Strawberry Nectar Colour Stability and Aroma: Influence of Cultivar, Harvest Time and Ripening Stage

Abstract

1. Introduction

2. Materials and Methods

2.1. Strawberry Fruits

2.2. Preparation of Nectars

2.3. Physical and Chemical Analysis of Puree

2.4. Colour Measurements

2.5. Determination of Furanone

2.6. Determination of Other Aroma Compounds

2.7. Statistical Analysis

3. Results

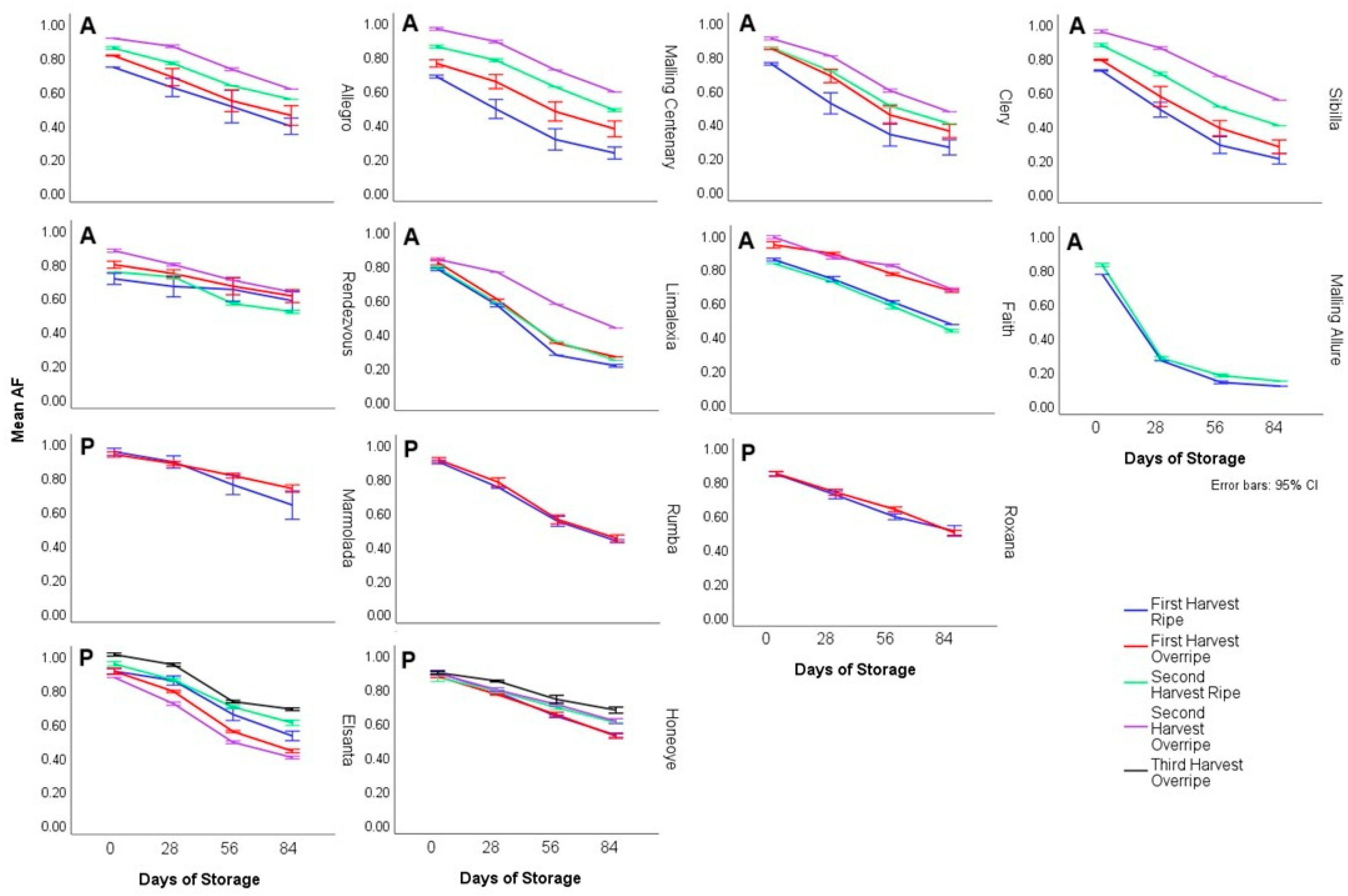

3.1. Effects on Colour Stability

3.1.1. Cultivar

3.1.2. Country of Origin

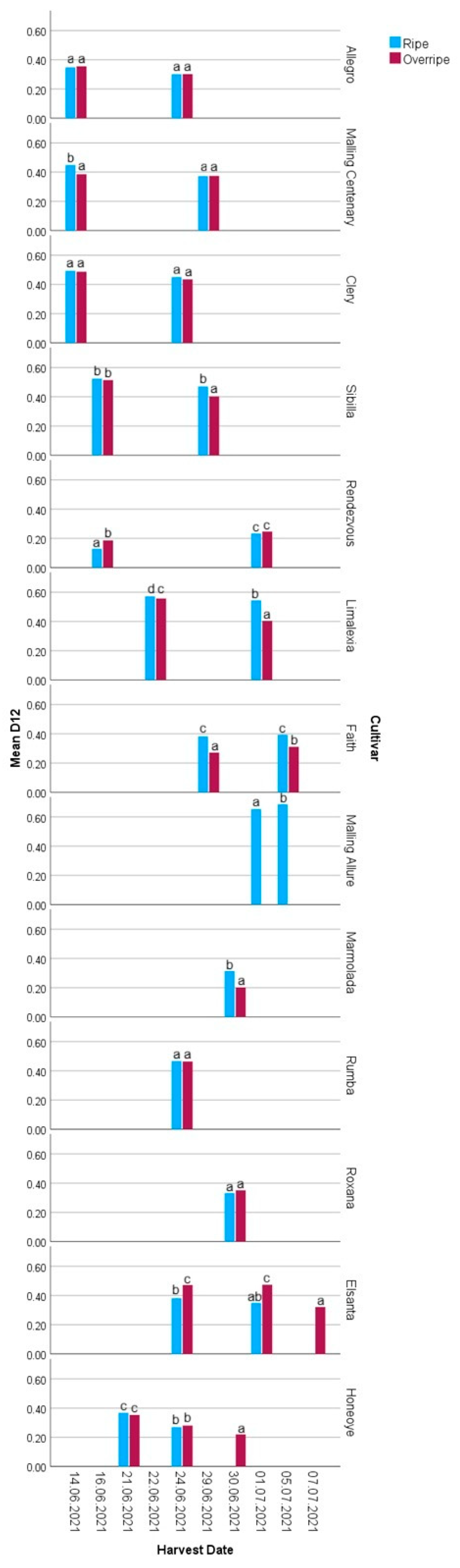

3.1.3. Ripening Stage and Harvest Time

3.2. Aroma Compounds

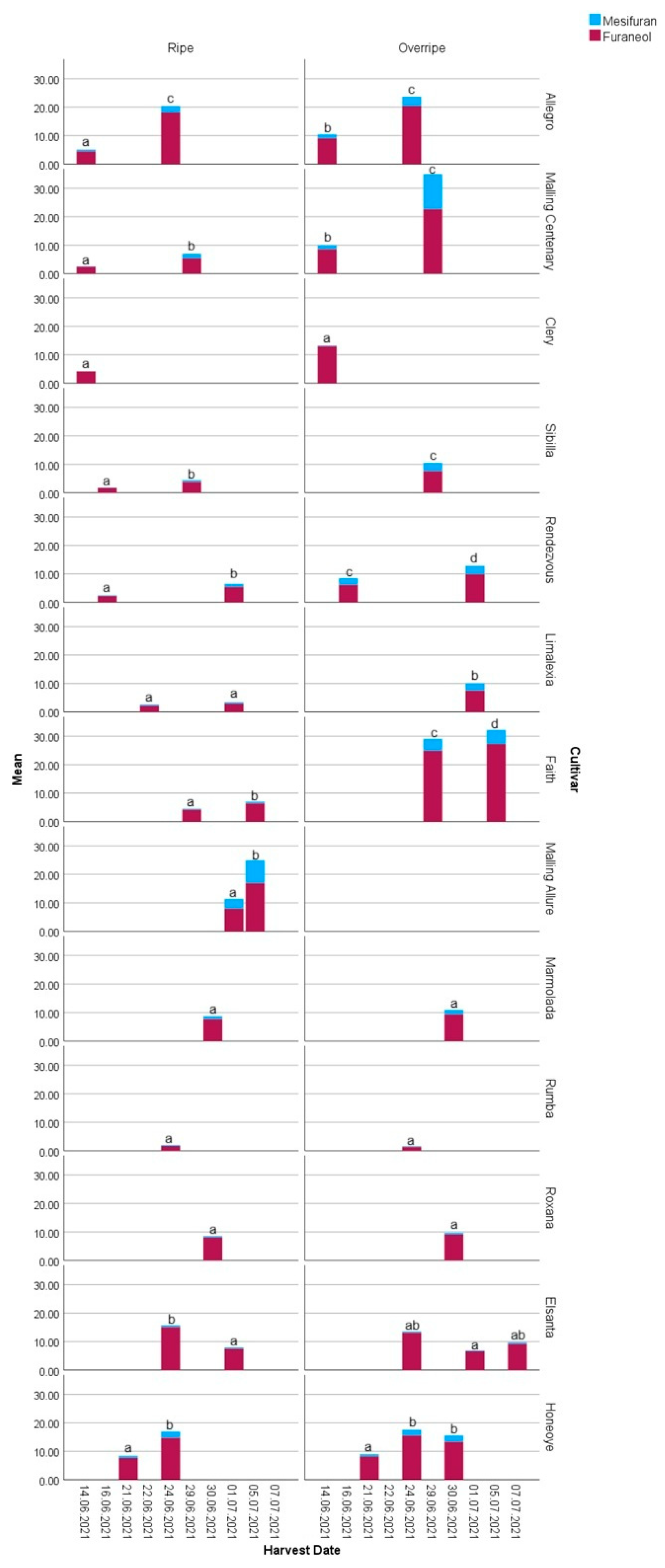

3.2.1. Furanones (Mesifuran and Furaneol)

Cultivar

Ripening Stage and Harvest Time

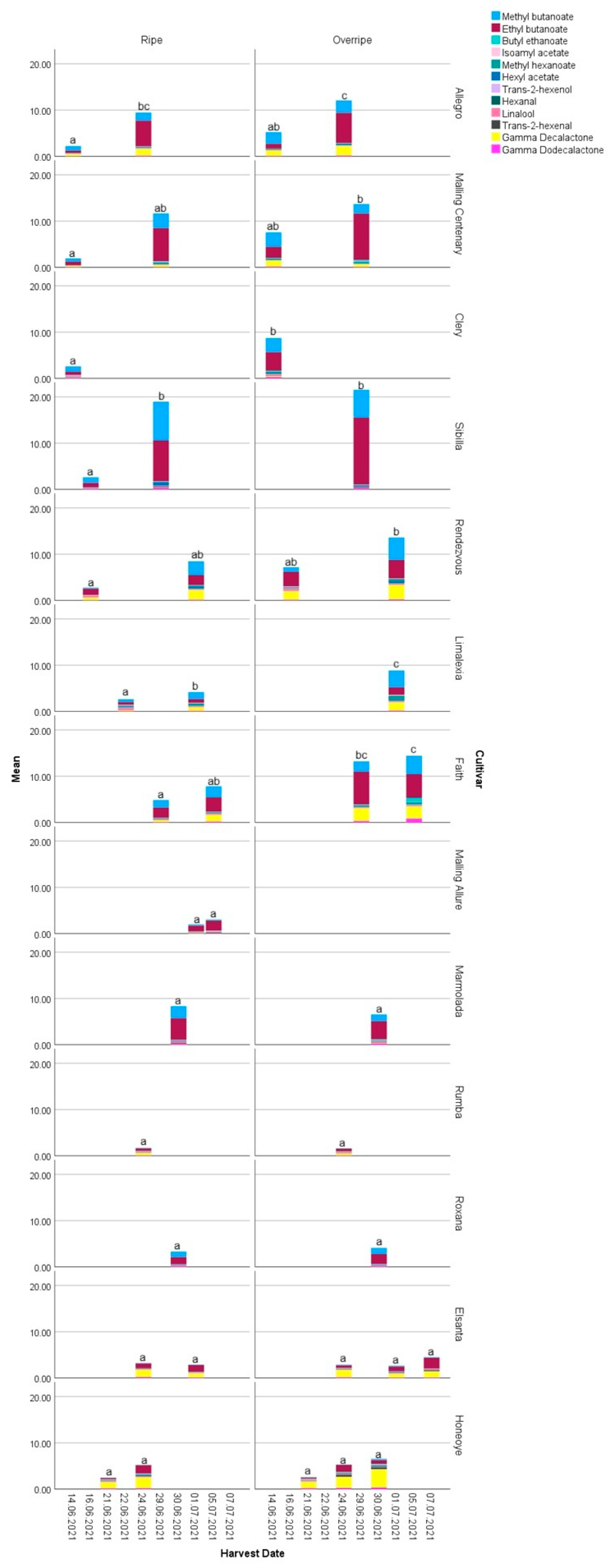

3.2.2. Esters

Cultivar

Ripening Stage and Harvest Time

3.2.3. C6 Compounds and Linalool

Cultivar

Ripening Stage and Harvest Time

3.2.4. Lactones

Cultivar

Ripening Stage and Harvest Time

3.2.5. Harvest Time

3.3. Correlation of Aroma Compounds with Colour and Colour Stability

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AF | Acceptance Factor |

| D | Difference in Acceptance Factor |

| DMHF | 2,5-dimethyl-4-hydroxy-3(2H)-furanone |

| DMMF | 2,5-dimethyl-4-methoxy-3(2H)-furanone |

| GC-FID | gas chromatography–flame ionisation detector |

| GC-MS | gas chromatography–mass spectrometry |

| MSD | mass selective detector |

| SPME | solid phase microextraction |

References

- Golaszewski, R.; Sims, C.A.; O’Keefe, S.F.; Braddock, R.J.; Littell, R.C. Sensory Attributes and Volatile Components of Stored Strawberry Juice. J. Food Sci. 1998, 63, 734–738. [Google Scholar] [CrossRef]

- Gössinger, M.; Mayer, F.; Radocha, N.; Höfler, M.; Boner, A.; Groll, E.; Nosko, E.; Bauer, R.; Berghofer, E. Consumer´s Color Accepance of Strawberry Nectars from Puree. J. Sens. Stud. 2009, 24, 78–92. [Google Scholar] [CrossRef]

- Teribia, N.; Buvé, C.; Bonerz, D.; Aschoff, J.; Hendrickx, M.; Loey, A.V. Impact of processing and storage conditions on color stability of strawberry puree: The role of PPO reactions revisited. J. Food Eng. 2021, 294, 110402. [Google Scholar] [CrossRef]

- Murray, H.; Dietl-Schuller, C.; Lindner, M.; Korntheuer, K.; Halbwirth, H.; Gössinger, M. Prediction of the potential colour stability of strawberry nectar by use of a Stability Prediction Value (SPV). LWT 2023, 173, 114233. [Google Scholar] [CrossRef]

- Gössinger, M.; Grünewald, J.; Kampl, C.; Wendelin, S.; Stich, K.; Berghofer, E. Impact of Provenance, Cultivar, Time of Harvest and Degree of Ripeness of Strawberries on Their Ingredients and Colour Stability of Strawberry Nectars Made from Puree. Acta Hortic. 2014, 1017, 109–118. [Google Scholar] [CrossRef]

- Brandes, W.; Baumann, R. Entwicklung einer neuen Methode für die quantitative Bestimmung von Furaneol (4-Hydroxy-2,5-dimethyl-3(2H)-furanon) und Mesifuran (2,5-dimethyl-4-methoxy- 3(2H)-furanon) in Erdbeeren, Erdbeerkonfitüren und Erdbeerbränden. Mitteilungen Klosterneuburg. 2021, 71, 266–274. [Google Scholar]

- Murray, H.; Stipkovits, F.; Wühl, J.; Halbwirth, H.; Gössinger, M. Strawberry Post-Harvest Anthocyanin Development to Improve the Colour Stability of Strawberry Nectars. Beverages 2024, 10, 36. [Google Scholar] [CrossRef]

- Murray, H.; Stipkovits, F.; Lindner, M.; Wühl, J.; Halbwirth, H.; Gössinger, M. Conductivity at varying frequencies as a method for differentiating strawberry ripeness and association with colour acceptance of strawberry nectars. J. Sci. Food Agric. 2024, 104, 9630–9639. [Google Scholar] [CrossRef]

- Teribia, N.; Buvé, C.; Bonerz, D.; Aschoff, J.; Goos, P.; Hendrickx, M.; van Loey, A. The effect of thermal processing and storage on the color stability of strawberry puree originating from different cultivars. LWT 2021, 145, 111270. [Google Scholar] [CrossRef]

- Jee, E.; Do, E.; Gil, C.S.; Kim, S.; Lee, S.Y.; Lee, S.; Ku, K.-M. Analysis of volatile organic compounds in Korean-bred strawberries: Insights for improving fruit flavor. Front. Plant Sci. 2024, 15, 1360050. [Google Scholar] [CrossRef]

- Ruth, T.K.; Rumble, J.N. Branding the Berries: Consumers’ Strawberry Purchasing Intent and their Attitude toward Florida Strawberries. J. Appl. Commun. 2016, 100, 28–42. [Google Scholar] [CrossRef]

- Yan, J.-W.; Ban, Z.-J.; Lu, H.-Y.; Li, D.; Poverenov, E.; Luo, Z.-S.; Li, L. The aroma volatile repertoire in strawberry fruit: A review. J. Sci. Food Agric. 2018, 98, 4395–4402. [Google Scholar] [CrossRef] [PubMed]

- Ulrich, D.; Kecke, S.; Olbricht, K. What Do We Know about the Chemistry of Strawberry Aroma? J. Agric. Food Chem. 2018, 66, 3291–3301. [Google Scholar] [CrossRef] [PubMed]

- Simkova, K.; Veberic, R.; Grohar, M.C.; Pelacci, M.; Smrke, T.; Ivancic, T.; Medic, A.; Cvelbar Weber, N.; Jakopic, J. Changes in the Aroma Profile and Phenolic Compound Contents of Different Strawberry Cultivars during Ripening. Plants 2024, 13, 1419. [Google Scholar] [CrossRef]

- Forney, C.F. Horticultural and other Factors Affecting Aroma Volatile Composition of Small Fruit. HortTechnology 2001, 11, 529–538. [Google Scholar] [CrossRef]

- Forney, C.F.; Kalt, W.; Jordan, M.A. The Composition of Strawberry Aroma Is Influenced by Cultivar, Maturity, and Storage. HortScience 2000, 35, 1022–1026. [Google Scholar] [CrossRef]

- Passa, K.; Simal, C.; Tsormpatsidis, E.; Papasotiropoulos, V.; Lamari, F.N. Monitoring of Volatile Organic Compounds in Strawberry Genotypes over the Harvest Period. Plants 2023, 12, 1881. [Google Scholar] [CrossRef]

- Azodanlou, R.; Darbellay, C.; Luisier, J.-L.; Villettaz, J.-C.; Amadò, R. Changes in flavour and texture during the ripening of strawberries. Eur. Food Res. Technol. 2004, 218, 167–172. [Google Scholar] [CrossRef]

- Pérez, A.G.; Rios, J.J.; Sanz, C.; Olías, J.M. Aroma components and free amino acids in strawberry variety Chandler during ripening. J. Agric. Food Chem. 1992, 40, 2232–2235. [Google Scholar] [CrossRef]

- Padilla-Jiménez, S.M.; Angoa-Pérez, M.V.; Mena-Violante, H.G.; Oyoque-Salcedo, G.; Montañez-Soto, J.L.; Oregel-Zamudio, E. Identification of Organic Volatile Markers Associated with Aroma during Maturation of Strawberry Fruits. Molecules 2021, 26, 504. [Google Scholar] [CrossRef]

- Vandendriessche, T.; Vermeir, S.; Mayayo Martinez, C.; Hendrickx, Y.; Lammertyn, J.; Nicolaï, B.M.; Hertog, M.L.A.T.M. Effect of ripening and inter-cultivar differences on strawberry quality. LWT Food Sci. Technol. 2013, 52, 62–70. [Google Scholar] [CrossRef]

- Porter, M.; Fan, Z.; Lee, S.; Whitaker, V.M. Strawberry breeding for improved flavor. Crop Sci. 2023, 63, 1949–1963. [Google Scholar] [CrossRef]

- Arihara, K.; Yokoyama, I.; Ohata, M. Chapter Six - DMHF (2,5-dimethyl-4-hydroxy-3(2H)-furanone), a volatile food component with attractive sensory properties, brings physiological functions through inhalation. In Advances in Food and Nutrition Research; Toldrá, F., Ed.; Academic Press: Cambridge, MA, USA, 2019; Volume 89, pp. 239–258. [Google Scholar]

- Jetti, R.R.; Yang, E.; Kurnianta, A.; Finn, C.; Qian, M.C. Quantification of Selected Aroma-Active Compounds in Strawberries by Headspace Solid-Phase Microextraction Gas Chromatography and Correlation with Sensory Descriptive Analysis. J. Food Sci. 2007, 72, S487–S496. [Google Scholar] [CrossRef]

- Pérez, A.G.; Olías, R.; Sanz, C.; Olías, J.M. Furanones in Strawberries: Evolution during Ripening and Postharvest Shelf Life. J. Agric. Food Chem. 1996, 44, 3620–3624. [Google Scholar] [CrossRef]

- Schieberle, P.; Hofmann, T. Evaluation of the Character Impact Odorants in Fresh Strawberry Juice by Quantitative Measurements and Sensory Studies on Model Mixtures. J. Agric. Food Chem. 1997, 45, 227–232. [Google Scholar] [CrossRef]

- Buvé, C.; Van Bedts, T.; Haenen, A.; Kebede, B.; Braekers, R.; Hendrickx, M.; Van Loey, A.; Grauwet, T. Shelf-life dating of shelf-stable strawberry juice based on survival analysis of consumer acceptance information. J. Sci. Food Agric. 2018, 98, 3437–3445. [Google Scholar] [CrossRef]

- International Fruit and Vegetable Juice Association. Method of Analysis No. 08. Determination of Soluble Solids. Available online: https://ifu-fruitjuice.com/page/ListofIFUMethods (accessed on 13 March 2025).

- International Fruit and Vegetable Juice Association. Method of Analysis No. 03. Determination of Titratable Acidity. Available online: https://ifu-fruitjuice.com/page/ListofIFUMethods (accessed on 13 March 2025).

- Kammerer, D.R.; Schillmöller, S.; Maier, O.; Schieber, A.; Carle, R. Colour stability of canned strawberries using black carrot and elderberry juice concentrates as natural colourants. Eur. Food Res. Technol. 2007, 224, 667–679. [Google Scholar] [CrossRef]

- Gössinger, M.; Koch, C.; Wendelin, S.; Kickenweiz, M.; Stich, K.; Vogl, K. Einfluss von Sorte, Reifegrad und Erntezeitpunkt auf die Farbstabilität von fruchtfleischhältigem Erdbeernektar. Mitteilungen Klosterneuburg. 2010, 60, 420–427. [Google Scholar]

- Rincon, S.; Murray, H.; Gössinger, M.; Ginies, C.; Goupy, P.; Dufour, C.; Dangles, O.; Le Bourvellec, C. Characterisation of phenolic compounds and polysaccharides in strawberry: Cultivar and harvest effects and their correlation with nectar colour stability. Food Chem. 2025, 473, 143112. [Google Scholar] [CrossRef]

- Fan, Z.; Plotto, A.; Bai, J.; Whitaker, V.M. Volatiles Influencing Sensory Attributes and Bayesian Modeling of the Soluble Solids–Sweetness Relationship in Strawberry. Front. Plant Sci. 2021, 12, 640704. [Google Scholar] [CrossRef]

- Fan, Z.; Hasing, T.; Johnson, T.S.; Garner, D.M.; Schwieterman, M.L.; Barbey, C.R.; Colquhoun, T.A.; Sims, C.A.; Resende, M.F.R.; Whitaker, V.M. Strawberry sweetness and consumer preference are enhanced by specific volatile compounds. Hortic. Res. 2021, 8, 66. [Google Scholar] [CrossRef] [PubMed]

| Mesifuran | Furaneol | Methyl Butanoate | Ethyl Butanoate | Butyl Ethanoate | Isoamyl Acetate | Methyl Hexanoate | Hexyl Acetate | trans-2-Hexenol | Hexanal | Linalool | trans-2-Hexenal | γ-Deca-lactone | γ-Dodeca-lactone | Total by GC-MS | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AF0 | 0.31 * | 0.54 ** | 0.13 | 0.43 ** | 0.37 * | 0.18 | −0.07 | 0.14 | 0.05 | 0.33 * | −0.09 | 0.28 | 0.28 | 0.46 ** | 0.41 ** |

| AF12 | 0.13 | 0.39 * | 0.11 | 0.33 * | 0.29 | 0.06 | 0 | 0.13 | 0.11 | 0.35 * | 0.15 | 0.27 | 0.55 ** | 0.45 ** | 0.39 ** |

| D12 | 0.03 | −0.23 | −0.06 | −0.15 | −0.14 | 0.04 | −0.05 | −0.08 | −0.11 | −0.24 | −0.25 | −0.14 | −0.54 ** | −0.29 | −0.25 |

| Mesifuran | Furaneol | Methyl Butanoate | Ethyl Butanoate | Butyl Ethanoate | Isoamyl Acetate | Methyl Hexanoate | Hexyl Acetate | trans-2-Hexenol | Hexanal | Linalool | trans-2-Hexenal | γ-Deca-lactone | γ-Dodeca-lactone | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AF0 | 0.03 | −0.03 | −0.45 ** | 0.23 | 0.28 | −0.13 | −0.35 * | −0.08 | −0.17 | 0.05 | −0.2 | 0.18 | 0.23 | 0.24 |

| AF12 | −0.06 | 0.06 | −0.32 * | 0.07 | 0.12 | −0.41 ** | −0.36 * | −0.24 | −0.29 | −0.2 | −0.18 | 0.07 | 0.34 * | 0.2 |

| D12 | 0.09 | −0.09 | 0.13 | 0.06 | 0.03 | 0.45 ** | 0.25 | 0.26 | 0.27 | 0.3 | 0.11 | 0.03 | −0.29 | −0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murray, H.; Brandes, W.; Sari, S.; Eder, P.; Dietl-Schuller, C.; Lindner, M.; Philipp, C.; Halbwirth, H.; Haselmair-Gosch, C.; Gössinger, M. Strawberry Nectar Colour Stability and Aroma: Influence of Cultivar, Harvest Time and Ripening Stage. Horticulturae 2025, 11, 617. https://doi.org/10.3390/horticulturae11060617

Murray H, Brandes W, Sari S, Eder P, Dietl-Schuller C, Lindner M, Philipp C, Halbwirth H, Haselmair-Gosch C, Gössinger M. Strawberry Nectar Colour Stability and Aroma: Influence of Cultivar, Harvest Time and Ripening Stage. Horticulturae. 2025; 11(6):617. https://doi.org/10.3390/horticulturae11060617

Chicago/Turabian StyleMurray, Helen, Walter Brandes, Sezer Sari, Phillip Eder, Claudia Dietl-Schuller, Marlene Lindner, Christian Philipp, Heidi Halbwirth, Christian Haselmair-Gosch, and Manfred Gössinger. 2025. "Strawberry Nectar Colour Stability and Aroma: Influence of Cultivar, Harvest Time and Ripening Stage" Horticulturae 11, no. 6: 617. https://doi.org/10.3390/horticulturae11060617

APA StyleMurray, H., Brandes, W., Sari, S., Eder, P., Dietl-Schuller, C., Lindner, M., Philipp, C., Halbwirth, H., Haselmair-Gosch, C., & Gössinger, M. (2025). Strawberry Nectar Colour Stability and Aroma: Influence of Cultivar, Harvest Time and Ripening Stage. Horticulturae, 11(6), 617. https://doi.org/10.3390/horticulturae11060617