Preharvest Foliar Application of Si–Ca-Based Biostimulant Affects Postharvest Quality and Shelf-Life of Clementine Mandarin (Citrus clementina Hort. Ex Tan)

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material and Treatments

2.2. Fruit Characteristics (Weight, Juice Content, Peel Thickness and Peel Colour)

2.3. Fruit Firmness

2.4. Juice Chemical Parameters (Juice pH, Total Soluble Solids, Total Acidity, Ascorbic Acid Content)

2.5. Total Phenolic Content

2.6. Total Antioxidant Capacity (FRAP Assay)

2.7. Fruit Decay during Storage

2.8. Statistical Analysis

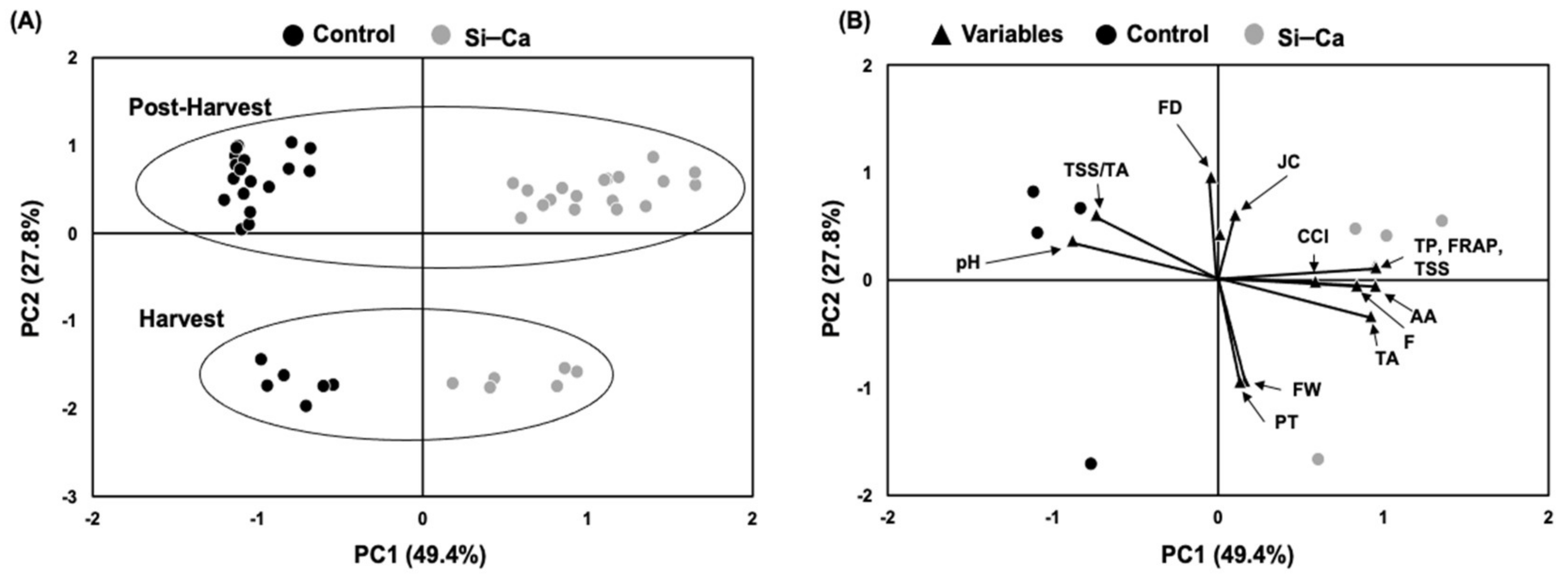

3. Results

3.1. Fruit Parameters and Fruit Decay

3.2. Juice Parameters (Total Soluble Solids Content, Total Acidity, TSS/TA Ratio and pH)

3.3. Juice Ascorbic Acid Content, Phenolics and Antioxidant Capacity

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Barzee, T.J.; Zhang, R.; Pan, Z. Citrus. In Integrated Processing Technologies for Food and Agricultural By-Products, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 217–242. ISBN 978-0-12-814138-0. [Google Scholar]

- FAO. Citrus Fruit Statistical Compendium 2020; FAO: Rome, Italy, 2021. [Google Scholar]

- Papoutsis, K.; Mathioudakis, M.M.; Hasperué, J.H.; Ziogas, V. Non-chemical treatments for preventing the postharvest fungal rotting of citrus caused by Penicillium digitatum (green mold) and Penicillium italicum (blue mold). Trends Food Sci. Technol. 2019, 86, 479–491. [Google Scholar] [CrossRef]

- Sheng, L.; Shen, D.; Luo, Y.; Sun, X.; Wang, J.; Luo, T.; Zeng, Y.; Xu, J.; Deng, X.; Cheng, Y. Exogenous γ-aminobutyric acid treatment affects citrate and amino acid accumulation to improve fruit quality and storage performance of postharvest citrus fruit. Food Chem. 2017, 216, 138–145. [Google Scholar] [CrossRef] [PubMed]

- Giuffrè, A.M. Bergamot (Citrus bergamia, Risso): The Effects of Cultivar and Harvest Date on Functional Properties of Juice and Cloudy Juice. Antioxidants 2019, 8, 221. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, P.; Singh, Z.; Tokala, V.Y.; Kyaw, P.N.; Walsh, B. Fruit canopy position and harvest date influence on color and quality of Imperial mandarin (Citrus reticulata Blanco). Aust. J. Crop Sci. 2020, 14, 660–666. [Google Scholar] [CrossRef]

- Aular, J.; Casares, M.; Natale, W. Factors affecting fruit quality: Emphasis on mineral nutrition. Cientifica 2017, 45, 64–72. [Google Scholar] [CrossRef]

- Tanou, G.; Ziogas, V.; Molassiotis, A. Foliar nutrition, biostimulants and prime-like dynamics in fruit tree physiology: New insights on an old topic. Front. Plant Sci. 2017, 8, 75. [Google Scholar] [CrossRef] [PubMed]

- Gomes, T.M.; Mazon, L.F.; Panceri, C.P.; Machado, B.D.; Brighenti, A.; Burin, V.M.; Bordignon-Luiz, M.T. Changes in vineyard productive attributes and phytochemical composition of sauvignon blanc grape and wine induced by the application of silicon and calcium. J. Sci. Food Agric. 2020, 100, 1547–1557. [Google Scholar] [CrossRef] [PubMed]

- Epstein, E. The anomaly of silicon in plant biology. Proc. Natl. Acad. Sci. USA 1994, 91, 11–17. [Google Scholar] [CrossRef] [PubMed]

- Savvas, D.; Ntatsi, G. Biostimulant activity of silicon in horticulture. Sci. Hortic. 2015, 196, 66–81. [Google Scholar] [CrossRef]

- Hernandez-Apaolaza, L. Can silicon partially alleviate micronutrient deficiency in plants? A review. Planta 2014, 240, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Mandlik, R.; Thakral, V.; Raturi, G.; Shinde, S.; Nikolić, M.; Tripathi, D.K.; Sonah, H.; Deshmukh, R. Significance of silicon uptake, transport, and deposition in plants. J. Exp. Bot. 2020, 71, 6703–6718. [Google Scholar] [CrossRef]

- Karagiannis, E.; Michailidis, M.; Skodra, C.; Molassiotis, A.; Tanou, G. Silicon influenced ripening metabolism and improved fruit quality traits in apples. Plant Physiol. Biochem. 2021, 166, 270–277. [Google Scholar] [CrossRef] [PubMed]

- Carrasco-Gil, S.; Rodríguez-Menéndez, S.M.; Fernández, B.; Pereiro, R.; de la Fuente, V.; Hernandez-Apaolaza, L. Silicon induced Fe deficiency affects Fe, Mn, Cu and Zn distribution in rice (Oryza sativa L.) growth in calcareous conditions. Plant Physiol. Biochem. 2018, 125, 153–163. [Google Scholar] [CrossRef] [PubMed]

- Mounika, M.; Kumar, T.S.; Kumar, A.K.; Joshi, V.; Sunil, N. Studies on the effect of foliar application of calcium, potassium and silicon on quality and shelf life of sweet orange (Citrus sinensis L.) cv. Sathgudi. J. Pharmacogn. Phytochem. 2021, 10, 1711–1713. [Google Scholar]

- Poovaiah, B. Role of calcium in prolonging storage life of fruits and vegetables. Food Technol. 1986, 40, 86–89. [Google Scholar]

- Madani, B.; Mohamed, M.T.M.; Watkins, C.B.; Kadir, J.; Awang, Y.; Shojaei, T.R. Preharvest calcium chloride sprays affect ripening of Eksotika II’papaya fruits during cold storage. Sci. Hortic. 2014, 171, 6–13. [Google Scholar] [CrossRef]

- Kinay, P.; Yildiz, F.; Sen, F.; Yildiz, M.; Karacali, I. Integration of pre- and postharvest treatments to minimize Penicillium decay of Satsuma mandarins. Postharvest Biol. Technol. 2005, 37, 31–36. [Google Scholar] [CrossRef]

- Martínez-Romero, D.; Valero, D.; Serrano, M.; Martínez-Sánchez, F.; Riquelme, F. Effects of post-harvest putrescine and calcium treatments on reducing mechanical damage and polyamines and abscisic acid levels during lemon storage. J. Sci. Food Agric. 1999, 79, 1589–1595. [Google Scholar] [CrossRef]

- Cid-López, M.L.; Soriano-Melgar, L.D.A.A.; García-González, A.; Cortéz-Mazatán, G.; Mendoza-Mendoza, E.; Rivera-Cabrera, F.; Peralta-Rodríguez, R.D. The benefits of adding calcium oxide nanoparticles to biocompatible polymeric coatings during cucumber fruits postharvest storage. Sci. Hortic. 2021, 287, 110285. [Google Scholar] [CrossRef]

- Alamri, S.; Hu, Y.; Mukherjee, S.; Aftab, T.; Fahad, S.; Raza, A.; Ahmad, M.; Siddiqui, M.H. Silicon-induced postponement of leaf senescence is accompanied by modulation of antioxidative defense and ion homeostasis in mustard (Brassica juncea) seedlings exposed to salinity and drought stress. Plant Physiol. Biochem. 2020, 157, 47–59. [Google Scholar] [CrossRef] [PubMed]

- Bhat, J.A.; Shivaraj, S.M.; Singh, P.; Navadagi, D.B.; Tripathi, D.K.; Dash, P.K.; Solanke, A.U.; Sonah, H.; Deshmukh, R. Role of Silicon in Mitigation of Heavy Metal Stresses in Crop Plants. Plants 2019, 8, 71. [Google Scholar] [CrossRef] [PubMed]

- Zargar, S.M.; Mahajan, R.; Bhat, J.A.; Nazir, M.; Deshmukh, R. Role of silicon in plant stress tolerance: Opportunities to achieve a sustainable cropping system. 3 Biotech 2019, 9, 73. [Google Scholar] [CrossRef]

- Wutscher, H.K. Growth and mineral nutrition of young orange trees grown with high levels of silicon. Hortscience 1989, 24, 275–277. [Google Scholar] [CrossRef]

- Matichenkov, V.; Calvert, D. Silicon fertilizers for citrus in Florida. Proc. Fla. State Hort. Soc. 1999, 112, 5–8. [Google Scholar]

- Singh, K.K.; Reddy, B.S. Post-harvest physico-mechanical properties of orange peel and fruit. J. Food Eng. 2006, 73, 112–120. [Google Scholar] [CrossRef]

- Sogvar, O.B.; Koushesh Saba, M.; Emamifar, A. Aloe vera and ascorbic acid coatings maintain postharvest quality and reduce microbial load of strawberry fruit. Postharvest Biol. Technol. 2016, 114, 29–35. [Google Scholar] [CrossRef]

- Hortwitz, W. Official Methods of AOAC International, 17th ed.; Association of Official Analytic Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar] [CrossRef]

- Benzie, I.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Moscoso-Ramírez, P.A.; Palou, L. Preventive and curative activity of postharvest potassium silicate treatments to control green and blue molds on orange fruit. Eur. J. Plant Pathol. 2014, 138, 721–732. [Google Scholar] [CrossRef]

- Ihaka, R.; Gentleman, R.R. A language for data analysis and graphics. J. Comput. Graph. Stat. 1996, 5, 299–314. [Google Scholar]

- Tesfay, S.Z.; Bertling, I.; Bower, J.P. Effects of postharvest potassium silicate application on phenolics and other anti-oxidant systems aligned to avocado fruit quality. Postharvest Biol. Technol. 2011, 60, 92–99. [Google Scholar] [CrossRef]

- Omar, A.E.-D.K.; El-Enin, M.S.A. Foliar spray with different agrochemicals on fruit quality and exportability of ‘Washington’ navel orange fruit (Citrus sinensis L.). Int. J. Fruit Sci. 2017, 17, 280–295. [Google Scholar] [CrossRef]

- Peris-Felipo, F.J.; Benavent-Gil, Y.; Hernández-Apaolaza, L. Silicon beneficial effects on yield, fruit quality and shelf-life of strawberries grown in different culture substrates under different iron status. Plant Physiol. Biochem. 2020, 152, 23–31. [Google Scholar] [CrossRef]

- Mditshwa, A.; Bower, J.P.; Bertling, I.; Mathaba, N.; Tesfay, S.Z. The potential of postharvest silicon dips to regulate phenolics in citrus peel as a method to mitigate chilling injury in lemons. Afr. J. Biotechnol. 2013, 12, 1482–1489. [Google Scholar]

- Won, M.Y.; Lee, S.J.; Min, S.C. Mandarin preservation by microwave-powered cold plasma treatment. Innov. Food Sci. Emerg. Technol. 2017, 39, 25–32. [Google Scholar] [CrossRef]

- Bang, I.H.; Kim, Y.E.; Min, S.C. Preservation of mandarins using a microbial decontamination system integrating calcium oxide solution washing, modified atmosphere packaging, and dielectric barrier discharge cold plasma treatment. Food Packag. Shelf Life 2021, 29, 100682. [Google Scholar] [CrossRef]

- D’Aquino, S.; Palma, A.; Chessa, I.; Satta, D.; De Pau, L.; Inglese, P.; Ochoa, J.M.; Glenn, D.M. Effect of Surround WP (a Kaolin-based particle film) on Ceratitis capitata infestation, quality and postharvest behaviour of cactus pear fruit cv Gialla. Sci. Hortic. 2021, 289, 110484. [Google Scholar] [CrossRef]

- Jayawardana, H.A.R.K.; Weerahewa, H.L.D.; Saparamadu, M.D.J.S. Effect of root or foliar application of soluble silicon on plant growth, fruit quality and anthracnose development of capsicum. Trop. Agric. Res. 2015, 26, 74. [Google Scholar] [CrossRef]

- González-Terán, G.E.; Gómez-Merino, F.C.; Trejo-Téllez, L.I. Effects of silicon and calcium application on growth, yield and fruit quality parameters of cucumber established in a sodic soil. Acta Sci. Pol. Hortorum Cultus 2020, 19, 149–158. [Google Scholar] [CrossRef]

- Weerahewa, D.; David, D. Effect of silicon and potassium on tomato anthracnose and on the postharvest quality of tomato fruit (Lycopersicon esculentum Mill.). J. Natl. Sci. Found. Sri Lanka 2015, 43, 273–280. [Google Scholar] [CrossRef]

- Lokesh, Y.; Varu, D.K. Effect of pre harvest spray and post harvest dipping of fruit on shelf life and quality of papaya. Asian J. Hortic. 2013, 8, 581–587. [Google Scholar]

- Jing, S.U.; Lan-chun, N.I.; Ying-bin, Q.; Miao-miao, W. Effect of foliar application of silicon and calcium on the firmness and related physiological metabolism of tomato fruits. Acta Hortic. Sin. 2016, 43, 789. [Google Scholar]

- Głazowska, S.; Baldwin, L.; Mravec, J.; Bukh, C.; Hansen, T.H.; Jensen, M.M.; Fangel, J.U.; Willats, W.G.; Glasius, M.; Felby, C. The impact of silicon on cell wall composition and enzymatic saccharification of Brachypodium distachyon. Biotechnol. Biofuels 2018, 11, 171. [Google Scholar] [CrossRef]

- García-Luis, A.; Duarte, A.; Kanduser, M.; Guardiola, J.L. The anatomy of the fruit in relation to the propensity of citrus species to split. Sci. Hortic. 2001, 87, 33–52. [Google Scholar] [CrossRef]

- Mohamed, H.M.; Omran, M.A.A.; Mohamed, S.M. Effect of foliar spraying of some materials on protecting Murcott mandarin fruits from sunburn injuries. Mid. East J. Agric. Res. 2019, 8, 514–524. [Google Scholar]

- Hoda, M.M.; Faten, A.A.-K.; Azza, A.M.A.-E. Effect of Magnetite and Some Biofertilizer Application on Growth and Yield of Valencia Orange Trees under El-Bustan Condition. Nat. Sci. 2013, 11, 46–61. [Google Scholar]

- Treeby, M.T.; Storey, R. Calcium-spray treatments for ameliorating albedo breakdown in navel oranges. Aust. J. Exp. Agric. 2002, 42, 495–502. [Google Scholar] [CrossRef]

- Liu, J.; Zong, Y.; Qin, G.; Li, B.; Tian, S. Plasma membrane damage contributes to antifungal activity of silicon against Penicillium digitatum. Curr. Microbiol. 2010, 61, 274–279. [Google Scholar] [CrossRef]

- Weerahewa, D.; Somapala, K. Role of silicon on enhancing resistance in tropical fruits and vegetables: A review. OUSL J. 2016, 11, 135–162. [Google Scholar] [CrossRef]

- Mvondo-She, M.A.; Gatabazi, A.; Laing, M.D.; Ndhlala, A.R. A review on the role of silicon treatment in biotic stress mitigation and citrus production. Agronomy 2021, 11, 2198. [Google Scholar] [CrossRef]

- Shen, G.H.; Xue, Q.H.; Tang, M.; Chen, Q.; Wang, L.N.; Duan, C.M.; Xue, L.; Zhao, J. Inhibitory effects of potassium silicate on five soil-borne phytopathogenic fungi in vitro. J. Plant Dis. Prot. 2010, 117, 180–184. [Google Scholar] [CrossRef]

- Hussain, S.B.; Shi, C.-Y.; Guo, L.-X.; Kamran, H.M.; Sadka, A.; Liu, Y.-Z. Recent advances in the regulation of citric acid metabolism in citrus fruit. Crit. Rev. Plant Sci. 2017, 36, 241–256. [Google Scholar] [CrossRef]

- Angioni, A.; Schirra, M. Long-term frozen storage impact on the antioxidant capacity and chemical composition of Sardinianmyrtle (Myrtus communis L.) berries. J. Agric. Sci. Technol. B 2011, 1, 1168–1175. [Google Scholar]

- Sharma, R.R.; Datta, S.C.; Varghese, E. Effect of Surround WP®, a kaolin-based particle film on sunburn, fruit cracking and postharvest quality of ‘Kandhari’ pomegranates. Crop Prot. 2018, 114, 18–22. [Google Scholar] [CrossRef]

- Giuffrè, A.M.; Zappia, C.; Capocasale, M. Physicochemical stability of blood orange juice during frozen storage. Int. J. Food Prop. 2017, 20, 1930–1943. [Google Scholar] [CrossRef]

- Cheong, M.W.; Liu, S.Q.; Zhou, W.; Curran, P.; Yu, B. Chemical composition and sensory profile of pomelo (Citrus grandis (L.) Osbeck) juice. Food Chem. 2012, 135, 2505–2513. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Hernández, M.G.; Núñez-Gómez, D.; Forner-Giner, M.; Hernández, F.; Pastor-Pérez, J.J.; Legua, P. Quality parameters of Spanish lemons with commercial interest. Foods 2021, 10, 62. [Google Scholar] [CrossRef]

- Poodeh, S.D.; Ghobadi, C.; Baninasab, B.; Gheysari, M.; Bidabadi, S.S. Effects of potassium silicate and nanosilica on quantitative and qualitative characteristics of a commercial strawberry (Fragaria × ananassa cv. ‘camarosa’). J. Plant Nutr. 2016, 39, 502–507. [Google Scholar] [CrossRef]

- Ayón-Reyna, L.E.; Tamayo-Limón, R.; Cárdenas-Torres, F.I.; López-López, M.E.; López-Angulo, G.; López-Moreno, H.S.; López-Cervantes, J.; López-Valenzuela, J.A.; Vega-García, M.O. Effectiveness of hydrothermal-calcium chloride treatment and chitosan on quality retention and microbial growth during storage of fresh-cut papaya. J. Food Sci. 2015, 80, C594–C601. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, H.I.M.; Al-Wasfy, M.M. The promotive impact of using silicon and selenium with potassium and boron on fruiting of Valencia orange tree grown under Minia region conditions. World Rural Obsrv. 2014, 6, 28–36. [Google Scholar]

- Farhangi-Abriz, S.; Torabian, S. Nano-silicon alters antioxidant activities of soybean seedlings under salt toxicity. Protoplasma 2018, 255, 953–962. [Google Scholar] [CrossRef] [PubMed]

- Fenech, M.; Amaya, I.; Valpuesta, V.; Botella, M.A. Vitamin C content in fruits: Biosynthesis and regulation. Front. Plant Sci. 2019, 9, 2006. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Sun, W.; Zhu, Y.G.; Christie, P. Mechanisms of silicon-mediated alleviation of abiotic stresses in higher plants: A review. Environ. Pollut. 2007, 147, 422–428. [Google Scholar] [CrossRef] [PubMed]

- Shahkoomahally, S.; Ramezanian, A. Hot water combined with calcium treatment improves physical and physicochemical attributes of kiwifruit (Actinidia deliciosa cv. Hayward) during storage. HortScience 2015, 50, 412–415. [Google Scholar] [CrossRef]

- Supapvanich, S.; Arkajak, R.; Yalai, K. Maintenance of postharvest quality and bioactive compounds of fresh-cut sweet leaf bush (Sauropus androgynus L. Merr.) through hot CaCl2 dips. Int. J. Food Sci. 2012, 47, 2662–2670. [Google Scholar] [CrossRef]

- Glenn, D.M.; Puterka, G.J.; Vanderzwet, T.; Byers, R.E.; Feldhake, C. Hydrophobic particle films: A new paradigm for suppression of arthropod pests and plant diseases. J. Econ. Entomol. 1999, 92, 759–771. [Google Scholar] [CrossRef]

- Rosati, A.; Metcalf, S.G.; Buchner, R.P.; Fulton, A.E.; Lampinen, B.D. Effects of kaolin application on light absorption and distribution, radiation use efficiency and photosynthesis of almond and walnut canopies. Ann. Bot. 2007, 99, 255–263. [Google Scholar] [CrossRef] [PubMed]

| Postharvest Time Point | 2019 | 2020 | Mean | ||||

|---|---|---|---|---|---|---|---|

| Control | Si–Ca | Control | Si–Ca | Control | Si–Ca | ||

| Fruit weight (g) | Harvest day | 95.13 ± 12.93 b | 90.46 ± 17.45 b | 75.67± 2.96 b | 77.45 ± 2.00 b | 85.4 ± 5.08 c | 83.95 ±7.77 c |

| 30 d at 5 °C | 53.10 ± 2.53 a | 61.41 ± 5.43 a | 67.48 ± 1.7 a | 67.56 ± 1.05 a | 60.29 ± 0.71 ab | 64.49 ± 2.66 b | |

| 30 d at 5 °C plus 3 d at 20 °C | 50.01 ± 2.76 a | 60.91 ± 0.31 a | 66.32 ± 1.77 a | 67.43 ± 1.36 a | 58.17 ± 0.66 ab | 64.17 ± 0.71 b | |

| 30 d at 5 °C plus 6 d at 20 °C | 48.52 ± 3.05 a | 61.27 ± 0.22 a | 65.17 ± 1.89 a | 63.71 ± 1.61 a | 56.84 ± 0.81 a | 62.49 ± 0.77 ab | |

| CCI | Harvest day | 11.32 ± 1.40 a | 10.76 ±0.86 a | 12.39 ±0.92 a | 14.04 ± 0.28 b | 11.85 ± 0.26 a | 12.40 ± 0.57 a |

| 30 d at 5 °C | 10.56 ± 1.33 a | 12.07 ± 1.56 a | 13.31 ± 0.62 ab | 12.33 ± 0.54 a | 11.93 ± 0.36 a | 12.20 ± 0.54 a | |

| 30 d at 5 °C plus 3 d at 20 °C | 11.24 ± 3.82 a | 15.53 ± 1.33 b | 13.11 ± 0.37 ab | 12.32 ± 0.57 a | 12.17 ± 1.74 a | 13.92 ± 0.88 b | |

| 30 d at 5 °C plus 6 d at 20 °C | 10.55 ± 1.42 a | 13.56 ± 0.45 ab | 12.74 ± 0.57 a | 12.34 ± 0.26 a | 11.64 ± 0.71 a | 12.96 ± 0.23 ab | |

| Skin Firmness (kg) | Harvest day | 2.78 ± 0.07 ab | 3.36 ± 0.34 de | 3.04 ± 0.12 bc | 3.30 ± 0.18 cd | 2.91 ± 0.09 ab | 3.33 ± 0.26 cd |

| 30 d at 5 °C | 2.81 ±0.12 abc | 3.09 ± 5.00 cde | 2.71 ± 0.14 a | 3.50 ± 0.10 c | 2.76 ± 0.1 a | 3.3 ± 0.05 cd | |

| 30 d at 5 °C plus 3 d at 20 °C | 2.74 ± 0.12 a | 3.20 ± 0.09 de | 2.83 ± 0.08 ab | 3.27 ± 0.14 cd | 2.78 ± 0.10 a | 3.24 ± 0.11 cd | |

| 30 d at 5 °C plus 6 d at 20 °C | 3.07 ± 3.38 bcd | 3.38 ± 0.18 e | 3.08 ± 0.08 bc | 3.44 ± 0.23 c | 3.07 ± 0.10 bc | 3.41 ± 0.20 d | |

| Rind Thickness (mm) | Harvest day | 3.00 ± 0.38 b | 3.52 ± 0.14 c | 3.40 ± 0.10 c | 3.61 ± 0.10 d | 3.20 ± 0.24 b | 3.57 ± 0.12 c |

| 30 d at 5 °C | 2.29 ± 0.12 a | 2.31 ± 0.15 a | 2.47 ± 0.13 ab | 2.56 ± 0.15 b | 2.38 ± 0.12 a | 2.44 ± 0.15 a | |

| 30 d at 5 °C plus 3 d at 20 °C | 2.10 ± 0.2 a | 2.24 ± 0.08 a | 2.32 ± 0.13 ab | 2.37 ± 0.07 ab | 2.21 ± 0.16 a | 2.31 ± 0.07 a | |

| 30 d at 5 °C plus 6 d at 20 °C | 2.13 ± 0.06 a | 2.41 ± 0.35 a | 2.26 ± 0.07 a | 2.54 ± 0.34 ab | 2.20 ± 0.06 a | 2.48 ± 0.35 a | |

| Juice Content (%) | Harvest day | 31.89 ± 1.64 a | 32.60 ± 2.95 a | 34.23 ± 2.00 a | 35.08 ± 2.40 a | 33.06 ± 1.81 a | 33.84 ± 2.61 a |

| 30 d at 5 °C | 37.01 ± 7.04 a | 35.64 ± 3.69 a | 40.76 ± 6.08 a | 37.88 ± 3.26 a | 38.88 ± 6.53 a | 36.76 ± 3.35 a | |

| 30 d at 5 °C plus 3 d at 20 °C | 34.36 ± 3.16 a | 33.03 ± 3.27 a | 35.49 ± 3.85 a | 35.98 ± 2.08 a | 34.92 ± 3.49 a | 34.51 ± 2.67 a | |

| 30 d at 5 °C plus 6 d at 20 °C | 36.00 ± 2.69 a | 37.40 ± 1.98 a | 37.50 ± 3.88 a | 39.46 ± 0.81 a | 36.75 ± 3.27 a | 38.43 ± 1.24 a | |

| Fruit Decay (%) | Harvest day | - | - | - | - | - | - |

| 30 d at 5 °C | 33.49 ± 1.41 a | 32.94 ± 2.68 a | 34.66 ± 2.69 a | 34.57 ± 2.26 a | 34.07 ± 1.89 a | 33.75 ± 2.47 a | |

| 30 d at 5 °C plus 3 d at 20 °C | 40.70 ± 1.46 b | 34.80 ± 1.90 a | 42.82 ± 1.62 cd | 37.70 ± 1.69 ab | 41.76 ± 1.54 cd | 36.25 ± 1.79 ab | |

| 30 d at 5 °C plus 6 d at 20 °C | 43.90 ± 1.71 c | 38.14 ± 0.65 b | 46.21 ± 2.97 d | 39.36 ± 0.93 bc | 45.05 ± 2.32 d | 38.75 ± 0.78 bc | |

| Postharvest Time Point | 2019 | 2020 | Mean | ||||

|---|---|---|---|---|---|---|---|

| Control | Si–Ca | Control | Si–Ca | Control | Si–Ca | ||

| Total Soluble Solids (°Brix) | Harvest day | 10.80 ± 0.56 a | 13.43 ± 0.81 b | 11.53 ± 0.21 a | 13.30 ± 0.17 bc | 11.17 ± 0.35 a | 13.37 ± 0.49 b |

| 30 d at 5 °C | 11.05 ± 2.15 a | 15.95 ± 0.94 c | 11.89 ± 1.14 ab | 15.12 ± 0.89 d | 11.47 ± 0.50 a | 15.53 ± 0.12 d | |

| 30 d at 5 °C plus 3 d at 20 °C | 10.54 ± 0.27 a | 16.13 ± 2.19 c | 11.86 ± 0.85 ab | 15.27 ± 1.21 d | 11.20 ± 0.53 a | 15.70 ± 0.52 d | |

| 30 d at 5 °C plus 6 d at 20 °C | 10.10 ± 0.56 a | 15.01 ± 1.82 b | 11.50 ± 0.56 a | 13.52 ± 0.81 c | 10.80 ± 0.44 a | 14.27 ± 0.55 c | |

| Acidity (% citric acid) | Harvest day | 0.62 ± 0.02 b | 0.93 ± 0.17 d | 0.53 ± 0.02 b | 0.69 ± 0.02 c | 0.58 ± 0 b | 0.81 ± 0.08 de |

| 30 d at 5 °C | 0.39 ± 0.01 a | 0.86 ± 0.12 cd | 0.54 ± 0.03 b | 0.83 ± 0.04 d | 0.47 ± 0.02 a | 0.84 ± 0.06 e | |

| 30 d at 5 °C plus 3 d at 20 °C | 0.40 ± 0.04 a | 0.78 ± 0.16 bcd | 0.46 ± 0.02 a | 0.71 ± 0.01 c | 0.43 ± 0.03 a | 0.75 ± 0.09 cd | |

| 30 d at 5 °C plus 6 d at 20 °C | 0.35 ± 0.02 a | 0.72 ± 0.14 bc | 0.45 ± 0.02 a | 0.68 ± 0.06 c | 0.40 ± 0 a | 0.70 ± 0.04 c | |

| TSS/Acidity | Harvest day | 17.45 ± 0.32 a | 14.71 ± 1.97 a | 21.65 ± 1.10 b | 19.20 ± 0.70 ab | 19.39 ± 0.61 ab | 16.56 ± 1.08 a |

| 30 d at 5 °C | 28.40 ± 6.02 cd | 18.75 ± 1.54 a | 21.98 ± 0.92 b | 18.18 ± 1.56 a | 24.71 ± 2.09 c | 18.44 ± 1.13 ab | |

| 30 d at 5 °C plus 3 d at 20 °C | 26.79 ± 3.30 bcd | 20.80 ± 1.92 ab | 26.02 ± 2.36 c | 21.53 ± 2.00 b | 26.33 ± 2.22 c | 21.15 ± 1.62 b | |

| 30 d at 5 °C plus 6 d at 20 °C | 29.23 ± 3.03 d | 21.75 ± 7.05 abc | 25.74 ± 0.40 c | 20.05 ± 2.82 ab | 27.22 ± 1.10 c | 20.47 ± 2.00 b | |

| Juice pH | Harvest day | 3.62 ± 0.05 cd | 3.30± 0.18 a | 3.72 ± 0.14 c | 3.23 ± 0.06 a | 3.67 ± 0.05 d | 3.27 ± 0.07 a |

| 30 d at 5 °C | 3.79 ± 0.12 d | 3.33 ± 0.05 ab | 3.75 ± 0.06 c | 3.44 ± 0.07 b | 3.77 ± 0.03 e | 3.39 ± 0.04 b | |

| 30 d at 5 °C plus 3 d at 20 °C | 4.02 ± 0.08 e | 3.53 ± 0.12 bc | 3.94 ± 0.06 d | 3.55 ± 0.12 b | 3.98 ± 0.02 f | 3.54 ± 0.08 c | |

| 30 d at 5 °C plus 6 d at 20 °C | 3.99 ± 0.07 e | 3.39 ± 0.14 ab | 3.97 ± 0.12 d | 3.41 ± 0.05 b | 3.98 ± 0.03 f | 3.40 ± 0.07 b | |

| Postharvest Time Point | 2019 | 2020 | Mean | ||||

|---|---|---|---|---|---|---|---|

| Control | Si–Ca | Control | Si–Ca | Control | Si–Ca | ||

| Ascorbic Acid (mg/100 mL) | Harvest day | 40.57 ± 9.45 a | 58.33 ± 6.56 b | 73.90 ± 4.51 b | 86.06 ± 3.40 c | 57.24 ± 4.91 b | 72.20 ± 3.90 c |

| 30 d at 5 °C | 36.58 ± 4.68 a | 85.71 ± 17.19 c | 74.15 ± 3.38 b | 102.11 ± 2.98 d | 55.36 ± 1.33 ab | 93.91 ± 8.56 d | |

| 30 d at 5 °C plus 3 d at 20 °C | 30.61 ± 7.21 a | 59.23 ± 4.71 b | 65.04 ± 2.98 a | 89.76 ± 7.04 c | 47.83 ± 3.01 a | 74.49 ± 5.52 c | |

| 30 d at 5 °C plus 6 d at 20 °C | 36.11 ± 5.21 a | 61.76 ± 3.41 b | 62.44 ± 1.95 a | 87.80 ± 5.16 c | 49.28 ± 1.81 ab | 74.78 ± 1.74 c | |

| Total Phenols (mg GAE/ mL) | Harvest day | 0.83 ± 0.03 abc | 0.96 ± 0.08 bcd | 0.48 ± 0.04 a | 0.63± 0.01 c | 0.65 ± 0.03 a | 0.80 ± 0.04 b |

| 30 d at 5 °C | 0.75 ± 0.09 a | 1.20 ± 0.11 e | 0.58 ± 0.02 b | 0.64 ± 0.01 c | 0.66 ± 0.04 a | 0.92± 0.05 d | |

| 30 d at 5 °C plus 3 d at 20 °C | 0.82 ± 0.08 abc | 1.10 ± 0.24 de | 0.58 ± 0.01 b | 0.73 ± 0.03 d | 0.70 ± 0.04 a | 0.92 ± 0.11 cd | |

| 30 d at 5 °C plus 6 d at 20 °C | 0.77 ± 0.05 ab | 1.02 ± 0.07 cde | 0.48 ± 0.04 a | 0.63 ± 0.01 c | 0.63 ± 0.01 a | 0.83 ± 0.04 bc | |

| FRAP (μmole Asc.Acid/mL) | Harvest day | 5.09 ± 0.70 ab | 5.94 ± 0.48 ab | 5.14 ± 0.08 a | 6.53 ± 0.50 b | 5.11 ± 0.31 a | 6.23 ± 0.37 bc |

| 30 d at 5 °C | 5.57 ± 0.60 ab | 7.73 ± 0.90 c | 5.22 ± 0.08 a | 7.32 ± 0.26 c | 5.40 ± 0.30 ab | 7.53 ± 0.43 d | |

| 30 d at 5 °C plus 3 d at 20 °C | 5.46 ± 0.75 ab | 6.35 ± 1.62 bc | 5.24 ± 0.10 a | 7.64 ± 0.49 c | 5.35 ± 0.42 ab | 6.99 ± 1.05 cd | |

| 30 d at 5 °C plus 6 d at 20 °C | 4.60 ± 0.59 a | 6.27 ± 0.64 bc | 5.10 ± 0.10 a | 6.57 ± 0.25 b | 4.85 ± 0.26 a | 6.42 ± 0.44 c | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ziogas, V.; Bravos, N.; Hussain, S.B. Preharvest Foliar Application of Si–Ca-Based Biostimulant Affects Postharvest Quality and Shelf-Life of Clementine Mandarin (Citrus clementina Hort. Ex Tan). Horticulturae 2022, 8, 996. https://doi.org/10.3390/horticulturae8110996

Ziogas V, Bravos N, Hussain SB. Preharvest Foliar Application of Si–Ca-Based Biostimulant Affects Postharvest Quality and Shelf-Life of Clementine Mandarin (Citrus clementina Hort. Ex Tan). Horticulturae. 2022; 8(11):996. https://doi.org/10.3390/horticulturae8110996

Chicago/Turabian StyleZiogas, Vasileios, Nikos Bravos, and Syed Bilal Hussain. 2022. "Preharvest Foliar Application of Si–Ca-Based Biostimulant Affects Postharvest Quality and Shelf-Life of Clementine Mandarin (Citrus clementina Hort. Ex Tan)" Horticulturae 8, no. 11: 996. https://doi.org/10.3390/horticulturae8110996

APA StyleZiogas, V., Bravos, N., & Hussain, S. B. (2022). Preharvest Foliar Application of Si–Ca-Based Biostimulant Affects Postharvest Quality and Shelf-Life of Clementine Mandarin (Citrus clementina Hort. Ex Tan). Horticulturae, 8(11), 996. https://doi.org/10.3390/horticulturae8110996