Abstract

Combined withering and shaking processes are key steps in the formation of characteristic floral and fruity aromas in black teas. However, the effect of the sequencing of withering and shaking on volatile compounds and aroma formation in black tea has not been evaluated to date. This study used headspace solid-phase microextraction and gas chromatography-tandem mass spectrometry to detect volatile compounds in black teas after withering-shaking and shaking-withering processing. Five main differentially volatile components were screened out by partial least squares discriminant analysis and odor activity value analysis, which were 3-carene, geraniol, β-myrcene, τ-cadinol, and β-ionone. Additionally, sensory evaluation showed black tea produced by withering-shaking was fruitier, while shaking-withering produced a more floral tea. This study provides a theoretical basis for the discrimination of aroma characteristics of black tea processed by shaking, as well as a technical guide for the precise production of black teas with different floral-fruity aroma biases.

1. Introduction

Black tea is widely used in food or consumed directly for its unique flavor and multiple health benefits [1,2]. The processing of black tea involves several processes, including withering, rolling, fermenting, and drying [3]. Notably, black tea manufacturing requires a long withering time [4], and the metabolic activities of the isolated fresh leaves during withering are accompanied by the hydrolysis of glycosides, fatty acids, proteins, polysaccharides, and other substances which provide the material basis for the subsequent formation of the tea’s flavor characteristics [5,6]. Therefore, withering is the key stage in establishing the unique flavor of black tea and changing the withering method is crucial to changing its quality characteristics.

Aroma is one of the most important factors determining the quality of black tea. The withering process can seriously affect aroma compounds, for example, increasing the concentrations of (E)-2-hexenonic acid, hexyl alcohol, and nerol, as well as enhancing benzaldehyde, (Z)-2-pentenol, (E)-2-hexenal, benzyl alcohol, salicylic acid, and other precursors of aroma compounds [7,8,9]. Traditional black tea is characterized mainly by a sweet aroma and is usually processed by the traditional static withering method [4]. In recent years, a method (which emerged from southeastern China) for imparting a floral-fruity aroma by adding a shaking process before or after withering has been widely used in black tea production [10,11,12]. Hou [13] investigated differences in volatile matter content following dynamic and static withering and found that dynamic withering (when tea leaves are in motion) significantly improved this floral-fruity aroma of black tea. It has also been demonstrated that shaking increased the accumulation of characteristic volatile compounds due to the trauma activating key metabolic genes in the leaves [14] (a key cause of floral-fruity aroma formation [15,16]).

Different processing steps have significant effects on volatile compounds [17], but there is a lack of detailed descriptions of the aroma qualities of black teas using different sequences of withering and shaking. This study assessed two methods—withering-shaking (WS) and shaking-withering (SW)—in combination with the traditional rolling and fermenting processing of black tea. Volatile compounds in processed black tea were detected by gas chromatography-tandem mass spectrometry (GC-MS/MS), and principal component analysis (PCA), partial least squares discriminant analysis (PLS-DA), cluster analysis, odor activity value (OAV) analysis, and sensory evaluation were used to analyze differences and overall aroma characteristics under the two treatments. This study provides a theoretical basis and technical guidance for precise, directed development of a floral-fruity aroma bias in black tea processing.

2. Materials and Methods

2.1. Processing and Sample Preparation

Fresh leaves (one bud and two leaves) of the “Jin Guanyin” black tea variety were harvested in Longquan City (28°13′ N, 119°22′ E), Zhejiang Province, China. The fresh leaves were divided equally into three treatment groups (100 kg each): withering-shaking (WS) and shaking-withering (SW). Withering was carried out in a constant temperature and humidity room at 22 °C and 70% relative humidity, withering for 15 h with fresh leaves spread at a thickness of 1–2 cm. The shaking protocol was: shake for 3 min, rest for 60 min, then shake for 5 min and rest for 60 min using a light shaking setting. The WS and SW groups were then rolled and fermented at the same time. The rolling protocol (rotating at 35 rpm) was: empty rolling for 10 min (the top of the rolling lid was aligned with the top of the rolling barrel), light rolling for 10 min (top of the rolling lid dropped by 7 cm), medium rolling for 10 min (top of the rolling lid dropped by 15 cm), heavy rolling for 5 min (top of the rolling lid dropped by 18 cm), and empty rolling for 5 min. Fermentation conditions were: temperature 30 °C, humidity 90%, turning every 30 min, and fermentation time 0–4 h. Drying conditions were: initial baking at 120 °C for 30 min, then re-baking at 90 °C for 60 min. Dried samples were stored in a −20 °C freezer for analysis. WS: WSR1F0, WSR1F1, WSR1F2, WSR1F3, WSR1F4, WSR1F5, WSR2F0, WSR2F1, WSR2F2, WSR2F3, WSR2F4, WSR3F0, WSR3F1, WSR3F2, WSR3F3, WSR4F0, WSR4F1, WSR4F2. SW: SWR1F0, SWR1F1, SWR1F2, SWR1F3, SWR1F4, SWR1F5, SWR2F0, SWR2F1, SWR2F2, SWR2F3, SWR2F4, SWR3F0, SWR3F1, SWR3F2, SWR3F3, SWR4F0, SWR4F1, SWR4F2. Explanation of sample names: W (withering), S (shaking), R (rolling), F (fermenting), and the numbers indicate the time in hours. After the above treatments, each group was sampled 3 times for grinding. The ground samples were stored at −20 °C for subsequent testing.

2.2. Sample Pretreatment

Each ground tea sample (0.1 ± 0.003 g) was weighed into a 20 mL headspace vial with 10 μL ethyl caprate (10 mg/L) (chromatographically pure; TCI Chemical Industry Development Co. Ltd., Shanghai, China), then 5 mL boiling distilled water was added, the cap immediately tightened, and a manual handle (SPME; Supelco, Bellefonte, PA, USA) was used to insert the sample cap rubber film with a DVB/CAR/PDMS extraction head (Supelco). The vial was placed in a 60 °C water bath for 60 min, after which the extraction head was inserted into the GC-MS inlet and desorbed at 250 °C for 5 min. Each sample was analyzed three times [18].

2.3. GC-MS/MS Analysis

A 7890B-7000C GC-MS (Agilent Corp., Santa Clara, CA, USA) was used to detect volatile components. GC analysis conditions were: HP-5ms Ultra Inert capillary chromatographic column (30 m × 0.25 mm, 0.25 μm), high purity He (99.999%) carrier gas, flow rate 1 mL/min, inlet temperature 250 °C, with a splitless inlet. The temperature program was: initial column temperature 50 °C held for 1 min, increasing to 170 °C at 3 °C/min, held for 2 min, then increasing to 250 °C at 5 °C/min and held for 2 min. MS analysis conditions were: electron bombardment ionization source, electron energy 70 eV, transmission line temperature 270 °C; ion source temperature 230 °C, mass scan range 33–450 amu [19].

2.4. Qualitative and Quantitative Analysis

For qualitative analysis, volatile compounds with more than 80% similarity to the NIST11 standard library were screened using the Agilent Mass Hunter unknown analysis program and the compounds were identified and confirmed in conjunction with relevant literature. The linear formula for n-alkanes (C7-C40) was calculated and compared with the theoretical retention indices, allowing the derivation of the Kovàts retention index for each compound. For quantitative analysis, the mass concentration of volatile compounds was calculated with reference to the internal standard:

where Ci is the concentration of the analyte (μg/L), Cis is the concentration of the internal standard (μg/L), Ai is the peak area of the analyte, and Ais is the peak area of the internal standard.

Ci = (Cis × Ai)/Ais

2.5. Odor Activity Value Analysis

The OAV value was calculated from the following ratio [20]:

where c is the concentration of the analyte in the sample (μg/L) and OT is the odor threshold of the corresponding volatile compound in water (μg/L).

OAV = c/OT

2.6. Sensory Evaluation

The sensory assessment method followed Zhu et al. [21] with slight modifications. A 3.0 g tea sample was immersed in 150 mL of boiling water for 5 min, and then the extract was poured into a tea bowl. The extracts were sniffed three times to assess the intensity and purity of the aroma. The sensory evaluation was performed by five tea experts (two males and three females) trained and certified by professional institutions and specialized in tea sensory evaluation for at least five years. Aroma characteristics and quality of samples were described according to the Chinese national standards “Tea sensory evaluation methods” (GB/T 23776-2018) and “Tea sensory review terminology” (GB/T 14487-2017), and5 were scored on a scale from 0 to 5 for the intensity of floral and fruity attributes. Higher scores indicated stronger intensity: 0 = none or cannot be perceived, 1 = very weak intensity, 2 = weak intensity, 3 = medium intensity, 4 = high intensity, and 5 = very high intensity. The final aroma quality was determined by calculating the mean of the five panelists’ scores.

2.7. Statistical Analyses

Each analysis was repeated three times and results were expressed as the mean of three replicates. Significance analysis of volatile compound concentrations was performed using Prism 5.01 (GraphPad Software, San Diego, CA, USA) according to different fixation methods. R 4.0.3 (Ross Ihaka and Robert Gentleman) was used for cluster analysis and PCA of volatile compounds under different fixation methods. PLS-DA was performed using SIMCA 13.0 (Umetrics, Umea, Sweden). Origin 8.0 (Origin Lab Inc., Northampton, MA, USA) was used to compare concentration differences of volatile compounds making major contributions under different withering treatments.

3. Results and Discussion

3.1. Analysis of Volatile Compounds

Volatile compounds were identified in 36 black tea samples processed under withering-shaking and shaking-withering treatments, combined with various combinations of rolling and fermentation, as well as traditionally processed black tea. Fifty-one volatile compounds were detected (Table S1), including twelve esters, eleven alcohols, ten alkenes, seven aldehydes, four ketones, and seven other types of compounds. Although no new volatile compound was formed by the inclusion of the shaking process, there was variation in the concentration of the compounds.

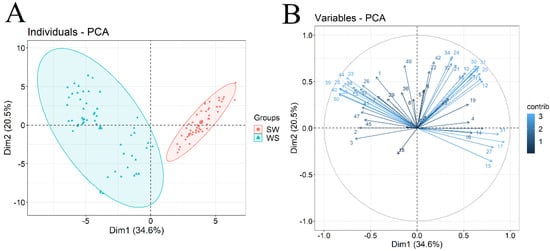

3.2. Principal Component Analysis

Unsupervised PCA was used to describe the volatile compound profile of black tea based on concentration (Figure 1). Samples were clearly separated into two groups according to WS and SW treatments (principal components 1 and 2 explained 34.6% and 20.5%, respectively; Figure 1A), indicating that the processes caused significant differences in volatile compound concentrations (p < 0.05). Figure 1B illustrates the contribution level of each volatile compound. Notably, some compounds with partial floral characteristics (Table S2), such as linalool, 3,7-dimethyl-1,5,7-octatrien-3-ol, (3R,6S) -2,2,6-trimethyl-6-vinyltetrahydro-2H-pyran-3-ol and geraniol, were more inclined to contribute to the SW treatment, while other compounds with a fruity-biased character, such as hexanal, cis-3-hexenyl acetate, hexyl hexanoate and trans-2-hexenal, were more inclined to contribute to the WS treatment, suggesting that the treatments contributed to differences in the aroma characteristics with WS enhancing fruity aromas and SW enhancing floral aromas.

Figure 1.

(A) Principal component analysis (PCA) scores plot and (B) contribution plot of volatile compounds in processed black teas. Groups: withering-shaking (WS) and shaking-withering (SW).

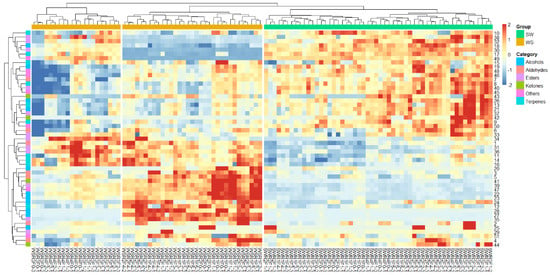

3.3. Multiple Experiment Viewer

Heat map clustering was used to analyze the concentrations of the 51 volatile compounds (Table S1) in black tea following the two treatments. As shown in Figure 2, SW samples were initially clustered into one category (right), while WS samples were divided into two categories according to their rolling times (3 h and 4 h on the left and 1 h and 2 h in the middle). This further indicated that the aroma of samples treated with WS and SW differed significantly. In addition, although the overall number of volatile compound species did not change by merely changing the order of withering and shaking, the concentrations of the compounds changed significantly. The heat map divided the fifty-one aroma compounds into two categories, the first including four alcohols, two aldehydes, six esters, two ketones, six alkenes and five others, which correlated more highly with the SW-treated floral aroma. The second category included seven alcohols, five aldehydes, six esters, two ketones, four alkenes and two others, which correlated more highly with the WS-treated fruity aroma. On one hand, withering is the initial stage of characteristic aroma formation in black tea. Along with the gradual loss of water from cells, the activities of endogenous β-sakuranosidase, β-glucosidase, galactosidase hydrolases, and oxidoreductase enzymes such as polyphenol oxidase are changed. Glycoside hydrolases hydrolyze the aroma fractions of glycosidic elements such as monoterpenes (linalool, geraniol), sesquiterpenes (nerolidol), and hypersesquiterpenes (violetone) that exist in monoglycoside or double glycoside combinations with strong and elegant floral, sweet and woody aromas. The resulting free aroma fractions further form the characteristic aromas of black tea [22,23,24]. On the other hand, shaking is a key step in the formation of floral and fruity aromas in tea products and is accompanied by a series of chemical reactions including degradation of lipids, generation of coupled oxidation products, hydrolysis and transformation of glycosidic substances via gradual damage to cellular tissues at the edges of the leaves caused by accelerated water dissipation, resulting in the transformation of the aroma from grassy to floral and fruity [25,26,27]. Changing the order of withering and shaking has a large influence on the release of volatile substances from fresh leaves.

Figure 2.

Clustering heat map of volatile compounds in black teas processed by withering-shaking and shaking-withering. The numbers in the row names of the heat map represent compounds, and the correspondence between numbers and compounds is shown in Table S1 of the Supplementary Materials.

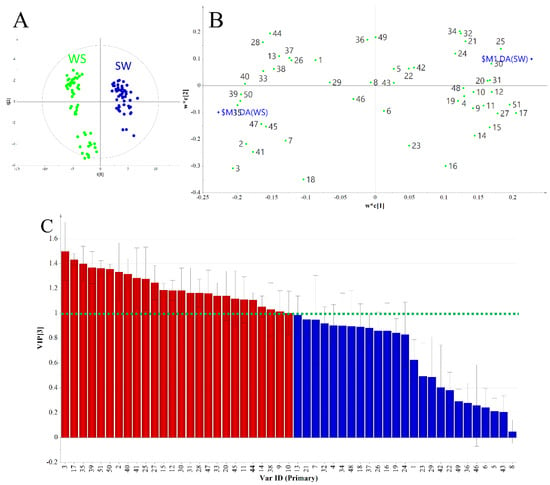

3.4. Partial Least Squares Discriminant Analysis

PLS-DA is a supervised discriminant analysis method that is widely used in food research because it allows better selection of characteristic variables that distinguish groups and determine relationships between samples [28,29,30]. PLS-DA modeling was used to analyze the effects of WS and SW treatments on the volatile components. As shown in Figure 3A, black tea samples were effectively separated into two groups, with WS treatment on the left and SW treatment on the right. This separation was consistent with the PCA results (Figure 1). The model was cross-validated for the two main components, giving a fit index of R2X (cum) = 0.626 for the independent variable, R2Y (cum) = 0.968 for the dependent variable, and Q2 (cum) = 0.959 for the predicted fit index, showing that the model had good cumulative explanatory and predictive power. The PLS-DA loading plot (Figure 3B) clearly shows the two treatments’ differences through volatile compound concentrations. Under the WS treatment, 2-methylbutanal, trans-2-hexenal, n-valeric acid cis-3-hexenyl ester, cis-3-hexenyl cis-hexanoate, hexyl hexanoate, and 2,2,6-trimethylcyclohexanone concentrations were significantly higher (p < 0.05); while under the SW treatment, 3-carene, α-calacorene, o-(diphenylmethyl)-hydroxylamine, geraniol, cis-5-ethenyltetrahydro-α, α-5-trimethyl-2-furanmethanol, and ethyl 2-(5-methyl-5-vinyltetrahydrofuran-2-yl) prop-2-yl carbonate concentrations were significantly higher (p < 0.05). Interestingly, among these differential compounds, there was a predominance of fruity characteristic compounds in the WS treatment, while the SW treatment was dominated by floral and woody characteristic compounds (Table S2).

Figure 3.

(A) Partial least squares discriminant analysis (PLS-DA) scores plot, (B) loading plot, and (C) variable importance prediction (VIP) plot of volatile compounds in black teas processed by withering-shaking and shaking-withering. (B,C): The numbers on the abscissa represent compounds, and the corresponding relationship between numbers and compounds is shown in Table S1 of the Supplementary Materials.

Variable importance prediction (VIP) plots were also constructed to identify the compounds responsible for the differences in aroma characteristics under the two treatments, with VIP > 1 indicating an important discriminating compound [31,32,33]. As shown in Figure 3C, 26 volatile compounds with VIP > 1 were obtained and could be used as potential markers to distinguish black teas processed by SW or WS.

3.5. Validation of Differential Compounds between SW and WS Processes

OAV (ratio of a volatile compound concentration to its odor threshold value) is an objective indicator of the odor contribution of volatile compounds and has been widely used to evaluate aroma components in tea [34,35]. An OAV > 1 indicates a contribution to the aroma, while OAV > 10 indicates a significant contribution [36,37]. OAV analysis was performed on the 26 volatile compounds identified by PLS-DA to determine the compounds that are the primary contributors to the characteristic aromas of the two treatment groups. The OAV and odor characteristics of 13 of the 26 compounds were obtained from known threshold information (Table S2), from which 6 compounds with OAV > 1 under either WS or SW treatment were selected (Table 1). Of these, β-ionone had OAV values > 10 in both treatment groups, indicating that it contributed significantly to the aroma characteristics in both groups. Hexanal, β-myrcene, 3-carene, geraniol and τ-cadinol (OAV > 1), however, were important components for discriminating the two groups. Notably, after WS treatment, the aroma contribution of these compounds was in the order β-ionone > 3-carene > τ-cadinol > geraniol when shaken for 1 h or 2 h, but in the order β-ionone > 3-carene > geraniol > τ-cadinol when shaken for 3 h or 4 h. After SW treatment, all samples showed the order β-ionone > 3-carene > geraniol > β-myrcene. This was consistent with the cluster analysis results (Figure 3), indicating that β-ionone, 3-carene, geraniol, β-myrcene, and τ-cadinol can be used to distinguish the aroma quality of the two black teas. In addition, these volatile compounds were all terpenes, and their release may have been due to damage to the leaf marginal cells caused by the shaking process, resulting in rapid water loss, an increase in the concentration and activity of enzymes involved in aroma synthesis, and conversion of more aroma precursors into volatile components. Reversing the withering and shaking had a significant impact on the concentrations of these components [13].

Table 1.

Principal volatile compounds responsible for aroma of the black tea samples and their odor activity values (OAVs).

Thus, PCA, clustering, PLS-DA and OAV analyses identified five major volatile compounds that could distinguish the aroma characteristics of the WS and SW treatments: β-ionone, 3-carene, geraniol, β-myrcene, and τ-cadinol.

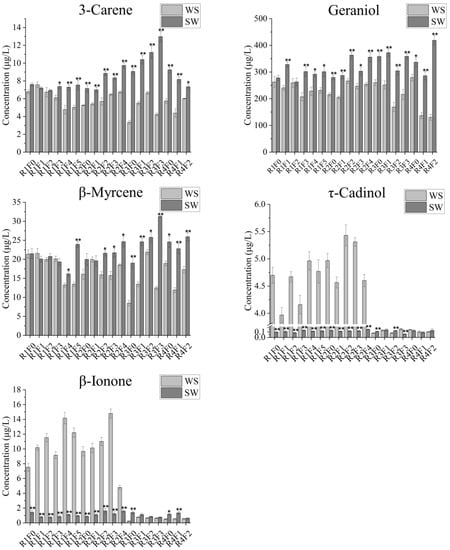

3.6. Analysis of Main Volatile Compounds

Figure 4 illustrates the differences in concentration of the five volatile compounds distinguishing black tea prepared using the WS and SW processes. The concentrations of 3-carene, geraniol and β-myrcene were generally higher after SW treatment than WS treatment (p < 0.05), but some differences were not significant. The concentrations of β-ionone and τ-cadinol were always lower after SW treatment, and were significantly higher after WS treatment with 1–2 h of rolling (p < 0.05). Geraniol, which has a rosy aroma, was the most abundant volatile compound after traditional processing of black tea [44]. Previous studies found that the static withering process promoted the accumulation of geraniol [45], while the shaking process decreased it [46]. Our results suggest that shaking followed by withering is more favorable for the retention of geraniol. β-myrcene, an important volatile compound in the formation of floral and fruity aroma characteristics of tea, can be significantly increased during shaking along with the metabolism of terpenoids and the cleavage of long-chain fatty acids [15]. Shaking followed by withering was also more favorable for the retention of β-myrcene. β-ionone is described as having a complex woody, fruity aroma, and both mechanical damage and low temperatures enhance its accumulation during withering [47]. The intense respiration of fresh leaves in the early postharvest period leads to relatively high internal temperatures, which may result in low levels of β-ionone under the SW process.

Figure 4.

Concentrations of the principal volatile compounds responsible for aromas in black teas processed by withering-shaking and shaking-withering (* p < 0.05, ** p < 0.01).

The withering process is accompanied by water loss and respiration, causing increased cell permeability and different enzymatic reactions that are important for the release of aroma substances [48]. The addition of shaking before or after withering may significantly disrupt the balance of aroma substance production. For example, adding shaking (which promotes respiration and high surface temperature in the fresh leaves) before withering is not conducive to the accumulation of β-ionone or τ-cadinol, which are readily produced at low temperatures, but it favors the accumulation of 3-carene, geraniol, and β-myrcene. Adding the mechanical damage caused by shaking after withering, when respiration is weakened and leaf surface temperatures are lower, favors the accumulation of β-ionone and τ-cadinol, while it is less favorable to 3-carene, geraniol, and β-myrcene release. These influences result in the differences observed in volatile compound concentrations [47,48,49].

Figure 4 and Table S2 show that the combination of a high concentration of geraniol with its floral aroma and 3-carene and β-myrcene with their sweet aromas was conducive to the formation of floral-leaning characteristics, while a high concentration of τ-cadinol with its tarry odor and β-ionone with its fruity or woody aroma contributed to the formation of fruity-leaning characteristics.

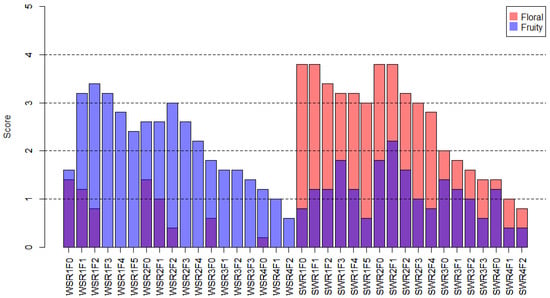

3.7. Sensory Characteristics of Black Tea Following SW and WS

Floral and fruity aromas are the main aroma characteristics of black tea processed with a shaking process. The floral and fruity aroma characteristics of black teas in the two treatment groups were evaluated (Figure 5). The overall intensity of the fruity aroma of the WS-treated black teas was greater than the floral aroma. The intensity of the floral aroma gradually decreased as the fermentation time was extended with a fixed rolling time, while the intensity of the fruity aroma tended to increase and then decrease with a longer fermentation time during the first two hours of rolling, and gradually decreased with longer fermentation in the second two hours of rolling. The overall characteristics of the SW-treated samples were the opposite of the WS treatment, with the intensity of floral aroma being greater than the fruity aroma. At a fixed rolling time, the floral intensity tended to decrease as fermentation time lengthened, while changes in the fruity aroma were similar to the WS treatment. Sensory evaluation showed that black tea produced by the WS method favored a fruity aroma, while the SW method favored a floral aroma. Interestingly, the intensity of floral aroma in both treatments was greatest at the start of fermentation then gradually decreased, while the fruity aroma tended to increase and then decrease with longer fermentation during the first two hours of rolling, indicating that fermentation was not conducive to the formation of a floral aroma but enhanced a fruity aroma. Furthermore, the intensity of the floral aroma was the same for the samples rolled for 1 h or 2 h without fermentation. It is speculated that this was due to the leaves being continuously turned during the rolling process, thus maintaining a low temperature inside the leaves (~22 °C) and facilitating greater enzymatic activity; whereas the leaves remained stationary during fermentation, resulting in a higher internal temperature (~30 °C) that led to decreased enzymatic activity and less accumulation of volatile compounds with floral aroma characteristics [49].

Figure 5.

Sensory evaluation scores of the aroma of black teas processed under various conditions. Purple is the color that appears when red and blue are stacked, indicating that this sample has both floral and fruity aromas.

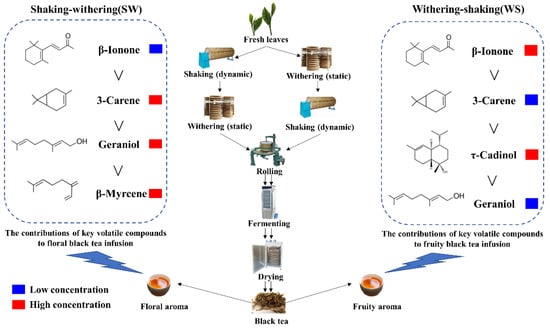

4. Conclusions

Different sequences of withering and shaking had significant effects on the formation of aroma characteristics of black tea. Five volatile compounds affecting the aroma quality of black tea were identified using PCA, MEV, PLS-DA and OAV analyses. The contribution of volatile compounds in black tea prepared by the WS process was β-ionone > 3-carene > τ-cadinol > geraniol; while the contribution of compounds after the SW process was β-ionone > 3-carene > geraniol > β-myrcene (Figure 6). Sensory evaluation showed that the fruitiness of black tea was stronger under the WS treatment and the floral aroma was stronger under the SW treatment.

Figure 6.

Schematic of experimental design and contribution of flavor-related volatile compounds to floral and fruity black teas.

The effects of the sequencing of withering and shaking on the formation of aroma characteristics and the contributions of major volatile compounds in black tea were elucidated, providing technical guidance for the precise and targeted production of black teas with floral and fruity aromas. However, this study only examined the effects of two processing treatments. Further exploration is required to determine the optimal combination of processes for the release of major volatile compounds in order to optimize the production of black teas with desired floral and fruity aromas.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/horticulturae8060549/s1, Table S1: All volatile compounds detected by GC-MS/MS in the black teas processed under various conditions; Table S2: Volatile compounds responsible for aroma of the black teas and their odor activity values (OAVs) and odor characteristics.

Author Contributions

J.L.: Conceptualization, data curation, investigation, methodology, visualization, writing—original draft. Z.T.: Data curation, methodology, investigation, writing—review and editing. H.Z.: Writing—review and editing. L.C.: Investigation, methodology. Y.W.: Investigation. Y.Y. (Yunfei Yang): Investigation. H.L.: Investigation. Y.Z.: Investigation, L.Y.: Supervision, writing—review and editing, methodology. Y.Y. (Yang Ye): Conceptualization, supervision, writing—review and editing, funding acquisition, resources, project administration. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the earmarked fund for China Agriculture Research System, grant number CARS-19, and the Zhejiang Province agricultural major technology cooperative extension project, grant number 2020XTTGCY02-03.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank CARS-19 (China Agriculture Research System) and 2020XTTGCY02-03 (Zhejiang Province agricultural major technology cooperative extension project) for funding this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Da Silva, P.M. Tea: A new perspective on health benefits. Food Res. Int. 2013, 53, 558–567. [Google Scholar] [CrossRef]

- Liu, Z.B.; Bruins, M.E.; Ni, L.; Vincken, J. Green and Black Tea Phenolics, Bioavailability; Transformation by Colonic Microbiota; and Modulation of Colonic Microbiota. J. Agric. Food Chem. 2018, 66, 8469–8477. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Ho, C.T.; Zhou, J.; Santos, J.S.; Armstrong, L.; Granato, D. Chemistry and Biological Activities of Processed Camellia sinensis Teas, A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1474–1495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xia, T. Manufacture of Tea, 3rd ed.; Agricultural Press of China: Beijing, China, 2014; p. 88. [Google Scholar]

- Tomlins, K.I.; Mashingaidze, A. Influence of withering; including leaf handling; on the manufacturing and quality of black teas—A review. Food Chem. 1997, 60, 573–580. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, P.-C.; Liu, P.-P.; Song, X.-W.; Guo, F.; Li, Y.-Y.; Ni, D.-J.; Jiang, C.-J. Novel insight into the role of withering process in characteristic flavor formation of teas using transcriptome analysis and metabolite profiling. Food Chem. 2019, 272, 313–322. [Google Scholar] [CrossRef]

- Kinoshita, T.; Hirata, S.; Yang, Z.; Baldermann, S.; Kitayama, E.; Matsumoto, S.; Suzuki, M.; Fleischmann, P.; Winterhalter, P.; Watanabe, N. Formation of damascenone derived from glycosidically bound precursors in green tea infusions. Food Chem. 2010, 123, 601–606. [Google Scholar] [CrossRef] [Green Version]

- Saijō, R.; Kuwabara, Y. Volatile Flavor of Black Tea, Part I. Formation of Volatile Components during Black Tea Manufacture. Agric. Biol. Chem. 1967, 31, 389–396. [Google Scholar] [CrossRef]

- Wang, D.M.; Yoshimura, T.; Kubota, K.; Kobayashi, A. Analysis of Glycosidically Bound Aroma Precursors in Tea Leaves. 1. Qualitative and Quantitative Analyses of Glycosides with Aglycons as Aroma Compounds. J. Agric. Food Chem. 2000, 48, 5411–5418. [Google Scholar] [CrossRef]

- Luo, L.F.; Liang, G.Z.; Yang, J.Y.; Feng, H.Y.; Mo, X.Y.; Liu, H.Y.; Li, Z.P. Study on 4 oolong tea varieties suitable for making floral-flavored black tea in southwest Guangxi. Chin. Hortic. Abstr. 2017, 33, 18–19. (In Chinese) [Google Scholar]

- Mei, S.; Chen, W.; Ma, C.Y.; Chen, D.; Qiao, X.Y. Comparative analysis of volatiles of flowery black teas and Dancong teas from Guangdong province. Mod. Food Sci. Technol. 2020, 36, 242–252. (In Chinese) [Google Scholar] [CrossRef]

- Pan, Y.B. Study on the Aroma Characteristic and the Key Technology of Congou Black Tea with Flowery-Fruity Flavor. Master’s Thesis, Fujian Agriculture and Forestry University, Fujian, China, 2014. (In Chinese). [Google Scholar]

- Hou, Z.-W.; Wang, Y.-J.; Xu, S.-S.; Wei, Y.-M.; Bao, G.-H.; Dai, Q.-Y.; Deng, W.-W.; Ning, J.-M. Effects of dynamic and static withering technology on volatile and nonvolatile components of Keemun black tea using GC-MS and HPLC combined with chemometrics. LWT 2020, 130, 109547. [Google Scholar] [CrossRef]

- Zeng, L.; Zhou, Y.; Fu, X.; Mei, X.; Cheng, S.; Gui, J.; Dong, F.; Tang, J.; Ma, S.; Yang, Z. Does oolong tea (Camellia sinensis) made from a combination of leaf and stem smell more aromatic than leaf-only tea? Contribution of the stem to oolong tea aroma. Food Chem. 2017, 237, 488–498. [Google Scholar] [CrossRef] [PubMed]

- Zeng, L.; Zhou, Y.; Fu, X.; Mei, X.; Cheng, S.; Gui, J.; Dong, F.; Tang, J.; Ma, S.; Yang, Z. Formation mechanism of the oolong tea characteristic aroma during bruising and withering treatment. Food Chem. 2018, 269, 202–211. [Google Scholar]

- Ma, C.Y.; Li, J.X.; Chen, W.; Wang, W.W.; Qi, D.D.; Pang, S.; Mao, A.Q. Study of the aroma formation and transformation during the manufacturing process of oolong tea by solid-phase micro-extraction and gas chromatography–mass spectrometry combined with chemometrics. Food Res. Int. 2018, 108, 413–422. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.Q.; Li, Q.S.; Xiang, L.P.; Liang, Y.R. Recent Advances in Volatiles of Teas. Molecules 2016, 21, 338. [Google Scholar] [CrossRef]

- Xu, Y.-Q.; Wang, C.; Li, C.-W.; Liu, S.-H.; Zhang, C.-X.; Li, L.-W.; Jiang, D.-H. Characterization of Aroma-Active Compounds of Pu-erh Tea by Headspace Solid-Phase Microextraction (HS-SPME) and Simultaneous Distillation-Extraction (SDE) Coupled with GC-Olfactometry and GC-MS. Food Anal. Method 2016, 9, 1188–1198. [Google Scholar] [CrossRef]

- Zhang, M.M.; Jiang, Y.W.; Hua, J.J.; Wang, J.; Yuan, H.B.; Yang, Y.Q. Effect of drying methods on chestnut-like aroma of green tea. Food Sci. 2020, 41, 115–123. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, W.; Lao, F.; Bi, S.; Pan, X.; Pang, X.; Hu, X.; Liao, X.; Wu, J. Insights into the major aroma-active compounds in clear red raspberry juice (Rubus idaeus L. cv. Heritage) by molecular sensory science approaches. Food Chem. 2021, 336, 127721. [Google Scholar]

- Zhu, Y.; Lv, H.-P.; Shao, C.-Y.; Kang, S.; Zhang, Y.; Guo, L.; Dai, W.; Tan, J.-F.; Peng, Q.-H.; Lin, Z. Identification of key odorants responsible for chestnut-like aroma quality of green teas. Food Res. Int. 2018, 108, 74–82. [Google Scholar] [CrossRef]

- Deb, S.; Jolvis Pou, K.R. A Review of Withering in the Processing of Black Tea. J. Biosyst. Eng. 2016, 41, 365–372. [Google Scholar] [CrossRef] [Green Version]

- Mizutani, M.; Nakanishi, H.; Ema, J.-I.; Ma, S.-J.; Noguchi, E.; Inohara-Ochiai, M.; Fukuchi-Mizutani, M.; Nakao, M.; Sakata, K. Cloning of β-Primeverosidase from Tea Leaves; a Key Enzyme in Tea Aroma Formation. Plant Physiol. 2002, 130, 2164–2176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.J.; Wang, F.M.; Liu, G.F.; He, Z.R.; Yang, H.; Wei, C.L.; Wang, X.C.; Wei, S. Correlation between spatiotemporal profiles of volatile terpenoids and relevant terpenoid synthase gene expression in Camellia sinensis. Acta Hortic. Sin. 2014, 41, 2094–2106. (In Chinese) [Google Scholar] [CrossRef]

- Feng, Z.; Li, Y.; Li, M.; Wang, Y.; Zhang, L.; Wan, X.; Yang, X. Tea aroma formation from six model manufacturing processes. Food Chem. 2019, 285, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.Y.; Baldermann, S.; Watanabe, N. Recent studies of the volatile compounds in tea. Food Res. Int. 2013, 53, 585–599. [Google Scholar] [CrossRef]

- Zhou, Y.; Zeng, L.; Liu, X.; Gui, J.; Mei, X.; Fu, X.; Dong, F.; Tang, J.; Zhang, L.; Yang, Z. Formation of (E)-nerolidol in tea (Camellia sinensis) leaves exposed to multiple stresses during tea manufacturing. Food Chem. 2017, 231, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Genis, D.O.; Sezer, B.; Durna, S.; Boyaci, I.H. Determination of milk fat authenticity in ultra-filtered white cheese by using Raman spectroscopy with multivariate data analysis. Food Chem. 2021, 336, 127699. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Yangming, H.; Górska-Horczyczak, E.; Wierzbicka, A.; Jeleń, H.H. Rapid analysis of Baijiu volatile compounds fingerprint for their aroma and regional origin authenticity assessment. Food Chem. 2021, 337, 128002. [Google Scholar] [CrossRef]

- Jia, W.; Shi, Q.Y.; Zhang, R.; Shi, L.; Chu, X.G. Unraveling proteome changes of irradiated goat meat and its relationship to off-flavor analyzed by high-throughput proteomics analysis. Food Chem. 2021, 337, 127806. [Google Scholar] [CrossRef]

- Qian, X.; Lan, Y.; Han, S.; Liang, N.; Zhu, B.; Shi, Y.; Duan, C. Comprehensive investigation of lactones and furanones in icewines and dry wines using gas chromatography-triple quadrupole mass spectrometry. Food Res. Int. 2020, 137, 109650. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, S.; Nie, Y.; Xu, Y. Characterization of volatile sulfur compounds in soy sauce aroma type Baijiu and changes during fermentation by GC × GC-TOFMS; organoleptic impact evaluation; and multivariate data analysis. Food Res. Int. 2020, 131, 109043. [Google Scholar] [CrossRef]

- Yang, Y.; Hua, J.; Deng, Y.; Jiang, Y.; Qian, M.C.; Wang, J.; Li, J.; Zhang, M.; Dong, C.; Yuan, H. Aroma dynamic characteristics during the process of variable-temperature final firing of Congou black tea by electronic nose and comprehensive two-dimensional gas chromatography coupled to time-of-flight mass spectrometry. Food Res. Int. 2020, 137, 109656. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Wang, X.L.; Song, X.B.; Zheng, F.; Li, H.; Chen, F.; Zhang, Y.; Zhang, F. Evolution of the key odorants and aroma profiles in traditional Laowuzeng baijiu during its one-year ageing. Food Chem. 2020, 310, 125898. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.Q.; Ma, W.J.; Shi, J.; Zhu, Y.; Lin, Z.; Lv, H.P. Characterization of the key aroma compounds in Longjing tea using stir bar sorptive extraction (SBSE) combined with gas chromatography-mass spectrometry (GC–MS); gas chromatography-olfactometry (GC-O); odor activity value (OAV); and aroma recombination. Food Res. Int. 2020, 130, 108908. [Google Scholar] [CrossRef] [PubMed]

- Liao, X.; Yan, J.; Wang, B.; Meng, Q.; Zhang, L.; Tong, H. Identification of key odorants responsible for cooked corn-like aroma of green teas made by tea cultivar ‘Zhonghuang 1’. Food Res. Int. 2020, 136, 109355. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.W.; Yao, Z.M.; Xiao, Z.B.; Wu, M.L. The study on characteristic aroma compounds in two lavender essential oils by AEDA and OAVs. Food Ind. 2016, 37, 264–268. (In Chinese) [Google Scholar]

- Flaig, M.; Qi, S.; Wei, G.D.; Yang, X.G.; Schieberle, P. Characterization of the Key Odorants in a High-Grade Chinese Green Tea Beverage (Camellia sinensis; Jingshan cha) by Means of the Sensomics Approach and Elucidation of Odorant Changes in Tea Leaves Caused by the Tea Manufacturing Process. J. Agric. Food Chem. 2020, 68, 5168–5179. [Google Scholar] [CrossRef]

- Guo, X.; Ho, C.-T.; Wan, X.; Zhu, H.; Liu, Q.; Wen, Z. Changes of volatile compounds and odor profiles in Wuyi rock tea during processing. Food Chem. 2021, 341, 128230. [Google Scholar] [CrossRef]

- Wang, H.; Hua, J.; Jiang, Y.; Yang, Y.; Wang, J.; Yuan, H. Influence of fixation methods on the chestnut-like aroma of green tea and dynamics of key aroma substances. Food Res. Int. 2020, 136, 109479. [Google Scholar] [CrossRef]

- Zhu, J.C.; Niu, Y.W.; Xiao, Z.B. Characterization of the key aroma compounds in Laoshan green teas by application of odour activity value (OAV); gas chromatography-mass spectrometry-olfactometry (GC-MS-O) and comprehensive two-dimensional gas chromatography mass spectrometry (GC × GC-qMS). Food Chem. 2021, 339, 128136. [Google Scholar] [CrossRef]

- Shu, C.; She, Y.B.; Xiao, Z.B.; Xu, L.; Niu, Y.W.; Zhu, J.C. Investigations on the aroma active compounds in fresh and aged Longjing tea by SPME/GC-MS/GC-O/OAV. Food Ind. 2016, 37, 279–285. (In Chinese) [Google Scholar]

- Zhang, Q.; Li, Q.Y.; Huang, M.Q.; Wu, J.H.; Li, H.H.; Sun, J.Y.; Sun, X.T.; Zhen, F.P.; Sun, B.G. Analysis of odor-active compounds in 2 sesame-flavor Chinese Baijius. Food Sci. 2019, 40, 214–222. (In Chinese) [Google Scholar] [CrossRef]

- Shu, Q.L.; Zhao, H.T.; Wang, Y.D. Study on the aroma components of Qimen black tea during the initial processing. J. Anhui Agric. Sci. 1989, 4, 91–94. (In Chinese) [Google Scholar] [CrossRef]

- Chen, L.; Chen, J.; Chen, Q.B.; Zhang, Y.G.; Song, Z.S.; Wang, L.L.; You, Z.M. Effects of green-making technique on aroma pattern of Oolong tea. J. Tea Sci. 2014, 34, 387–395. (In Chinese) [Google Scholar] [CrossRef]

- Shi, Y.F.; Di, T.M.; Yang, S.L.; Wu, L.Y.; Chen, Y.Q.; Xia, T.; Zhang, X. Changes in aroma components in the processing of flowery black tea. Food Sci. 2018, 39, 167–175. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.M.; Zhang, N.; Zhao, M.Y.; Jing, T.; Jin, J.; Wu, B.; Wan, X.; Schwab, W.; Song, C. Carotenoid Cleavage Dioxygenase 4 Catalyzes the Formation of Carotenoid-Derived Volatile β-Ionone during Tea (Camellia sinensis) Withering. J. Agric. Food Chem. 2020, 68, 1684–1690. [Google Scholar] [CrossRef] [PubMed]

- Wan, X.C. Tea Biochemistry, 3rd ed.; Agricultural Press of China: Beijing, China, 2003. [Google Scholar]

- Zhu, H.K.; He, H.F.; Ye, Y.; Dong, C.W.; Gui, A.H.; Gao, M.Z.; Chen, L. Influence of rolling temperature on physicochemical quality of Congou black tea. Mod. Food Sci. Technol. 2017, 33, 168–175. (In Chinese) [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).