Study on the Application of Electronic Nose Technology in the Detection for the Artificial Ripening of Crab Apples

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

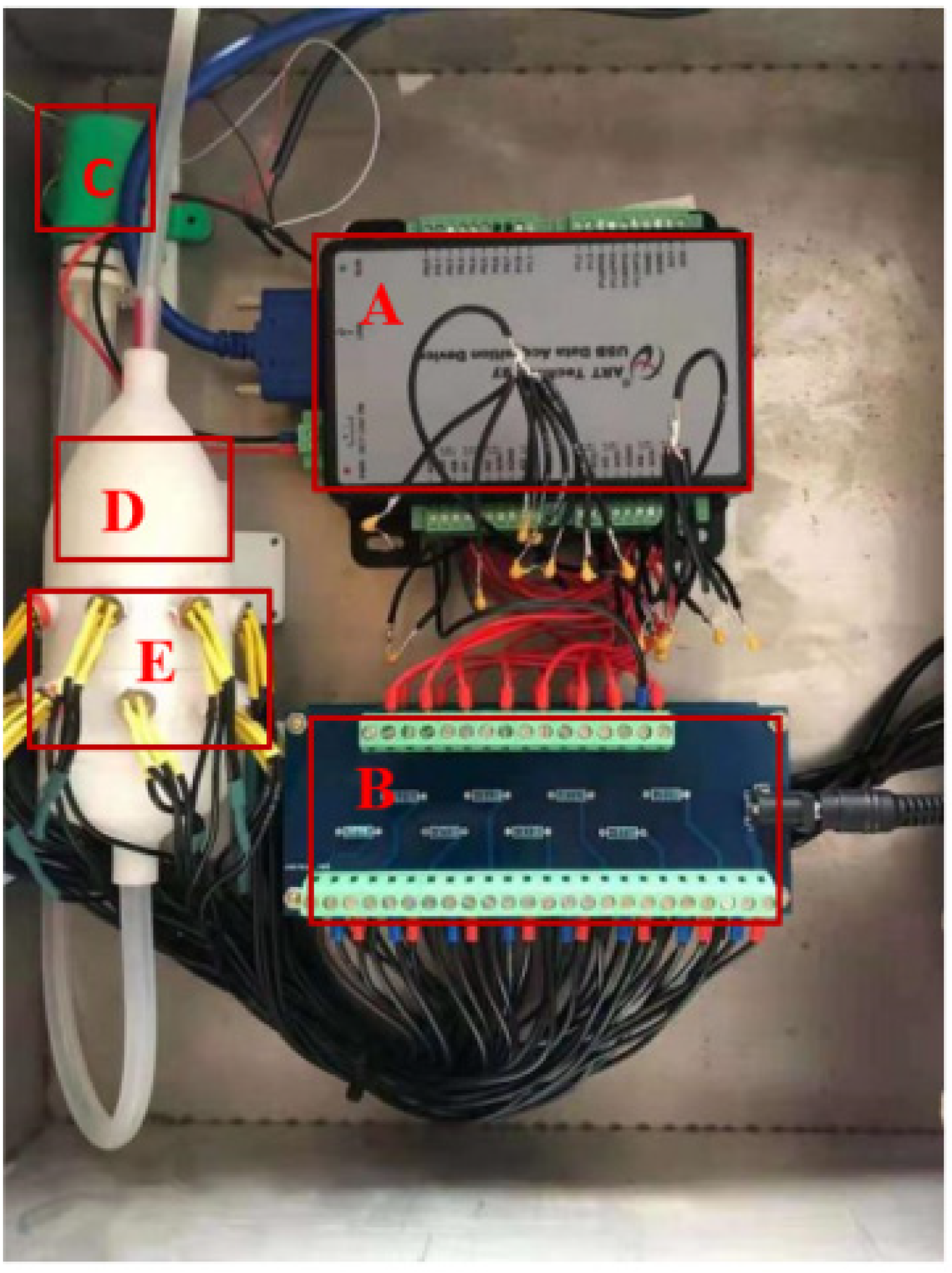

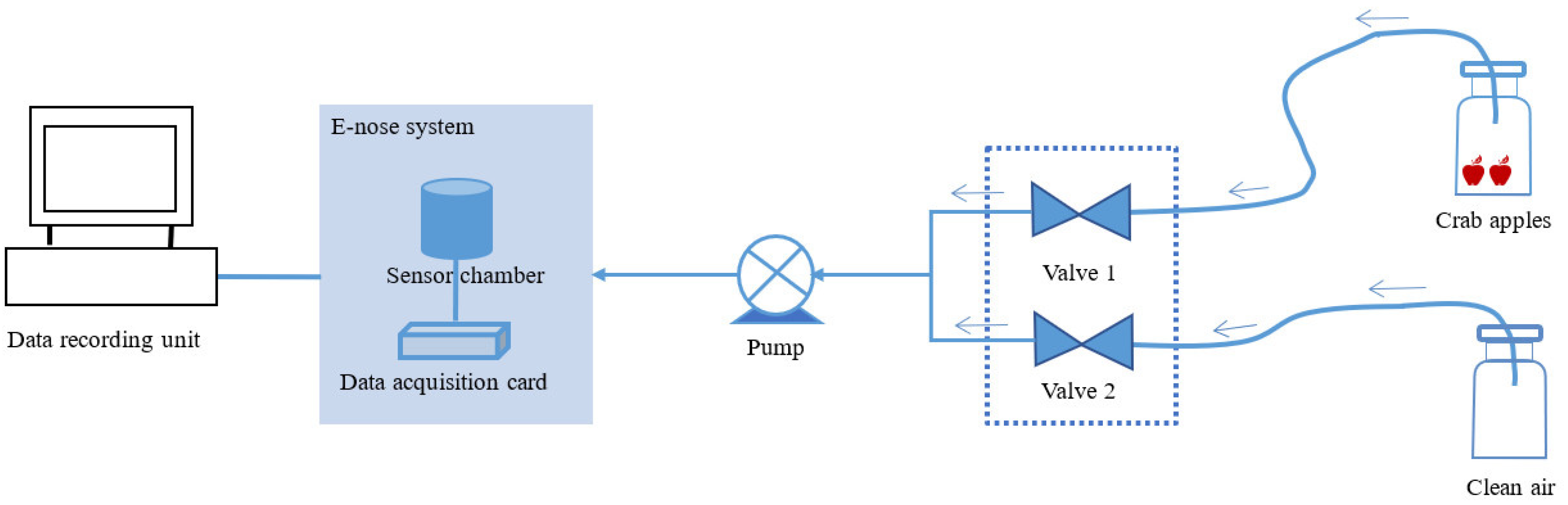

2.2. E-Nose Detection

2.3. Determination of Fruit Quality Indexes

2.4. Analysis of E-Nose Data

2.4.1. Feature Extraction Methods

2.4.2. Classifiers

2.4.3. PLSR

3. Results

3.1. Effects of Artificial Ripening Treatment on Fruit Quality Indexes

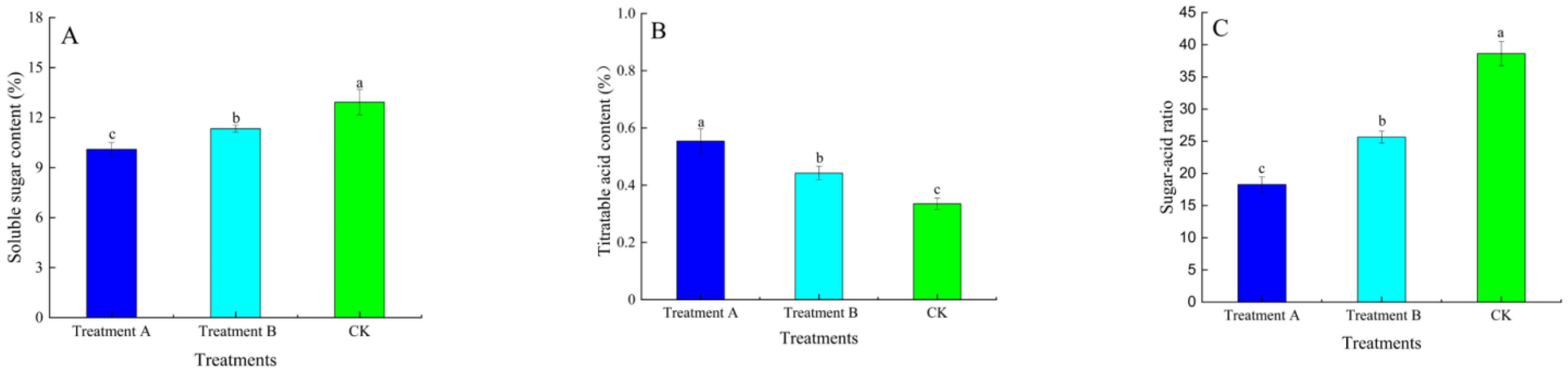

3.1.1. Soluble Sugar Content, Titratable Acid Content and Sugar–Acid Ratio of Fruit

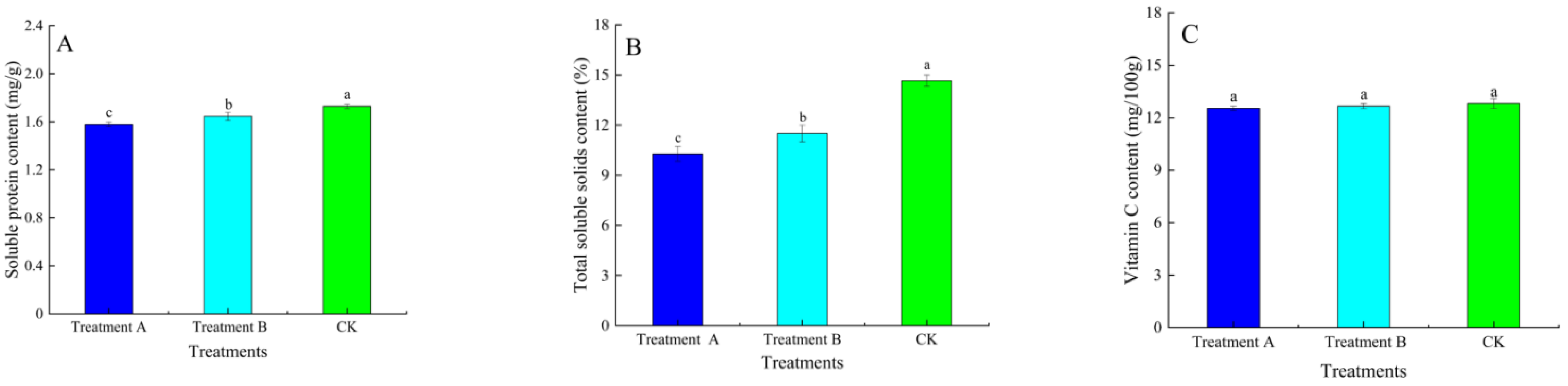

3.1.2. Content of Soluble Protein, Soluble Solids, and Vitamin C

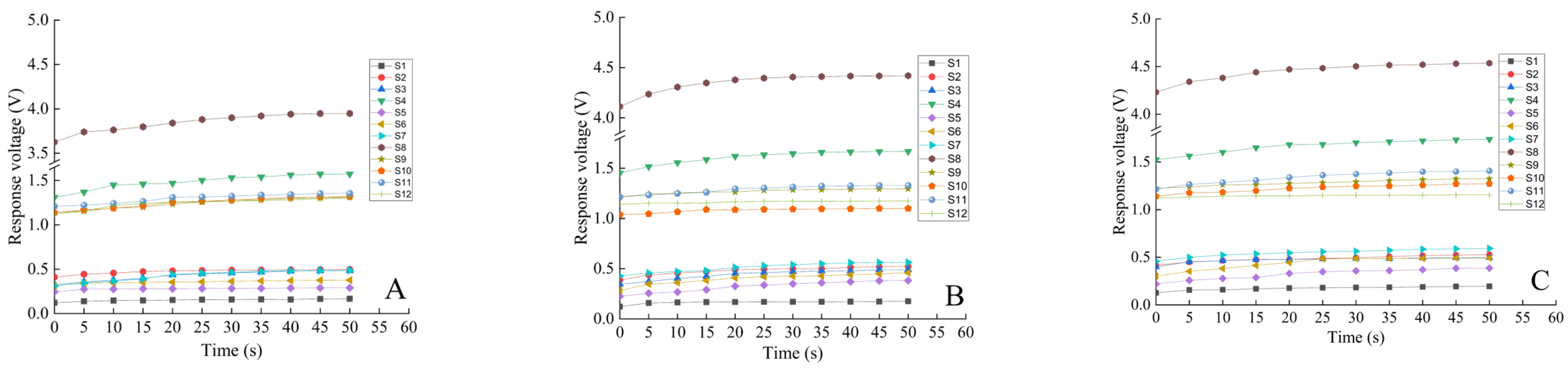

3.2. E-Nose Detection Results of Fruit

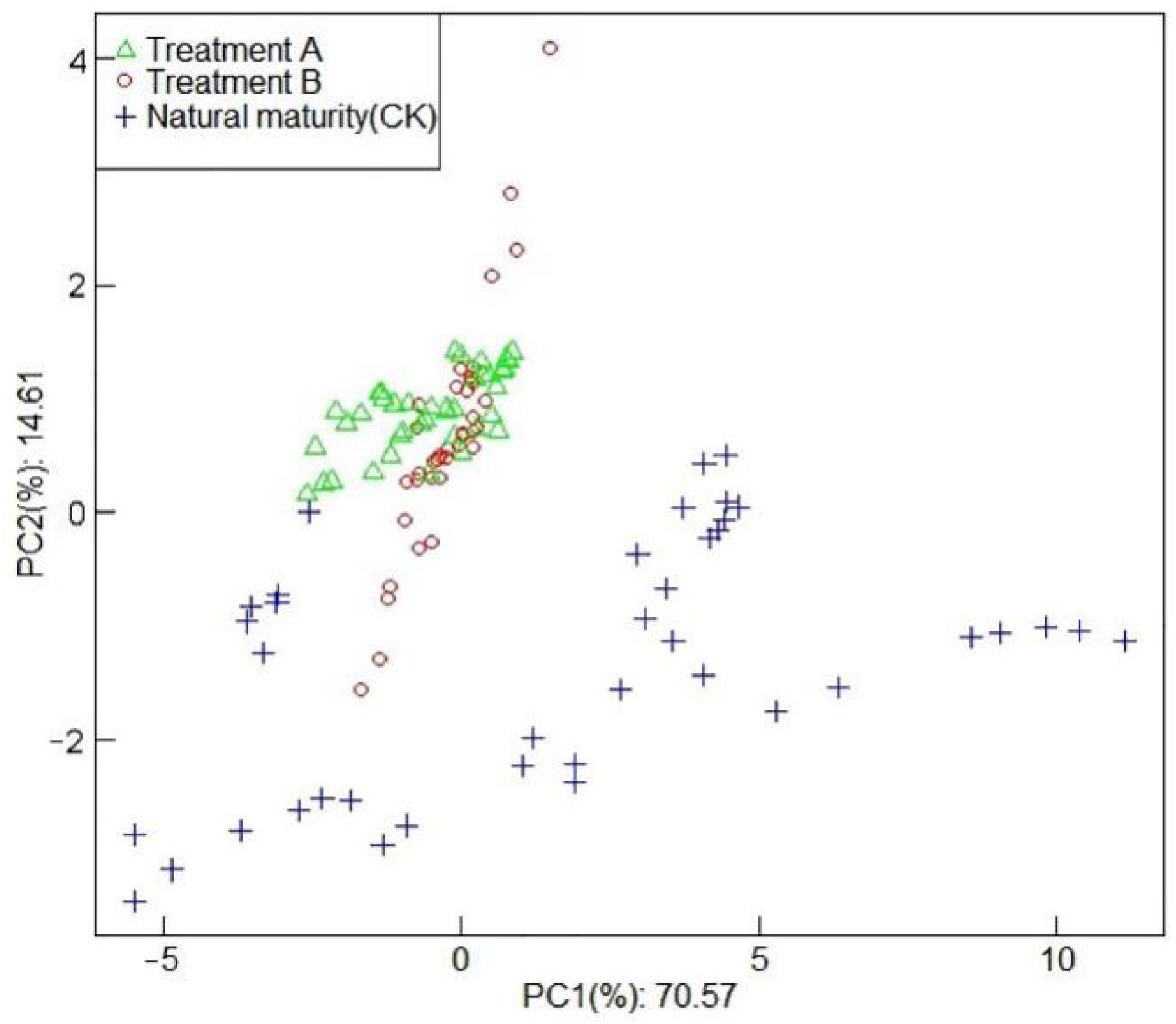

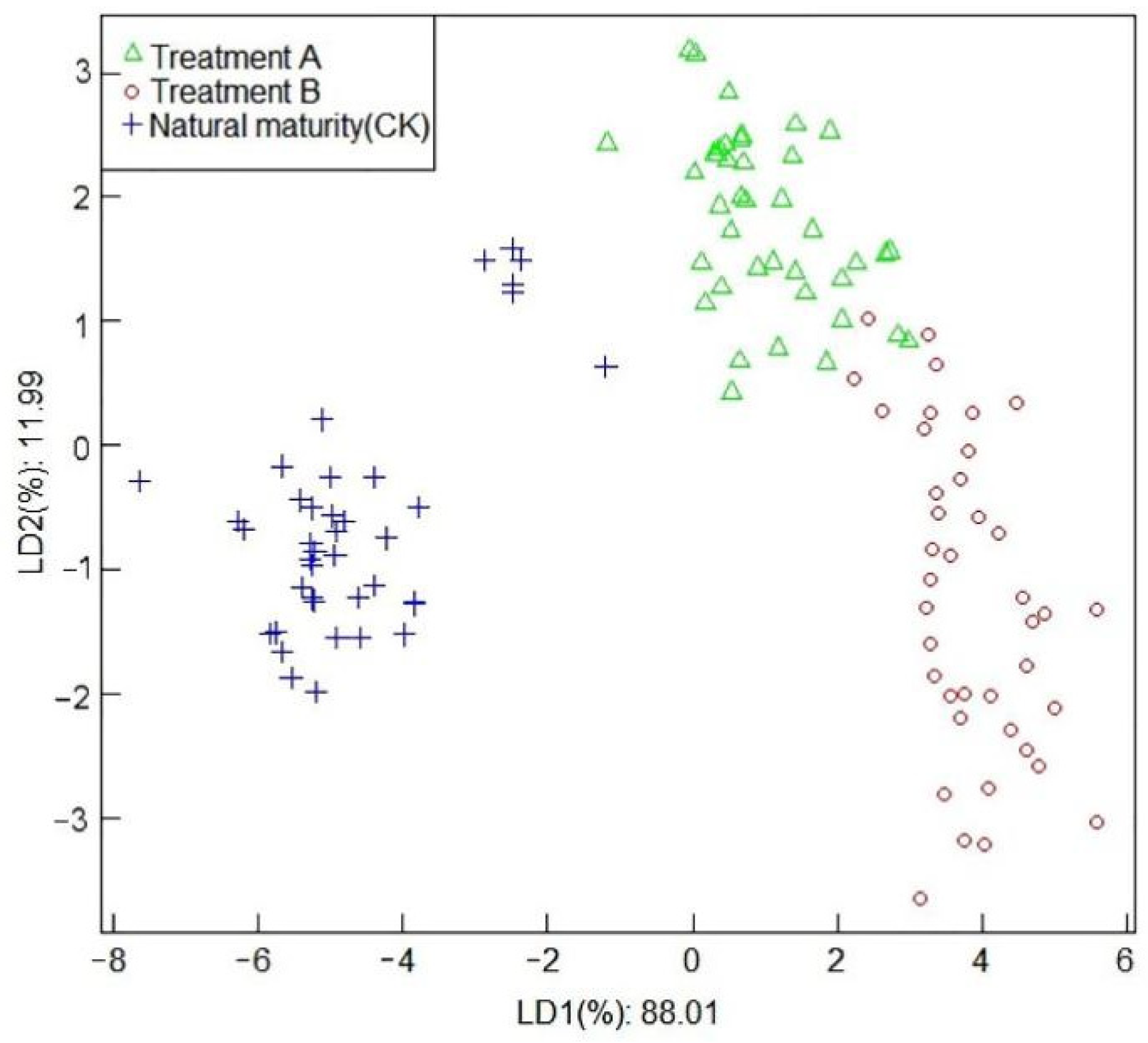

3.2.1. The Classification Results Based on Principal Component Analysis (PCA) and Linear Discriminant Analysis (LDA)

3.2.2. The Classification Results Based on SVM and RF

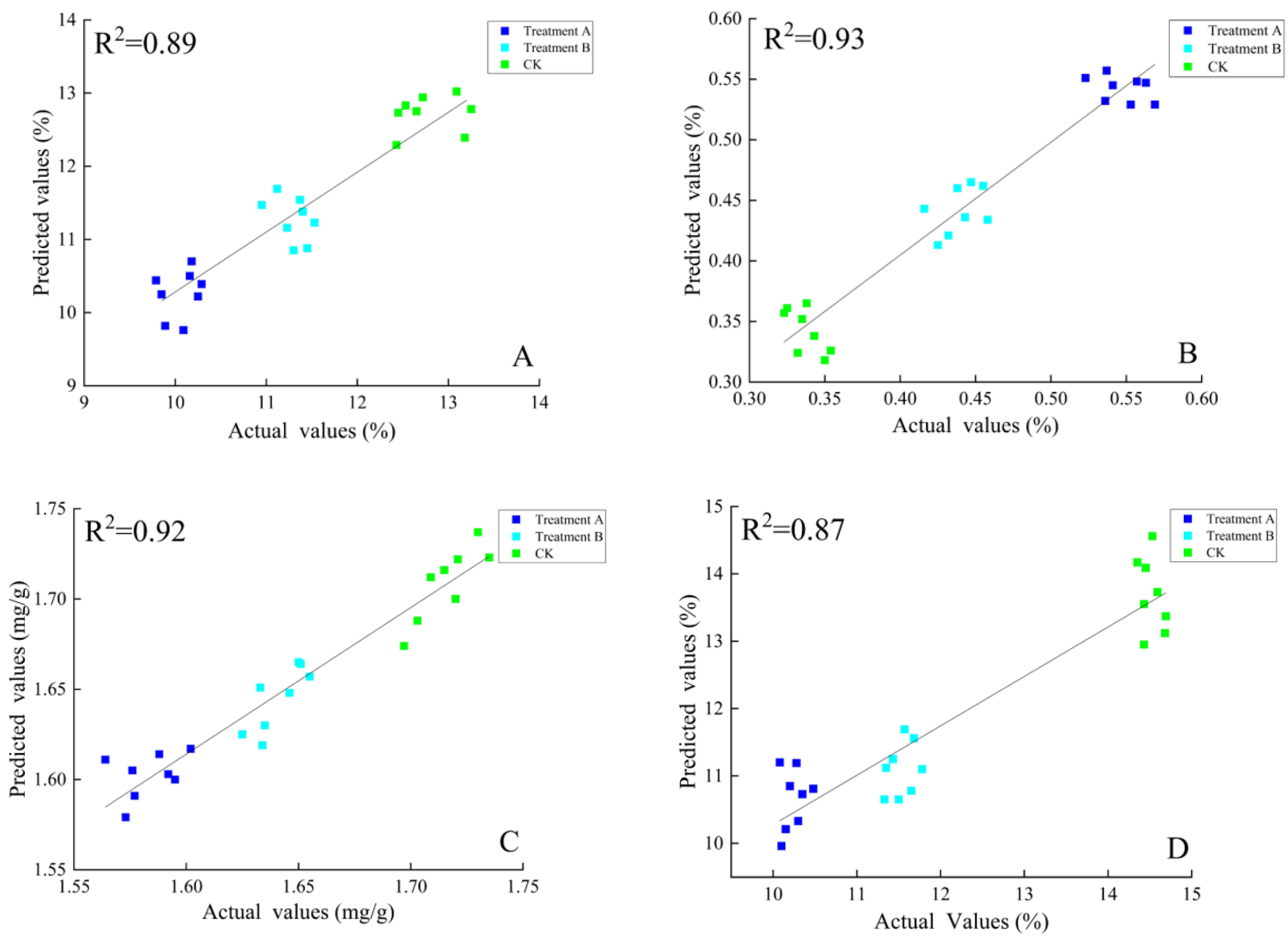

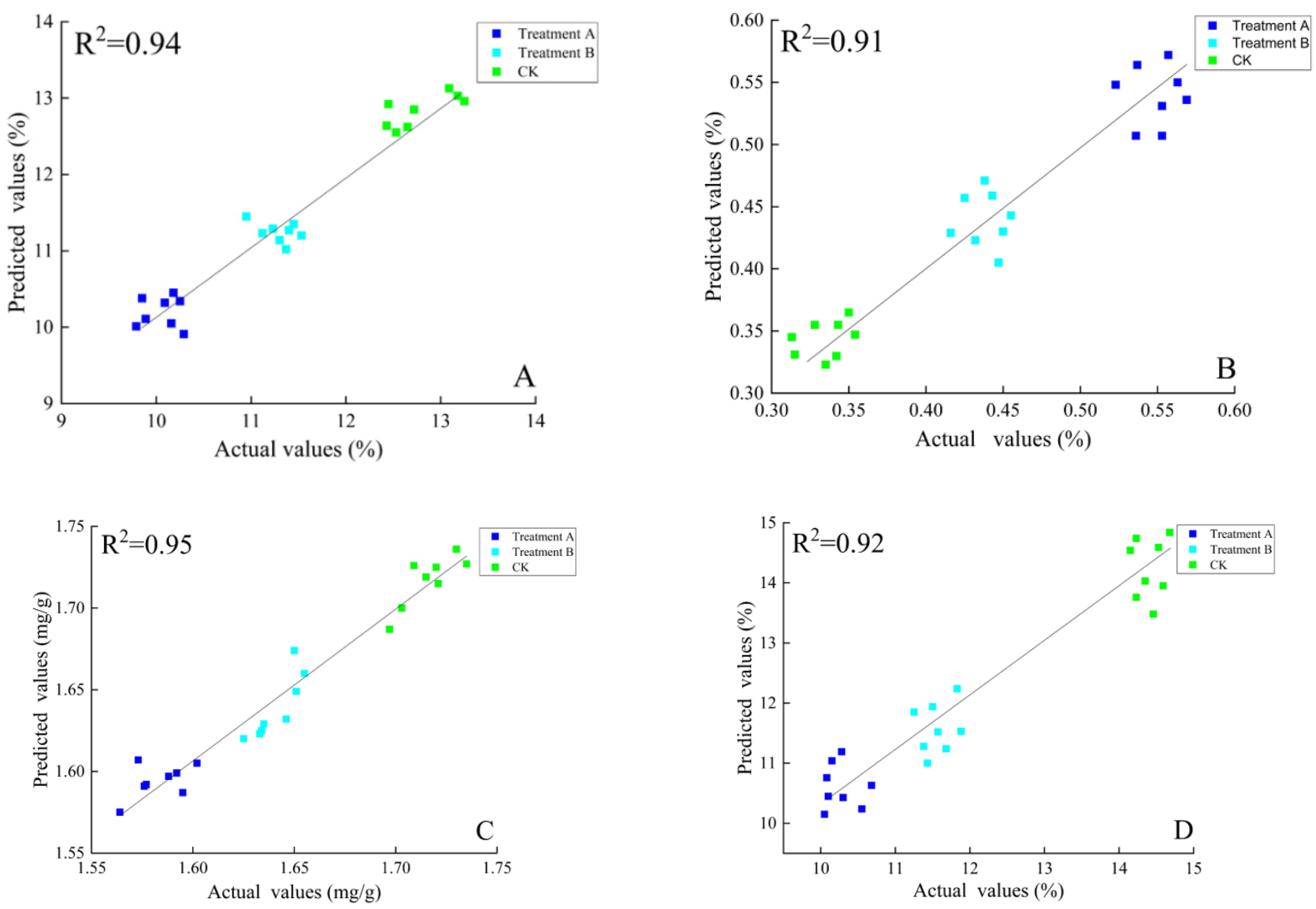

3.2.3. Predicting the Fruit Quality Indexes Based on E-Nose Response Data

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Costa, F.; Cappellin, L.; Longhi, S.; Guerra, W.; Magnago, P.; Porro, D.; Soukoulis, C.; Salvi, S.; Velasco, R.; Biasioli, F.; et al. Assessment of apple (Malus × domestica Borkh.) fruit texture by a combined acoustic-mechanical profiling strategy. Postharvest Biol. Technol. 2011, 61, 21–28. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.; Zhang, W. Detecting internal quality of peanuts during storage using electronic nose responses combined with physicochemical methods. Food Chem. 2015, 177, 89–96. [Google Scholar] [CrossRef]

- Rajkumar, P.; Wang, N.; Eimasry, G.; Raghavan, G.S.V.; Gariepy, Y. Studies on banana fruit quality and maturity stages using hyperspectral imaging. J. Food Eng. 2012, 108, 194–200. [Google Scholar] [CrossRef]

- Pearce, T.C.; Schiffman, S.S.; Nagle, H.T.; Gardner, J.W. Handbook of Machine Olfaction: Electronic Nose Technology; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar]

- Martínez Gila, D.M.; Gámez García, J.; Bellincontro, A.; Mencarelli, F.; Gómez Ortega, J. Fast tool based on electronic nose to predict olive fruit quality after harvest. Postharvest Biol. Technol. 2020, 160, 111058. [Google Scholar] [CrossRef]

- Suman, M.; Riani, G.; Dalcanale, E. MOS-based artificial olfactory system for the assessment of egg products freshness. Sens. Actuators B Chem. 2007, 125, 40–47. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, J. Internal quality detection of Chinese pecans (Carya cathayensis) during storage using electronic nose responses combined with physicochemical methods. Postharvest Biol. Technol. 2016, 118, 17–25. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, F.; Wang, L.; Niu, Y.; Xiao, Z. Evaluation of the synergism among volatile compounds in Oolong tea infusion by odour threshold with sensory analysis and E-nose. Food Chem. 2017, 221, 1484–1490. [Google Scholar] [CrossRef]

- Peris, M.; Escuder-Gilabert, L. Electronic noses and tongues to assess food authenticity and adulteration. Trends Food Sci. Technol. 2016, 58, 40–54. [Google Scholar] [CrossRef] [Green Version]

- Wu, H.; Yue, T.; Xu, Z.; Zhang, C. Sensor array optimization and discrimination of apple juices according to variety by an electronic nose. Anal. Methods 2017, 9, 921–928. [Google Scholar] [CrossRef]

- Xing, M.; Sun, K.; Liu, Q.; Pan, L.; Tu, K. Development of Novel Electronic Nose Applied for Strawberry Freshness Detection during Storage. Int. J. Food Eng. 2018, 14, 20180111. [Google Scholar] [CrossRef]

- Wang, Q.; Li, L.; Ding, W.; Zhang, D.; Wang, J.; Reed, K.; Zhang, B. Adulterant identification in mutton by electronic nose and gas chromatography-mass spectrometer. Food Control 2019, 98, 431–438. [Google Scholar] [CrossRef]

- Xin, R.; Liu, X.; Wei, C.; Yang, C.; Liu, H.; Cao, X.; Wu, D.; Zhang, B.; Chen, K. E-Nose and GC-MS Reveal a Difference in the Volatile Profiles of White- and Red-Fleshed Peach Fruit. Sensors 2018, 18, 765. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, S.; Lü, E.; Lu, H.; Zhou, Z.; Wang, Y.; Yang, J.; Wang, Y. Quality Detection of Litchi Stored in Different Environments Using an Electronic Nose. Sensors 2016, 16, 852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oshita, S.; Shima, K.; Haruta, T.; Seo, Y.; Kawagoe, Y.; Nakayama, S.; Takahara, H. Discrimination of odors emanating from ‘La France’ pear by semi-conducting polymer sensors. Comput. Electron. Agric. 2000, 26, 209–216. [Google Scholar] [CrossRef]

- Qiu, S.; Wang, J.; Du, D. Assessment of high pressure processed mandarin juice in the headspace by using electronic nose and chemometric analysis. Innov. Food Sci. Emerg. 2017, 42, 33–41. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, M.; Guo, Z. Discrimination of fresh-cut broccoli freshness by volatiles using electronic nose and gas chromatography-mass spectrometry. Postharvest Biol. Technol. 2019, 148, 168–175. [Google Scholar] [CrossRef]

- Wen, T.; Zheng, L.; Dong, S.; Gong, Z.; Sang, M.; Long, X.; Luo, M.; Peng, H. Rapid detection and classification of citrus fruits infestation by Bactrocera dorsalis (Hendel) based on electronic nose. Postharvest Biol. Technol. 2019, 147, 156–165. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, K.; Zhao, N.; Yang, J.; Zhang, Y.; Ma, C.; Pan, L.; Tu, K. Information fusion of hyperspectral imaging and electronic nose for evaluation of fungal contamination in strawberries during decay. Postharvest Biol. Technol. 2019, 153, 152–160. [Google Scholar] [CrossRef]

- Pathange, L.P.; Mallikarjunan, P.; Marini, R.P.; O’Keefe, S.; Vaughan, D. Non-destructive evaluation of apple maturity using an electronic nose system. J. Food Eng. 2006, 77, 1018–1023. [Google Scholar] [CrossRef] [Green Version]

- Brezmes, J.; Llobet, E.; Vilanova, X.; Orts, J.; Saiz, G.; Correig, X. Correlation between electronic nose signals and fruit quality indicators on shelf-life measurements with pinklady apples. Sens. Actuators B Chem. 2001, 80, 41–50. [Google Scholar] [CrossRef]

- Ali, S.; Khan, A.S.; Malik, A.U.; Shahid, M. Effect of controlled atmosphere storage on pericarp browning, bioactive compounds and antioxidant enzymes of litchi fruits. Food Chem. 2016, 206, 18–29. [Google Scholar] [CrossRef]

- Yan, J.; Guo, X.; Duan, S.; Jia, P.; Wang, L.; Peng, C.; Zhang, S. Electronic Nose Feature Extraction Methods: A Review. Sensors 2015, 15, 27804–27831. [Google Scholar] [CrossRef] [PubMed]

- Esteki, M.; Farajmand, B.; Kolahderazi, Y.; Simal-Gandara, J. Chromatographic Fingerprinting with Multivariate Data Analysis for Detection and Quantification of Apricot Kernel in Almond Powder. Food Anal. Method. 2017, 10, 3312–3320. [Google Scholar] [CrossRef]

- Hartyáni, P.; Dalmadi, I.; Knorr, D. Electronic nose investigation of Alicyclobacillus acidoterrestris inoculated apple and orange juice treated by high hydrostatic pressure. Food Control 2013, 32, 262–269. [Google Scholar] [CrossRef]

- Pardo, M.; Sberveglieri, G. Classification of electronic nose data with support vector machines. Sens. Actuators B Chem. 2005, 107, 730–737. [Google Scholar] [CrossRef]

- Voss, H.G.J.; Stevan, S.L.; Ayub, R.A. Peach growth cycle monitoring using an electronic nose. Comput. Electron. Agric. 2019, 163, 104858. [Google Scholar] [CrossRef]

- Tripoliti, E.E.; Fotiadis, D.I.; Manis, G. Modifications of the construction and voting mechanisms of the Random Forests Algorithm. Data Knowl. Eng. 2013, 87, 41–65. [Google Scholar] [CrossRef]

- Brezmes, J.; Llobet, E.; Vilanova, X.; Saiz, G.; Correig, X. Fruit ripeness monitoring using an Electronic Nose. Sens. Actuators B Chem. 2000, 69, 223–229. [Google Scholar] [CrossRef]

- Chen, L.; Wu, C.; Chou, T.; Chiu, S.; Tang, K. Development of a Dual MOS Electronic Nose/Camera System for Improving Fruit Ripeness Classification. Sensors 2018, 18, 3256. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Zhou, Y. Electronic-nose technique: Potential for monitoring maturity and shelf life of tomatoes. N. Z. J. Agric. Res. 2007, 50, 1219–1228. [Google Scholar] [CrossRef]

- Gómez, A.H.; Hu, G.; Wang, J.; Pereira, A.G. Evaluation of tomato maturity by electronic nose. Comput. Electron. Agric. 2006, 54, 44–52. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohammad-Razdari, A.; Yoosefian, S.H.; Izadi, Z.; Rabiei, G. Selection of an optimized metal oxide semiconductor sensor (MOS) array for freshness characterization of strawberry in polymer packages using response surface method (RSM). Postharvest Biol. Technol. 2019, 151, 53–60. [Google Scholar] [CrossRef]

| Number | Sensors | Main Applications | Manufacturer and Country |

|---|---|---|---|

| S1 | TGS2612 | Hydrocarbons, Methane, Liquefied Petroleum Gas | Figaro, Osaka, Japan |

| S2 | GSBT11 | Volatile Organic Compounds (VOC), e.g., Acetone | Ogam, Jeollanam-do, Korea |

| S3 | WSP2110 | Benzene, Toluene, Formaldehyde | Winsen, Zhengzhou, China |

| S4 | MP135 | Ethanol, Cigarette Smoke, Air Pollutants | Winsen, Zhengzhou, China |

| S5 | MS1100 | VOC, Toluene, Benzene, Formaldehyde, | Ogam, Jeollanam-do, Korea |

| S6 | MP901 | Alcohol, Cigarette smoke, Formaldehyde, Toluene, Benzene, Acetone | Winsen, Zhengzhou, China |

| S7 | TGS2611 | Natural Gas, Methane | Figaro, Osaka, Japan |

| S8 | TGS2620 | VOC, Alcohols, Organic Solvents Steam | Figaro, Osaka, Japan |

| S9 | TGS2602 | Ammonia, Hydrogen Sulfide (high sensitivity to VOC and odorous gases) | Figaro, Osaka, Japan |

| S10 | TGS2610 | Alcohols, Butane, Liquid Petroleum Gas, Propane | Figaro, Osaka, Japan |

| S11 | TGS2600 | Ethanol, Hydrogen, Hydrocarbons, etc. | Figaro, Osaka, Japan |

| S12 | TGS2603 | Trimethyl Amine, Methyl Mercaptan, Hydrogen Sulfide, etc. | Figaro, Osaka, Japan |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, J.; Su, G.; Liu, C.; Zou, Y.; Chang, Z.; Yu, H.; Wang, L.; Guo, R. Study on the Application of Electronic Nose Technology in the Detection for the Artificial Ripening of Crab Apples. Horticulturae 2022, 8, 386. https://doi.org/10.3390/horticulturae8050386

Qiao J, Su G, Liu C, Zou Y, Chang Z, Yu H, Wang L, Guo R. Study on the Application of Electronic Nose Technology in the Detection for the Artificial Ripening of Crab Apples. Horticulturae. 2022; 8(5):386. https://doi.org/10.3390/horticulturae8050386

Chicago/Turabian StyleQiao, Jianlei, Guoqiang Su, Chang Liu, Yuanjun Zou, Zhiyong Chang, Hailing Yu, Lianjun Wang, and Ruixue Guo. 2022. "Study on the Application of Electronic Nose Technology in the Detection for the Artificial Ripening of Crab Apples" Horticulturae 8, no. 5: 386. https://doi.org/10.3390/horticulturae8050386

APA StyleQiao, J., Su, G., Liu, C., Zou, Y., Chang, Z., Yu, H., Wang, L., & Guo, R. (2022). Study on the Application of Electronic Nose Technology in the Detection for the Artificial Ripening of Crab Apples. Horticulturae, 8(5), 386. https://doi.org/10.3390/horticulturae8050386