Evaluation of Zinc Concentrations in Fruit from Various Pear Strains and Cultivars in China for Establishing a Standard for Zinc-Enriched Pears

Abstract

:1. Introduction

2. Materials and Methods

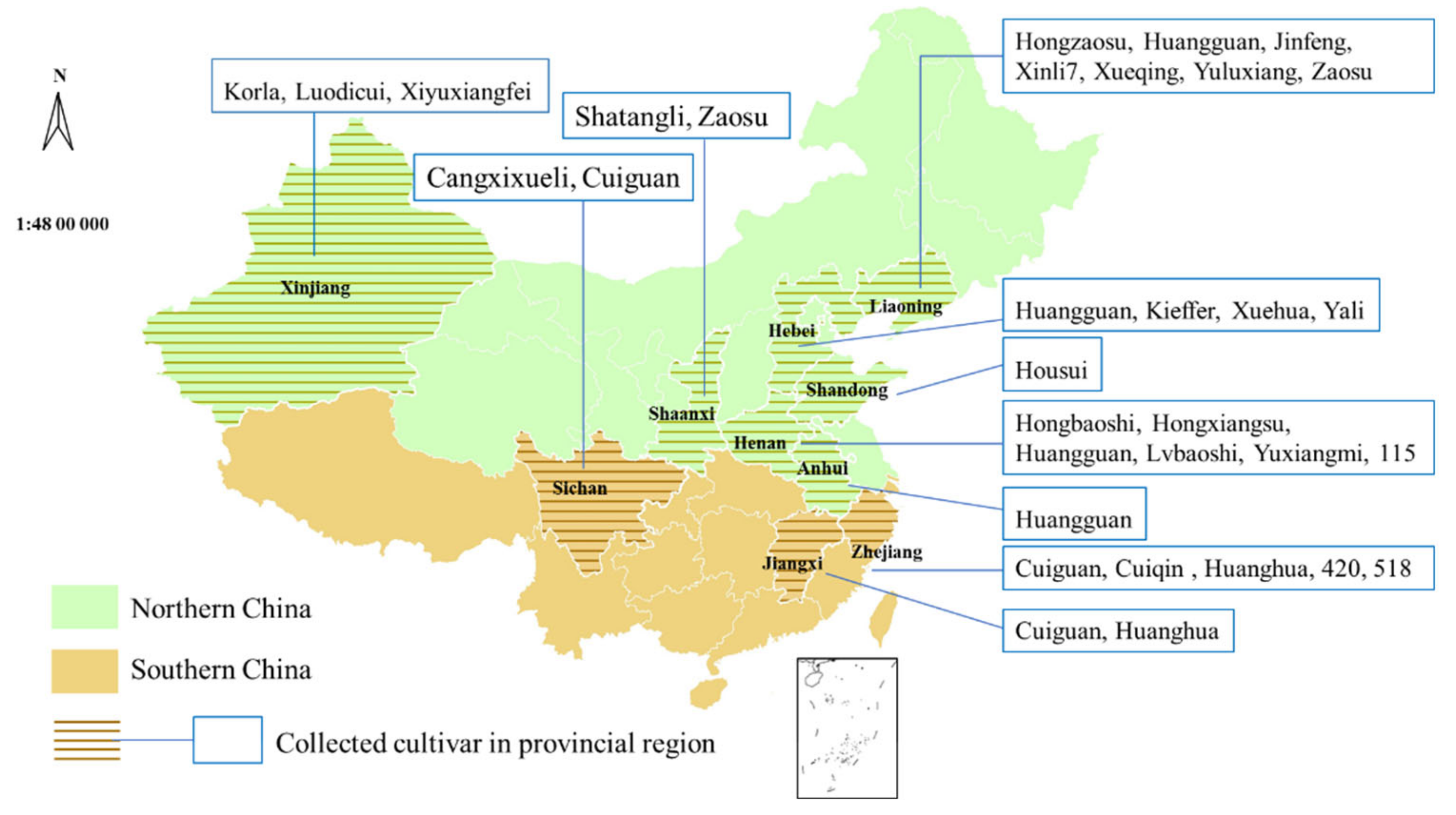

2.1. Investigation on Fruit Zn Concentration of Pear Germplasm Resources

2.2. Pre-Processing of Pulp Samples

2.3. Determine Method of Fruit Zn Concentration

2.4. Statistical Analysis

3. Results

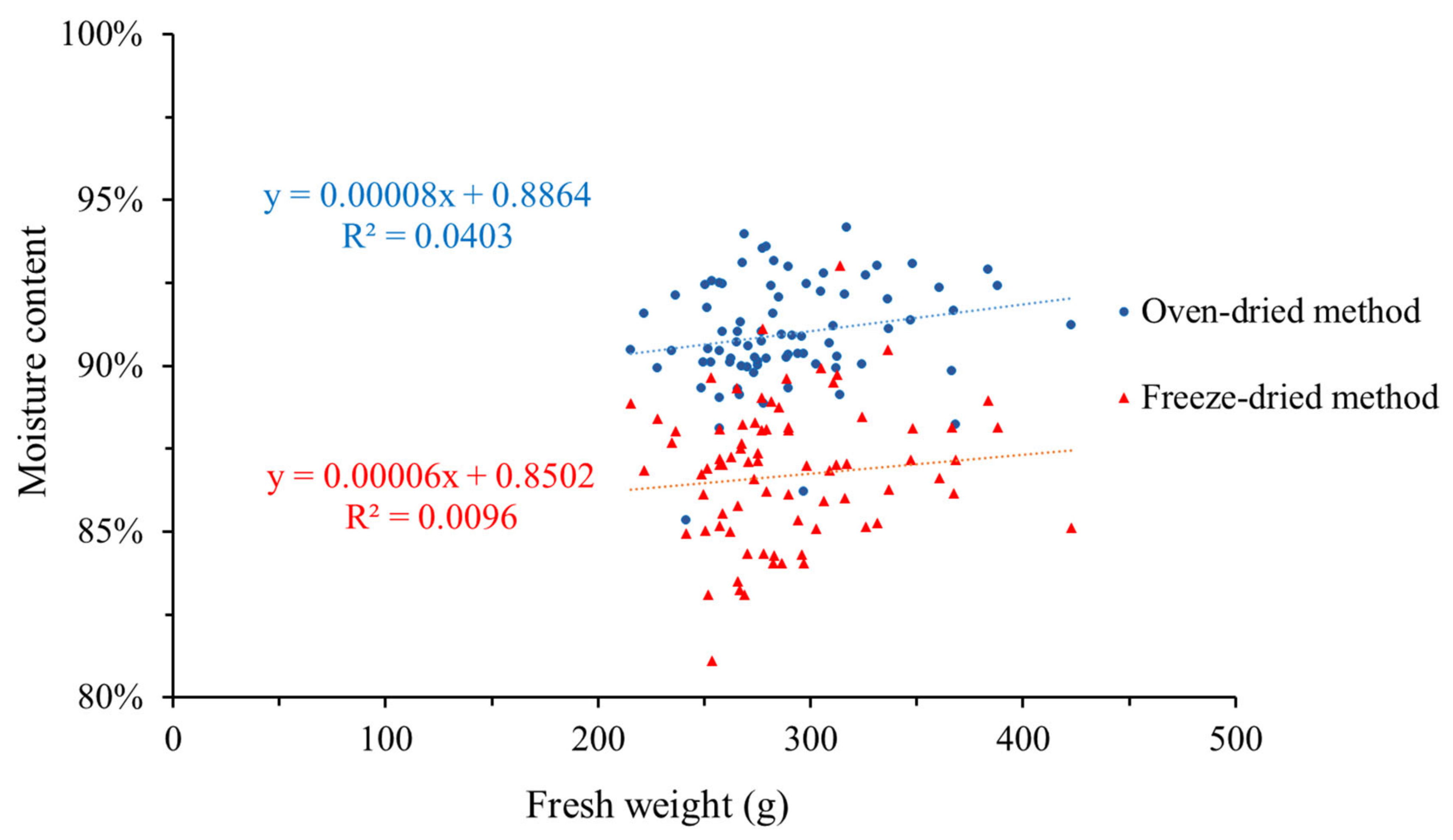

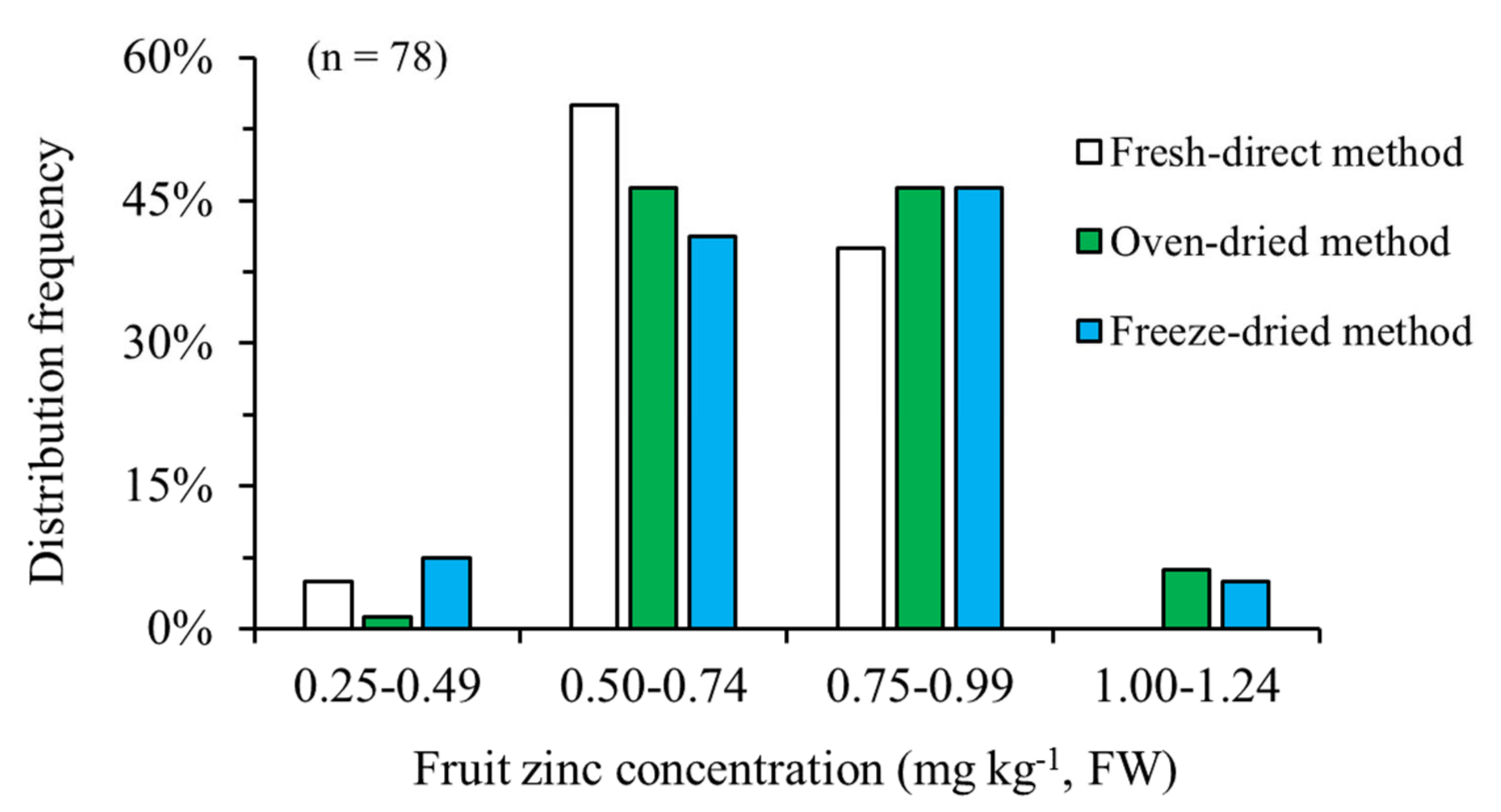

3.1. Determination of the Optimal Pre-Treatment Method for Obtaining Pear Zn Concentrations

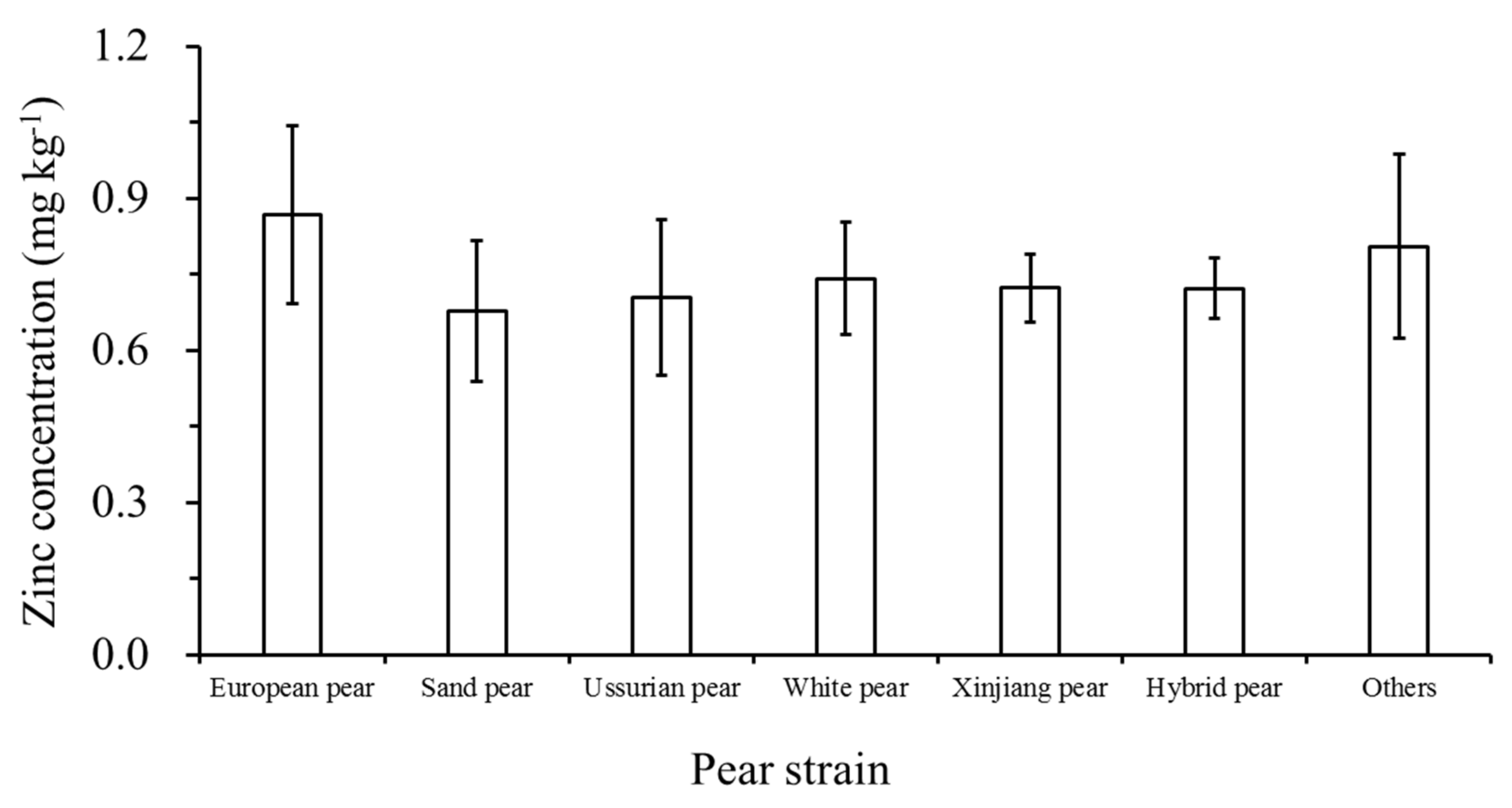

3.2. Comparison of Zn Concentrations in Pear Fruits at the Regional, Strain, and Cultivar Levels

4. Discussion

4.1. Choice of Method for Sample Preparation

4.2. Dilution Effect of Fruit Zn Concentration

4.3. Standard Fruit Zn Concentration Level for Zn-Enriched Pears

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Li, X.; Li, X.; Wang, T.; Gao, W. Nutritional Composition of Pear Cultivars (Pyrus spp.). In Nutritional Composition of Fruit Cultivars; Academic Press: Cambridge, MA, USA, 2016; pp. 573–608. [Google Scholar] [CrossRef]

- Chasapis, C.T.; Loutsidou, A.C.; Spiliopoulou, C.A.; Stefanidou, M.E. Zinc and human health: An update. Arch. Toxicol. 2012, 86, 521–534. [Google Scholar] [CrossRef] [PubMed]

- Natasha, N.; Shahid, M.; Bibi, I.; Iqbal, J.; Khalid, S.; Murtaza, B.; Bakhat, H.F.; Farooq, A.B.U.; Amjad, M.; Hammad, H.M.; et al. Zinc in soil-plant-human system: A data-analysis review. Sci. Total Environ. 2022, 808, 152024. [Google Scholar] [CrossRef] [PubMed]

- Prasad, A.S. Discovery of human zinc deficiency: 50 years later. J. Trace Elem. Med. Biol. 2012, 26, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Banuelos, G.S.; Lin, Z.Q. Use and Development of Biofortified Agricultural Products; CRC Press: Boca Raton, FL, USA, 2009; pp. 272–292. [Google Scholar]

- Deshpande, J.; Joshi, M.; Giri, P. Zinc: The trace element of major importance in human nutrition and health. Int. J. Med. Sci. Public Health 2013, 2, 1–6. [Google Scholar] [CrossRef]

- Lim, K.H.; Riddell, L.J.; Nowson, C.A.; Booth, A.O.; Szymlek–Gay, E.A. Iron and zinc nutrition in the economically developed world: A review. Nutrients 2013, 5, 3184–3211. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y. Effects of Selenium Fertilizer and Zinc Fertiltzer on the Quality and Fresh-Cut Fresh-Keeping Effect of Two Kinds of Pears. Master’s Thesis, Henan University of Science and Technology, Luoyang, China, 2020. [Google Scholar]

- Wójcik, P.; Popiñska, W. Response of Lukasovka pear trees to foliar Zn sprays. J. Elementol. 2009, 14, 181–188. [Google Scholar]

- Liu, M.; Xu, M.; Yu, H.; Fu, H.; Tang, S.; Ma, Q.; Li, Y.; Wu, L. Spraying ZnEDTA at high concentrations: An ignored potential for producing zinc-fortified pear (Pyrus spp.) fruits without causing leaf and fruitlet burns. Sci. Hortic. 2023, 322, 112380. [Google Scholar] [CrossRef]

- Guo, J.X.; Feng, X.M.; Hu, X.Y.; Tian, G.L.; Ling, N.; Wang, J.H.; Shen, Q.R.; Guo, S.W. Effects of soil zinc availability, nitrogen fertilizer rate and zinc fertilizer application method on zinc biofortification of rice. J. Agric. Sci. 2016, 154, 584–597. [Google Scholar] [CrossRef]

- Xu, M.; Du, L.; Liu, M.; Zhou, J.; Pan, W.; Fu, H.; Zhang, X.; Ma, Q.; Wu, L. Glycine-chelated zinc rather than glycine-mixed zinc has lower foliar phytotoxicity than zinc sulfate and enhances zinc biofortification in waxy corn. Food Chem. 2022, 370, 131031. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Liu, M.; Liu, F.; Zheng, N.; Tang, S.; Zhou, J.; Ma, Q.; Wu, L. A safe, high fertilizer-efficiency and economical approach based on a low-volume spraying UAV loaded with chelated-zinc fertilizer to produce zinc-biofortified rice grains. J. Clean. Prod. 2021, 323, 129188. [Google Scholar] [CrossRef]

- Meng, X.; Mengjiao, L.; Linlin, S.; Qingxu, M.; Tao, S.; Jun, W.; Kaijun, C.; Xiangjie, W.; Lianghuan, W. Spraying high concentrations of chelated zinc enhances zinc biofortifification in wheat grain. J. Sci. Food Agric. 2022, 102, 3489–3924. [Google Scholar]

- Velu, G.; Ortiz-Monasterio, I.; Cakmak, I.; Hao, Y.; Singh, R.Á. Biofortification strategies to increase grain zinc and iron concentrations in wheat. J. Cereal Sci. 2014, 59, 365–372. [Google Scholar] [CrossRef]

- Meng, X.; Mengjiao, L.; Qingxu, M.; Lianghuan, W. Glycine-chelated zinc lowered foliar phytotoxicity than excess zinc sulfate and improved zinc use efficiency in two sweet potato cultivars. Sci. Hortic. 2022, 295, 110880. [Google Scholar]

- Bouis, H.E.; Saltzman, A. Improving nutrition through biofortification: A review of evidence from HarvestPlus, 2003 through 2016. Glob. Food Secur. 2017, 12, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, Z.; Wu, J.; Wang, Q.; Hu, X. Chemical compositional characterization of eight pear cultivars grown in China. Food Chem. 2007, 104, 268–275. [Google Scholar] [CrossRef]

- Read, T.L.; Doolette, C.L.; Cresswell, T.; Howell, N.R.; Aughterson, R.; Karatchevtseva, I.; Donner, E.; Kopittke, P.M.; Schjoerring, J.K.; Lombi, E. Investigating the foliar uptake of zinc from conventional and nano-formulations: A methodological study. Environ. Chem. 2019, 16, 459–469. [Google Scholar] [CrossRef]

- Azam, M.M.; Padmavathi, S.; Fiyaz, R.A.; Waris, A.; Ramya, K.; Neeraja, C.N. Effect of different cooking methods on loss of iron and zinc micronutrients in fortified and non-fortified rice. Saudi J. Biol. Sci. 2021, 28, 2886–2894. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; Deepti, B.; Singh, H.K. Foliar nutrition: A key to utilize production potential of horticultural crops. Ann. Agri Bio Res. 2013, 18, 20210–20213. [Google Scholar]

- Fernández, V.; Brown, P.H. From plant surface to plant metabolism: The uncertain fate of foliar-applied nutrients. Front. Plant Sci. 2013, 4, 289. [Google Scholar] [CrossRef] [PubMed]

- Montalvo, D.; Degryse, F.; Da Silva, R.C.; Baird, R.; McLaughlin, M.J. Agronomic effectiveness of zinc sources as micronutrient fertilizer. Adv. Agron. 2016, 139, 215–267. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Yu, H.; Liu, L.; Ma, Z.; Zhou, J.; Tang, S.; Wu, L.; Fu, G.; Li, Y.; Xu, M. Evaluation of Zinc Concentrations in Fruit from Various Pear Strains and Cultivars in China for Establishing a Standard for Zinc-Enriched Pears. Horticulturae 2023, 9, 1148. https://doi.org/10.3390/horticulturae9101148

Liu M, Yu H, Liu L, Ma Z, Zhou J, Tang S, Wu L, Fu G, Li Y, Xu M. Evaluation of Zinc Concentrations in Fruit from Various Pear Strains and Cultivars in China for Establishing a Standard for Zinc-Enriched Pears. Horticulturae. 2023; 9(10):1148. https://doi.org/10.3390/horticulturae9101148

Chicago/Turabian StyleLiu, Mengjiao, Huili Yu, Longfei Liu, Zhengbo Ma, Jingjie Zhou, Sheng Tang, Lianghuan Wu, Guohai Fu, Yanqing Li, and Meng Xu. 2023. "Evaluation of Zinc Concentrations in Fruit from Various Pear Strains and Cultivars in China for Establishing a Standard for Zinc-Enriched Pears" Horticulturae 9, no. 10: 1148. https://doi.org/10.3390/horticulturae9101148

APA StyleLiu, M., Yu, H., Liu, L., Ma, Z., Zhou, J., Tang, S., Wu, L., Fu, G., Li, Y., & Xu, M. (2023). Evaluation of Zinc Concentrations in Fruit from Various Pear Strains and Cultivars in China for Establishing a Standard for Zinc-Enriched Pears. Horticulturae, 9(10), 1148. https://doi.org/10.3390/horticulturae9101148