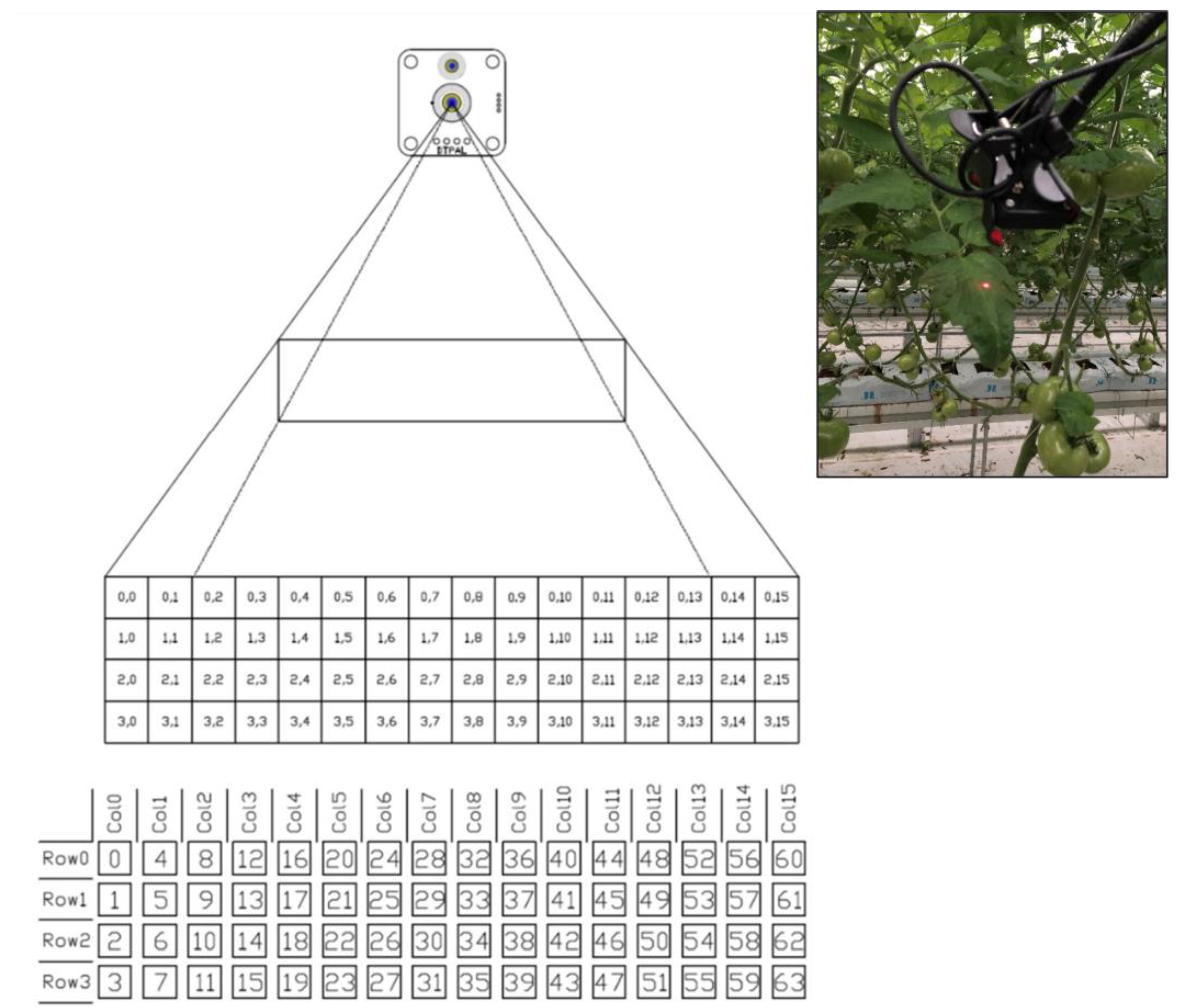

2.1. Design of a Leaf Temperature Sensor

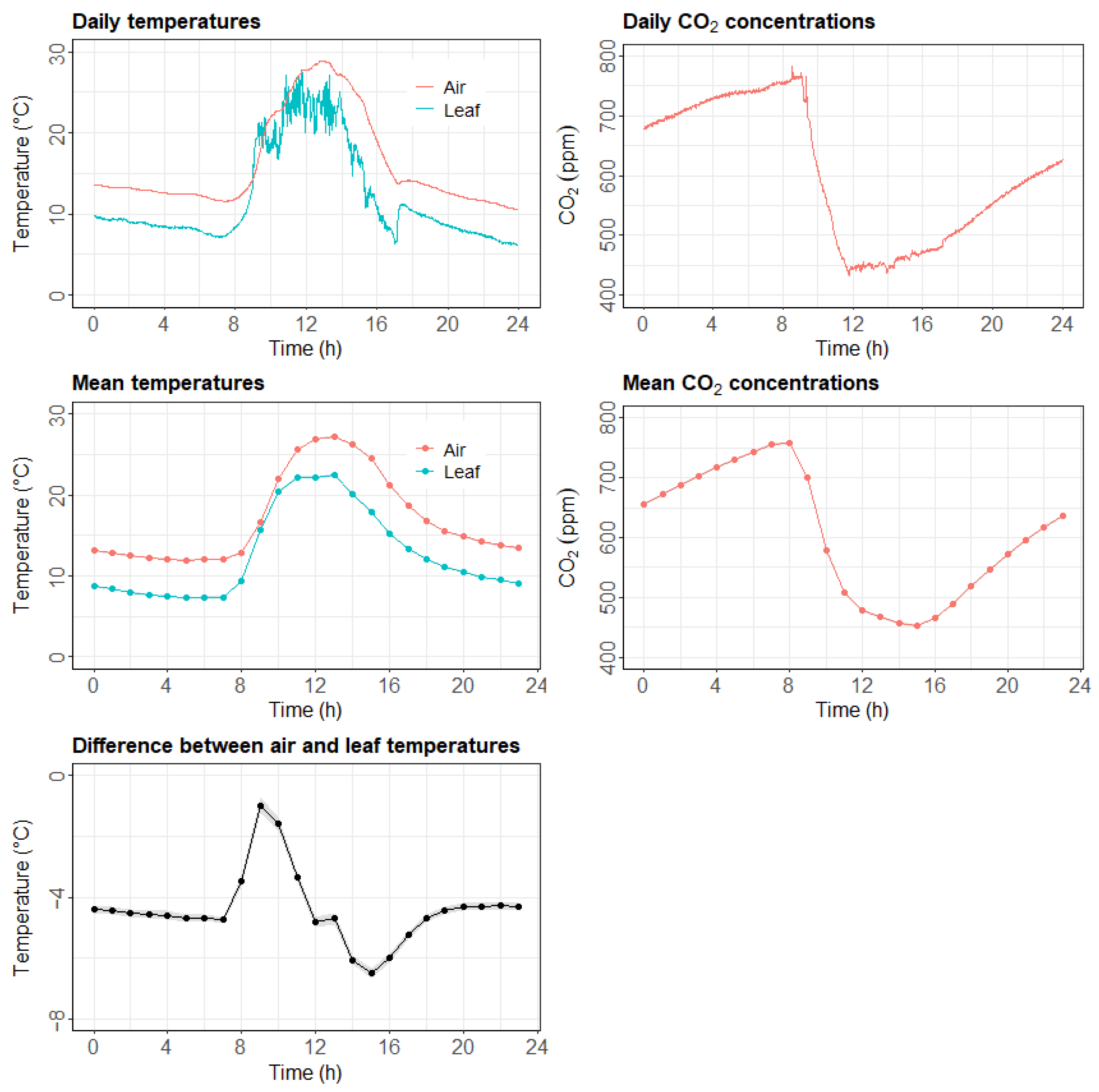

- When supplying nutrient solutions to vegetables, leaf temperature tends to decrease, suggesting increased transpiration cooling [27]. Leaf temperature is usually negatively correlated with transpiration by enhanced photosynthetic rate and heat distribution.

- CO2 assimilation patterns depend more on leaf temperature changes than air temperature [28]. Leaf CO2 assimilation is characterized by the thermal optimum, which is crop-specific and a function of temperatures in proximity.

- A lower range of leaf temperatures than air temperatures is expected, for example, when controlling window panels or heating. If this is the case, temperature stress will likely limit crop growth.

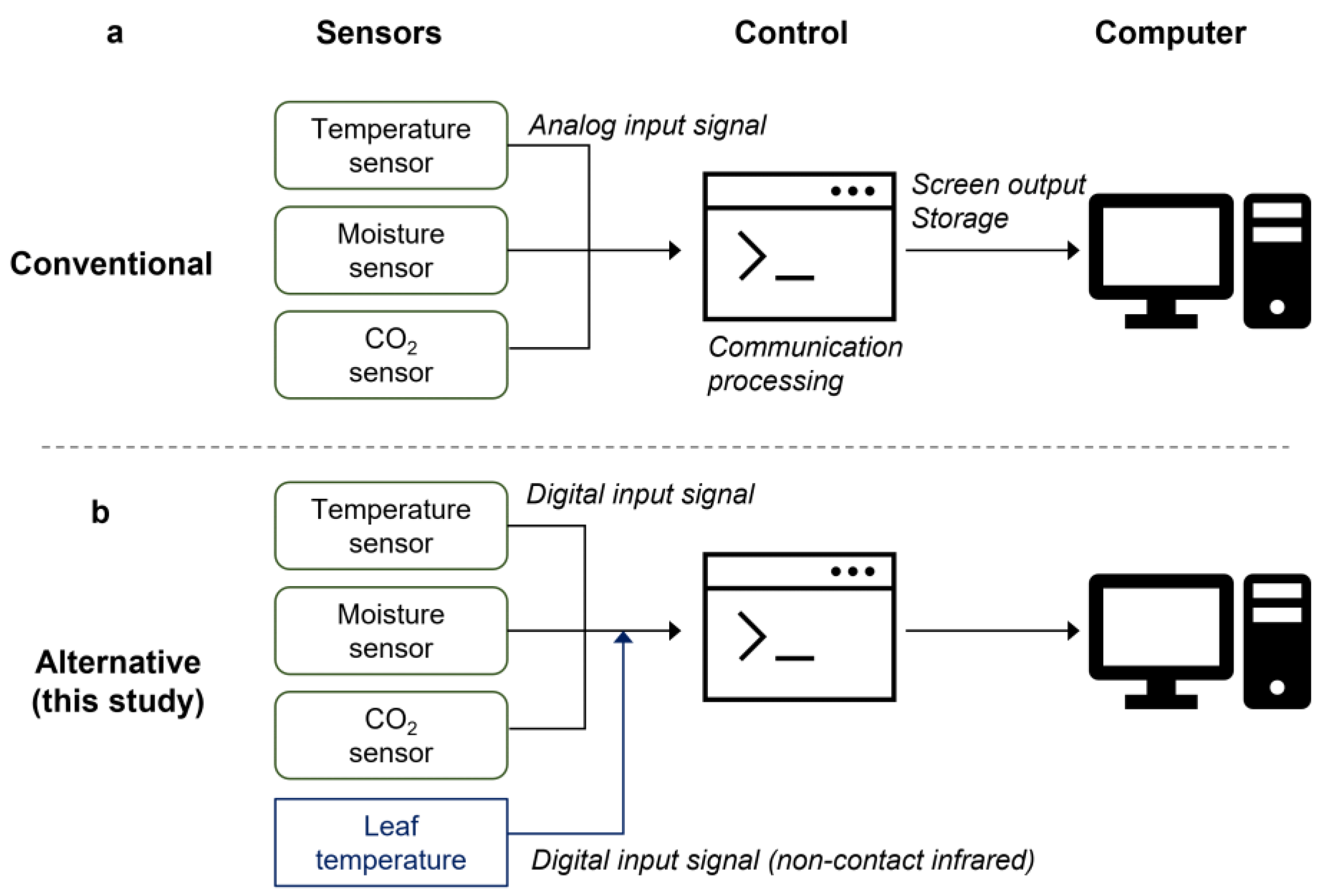

2.2. Development of New Hardware Components for Sensing

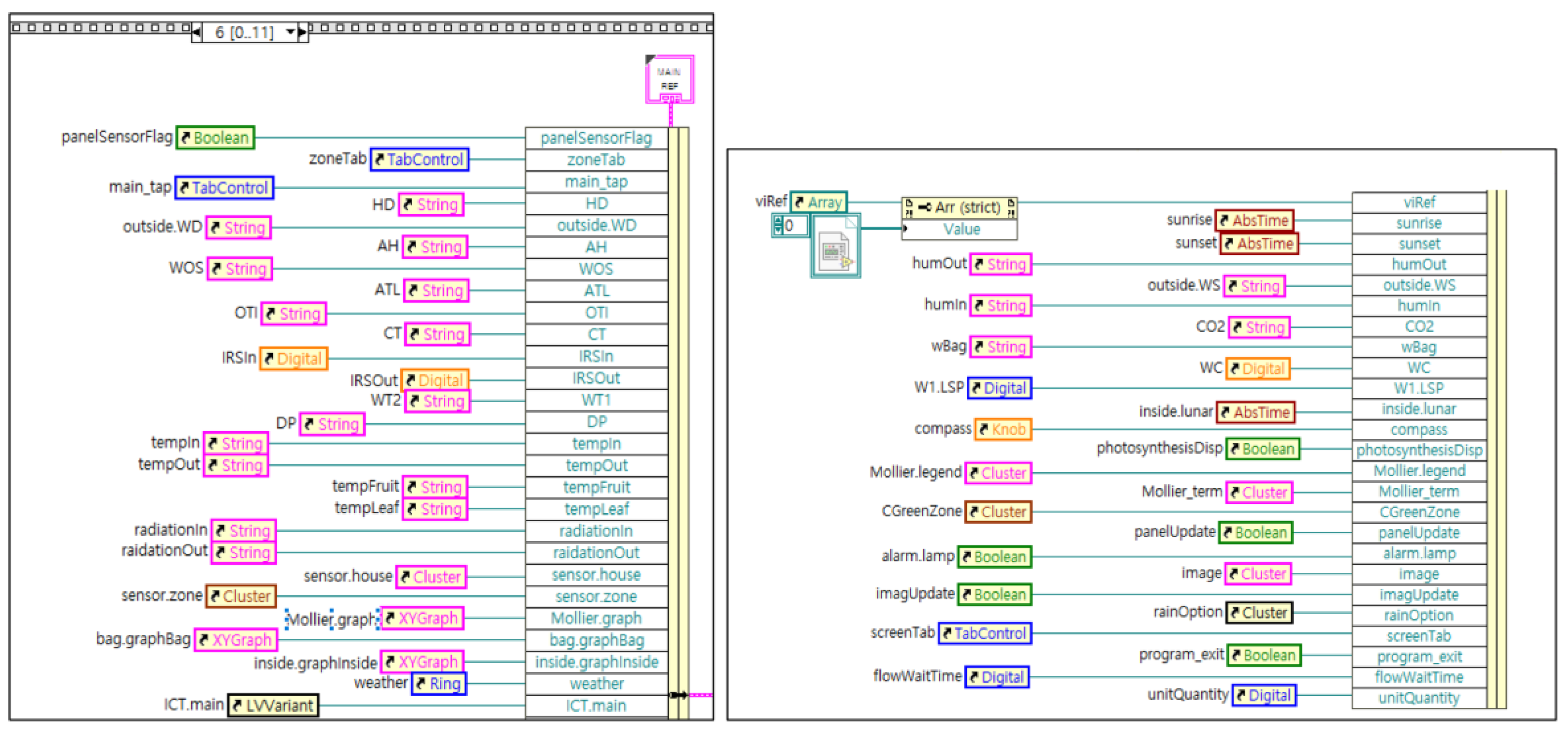

2.3. New Software Components for the Collection and Analysis of Sensing Data

2.4. Case Studies—Status of Smart Farms in the Republic of Korea

2.5. Data Analyses

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Management Element | Data |

|---|---|

| User Management |

|

| Sensor Management |

|

References

- Engler, N.; Krarti, M. Review of energy efficiency in controlled environment agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786. [Google Scholar] [CrossRef]

- McCartney, L.; Lefsrud, M.G. Protected agriculture in extreme environments: A review of controlled environment agriculture in tropical, arid, polar, and urban locations. Appl. Eng. Agric. 2018, 34, 455–473. [Google Scholar] [CrossRef]

- Wang, L.P.; Iddio, E.; Ewers, B. Introductory overview: Evapotranspiration (ET) models for controlled environment agriculture (CEA). Comput. Electron. Agric. 2021, 190, 106447. [Google Scholar] [CrossRef]

- Ragaveena, S.; Edward, A.S.; Surendran, U. Smart controlled environment agriculture methods: A holistic review. Rev. Environ. Sci. Biotechnol. 2021, 20, 887–913. [Google Scholar] [CrossRef]

- Jensen, M.H.; Malter, A.J. Protected Agriculture, A Global Review; The World Bank: Washington, DC, USA, 1995. [Google Scholar]

- Maureira, F.; Rajagopalan, K.; Stöckle, C.O. Evaluating tomato production in open-field and high-tech greenhouse systems. J. Clean. Prod. 2022, 337, 130459. [Google Scholar] [CrossRef]

- Cohen, A.R.; Chen, G.; Berger, E.M.; Warrier, S.; Lan, G.H.; Grubert, E.; Dellaert, F.; Chen, Y.S. Dynamically controlled environment agriculture: Integrating machine learning and mechanistic and physiological models for sustainable food cultivation. ACS ES&T Eng. 2022, 2, 3–19. [Google Scholar] [CrossRef]

- Nemali, K. History of controlled environment horticulture: Greenhouses. HortScience 2022, 57, 239–246. [Google Scholar] [CrossRef]

- Baudoin, W.; Nersisyan, A.; Shamilov, A.; Hodder, A.; Gutierrez, D.; De Pascale, S.; Nicola, S.; Gruda, N.; Urban, L.; Tany, J. Good Agricultural Practices for Greenhouse Vegetable Production in the South East European Countries: Principles for Sustainable Intensification of Smallholder Farms; FAO: Rome, Italy, 2017. [Google Scholar]

- Shamshiri, R.R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22. [Google Scholar] [CrossRef]

- Katul, G.G.; Oren, R.; Manzoni, S.; Higgins, C.; Parlange, M.B. Evapotranspiration: A process driving mass transport and energy exchange in the soil-plant-atmosphere-climate system. Rev. Geophys. 2012, 50. [Google Scholar] [CrossRef]

- Xin, P.P.; Li, B.; Zhang, H.H.; Hui, J. Optimization and control of the light environment for greenhouse crop production. Sci. Rep. 2019, 9, 8650. [Google Scholar] [CrossRef]

- Massa, G.D.; Kim, H.H.; Wheeler, R.M.; Mitchell, C.A. Plant productivity in response to LED lighting. HortScience 2008, 43, 1951–1956. [Google Scholar] [CrossRef]

- O’Sullivan, C.A.; Bonnett, G.D.; McIntyre, C.L.; Hochman, Z.; Wasson, A.P. Strategies to improve the productivity, product diversity and profitability of urban agriculture. Agric. Syst. 2019, 174, 133–144. [Google Scholar] [CrossRef]

- Tan, B.; Li, Y.H.; Liu, T.G.; Tan, X.; He, Y.X.; You, X.J.; Leong, K.H.; Liu, C.; Li, L.G. Response of plant rhizosphere microenvironment to water management in soil- and substrate-based controlled environment agriculture (CEA) systems: A review. Front. Plant Sci. 2021, 12, 691651. [Google Scholar] [CrossRef]

- Rai, M.; Ingle, A. Role of nanotechnology in agriculture with special reference to management of insect pests. Appl. Microbiol. Biotechnol. 2012, 94, 287–293. [Google Scholar] [CrossRef] [PubMed]

- Rayhana, R.; Xiao, G.G.; Liu, Z. Printed sensor technologies for monitoring applications in smart farming: A review. IEEE Trans. Instrum. Meas. 2021, 70, 9513419. [Google Scholar] [CrossRef]

- Nicholson, C.F.; Harbick, K.; Gómez, M.I.; Mattson, N.S. An Economic and Environmental Comparison of Conventional and Controlled Environment Agriculture (CEA) Supply Chains for Leaf Lettuce to US Cities. In Food Supply Chains in Cities: Modern Tools for Circularity and Sustainability; Aktas, E., Bourlakis, M., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 33–68. [Google Scholar]

- Adegbeye, M.J.; Reddy, P.R.K.; Obaisi, A.I.; Elghandour, M.M.M.Y.; Oyebamiji, K.J.; Salem, A.Z.M.; Morakinyo-Fasipe, O.T.; Cipriano-Salazar, M.; Camacho-Diaz, L.M. Sustainable agriculture options for production, greenhouse gasses and pollution alleviation, and nutrient recycling in emerging and transitional nations—An overview. J. Clean. Prod. 2020, 242, 118319. [Google Scholar] [CrossRef]

- Sicari, S.; Rizzardi, A.; Grieco, L.A.; Coen-Porisini, A. Security, privacy and trust in Internet of Things: The road ahead. Comput. Netw. 2015, 76, 146–164. [Google Scholar] [CrossRef]

- Li, H.X.; Guo, Y.; Zhao, H.J.; Wang, Y.; Chow, D. Towards automated greenhouse: A state of the art review on greenhouse monitoring methods and technologies based on internet of things. Comput. Electron. Agric. 2021, 191, 106558. [Google Scholar] [CrossRef]

- Kobza, J.; Edwards, G.E. Influences of leaf temperature on photosynthetic carbon metabolism in wheat. Plant Physiol. 1987, 83, 69–74. [Google Scholar] [CrossRef]

- Gates, D.M. Transpiration and leaf temperature. Annu. Rev. Plant Physiol. 1968, 19, 211–238. [Google Scholar] [CrossRef]

- Yu, L.; Wang, W.; Zhang, X.; Zheng, W. A Review on Leaf Temperature Sensor: Measurement Methods and Application. In Proceedings of the Computer and Computing Technologies in Agriculture IX, Beijing, China, 27–30 September 2015; pp. 216–230. [Google Scholar]

- Wang, S.; Deltour, J. An experimental model for leaf temperature of greenhouse-grown tomato. In Proceedings of the International Symposium Greenhouse Management for Better Yield & Quality in Mild Winter Climates, Antalya, Turkey, 3 November 1997; pp. 101–106. [Google Scholar]

- Mellor, R.S.; Salisbury, F.B.; Raschke, K. Leaf temperatures in controlled environments. Planta 1964, 61, 56–72. [Google Scholar] [CrossRef]

- Gates, D.M. Leaf temperature and transpiration. Agron. J. 1964, 56, 273–277. [Google Scholar] [CrossRef]

- Laing, W.A. Temperature and light response curves for photosynthesis in kiwifruit (Actinidia chinensis) cv. Hayward. N. Z. J. Agric. Res. 1985, 28, 117–124. [Google Scholar] [CrossRef]

- Darwin, B.; Dharmaraj, P.; Prince, S.; Popescu, D.E.; Hemanth, D.J. Recognition of bloom/yield in crop images using deep learning models for smart agriculture: A review. Agronomy 2021, 11, 646. [Google Scholar] [CrossRef]

- Jabir, B.; Falih, N. Deep learning-based decision support system for weeds detection in wheat fields. Int. J. Electr. Comput. Eng. 2022, 12, 816–825. [Google Scholar] [CrossRef]

- Statistics Korea. Vegetable Production—Fruits and Vegetables. 2021. Available online: https://kosis.kr/ (accessed on 20 January 2023).

- Smart Farm Korea. Smart Farm Status. 2022. Available online: https://www.smartfarmkorea.net (accessed on 20 January 2023).

- Dickey, D.A.; Fuller, W.A. Distribution of the estimators for autoregressive time series with a unit root. J. Am. Stat. Assoc. 1979, 74, 427–431. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021. [Google Scholar]

- Harrell, F.E., Jr. Hmisc: Harrell Miscellaneous. R Package Version 4.7-1. 2022. Available online: https://CRAN.R-project.org/package=Hmisc (accessed on 20 January 2023).

- Wittwer, S.H.; Castilla, N. Protected cultivation of horticultural crops worldwide. HortTechnology 1995, 5, 6–23. [Google Scholar] [CrossRef]

- Shamshiri, R.R.; Bojic, I.; van Henten, E.; Balasundram, S.K.; Dworak, V.; Sultan, M.; Weltzien, C. Model-based evaluation of greenhouse microclimate using IoT-sensor data fusion for energy efficient crop production. J. Clean. Prod. 2020, 263, 121303. [Google Scholar] [CrossRef]

- Ramegowda, V.; Senthil-Kumar, M. The interactive effects of simultaneous biotic and abiotic stresses on plants: Mechanistic understanding from drought and pathogen combination. J. Plant Physiol. 2015, 176, 47–54. [Google Scholar] [CrossRef]

- Wise, R.R.; Olson, A.J.; Schrader, S.M.; Sharkey, T.D. Electron transport is the functional limitation of photosynthesis in field-grown Pima cotton plants at high temperature. Plant Cell Environ. 2004, 27, 717–724. [Google Scholar] [CrossRef]

- Lalic, B.; Eitzinger, J.; Marta, A.D.; Orlandini, S.; Sremac, A.F.; Pacher, B. Agricultural Meteorology and Climatology; Firenze University Press: Firenze, Italy, 2018; p. 353. [Google Scholar]

- Pieters, G.A.; Schurer, K. Leaf temperature measurement I. Thermocouples. Acta Bot. Neerl. 1973, 22, 569–580. [Google Scholar] [CrossRef]

- Hatfield, J.L.; Burke, J.J. Energy exchange and leaf temperature behavior of three plant species. Environ. Exp. Bot. 1991, 31, 295–302. [Google Scholar] [CrossRef]

| Component | Group | Variable | Description | Detection Range 1 |

|---|---|---|---|---|

| Standard sensors | Air (weather) | Temperature | Indoor and outdoor air temperature | −20–80 °C |

| Humidity 2 | Relative humidity in the atmosphere | 0–100% | ||

| Light intensity | Light intensity (solar radiation) inside and outside the greenhouse | 0–2000 Watts m−2 | ||

| Light integral | The number of active photons in the 400–700 nm range | 0–2000 µmol m−2 s−1 | ||

| CO2 | The concentration of CO2 in the atmosphere | 0–3000 ppm | ||

| Wind | Wind speed and wind direction | 0–40 m s−1; 0–360 azimuth | ||

| Supply/ drainage solution | EC | The electrical conductivity (EC) of a supply or drainage solution | 0–10 dS m−1 | |

| pH | The H+ ion concentration (acidity) of a supply or drainage solution | 2–12 | ||

| Soil | Temperature | The temperature of soil, media, nutrient solution, and root zone | −20–80 °C | |

| Water tension | Soil water tension (tensiometer) | 0–100 kPa | ||

| Water content | The volumetric water content of soil | 0–100% | ||

| Standard node | Data/ communi- cation | Sensor node | A device that can gather data and process the sensor information to monitor the environment and communicate with other nodes | |

| New sensor (this study) | Crop | Leaf (fruit) temperature | The leaf temperature of a crop using non-contact infrared radiation energy | −20–50 °C |

| Task | Description |

|---|---|

| Operation system | Microsoft Windows 10 Pro (64 bits) |

| Communication method | RS232C 1, TCP/IP 2, RS485 Modbus |

| Source code | Written in C/C++, Python |

| Hardware/sensors |

|

| Data collection/ display |

|

| Data interpretation |

|

| Maximum number of connection nodes | 255 channels |

| Farm Type | Sensing Type | Commodity | Number of Farms | Year Established |

|---|---|---|---|---|

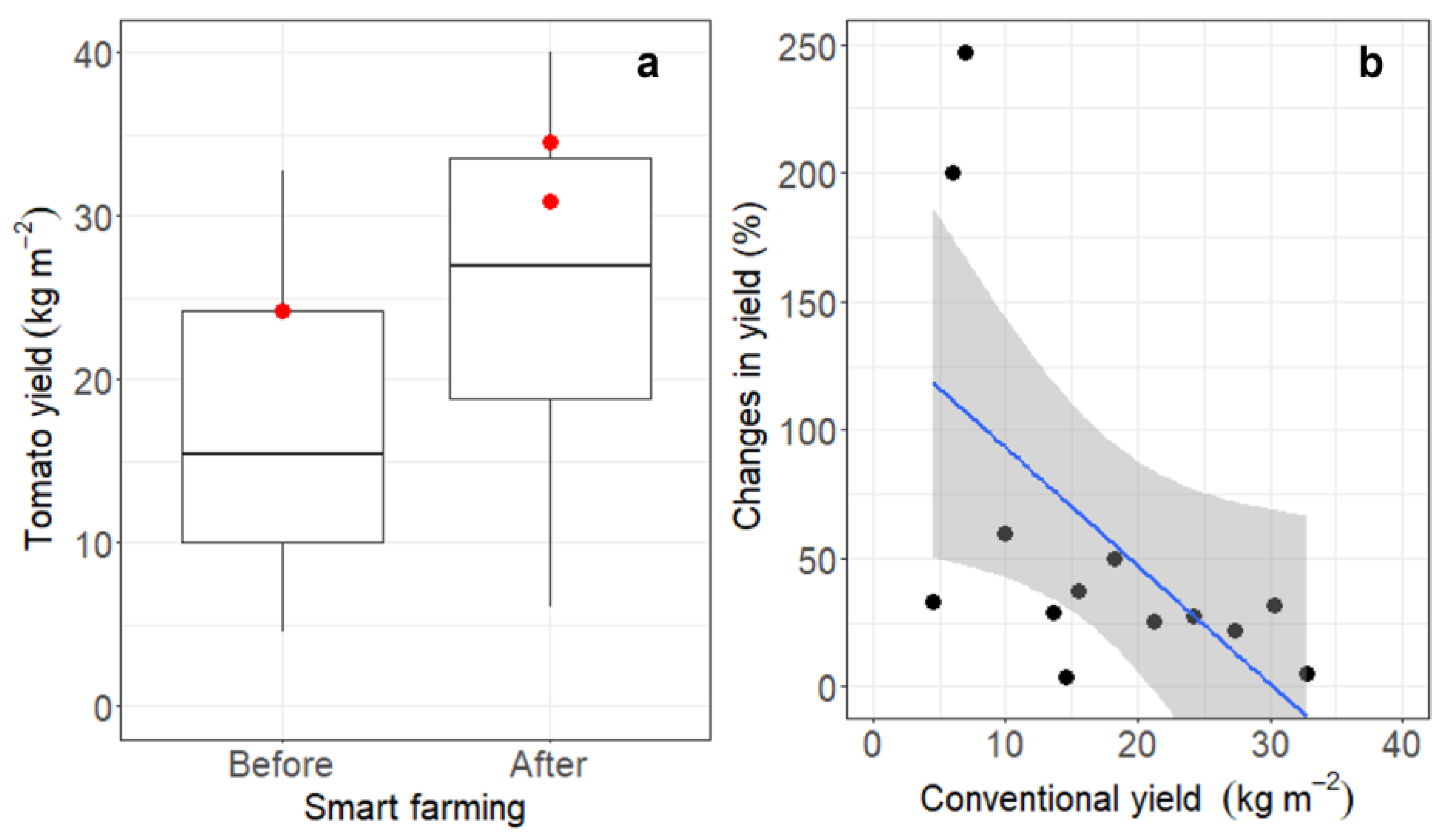

| Leading case | Standard data | Tomatoes | 16 | 11 farms (2016), 2 farms (2017), 3 farms (2019) |

| Case study 1 | Leaf temperature | Tomato | 1 | 2017 |

| Case study 2 | Leaf temperature | Tomato | 1 | 2021 |

| Leaf temperature | Strawberry | 2 | 2021 |

| Variable | r | p-Value |

|---|---|---|

| Indoor air temperature | 0.79 | <0.01 |

| Outdoor air temperature | ns | 0.613 |

| Soil (or growth media) temperature | −0.33 | <0.01 |

| Temperature of drainage solution | −0.08 | <0.01 |

| Dew point | 0.86 | <0.01 |

| Indoor air humidity | 0.08 | <0.01 |

| Outdoor air humidity | −0.49 | <0.01 |

| Humidity deficiency | 0.23 | <0.01 |

| Absolute humidity | 0.82 | <0.01 |

| CO2 concentrations inside the greenhouse | −0.54 | <0.01 |

| Light intensity inside the greenhouse | 0.72 | <0.01 |

| Light intensity outside the greenhouse | ns | 0.993 |

| Light integral inside the greenhouse | 0.07 | 0.016 |

| Light integral outside the greenhouse | ns | 0.634 |

| EC of supply solution | 0.20 | <0.01 |

| EC of drainage solution | 0.14 | <0.01 |

| pH of supply solution | −0.07 | 0.015 |

| pH of drainage solution | −0.19 | <0.01 |

| Weight of growth media | ns | 0.877 |

| Total amount of drainage solution | −0.07 | <0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, K.-H.; Sim, H.-S.; Lee, J.-K.; Lee, J. Precise Sensing of Leaf Temperatures for Smart Farm Applications. Horticulturae 2023, 9, 518. https://doi.org/10.3390/horticulturae9040518

Son K-H, Sim H-S, Lee J-K, Lee J. Precise Sensing of Leaf Temperatures for Smart Farm Applications. Horticulturae. 2023; 9(4):518. https://doi.org/10.3390/horticulturae9040518

Chicago/Turabian StyleSon, Ki-Ho, Han-Sol Sim, Jae-Kyoung Lee, and Juhwan Lee. 2023. "Precise Sensing of Leaf Temperatures for Smart Farm Applications" Horticulturae 9, no. 4: 518. https://doi.org/10.3390/horticulturae9040518

APA StyleSon, K.-H., Sim, H.-S., Lee, J.-K., & Lee, J. (2023). Precise Sensing of Leaf Temperatures for Smart Farm Applications. Horticulturae, 9(4), 518. https://doi.org/10.3390/horticulturae9040518