Growth and Quality of Strawberry (Fragaria ananassa Dutch. cvs. ‘Kuemsil’) Affected by Nutrient Solution Supplying Control System Using Drainage Rate in Hydroponic Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials and Cultivation Management

2.2. Irrigation Treatment

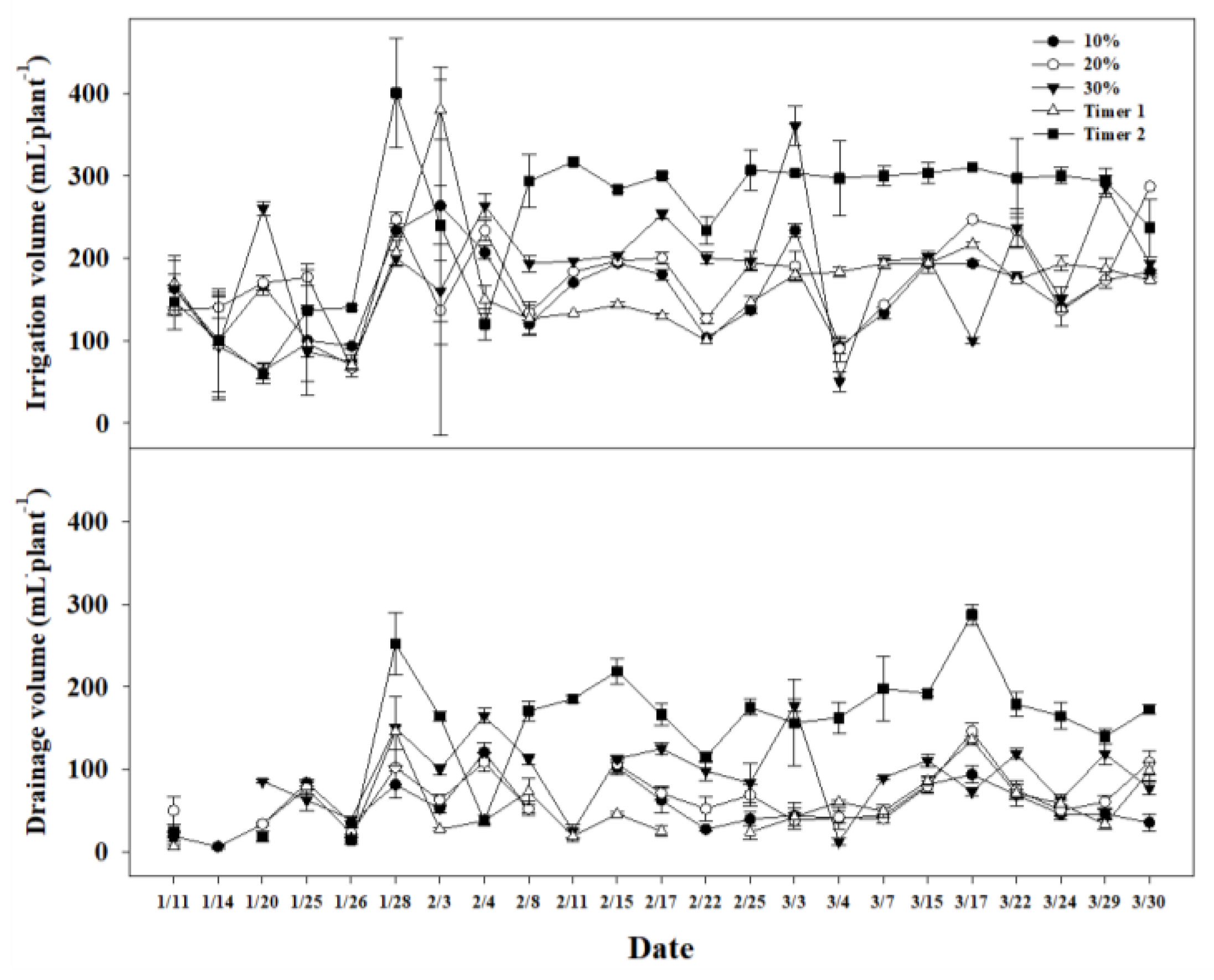

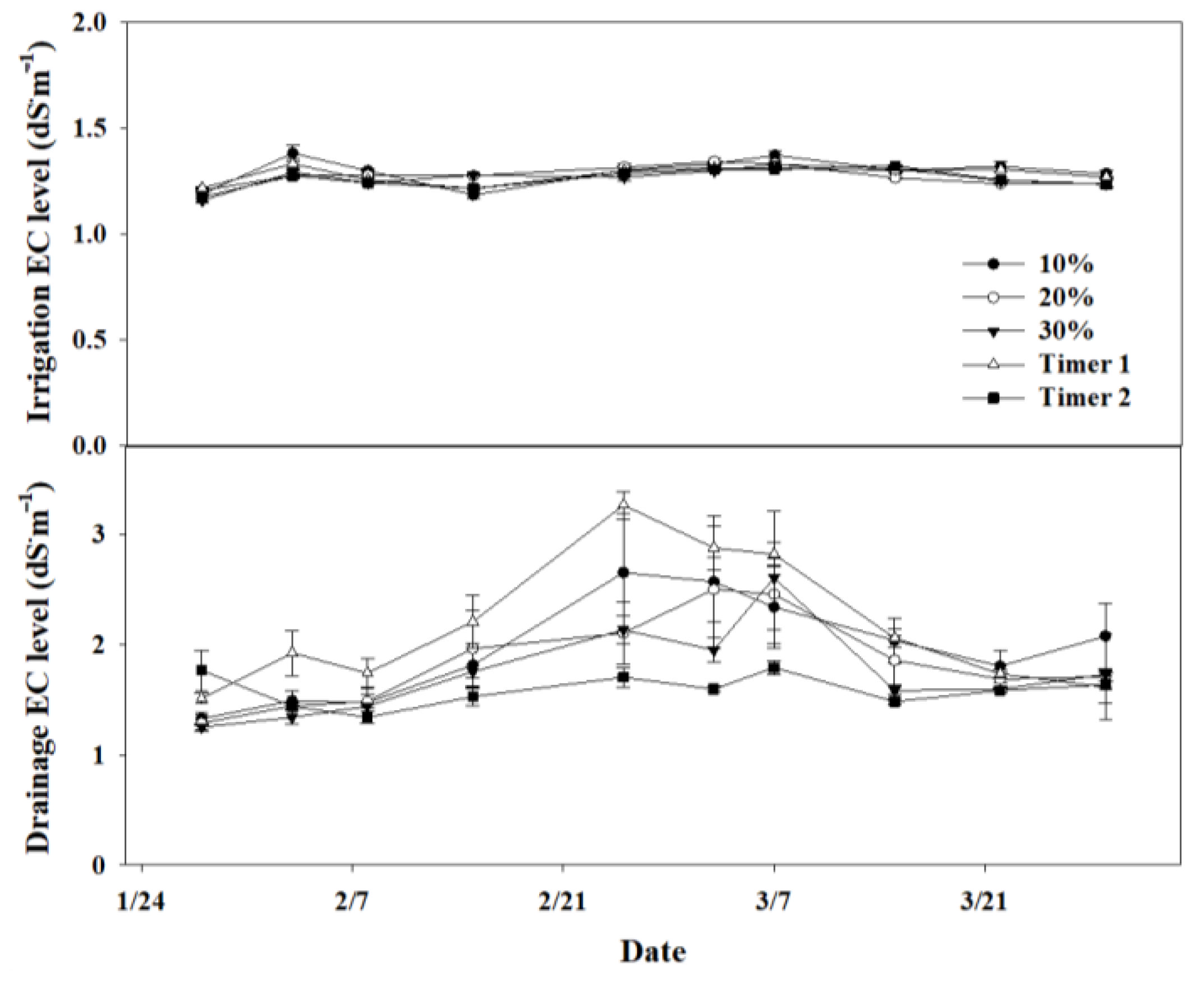

2.3. Supply and Drainage Characteristics

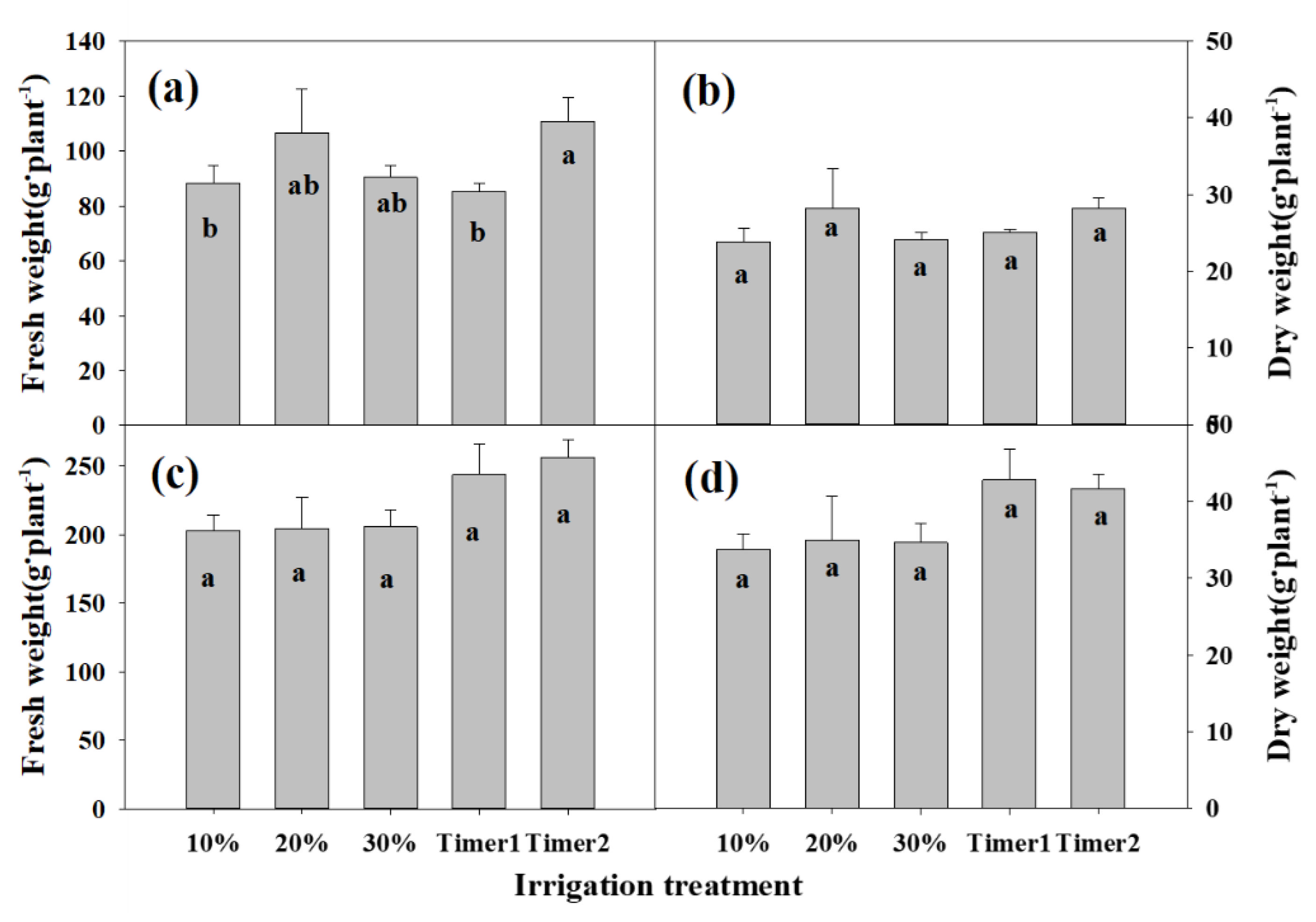

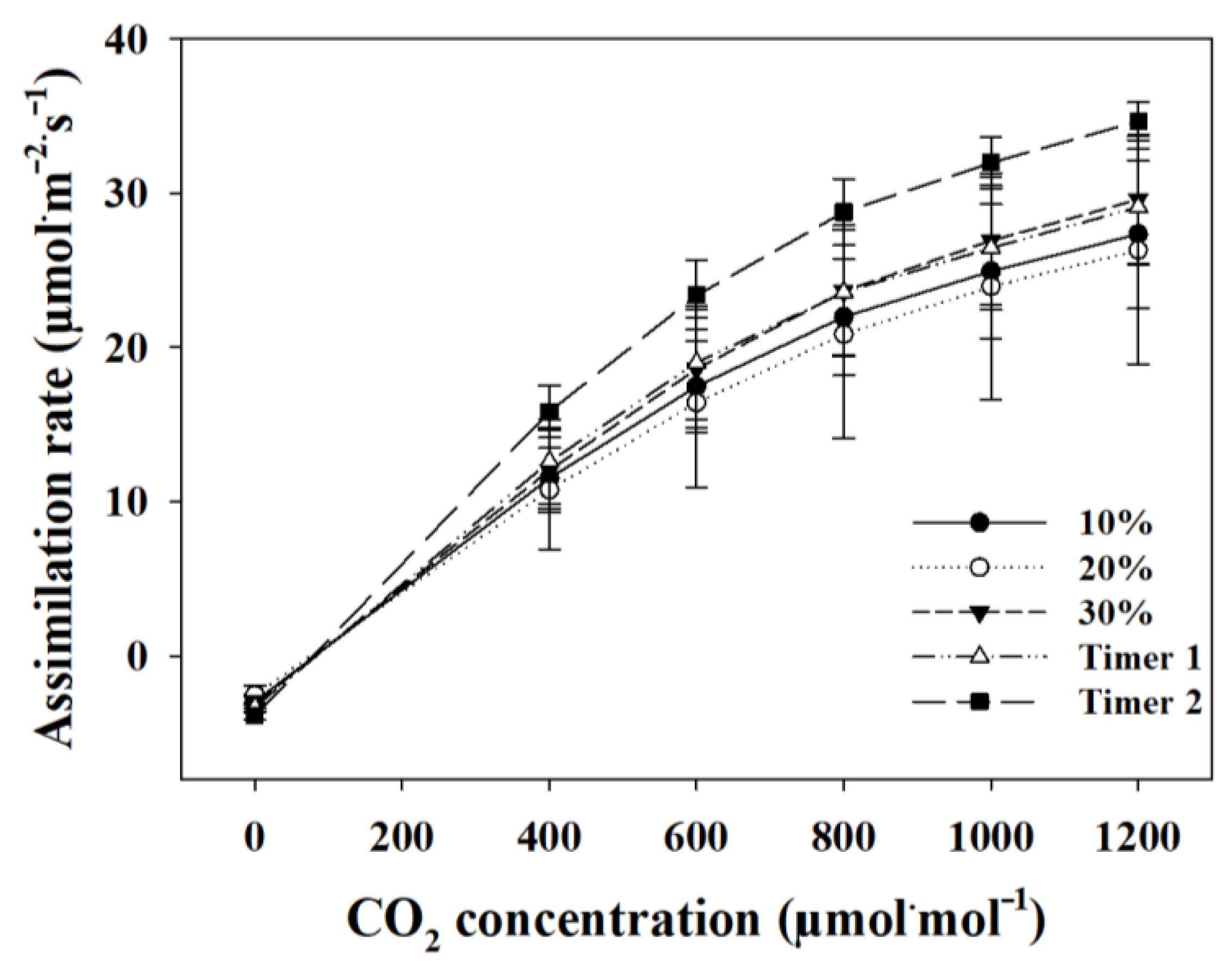

2.4. Growth, Fruit Quality, and Photosynthetic Characteristics

2.5. Yield Characteristics

2.6. Mineral Contents

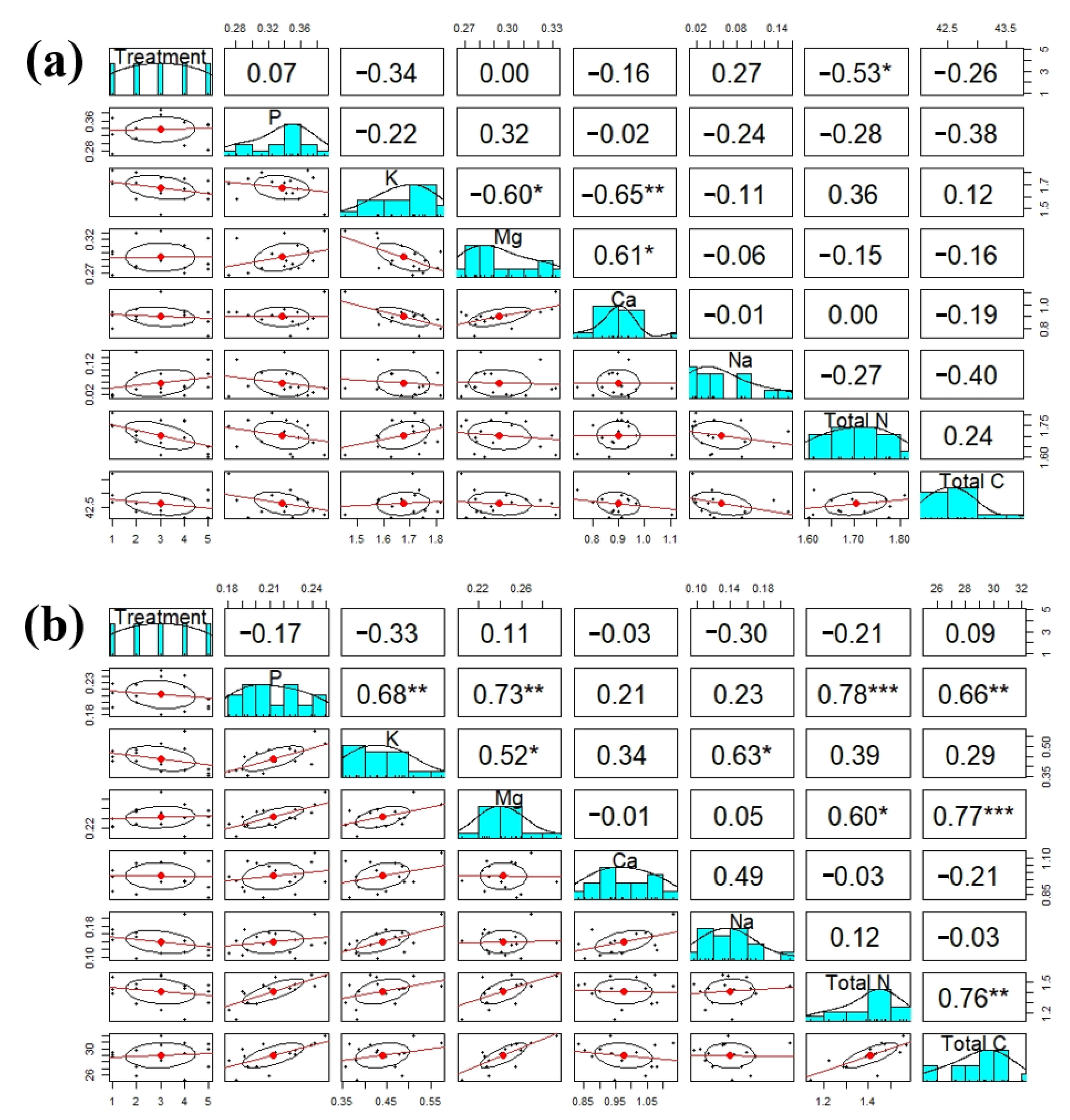

2.7. Statistical Analysis

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- MAFRA. Agricultural Production Index. 2021. Available online: https://mafra.go.kr/bbs/mafra/131/327493/artclView (accessed on 7 July 2021).

- KOSTAT. Agricultural Area Survey. 2021. Available online: https://kosis.kr/statHtml/statHtml.do?orgId=101&tblId=DT_1ET0017&conn_path=I2 (accessed on 28 June 2021).

- Ahn, T.I.; Shin, J.W.; Son, J.E. Analysis of Changes in Ion Concentration with Time and Drainage Ratio Under EC-Based Nutrient Control in Closed-Loop Soilless Culture for Sweet Pepper Plants (Capsicum annum L. ‘Boogie’). J. Bio Environ. Control 2010, 19, 298–304. [Google Scholar]

- Dorais, M.; Papadopoulos, A.; Gosselin, A. Greenhouse Tomato Fruit Quality. Hortic. Res. 2001, 26, 239–319. [Google Scholar]

- Choi, K.L. Characteristics of Water and Nutrient Uptake in Hydroponics and Management of Nutrient Solution in Tomato Cultivation Using Coir Substrate. Ph.D. Thesis, Gyeongsang National University, Jinju, Korea, 2017; pp. 37–39. [Google Scholar]

- RDA. Smart Greenhouse Guideline; RDA: Jeonju, Korea, 2018; pp. 68–73. [Google Scholar]

- Choi, S.H.; Kim, S.H.; Choi, G.L.; Jeong, H.J.; Lim, M.Y.; Kim, D.Y.; Lee, S.Y. Growth and Quality of the Strawberry (Fragaria ananassa Dutch. cvs. ‘Sulhyang’) as affected by Complex Nutrient Solution Supplying Control System using Integrated Solar Irradiance and Substrate Moisture Contents in Hydroponics. J. Bio Environ. Control 2021, 30, 367–376. [Google Scholar] [CrossRef]

- Lim, M.Y.; Choi, S.H.; Choi, G.L.; Kim, S.H.; Jeong, H.J. Effects of Irrigation Amount on Fruiting Period and EC Level by Growth Period on Growth and Quality of Melon (Cucumis melo L.) Using Coir Substrate Hydroponics During Autumn Cultivation. Hortic. Sci. Technol. 2021, 39, 446–455. [Google Scholar] [CrossRef]

- Choi, S.H.; Lim, M.Y.; Choi, G.L.; Kim, S.H.; Jeong, H.J. Growth and Quality of Two Melon Cultivars in Hydroponics Affected by Mixing Ratio of Coir Substrate and Different Irrigation Amount on Spring Season. Protected Hort. Plant Fac. 2019, 28, 376–387. [Google Scholar] [CrossRef]

- Choi, K.Y.; Choi, E.Y.; Kim, I.S.; Lee, Y.B. Improving Water and Fertilizer Use Efficiency during the Production of Strawberry in Coir Substrate Hydroponics Using A FDR Sensor-Automated Irrigation System. Hortic. Environ. Biotechnol. 2016, 57, 431–439. [Google Scholar] [CrossRef]

- Bunt, A.C. Physical Properties of Mixtures of Peats and Minerals of Different Particle Size and Bulk Density for Potting Substrates. Acta Hortic. 1984, 150, 143–154. [Google Scholar] [CrossRef]

- Park, B.L.; Cho, H.M.; Kim, M.S. Environmental Impact of Hydroponic Nutrient Wastewater, Used Hydroponic Growing Media, and Crop Wastes from Acyclic Hydroponic Farming System. J. Korea Org. Resour. Recycl. Assoc. 2021, 29, 19–27. [Google Scholar]

- Massa, D.; Germano, R.; Carmassi, G.; Incrocci, L.; Montesano, F.; Parente, A.; Burchi, G.; Pardossi, A. Increased Phosphorus Use Efficiency in Basil Grown Hydroponically with Low Phosphorus Concentration and Saline Water. Acta Hortic. 2019, 1242, 327–334. [Google Scholar] [CrossRef]

- Massa, D.; Incrocci, L.; Maggini, R.; Carmassi, G.; Campiotti, C.A.; Pardossi, A. Strategies to Decrease Water Drainage and Nitrate Emission from Soilless Cultures of Greenhouse Tomato. Agric. Water Manag. 2010, 97, 971–980. [Google Scholar] [CrossRef]

- Massa, D.; Magán, J.J.; Montesano, F.F.; Tzortzakis, N. Minimizing Water and Nutrient Losses from Soilless Cropping in Southern Europe. Agric. Water Manag. 2020, 241, 1–14. [Google Scholar] [CrossRef]

- Hwang, Y.H.; An, C.G.; Chang, Y.H.; Yoon, H.S.; An, J.U.; Shon, G.M.; Rho, C.W.; Jeong, B.R. Effect of Zero Drainage Using Drainage Zero Sensor on Root Zone Environment, Growth and Yield in Tomato Rockwool Culture. J. Bio Environ. Control 2012, 21, 398–403. [Google Scholar] [CrossRef]

- RDA. Manual for Strawberry Cultivation; RDA: Jeonju, Korea, 2019; p. 144. [Google Scholar]

- RDA. Research Data Standards Manual for Vegetables-Strawberris; RDA: Jeonju, Korea, 2021; pp. 10–35. [Google Scholar]

- RDA. Agricultural Science and Technology Research Analysis Standard; RDA: Jeonju, Korea, 2012; p. 21. [Google Scholar]

- Meric, M.K.; Tuzel, I.H.; Tuzel, Y.; Oztekin, G.B. Effects of Nutrition Systems and Irrigation Programs on Tomato in Soilless Culture. Agric. Water Manag. 2011, 99, 19–25. [Google Scholar] [CrossRef]

- Adams, P. Nutrient Uptake by Tomatoes from Recirculating Solutions. In Proceedings of the 6th ISOSC, Lunteren, The Netherlands, 29 April–5 May 1984; The Secretariat of ISOSC: Wageningen, The Netherlands, 1984; pp. 71–80. [Google Scholar]

- Moorby, J.; Graves, C.J. Root and Air Temperature Effects on Growth and Yield of Tomatoes and Lettuce. Acta Hortic. 1980, 98, 29–44. [Google Scholar] [CrossRef]

- Barker, J.C.; Welles, G.W.H.; Van Uffelen, J.A.M. The Effects of Day and Night Humidity on Yield and Quality of Glasshouse Cucumbers. J. Hortic. Sci. 1987, 62, 363–370. [Google Scholar] [CrossRef]

- Chrétien, S.; Gosselin, A.; Dorais, M. High Electrical Conductivity and Radiation-Based Water Management Improve Fruit Quality of Greenhouse Tomatoes Grown in Rockwool. HortScience 2000, 35, 627–631. [Google Scholar] [CrossRef]

- Gislerød, H.R.; Adams, P. Diurnal Variations in the Oxygen Content and Acid Requirement of Recirculating Nutrient Solutions and in the Uptake of Water and Potassium by Cucumber and Tomato Plants. Sci. Hortic. 1983, 21, 311–321. [Google Scholar] [CrossRef]

- Aljibury, F.K.; May, D.M. Irrigation Schedules and Production of Processed Tomatoes on the San Joaquin Westside. Calif. Agric. 1970, 24, 10–11. [Google Scholar]

- Koh, S.C.; Oh, S.J.; Lee, J.H.; Ko, K.S. Chlorophyll Fluorescence and CO2 Fixation Capacity in Leaves of Camellia sinensis, Camellia japonica, and Citrus Unshiu. Korean J. Environ. Biol. 2012, 30, 98–106. [Google Scholar]

- Celiktopuz, E.; Kapur, B.; Sarıdas, M.A.; Kargı, S.P. Response of Strawberry Fruit and Leaf Nutrient Concentrations to the Application of Irrigation Levels and a Biostimulant. J. Plant Nutr. 2021, 44, 153–165. [Google Scholar] [CrossRef]

- Perin, E.C.; Messias, R.D.S.; Galli, V.; Borowski, J.M.; De Souza, E.R.; De Avila, L.O.; Bamberg, A.L.; Rombaldi, C.V. Mineral Content and Antioxidant Compounds in Strawberry Fruit Submitted to Drough Stress. Food Sci. Technol. 2019, 39 (Suppl. S1), 245–254. [Google Scholar] [CrossRef]

- Mengel, K.; Kirkby, E.A. Principles of Plant Nutrition; International Potash Institute: Worblaufen-Bern, Switzerland, 1987; pp. 607–676. [Google Scholar]

- Jeong, S.K.; Choi, J.M.; Cha, K.H.; Chung, H.J.; Choi, J.S.; Seo, K.S. Deficiency Symptom, Growth Characteristics, and Nutrient Uptake of ‘Nyoho’ Strawberry Affected by Controlled Calcium Concentrations in Fertilizer Solution. J. Korean Soc. Hortic. Sci. 2001, 42, 284–288. [Google Scholar]

- Sainju, U.M.; Allen, B.L.; Lenssen, A.W.; Mikha, M. Root and Soil Total Carbon and Nitrogen Under Bioenergy Perennial Grasses with Various Nitrogen Rates. Biomass Bioenergy 2017, 107, 326–334. [Google Scholar] [CrossRef]

- Yoon, H.S.; Jin, H.J.; Oh, J.Y. “Kuemsil”, a Strawberry Variety Suitable for Forcing Culture. Korean J. Breed. Sci. 2020, 52, 184–189. [Google Scholar] [CrossRef]

| Harvest Season | Treatment z | No. of Leaves | Plant Height (cm) | Petiole Length (cm) | Leaf Length (cm) | Leaf Width (cm) | Crown Diameter (mm) |

|---|---|---|---|---|---|---|---|

| Early | 10% | 10.4a y | 26.6a | 9.9a | 6.4a | 5.3a | 19.9a |

| 20% | 10.1a | 26.4a | 10.4a | 6.8a | 5.5a | 20.5a | |

| 30% | 10.4a | 26.6a | 12.1a | 6.6a | 5.5a | 20.4a | |

| Timer 1 | 10.2a | 27.3a | 9.5a | 6.5a | 5.3a | 20.3a | |

| Timer 2 | 10.3a | 27.4a | 9.9a | 6.4a | 5.3a | 20.5a | |

| Late | 10% | 14.3a | 27.2a | 12.4a | 7.9ab | 7.2ab | 20.3a |

| 20% | 15.0a | 28.6a | 13.3a | 8.9a | 7.9a | 20.9a | |

| 30% | 14.2a | 24.4a | 10.9a | 7.8ab | 7.0a–c | 20.3a | |

| Timer 1 | 15.4a | 24.7a | 10.9a | 7.8ab | 6.6bc | 20.6a | |

| Timer 2 | 14.5a | 26.6a | 11.7a | 7.2b | 6.1c | 20.3a |

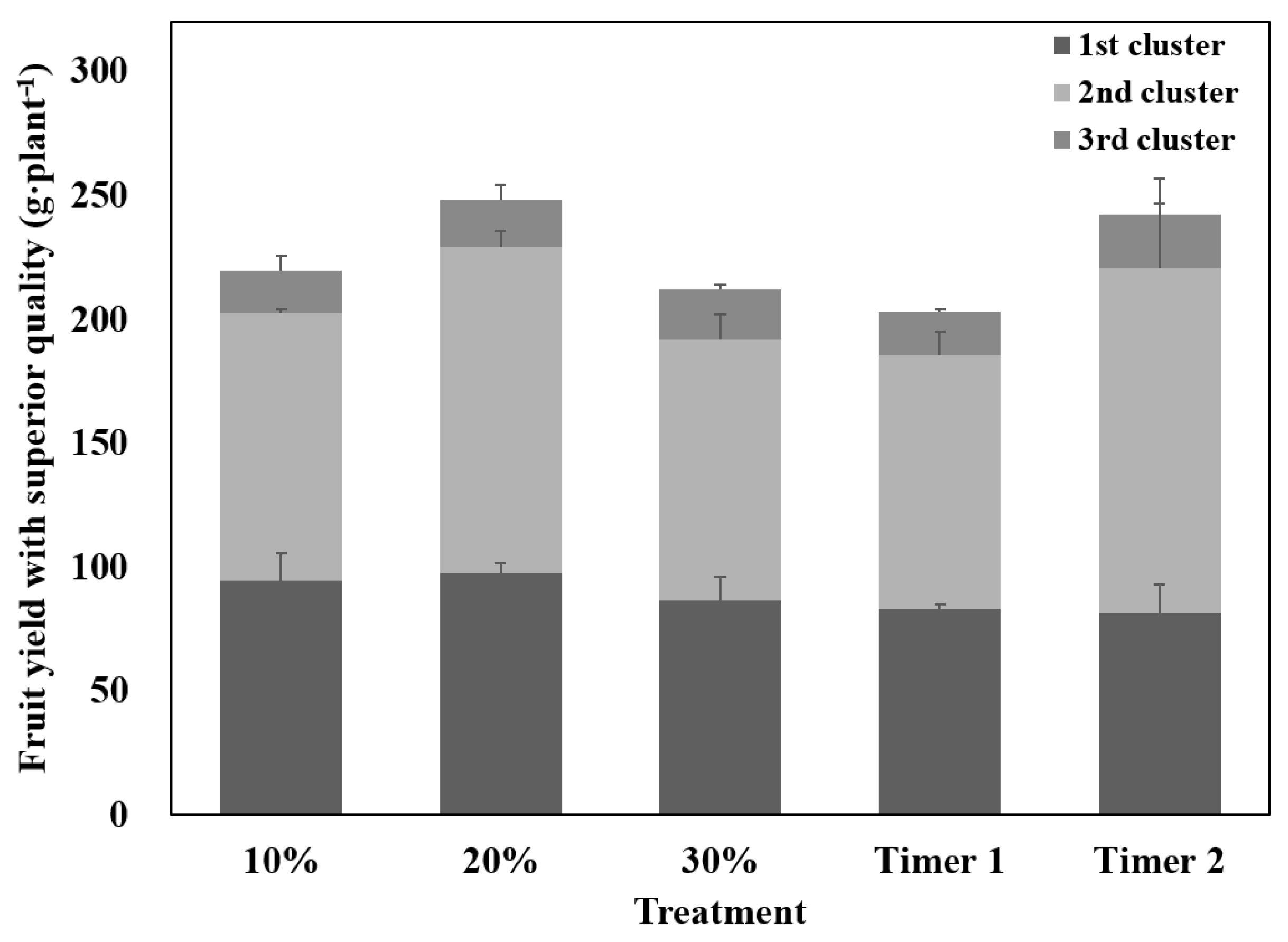

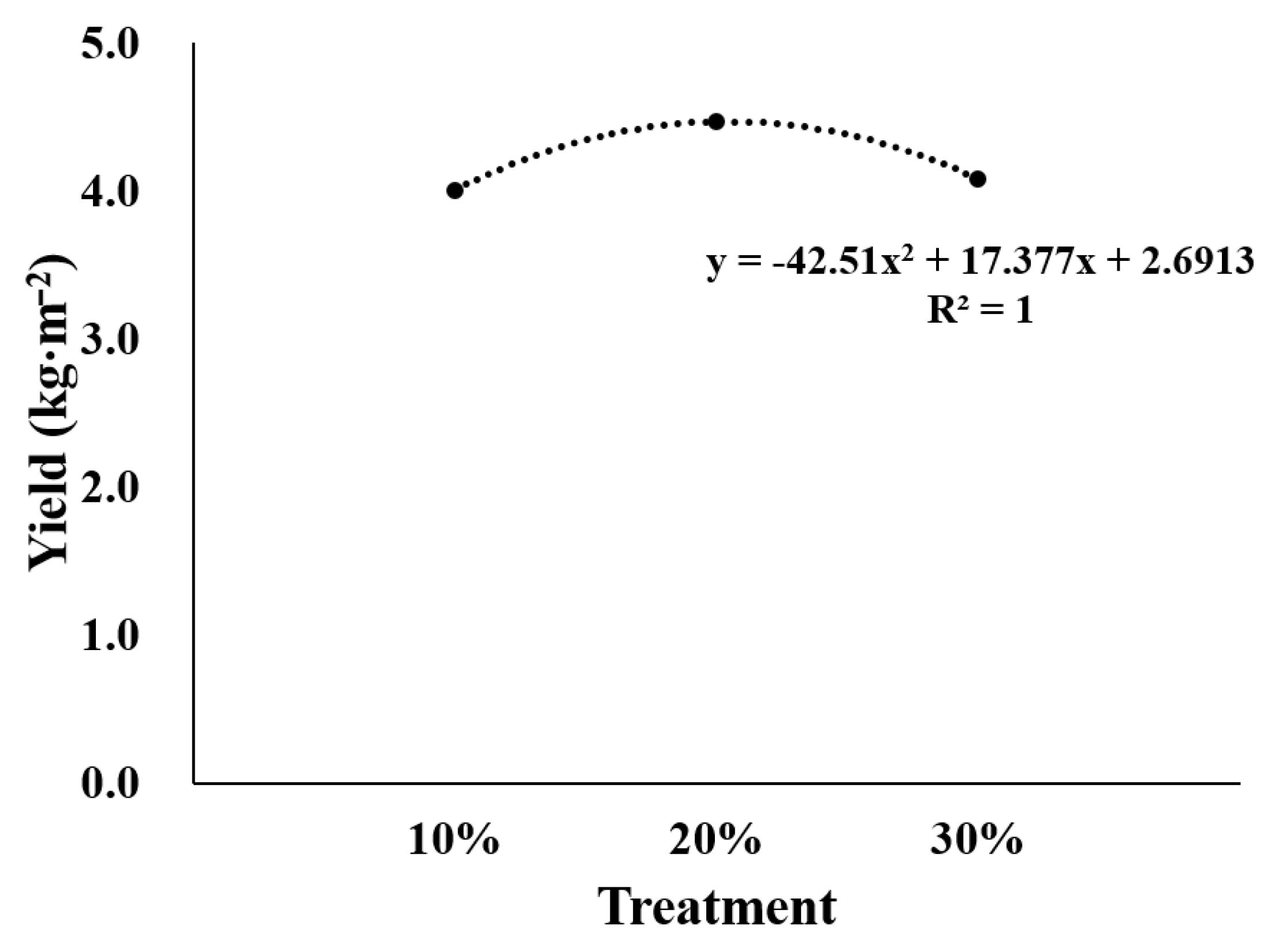

| Treatment z | Marketable Fruit Yield (g∙plant−1) | Yield (kg∙m−2) | Marketable Fruit Ratio | |||

|---|---|---|---|---|---|---|

| 1st Cluster | 2nd Cluster | 3rd Cluster | Total | |||

| 10% | 161a y | 127a | 18.2a | 306a | 4.00a | 86.6a |

| 20% | 175a | 148a | 19.2a | 342a | 4.47a | 86.1a |

| 30% | 159a | 129a | 24.9a | 312a | 4.08a | 85.3a |

| Timer 1 | 153a | 123a | 21.0a | 296a | 3.87a | 85.5a |

| Timer 2 | 162a | 155a | 24.3a | 341a | 4.46a | 86.3a |

| Treatment z | Fruit Weight | Fruit Height | Fruit Width | Soluble Solid Content | Firmness | Acidity | Soluble Solid-Acid Ratio |

|---|---|---|---|---|---|---|---|

| (g) | (cm) | (cm) | (°Brix) | (g·mm−2) | (%) | ||

| 10% | 40.6a y | 5.6a | 4.5a | 11.9a | 24.9b | 0.61a | 19.6a |

| 20% | 44.0a | 5.7a | 4.5a | 11.9a | 28.1a | 0.61a | 19.5a |

| 30% | 46.9a | 5.9a | 4.5a | 12.7a | 29.8a | 0.59a | 21.4a |

| Timer 1 | 38.4a | 5.6a | 4.3a | 12.3a | 28.2a | 0.59a | 20.9a |

| Timer 2 | 40.7a | 5.7a | 4.4a | 11.7a | 27.7a | 0.54a | 21.6a |

| Treatment z | TIV | TDV | TRV | WUE |

|---|---|---|---|---|

| (L∙plant−1) | (L∙plant−1) | (L∙plant−1) | (g∙L−1/plant) | |

| 10% | 14.5bc y | 4.3c | 10.1a | 43.6a |

| 20% | 15.6bc | 5.1c | 10.5a | 48.4a |

| 30% | 16.5b | 7.2b | 9.3a | 49.6a |

| Timer 1 | 14.1c | 4.0c | 10.2a | 43.6a |

| Timer 2 | 21.5a | 11.3a | 10.2a | 49.7a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.-H.; Kim, D.-Y.; Lee, S.Y.; Chang, M.-S. Growth and Quality of Strawberry (Fragaria ananassa Dutch. cvs. ‘Kuemsil’) Affected by Nutrient Solution Supplying Control System Using Drainage Rate in Hydroponic Systems. Horticulturae 2022, 8, 1059. https://doi.org/10.3390/horticulturae8111059

Choi S-H, Kim D-Y, Lee SY, Chang M-S. Growth and Quality of Strawberry (Fragaria ananassa Dutch. cvs. ‘Kuemsil’) Affected by Nutrient Solution Supplying Control System Using Drainage Rate in Hydroponic Systems. Horticulturae. 2022; 8(11):1059. https://doi.org/10.3390/horticulturae8111059

Chicago/Turabian StyleChoi, Su-Hyun, Dae-Young Kim, Sun Yi Lee, and Min-Sun Chang. 2022. "Growth and Quality of Strawberry (Fragaria ananassa Dutch. cvs. ‘Kuemsil’) Affected by Nutrient Solution Supplying Control System Using Drainage Rate in Hydroponic Systems" Horticulturae 8, no. 11: 1059. https://doi.org/10.3390/horticulturae8111059

APA StyleChoi, S.-H., Kim, D.-Y., Lee, S. Y., & Chang, M.-S. (2022). Growth and Quality of Strawberry (Fragaria ananassa Dutch. cvs. ‘Kuemsil’) Affected by Nutrient Solution Supplying Control System Using Drainage Rate in Hydroponic Systems. Horticulturae, 8(11), 1059. https://doi.org/10.3390/horticulturae8111059