Development of Nutrient Solution Compositions for Paprika Cultivation in a Closed Coir Substrate Hydroponic System in Republic of Korea’s Winter Cropping Season

Abstract

1. Introduction

2. Materials and Methods

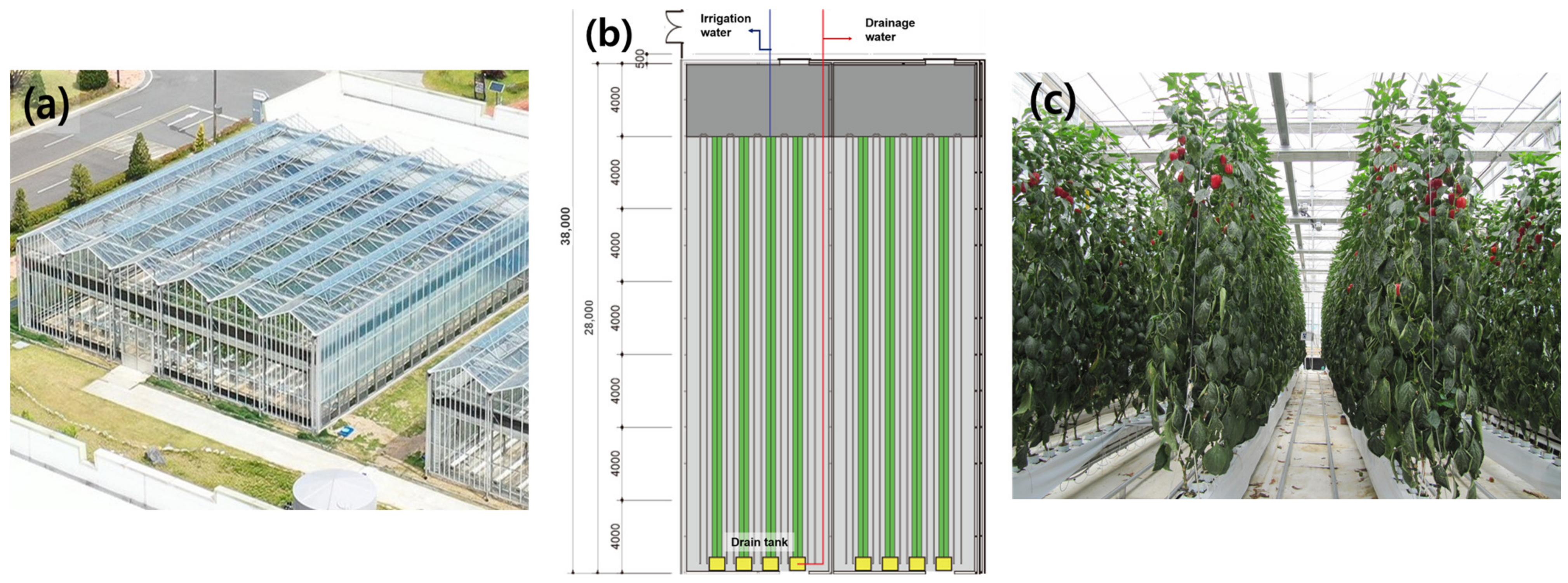

2.1. Experimental Site and Conditions

2.2. Plant Materials

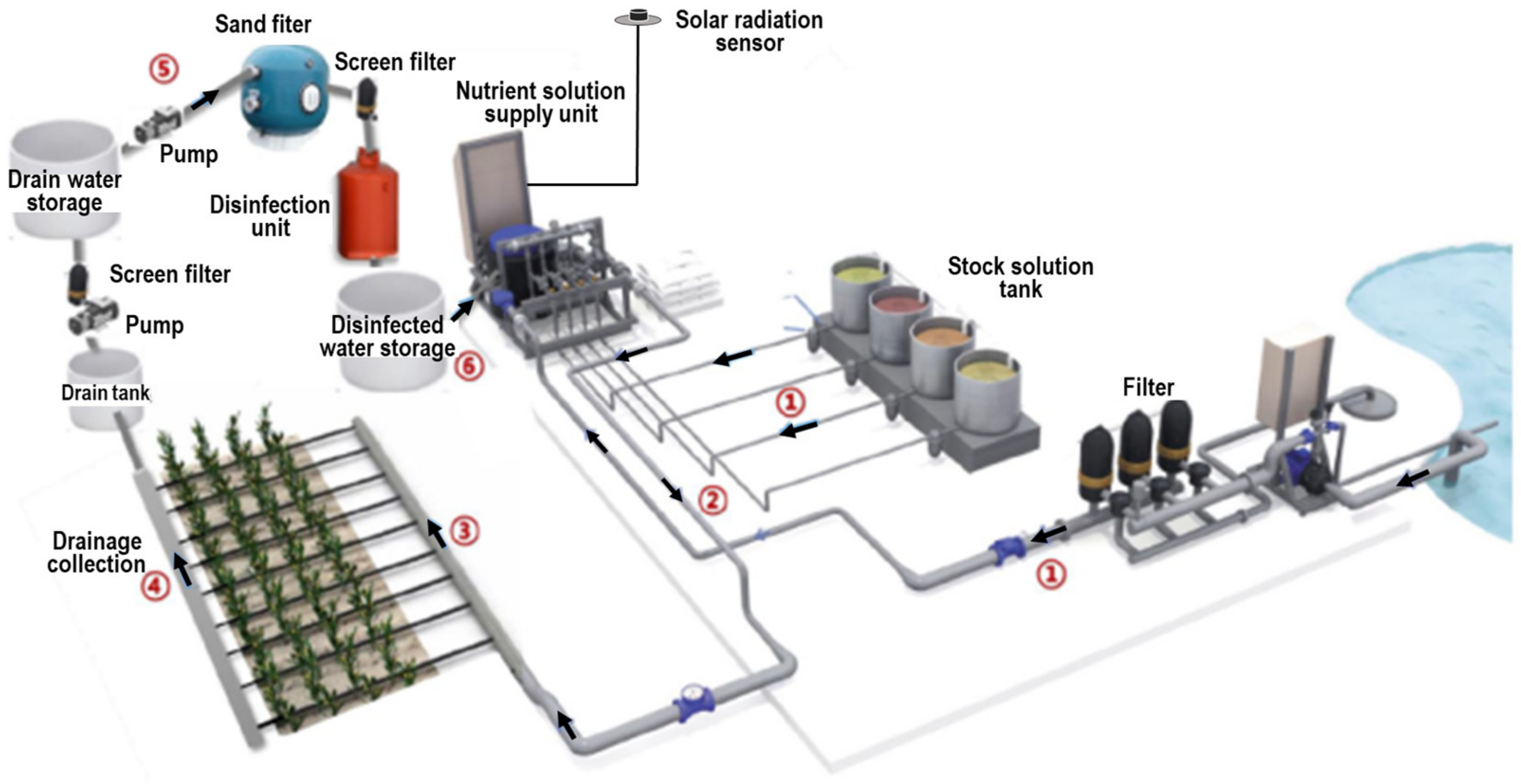

2.3. Closed Hydroponics System Setup

2.4. Experimental Design

2.4.1. Nutrient Solution Preparation and Management for Exp. 1

2.4.2. Nutrient Solution Preparation and Management for Exp. 2

2.4.3. Nutrient Solution Preparation and Management for Exp. 3

2.4.4. The pH, EC, and Mixing Ratio of the Reused Nutrient Solution

2.5. Measurements

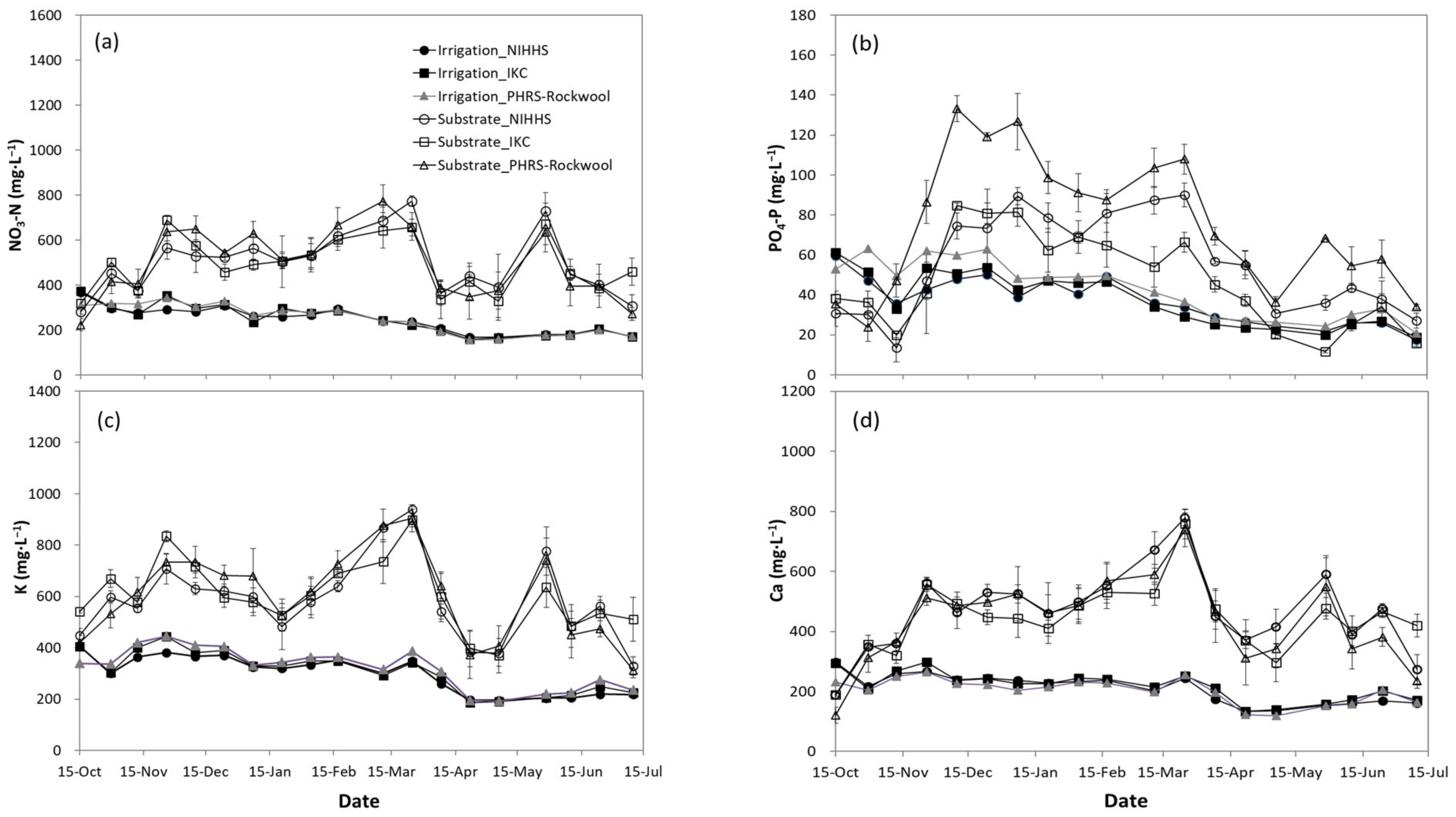

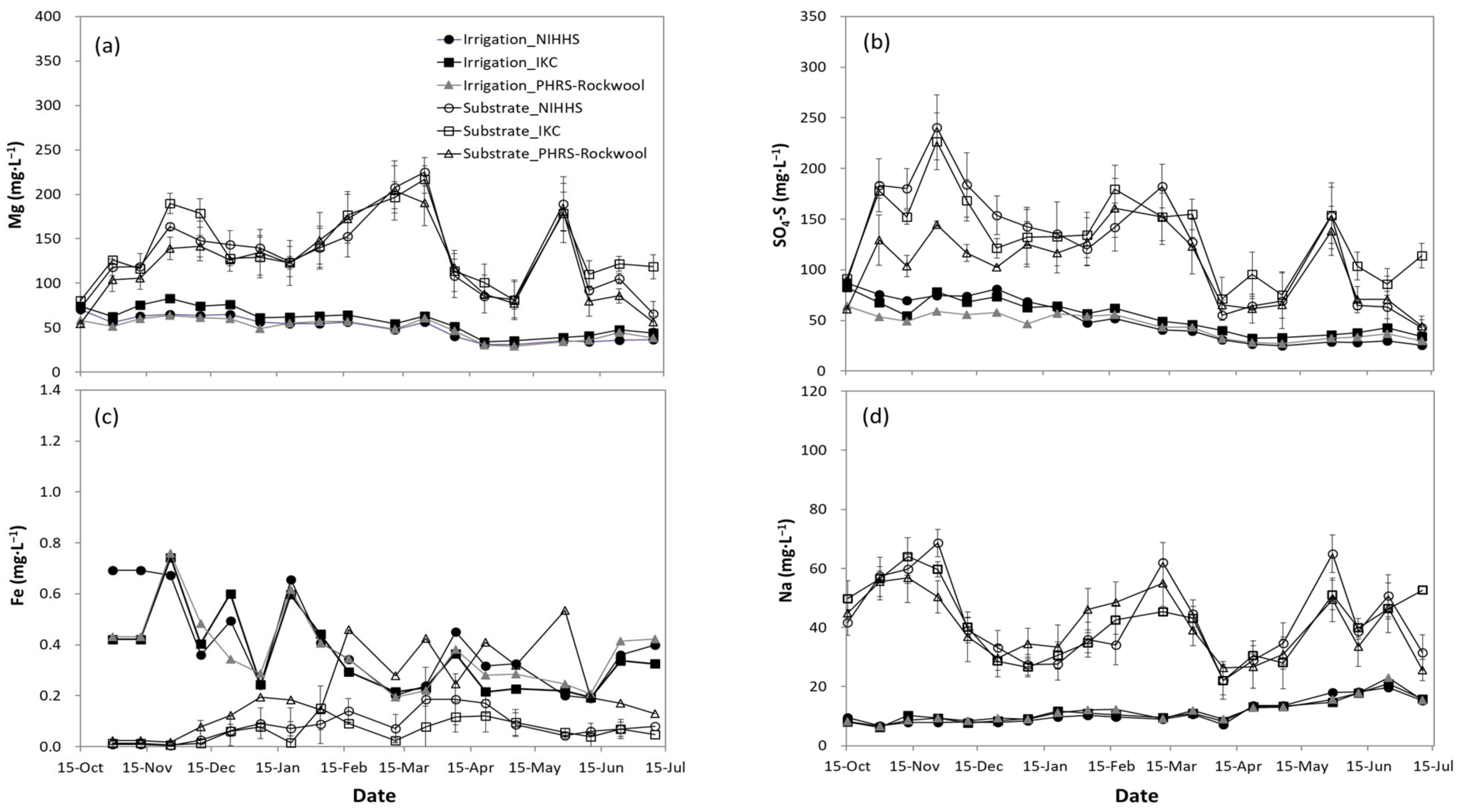

2.5.1. Changes in pH, EC, and Mineral Ions in Irrigation, Drainage, and Root Zone

2.5.2. Yield and Fruit Quality

2.5.3. Photosynthetic Characteristics

2.6. Statistical Analyses

3. Results and Discussion

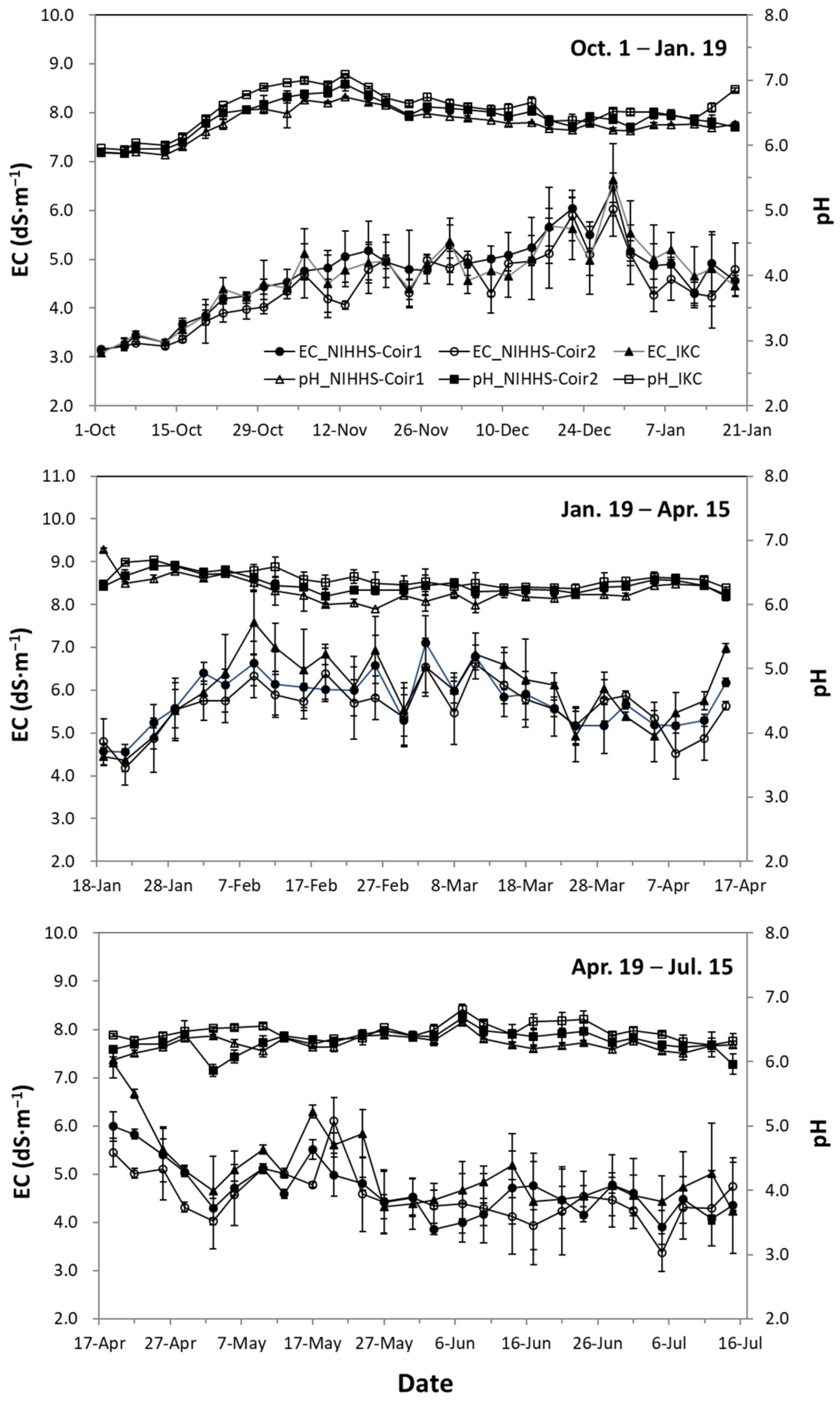

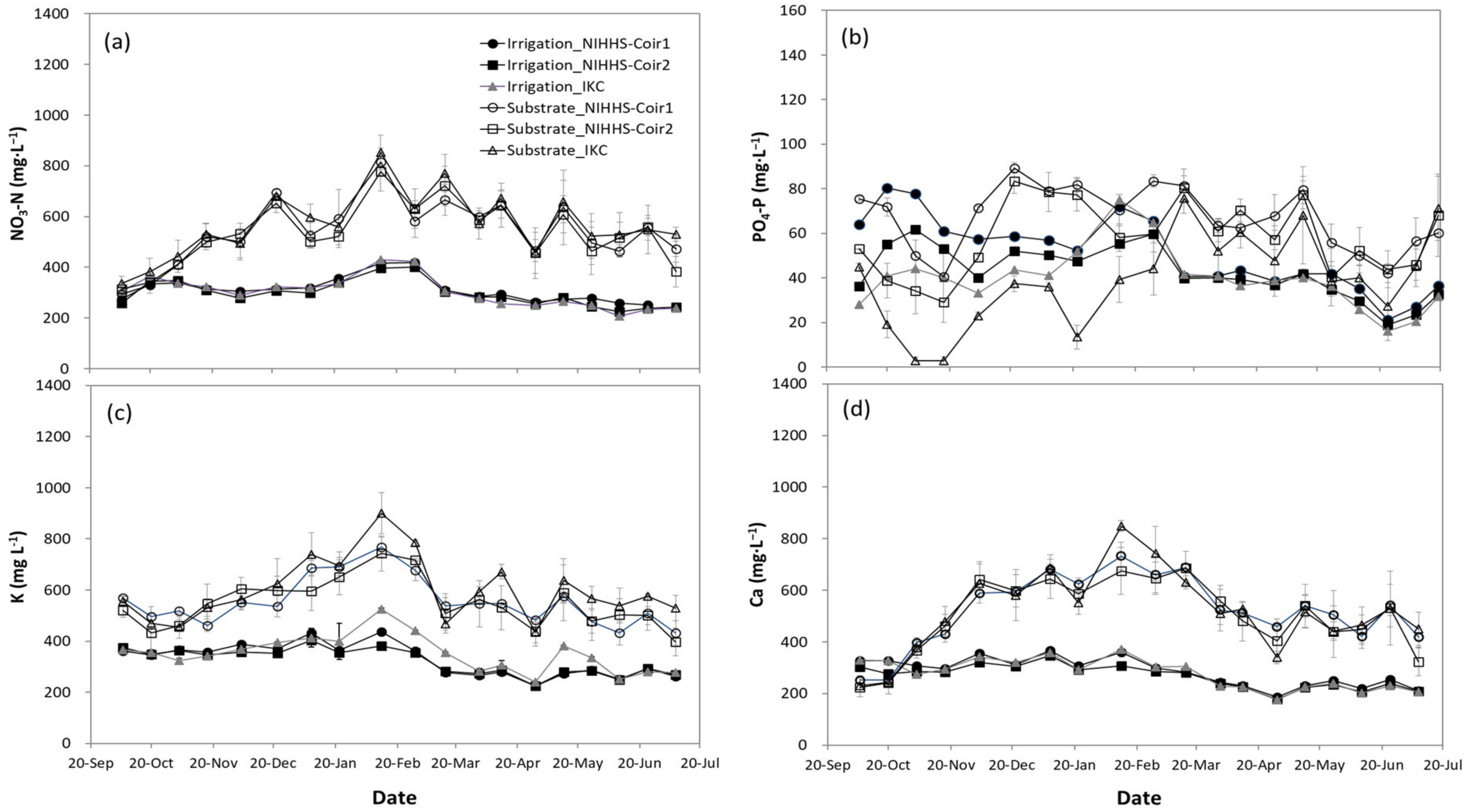

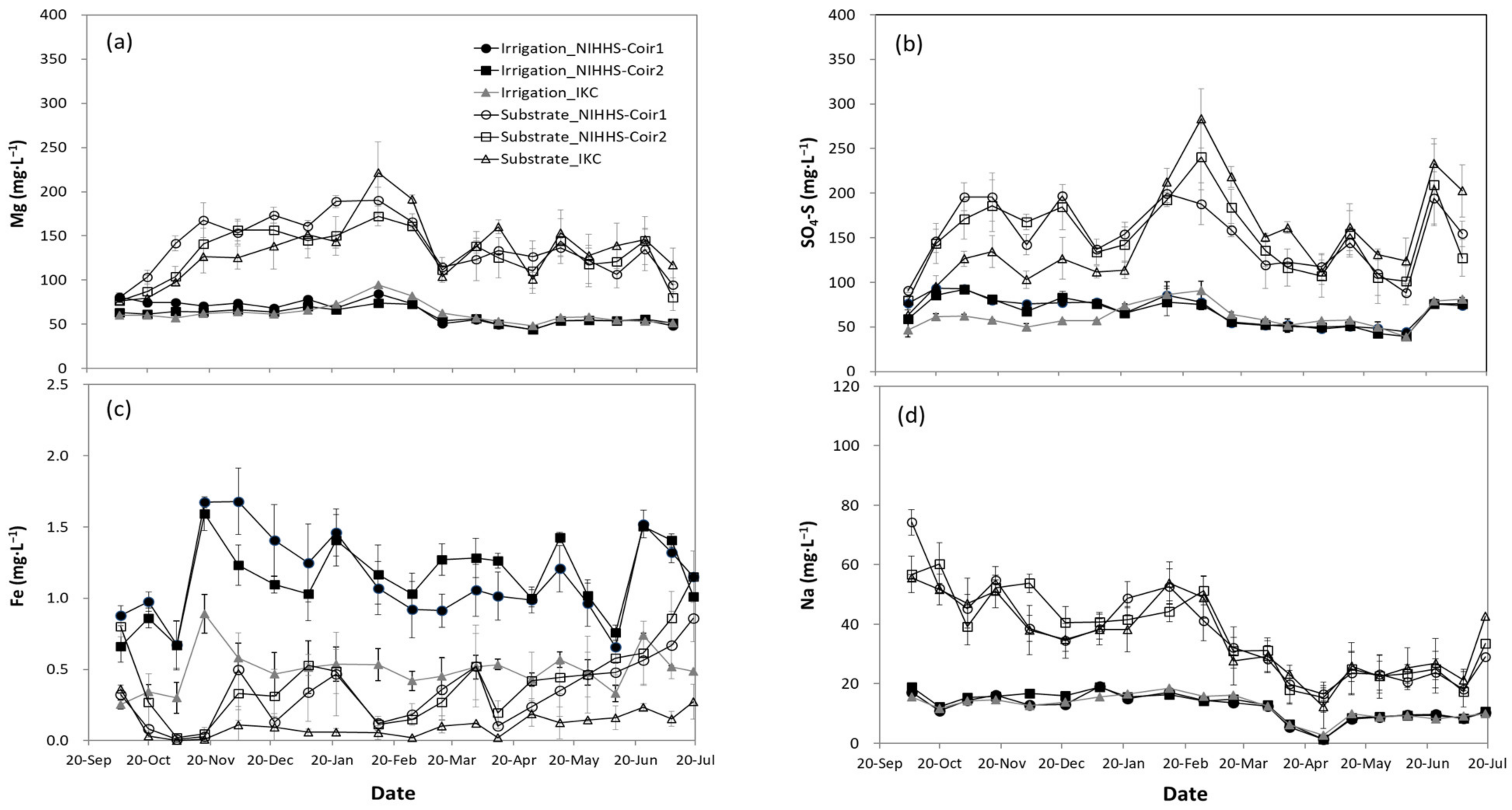

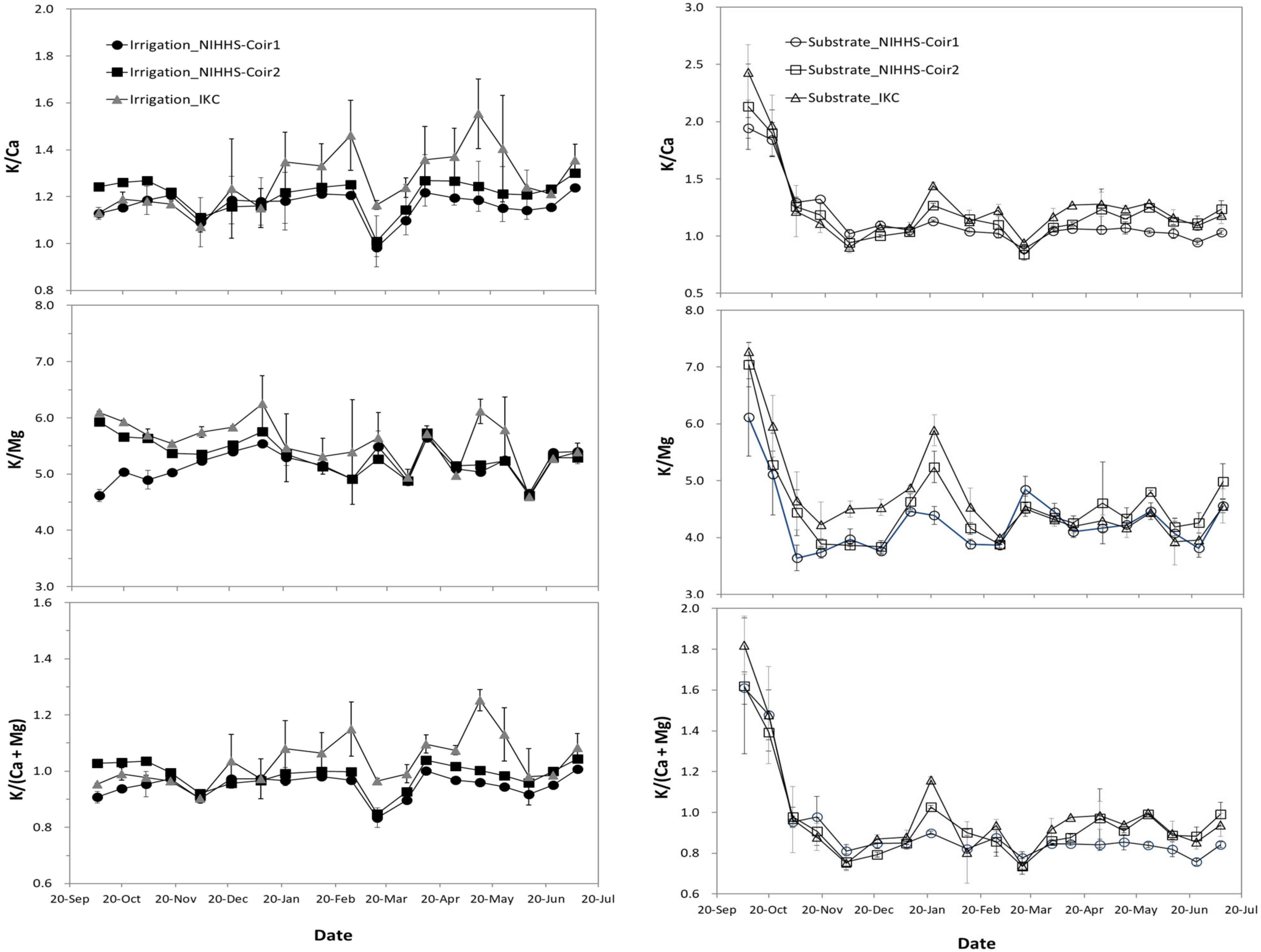

3.1. Changes in pH, EC, and Macronutrients in the Root Zone

3.2. Paprika Productivity and Quality Based on the Nutrient Solution Compositions

3.3. The pH and EC of the Newly Formulated Nutrient Solution

3.4. Suitability Evaluation of the Newly Formulated Nutrient Solution

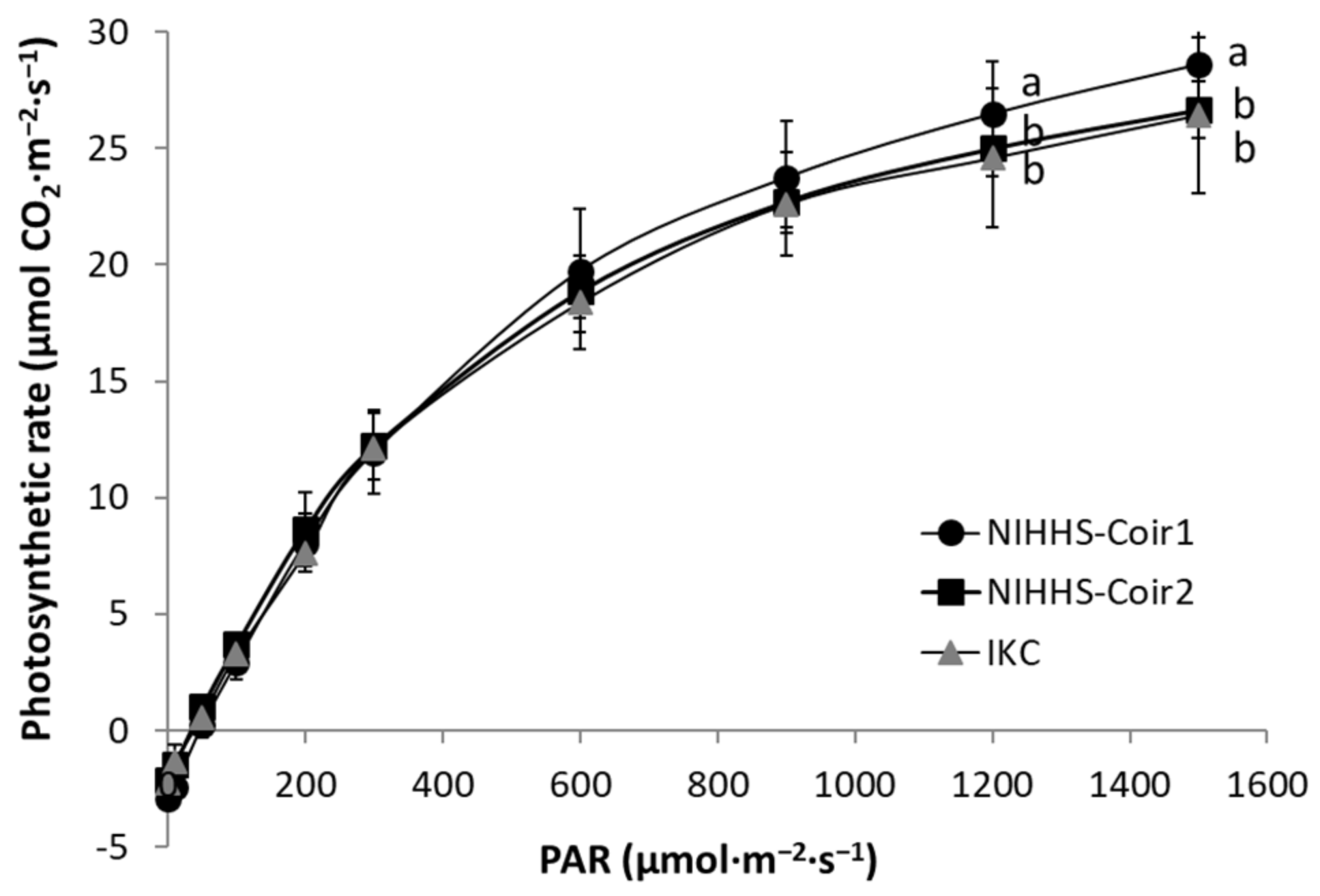

3.5. Photosynthetic Responses, Yield, and Fruit Characteristics of Paprika

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gieling, T.H. Control of Water Supply and Specific Nutrient Application in Closed Growing Systems. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2001. [Google Scholar]

- Van Gemert, J. Milieu-Aspecten van de Potplantenteelt Onder Glas; (LEI-DLO) 4.136; Landbouw-Economisch Instituut: Wageningen, The Netherlands, 1994; Volume 91, ISBN 9789052422664. [Google Scholar]

- Gieling, T.H.; Van Straten, G.; Janssen, H.J.J.; Wouters, H. ISE and Chemfet sensors in greenhouse cultivation. Sens. Actuators B 2005, 105, 74–80. [Google Scholar] [CrossRef]

- Yeo, K.H.; Choi, E.Y.; Lee, Y.B. Nutrient uptake of single-stemmed roses under macro- and microelement amendments in a closed aeroponic system. Hortic. Environ. Biotechnol. 2009, 52, 455–465. [Google Scholar] [CrossRef]

- Savvas, D. Nutrient solution recycling. In Hydroponic Production of Vegetables and Ornamentals; Savvas, D., Passam, H.C., Eds.; Embryo Publications: Athens, Greece, 2002; pp. 299–343. [Google Scholar]

- Sonneveld, C. Composition of nutrient solutions. In Hydroponic Production of Vegetables and Ornamentals; Savvas, D., Passam, H., Eds.; Embryo Publication: Athens, Greece, 2002; pp. 179–210. [Google Scholar]

- Lim, M.Y.; Jeong, E.S.; Roh, M.Y.; Choi, G.L.; Kim, S.H.; Lee, C.K. Changes of plant growth and nutrient concentrations of the drainage according to drainage reuse and substrate type in sweet pepper hydroponics. J. Bio Environ. Control 2022, 31, 476–484. [Google Scholar] [CrossRef]

- Ahn, T.I.; Son, J.E. Changes in ion balance and individual ionic contributions to EC reading at different renewal intervals of nutrient solution under EC-based nutrient control in closed-loop soilless culture for sweet peppers (Capsicum annum L. ‘Fiesta’). Korean J. Hortic. Sci. Technol. 2013, 29, 29–35. [Google Scholar]

- Jang, D.; Choi, K.Y.; Kim, I.S. Effect of drainage reusing ratio on growth and yield of summer-cultivated Paprika in Recycling Hydroponic Cultivation. phpf Prot. Hortic. Plant Fact 2017, 26, 7–12. [Google Scholar] [CrossRef]

- Ministry of Agriculture, Food and Rural Affairs. The Status of Greenhouse and Vegetable Production in 2020; Ministry of Agriculture, Food and Rural Affairs: Sejong, Republic of Korea, 2021.

- Rural Development Administration. Agricultural Production Cash Costs and Returns in 2022; Rural Development Administration: Jeonju, Republic of Korea, 2022.

- Lee, J.N.; Lee, E.H.; Im, J.S.; Kim, W.B.; Yeoung, Y.R. 2008, Fruit characteristics of high temperature period and economic analysis of summer paprika (Capsicum annuum L.) grown at different altitudes. Korean J. Hortic. Sci. Technol. 2008, 26, 230–233. [Google Scholar]

- Rhee, H.C.; Choi, G.L.; Yeo, K.H.; Cho, M.W.; Cho, I.W. Effect of fog-cooling on the growth and yield of hydroponic paprika in grown summer season. PHPF Prot. Hortic. Plant Fact 2015, 24, 258–263. [Google Scholar] [CrossRef]

- Choi, K.Y.; Ko, J.Y.; Yoo, H.J.; Choi, E.Y.; Rhee, H.C.; Lee, Y.B. Effect of cooling timing in the root zone on substrate temperature and physiological response of sweet pepper in summer cultivation. Korean J. Hortic. Sci. Technol. 2014, 32, 53–59. [Google Scholar] [CrossRef]

- Inden, H.; Torres, A. Comparison of four substrates on the growth and quality of tomatoes. Acta Hortic. 2004, 644, 205–210. [Google Scholar] [CrossRef]

- Choi, S.H.; Lim, M.Y.; Choi, K.L.; Kim, S.H.; Jeong, H.J. Growth and quality of two melon cultivars in hydroponics affected by mixing ratio of coir substrate and different irrigation amount on spring season. PHPF Prot. Hortic. Plant Fact 2019, 28, 376–387. [Google Scholar] [CrossRef]

- Pressman, E.; Moshkovitch, H.; Rosenfeld, K.; Shaked, R.; Gamliel, B.; Aloni, B. Influence of low night temperatures on sweet pepper flower quality and the effect of repeated pollinations, with viable pollen, on fruit setting. J. Hortic. Sci. Biotechnol. 1998, 73, 131–136. [Google Scholar] [CrossRef]

- Schröder, F.G.; Lieth, J.H. Irrigation control in hydroponics. In Hydroponic Production of Vegetables and Ornamentals; Savvas, D., Passam, H.C., Eds.; Embryo Publications: Athens, Greece, 2002; pp. 265–296. [Google Scholar]

- Noguera, P.; Abad, M.; Noguera, V.; Puchades, R.; Maquieira, A. Coconut coir waste, a new and viable ecologically- Friendly peat substitute. Acta Hortic. 2000, 517, 279–286. [Google Scholar] [CrossRef]

- Raviv, M.; Mallach, R.; Silber, A. Substrates and their analysis. In Hydroponic Production of Vegetables and Ornamentals; Savvas, D., Passam, H.C., Eds.; Embryo Publications: Athens, Greece, 2002; pp. 25–101. [Google Scholar]

- Sonneveld, C.; Straver, N. Nutrient Solutions for Vegetables and Flowers Grown in Water or Substrates; Proefstation Tuinbouw Onder Glas Naaldwijk Proefstation Bloemisterij Aalsmeer: Naaldwijk, The Netherlands, 1992; pp. 19–20. [Google Scholar]

- Yeo, K.H.; Rhee, H.C.; Choi, G.L.; Lee, S.C.; Cheong, J.W.; Choi, K.Y. Nutrient absorption characteristics of paprika ‘Cupra’ with growth stages in the hydroponic system with a coconut coir substrate. Korean J. Hortic. Sci. Technol. 2015, 33, 86–87. (In Korean) [Google Scholar]

- Eom, Y.C.; Kim, W.S.; Kim, C.S. Study on the Hydroponic Culture Techniques for Fitting in Korean Climate Under the Glasshouse Condition; Rural Development Administration: Suwon, Republic of Korea, 2012; p. 101.

- IKC. Bemestingsadviesbasis glastuinbouw 1994–1995. Informatie en Kennis Centrum Akker-En Tuinbouw, Afdeling; Glasgroenten en Bloemisterij: Aalsmeer/Naaldwijk, The Netherlands, 1994; p. 172. [Google Scholar]

- De Kreij, C.; Voogt, W.; Van den Bos, A.L.; Baas, R. Bemestingsadviesbasis Substraten; Proefstation voor Bloemisterij en Glasgroente Naaldwijk: Naaldwijk, The Netherlands, 1999; pp. 18–46. [Google Scholar]

- Hartz, T.K.; Hochmuth, G.J. Fertility management of drip-irrigated vegetables. HortTechnology 1996, 6, 168–172. [Google Scholar] [CrossRef]

- Incrocci, L.; Massa, D.; Pardossi, A. New trends in the fertigation management of irrigated vegetable crops. Horticulturae 2017, 3, 37. [Google Scholar] [CrossRef]

- Bar-Yosef, B. Fertigation management and crops response to solution recycling in semi-closed greenhouses. In Soilless Culture, Theory and Practices; Raviv, M., Lieth, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 341–424. [Google Scholar]

- Lee, H.J.; Oh, J.S.; Choi, K.Y.; Lee, Y.B.; Bae, J.H.; Rhee, H.C.; Kim, D.E. Analysis of contributing factor for cation ratio to calcium in nutrient solution on the incidence of blossom-end rot in sweet pepper ‘RZ208’ Grown in Hydroponics. Korean J. Hortic. Sci. Technol. 2012, 30, 27–33. [Google Scholar] [CrossRef]

- Incrocci, L.; Malorgio, F.; Della Bartola, A.; Pardossi, A. The influence of drip irrigation or subirrigation on tomato grown in closed-loop substrate culture with saline water. Sci. Hortic. 2006, 107, 365–372. [Google Scholar] [CrossRef]

- Savvas, D.; Chatzieustratiou, E.; Pervolaraki, G.; Gizas, G.; Sigrimis, N. Modelling Na and Cl concentrations in the recycling nutrient solution of a closed-cycle pepper cultivation. Biosyst. Eng. 2008, 99, 282–291. [Google Scholar] [CrossRef]

- Savvas, D.; Gizas, G. Response of hydroponically grown gerbera to nutrient solution recycling and different nutrient cation ratios. Sci. Hortic. 2002, 96, 267–280. [Google Scholar] [CrossRef]

- Ko, M.T.; Ahn, T.I.; Son, J.E. Comparisons of ion balance, fruit yield, water, and fertilizer use efficiencies in open and closed soilless culture of paprika (Capsicum annuum L.). Korean J. Hortic. Sci. Technol. 2013, 31, 423–428. [Google Scholar] [CrossRef]

- Postma, J.; van Os, E.; Bonants, P.J.M. Pathogen detection and management strategies in soilless plant growing systems. In Soilless Culture, Theory and Practices; Raviv, M., Lieth, H., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 425–457. [Google Scholar]

- Bar-Yosef, B.; Markovich, T.; Levkovich, I. Pepper response to leachate recycling in a greenhouse in Israel. Acta Hortic. 2001, 548, 357–364. [Google Scholar] [CrossRef]

- Ehret, D.L.; Menzies, J.G.; Helmer, T. Production and quality of greenhouse roses in recirculating nutrient systems. Sci. Hortic. 2005, 106, 103–113. [Google Scholar] [CrossRef]

- De Kreij, C. Latest insights into water and nutrient control in soilless cultivation. Acta Hortic. 1995, 408, 47–62. [Google Scholar] [CrossRef]

- Voogt, W. Effect of the pH on rockwool grown carnation (Dianthus caryophyllus). Acta Hortic. 1995, 401, 327–336. [Google Scholar] [CrossRef]

- Ropokis, A.; Ntatsi, G.; Rouphael, Y.; Kotsiras, A.; Kittas, C.; Katsoulas, N.; Savvas, D. Responses of sweet pepper (Capsicum annum L.) cultivated in a closed hydroponic system to variable calcium concentrations in the nutrient solution. J. Sci. Food Agric. 2021, 101, 4342–4349. [Google Scholar] [CrossRef]

- Engels, C.; Kirkby, E.; White, P. Mineral nutrition, yield and source-sink relationships. In Marschner’s Mineral Nutrition of Higher Plants, 3rd ed.; Marschner, P., Ed.; Elsevier Ltd.: London, UK, 2012; pp. 85–131. [Google Scholar]

- Sitko, K.; Gieroń, Ż.; Szopiński, M.; Zieleźnik-Rusinowska, P.; Rusinowski, S.; Pogrzeba, M.; Daszkowska-Golec, A.; Kalaji, H.M.; Małkowski, E. Influence of short-term macronutrient deprivation in maize on photosynthetic characteristics, transpiration and pigment content. Sci. Rep. 2019, 9, 14181. [Google Scholar] [CrossRef] [PubMed]

| Nutrient Solution | NO3-N | NH4-N | P | K | Ca | Mg | SO4-S | Fe | |

|---|---|---|---|---|---|---|---|---|---|

| (ppm) | |||||||||

| NIHHS z | Groups w 1–2 | 217 | 18 | 37 | 254 | 190 | 36 | 56 | 0.84 |

| Groups 3–6 | 196 | 16 | 37 | 228 | 152 | 29 | 28 | 0.84 | |

| IKC y | 245 | 11 | 42 | 278 | 209 | 46 | 51 | 0.84 | |

| PHRS-Rockwool x | 188 | 18 | 40 | 235 | 140 | 28 | 24 | 0.84 | |

| Nutrient Solution z | Groups y | NO3-N | NH4-N | P | K | Ca | Mg | SO4-S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| (ppm) | |||||||||

| NIHHS-Coir1 | 1–2 | 195 | 16 | 37 | 229 | 190 | 33 | 51 | 1.68 |

| 3–6 | 195 | 16 | 35 | 217 | 171 | 33 | 46 | 1.68 | |

| NIHHS-Coir2 | 1–2 | 184 | 15 | 37 | 216 | 171 | 31 | 48 | 1.68 |

| 3–6 | 186 | 15 | 33 | 205 | 152 | 31 | 41 | 1.68 | |

| Marketable Yield (kg/m2) | Marketable Fruit Ratio (%) | Fruit Weight (kg)/Plant (n = 30) | No. of Fruits/Plant (n = 30) | ||

|---|---|---|---|---|---|

| Groups (G) x | |||||

| 1–2 | 4.95 c z | 98.1 a | 1.45 c | 7.9 c | |

| 3–4 | 7.10 a | 97.1 a | 2.09 a | 13.2 b | |

| 5–6 | 5.60 b | 90.6 b | 1.76 b | 17.8 a | |

| Nutrient solutions (NS) | |||||

| NIHHS | 6.03 a | 96.2 a | 1.79 | 13.2 | |

| IKC | 5.97 a | 96.4 a | 1.77 | 13.2 | |

| NIHHS-Rockwool | 5.65 b | 93.2 b | 1.74 | 12.4 | |

| G × NS | |||||

| 1–2 | NIHHS | 5.06 d | 98.3 a | 1.47 | 7.8 |

| IKC | 4.78 e | 98.7 a | 1.38 | 7.3 | |

| NIHHS-Rockwool | 5.02 d | 97.2 ab | 1.50 | 8.5 | |

| 3–4 | NIHHS | 7.14 a | 97.1 ab | 2.10 | 13.6 |

| IKC | 7.21 a | 98.3 a | 2.09 | 12.2 | |

| NIHHS-Rockwool | 6.96 b | 95.9 b | 2.09 | 13.9 | |

| 5–6 | NIHHS | 5.88 c | 93.0 c | 1.81 | 18.0 |

| IKC | 5.93 c | 92.2 c | 1.84 | 17.8 | |

| NIHHS-Rockwool | 4.97 d | 86.5 d | 1.64 | 17.6 | |

| Significance y | |||||

| G | *** | *** | *** | *** | |

| NS | *** | *** | NS | NS | |

| G × NS | *** | ** | NS | NS | |

| Marketable Yield (kg/m2) | Marketable Fruit Ratio (%) | Fruit Weight (kg)/Plant (n = 30) | No. of Fruits/Plant (n = 30) | ||

|---|---|---|---|---|---|

| Groups (G) x | |||||

| 1–2 | 4.26 a z | 99.4 a | 1.22 b | 6.7 c | |

| 3–4 | 4.03 b | 89.8 b | 1.30 ab | 9.4 b | |

| 5–6 | 4.07 b | 80.6 c | 1.45 a | 14.3 a | |

| Nutrient solutions (NS) | |||||

| NIHHS-Coir1 | 4.30 a | 92.4 a | 1.36 | 10.3 | |

| NIHHS-Coir2 | 3.96 b | 88.3 b | 1.29 | 9.9 | |

| IKC | 4.10 b | 89.0 b | 1.33 | 10.2 | |

| G × NS | |||||

| 1–2 | NIHHS-Coir1 | 4.39 a | 99.8 | 1.26 | 6.8 |

| NIHHS-Coir2 | 4.35 ab | 99.1 | 1.25 | 6.9 | |

| IKC | 4.04 c | 99.4 | 1.16 | 6.3 | |

| 3–4 | NIHHS-Coir1 | 4.17 abc | 93.8 | 1.32 | 9.4 |

| NIHHS-Coir2 | 3.76 d | 88.1 | 1.22 | 8.9 | |

| IKC | 4.16 abc | 87.6 | 1.36 | 9.7 | |

| 5–6 | NIHHS-Coir1 | 4.33 ab | 83.6 | 1.50 | 14.6 |

| NIHHS-Coir2 | 3.78 d | 77.7 | 1.39 | 13.9 | |

| IKC | 4.11 bc | 80.2 | 1.46 | 14.4 | |

| Significance y | |||||

| G | ** | *** | * | *** | |

| NS | *** | ** | NS | NS | |

| G × NS | ** | NS | NS | NS | |

| Nutrient Solution | Groups | NO3-N | NH4-N | P | K | Ca | Mg | SO4-S | Fe | K/Ca Ratio |

|---|---|---|---|---|---|---|---|---|---|---|

| (ppm) | ||||||||||

| NIHHS-Coir (closed) | 1–2 | 200 | 13 | 35 | 227 | 190 | 33 | 51 | 1.68 | 1.19 |

| 3–6 | 190 | 15 | 33 | 217 | 162 | 33 | 43 | 1.68 | 1.33 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeo, K.-H.; Choi, G.-L.; Lee, J.-H.; Park, K.-S.; Choi, K.-Y. Development of Nutrient Solution Compositions for Paprika Cultivation in a Closed Coir Substrate Hydroponic System in Republic of Korea’s Winter Cropping Season. Horticulturae 2023, 9, 412. https://doi.org/10.3390/horticulturae9040412

Yeo K-H, Choi G-L, Lee J-H, Park K-S, Choi K-Y. Development of Nutrient Solution Compositions for Paprika Cultivation in a Closed Coir Substrate Hydroponic System in Republic of Korea’s Winter Cropping Season. Horticulturae. 2023; 9(4):412. https://doi.org/10.3390/horticulturae9040412

Chicago/Turabian StyleYeo, Kyung-Hwan, Gyeong-Lee Choi, Jae-Han Lee, Kyung-Sub Park, and Ki-Young Choi. 2023. "Development of Nutrient Solution Compositions for Paprika Cultivation in a Closed Coir Substrate Hydroponic System in Republic of Korea’s Winter Cropping Season" Horticulturae 9, no. 4: 412. https://doi.org/10.3390/horticulturae9040412

APA StyleYeo, K.-H., Choi, G.-L., Lee, J.-H., Park, K.-S., & Choi, K.-Y. (2023). Development of Nutrient Solution Compositions for Paprika Cultivation in a Closed Coir Substrate Hydroponic System in Republic of Korea’s Winter Cropping Season. Horticulturae, 9(4), 412. https://doi.org/10.3390/horticulturae9040412